Page 1

INSTALLATION

D INSTRUCTIONS

Models SVE47600, SVE47500, mmi_JENN.AIR

Range

403WESTFOURTHSTREET,NORTH• NEWTON,IA 50208

SVE47100, SCE30600, SCE30500

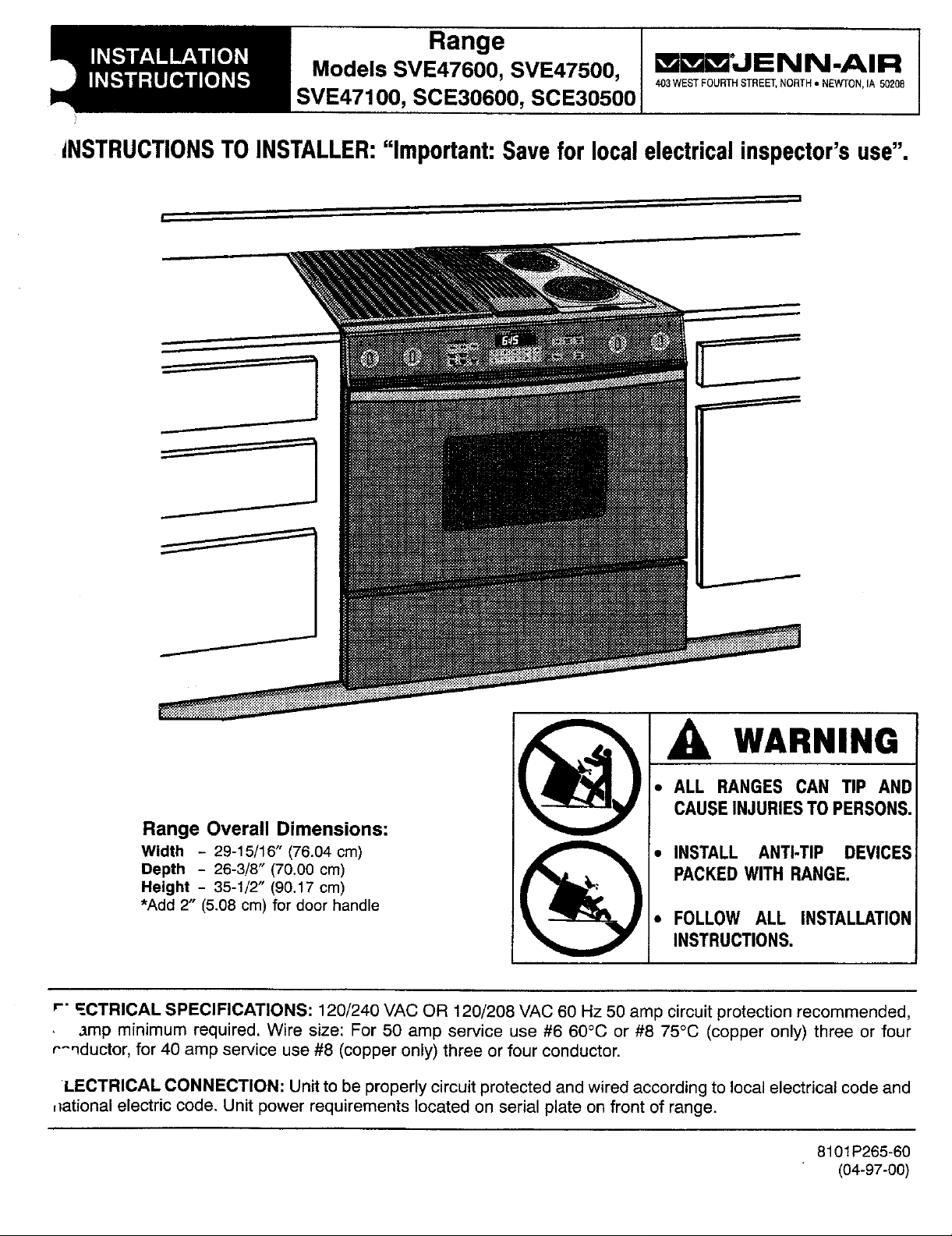

iNSTRUCTIONSTOINSTALLER:"Important:Saveforlocalelectricalinspector'suse".

• ALL RANGESCANTiP AND

CAUSEINJURIESTOPERSONS.

RangeOverall Dimensions:

Width - 29-15/16" (76.04 cm) _ • INSTALL ANTI-TIP DEVICES

Height - 35-1/2" (90.17cm)

•Add 2" (5.08cm)for doorhandle

Depth - 26-3/8" (70.00cm) _ PACKEDWITH RANGE.

r" =.CTRICAL SPECIFICATIONS: 120/240 VAC OR 120/208 VAC 60 Hz 50 amp circuitprotectionrecommended,

,Imp minimum required. Wire size: For 50 amp service use #6 60°(3 or #8 75°C (copper only)three or four

r^_ductor, for 40 amp service use#8 (copperonly)three orfour conductor.

LECTRICAL CONNECTION: Unitto be properlycircuitprotectedand wired accordingto localelectricalcode and

,_ationalelectriccode, Unit power requirementslocated on serial plate on front of range.

I

• FOLLOWALL INSTALLATION

INSTRUCTIONS.

WARNING

8101P265-60

(04-97-00)

