Page 1

Professional30"and36"

DualFuelRangeModels

IS]ENN-AIR

400WESTFOURTHSTREET,NORTH"NEWTON,IA50208

Retain this manual for future reference.

0®®

17665 REVC 04/2004

Page 2

A MESSAGETO OUR CUSTOMERS

For your convenience, product questions can be answered by Jenn-Air Customer Assistance

1-800dENNAIR (1-800-536-6247)

1-800-688-2080 (U.S.TTY for hearing or speech impaired)

Mon. - FrL,8 am - 8 pm Eastern Time

Internet: www.jennair.com

Maytag Services sm

Attn: CAIRRCenter

RO. Box 2370

Cleveland, TN 37320-2370

/k WARNING

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

WARNING

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

IF YOU SMELL GAS:

! Do not try to light any appfiance.

! Do not touch any electrical switch; do not use any phone in your building.

! Immediately call your gas suppfier from a neighbor's phone. Follow the gas

supplier's instructions.

m,If you cannot reach your gas suppfier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

WARNING:

Gas leaks may occur in your system and result in a dangerous situation. Gas

leaks may not be detected by smell alone. Gas suppliers recommend you

purchase and install an UL approved gas detector. Install and use in

accordance with the manufacturer's instructions.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Page 3

TABLE OF CONTENTSJ

INTRODUCTION ..................................................................................................................................................................3

MODEL IDENTIFICATION .............................................................................................................................................4

UNPACKING AND HANDLING .............................................................................................................................5-6

VENTILATION REQUIREMENTS ...............................................................................................................................7

INSTALLING ANTI-TIP DEVICE .................................................................................................................................8

CABINET PREPARATION .........................................................................................................................................9-11

BACKGUARD INSTALLATION .................................................................................................................................12

ELECTRICAL / GAS CONNECTIONS .............................................................................................................12-13

HOOK-UP TO GAS SUPPLY ................................................................................................................................13-I 4

INSTALLER FINAL CHECKLIST ...............................................................................................................................15

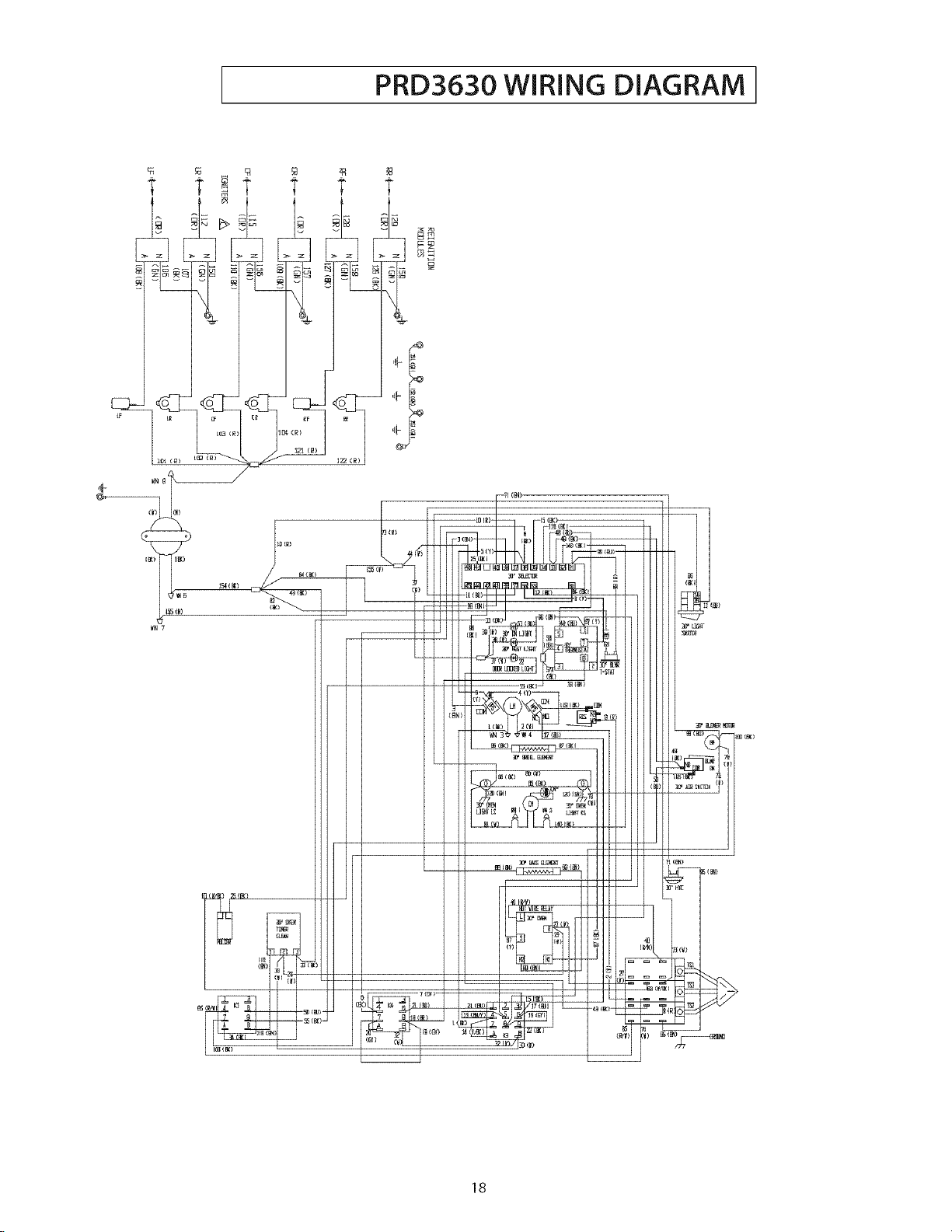

WIRING DIAGRAMISCHEMATIC ....................................................................................................................16-19

PRD3030 WIRING DIAGRAM ........................................................... 16

PRD3030 SCHEMATIC ................................................................. 17

PRD3630 WIRING DIAGRAM ........................................................... 18

PRD3630 SCHEMATIC ................................................................. 19

WARRANTY ...................................................................................................................................................................20-21

Page 4

INTRODUCTION

Jenn-Air Professional Ranges are designed with a number of unique features certain to provide years

of cooking enjoyment for the novice or experienced chef. Ranges are available in 30"and 36"widths.

The large capacity electric ovens of the Dual Fuel Range are self-cleaning and feature convection

baking. All models offer a minimum of (4) 15,000 Btu/hr sealed top burners. Dual-flow simmer

burners are provided, and offer a low turn clown of 570-1,200 Btu/hr.

IMPORTANT INSTALLATION INFORMATION

The Jenn-Air Professional Series is tested in accordance to UL Standard 858 and ANSI Z21.1. These

ranges must be installed in conjunction with a suitable overhead vent hood. Due to the high heat

capacity of this unit, particular attention should be paid to the hood and duct work installation to

ensure it meets local building codes. To eliminate risk of burns or fire by reaching over heated surface

units, cabinet storage located above the surface units should be avoided.

Check local building codes for the proper method of range installation. Local codes vary. Installation,

electrical connections, and grounding must comply with all applicable codes. In the absence of local

codes, the range should be installed in accordance with the National Fuel Gas Code ANSI Z223.1-1988

and National Electrical Code ANSI / NFPA 70-] 990. Be sure that the unit being installed is set up for the

kind of gas being used. The dual fuel range is shipped from the factory set and adjusted for Natural

Gas. It can be field-converted for LP (propane) by a qualified technician using the orifices provided

with the unit. Refer to instructions included with the conversion kit that is packed with the unit. Verify

that the range is compatible with gas supply at the installation site before proceeding further.

