5-376-000086

REV. 4 - 07/10

© 2010 Jerr-Dan Corporation. All Rights Reserved.

MPL40

OPERA TIONS AND MAINTENANCE

MANUAL

$35.00

1080 Hykes Road

Greencastle, P A 17225

Phone (717) 597-71 1 1

www.jerr-dan.com

5-376-000086

REV. 4 - 07/10

5-376-000086

REV. 4 - 07/10

© 2010 Jerr-Dan Corporation. All Rights Reserved.

FOREWORD

This manual is intended to serve as a guide to the owner and operator in the

safe operation and optimum performance of this Jerr-Dan equipment.

Establishment of good operating habits and familiarity with the equipment

and its capabilities combined with good judgement are essential.

Before attempting to operate the unit carefully read all sections of this manual.

This manual is intended to serve as a guide to the owner and operator in the

safe operation and optimum performance of this Jerr-Dan equipment.

This manual should be kept with the equipment at all times and referred to

whenever in doubt of proper operation.

Information contained in this manual reflects how this vehicle was built at the

factory. Modifications or additions by the distributor or owner are not reflected in this manual.

This manual does not include operation and maintenance information for the

commercial chassis (IHC, Ford, GM, etc.). This information is provided by

the chassis manufacturer .

When inquiring about operation, maintenance or warranty, please refer to

your equipment’s Sales Order Number , Serial Number and Model Number .

This information can be found on the aluminum tag riveted inside the driver’s

side toolbox on the back wall in the upper right corner .

001

001

VEHICLE

IDENT. NO.

MODEL NO.

SERIAL NO.

MANUFACTURED BY

GREENCASTLE, PENNSYLVANIA

An Oshkosh Truck Corporation Company

5-376-000086

REV. 4 - 07/10

Jerr-Dan Corporation strives to provide information that is accurate, complete and useful. All information contained in this manual is as accurate as

known at the time of publication and is subject to change, without notice, as

a result of continuous product improvements. Jerr-Dan reserves the right to

amend the information in this document at any time without prior notice.

Should you find inadequacies in the text, please send your comments to the

following address:

Jerr-Dan Corporation

Attn: T echnical Publications

1080 Hykes Road

Greencastle, P A 17225

Additional or replacement manuals or replacement safety warning labels

can be ordered by calling Jerr-Dan Parts at 717-597-71 1 1. Price and availability will be quoted at time of the request.

The material in this document is confidential and the property of Jerr-Dan

Corporation. No part of this document may be photocopied, reproduced or

translated to another language without the express written consent of JerrDan Corporation.

Manufactured under one or more of the following patents: 5,575,606;

5,672,042; 5,697,741; 5,713,714; 5,722,810; 5,782,596; 5,839,755; and

6,315,515 B1 with other Patents Pending.

Jerr-Dan and the Jerr-Dan logo are registered trademarks and Run Hard is a

service mark of Jerr-Dan Corporation, Greencastle, P A. USA

5-376-000086

REV. 4 - 07/10

Page i

LIMITED WARRANTY

Manufacturer's Warranty. Manufacturer's sole warranty shall be the following, which

Distributor shall make on behalf of Manufactuer by conspicuous notice in writing

accompanying each contract or memorandum of sale:

1. Warranty. Jerr-Dan Corporation, ("Manufacturer") warrants each new product made

by it to be free from defects in material or workmanship for one year from the date of

initial sale, lease, rental, or other disposition of such product, and agrees only to repair or

replace at its own expense, f.o.b. the place or places of manufacture, at manufacturer's

option, any part or parts of the product found to be defective in material or workmanship,

provided Manufacturer is notified of such defect or defects within the one year warranty

period and given a reasonable time to correct the defect. In no case, shall the warranty

extend to defects in materials, components, or services furnished by third parties. Defects

caused by chemical action, or the presence of abrasive materials and defects arising

following the operation beyond rated capacity or the improper use or application of any

Products shall not be considered defects within the scope of the foregoing warranty. If any

repairs or alterations are made or any parts are replaced during the period covered by any

warranty above mentioned by other than an authorized Manufacturer's Distributor in

accordance with authorized Manufactuerer's service manuals or with other than parts,

accessories, or attachments authorized by Manufacturer for use in its products, customer

shall pay for all such repairs or parts without recourse against Manufacturer, and Manufacturer

shall be relieved of responsibility for fulfillment of this warranty with respect to parts or

components of all repairs, alterations or replacements so made. No claims for labor shall

be considered unless authorized by Manufacturer.

2. Disclaimer as to Consequential or Special Damages. Under no circumstances

shall Manufacturer be liable for any consequential or special damage which any person,

firm, corporation, or other entity may suffer or claim to suffer or incur or claim to incur as

a result of any defect in the product or in any correction or alteration thereof made or

furnished by Manufacturer or others. "Consequential" or "special damages" as used herein

includes but is not limited to costs of transportation, lost sales, lost orders, lost profits,

lost income, increased overhead, labor and material costs and cost of manufacturing

variances and operational inefficiencies.

3. Maximum Liability. The maximum liability of Manufacturer under the exclusive

warranty set forth herein shall be the amount paid to Manufacturer by the vendor of the

component with respect to the product to which such vendor warranty applies.

4. Limitation of Liability. The limitation of liability provisions herein shall apply to

any and all claims or suits brought against Manufacturer, including any claim based upon

negligence, breach of contract, breach of warranty, strict liability or any other theories

upon which liability may be asserted against Manufacturer.

1080 Hykes Road

Greencastle, P A 17225

(717) 597-71 1 1

WARRANTY

5-376-000086

REV. 4 - 07/10

Page ii

5. Exclusive and Entire Warranty. The warranty constitutes Manufacturer's entire

warranty as to the product and it is expressly agreed that the remedies of dealer and those

claiming under dealer as stated in this warranty are exclusive. Manufacturer does not

assume (and has not authorized any other person to assume on its behalf) any other

warranty or liability in connection with any product covered by this warranty.

MANUFACTURER EXPRESSLY DISCLAIMS ANY AND ALL OTHER WARRANTIES OF

ANY KIND WHA TSOEVER AS T O THE PRODUCT FURNISHED HEREUNDER, INCLUDING

BUT NOT LIMITED T O EXPRESS OR IMPLIED W ARRANTIES AS T O MERCHANT ABILITY,

FITNESS FOR PARTICULAR PURPOSES SOLD, DESCRIPTION OR QUALITY OF THE

PRODUCT FURNISHED HEREUNDER.

6. Notice of Occurrence. This warranty shall be void if, upon the occurrence of any

incident involving any product made by Manufacturer, and resulting in any personal injury

or property damage, customer shall fail to notify Manufacturer within 24 hous of such

occurrence or permit Manufacturer audit representatives to have immediate access to

such product and to all records of and within the control of the customer and/or distributor

relating to the product and the occurrence.

7. Filing of Warranty Claim. Upon notifying the Manufacturer of a failure, the

Manufacturer or its representative will verbally authorize and comfirm by letter the repairs

to be made. Verbal authorization will require the following information:

A) Owner's name and telephone number.

B) The dealer's name from whom it was purchased.

C) The Manufacturer's unit serial number.

D) Telephone number of the party making the repairs.

E) The part numbers needed to make repairs.

F) Owner to be informed of C.O.D. on parts (if deemed necessary) to assure return of

defective parts for manufacturer’s evaluation.

At this time, the Manufacturer will ship as soon as practical the parts needed to make the

repair. Included with the parts will be the invoice for the parts and a Request for Warranty

form, with the Warranty Return Tags.

The vehicle owner/dealer will complete the Request for Warranty form and the Warranty

Return Tag marked "Return with Shipping Notice." Both documents should be attached to

the shippping notice and returned to the Manufacturer by mail. The parts to be returned

shall be tagged with the Warranty Return Tag (more than one part pertaining to the same

warranty claim shall be identified with the same warranty claim number - see number on

Warranty Return Tag). All parts under this claim shall be returned to the Manufacturer prepaid for warranty evaluation.

Upon receiving the part or parts for warranty evaluation, the part will be inspected and

tested. After being inspected and tested, the decision to honor or deny warranty claim shall

be based on analysis of all available information.

When warranty is honored, the Manufacturer will reimburse the owner/dealer in the amount

agreed to by both parties.

If warranty is denied, the owner and distributor will be notified in writing of the decision and

a full explanation for the decision will be given.

8.Manufacturer may at any time amend the foregoing form of warranty without prior

notice.

5-376-000086

REV. 4 - 07/10

Page iii

TABLE OF CONTENTS

Section I: Safety

Safety (General).......................................................................1

Ratings: MPL40 .......................................................................3

Safety Chains ..........................................................................8

Lift Safety ................................................................................9

Boom Safety .......................................................................... 1 0

Sling Safety ........................................................................... 14

Safety Warning Decals .......................................................... 16

Section II: Operation

Wheel -Lift .............................................................................1 9

Tie-Down S traps.....................................................................25

Wheel Grid Sp acers ............................................................... 2 8

T owball Hitch Attachment.......................................................29

Wrecker Boom - Single Line Boom - Worm Gear Winch ....... 31

Wrecker Boom - Single Line Boom - Planetary Gear Winch ..3 7

Wrecker Boom - Dual Line Boom - Worm Gear Winches ...... 4 2

T ow Sling (Optional) ...............................................................48

Motorcycle T owing Adapter (Optional) .................................... 58

Dolly S torage (Optional) ......................................................... 65

Dollies (Optional) ...................................................................70

Section III: Maintenance

Maintenance and Lubrication ................................................. 73

Oils and Greases ................................................................... 76

Wire Rope Handling and Inspection ....................................... 77

Underlift Level S top Assist System ........................................ 79

Lubrication Points .................................................................. 80

Trouble Shooting ....................................................................81

Hydraulic System .................................................................. 81

Hydraulic Clutch Pump .......................................................... 82

P.T .O. Functioning Improperly ................................................83

Hydraulic Pump ..................................................................... 83

Winch Functioning Improperly................................................84

Section IV: Glossary

Glossary ................................................................................85

5-376-000086

REV. 4 - 07/10

Page iv

THIS P AGE INTENTIONALL Y LEFT BLANK

Section I: Safety

Page 1

5-376-000086

REV. 4 - 07/10

The safe operation of your MPL40 is your responsibility . Read this manual

and the truck manufacturer’s manual and thoroughly understand them. Y ou

can be held legally responsible for injuries or damage resulting from unsafe

operating practices.

Our recommendations for operating your equipment can help you avoid

unsafe practices and their bad consequences. These recommendations

are contained in this manual.

Jerr-Dan Corporation is not responsible for the results of any unsafe practice

of tow operators or for the failure of your equipment or its accessories resulting

from improper use or maintenance.

The danger from a vehicle continues after it is disabled or wrecked.

Recovering or towing vehicles can be dangerous too! The danger threatens

tow operators and everyone else close by. As a tow operator you must

develop an awareness of the hazards involved. Y ou must use every safeguard

within reason to prevent injuries.

Careful consideration of the immediate surrounding conditions such as the

weather, terrain, type or condition of the vehicle to be recovered and the

condition and experience of the operator is foremost to the safety and

success of the operation.

Tie-down straps are provided for use with your new Jerr-Dan Recovery V ehicle.

Periodically inspect all straps for any signs of fatigue or damage. Don’t

overlook the hooks; be sure they have not been bent or deformed. If strap or

hook damage is noted, they must be replaced before being used.

Wire rope cables wear out or can become damaged. Periodically inspect

the wire rope cable for any signs of fatigue or damage. Don’t overlook the

hooks; be sure they have not been bent or deformed. Refer to the Wire

Rope Handling and Inspection Section.

For each step in operating your equipment develop the habit of asking yourself

"is it safe to proceed?" Carefully check your set up before starting a lift or

tow.

Because recoveries can be so different, we cannot warn you of all the possible

dangers you will encounter , but we will tell you of the most common hazards

that we know about. We also recommend that you receive specialized and

advanced training from a professional T owing and Recovery instructor before

SAFETY

Section I: Safety

Page 2

5-376-000086

REV. 4 - 07/10

operating any recovery equipment and that the V ehicle Manufacturers T owing

Manual and/or American Automobile Association (AAA) T owing Manuals be

used as a reference for operating safety methods.