Page 2

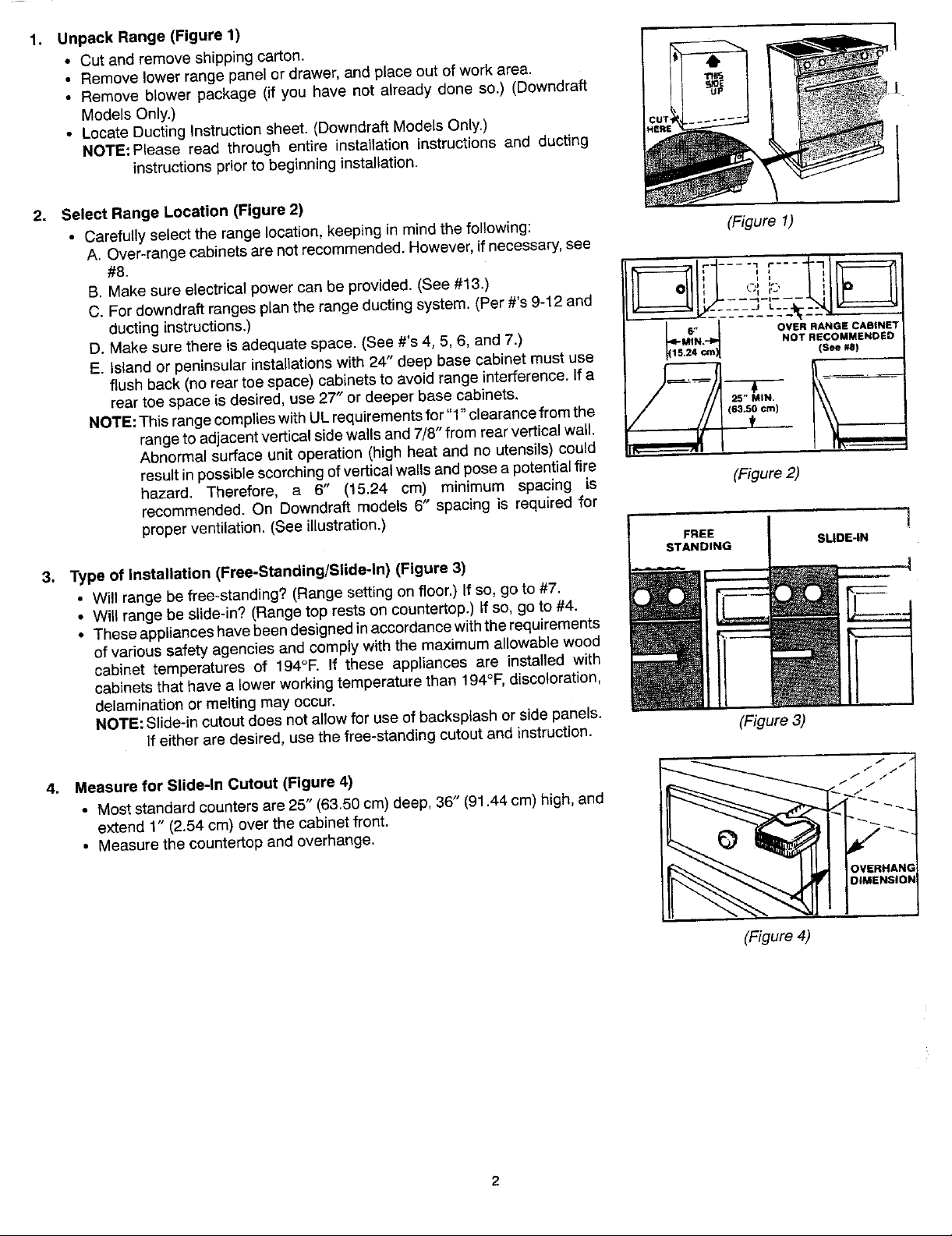

1. UnpackRange (Figure1)

• Cut and remove shippingcarton.

• Removelowerrangepanelordrawer,andplaceoutofwork area.

• Removeblower package (if you havenot alreadydone so.) (Downdraft

ModelsOnly.)

• LocateDuctingInstructionsheet.(DowndraftModelsOnly.)

NOTE:Please read through entire installation instructionsand ducting 1

instructionspriorto beginninginstallation.

2. SelectRange Location(Figure2)

• Carefullyselecttherangelocation,keepinginmindthefollowing: (Figure 1)

A. Over-rangecabinetsarenotrecommended.However,ifnecessary,see

B. Makesure electricalpowercan be provided.(See#13.) _- _ _"

C.For downdraftrangesplanthe rangeductingsystem. (Per#'s9-12and ', --"q-',_- -- '

ductinginstructions.) ._________L__.._--.

D.Makesure thereis adequatespace. (See#'s 4, 5, 6, and7.) L_'N.J OVERNoTRECOMMIENDEDRANG[=CABINET

E. islandor peninsularinstallationswith 24" deepbase cabinet must use _lscr,)1.24 (s_,)

rear toespace is desired,use 27" or deeper base cabinets.

NOTE:ThisrangecomplieswithULrequirementsfor"1"clearancefrom the _63._o¢,,)

rangeto adjacentverticalsidewallsand7/8" fromrearverticalwall. t ..

flushback (no reartoe space)cabinetstoavoid rangeinterference,lfa _, .' (

Abnormalsurfaceunitoperation(highheatand noutensils)could I,r_

resultinpossiblescorching,ofverticalwailsandposea potentialfire

hazard. Therefore, a _, (15.24 cm) minimum spacing is (Figure2)

recommended.On Downdraftmodels6" spacingis requiredfor

properventilation.(Seeillustration.)

3. Typeof Installation(Free-Standing/Slide-In)(Figure3)

• Willrangebefree-standing?(Rangesettingonfloor.)Ifso, goto #7.

• Willrangebe slide-in?(Rangetoprestsoncountertop.)If so,goto#4.

• Theseapplianceshavebeendesignedinaccordaneewiththerequirements

ofvarioussafetyagenciesandcomplywiththemaximumallowablewood

cabinet temperatures of 194°F. If these appliancesare installed with

cabinetsthathavea lowerworkingtemperaturethan194°F,discoloration,

delaminationor meltingmayoccur.

NOTE:Slide-incutoutdoesnotallowfor useofbacksplashorsidepanels.

Ifeitheraredesired,usethefree-standingcutoutand instruction. (Figure3)

• Moststandardcountersare25" (63.50cm)deep,36" (91.44cm)high,and

extend1" (2.54cm) overthecabinet front.

• Measurethe countertop andoverhange.

25" MIN.