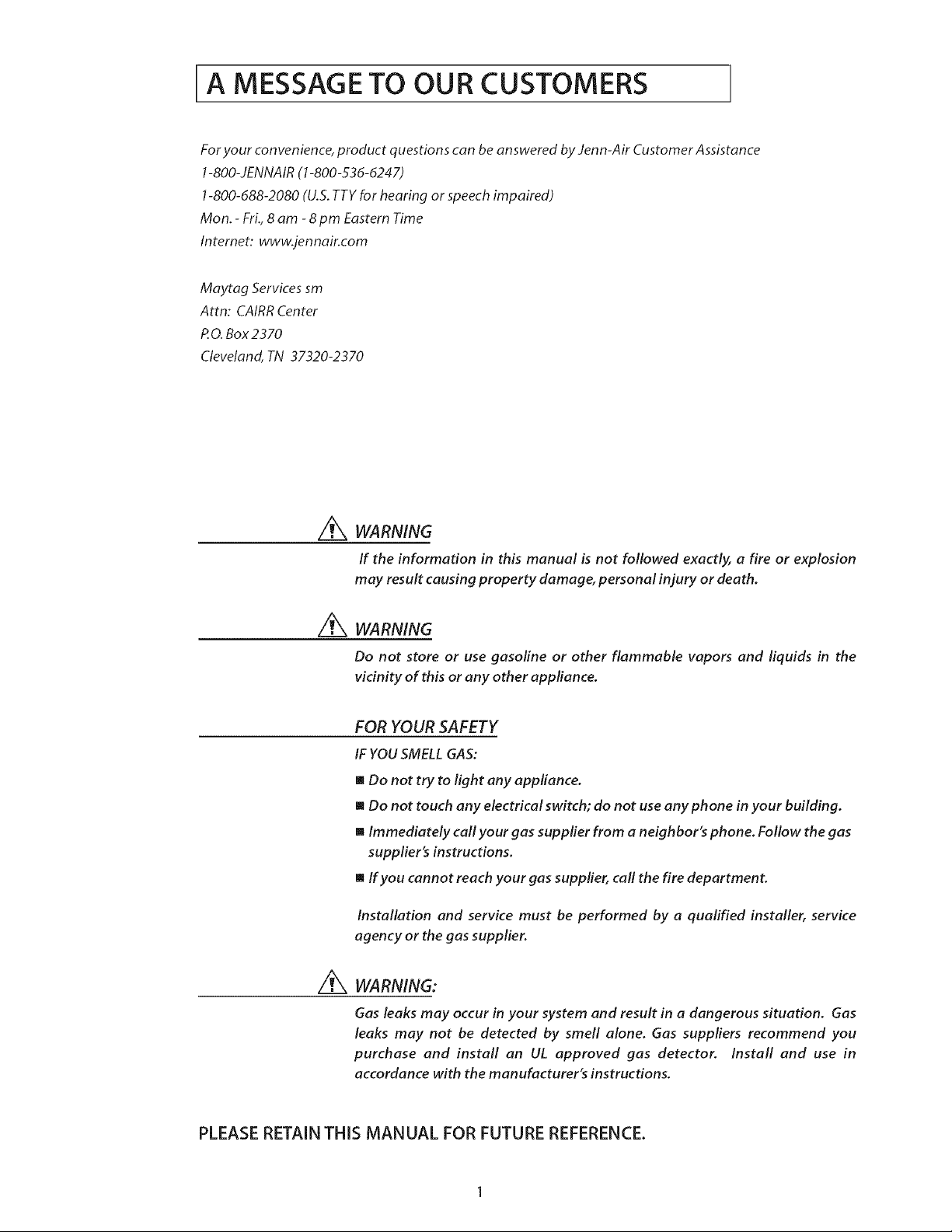

All ranges must be installed with one of three backguards (This piece must be ordered separately)

except model PRD3030, which is shipped standard with a 9" low backguard. See figure below for sizes

and model numbers.

22" High Shelf Backguard option

Model PRAD3022 (30")

Model PRAD3622 (36")

12" Lowback option

Model PRAD3612

9" Lowback

(30 models only)

Island Trim

Model PRAD3001 (30")

Model PRAD3601 (36")