AAA address and phone number:

THE AMERICAN AUTOMOBILE ASSOCIA TION

1000 AAA Drive

Heathrow, FL 32746-9970

(800)222-4357

T o alert personnel to hazardous operating practices, safety messages are

used throughout the manual. Each safety message contains a safety alert

symbol and a signal word to identify the hazard's degree of seriousness.

CAUTION:

Identifies when a potentially hazardous situation exists and may

result in a minor or moderate injury or property damage.

W ARNING:

Identifies when a potentially hazardous situation exists and could

result in death or serious injury .

DANGER:

Identifies when an imminently hazardous situation exists and can

result in death or serious injury .

Section I: Safety

Page 3

5-376-000086

REV. 4 - 07/10

DO NOT EXCEED THE FOLLOWING RA TINGS:

MPL40 Underlift Rating ....................................... 4,000 lbs “L” Arm

2

T ow Rating ..................................................................... 7,500 lbs.

2

Boom Rating: (Extended)...............................................6,000 lbs.

(Retracted) ............................................16,000 lbs.

Winch Rating: (Ramsey Worm Gear Winches)

1

.....................

8,000 lbs.

(Warn Planetary Gear Winch)

1

.........................

9,000 lbs.

Wire Rope:

Working Limit ................................................4,100 lbs.

Construction ............................ 6 x 25 EIPS RRL IWRC

Diameter ........................................................... 3/8 inch

S tandard Length ..............................................100 Feet

1

SAE J706: Surface V ehicle Recommended Practices - Rating of Winches

2

SAE J2512: Surface Vehicle Recommended Practices - Towing

Equipment Ratings and Practices

MAXIMUM LIFTING CAP ACITY - THE MAXIMUM LOAD THA T CAN BE LIFTED.

GROSS COMBINED WEIGHT RA TING (GCWR) - THE V ALUE SPECIFIED BY THE VEHICLE

MANUFACTURER AS GCW.

GROSS COMBINED WEIGHT (GCW) - ACTUAL WEIGHT OF THE ENTIRE VEHICLE A T THE

GROUND WITH TRAILER OR TRAILERS, INCLUDING VEHICLE EQUIPMENT, DRIVER, PASSENGER, FUEL AND P A YLOAD (EVERYTHING THA T MOVES WITH THE VEHICLE).

Section I: Safety

Page 4

5-376-000086

REV. 4 - 07/10

NOTE

These ratings apply to the structural design of the Standard Duty Carrier only

and may be limited by the axle rating and gross vehicle weight rating of the truck

chassis.

The payload and towing capacity of any towing vehicle must meet the

following:

- The actual payload on the towing vehicle must not exceed the posted

rating and, if applicable, the towed vehicle load must not exceed

the posted lift / towing ratings.

- The total weight of the towing vehicle (cab chassis, body, payload,

driver, passenger(s), tools, fuel, etc.) and, if applicable, the towed

vehicle load must not exceed the GVWR (Gross Vehicle Weight Rating)

of the towing vehicle.

- The total weight of the towing vehicle and, if applicable, the towed

vehicle load must be distributed so that each axle’s GAWR (Gross Axle

Weight Rating) is not exceeded.

- The total weight of the towing vehicle and towed vehicle (everything

that moves with the towing vehicle) must not exceed the GCWR

(Gross Combination Weight Rating) of the towing vehicle.

Staying within these ratings is necessary to maintain the safety and

performance of the towing vehicle.

CHECK TRUCK MANUAL FOR SPECIFIC GVW & AXLE RATINGS. ALSO

REFERENCE THE CERTIFICA TION DECAL AFFIXED T O DRIVER’S SIDE DOOR

JAMB, HINGE PILLAR OR LA TCH POST AND THE S.T.A.R. PLACARD ON THE

DRIVER'S SIDE OF THE HEADBOARD.

Section I: Safety

Page 5

5-376-000086

REV. 4 - 07/10

Certification Decal

Affixed to the Driver's Side DoorJam, Hinge Pillar or Latch Post

Provided by the Final St age Vehicle Manufacturer according to Title 49

Part 567 of the Code of Federal Regulations (CFR)

MFG BY:_______________________________________

______________________________________________

DATE OF MFR:MO______________YR.______________

GVWR:_________________KG (_________________LB)

GAWR-FRONT:

______________________KG (__________________LB)

WITH____________________________________TIRES,

______________________RIMS,@______________KPA

(___________________PSI) COLD__________________

GAWR-INTERMEDIATE(1):

______________________KG (__________________LB)

WITH____________________________________TIRES,

______________________RIMS,@______________KPA

(___________________PSI) COLD__________________

GAWR-INTERMEDIATE(2):

______________________KG (__________________LB)

WITH____________________________________TIRES,

______________________RIMS,@______________KPA

(___________________PSI) COLD__________________

GAWR-REAR:

______________________KG (__________________LB)

WITH____________________________________TIRES,

______________________RIMS,@______________KPA

(___________________PSI) COLD__________________

MO._______________________YR._________________

VEHICLE IDENTIFICATION NUMBER:

_______________________________________________

VEHICLE TYPE:

_______________________________________________

THIS VEHICLE HAS BEEN COMPLETED IN ACCORDANCE WITH

THE PRIOR MANUFACTURERS' IVD, WHERE APPLICABLE.

THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL

MOTOR VEHICLE SAFETY STANDARDS, [AND BUMPER AND

THEFT PREVENTION STANDARDS, IF APPLICABLE] IN EFFECT IN:

Section I: Safety

Page 6

5-376-000086

REV. 4 - 07/10

• Don’t use a recovery vehicle that has not

been properly maintained. Pay special

attention to the mounting bolts, and

lubrication of moving parts.

• Don’t operate the wrecker’s engine faster than

recommended. Excessive speeds can

damage PTO, hydraulic pumps, and winches.

• Don’t pick-up and tow a vehicle that reduces

the weight on the front wheels of the wrecker

more than 50 percent.

• Don’t travel with the PTO or Clutch Pump

engaged. Damage to the trucks transmission,

engine or hydraulic components will occur.

Engage it only while operating the controls.

• After you have hooked up a vehicle for

towing, don’t start the tow until you have

double checked the hook-up, installed safety

chains, and released the parking brakes of

the towed vehicle.

• Don’t operate the wrecker’s engine faster than

recommended. Excessive speeds can

damage PTO, hydraulic pumps, and winches.

• Don’t rely on anti-theft steering locks to secure

the steering wheel. Use a special steering

wheel clamping device designed for this

purpose.

Section I: Safety

Page 7

5-376-000086

REV. 4 - 07/10

• Don’t tow a vehicle on its front wheels

unless the steering wheel is secured with

the front wheels straight ahead.

• Don’t tow a vehicle on its front wheels if

they are damaged.

Section I: Safety

Page 8

5-376-000086

REV. 4 - 07/10

SAFETY CHAINS MUST BE USED WHEN TOWING

AND TRANSPORTING

Safety chains are provided for use with your new Jerr-Dan Recovery V ehicle.

Periodically inspect all chains for any signs of fatigue or damage. Don’t

overlook the hooks; be sure they have not been bent or deformed. If chain or

hook damage is noted, they must be replaced before being used. Do not

use safety chains for recovery operations.

Many states require that the towed vehicle be secured to the wrecker body

with safety chains. Check your local regulations and use your safety chains.

Safety chains are provided for use with your new JERR-DAN.

• Never attach the chain hooks in such a

way as to damage brake lines or other

functional parts.

• Keep in mind that driving over bumps and

hollows and around corners will tend to

tighten or loosen the chains.

• Check that the chain does not become over

tensioned when raising the towed vehicle to the

towing position or during the towing operation.

• Always use two safety chains when towing all

vehicles, regardless of distance.

Section I: Safety

Page 9

5-376-000086

REV. 4 - 07/10

LIFT SAFETY

Careful consideration of the immediate surrounding conditions such as the

weather, terrain, type or condition of the vehicle to be recovered and the

condition and experience of the operator is foremost to the safety and

success of the operation. In addition, the intent of the design of this unit

should be taken before the undertaking of its use.

Your MPL40 is unique. It not only can make lifts from level surfaces, our

boom tilt feature allows pickup of vehicles that are parked on both inclines

and declines.

• You should never make a lift or movement

while close to or under the vehicle being

lifted!

• Always use jack stands to support the vehicle

if it is necessary to work under it.

• Towing lights are required in many areas and are always recommended for safe

tows.

Section I: Safety

Page 10

5-376-000086

REV. 4 - 07/10

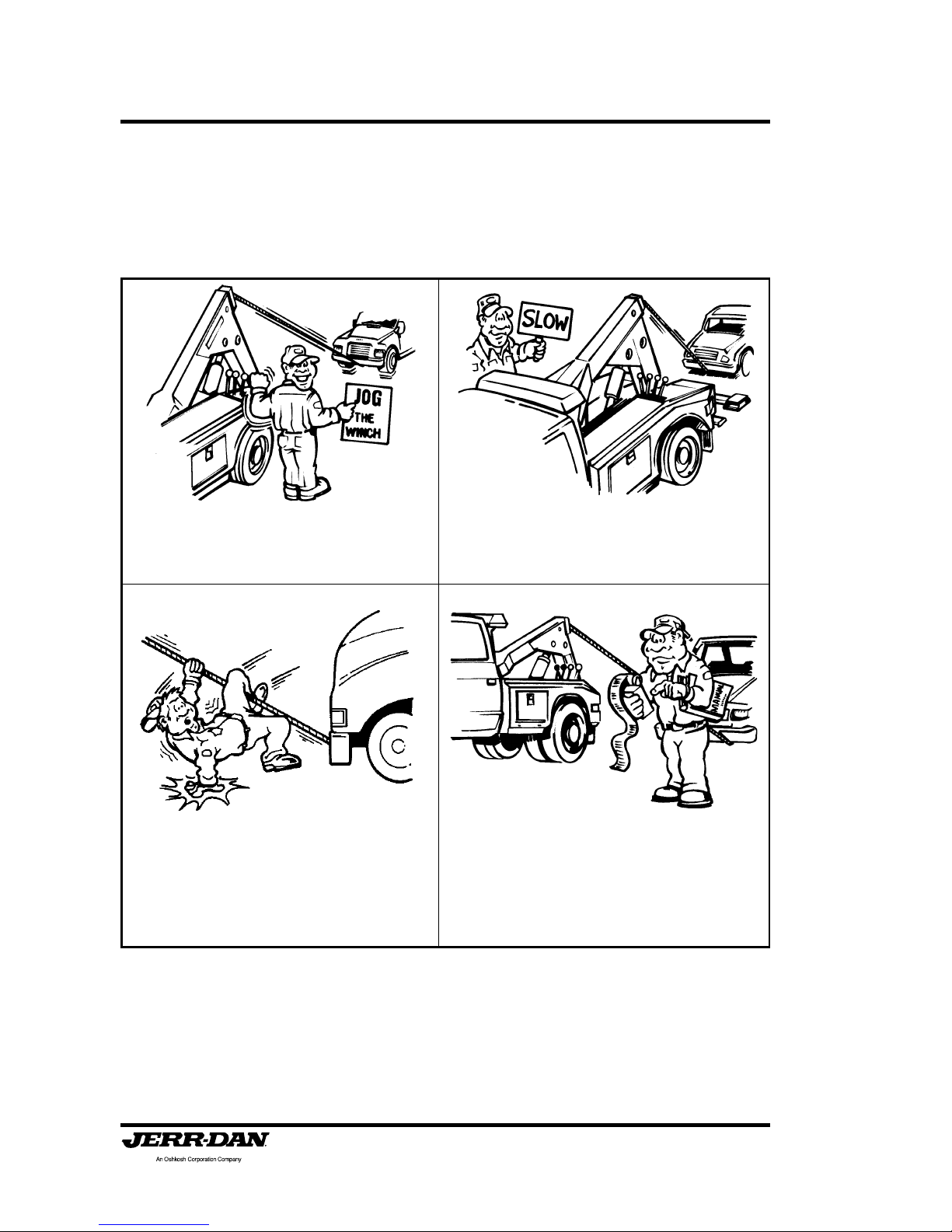

• Jog the winch control lever to be sure of

complete engagement of the clutch gears

before making a lift or pull.

• Never stand on or straddle a working wire

rope.

• Take up the wire rope slowly and be sure

the hook is securely set.