SLIDE-IN

4. Measurefor Slide-InCutout (Figure4) _!iii

(Figure4)

Page 3

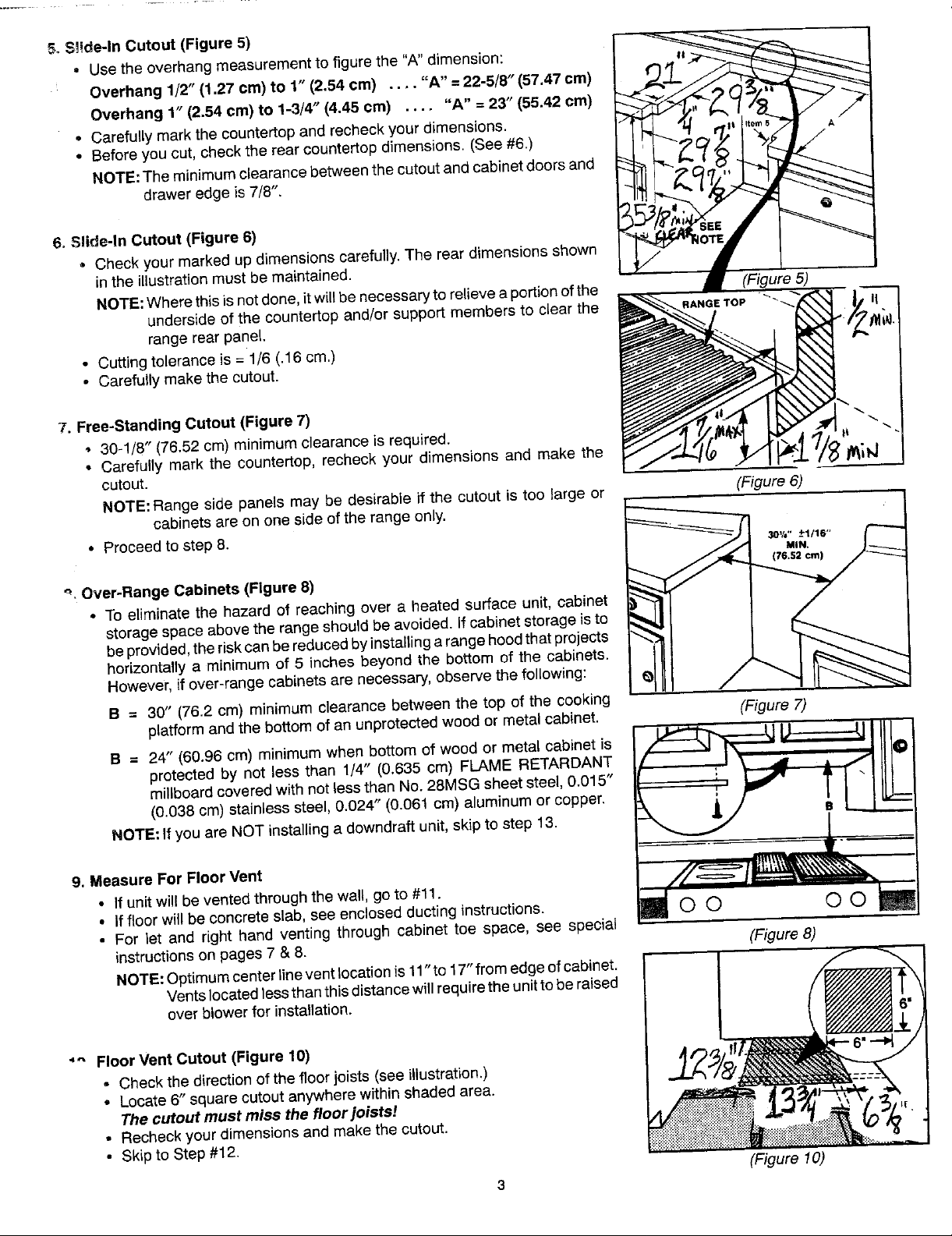

5.Slide-In Cutout (Figure5)

* Usethe overhangmeasurementtofigure the "A"dimension:

Overhang 1/2" (1.27cm) to 1" (2.54cm) .... "A" = 22-5/8"(57,47cm)

Overhang1" (2.54cm) to 1-3/4" (4.45cm) .... "A" =23" (55.42cm)

. Carefullymarkthe countertopand recheckyourdimensions.

• Beforeyou cut,checkthe rear countertopdimensions. (See#6.)

NOTE:The minimumclearancebetweenthe cutoutandcabinetdoorsand

drawer edgeis7/8".

6. Slide-In Cutout (Figure6)

• Check your markedup dimensionscarefully.The rear dimensionsshown

inthe illustrationmustbe maintained.

NOTE:Wherethis isnot done,it willbenecessaryto relieveaportionofthe (Figure5)

undersideof the countertopand/orsupport membersto clear the

rangerear panel.

• Cuttingtolerance is = 1/'6(.16 cm.)

• Carefullymakethe cutout.

7. Free-StandingCutout (Figure7)

• 30-1/'8"(76.52cm) minimumclearance is required.

• Carefully markthe countertop,recheckyour dimensions and make the

cutout.

NOTE:Range side panels may be desirable if the cutout is too large or (Figure6)

• Proceedto step 8. 3or.-_.1/le,,

_, Over-RangeCabinets (Figure8)

- Toeliminatethe hazard of reachingover a heated surface unit, cabinet _-"'T_'[

storagespaceabovethe rangeshould beavoided. Ifcabinet storageisto

beprovided,theriskcanbereducedbyinstallingarangehoodthatprojects

horizontallya minimumof 5 inches beyond the bottom of the cabinets.

However,if over-rangecabinetsare necessary,observethe following:

B = 30" (76.2cm) minimumclearance betweenthe top of the cooking

B = 24" (60,96ore) minimumwhen bottomof wood or metal cabinetis _J_______._-_. _

NOTE:

9. MeasureFor FloorVent //_/_

• If unit will beventedthrough the wall,go to #11. IF /

• Iffloor willbe concreteslab,see enclosedductinginstructions. _ O O O O

• For let and right hand venting through cabinet toe space, see special

instructionsonpages7 & 8. (Figure8)

NOTE:Optimumcenterlineventlocationis 11"to17"fromedgeofcabinet.

cabinetsare on one sideofthe rangeonly. __.,._,.-_1/_

platformand the bottomof anunprotectedwoodor metal cabinet. (Figure7)

protectedby not less than 1/4" (0.635cm) FLAME RETARDANT _)

millboardcoveredwithnotlessthan No.28MSGsheet steel, 0.015" _

(0.038cm)stainless steel,0.024" (0.061cm) aluminumor copper. _ _)" "" I _--

If

youare NOT installinga downdraftunit,skip to step 13. _ T

Ventslocatedlessthanthisdistancewill requiretheunittobe raised

overblowerfor installation.

_" FloorVent Cutout(Figure 10)

- Checkthe directionof the floorjoists (seeillustration.)

• Locate6" squarecutout anywherewithin shadedarea.

The cutout must miss the floor joists!

• Recheckyourdimensionsandmakethe cutout.