Fig. I

Page 5

MODEL IDENTIFICATION I

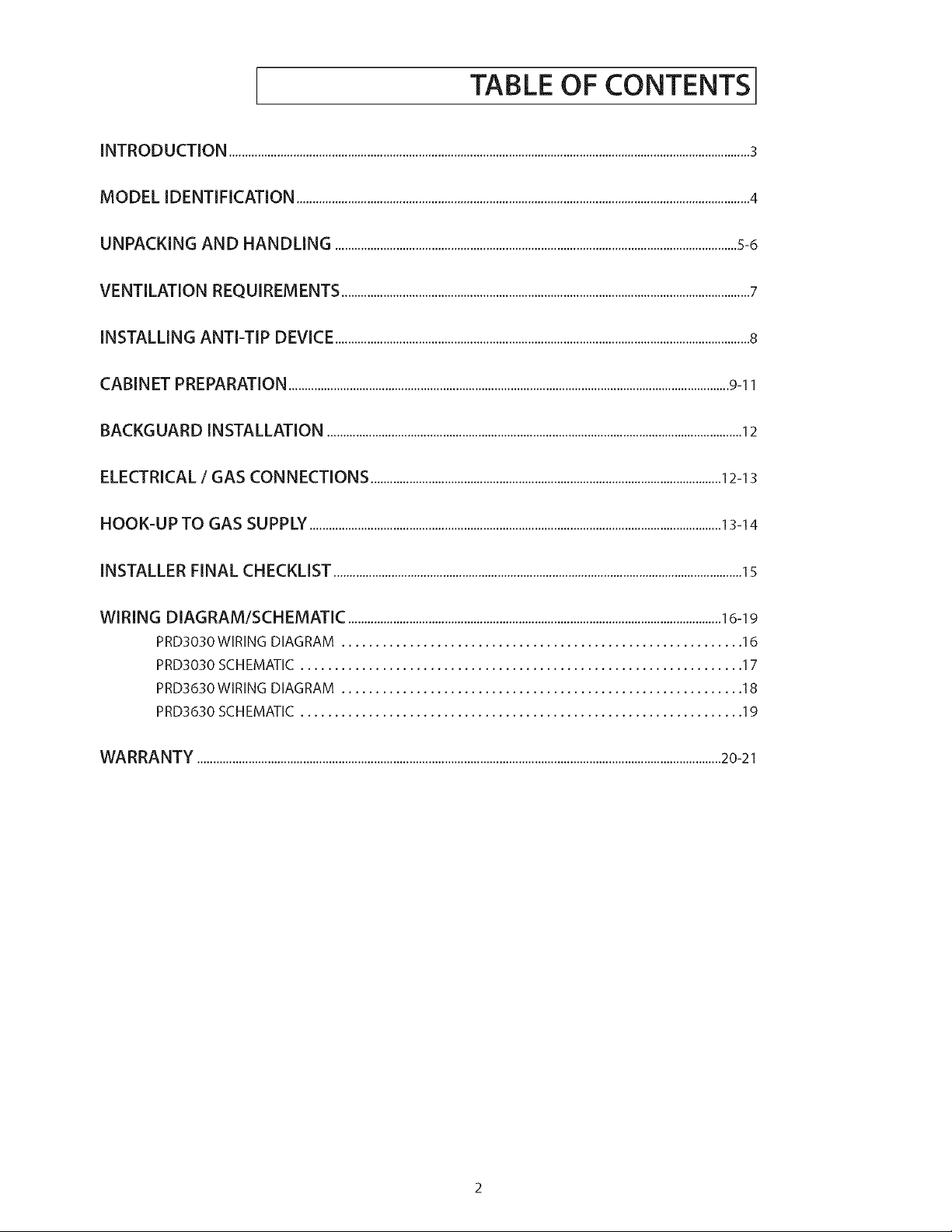

36" DUAL FUEL RANGE MODEL

MODEL PRD3630

30" DUAL FUEL RANGE MODEL

MODEL PRD3030

Page 6

UNPACKING AND HANDLING

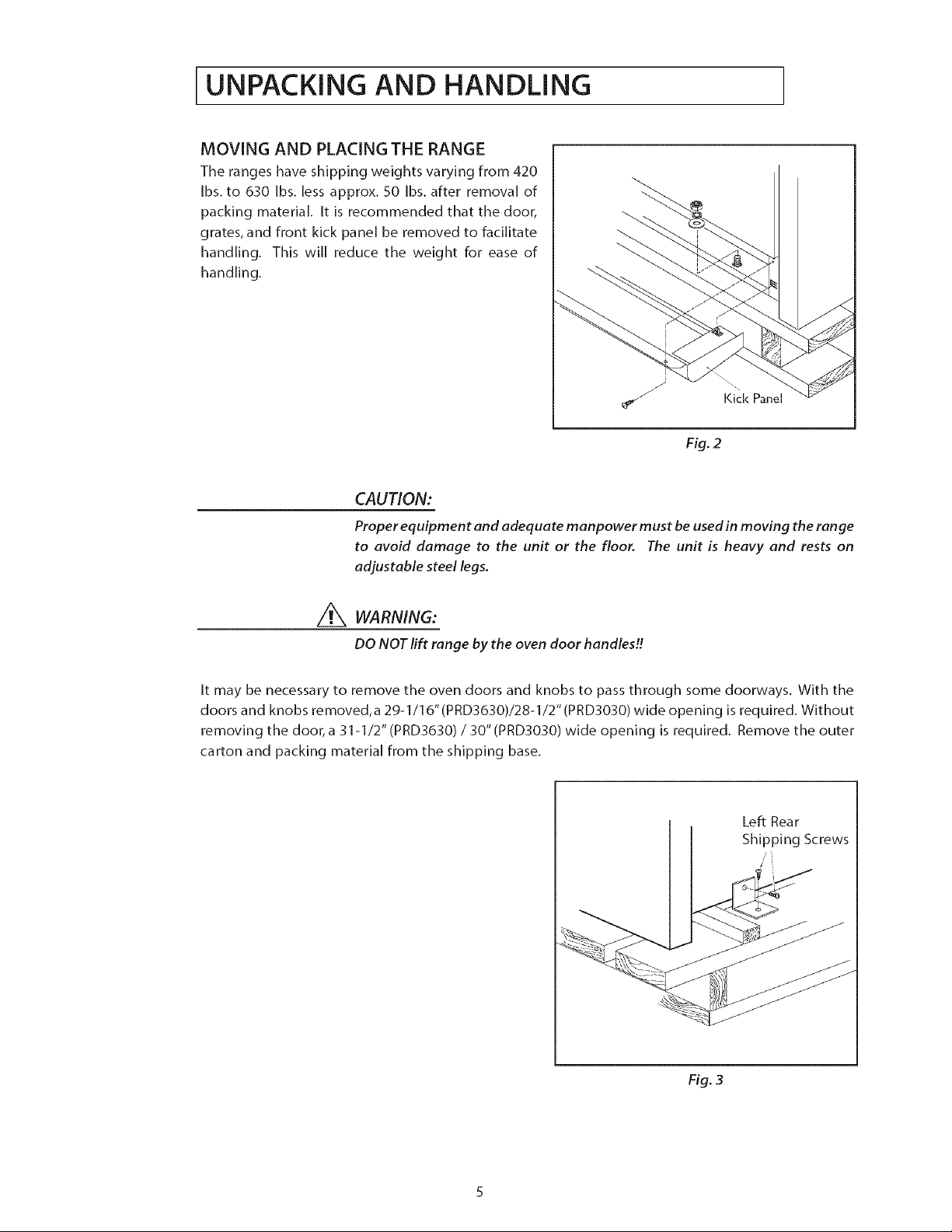

MOVING AND PLACING THE RANGE

The ranges have shipping weights varying from 420

Ibs. to 630 Ibs. less approx. SO Ibs. after removal of

packing material. It is recommended that the door,

grates, and front kick panel be removed to facilitate

handling. This will reduce the weight for ease of

handling.

CAUTION:

Proper equipment and adequate manpower must be used in moving the range

to avoid damage to the unit or the floor. The unit is heavy and rests on

adjustable steel legs.

1

Fig. 2

Z_ WARNING:

DO NOT lift range by the oven door handles!!

It may be necessary to remove the oven doors and knobs to pass through some doorways. With the

doors and knobs removed, a 29-1/16"(PRD3630)/28-1/2" (PRD3030) wide opening is required. Without

removing the door, a 31-1/2" (PRD3630) /30" (PRD3030) wide opening is required. Remove the outer

carton and packing material from the shipping base.

Left Rear

Shipping Screws

i

Fig. 3

Page 7

UNPACKING AND HANDLING

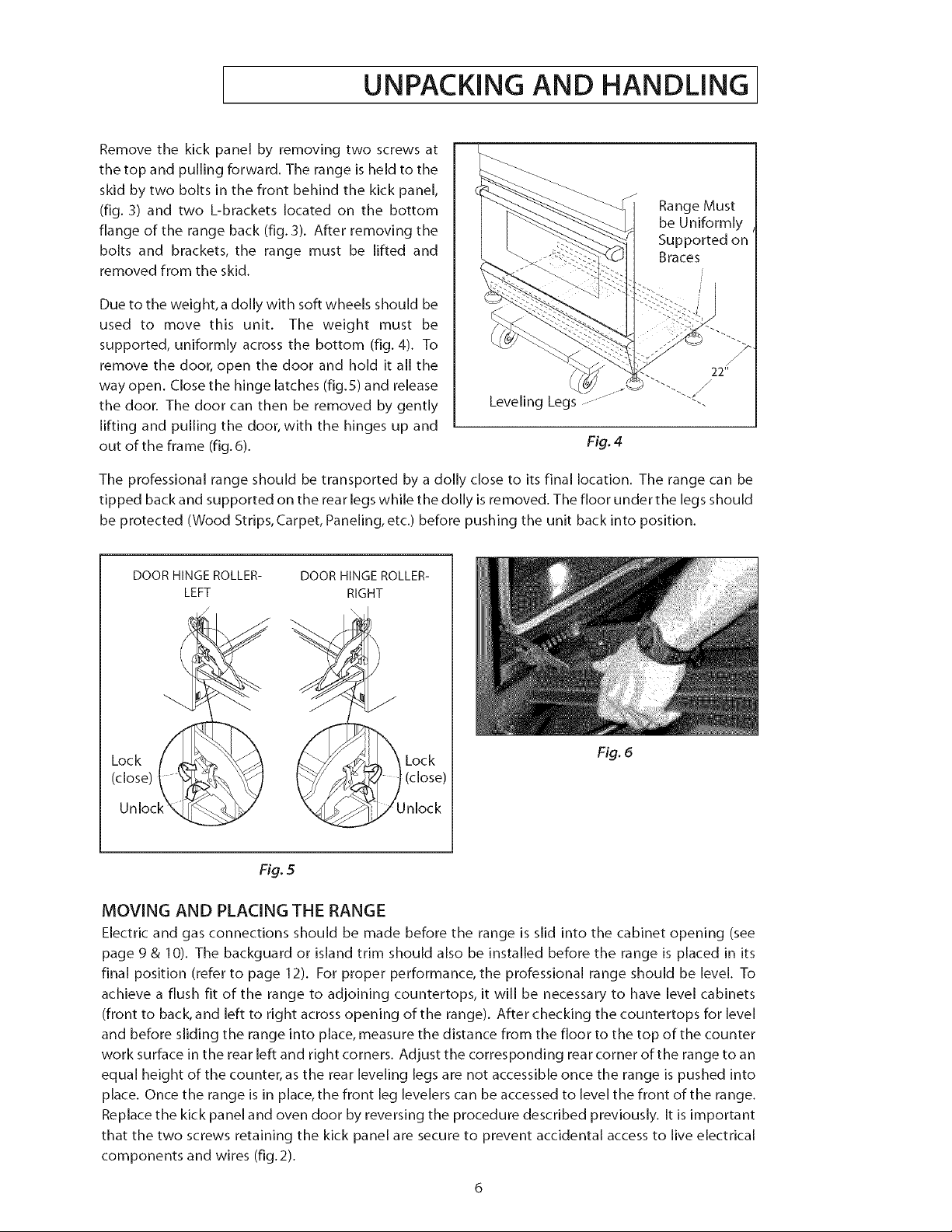

Remove the kick panel by removing two screws at

the top and pulling forward. The range is held to the

skid by two bolts in the front behind the kick panel,

(fig. 3) and two L-brackets located on the bottom

flange of the range back (fig. 3). After removing the

bolts and brackets, the range must be lifted and

removed from the skid.

Due to the weight, a dolly with soft wheels should be

used to move this unit. The weight must be

supported, uniformly across the bottom (fig. 4). To

remove the door, open the door and hold it all the

way open. Close the hinge latches (fig.5) and release

the door. The door can then be removed by gently

lifting and pulling the door, with the hinges up and

out of the frame (fig. 6).

The professional range should be transported by a dolly close to its final location. The range can be

tipped back and supported on the rear legs while the dolly is removed. The floor under the legs should

be protected (Wood Strips, Carpet, Paneling, etc.) before pushing the unit back into position.

Fig. 4

Range Must

be Uniformly

Supported on

Braces

DOOR HINGEROLLER-

LEFT

./

DOORHINGEROLLER-

RIGHT

Fig. 6

Unloc_

Fig. 5

MOVING AND PLACING THE RANGE

Electric and gas connections should be made before the range is slid into the cabinet opening (see

page 9 & 10). The backguard or island trim should also be installed before the range is placed in its

final position (refer to page 12). For proper performance, the professional range should be level. To

achieve a flush fit of the range to adjoining countertops, it will be necessary to have level cabinets

(front to back, and left to right across opening of the range). After checking the countertops for level

and before sliding the range into place, measure the distance from the floor to the top of the counter

work surface in the rear left and right corners. Adjust the corresponding rear corner of the range to an

equal height of the counter, as the rear leveling legs are not accessible once the range is pushed into

place. Once the range is in place, the front leg levelers can be accessed to level the front of the range.