• Be sure of your lift or pull and do not exceed

the working strength of the wire rope or hook.

Rig to keep the estimated amount of pull

well within equipment ratings. Use wire rope

breaking strength ratings only for selecting

replacement wire rope.

BOOM SAFETY

Your MPL40 is equipped with a recovery winch and the following safety

procedures must be observed:

Section I: Safety

Page 11

5-376-000086

REV. 4 - 07/10

• Never lift or pull over or around a sharp obstacle.

• Never completely unwind wire rope from a

winch while loaded. Always be sure that a

minimum of five (5) wraps of wire rope are on

the drum at all times.

• Never tie down the front end of your wrecker

for recovery work of heavy lifts. You will

likely damage the truck frame if you do.

• Never allow the wire rope to cross wrap

(criss-cross) on the winch drum. Crushing

of the wire rope can cause wire rope failure.

• Never make a lift or pull with the wire rope

attached to light gauge or sheet metal parts;

use the frame or major structural members.

• Don’t disengage the winch drum clutch while

the wire rope is loaded.

Section I: Safety

Page 12

5-376-000086

REV. 4 - 07/10

• Don’t permit bystanders in the area while

performing recovery work.

• Never wrap the wire rope around frames or

cross members. Use chains and hook the

wire rope to the chains.

• Don’t use damaged wire ropes on your

wrecker. Become familiar with the various

types of wire rope damage and periodically

inspect the entire wire rope for wear and

corrosion. Never use wire rope menders.

Replace with similar rated wire rope and

hooks.

• Be sure all brakes and locks are properly

set on the recovery vehicle.

• Never under any circumstances use the

winch or boom to lift people!

• Lubricate and maintain both the wire rope

and winch on regular intervals. (See

maintenance charts.)

Section I: Safety

Page 13

5-376-000086

REV. 4 - 07/10

• All boom placement functions should be

made with the winch wire ropes set in “free

spool” to avoid over tensioning or breaking

the winch wire ropes.

• Avoid using the boom raise or boom up

control to lift a load. This causes undue

stress and weight loading on the rear axle.

Use the winch to lift the load.

• After rigging wire ropes, don’t begin pulling

without rechecking connections. Make sure

that all wire ropes and snatch blocks are

securely attached and cannot accidently

pull loose.

• Don’t tow a vehicle on its drive wheels unless

steps have been taken to protect its

transmission and differential. Follow the

recommendations of the vehicle manufacturer. As an alternative, use a towing

dolly.

• To avoid birdnesting and premature failure

of the wire rope, always keep tension on

the wire rope when unwinding.

• Don’t exceed ratings of booms, wire ropes,

snatch blocks, or winches. Stay within

nameplate ratings.

Section I: Safety

Page 14

5-376-000086

REV. 4 - 07/10

• Hook up and make the lift in strict

accordance with AAA’s instructions.

• Never attach the chain hooks in such a

way as to damage brake lines or other

functional parts.

• Be sure the chains and hooks are attached

to frame members and not sheet metal.

• Never make a front lift without unlatching

the hood of the vehicle.

SLING SAFETY

If your MPL40 is equipped with an optional tow sling certain safety

precautions must be taken to ensure safe operation. Consult the AAA

Towing Manual for the make and model of the vehicle to be towed and

observe the following safety procedures:

Section I: Safety

Page 15

5-376-000086

REV. 4 - 07/10

• The bottom anchor assembly (round tube) must never be higher than the attachment point on

the rear of the MPL40. The rear stand off bar assembly acts as a pivot in the event of a

sudden stop. This will asure that the casualty vehicle will not catapult forward onto the deck of

the recovery vehicle.

Section I: Safety

Page 16

5-376-000086

REV. 4 - 07/10

CAUTION

424

424

TOWHITCHBRACKET

MUST BE REMOVED

BEFORE UNFOLDING

THEBOOMDOWNFOR

WHEEL GRID OPERATION

TOW HITCH BRACKET

MUST BE REMOVED

BEFORE UNFOLDING

THE BOOM DOWN FOR

WHEEL GRID OPERATION

SAFETY WARNING DECALS

As an extra safety precaution, your MPL40 has specific safety and warning

decals affixed to prominent locations. These decals must not be obliterated,

removed or painted over . They are there to remind and protect the operator .

CAUTION

034

CHECK HYDRAULIC FLUID LEVEL

FILL ONLY WITH APPROVED FLUID

(SEE OPERATOR'S MANUAL)

T

WARNING

122

122

TOWED VEHICLE MUST BE

CONNECTED TO TOW TRUCK BODY

WITH SAFETY CHAINS

TOWED VEHICLE MUST BE

CONNECTED TO TOW TRUCK BODY

WITH SAFETY CHAINS

546

A MINIMUM OF 5 WRAPS OF CABLE MUST

BE LEFT

O

N WINCH DRUM TO ACHIEVE

RATED L

OAD.

DO NOT USE WINCH TO MOVE OR LIFT

PERSONS.

WARNIN

G

WARNING

WARNING

036

036

VEHICLE MUST BE SECURED TO WHEEL

GRID USING BOTH TIE DOWN STRAPS

PRIOR

TO LEAVING LOADING

SITE

VEHICLE MUST BE SECURED TO WHEEL

GRID USING BOTH TIE DOWN STRAPS

PRIOR

TO VING LOADING

Section I: Safety

Page 17

5-376-000086

REV. 4 - 07/10

BODY NO:

SERIAL NO:

TOW RATING: LBS. (MAXIMUM)

UNDER LIFT NO:

UNDER LIFT CAPACITY: LBS. *

VIN C.A. IN.

* NOTE: LIFT CAPACITY INDICATES THE

STRUCTURAL CAPACITY OF THE LIFT MECHANISM,

NOT THE MAXIMUM EFFECTIVE TRANSPORT LOAD.

REAR AXLE WEIGHT RATING (GAWR): LBS.

TRUCK CHASSIS INFORMATION

THE MAXIMUM EFFECTIVE TRANSPORT LOAD OF

THIS UNIT BASED ON TRUCK CHASSIS

G.A.W.R. AND G.V.W.R SPECIFICATIONS

DO NOT EXCEED THE FOLLOWING WEIGHTS

LBS. AT FULL EXTENSION

LBS. AT 10” EXTENSION

LOSS OF VEHICLE CONTROL, WHICH COULD RESULT

IN SERIOUS BODILY INJURY OR DEATH, CAN OCCUR

IF THE EFFECTIVE TRANSPORT LOAD IS EXCEEDED.

MAXIMUM EFFECTIVE TRANSPORT LOAD IS AFFECTED BY THE CHASSIS

ON WHICH THE TOWING EQUIPMENT IS INSTALLED. BEFORE

ATTEMPTING TO USE THIS EQUIPMENT ON A CHASSIS OTHER THAN

THAT SPECIFIED ABOVE, CONTACT JERR-DAN TO OBTAIN

A REVISED RATING.

SAFETY IS NO ACCIDENT.

REVIEW OPERATOR’S PRE-TRANSPORT CHECKLIST IN THE OWNER’S

MANUAL EACH TIME YOU MOVE A VEHICLE. FOLLOW ALL

INSTRUCTIONS ON CONTROLS AND UNIT.

© COPYRIGHT 1999

JERR-DAN CORPORATION

307

Hazardous voltage.

Will cause severe

injury or death.

Hazardous voltage.

Will cause severe

injury or death.

Do not raise, lower

or move boom within

near power lines.

Do not raise, lower

or move boom within

near power lines.

203

203

DANGER

DANGER

WARNING

037

MOVING PARTS

KEEP HANDS AND FEET CLEAR

OF THIS AREA

Section I: Safety

Page 18

5-376-000086

REV. 4 - 07/10

THIS P AGE INTENTIONALL Y LEFT BLANK

Section II: Operation

Page 19

5-376-000086

REV. 4 - 07/10

WHEEL-LIFT OPERATION

Your MPL40 is one of the most useful and efficient towing and recovery

vehicles available. It is hydraulically powered and careful consideration should

be given to the selection of commands. You can afford to work smart, the

vehicle will do most of the work for you.

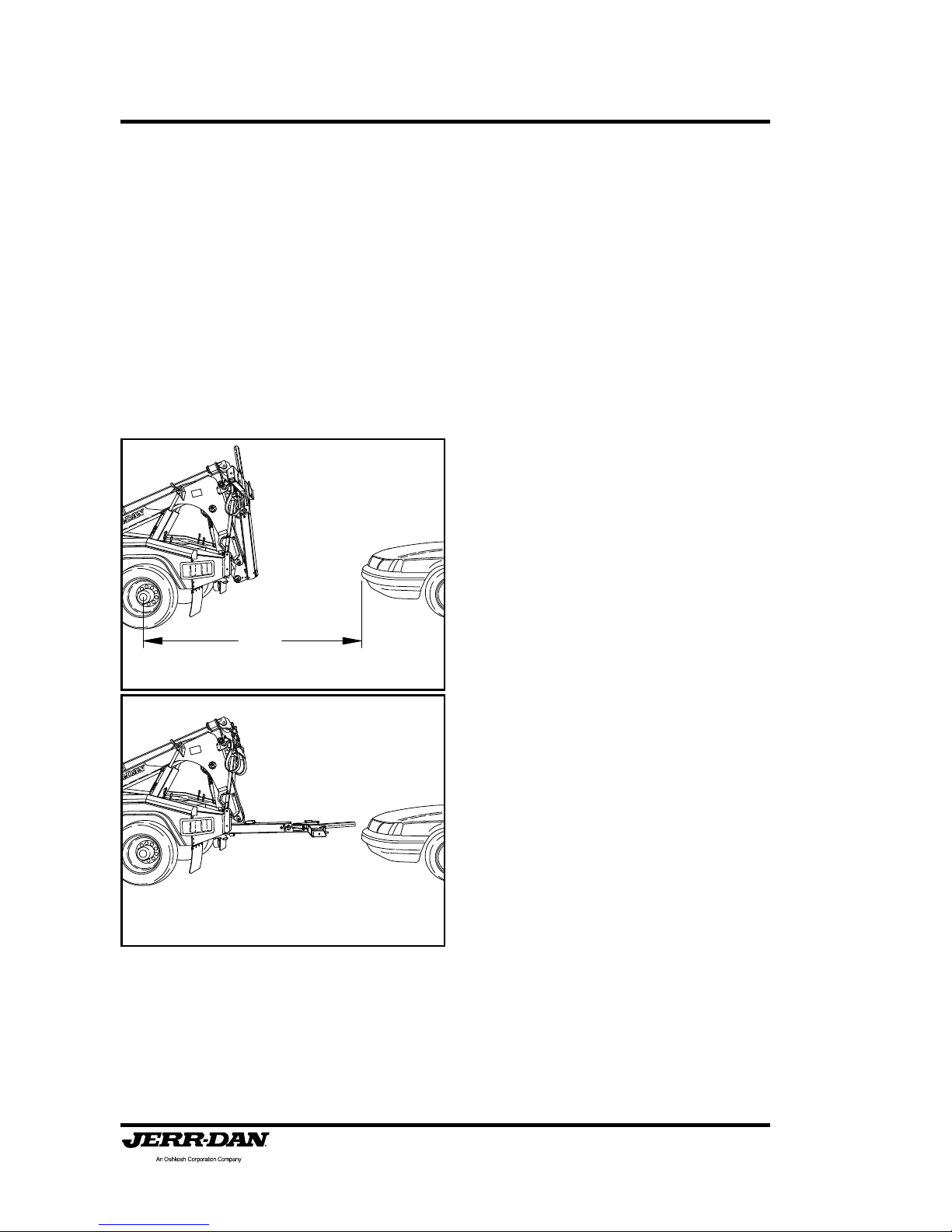

Follow these simple steps:

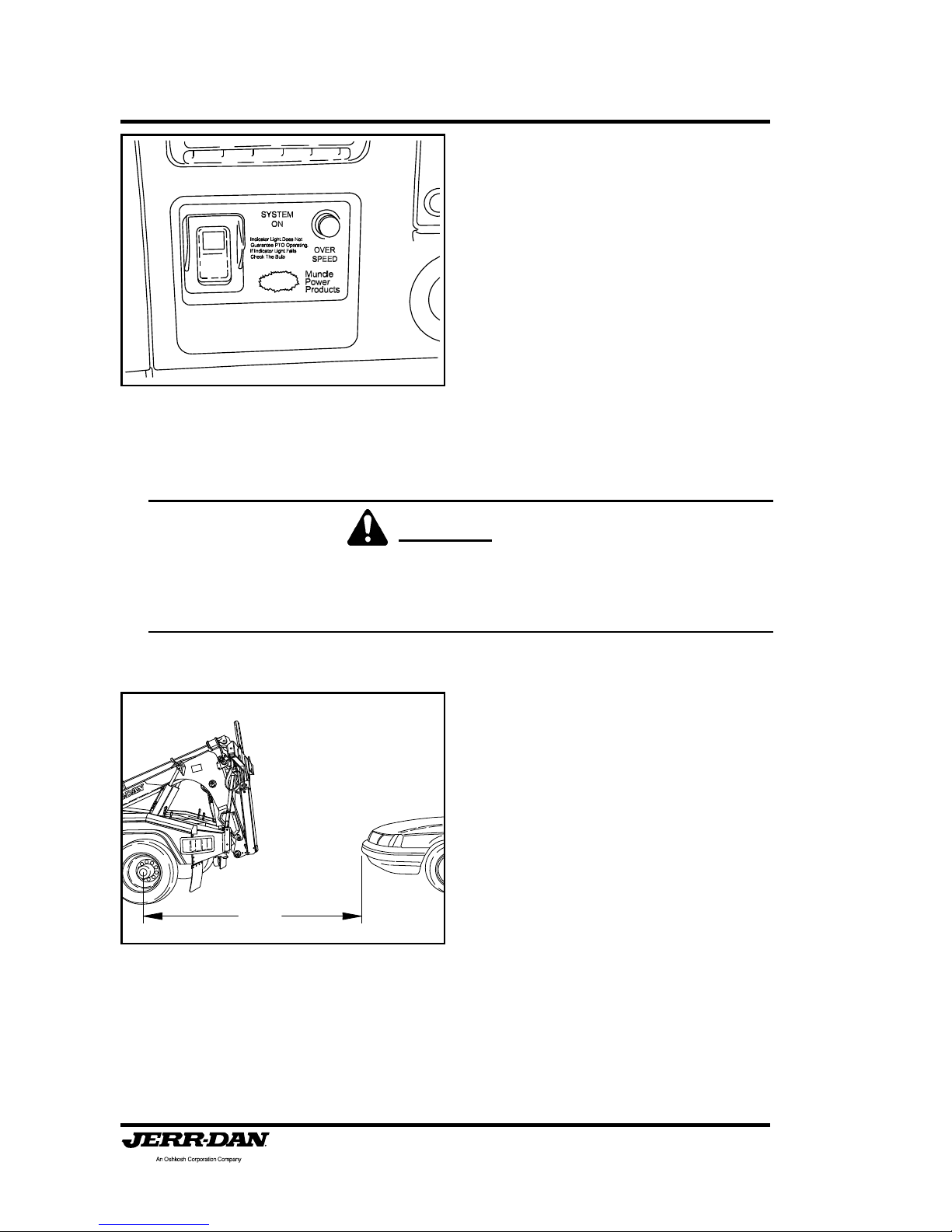

1. Turn on the safety and work

lights. (Switches located on the

dash panel).

2. Position the truck within 9 ft. of

the subject vehicle and as close

to the direction of the pull as

possible.

3. Set the truck’s parking brakes

and put the transmission in park

or neutral.

9 FT

OPERATION

Section II: Operation

Page 20

5-376-000086

REV. 4 - 07/10

4. Engage the Power-Take-Off

(PTO) or Clutch Pump and the

hand controller using the “Control”

switch in the switch panel. Most

trucks will automatically throttle

up when the parking brake is set

and the transmission is park or

neutral. NEVER TRAVEL WITH

THE POWER-TAKE-OFF or

CLUTCH PUMP CONTROL

ENGAGED. This could result in

damage to the PTO or Clutch

Pump unit and the truck

transmission.

CAUTION:

Never exceed 1,500 R.P.M. When your hook up is complete, reset

the engine idle to normal.

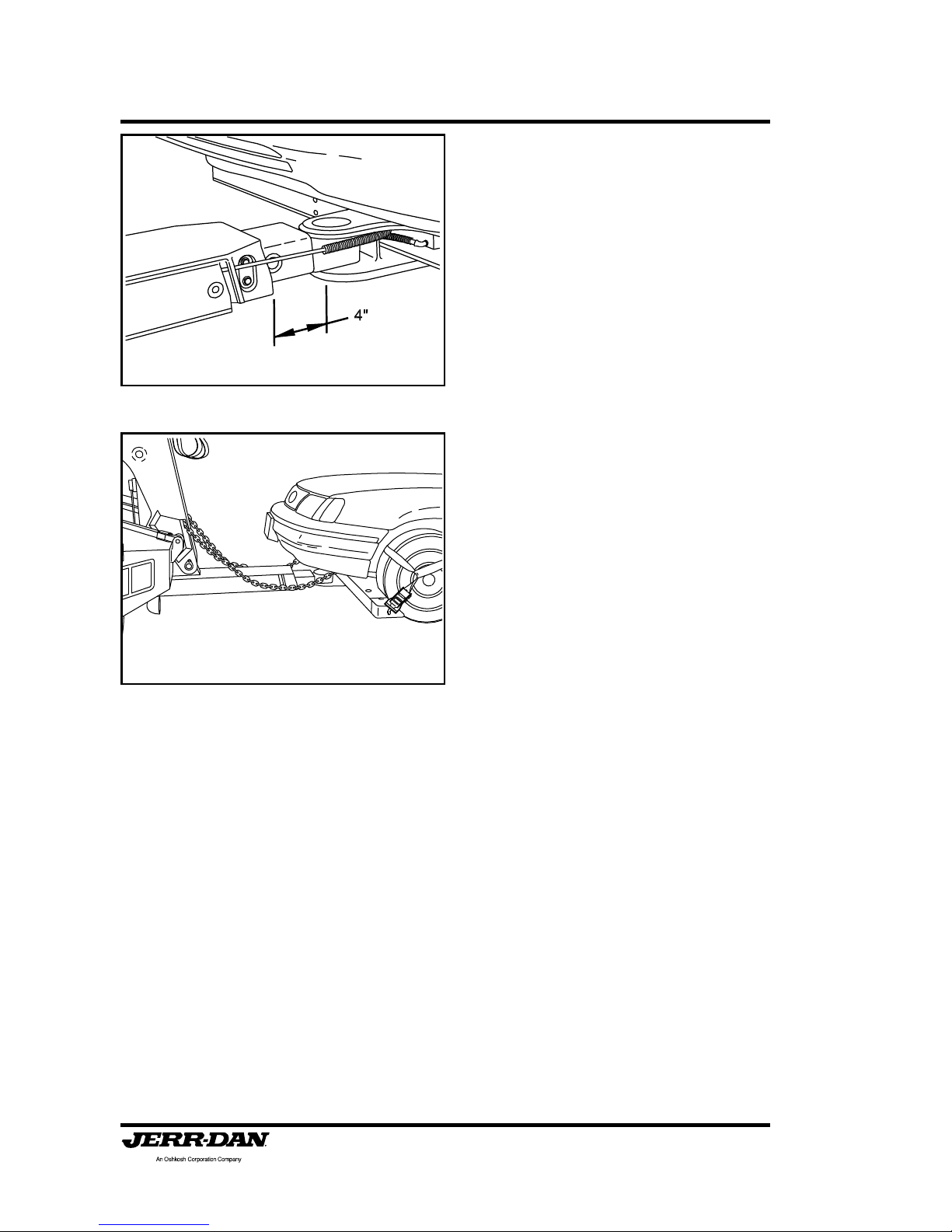

5. Confirm the truck’s position in

relation to the vehicle to be towed.

Nine (9) feet is recommended.

Reposition the MPL40 if

necessary. Be sure the towed

vehicle is not in gear or park.

Keep the brake set.

9 FT

Section II: Operation

Page 21

5-376-000086

REV. 4 - 07/10

6. Using the hand controller or

manual controls located at the

rear of the body, unfold the

underlift using the tilt down

function. The underlift level stop

assist system will stop the

underlift travel at a preset position.

7. Next, lower the underlift using the

underlift down funtion on the hand

controller . The underlift level stop

assist system will stop the

underlift travel at a preset position

about 1-1/2" to 2” from the ground.

NOTE:

To override either stop

position, simply release the

control function and

reactivate the same control

function again to achieve

further travel of the underlift.

Section II: Operation

Page 22

5-376-000086

REV. 4 - 07/10

8. Extend the underlift under the

vehicle being sure that all under

carriage parts are cleared and that

the front portion of the grid is in

contact with both tires. Lower the

grid fully to the ground. There is

no reason for the operator to

get under the vehicle.

9. Visually inspect the tire to grid

contact before proceeding.

10. Close the grid arms around the

tires to secure the towed vehicle.

Make sure that the arm is fully

closed and in its over center

locked position.

11. After securing the grid arms

around the towed vehicles tires

and before making the actual lift,

check to be sure the towed

vehicle’s parking brake is

released, the transmission is in

neutral, and the wheels are

straight.

NOTE:

If vehicle to be towed is on a

slope, do not release the

brake until the tie-down

straps are installed. Observe

the wheels in the grid for any

slippage.

12. It is recommended that the

steering wheel be secured by a

steering wheel strap for any tow.

Section II: Operation

Page 23

5-376-000086

REV. 4 - 07/10

13. Lift the vehicle high enough to

allow the tires to clear the ground.

Make sure that the grid is not in

contact with any engine or body

components.

14. Remove the tie down straps from

tool boxes and attach the tie

down straps. (See Tie-Down

Strap instructions).

15. With the straps in place, the

vehicle in neutral and the parking

brake released, you can move the

vehicle safely up, down, in or out.

All of these movements are

hydraulically controlled by the

hand controller .

16. Raise the vehicle into the final

towing position observing the far

end for sufficient ground

clearance. It is possible to set the

rear of a front lifted vehicle

completely onto the ground,

causing damage. Take irregular

roadsurfaces into consideration.

Observe the lift function from the

side and away from both vehicles

if possible.

NOTE:

For the best towing and

maneuverability the boom

should be as close to

horizontal as possible.

Section II: Operation

Page 24

5-376-000086

REV. 4 - 07/10

17. Power retract the grid boom until

the towed vehicle is about 3 to 4

feet from the back of the truck.

Leave enough room to maneuver

around corners without corner

binding or causing contact

between the two (2) vehicles. Be

sure that the boom is extended

at least 4" to ensure

unobstructed crossbar

pivoting.

18. Be sure to maintain sufficient

clearances with the bottom of the

towed vehicle.

19. Attach the safety chains and

towing lights. Safety chains

should be crossed from one

side of the recovery vehicle to

the opposite side of the towed

vehicle.

Section II: Operation

Page 25

5-376-000086

REV. 4 - 07/10

TIE DOWN STRAPS

The MPL40 is supplied with a set of high strength polyester web tie down

straps. They are to be used to secure wheels of the towed vehicle to the

wheel lift grid. NEVER TOW A VEHICLE WITHOUT THE TIE DOWN

STRAPS INST ALLED.

The tie down strap assembly is

comprised of 2 basic components:

1. The S trap/Hook Assembly

2. The Ratchet S pool

Mechanism

The following steps should be

followed to properly install the tie

down straps:

USING THE RATCHET SPOOL MECHANISM

1. First the spool must be set into

“free spool”. This is done by

pulling the lock bar out and

swinging the handle upward until

it rests in the free spool notch and

then simply pulling out the

amount of strap required to fit over

the tire.

2. Now pull on the lock bar and move

it downward until it engages the

ratchet teeth on the take up spool.

By pushing and pulling the handle

up and down, the strap will be

wound onto the spool.

Section II: Operation

Page 26

5-376-000086

REV. 4 - 07/10

3. T o release the ratchet, simply pull

on the locking bar, disengaging

the teeth and raise the handle to

the “free spool” position.

INSTALLING THE TIE DOWN STRAP

1. With the vehicle lifted just barely

off the ground, insert the end of

the strap through the sewn loop

on the other end of the strap to

form a loop. Put the loop over

the tire as shown with the strap

resting on the tire at the ten

o’clock and two o’clock positions.