• Skipto Step#12.

3

(Figure 10)

Page 4

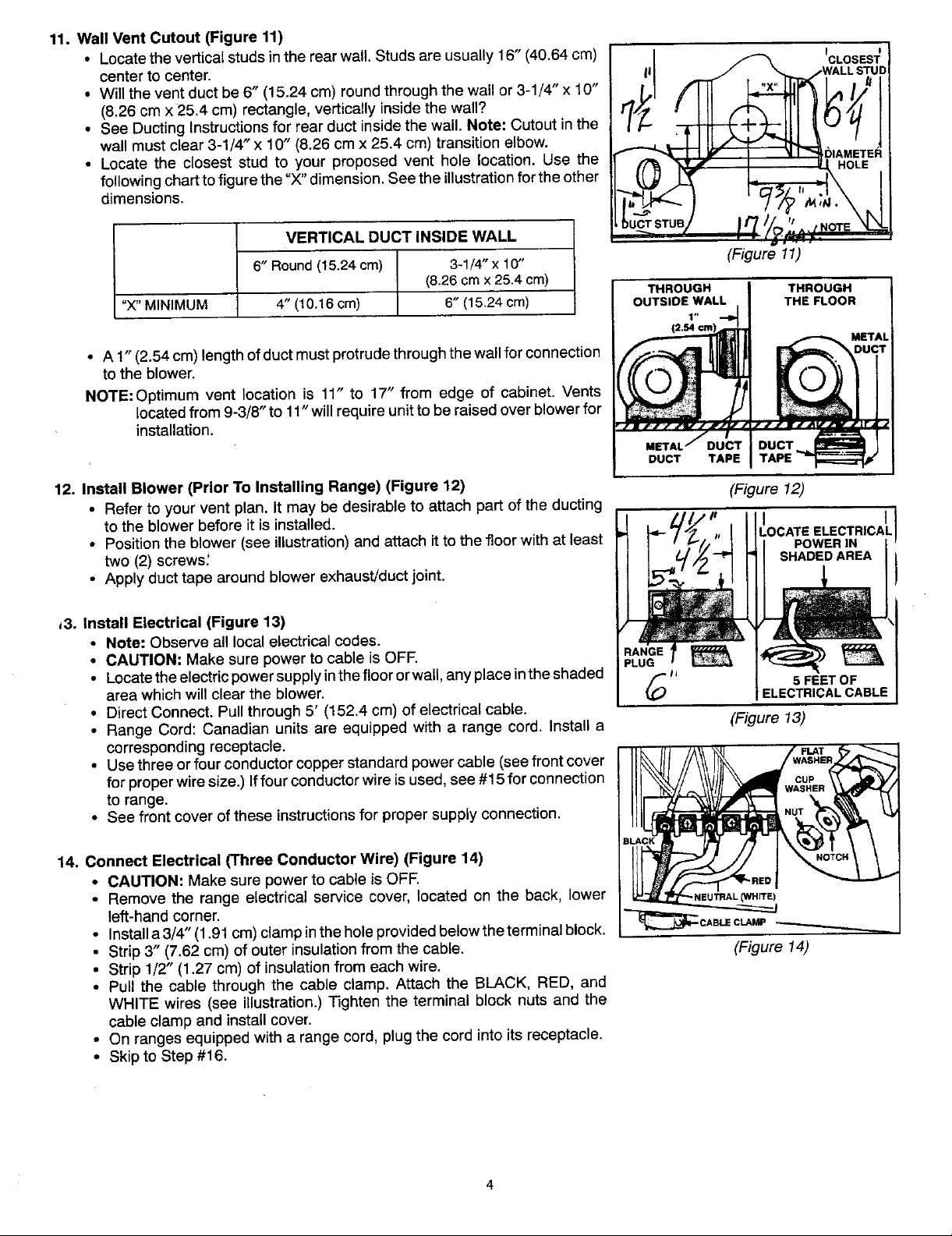

11. WallVentCutout (Figure11)

center to center. II _- _ . WALLSTUD

• Willtheventductbe6" (15.24cm) roundthroughthewallor3-1/4" x 10"

(8.26cmx 25.4cm) rectangle,verticatlyinsidethewall? /"

• See DuctingInstructionsfor rearduct insidethe wall. Note: Cutoutin the

wallmust clear3-1/4" x 10" (8.26cm x 25.4 cm)transition elbow.

• Locate the closest stud to your proposed vent hole location. Use the r_ (/_._

followingcharttofigurethe "X"dimension.Seetheillustrationforthe other

dimensions.

oceeveasuserr.uareusua0 c°si

"X"MINIMUM 4"(10.16cm) 6"(15.24cm) OUTSIDEWALL THEFLOOR

• A 1" (2.54cm)lengthofduct mustprotrudethroughthewallforconnection _- --"=""_._"D'U'_Th

tOthe blower. (_

NOTE:Optimum vent location is 11" to 17" from edge of cabinet.Vents _1_] J'J_fT

12. InstallBlower (PriorToInstallingRange) (Figure 12) (Figure 12)

,3. InstallElectrical(Figure13)

locatedfrom9-3/8"to 11"will requireunittobe raisedover blowerfor

installation. METALJOUCTDucTTAPE I DUCT_TAPE

• Refertoyourvent plan. it maybe desirableto attachpart ofthe ducting

to theblowerbeforeit isinstalled. L'IOCATEELECTRICA_'L

• Positiontheblower(seeillustration)andattachitto thefloorwithat least POWERIN

two(2)screws: SHADEDAREA I

• Applyducttapearoundblowerexhaust/ductjoint.

• Note: Observealllocalelectricalcodes.

• CAUTION:Makesure powertocable is OFF. _

• Locatetheelectricpowersupplyinthefloororwall,anyplaceinthe shaded /.-_, 5FEETOF

areawhichwillcleartheblower. _) ELECTRICALCABLE

• DirectConnect.Pullthrough5' (152.4 cm)of electricalcable.

• RangeCord:Canadianunitsareequippedwitha range cord.Installa (Figure 13)

correspondingreceptacle.

VERTICALDUCTINSIDEWALL . . .