Replace the kick panel and oven door by reversing the procedure described previously. It is important

that the two screws retaining the kick panel are secure to prevent accidental access to live electrical

components and wires (fig.2).

Page 8

VENTILATION REQUIREMENTS

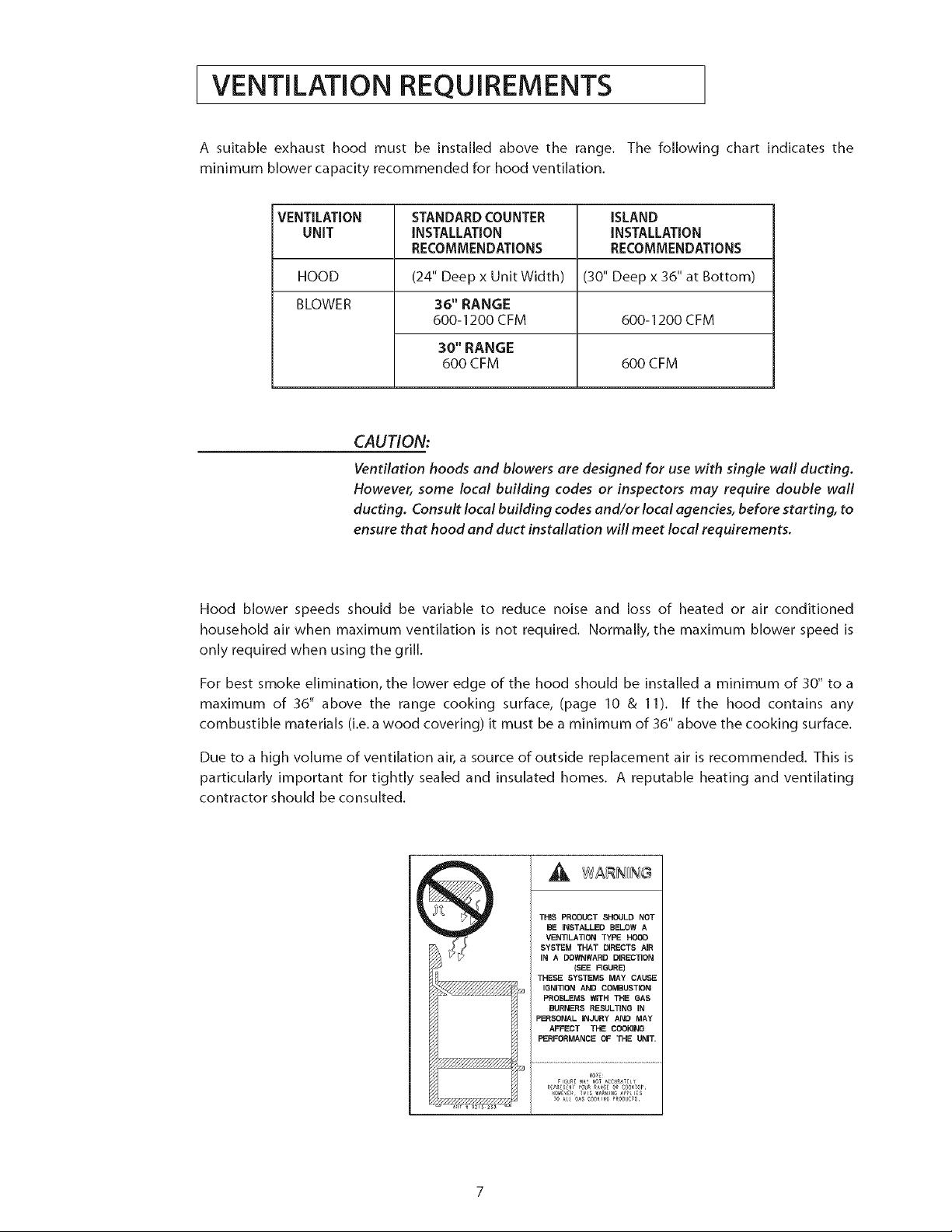

A suitable exhaust hood must be installed above the range. The following chart indicates the

minimum blower capacity recommended for hood ventilation.

VENTILATION STANDARD COUNTER ISLAND

UNIT INSTALLATION INSTALLATION

RECOMMENDATIONS RECOMMENDATIONS

HOOD (24" Deep x Unit Width) (30" Deep x 36" at Bottom)

BLOWER 36" RANGE

600-1200 CFM 600-1200 CFM

30" RANGE

600 CFM 600 CFM

CAUTION:

Ventilation hoods and blowers are designed for use with single wall ducting.

However, some local building codes or inspectors may require double wall

ducting. Consult local building codes and/or local agencies, before starting, to

ensure that hood and duct installation will meet local requirements.

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned

household air when maximum ventilation is not required. Normally, the maximum blower speed is

only required when using the grill.

For best smoke elimination, the lower edge of the hood should be installed a minimum of 30" to a

maximum of 36" above the range cooking surface, (page 10 & 11). If the hood contains any

combustible materials (i.e.a wood covering) it must be a minimum of 36" above the cooking surface.

Due to a high volume of ventilation air, a source of outside replacement air is recommended. This is

particularly important for tightly sealed and insulated homes. A reputable heating and ventilating

contractor should be consulted.

WARNONG

THiS PRODUCT SHOULD NOT

BE INSTALLED BELOW A

VENTILATION TYPE HOOD

SYSTEM THAT DIRECTS AiR

IN A DOWNWARD DIRECTION

(SEE FIGURE)

THESE SYSTEMS MAY CAUSE

IGNITION AND COMBUSTION

PROBLEMS WITH THE GAS

BURNERS RESULTING IN

PI_RGONAL INJURY AND MAY

AFFECT THE COOKING

PERFORMANCE OF THE UNIT.

_o_

FIGURE_AY _0__CC_R_T_y

R_R_s_r YOURRANGEORC00K_01';

Page 9

INSTALLING ANTI-TIP DEVICE

All ranges must have an antFtip device

correctly installed as per the following

instructions. If you pull the range out

from the wall for any reason, make sure

that the device is properly engaged

when you push the range back against

the wall. If it is not, there is a possible

risk of the range tipping over and

causing injury if you or a child stand, sit

or lean on an open oven door.

(2)Small Holes for

Wood Installations

(2) Large Holes for BACK

Concrete Installations WALL

INCLUDED PARTS:

Included with this kit are:

(4) #10 x 2"wood screws,

(1) AntFtip bracket, and (1)Installation

Instructions.

INSTALLING THE KIT:

Instructions are provided for wood

and cement floors. Any other type of

construction may require special instal-

lation techniques as deemed necessary

to provide adequate fastening of the Anti-tip

bracket to the floor and wall. The use of this bracket

does not preclude tipping of the range when not

properly installed.

(2) Wood Screws into

Back Wall (ALL

Installations)

Fig. 7

A= I/4" 5/8"

Model

Series PRD3030 PRD3630

WOOD CONSTRUCTION:

Place the bracket against the back wall, into the right

rear corner where the range is to be located. Leave a

gap between the wall (or side of range) and the

bracket (see fig.7). Drill (2) 1/8"diameter pilot holes

in the centerofthe small holes. A nail or awl may be

used if a drill is not available. Fasten the bracket

securely to the floor and wall.

CONCRETE OR CEMENT CONSTRUCTION:

/_ WARNING

= ALL RANGES CAN TiP

i INJURY COULD RESULT

® INSTALL ANTI-TIP

BRACKET PACKED

INSIDE OVEN

• SEE INSTRUCTIONS

Hardware Required:

(2) sleeve anchors, lag bolts, and washers (not

provided). Locate the bracket as described above.

Drill the recommended size holes for the hardware.

Install the sleeve anchors into the holes and then install the lag bolts through the bracket.The bolts

must be properly tightened as recommended for the hardware. Fasten the bracket securely to the

floor and wall.

Fig. 8

ONCE INSTALLED:

Complete the range installation per the instructions provided with the product. Check for proper

installation of the range and Anti-tip device by grasping the back of the unit and carefully attempt to

tilt the range forward.

Page 10

CABINET PREPARATION

1) The range is a free standing unit. If the unit is to be placed adjacent to cabinets, the clearances

shown in fig.9 (PRD3630) & fig. 10 (PRD3030) are required. The same clearances apply to island

installations.

2) The range can be placed in various positions with respect to the cabinet front, with the front either

flush or projecting, depending on the countertop depth.

3) The gas and electrical supply should be within the zones shown (fig.9, 10 & 11).

4) The maximum depth of over head cabinets installed on either side of the hood is 13"

S) Any openings in the wall behind the range and in the floor under the range must be sealed.