The choker strap should be

across the center of the tire.

2. Place the rear hook of the strap

assembly into a hole on the back

side of the grid arm. Try to use

the hole that is closest to the tire.

Section II: Operation

Page 27

5-376-000086

REV. 4 - 07/10

3. Place the hook of the ratchet into

one of the holes on the front side

of the grid. Again, try to use the

hole that is closest to the tire.

NOTE:

The hole on the outside of the

grid can be used to hook the

ratchet in if you need to clear

body mouldings or wide tires.

4. Take up the slack in the strap by

ratcheting the takeup spool arm.

Continue until the tires show

some compression. Notice that

the strap in the ratchet is

pulling down and forward on

the loop over the tire.

5. Raise the wheel grid to the towing position. RE-TIGHTEN THE

RATCHET PERIODICALLY AS

THE TIRE SETTLES IN GRID

FROM TOWING.

NOTE:

Never tow a vehicle without

tire tie-down straps and

safety chains installed.

Section II: Operation

Page 28

5-376-000086

REV. 4 - 07/10

WHEEL GRID SPACERS

The MPL40 with the self loading grid is supplied with a set wheel grid spacers.

They can be used to pick up a vehicle with small diameter tires or even a

vehicle without wheels and tires.

The following steps should be

followed to properly install the wheel

grid spacers:

1. Slide the back side of the wheel

spacer over the wheel grid arm.

2. Close the grid arms around the

tires to secure the towed vehicle.

Make sure that the arm is fully

closed and in its over center

locked position.

3. Visually inspect the tire to grid

contact before proceeding.

Section II: Operation

Page 29

5-376-000086

REV. 4 - 07/10

TOWBALL HITCH ATTACHMENT

The MPL40 is supplied with a Towball Hitch attachment that will allow you

to recover and tow trailers requiring a tow ball hookup.

DO NO EXCEED THE FOLLOWING RA TINGS:

1-7/8 in. Ball:................................5,000 lbs. (GTW)*

2 in. Ball: .....................................5,000 lbs. (GTW)*

2-5/16 in. Ball:..............................7,500 lbs. (GTW)*

50 MM Ball: .................................5,000 lbs. (GTW)*

* Gross T ongue W eight

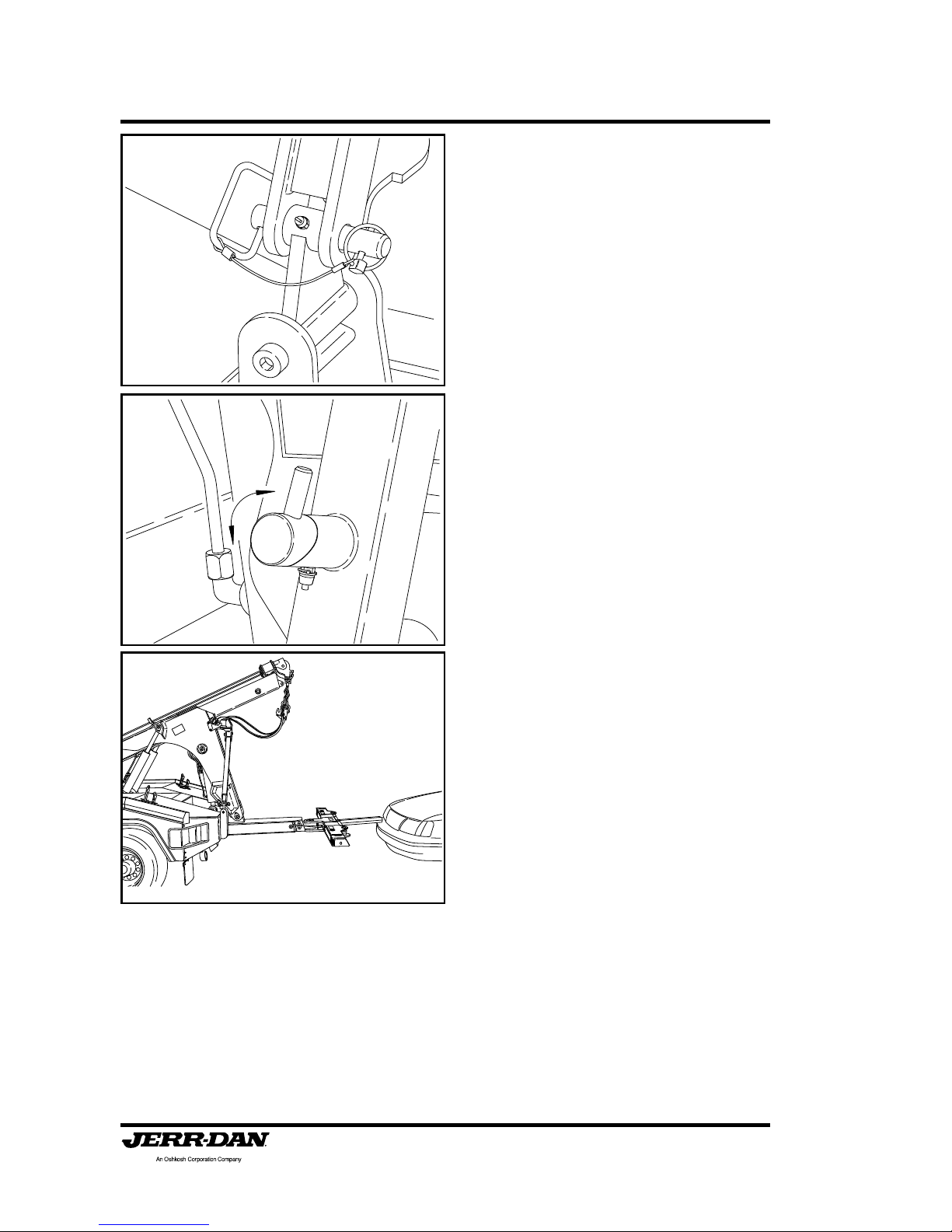

1. Remove the towball hitch

attachment from the toolbox.

2. Install the towball hitch to the

bottom on the underlift boom using

the hitch pins.

3. Secure the hitch pins with the

linch pins.

Section II: Operation

Page 30

5-376-000086

REV. 4 - 07/10

4. Install the desired towball to

the towball hitch.

5. Position the ball coupler over

the ball and lock into place.

CAUTION:

Make sure that the ball and

coupler are of the same

matched size.

6. Connect the trailer lights and

attach safety chains.

Section II: Operation

Page 31

5-376-000086

REV. 4 - 07/10

WRECKER BOOM OPERATION

SINGLE LINE BOOM - WORM GEAR WINCH

The MPL40 wrecker boom is an extremely effective tool in recovery or retrieval

prior to lifting and towing. To operate the wrecker boom effectively, care and

thought must be given.

Boom Rating: (Extended) .....................................6,000 lbs.

(Retracted) ..................................16,000 lbs.

Winch Rating: (Ramsey Worm Gear)...................8,000 lbs.

Wire Rope Working Limit: ....................................4,100 lbs.

Wire Rope Construction: ................ 6 x 25 EIPS RRL IWRC

Wire Rope Size:.................................... 3/8 inch x 100 Feet

*All ratings comply with SAE J2512 and SAE J706 Recommended Practice

WARNING:

Do not exceed the working limit of the wire rope. Use snatch blocks

and multiple lines to reduce the load on the wire rope.

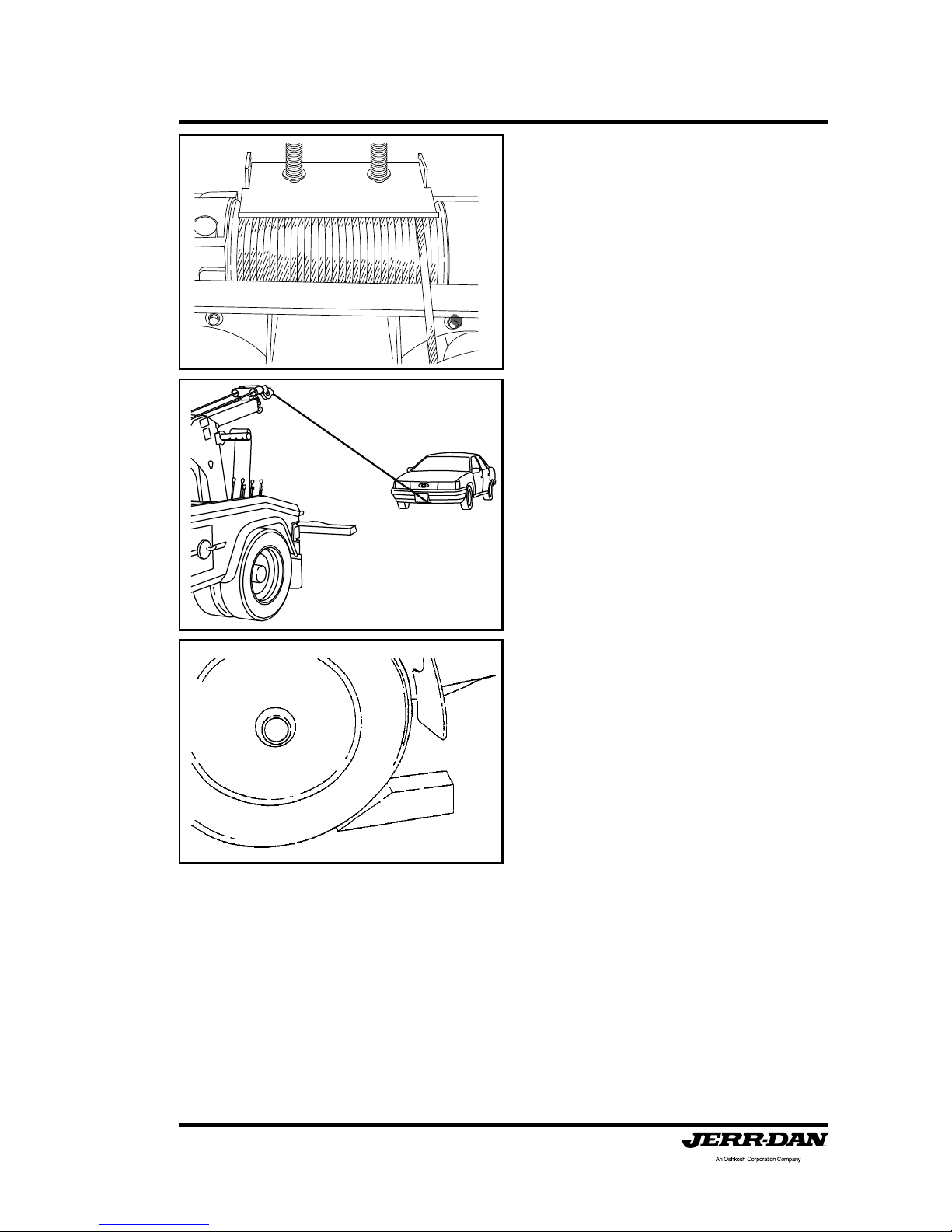

1. Check the direction you wish the

work to travel, being sure there

are no major obstacles in the

way.

Section II: Operation

Page 32

5-376-000086

REV. 4 - 07/10

2. Position and align the truck to

obtain as direct a pull as possible.

Straight line pulls are the best and

most efficient.

3. Set the brakes on your Jerr-Dan

unit.

4. Unfold the under lift boom.

5. If a heavy lift or pull is to be made

additional lines may be

necessary. Always use more

stabilizing lines than pull lines.

RIG FOR SAFETY. The use of

scotch blocks is also

recommended.

6. Unhook the wire rope cables from

the top of the tow sling.