6"Round(15.24cm) 3-1/4"x10" (Figure11)

(8.26cmx25.4cm)

THROUGH THROUGH

12.54cm

I" )_

_ / j f j _r _.-iJ / _,3rf / _ _ _ Jrf Jttf n_f IF •

I

for properwiresize.)Iffour conductorwireisused,see #15for connection / _ cup

to range, w_s,eR

• Seefrontcoveroftheseinstructionsfor propersupplyconnection.

• CAUTION:Makesurepowerto cable is OFF.

14. ConnectElectrical(Three ConductorWire)(Figure 14) __o t

• Remove the range electricalservicecover,located on the back, lower "-NEU'mAL(WHITE)

• Usethree orfourconductorcopperstandardpowercable (seefront cover __,_ w____

left-handcorner.

• Installa3/4" (1.91cm)clampintheholeprovidedbelowtheterminalblock. ,

• Strip3" (7.62cm) of outer insulationfromthe cable. (Figure 14)

• Strip1/2" (1.27cm) of insulationfromeachwire,

• Pull the cablethrough the cable clamp. Attach the BLACK, RED, and

WHITE wires (see illustration.) Tightenthe terminal block nuts and the

cableclamp andinstallcover.

• On rangesequippedwith a rangecord, plugthe cord into its receptacle.

• Skipto Step #16.

_CABLE CLAMP_

Page 5

15. ConnectElectrical(FourConductorWire) (Figure15)

• Removethe range electrical servicecover,locatedon the back, lower _ ;'_

left-handcorner.

• Removethe grounstrapscrewandbendthe strapupasshown.Installa3/4"

(1.91cm) cable clampin the hole provided,belowthe terminalblock. I,_NOl

c oo. a esure oweroa.e

• Strip3" (7.62cm)of outer insulationfrom the cable. ,GROUND

• Strip 1/2" (1,27cm)of insulationfromeach wire. WIRE

• Pullthe cablethroughthe cableclamp.

• Makealoopinthe bare groundwire andattachitto the rangewiththe screw "BASe

that heldthe ground strap, _. _'OROUNC)wlSE

• Attach the BLACK,RED,and WHITEwires (see#14.) Tightenthe terminal

blocknuts andthe cable clamp. (Figure 15)

• Tapethe groundstrapto theWHITE wire as shown.Installelectricalcover.

16. Install Options (Figure 16)

• If the backsplash or side panels are to be used, install according to

instructionsincluded inthose accessories.

17. PositionRange(Figure 17)

• Free-Standing,Adjustthe rangefeetsothe rangeandcabinetheightwill be

approximatelythe same. Slide the range into place, taking care not to --

damagefloor covering. . J'

• Slide-In. Adjust rangefeet so that range top clears countertop.Slide/lift " /

range intoplace.Adjustfeet so rangeis adjacentto countertop surface. 4 I

18, Anti-Tip DeviceInstallation (Figure16)

NOTE: A risk of range tip over exists if the appliance is not installed in

accordancewith the installationinstructionsprovided.The proper use ofthese

devicesminimizesthe risk ofTIP-OVER.In usingthesedevices the consumer

muststillobservesafetyprecautionsas statedin the USEandCAREMANUAL

andavoid usingthe oven door and/orlowerdrawer as a step stool.

Instructionsare providedfor installationin eithera wood or concretefloor.Any

othertypeofconstructionmayrequirespecialinstallationtechniquesasdeemed

necessaryto provideadequatefastening ofthe ANTI-TIPbracketto the floor.

STEP1 - LocatingThe Brackets

• Placetheunitinitsfinallocation.

• Removethe storagedrawer or lowerdoor panel(dependingon model

beinginstalled.) (Figure 17)

• Marktheflooratthe rightandleftwherethe rangefront meetsthefloor.

NOTE:Protectthe floorwith maskingtape prior to marking.

• Removethe rangefor access to the bracket mountingpositions.Use

caretoavoid damageto floor.

• Drawalineon theflooratthe backofthecutoutwhich isoffset23-5/16"

fromthe marksmade atthe front of the range(seeillustration.) _1

• Locate the center (side to side) of the cutout. See illustration for

free-standingand slide-indimensions.

• = [59.21 cm]

Positionbrackets13-7/8"fromcenterline andflushto thebackline as _1 2_5/16TYP

shownin the illustration.

• Usethe bracketto markholesfor drilling.Proceedto STEP2. _ _'F.o._0RAw_0_L'NES.AN_EAT

STEP2 - InstallingThe Brackets I

1"

,5,1

markedholepositions(anailorawlmaybeusedif adrilJisnotavailable.) F"_E-STAN0_(_6S2=,)

• Wood Construction:Drilla I/8" pilot hole in the centerof each of the SL_E-_N _01/_" [5_/_6"

Securethe ANTI-TIP brackets with the screwsprovided. Proceedto 1(75.8s_) (379__s/_S.m)_1 II

STEP3.

• Cement or Concrete Construction: Suitable screws for concrete (Figure 18)

constructioncanbeobtainedat a hardwarestore.Drillthe requiredsize

hole for the screw obtained in the center of each of the markedhole _._,-e._v_.ms

positions.SecuretheANTI-TIPbracketsto the floor, _ .._OKEr

STEP3- RangeInstallation __/_. - -

• Alignthe rangetoits designatedlocationandslideitbackintoposition.

Makesurethat therearlevelingfeet arefully insertedintoandsecured ___._"

by the ANTI-TIP brackets.NOTE: Leg levelers must be screwed out

1-1/2turns.

5

I .A-_L. (_8"2_'=.>

2g 7/8

Page 6

19. Level Range(Figure19) --IL ll

• Free-Standing.Adjustthelevelerfeettolevelrangewiththe countertop.

• Slide.ln.Adjustthelevelerfeettotakesomeoftheweightoffefthecountertop.

• Unit must be levelfor optimum bakingperformance.Check levelness inside

oven usingalevel that is placedonoven rack.

• Fornon-downdraftunitsgo to step 22.

(Figure 19)

20. Connect Blower Electrical (Downdraft Units Only) (Figure20) ,ow_,co,o

BLOWER ]lJ

• Connectthe blowerpowercordon the rangetothe blower (see illustration.) _]__ iolli i I

21. Install Flex Duct (Downdraft Units Only) (Figure21)

• Attach the flex duct to the blower and range (see illustration.) Using a

screwdriver,securelytightenduct clampat each connection. (Figure20)

22. CheckOperation (Figure22) _! _,f _k,_

• Unpackand install grill elementin one side and optional cookingcartridge in

otherside.