6) When there is less than a 12"clearance between combustible material and the back edge of the

range (above the cooking surface), a Low backguard or High Shelf backguard must be installed,

(fig. 12-Island ). When clearance to combustible material is over 12'[ an island trim may be

installed (fig. 12-Standard). These parts must be ordered separately (model PRD3030 is shipped

standard with a 9" Low backguard). Fig. 12 indicates the space required for each type of

backguard.

7) Always keep the appliance area clear and free from combustible materials, gasoline and other

flammable vapors and liquids.

8) Do not obstruct the flow of combustion and ventilation air to the unit.

0 0/

LM .

1 12 rain.tocombustible-

18"Min. __I 4" material eachside

O

3-1/2"electrical

supply

gasSupply

l

35-3/8"max.forlevelcounter,

36-3/4"max.with range

levelinglegsfullyextended

AAsdefinedinthe"Nati0nalFuelGasCode"

(ANSIZ223.1,lastestedition).

CAUTION:

36"rain,to

combustible

material

fromcookng

surface

Thehorizontalsurfaces0fthe rangetop(c00kt0p)

trimmustnotbebelowc0untert0plevel.

Fig. 9 PRD3630 Model Only

Page 11

35-3/4"max,forlevelcounter,

37"max,with range

levelinglegsfullyextended

CABINET PREPARATION

AAsdefinedinthe"NationalFuelGasCode"

(ANSIZ223,%lastestedition),

Thehorizontalsurfacesoftherangetop(cooktop)

trimmustnotbebelowcountertoplevel.

Fig. 10 PRD3030 Model Only

ManualShut-Off

Valvemustbe

2"Maximum

ProtrusionfromWall

forGasSupply

EasilyAccessible

FlexLinetoRange,.

Electrical

: "'i"-.

_ ! ""--..•.

Supply

Fig. 11 All PRD Models

10

NEMA14-SO

Receptacle

Page 12

[CABINET PREPARATION

STANDARD INSTALLATION: ISLAND INSTALLATION:

12"Min.to

Combustibles/X

without backguard

High Shelf Backguard

A

(bim."A")

I

LowBackguard

(Dim."B")

I

_/Island Trim

_ 0" Clearance

D

_E_IIIIIIIIIIIIIIIIIIII _" _i_

_F

A Asdefinedin the

"NationalFuelGasCode"

(ANSIZ223.1,LatestEdition).

Thehorizontal surfacesof the rangetop (cooktop)

trim must notbebelowcountertop level,

Fig. 12 All PRD Models Product / installation Clearance Specifications

36"Min.to

Combustibles_.

PRD3630

PRD3030

0 0 0 00oa

--K--

PRD3630 Model

A B ¢ D E F G H I J K

22" 12" 2" 35-1/2"min.-37"max. 30-1/4" 44-1/2" 28-1/4" 1-5/16" 25" 27-3/8" 35-7/8"

22" 9" 2" 35-3/4"min.-37"max. 28-3/16" 43-7/8" 27-3/8" 1-5/16" 24-3/16" 26-3/4" 29-7/8"

O0 0 O0 u

--K--

PRD3030 Model

11

Page 13

BACKGUARD INSTALLATION

BACKGUARD KITS:

Model PRD3030 is shipped standard with a 9" Low backguard. High Shelf backguards, Island Trims and

the Low Back for Model PRD3630 must be ordered separately. Specific instructions for installation of

the High Shelf backguard, Low backguard or Island Trim Backguard can be found packaged with the

backguard. All backguards or island trims must be installed on the range before the unit is pushed

into the cabinet. A backguard must be installed when there is less than a 12" clearance between

combustibles and the back of the range (above the cooking surface). See fig. 12. Refer to page 3 for

backguard model numbers.

ELECTRICAL/ GAS CONNECTIONS

ELECTRICAL CONNECTIONS

PRD3630 model

Always disconnect electric supply cord from the wall outlet or service disconnect before servicing this

appliance. Observe all governing codes and ordinances when grounding, in absence of which,observe

National Electrical Code ANSI / NFPA No. 70-I 990. The electrical supply must be a 120/240 volt, 3 wire

(plus ground) 60 Hz single phase, S0 AMP circuit. The power receptacle must be a NEMA 14-50 device

to accept the four prong plug supplied with the

unit.The receptacle should be located within the

area shown in fig.9 page 9.

PRD3030 MODEL

The electrical supply must be a 120/240 volt, 3

wire (plus ground), 60 Hz, 30 AMP circuit. The

power receptacle must be a NEMA 14-50 device

to accept the four prong plug supplied with the

unit. The receptacle should be located within the

area shown in fig. 10, page 10.

_- Electrical Supply

--. j

12

\ _-..

NEMA 14-50

Receptacle

Fig. 13

Page 14

ELECTRICAL/ GAS CONNECTIONS

RECOMMENDED GROUNDING METHOD

This appliance is factory equipped with a power supply cord with a four-prong grounding plug. It

must be plugged into a mating grounding, type receptacle, connected to a correctly polarized 120/240

volt circuit. If the circuit does not have a grounding type receptacle, it is the responsibility and

obligation of the installer to have the existing receptacle changed to a properly grounded and

polarized receptacle in accordance with all applicable local codes and ordinances by a qualified

electrician. In the absence of local codes and ordinances, the receptacle replacement shall be in

accordance with the National Electrical Code.

THE FOURTH PRONG (ROUND GROUNDING PIN) SHOULD NOT, UNDER ANY

CIRCUMSTANCES, BE CUT OR REMOVED.

GAS REQUIREMENTS

Verify the type of gas supplied to the location. The range is shipped from the factory set up and

adjusted for natural gas. It can be field-converted for LP (propane) gas. Refer to instructions included

with the conversion kit that is packed with the unit.

NATURAL GAS

ll Connection: 1/2" N.P.T.Minimum 5/8"dia.flex line.

ll Supply Pressure: 6"to 14"W.C.

LPGAS

m Connection: I/2" N.P.T.Minimum 5/8 dia.flex line. m Supply Pressure: 11"to 14"W.C.

A regulator is required at the LP source to provide a maximum of 14"W.C.to the range regulator.

lNOOK-UPTO GAS SUPPLY J

HOOK-UP

A manual valve must be installed external to the appliance, in an accessible location from the front for

the purpose of shutting offthe gas supply. The supply line must not protrude beyond the back of the

unit. Make sure the gas supply is turned offat the wall valve before connecting the appliance.

The gas supply connections should be made by a qualified technician and in accordance with local

codes or ordinances. In the absence of a local code, the installation must conform to the National Fuel

Gas Code ANSI 223.1-1988, latest edition.

13

Page 15

HOOK-UP TO GAS SUPPLY

CAUTION:

The appliance must be isolated from the building's gas supply piping system

by closing its individual manual shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than I/2 psig

(3.SkPa.). The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of the system at

the test pressures in excess of I/2 psig (3.SkPa.)." When checking the manifold

gas pressure, the inlet pressure to the regulator should be at least 7.0" W.C.

(Water Column) for natural gas or 12.0"for LP.

NOTE: The flex line for the gas supply must be metal and be approved by an approved

certifying agency (AGA, CGA, or UL). Never use a hose made of rubber or other

synthetic material, as the heat may cause the hose to melt and develop leaks.

When hooking up the gas supply from

range rear hard pipe to wall hard pipe,

installation length of flex line between

range/wall hard piping must

accommodate range being pulled

from wall for cleaning or servicing

purposes. When range is pulled from

wall, no strain should occur at range or

wall hard pipe connections (fig. 14).

| Manual

Valve must be

Easily Accessible

WALL

Hard Pipe

Connection

14

Hard Pipe

1/2" N PT

Fig. 14

Page 16

[INSTALLER FINAL CHECKLIST

GENERAL

FI Placement of unit.

FI Specified clearance maintained to cabinet surfaces.

r] Unit Level - front to back, side to side.

FI All packaging material and tie straps removed, drip pans clean and empty.

FI Backguard attached if there is less than 12" clearance above the cooking surface to combustibl

construction behind unit.

FI Island trim attached if there is more than 12" clearance above the cooking surface to the

combustible construction behind the unit.

ELECTRICAL

r] Receptacle with 50 ampere over-current protection (30A for PRD3030) is provided for service

cord connection.

r] Adequate ground connection.

r] Front kick panel in place and two (2) screws secure.

GAS SUPPLY

r] Connection: 1/2 NPT with a minimum 5/8" diameter flex line. Site gas supply is compatible with

range model, & sufficient pressure is available (see gas requirements pg. 13).

FI The pressure regulator which is connected to the manifold is set for 5.0 W.C. for natural gas or

10.0 W.C. for LR

FI Manual gas shut-offvalve installed in an accessible location.

FI Unit tested and free of gas leaks.