Section II: Operation

Page 33

5-376-000086

REV. 4 - 07/10

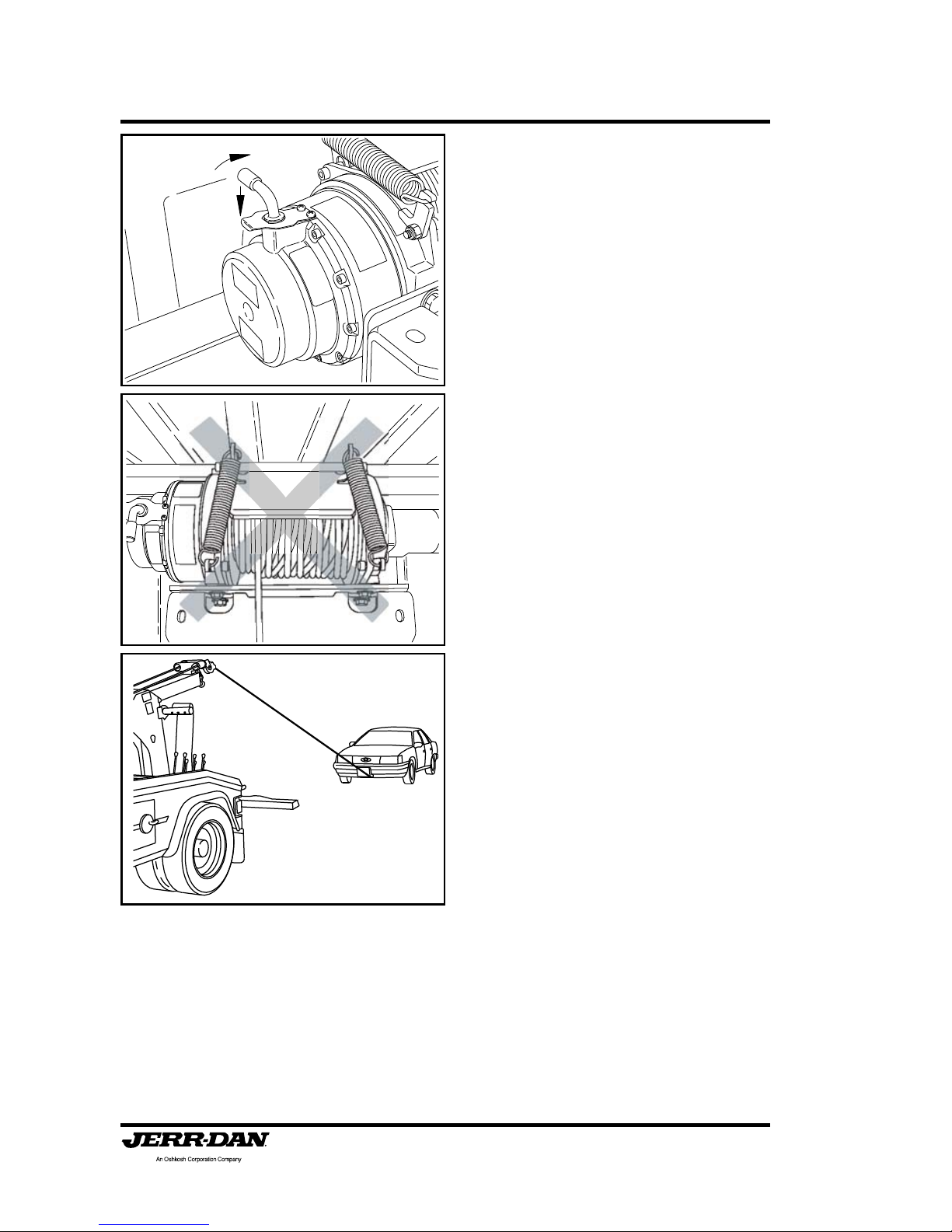

7. Disengage the winch “free-spool”

by pulling out on the “T” handle

and turning the handle 90°. The

handle should remain in the “freespool” position. Never turn this

handle while the wire rope is

under load! This allows the wire

rope to be pulled directly off the

drum to the work.

8. Position the boom head by using

the boom up and down control

lever and the boom in and out

lever .

Section II: Operation

Page 34

5-376-000086

REV. 4 - 07/10

9. Attach the wire rope hook to a

chain sling, or bridle and hook

securely to the work. Be sure of

this hook up; you don’t want it

breaking loose during the pull.

(See the safety sections earlier

in this manual). Do not connect

to thin or loose body panels or

components that could break

loose during the winching

operation. Slings and bridles are

usually designed with hook

clusters on them. Most chassis

manufacturer’s provide tie-down

hooks and/or slots in chassis

frames that may be able to be

used as recovery attachment

points. (Consult the Chassis

Manufacturer’s Towing Manual

and/or the American Automobile

Association (AAA) Towing

Manuals.)

10. Reengage the winch “free-spool”

by turning the handle back 90°.

11. Jog the winch control until the

handle retracts into the engaged

position. Now slowly take up the

slack in the wire rope.

Section II: Operation

Page 35

5-376-000086

REV. 4 - 07/10

12. With the wire rope tight, slowly

wind it in, observing both the work

and the drum. Be sure the wire

rope strands do not cross wrap

or criss-cross on the drum.

Observe the path the work must

travel for snags or obstructions

which could stall the movement

and overload the wire rope.

13. Once the work is in the desired

position, apply the towed vehicles

parking brake or use blocks or tie

the work down if there is any

question about stability. Slowly

reduce the wire rope tension.

After enough wire rope has been

unwound, you may remove the

hookup.

Section II: Operation

Page 36

5-376-000086

REV. 4 - 07/10

14. Now slowly retrieve the wire rope,

carefully winding the wire rope

onto the drum. Many operators

take this opportunity to do a

visual inspection. When you’ve

finished rewinding the wire rope,

be sure you don’t overwind it.

Always wear safety glasses and

gloves when doing recovery work

or handling the wire rope.

Remember, most wire rope failures are caused by cable

crushing or the operator underestimating the pull or over

estimating the wire rope strength.

Section II: Operation

Page 37

5-376-000086

REV. 4 - 07/10

WRECKER BOOM OPERATION

SINGLE LINE BOOM - PLANETARY GEAR WINCH

The MPL40 wrecker boom is an extremely effective tool in recovery or retrieval

prior to lifting and towing. To operate the wrecker boom effectively, care and

thought must be given.

Boom Rating: (Extended) .....................................6,000 lbs.

(Retracted) ..................................16,000 lbs.

Winch Rating: (Warn Planetary Gear) ..................9,000 lbs.

Wire Rope Working Limit: ....................................4,100 lbs.

Wire Rope Construction: ................ 6 x 25 EIPS RRL IWRC

Wire Rope Size:.................................... 3/8 inch x 100 Feet

*All ratings comply with SAE J2512 and SAE J706 Recommended Practice

WARNING:

Do not exceed the working limit of the wire rope. Use snatch blocks

and multiple lines to reduce the load on the wire rope.

1. Check the direction you wish the

work to travel, being sure there

are no major obstacles in the

way.

Section II: Operation

Page 38

5-376-000086

REV. 4 - 07/10

2. Position and align the truck to

obtain as direct a pull as possible.

Straight line pulls are the best and

most efficient.

3. Set the brakes on your Jerr-Dan

unit.

4. Unfold the under lift boom.

5. If a heavy lift or pull is to be made

additional lines may be

necessary. Always use more

stabilizing lines than pull lines.

RIG FOR SAFETY. The use of

scotch blocks is also

recommended.

6. Unhook the wire rope cables from

the top of the tow sling.

Section II: Operation

Page 39

5-376-000086

REV. 4 - 07/10

7. Release the free spooling lever

on the winch by pushing down on

the spring steel latch plate and

turning the handle 180°. Never

turn this handle while the wire

rope is under load! This allows

the wire rope to be pulled directly

off the drum to the work. Unwind

enough wire rope to make the

hook-up being sure that a

minimum of at least five (5) wraps

of wire rope remains on the

drums.

8. Position the boom head by using

the boom up and down control

lever and the boom in and out

lever .

9. Attach the wire rope hook to a

chain sling, or bridle and hook

securely to the work. Be sure of

this hook up; you don’t want it

breaking loose during the pull.

(See the safety sections earlier

in this manual). Do not connect

to thin or loose body panels or

components that could break

loose during the winching

operation. Slings and bridles are

usually designed with hook

clusters on them. Most chassis

manufacturer’s provide tie-down

hooks and/or slots in chassis

frames that may be able to be

used as recovery attachment

points. (Consult the Chassis

Manufacturer’s Towing Manual

and/or the American Automobile

Association (AAA) Towing

Manuals.)

Section II: Operation

Page 40

5-376-000086

REV. 4 - 07/10

10. Re-engage the winch drive by

pushing down on the spring steel

latch plate and turning the handle

180°. Confirm winch engagement

by jogging the winch control. Now

slowly take up the slack in the

wire rope.

11. With the wire rope tight, slowly

wind it in, observing both the work

and the drum. Be sure the wire

rope strands do not cross wrap

or criss-cross on the drum.

Observe the path the work must

travel for snags or obstructions

which could stall the movement

and overload the wire rope.

Section II: Operation

Page 41

5-376-000086

REV. 4 - 07/10

Remember, most wire rope failures are caused by cable

crushing or the operator underestimating the pull or over

estimating the wire rope strength.

12. Once the work is in the desired

position, apply the towed vehicles

parking brake or use blocks or tie

the work down if there is any

question about stability. Slowly

reduce the wire rope tension.

After enough wire rope has been

unwound, you may remove the

hookup.

13. Now slowly retrieve the wire rope,

carefully winding the wire rope

onto the drum. Many operators

take this opportunity to do a

visual inspection. When you’ve

finished rewinding the wire rope,

be sure you don’t overwind it.

Always wear safety glasses and

gloves when doing recovery work

or handling the wire rope.

Section II: Operation

Page 42

5-376-000086

REV. 4 - 07/10

WRECKER BOOM OPERATION

DUAL LINE BOOM - WORM GEAR WINCHES

The MPL40 wrecker boom is an extremely effective tool in recovery or retrieval

prior to lifting and towing. To operate the wrecker boom effectively, care and

thought must be given.

Boom Rating: (Extended) .....................................6,000 lbs.

(Retracted) ..................................16,000 lbs.

Winch Rating: (Ramsey Worm Gear)...................8,000 lbs.

Wire Rope Working Limit: ....................................4,100 lbs.

Wire Rope Construction: ................ 6 x 25 EIPS RRL IWRC

Wire Rope Size:.................................... 3/8 inch x 100 Feet

*All ratings comply with SAE J2512 and SAE J706 Recommended Practice

WARNING:

Do not exceed the working limit of the wire rope. Use snatch blocks

and multiple lines to reduce the load on the wire rope.

1. Check the direction you wish the

work to travel, being sure there

are no major obstacles in the

way.

Section II: Operation

Page 43

5-376-000086

REV. 4 - 07/10

2. Position and align the truck to

obtain as direct a pull as possible.

Straight line pulls are the best and

most efficient.

3. Set the brakes on your Jerr-Dan

unit.

4. Unfold the under lift boom.

5. If a heavy lift or pull is to be made

additional lines may be

necessary. Always use more

stabilizing lines than pull lines.

RIG FOR SAFETY. The use of

scotch blocks is also

recommended.

6. Unhook the wire rope cables from

the top of the tow sling.