• Be sureto removeall packagingmaterialsfrom unit priorto applying power.

• Switchthe electricalcircuitbreakerto the ON position.

• ConsultUse & Care Manualfor operation. (Figure21)

• Checkrangetop elements.Fancomesonautomaticallywhengrillis turnedon, C.ECK .EAT pOWE,O,

•• Checkoven.C°°kingcheckventCartridgefan,doesnotenergize fan automatically. __A,,

there are noair leaks.Verifyproperairflowwith airflowcard.

• With vent fanon, check all vent duct connectionsto the outsideto makesure __"

23. Install Lower Left and Right Side Toe Plates (Figure 23) (Figure22)

• Pull protectivebackingfrom tape. ..,,, _ _.._--_ :

• Set Sideplate on floor guide plate between cabinet and range until plate is

positionedover the sidetrim. Pressplate againstsidetrim on rangeto insure

tape hasbonded.

• For Non-Downdraftunits,finish your installationby replacingthedrawer.

ROLS

24. Install AccessPanel and LowerAdjustable Panel(Figure24) (Figure23)

• After checkingfor airleaksat duct connections,installthelower rangedoor.

• Measurethedistancebetweenthelowerpanelclipandthefloor.Dimension"A".

• Cutcovemolding (providedonsome units- seeNote2)to thisDimension"A".

• Insertcovemolding (orotherselected material) into lower panelclip.

NOTE: 1) It will be easierto attachthe cove molding if the accessdoor is

removedfrom therange.

2) Tomatchyourinstallation,variouscolorsofcove moldingmaybe

purchasedfromanybuildingsupplystore, i_,._S::._ '

25. Install Jars (Downdraft Units Only) (Figure25)

• Openaccess panel. (Figure24)

• Placedrainjars intotheir holderslocatedbehindthe front legsofthe range.

NOTE:Onunits with oneside grilling,onlyone drainjar issupplied.

(Figure25)

6

Page 7

_peCial Instructi---onsFor Ven_net Toe S )ace

Additionalinstructionsfor ventingthroughthe base cabinettoe space oneithersideofthe rangewhen it isnotpossibleto vent

throughthe floor or througha rear wall.

AdditionalMaterialsRequired

1.5" Dia.x 19" long(12.7cm x 48.26cm) Flex Duct* (P/N702935) _ "

1 6" (15.24cm)90° Elbow Left 31.19" Right

• Cabinet 79.22_ Cabinet

2. HoseClamps*(P/N702331)

1 5" to3-1/4" x 10" (12.7cm to 8.26 cmx 25.4 cm)Transition* _-17.12S",-_ _-17.125"-,_

• 5._o' I (_'_ cm) (43.49_) I 5.so'

2. Wood Spacers (rightsidevent only) 1-1/2" Thick x 9" Long (3.81cm Dis-Hole| ' | Dis.Hole

X22.86cm) (,3.,7._. ._..9, or,,

*Seeyourlocaldealerorauthorizedservicecontractorfortheseaccessories. =']-.C-"-_-----"--"- '_ ---------_'---_r =

Step 1

Cut a hole in either the left or rightsideof the cabinetwall as shown in (Figure 1)

Figure1.

// -- //

!

Step2 "h J,.

shownbythe shadedareasin Figure2 or Figure3. t=7

.===.J==_

Makea cutout in the cabinetfloor of either the left or right cabinet as _r__ .---t.-

Step3 I'_'_(e=.7_m)=! _o_OT_o"N

_elocatethe mountngbracketson the blowerhousing(see Figure4.)

NOTE: The mountingbracketshown in Figure 4 are as asssembled Left Cabinet(TopView)

atthe factory for flooror rearwallventing.

(Figure2)

A. RightSide Venting ..¢ iNu='-rltd. _ 14.

2. Removebracketandreattachitwithstuds 1and2insertedinholes 11"

A and C and replaceall 3 nuts.

3. Removenutsfromstuds 5,6 and7 on air inlet side• =

4. Removebracketandreattachitwithstuds5and6insertedinholes s,owe, I- (_o=_7"-m)----'_

Dand B and replaceall 3 nuts. ,OCt'nON

(Figure3)

B. Left SideVenting RightCabinet (TopView)

1.Removenutsfromstuds1,2, 3 and 4 onmotorside. Motor Side Air Inlet Side

2. Removebracket.

4. Reattachbracketwithstuds4 and1insertedinholesA andCand

replaceall 4 nuts.

5. Removenutsfrom studs 5, 6, 7and 8 on air inlet side.

6. Removebracketandreattachitwithstuds8and5insertedinholes Mounting

Dand B and replaceall4 nuts. srecket

....

(Figure4)

BlowerAssembly

Page 8

Step4

Attachthe blowerhousingtothefloorwiththe outlettowardthedirection Right Side Left Side I

ofventing andthe inlettoward thefront of the cabinets. (SeeFigures2 Venting Venting

and 3 for specific location.) in addition,for left side venting, aspacer I

{erthemountingbracketflanges oftheblowerassembly.(SeeFigure

Step5

_,_proximately1-1/2"thick x 9" long (3.81cm x 22.86 cm)is required __

Removetheinside wire andtheoutsidestringfrom thefirst 1-1/2inches Spacer/

(3.81cm) ofoneend ofthe 5" (12.7cm)flexduct (P/N702935.)Stretch

thisend ofthe flex duct overthe end of the 5" to 3-1/4" x 10" (12.7cm (Figure5)

to 8.26 cm x 25.4 cm) transitionand secure it witha hose clamp (P/N ViewfromAir Inlet Side of Blower

702331.)

Step 6

Whenthe rangeisplacedinto position,feed the open endofthe 5" (12.7cm)flex ductthroughthe hole inthe cabinetsidewall

and throughthe sideof the range,attachitto the outletof the blowerhousingand secureit with a hose clamp (P/N 702331.)

Thetransitionshouldthenbeattachedtothe 3-1/4"x 10" (8.26cmx 25.4cm)ductinginthecabinettoespacethroughthe cabinet

floor cutout.

Step7

Installthe6" (_5.24cm)elbowto theinlet of thebtowerhousingand secureit withducttape. Theopenendofthe elbowshould

bepointedtothe left.Attachthe 6" (15.24cm)flex duct (providedwiththe range)to the elbowandto the range.Secure it with

2 hoseclamps (P/N702331.)See Step21of the installationinstructions.