OPERATION

F1All internal packing materials removed. Check below grate, pans and drip drawers.

F1If used on LPgas, verify that pressure regulator, orifices, and valve bypass jets have been set for

use with LP gas.

F1 Bezels centered on burner knobs and knobs turn freely.

FI Each burner lights satisfactorily, both individually and with other burners.

FI Oven door hinges seated and door opens and closes properly.

FI Burner grates correctly positioned, level, and do not rock.

15

Page 17

PRD3030 WIRING DIAGRAM

LF

16

Page 18

]s]

£41 sw_

]$3

l

S_RFAEE_ L_ _ RR

v

VAL

]

ATND Y

IL._ A

E_K

HWR

NOTES:

AS = AIR_ZTO_

IKI = EdT_R@_ ILE_NI

IK_ = _ BAKEELE_NT

IL_F

ISIAT=_ TFER_AT

- OJ]SE_ RISE

IR = _OIL

[_ = EIINVEETI_B_E

[L = O-EAN

CH = EOg_EETIONMOIOR

ITNILI=UC_TTNIINDI_IOR

@R = 111VI_ REL_

H_E = HI_ l_F OJTOUI

I_N - IGNIT_R

K[ = O__4N_L_Y _Ol

K3 = LATO_ELOSERELAY

K4 = LAI04_o_ ___

LF = L@7 FR3NI

L£ = LAI04_TOR,10JR

LR = LEFTREAR

LT = LI_dT

N[ _ NO_4ALLY[LOSEI

NO = NO_4ALLYOPEN

PLSR = _ PdLS_

R_IG_I = _IGNITION

I

0

0

I

m

m

12i V __

BLURNo]STk_ I

III_I<II(_IR

S_ = Gg_ S_

(I_:>IK>_<_II>[L)

S_ = @ITGH

T_XTAT MAIN'0_{111___([_ IN[!R=LA_

NO,[_ IN [LEANl_tY

L]£K = U]L<Y_l

T-STA[ [I_EO < ZSTF

(L_[_ _ IN _N)

TSI = TE_INALST_I_LI

- _IN F{]_ SdFfLY

TS2 = TE_IN_LSI!_I_L_

- _IN F_]_9_]FfLY

TS3 = TE_INALST_IF_b]_L

T_4 = TE_INALST_IF

_I_L TIPA}_A

IS5 = TE_INALSI_I_L2

LIVE-T_

I_ = TE_IN_LSI_I_

Page 19

(I) (_)

PRD3630 WIRING DIAGRAM

_8

7

_fzfr_

L

_ mmB__imJ_

6" _ #lFr_ (I)

(_)

= T_L

1Q

18

Page 20

_s]

TS3

240

!20 V

LF LR

30'HWR

L

AIRSWITCH

BAKE

BZ]WE_]_3STAT

- CLI]SEEN RISE

&E_ER _T[R

_ROIL RF = RIGHTFRONT

CI]qVECTIONBA!_ RIS : R_IKINTERLOEKS_[PEH

O_IERI:_II_ RR = RIGHTRE&R

OFAN SEL = OVENSELEETQR

ILIBWECTI[N_BTER (OFF.BK[BK BREL)

REAR SW : S_ITEH' ' '

R]SITI_ SWITCH T-STAT: OVENTHERMRSP&T

Q_EAN_ELAYDPDT [-3 [YCLING[ONTAIT

LAT_OZ_R&AY 3POT 4-5 [&MUPER&TED-

LATO_B_EN_AYCPBT OPENIN [LE&N

LE_FRB_ POSITION& OFF

LAI'O_, _ 0-7_PEN> 550_F

LEFf@FAR (LBEKSDDDR)

LI[_T TS[ = TERMINALSTRIPL[

[YEN& RIVING - MAINPORERSUPPLY

II_AROSEL[5_ TS2 = TERMINALSTRIPL2

CL[]SB]&[]RIVING - M&INPOWERSUPPLY

I_AEIS[PBI TS3 = TERMINALSTRIPNEUTRAL

F_TW[RERELAY M&INPOWERSUPPLY

HI_II_Q]IlZiT TS4 = TERNIN&LSTRIP

IBNIIER NEUTR<OP&RE&

I'I]II_P[EITZ[_SWlTCHTS5 = TERMIN&LSTRIPL2

50%PLLSER LIVE-TOP&RE&

\ S_I_CH

TS_ : TERMIN&LSTRIP

:X)

_J

0

I

m

_B

m

IS2

Page 21

L WARRANTY 1

FULL ONE YEAR WARRANTY - PARTSAND LABOR

For one (I) year from the original retail purchase date, any part which fails in normal home use will be

repaired or replaced free of charge.

Limited Warranties - Parts Only

Second Year - After the first year from the original purchase date, parts which fail in normal home use

will be repaired or replaced free of charge for the part itself, with the owner paying all other costs,

including labor, mileage and transportation, trip charge and diagnostic charge, if required.

Third Through Fifth Year - From the original purchase date, parts listed below which fail in normal

home use will be repaired or replaced free of charge for the part itself, with the owner paying all other

costs, including labor, mileage and transportation, trip charge and diagnostic charge, if required.

[] Electronic Controls

[] Electric Heating Elements: Broil and bake elements on gas and electric cooking appliances.

[] Sealed Gas Burners

CANADIAN RESIDENTS

The above warranties only cover an appliance installed in Canada that has been certified or listed by

appropriate test agencies for compliance to a National Standard of Canada unless the appliance was

brought into Canada due to transfer of residence from the United States to Canada.

Limited Warranty Outside the United States and Canada - Parts Only

For two (2) years from the date of original retail purchase, any part which fails in normal home use will

be repaired or replaced free of charge for the part itself, with the owner paying all other costs,

including labor, mileage and transportation, trip charge and diagnostic charge, if required.

The specific warranties expressed above are the ONLY warranties provided by the manufacturer. These warranties give you specific

legal rights, and you may also have other rights which vary from state to state.

WHAT IS NOT COVERED BY THESE WARRANTIES:

1. Conditions and damages resulting from any of the following:

a. Improper installation, delivery, or maintenance.

b. Any repair, modification, alteration, or adjustment not authorized by the manufacturer or an

authorized servicer.

c. Misuse, abuse, accidents, or unreasonable use.

d. Incorrect electric current, voltage, or supply.

e. Improper setting of any control.

2 Warranties are void if the original serial numbers have been removed, altered, or cannot be

readily determined.

3. Light bulbs.

4. Products purchased for commercial or industrial use.

5. The cost of service or service call to:

a. Correct installation errors.

b. Instruct the user on the proper use of the product.

c. Transport the appliance to the servicer.

2O

Page 22

[WARRANTY

6. Consequential or incidental damages sustained by any person as a result of any breach of these

warranties. Some states do not allow the exclusion or limitation of consequential or incidental

damages, so the above exclusion may not apply.

IF YOU NEED SERVICE

[] Call the dealer from whom your appliance was purchased or call Maytag Services sM,Jenn-Air

Customer Assistance at 1-800-JENNAIR (1-800-536-6247) to locate an authorized servicer.

[] Be sure to retain proof of purchase to verify warranty status. Refer to WARRANTY for further

information on owner's responsibilities for warranty service.

[] If the dealer or service company cannot resolve the problem, write to Maytag Servkes% Attn:

CAIR_ Center, RO. Box 2370, Cleveland,TN 37320-2370, or call 1-800-JENNAIR (1-800-536-6247).

U.S.customers using TTY for deaf, hearing impaired or speech impaired, call 1-800-688-2080.

NOTE:When writing or calling about a service problem, please include the following information:

a. Your name, address and telephone number;

b. Model number and serial number;

c. Name and address of your dealer or servicer;

d. A clear description of the problem you are having;

e. Proof of purchase (sales receipt).

[] User's guides, service manuals and parts information are available from Maytag Services%

Jenn-Air Customer Assistance.