Section II: Operation

Page 44

5-376-000086

REV. 4 - 07/10

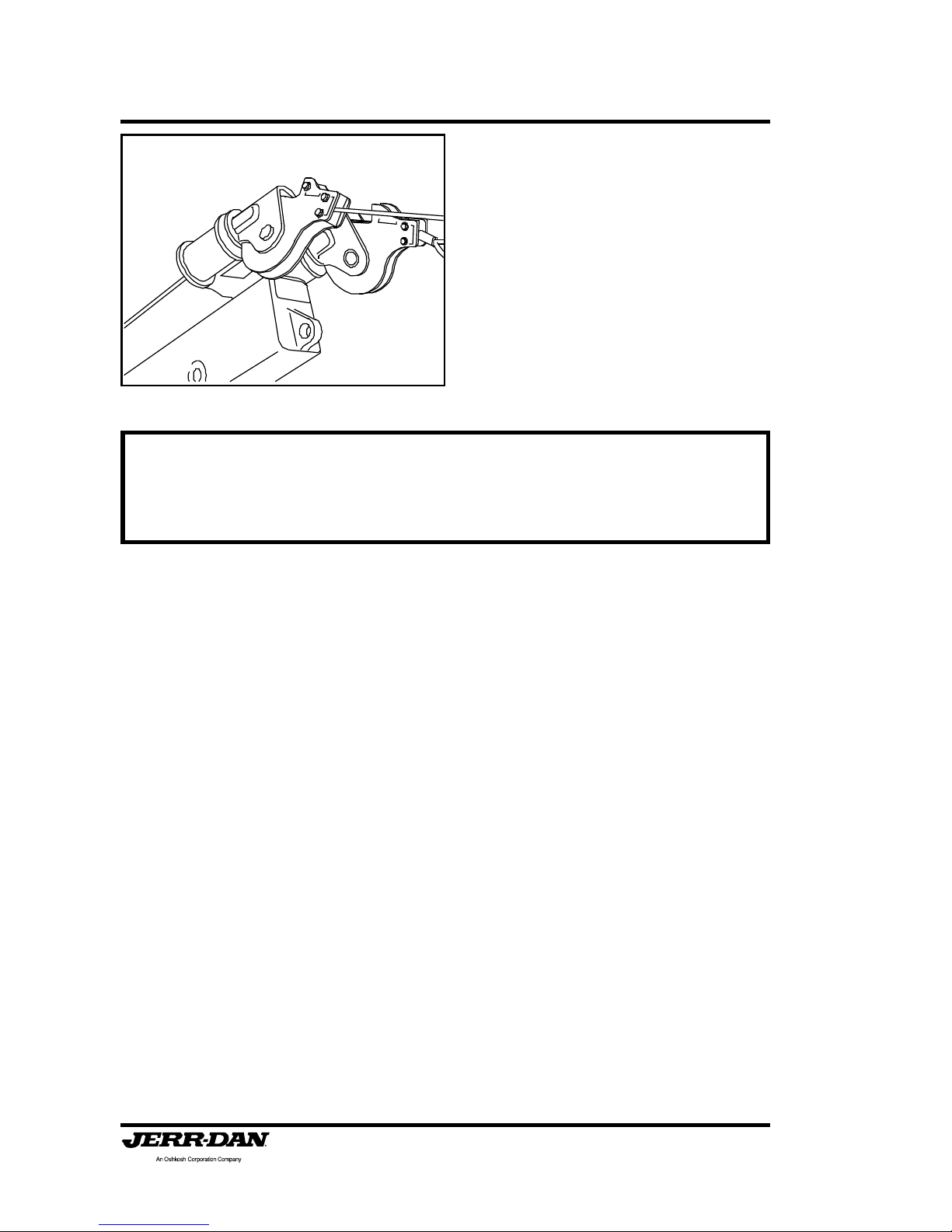

7. Set both boom winches into “free

spool” using the disengagement

levers. Raise, lift, and pull out on

the free-spool lever handle. Lower

the free-spool lever handle

capturing the lever stop bar on the

outside of the bracket locking the

winch in free-spool. Never pull

this handle while the wire

rope is under load! Moving the

boom head with the wire rope

locked can result in damage to

both the wire ropes and the boom.

Be sure both winches are free

spooling. This allows the wire

rope to be pulled directly off the

drum to the work. Unwind

enough wire rope to make the

hook-up being sure that a

minimum of at least five (5) wraps

of wire rope remains on the

drums.

8. Position the boom head by using

the boom up and down control

lever and the boom in and out

lever .

Section II: Operation

Page 45

5-376-000086

REV. 4 - 07/10

9. Attach the wire rope hook to a

chain sling, or bridle and hook

securely to the work. Be sure of

this hook up; you don’t want it

breaking loose during the pull.

(See the safety sections earlier

in this manual). Do not connect

to thin or loose body panels or

components that could break

loose during the winching

operation. Slings and bridles are

usually designed with hook

clusters on them. Most chassis

manufacturer’s provide tie-down

hooks and/or slots in chassis

frames that may be able to be

used as recovery attachment

points. (Consult the Chassis

Manufacturer’s Towing Manual

and/or the American Automobile

Association (AAA) Towing

Manuals.)

10. Re-engage the winches by

placing the free-spool levers back

to their original position. Confirm

winch engagement by jogging the

winch controls. Now slowly take

up the slack in the wire rope.

Inspect the hookup points for

slippage before continuing the lift

or pull.

Section II: Operation

Page 46

5-376-000086

REV. 4 - 07/10

11. With the wire rope tight, slowly

wind it in, observing both the work

and the drum. Be sure the wire

rope strands do not cross wrap

or criss-cross on the drum.

Observe the path the work must

travel for snags or obstructions

which could stall the movement

and overload the wire rope.

12.Once the work is in the desired

position, apply the towed vehicles

parking brake or use blocks or tie

the work down if there is any

question about stability. Slowly

reduce the wire rope tension.

After enough wire rope has been

unwound, you may remove the

hookup.

Section II: Operation

Page 47

5-376-000086

REV. 4 - 07/10

Remember, most wire rope failures are caused by cable

crushing or the operator underestimating the pull or over

estimating the wire rope strength.

13. Now slowly retrieve the wire rope,

carefully winding the wire rope

onto the drum. Many operators

take this opportunity to do a

visual inspection. When you’ve

finished rewinding the wire rope,

be sure you don’t overwind it.

Always wear safety glasses and

gloves when doing recovery work

or handling the wire rope.

Section II: Operation

Page 48

5-376-000086

REV. 4 - 07/10

TOW SLING OPERATION

(OPTIONAL)

Sling Rating: (50 M.P.H. Transport S peed)

Single Line Boom................................... 4,000 lbs.

Dual Line Boom...................................... 4,000 lbs.

If your MPL40 is equipped with a towing sling, consult the AAA

T owing Manual for hook up and follow these step s:

1. Position the truck within 9 ft.

of the subject vehicle and as

close to the direction of the tow

as possible.

2. Unfold the underlift.

9 FT

Section II: Operation

Page 49

5-376-000086

REV. 4 - 07/10

3. Remove the tow sling hold back

bar retaining pins allowing the hold

back bars to swing out of its

retaining brackets on the sides

of the boom.

4. Rotate the “CAM” handles on the

hold back bars 180° to the open

position.

5. Swing the hold back bars out

toward the lower tow sling lugs

on the back of the body. Allow

the hold back bars to extend as

necessary.

Section II: Operation

Page 50

5-376-000086

REV. 4 - 07/10

6. Connect the hold back bars to

the tow sling lugs using the pins

that you removed earlier .

7. Rotate the “CAM” handles on

the hold back bars 180° to the

close position. Raise or lower

the boom slightly until the cam

locks on the tow sling hold bars

snap into the closed position.

8. Extend the wrecker boom and

adjust the wire rope cable(s) to

lift the top of the tow sling and

tow sling straps. Extend the

boom to the yellow indicator

mark on the inner boom

section of the wrecker boom.

Section II: Operation

Page 51

5-376-000086

REV. 4 - 07/10

9. Lower the boom to allow the

tow sling head to raise out of it

holder on the back side of the

boom.

10. Carefully extend and lower the

wrecker boom to allow the tow

sling head to rotate outward and

down away from boom.

11. Lower the tow sling to the

ground.

Section II: Operation

Page 52

5-376-000086

REV. 4 - 07/10

12. Rotate the “CAM” handles on the

hold back bars 180° to the open

position.

13. Maneuver the sling under the

vehicle to be towed, far enough

under so the vehicle will ride on

the rubber belts.

14. Attach hook-up chains. The

chain J hooks must be secured

firmly around the axle or the frame

of the towed vehicle. When

fastening the J hook, be sure that

it is attached to the towed vehicle

in such a manner as to prevent

any damage to the brake lines or

other functional parts of the

vehicle.

Section II: Operation

Page 53

5-376-000086

REV. 4 - 07/10

15. With the chain securely fastened

in the hook on each side of the

bottom bar assembly, the chain

should then be wrapped around

the bottom bar. Secure the

remaining chain to the hook at the

top of the tow sling.

16. Using the tow sling with late

model vehicles, it may be

necessary to use spacer blocks

or a cross beam in order to get

sufficient height to prevent any

damage to body parts. The AAA

T owing Manual will diagram this.

17. Be sure the fuel tank is not in

contact with the sling or towing

mechanism. The fuel tank must

not support any weight

whatsoever.

18. Raise the vehicle using the

wrecker boom winches. (Read

the safety and operating

instructions for the boom and

winches beforehand.) The vehicle

should be raised until the wheels

are a minimum of ten inches off

the ground. Observe the opposite

end of the vehicle for ground

clearance.

19 . Be sure that both wire ropes are

retracted with equal tension.

Section II: Operation

Page 54

5-376-000086

REV. 4 - 07/10

20. Rotate the “CAM” handles on the

hold back bars 180° to the closed

position.

21. Retract the boom slowly drawing

the vehicle forward until the stand

offs are fully retracted and the

“CAM” handles retract to the

closed position for traveling.

22 .Install safety chains and towing

lights.

Section II: Operation

Page 55

5-376-000086

REV. 4 - 07/10

CAUTION:

The Bottom Anchor Assembly (round tube) must never be higher

than the attachment point on the rear of the truck. The Stand Off

Bar Assembly acts as a pivot in the event of a sudden stop. This

will assure that the towed vehicle will not catapult forward onto the

deck of the MPL40.

23. After the tow is complete, reverse

the procedures to unload the

vehicle.

24. With the vehicle unloaded and the

tow sling extended, use the

underlift fold function to bring the

tow sling head back up into its

storage position.

25. Rotate the “CAM” handles on the

hold back bars 180° to the open

position.

Section II: Operation

Page 56

5-376-000086

REV. 4 - 07/10

26. Remove the pins from the hold

back bars at the rear of the body .

27. Swing the hold back bars in

toward the tow sling storage

brackets on the side of the boom.

Allow the hold back bars to

retract as necessary .

28. Connect the hold back bars to

the tow sling storage brackets

using the pins that you removed

earlier.

Section II: Operation

Page 57

5-376-000086

REV. 4 - 07/10

29. Rotate the “CAM” handles on the

hold back bars 180° to the closed

position.

30.Retract the wrecker boom, snug

up the wire rope(s) and fold up

the underlift.

Section II: Operation

Page 58

5-376-000086

REV. 4 - 07/10

MOTORCYCLE TOWING ADAPTER OPERATION

(OPTIONAL)

If your MPL40 is equipped with a motorcycle towing adapter follow

these steps:

1. Lower the boom flat to the

ground.

2. Extend the wheel lift at least 6”.

3. Close the grid arms like you would

if you were loading a vehicle.

6 IN

Section II: Operation

Page 59

5-376-000086

REV. 4 - 07/10

4. Hook the loading ramp onto the

wheel grid and engage the rear

hooks on the back side of the

grid.

5. Completely retract the wheel grid

for loading.

6. Attach the lower trough and

vertical stop into the mounting

bracket at the front of the boom

with the pin and retaining pin.

Section II: Operation

Page 60

5-376-000086

REV. 4 - 07/10

7. Adjust the upper and lower tire

stops so that they will contact and

restrain the front tire when loaded.

8. Align the motorcycle with wheel

lift boom and ramp.

Section II: Operation

Page 61

5-376-000086

REV. 4 - 07/10

9. Push the motorcycle up the ramp

until the front wheel is resting in

and against the tire stops in the

front brackets.

10. Check front tire for fit with the

upper and lower tire stops. When

the motorcycle is rocked side to

side the front tire should feel solid

in the tire stops and centered in

the trough. If the front tire is not

clamped in the stops, back the

motorcycle off and readjust the

stops as necessary.

1 1. With the motorcycle stable in the

towing adapter , strap the front tire

to the wheel lift boom. Place the

hooks of the “middle” wheel

straps over the end of the boom

top plate and run the other ends

of the straps thru the front tire.

Insert the lose end of the wheel

strap into the ratchet on the end

other strap and tighten.

Section II: Operation

Page 62

5-376-000086

REV. 4 - 07/10

12. After securing the front tire,

extend the wheel lift under the

rear tire of the motorcycle raising

the rear tire of the motorcycle onto

the ramp.

13.Tie down the rear of the

motorcycle. Place the hook on

one end of the “rear” strap into

the hole on the front side of the

grid. Place the other hook onto

the motorcycle and tighten.

Repeat for the other side.

14. Raise the underlift boom to the

desired towing height.

CAUTION:

Care should be taken when lifting

the boom. Do not try to level the

underlift. The straps may

overtighten or become loose.

Section II: Operation

Page 63

5-376-000086

REV. 4 - 07/10

15.Tie the front of the motorcycle to

the rear of the wrecker body.

Attach the lasso style straps to

each of the handle bars.

16. Place the hook on one end of the

“front” strap to the loop of the

lasso strap on the handle bars

and place the hook on the other

end to the rear of the wrecker

body and tighten with the ratchet.