NOTE:Forrightsideventing,the6" (15.24cm)diameterflexductmay becutinhalfanduseonesectioninsteadofthefull length.

"- makeit easierto assemble.

'JENN-AIR

403WESTFOURTHSTREET,NORTH• NEWTON,IA50208

Page 9

DUCTING

INSTALLATION c o M _= A N Y

I GRILL-RANGEMODELS E N N-AI R

INSTRUCTIONS 3o3_S.ADEL*ND• ,NO,_NAPOL'S,'N46226o9ol

. DROP-IN

k

FREE-STANDING

SLIDE-IN

DUCTING MUST CONFORM TO LOCAL CODE MATERIALS AND "MAKE-UP" REQUIREMENTS--

300 CFM MINIMUM

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE

• DUCTING A JENN-AIR GRILL-RANGE IS EASY BUT CRITICAL FOR PROPER

PERFORMANCE.

• AFTER READING THESE INSTRUCTIONS PLAN THE DUCT RUN.

• USE THE 'DUCT LENGTH CHART' TO FIND THE EQUIVALENT LENGTH OF THE RUN.

• SHIFTTHE BLOWER TO 'HIGH RANGE' IF INDICATED (DONE BY SNAPPING THE

'RESTRICTER RING' OUT OF THE BLOWER INLET), BE SURE BLOWER IS

NOT RUNNING.

• INSTALL THE DUCT HARDWARE.

• ENJOY GRILLING AND COOKING AT ITS FINEST!

THIS UNIT IS RATED AT 60 FEET OF STRAIGHT DUCT

LOW RANGE IS UP TO 30 FEET--HIGH RANGE IS 31 TO 60 FEE'[

IMPORTANT

GENERAL CONSIDERATIONS:

1. Use 6" diameter round or 37/4"x 10"rectangularonly, 5.The numberofdownstreamelbowsortransitionsshould

except as follows: For Electric Models, 5" diameter belimitedtothree.Theinitial5"to6"straighttransition,if

roundMay beusedfor ventingstraightout the backof used,neednot becountedinthis number.

therangeanddirectlythroughthewallfor10feetor less.

For Gas Models with Electric Ovens, 5" diameter 6. Handmadecrimpsarelikelyto causerestrictions.

roundMust be usedif the ductlengthis10feetor less.

7. Ifan alternatewall or roof cap is used,be certain duct

2. Donotuse 5"elbowsexceptin a5"system.Instead,use sizeisnotreduced,andthatthereisabackdraftdamper.

a5"to6"transitionfollowedbya6"elbow,ora5"to31/4,, It is best to use listed caps to be certain of proper

x10"elbowtransition, performance.

3. Usequalitymetalductofat least26gaugegalvanizedor 8. Thermalbreaks:Inareasofextremecoldweather,it may

24gaugealuminum.Inferiorqualitypipeandfittingscan be necessaryto provide a short length of nonmetallic

cause up to twice the restrictionshown and is a poor ductas closetothe wallaspossible,to preventconduc-

value. See box on page4 for optionalunder-slabduct- tJonalongthemetaJduct.

ing.Local codesmay require a heaviergauge material

orrestrictPVC. 9. High altitude installations: It is advisable to reduce

allowableductrun by20%.

4. Distancebetweenadjacentfittings (elbows,transitions,

etc.)shouldbe atleast18".Thefartherthebetter.Closer 10. Followthe duct calculationon page 2 carefullyfor best

distancepromotesturbulencewhichreducesairflow, performanceandsatisfaction.

1 PART NO. 204754D

Page 10

PLAN THE DUCT RUN

1. Make a sketch of the total system. Identify the type of each fitting and the length of straight pipe.

2. Enter your run into the 'Duct Length Chart' in the next section.

ExampleI Example2

__ _.5"to 6"Transition to6" Transition

2' of 6" ound

Elbow

2' of6" Round

\ 6"Elbow

' \ 4' of6" Round )_"

. 6 of6 Round

.6' Elbow 6" Round

6"Elbow ;"Elbow

4' of 6" Round

6"WallCap

10'of3¼"x 10"Straig C,..,.

31/4" X10"Transition

DUCT LENGTH CHART

1. Elbows, wall caps and other fittings are shown in the table on page 3 with their equivalent straight duct

length. Each fitting value must be added to the amount of straight duct length used, to determine the

overal! straight duct equivalent length.

2. Using the examples above:

ExampleI Example2

DuctFitting No.ofFittings TotalEquivalent DuctFitting No.ofFittings TotalEquivalent

Equivalent Length-Fittings Equivalent Length-Fittings

Length Length

5"to6"Transition 1 1 1 5"to6"Transition 1 1 1

6"Straight "f 2+4+6= 12 12 6"Straight t 2+4+6+4= 16 "t6

6"Elbow 5 2 10 6"Elbow 5 3 15

6"WallCap 0 1 0 6"to31/:_' x10"

Total 23 31/4,x10,Straight 1 10 10

Transition 1 1 1

31/4"x10"WallCap 0 1 0

Total 43

INSTALLTHE DUCT HARDWARE

1. Using good quality ducting material, install per these instructions. Follow the General Considerations

page 1, Do's and Don'ts box on page 4, and Grill-Range Installation Instructions. A few minutes an£1

pennies spent now will pay long term dividends for the life of the range.

2

Page 11

USE TABLE BELOW TO CALCULATE TOTAL SYSTEM

DUCT FITTING EQUIVALENT LENGTH NO. OF FITTINGS LENGTH-FITTING

6" Dia. 90 ° Elbow 5 FL (1.52 m)

6" Dia. 45 ° Elbow 2.5 Ft. (.76 m)

5" to 6" Transilion .._

P/N A456 _mn.owTHZS

o27c=to_24cm} _ _ 1.0 Ft. (,30 rn)

6" tO3%" x 10 " 90_ Elbow

(1524 c rn tO 8 25 cm X 254 cm)

WN A496 5 Ft. (1.52 m)

3%"X 10 " to 6" 90" ELBOW

{826-cm • 254 cm to 1524 Crn)

P/N A496 9 Ft. (2.75 m)

6" to 3V,'*x 10" Ttansitton _._"_

(1524 Ctn to 826 cm x 254 cm}

P/N A463 1 Ft. (.30 m)

(Also PiN A453 _nS_de O_¢t) AIR F'LOW

3%"x 10" to 6" TransilJ_l ../_

(82Scmx254cmto15.24cm)

WN A463 4.5 Ft. (1.37 m)

5" to 3%"x 10" 90° E_¢ N /_.,_

[12,7 cm to 8,26 cm X 25.4 cm)

P/N A4g5 AmRow T,_s 6 Ft. (1.83 m)

3,1,"x 10" 90° Elbow

omECT_0N_OT

RECOI_Eta_tD AIRFLQW

AIR F1-OW

AIR FLOW

AIR FLOW

DIREC*_ NOT

REOOMI4EN[_ AERF].O_

DUCT F|TTING TOTAL EQUIVALENT

is.2s¢,_x_.4 cm) _ 5 Ft. (1.52 m)

3%"X 10" Flat Elbow

[8:26cmx2s4cml _ 12Ft.