1-800-JENNAIR (1-800-536-6247) 1-800-688-2080 (U.S.TTY for hearing or speech impaired)

Mon.- Fri.,8 am - 8 pm Eastern Time Intemet: www.jennaincom

Maytag Services _m

Attn: CAIR®Center, RO. Box 2370, Cleveland, TN 37320-2370

21

Page 23

22

Page 24

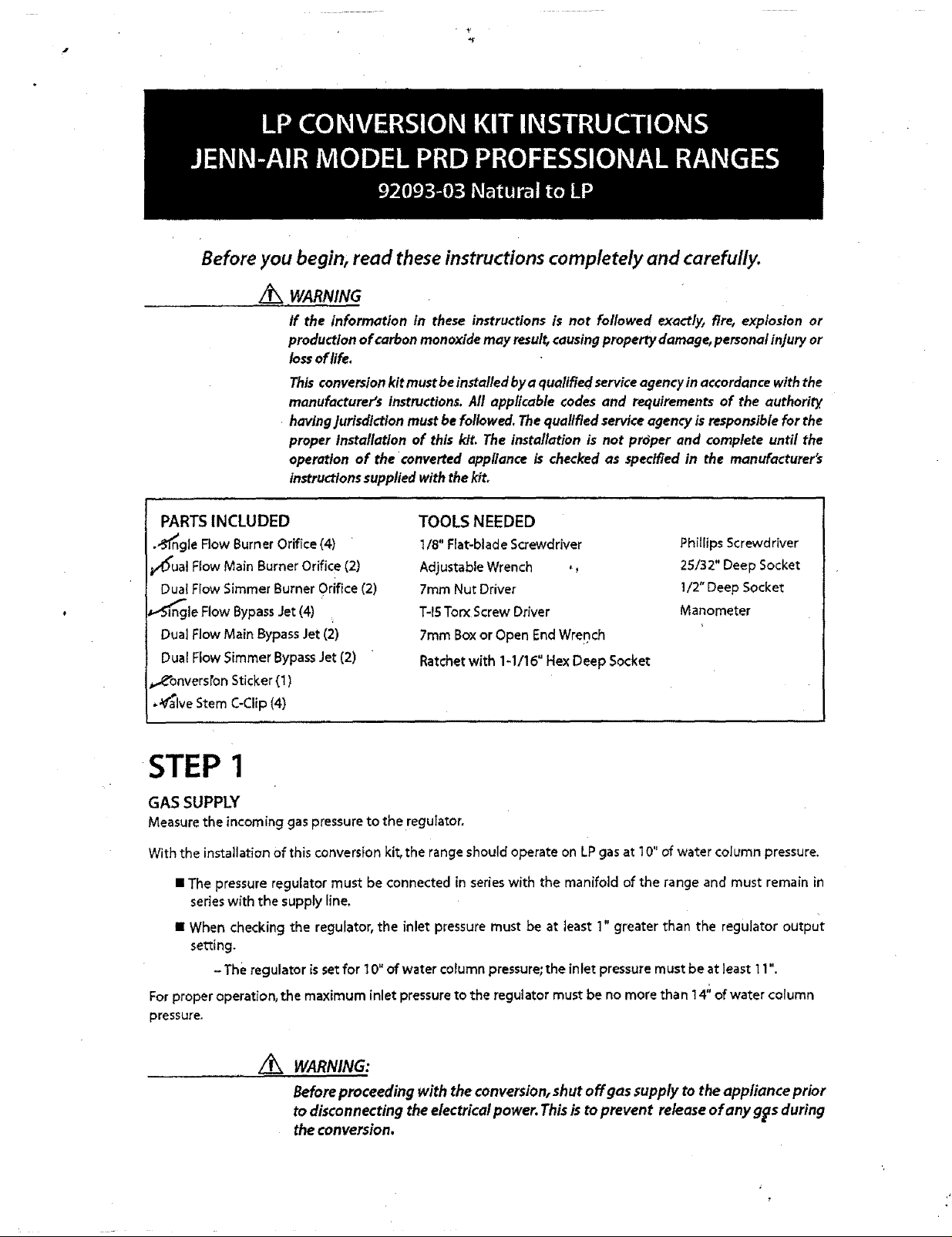

Before you begin, read these instructions completely and carefully.

/h

WARNING

If the information tn these instructions is not followed exactly, firet explosion or

production of carbon monoxide may result_causing property damage, personal injury or

lossof life.

Thisconversion kit must be installed bya qualified serviceagency in accordance with the

manufacturer's instructions. All applicable codes and requirements of the authority

having jurisdiction must be followed. The qualified service agency is responsible for the

proper Installation of this kit. The installation is not prdper and complete until the

operation of the converted appliance is checked as specified in the manufacturer's

instructions supplied with the kit.

PARTS INCLUDED

,_ng]e Flow Burner Orifice (4)

_5'*uatFlow Main Burner Orifice (2)

Dual Flow Simmer Burner Orifice (2)

I_ngie Flow Bypass Jet (4)

Dual Flow Main Bypass Jet (i)

Dual Flow Simmer BypassJet (2)

_ onversi'on Sticker (1)

_t'_lveStem C-Clip (4)

TOOLS NEEDED

1/8" Flat-blade Screwdriver

Adjustable Wrench ,,

7mm Nut Driver

T-ISTorx Screw Driver

7ram Box or Open End Wrench

Ratchet with 1-1/16" Hex Deep Socket

Phillips Screwdriver

25/32" Deep Socket

1/2" Deep Socket

Manometer

STEP 1

GAS SUPPLY

Measure the incoming gas pressure to the regulator.

With the installation of this conversion kit, the range should operate on LP gas at 10" of water column pressure.

• The pressure regulator must be connected in series with the manifold of the range and must remain in

series with the supply line.

• When checking the regulator, the inlet pressure must be at least 1" greater than the regulator output

se=ing.

- The regulator is set for 10" of water column pressure; the inlet pressure must be at least 11".

For proper operation, the maximum inlet pressure to the regulator must be no more than 14;' of water column

pressure.

z_ WARNING:

Beforeproceeding with theconversion, shut off gas supply to theappfiance prior

todisconnecting the electricaI power. Thisis to prevent releaseof any g_s during

theconversion.

Page 25

IMPORTANT:

Disconnect the range and the individual shut-off valve from the gas supply piping system

during ony pressure testing of that system at test pressures greater than 1/2 psig. isolate

the range from the gas supply piping system by closing the individual manual shut-off

valve to the range during any pressure testing of the gas supply piping system at test

pressures equal to or less than 7/2 psig.

Connection: I/2" N.P.T. - minimum 5/8" dia. metal flex line.

NOTE: Gas conversion should be done before pushing the range into the cabinet.

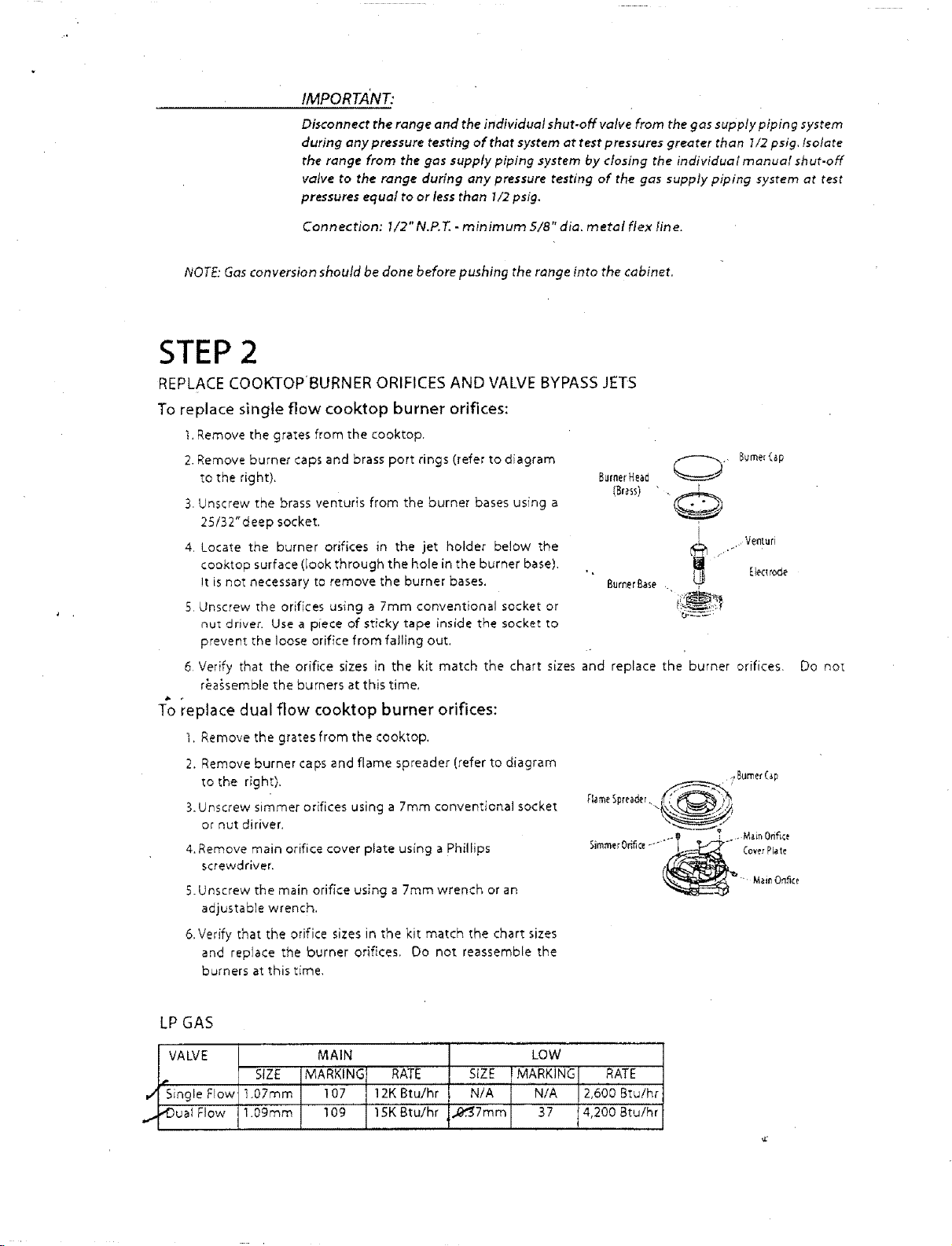

STEP 2

REPLACE COOK'I-OP'BURNER ORIFICES AND VALVE BYPASS JETS

To replace single flow cooktop burner orifices:

1,Remove the grates from the cooktop.