Repeat for the other side.

17. Use the wheel lift safety chains

to prevent the wheel grid from

pivoting during travel. Loop the

end of the safety chain around the

grid and secure with the grab

hook. Remove the slack in the

chain and secure the chain in the

keyslot of the chain box.

Section II: Operation

Page 64

5-376-000086

REV. 4 - 07/10

18 . Attach towing lights.

19. Reverse the loading procedures

to unload the motorcycle.

Section II: Operation

Page 65

5-376-000086

REV. 4 - 07/10

DOLLY STORAGE OPERATION

(OPTIONAL)

If your MPL40 is equipped with a towing dolly , follow these steps for

dolly removal and storage:

1. Remove the retaining bolts and

wing nuts or pad locks, which

ever your unit may have.

2. Open dolly the retaining latch by

pulling the top toward you.

Section II: Operation

Page 66

5-376-000086

REV. 4 - 07/10

3. After you have the latch open, the

dolly is free to be removed.

4. Remove the dolly wheel

assemblies, the axle cross tube

rails and the pry bar/jack bar .

5. Load dollies. (See Dolly

Operation instructions).

6. Afterloading the dollies, place the

pry bar/jack bar back into the

storage bracket by inserting the

end of the bar with the ring around

it thru the cutout in the front

bracket. Allow the other end of

the bar to rest on the rear bracket.

Section II: Operation

Page 67

5-376-000086

REV. 4 - 07/10

7. Close the dolly latch by pushing

the top away from you.

8. Install the retaining bolts and

wing nuts or pad locks.

9. After using the dollies, store them

back on the deck in basically the

reverse order. Remove the

retaining bolts and wing nuts or

pad locks and open the latch.

10. Place the axle cross tube rails

back into the storage bracket by

inserting the tab on the end of the

axle tube into the cutout in the

storage bracket.

Section II: Operation

Page 68

5-376-000086

REV. 4 - 07/10

1 1. The axle cross tube rails need to

be stored with the wheel ramp

plates turned in and up.

12.Allow the axle cross tube rails to

hang from the bracket by the tab.

13. Place the dolly wheel assemblies

back into the storage brackets.

Section II: Operation

Page 69

5-376-000086

REV. 4 - 07/10

14. The tab on the storage bracket

should be placed through the dolly

pocket of the dolly wheel

assembly.

15. Close the dolly retaining latch by

pushing the top away from you.

16. Install the retaining bolts and

wing nuts or pad locks.

Section II: Operation

Page 70

5-376-000086

REV. 4 - 07/10

DOLLY OPERATION

(OPTIONAL)

Specifications:

Dolly Capacity: ................................................ 2,360 lbs.

Tire/Wheel: ............................................4.80 x 4.00/8Tire

Axle: .................................................... 2 1/2 Sq. Tube

Max. Speed: .................................................... 50 M.P.H.

The Quick Loading Dolly is simple to use once the principles of the unit are

understood.

1. Extend telescopic cross rails by first depressing spring-loaded

plunger and sliding inner (male) tube until plunger locks into the

hole that matches the width of vehicle to be towed.

2. Place cross rails on ground, fore and aft of vehicle’s tires.

3. Place dolly in the fully collapsed position with the dolly tires closest

to each other .

4. Set rail ends into dolly pockets, adjusting for the size of vehicle’s

tires, positioning rails as close as possible to tires.

5. Make sure safety locks are disengaged, allowing trip assemblies

freedom of movement while lifting vehicle.

6. Engage ratchet assemblies to prevent injury and damage to the

operator and vehicle in case pry bar slips from hand.

7. Insert pry bar into pry bar pocket.

8. Swing outer end of pry bar in an arc until trip assembly rises then

locks spindle assembly in the down position. Do not release pry

bar until spindle assembly is locked down.

9. Repeat this action for all four (4) assemblies. Dolly is now raised.

10 . After dolly is in the raised position, engage safety locks over trip

assemblies to prevent releasing while vehicle is in tow .

Section II: Operation

Page 71

5-376-000086

REV. 4 - 07/10

11. Safety tie-down straps should be used to secure dolly to vehicle in

case of rough road. Dolly is now ready for towing.

BE SURE EACH WHEEL IS SECURELY HELD IN ITS DOLLY AND

INSPECT THE GROUND CLEARANCE OF THE VEHICLE BEFORE

A TTEMPTING A TOW.

T o unload the vehicle, stand clear of both the vehicle and the dollies and slip

the chain link off of the cam bar. Carefully slide the jack handle over the

cam bar and slowly lift the handle allowing the vehicle to drop. Repeat this

step on the other dolly and then remove the axles from the dollies.

USE CARE WHEN RELEASING OR UNLOCKING THE CAM BAR AS IT

CAN MOVE SUDDENL Y AND WITH FORCE, CAUSING INJURY. JERRDAN ASSUMES NO LIABILITY FOR THE USE OR MISUSE OF THESE

DOLLIES OR ANY DAMAGE CAUSED BY THEM.

Section II: Operation

Page 72

5-376-000086

REV. 4 - 07/10

THIS P AGE INTENTIONALL Y LEFT BLANK

Section III: Maintenance

Page 73

5-376-000086

REV. 4 - 07/10

MAINTENANCE AND LUBRICATION

Y our MPL40 has been designed to give you excellent service and long life

but like all equipment, it requires proper and periodic maintenance. The

truck chassis itself is on a maintenance schedule recommended by the

manufacturer . Follow these guidelines and protect your vehicle warranty.

There are a number of different lubricants used on your MPL40 and the

following chart details the proper lubricant and the most common brands

and specification which meet the requirements.

Use only safe practices when maintaining this equipment. Always shut off

the engine before reaching into pinch areas.

Inspect the vehicle and underlift system periodically for damage or evidence

of pending failure. Damaged or broken parts should be replaced immediately .

Never operate a machine which is known to be defective or operating

improperly. The cause of any binding or leakage should be determined

immediately and the problem promptly fixed.

Y our MPL40 has Jerr-Dans “No-Lube” maintenance-free pivot joint system.

Most of the pivot joints utilize high strength composite bearings with

hardened and plated pins to drastically reduce maintenance, down-time

and the cost of lubrication over the life of the product. There are however a

few areas that still require some lubrication or maintenance. Sliding surfaces

should be cleaned periodiacally. The following chart and diagram shows

the location of these points, and when and what type of lubricant to use.

Check the hydraulic oil level bi-monthly or after any leakage. The proper oil

level is best checked with all cylinders fully retracted. The hydraulic oil

should just cover the bottom of the screen in the oil filler neck of the hydraulic

tank. Use a Super Premium Grade Multi-Viscosity hydraulic oil. (See Chart)

(Automatic transmission fluid may be used in the hydraulic system if

necessary.)

The hydraulic filter located on the return side of the hydraulic tank comes

equipped with a restriction indicator gauge. This gauge shows the operator

the condition of the filter element. When the needle reaches the red band

(25 psi), the filter is starting to bypass and the element needs to be changed.

Failure to change the element will result in premature wear and/or failure of

any or all of the hydraulic components. Check gauges when the hydraulic

MAINTENANCE

Section III: Maintenance

Page 74

5-376-000086

REV. 4 - 07/10

fluid is at operating temperatures. Cold oil is more dense and will

give a false indicator gauge reading.

If a cylinder seal leaks, disassemble the cylinder and ascertain the cause

of the leak. Small scores caused by chips or contaminated fluid can usually

be worked out with fine emery cloth to avoid repetition of the trouble. Whenever

any seal replacement is necessary, it is always advisable to replace all

seals in that component. These seals are available in kits. Also, thoroughly

clean all components before reassembly .

The body of your Jerr-Dan has been built from high strength aluminum which

has been carefully assembled and polished in our factory . To keep it clean

and free of dirt use any non-abrasive soap or detergent recommended for

automotive finishes. Use a soft cloth or sponge and finish with a thorough

rinsing. Drying with a soft cloth or chamois will prevent spotting or streaking.

A coat of automotive wax is recommended.

The MPL40 is mounted to the truck chassis by bolts. These bolts are

torqued at the factory to 70 ft. lbs. The MPL40 aluminum body is mounted

to the subframe by bolts. These bolts are torqued at the factory to 70 ft.

lbs. We recommend periodic inspection and retorquing of these bolts. Your

truck is equipped with winches and the winch mounting bolts should be

regularly inspected and tightened if necessary. Replace any broken or

damaged bolts immediately .

Section III: Maintenance

Page 75

5-376-000086

REV. 4 - 07/10

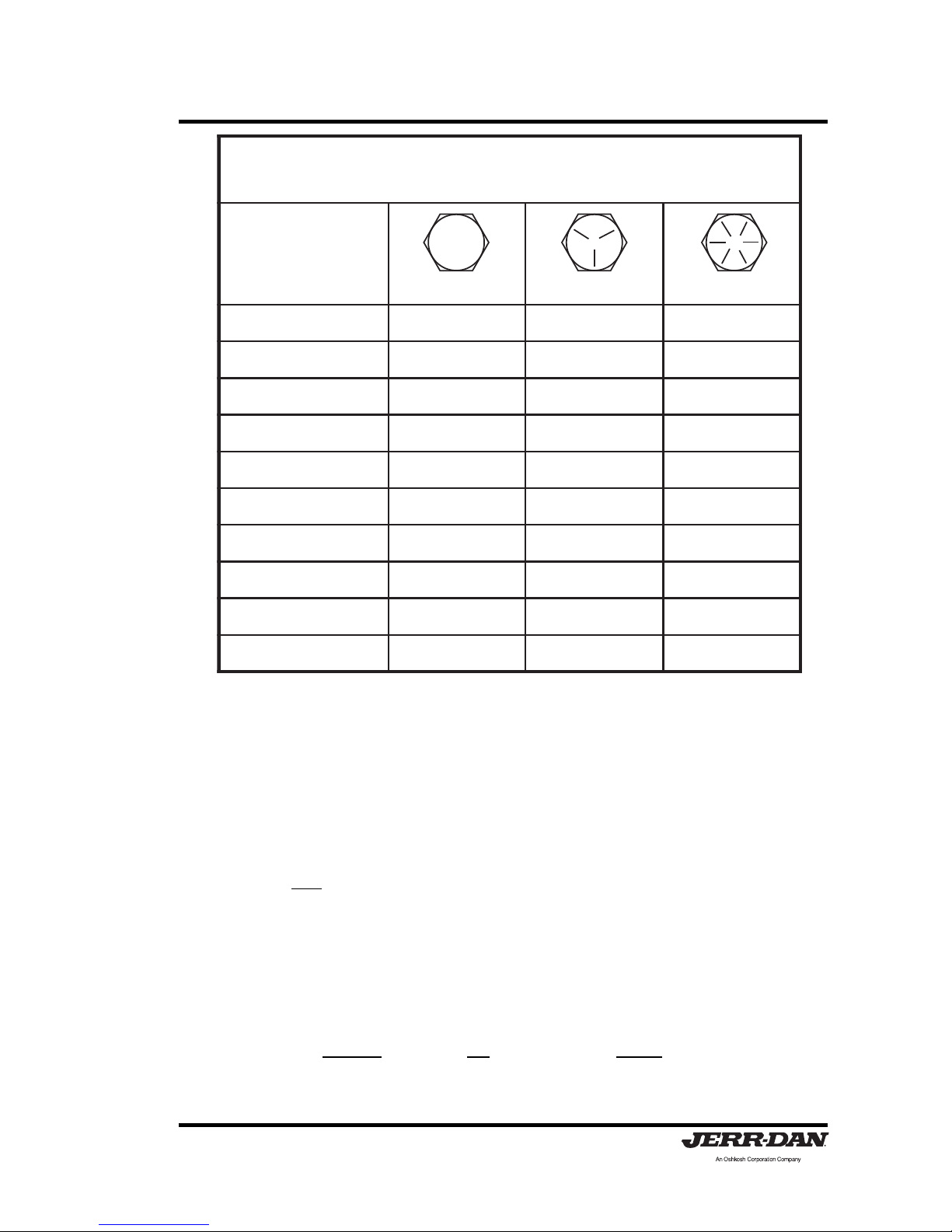

· All torque values shown are for bolts (cap screws) and nuts that are either zincplated or lubricated.

· Torques shown above apply to screws and nuts used for assembly and

installation of all wrecker components.