6" Wall Cap 5" Wall Cap m,_

(15.24 crn) (12.7 ¢m)

P/NA406 PIN A405 0 Ft. (0 m)

3%"• 10" Wall Cap

_s26cmx2s.4cm_

WN A4D3 0 Ft. (0 m)

10" • 10" Roof ,lack

USE LEIGHPRODUCTS 0 Ft. ((] m)

P/N 5850

(Z5 4 °q x 25'4 cm_

IAblO mmt4Hle R J_nn-AIr p/N ?01943)

5" P/N 708786

6" P/N 715557 2 Ft. (.61 m)

THERMALBREAK

6" DIAMETER (For flex duct,

STRAIGHTDUCT- FEET multiplyby 2) 1 Ft. 1.30 rn)

3V,"x10"

STRAIGHTDUCT. FEET 1 Ft. (.30 m)

(Short Run)

(3.66 rn)

SYSTEMTOTAL

1.Thisgrill-rangeisequippedwith adualrangeblower.Itis shippedfromthefactory

SHIFTINGinLOW THE BLOWER FROM 'LOW RANGE' TO 'HIGH RANGE' _

RANGEformostinstallations.IftheEquivalentDuct Lengthexceeds

30 feet it must beshifted to HIGH RANGE. Do not shift to high rangefor _ J_,,,'11

1.BLOWER

OFF

affecttheflamepatternongas units.

In theexamplesonthe precedingpage,the blowerin example#1 shouldbe

installed as received from the factory.The blower jnexample #2 should beshiffed_ighRange, ,_

.o shift to HIGH RANGE,be sure blower is stopped and carefully remove

thespring loaded"RESTRICTERRING'out of the blower inlet.Seeillustration

at fight.

shorter lengths.Thiswill causeexcessivenoise,conditionedair loss and _ 2. SNAPOUT RESTRICTERRING

3

Page 12

' s"ola.su=t TYPICALDUCT ARRANGEMENTS

Typical througft

Rein" DUCt

(Outside Waft)

(|l_.side Wall) (See special instructions

Through Cabinet Toe Space

204917)

OPTIONAL DUCT ARRANGEMENT UNDER CONCRETE SLAB

NOTE; PVC sewer pipe Wpe PSM 12454-S

Also Required: Jenn-AW Kit P/N 712139,

Ilvaileble trom your authorized set-

t

Sewer Pipe

Coupling

Sewer Pipe Elbow Sewer Pipe Elbow

Pack tightly with

gravel or =rand

completely around pipe, I

Note: Window WeB installation Wall Cup - Sewer Pipe

for electric models only.

12" Min, _ * Cut Off Pipe at

!

Sell the space between outside of gravel or sand

wall ¢mp inlet and inside of PYC 6" Dla. PVC completely around pipe.

couf_kl g wit_ ¢au_blg m_te_L Couplleg

use 5" 112.7 cm), 6" (15,24 cm), Use 4" (1016 ore) dryer vent pipe

or 3_/," x 10" (8,255 cm x 254 cm), or flex duct,*

piPe as recommended for your !

Use rec<;mmende_Wallcap_ Use launary type wallCap.

model. _ (_

UsenomomthanOneg0°e_owwim Over run your systenn with too

fiveinch (1P.7 ore)duct _r thr_._g0* marly b_rtd$aridtu_$.

eLb0wswilhsixinch(15.2cm)or3"x10" Pad 708786

(8255 crn x25 4 ore) _u_ Fits 5" (t 2.7 cm) Round MODEL ._.d$

Dum systemto the 0uts,:le and conc_lled spaceofa building. PART _15557 MOD_tL

Mix 6" (15.24¢m)duct ar',d3'/," x10" Reclucebackto 5" {12 7 cm) system Duct. Adds 2 ft. to duct Duct, Requires6%" (15.875

duct (8.255 cm x 25A cm) within the atterusieg 6" (15.24cm)or 3V,"x 1G*' length calculation cm) 0ia. opening,

samesystem rf necessary (8.255 cm x 25.4 cmt.

Tape all joints securely witi_ Butt joints, atwaysuse male-female _ f_

severalwrapsof fade. Connectiorl$_ndirectronof flow.

0se one unit per duct system. Exhaust mote than one unit into a

"Althougrtriot recommended,5" Or 6'* metal flex duct maybe LISe_.Due to Single-darrtper, down P/N 5950

_eltregu/arsutfac_°tf_exib_e_'uct_'_'eacrtfc_off!exduCtc°unfaastw°l_l diScftargetofit3%'xlO" RoofJacktO'xt(_"

feet of regular metal _uct. Also, eachelbow made inflex _luctwc_JIdcount {E.25_cm x 25.4 cm) duct. (254 crnx 254 cm)

twice as muct_ as standard metatel_ow. The 0est idea withftexibleducting

istOkeePitasellorl and as _t_'_ightas _ossi_e.

oo oo.'r WALLCAPS/THERMALBREAKS

Vecltintoartatticor ¢r_wlspace,walls cm) Dia opening.

sJn21esyst(_n

Pack tightly "t_th

Duct. Acids 2 ft. to duct Pits 5" (127 cm) Round

length CalCulation. Duct. R_uire_ 5%" (13.34

PitsS"(15._ ore)Round Fits 6" t15.24 cm) Round

MODEL A44_ LEIGH PRODUCTS

Sewer Pipe Elbow

4 PARTNO. 204754D

Loading...

Loading...