2. Remove burner caps and brass port rings (refer to diagram

to the right).

3. Unscrew the brass venturis from the burner bases using a

25i32"deep socket•

4. Locate the burner orifices in the jet holder below the

cooktop surface (Iook through the hole in the burner base).

It is not necessary to remove the burner bases,

S, Unscrew the orifices using a 7ram conventional socket or

nut driver, Use a piece of sticky tape inside the socket to

prevent the loose orifice from falling out,

6 Verify that the orifice sizes in the kit match the chart sizes and replace the burner orifices.

r_a_semble the burners at this time.

BurnerHead 0" Bume_Cap

(Brass) I

l

B_merBase .

_l Declr0de

Vemuri

Do not

To replace dual flow cooktop burner orifices:

1. Remove the grates from the ¢ooktop.

2. Remove burner caps and flame spreader (refer to diagram

to the right).

3. Unscrew simmer orifices using a 7ram conventional socket

or nut diriver.

4. Remove main orifice cover plate using a phillips

screwdriver.

5. Unscrew the main orifice using a 7ram wrench or an

adjustable wrench.

&Verify that the orifice sizes in the kit match the chart sizes

and replace the burner orifices. Do not reassemble the

burners at this time.

LP GAS

VALVE MAIN

SIZE MARKINC RATE

tSingle Flow t,07mm 107 12K Btu/hr

,/

,,_uat Flow 1.09ram 109 1SK Btu/hr

J, SIZE

,_'_7mm

N/A

LOW

MARKING

NiA

37

.,BUrner(_p

FlameSl_r,,d,,. _£

"_/

" MainOnfice

RATE

2,600 Btuihr

4,200 Btu/hr'

Page 26

TOREPLACETHEVALVEBYPASSJETS:

i. Removethecontrol knobs from the valve shafts and thermostat.

2. Remove the two screws that attach valve panel to thermostat bracket (located behind thermostat knob),

3. Remove the four mounting screws from the corners of the valve par_e! (T-15 Torx Screw).

4. Put] the paneI forward over the vaJve stems.

5. Disconnect the wiring terminals at the light switch. Unsnap the indicator lights from the back of the valve

panel, being careful not to allow the lenses to fall from the face of the panet.

6, Remove the C-ctips that retain the valve switches and slide the switches off of the valve shafts,

7. Locate the valve bypass jets [n the vatve bodies. Using a flat blade screwdriver, unscrew the bypass iets

and remove from valves,

8. Verify that the vaIve bypass jet sizes in the kit match the chart sizes and replace the valve bypass jets.

Screw the jet into the valve body until fully seated. Do not re-install the vatve panel at thFs time,

BYPASS JET

VALVE

VALVE ORIFICE

VALVE LP

SIZE MARKING

*.I "Singte F]ow 0.46mm 46

Dual Flow Main 0.53mm 53

Dual Flow Simmer 0.34mm 34

.......... i

STEP 3

CONVERT THE PRESSURE REGULATOR

Z_ WARNING

Do not remove the pressure regulator from the range.

SINGLE FLOW

RATE

2,600 Btuihr

4,200 Btu!hr

1,000 Btu!hr

BYPASS JET

DUAL FLOW

SIMMER

JET

MAIN

BYPASSJET

To access the regulator, remove the kick panel, located below the range door. To convert the regulator from

Natural gas to LP gas, reverse the set screw in the regulator. See diagram.

Burner Cap

Page 27

STEP 4

CHECK FOR LEAKS

,/'fX,WARNING

Check for leaks before attempting to light the burners or use the oven.

• Check to be sure all controls are in the OFF position,

III Turn on the gas supply at the shut-off valve.

In Use a leak detector at all connections. If a leak is detected, tighten the connection and test again,

DO NOT USE A FLAME TO CHECK FOR GAS LEAKS.

STEP 5

RE-ASSEMBLE SURFACE BURNERS, CHECK OPERATION

Cooktop Section

Re-assemble the burners and valve panet in the reverse order shown in Step 2 above. Use supplied "C" clips to

secure valve switches. Make sure the brass port rings are properly engaged in the burner bases.

Check for proper ignition:

• Connect electrical power.

• Push in one control knob and turn 90_ to"Hl"position.

II The igniter will spark and the burner wiJ[ Iight; the igniter will cease sparking when the burner is lit, (Note

that at} burners will spark.)

• The first test may require some time while air is flushed out of the gas Iine.

• T[Jrn knob to"OFF"

• Repeat the procedure for each burner,

Check Flame Quality

Check for proper burner flame characteristics (see diagram, page 5).

Burner flames should be blue and stable. Some yellow tipping is normal on LP Gas.The flame should not have

excessive noise or exhibit lifting of the flame from the burner. Due to differences in gas characteristics and burner

usage (i,e. gas pressure, cleanliness, etc.), burners may perform differently.

Burner Operation

This gas range is equipped with one (PRD3030) or two (PRD3630)dual flow simmer burners. These burners

have three rings off[ames when in operation between the"HIGH"control knob setting and the tow position

detent. When the knob is rotated past the low position detent, only one ring of flame is present around _he

small inner burner cap,

The remaining burners are of the traditional single flow design, The single ring of flame is regulated between

the"HtGH" and "LOW" control knob settings, Refer to the following diagrams,

Page 28

Burner Adjustment

i There is no air shutter adjustment, etc, on this burner.

SINGLE FLOW

Cap

Simmer

Flame

DUAL FLOW

Burner Cap

High to Low

Flame

STEP 6

COMPLETE AND ADHERE CONVERSION LABEL TO THE REAR OF THE RANGE

Complete the required information on the Conversion Label. Adhere the label to the rear of the range next to

Rating Label.The Conversion Label MUST reflect the change of fuel.

CONVERSION STICKER SAMPLES

From Natural Gas to LP

"11-II$CONVEI_ION _TING !,,AI_L I_L&,T_$TO THE FOLLOWING

JENI_AIRMODEL_,:

SUPPLYPRE.&SURE_MINIMUM 1_*W,C,

MANIFOLD PI_$SURE -I _'w,c.

INPttT I_T1NGS.

COI_ON )_TFEAST.92093-03

114tS_PIJaNCE HASIIEEt_¢ONV'_IZD ON I

FROMNATURA!.GASTOLP GASWITH CONVERSIONKIT

R_ NO,g2093_03

WNO ACCEPTSp,,£.&_OF_4B_L'T'_T'Y._OR_ ¢Of_ECTN_S OF

CONV'EF_ON

MAXIMUM 14"W.C

_ _NG_I_FLOW_URNE,_S

DUAL FLOWBURNrfl_S

* 12,0O0STU/N_

- 1$_00 _t%l,'14R

I

I

I

]

Page 29

JENN-AIR

1-800-JENNAIR (1-800-536-6247)

1-800-688-2080 (U.S.TTY for hearing or speech impaired)

Mon.- Fri.,8 am - 8 pm Eastern Time Internet: www.jennaincom

1-800-688-2080 (ATS Etats-Unis pour les malentendants et les handicap6s de la parole)

du lundi au vendredi, de 8 h O0 _ 20 h 00, heure de I'est Internet: www.jennair.com

1-800-688-2080 (TTY para personas con problemas auditivos o impedimentos del habla)

De lunes a viernes de 8 am a 8 pm hora del este Internet: www.jennair.com

Maytag Services _"

Attn: CAIR_ Center, P.O.Box 2370, Cleveland,TN 37320-2370

Loading...

Loading...