Jenn-Air JUIFX15HX, JUIFN15HX Installation Instructions

INTRODUCTION

INTRODUCTION

MACHINE À GLAÇONS ENCASTRÉE SOUS LE COMPTOIR

Installation guide

BUILT-IN UNDERCOUNTER ICE MAKER

Guide dinstallation

W11528111A

INTRODUCTION | 1

INTRODUCTION

SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately follow instructions.

DANGER

You can be killed or seriously injured if you don't follow instructions.

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

INTRODUCTION

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

including the following:

Children should be supervised to ensure that they do not

play with the appliance.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their

safety.

Do not use an extension cord.

If power supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or a similarly qualified

person in order to avoid a hazard.

To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions,

SAVE THESE INSTRUCTIONS

Connect to potable water supply only.

This appliance is intended to be used in household and

similar applications such as: staff kitchen areas in shops,

offices, and other working environments; farm houses and

by clients in hotels, motels, and other residential-type

environments; bed and breakfast-type environments; and

catering and similar non-retail applications.

Do not store explosive substances such as aerosol cans

with a flammable propellant in this appliance.

Do not use replacement parts that have not been

recommended by the manufacturer (e.g., parts made at

home using a 3D printer).

INTRODUCTION | 3

INTRODUCTION

TABLE OF CONTENTS

REGISTERING YOUR

APPLIANCE

Gain access to our concierge-level customer

support by registering your appliance. We make

product registration simple and straightforward

so that you can start using your exclusive

JennAir benefits today.

Registering your appliance allows you to:

■ Streamline your warranty service

If we have your product information, we

can help you faster.

■ Protect your purchase

In case of an insurance loss such as fire,

flood, or theft your product registration

could serve as a proof of purchase.

■ Keep your family safe

We’ll notify you in the rare case of a safety

notification.

Start taking advantage of these benefits today

by going online to register your product at

jennair.com/customer-care.

PRODUCT IDENTIFICATION

Your product identification, which includes

the model and serial number, is listed on the

product rating plate.

Recording this information below allows us to

more easily assist you if your product should

ever require service from one of our Whirlpool

Authorized Service Providers.

Model Number: _______________________________

Serial Number: ________________________________

Date of Installation: ___________________________

Authorized Dealer: ___________________________

Authorized Dealer Phone #: __________________

INTRODUCTION

Safety .............................................................................. 3

Registering Your Appliance ............................ 4

Product Identification ........................................ 4

GETTING STARTED

Before installation .................................................. 5

Tools Required ..........................................................5

Parts Provided .......................................................... 5

Vacation or Extended Time

Without Use ............................................................... 6

Unpack the Ice Maker ......................................... 6

Optional Personalizations ................................ 6

SITE PREPARATION

Product and

Opening Dimensions .......................................... 7

Location Requirements ..................................... 8

Electrical Requirements .................................... 9

Water Supply Requirements .......................... 10

Drain Supply Requirements ........................... 11

Gravity Drain System ........................................... 11

Drain Pump System ............................................. 11

DOOR REVERSAL

Removing Hinge Covers ....................................12

Removing the Hinges ......................................... 14

Preparing the Bottom Hinges....................... 18

Reversing the Hinges .......................................... 20

4 | INTRODUCTION

INSTALLATION

Installing the Drain Pump -

Site Preparation .......................................................22

If Ice Maker is Currently Installed ...............22

Installing the Drain Pump

and Drain Hose ........................................................ 24

Connecting the Water supply ....................... 28

Leveling and Securing ........................................ 30

Custom Wood Door Panel ............................... 34

Connecting the Drain ......................................... 36

Installing Auxiliary Grill ....................................... 38

APPENDIX

Accessories ................................................................. 40

TABLE DES MATIÈRES............44

GETTING STARTED

BEFORE INSTALLATION

Gather the required tools and parts before

starting installation. Read and follow the

instructions provided with any tools listed.

IMPORTANT: These instructions are intended

as a general guide only and do not supersede

any national or local codes in any way.

Compliance with all local, state, or national

codes pertaining to this type of installation

should be determined prior to installation.

Installer: Please be sure to leave Installation

Instructions with the homeowner.

Homeowner: Keep the Installation Instructions

for future reference.

TOOLS REQUIRED

Gather the required tools before starting

installation.

TOOLS REQUIRED

Drill and drill bits

Phillips screwdriver

Pencil

Masking tape

Two adjustable wrenches

Level

Wood screws

2" Hole saw or 2" Forstner bit

3/16" hex driver

1/4" nut driver

Pliers

Right angle drivers

TORX T20, T25† screwdriver

Tape measure

PARTS PROVIDED

Cabinet brackets

Drain hose and clamp (in hose bag) - on

some models only

#8 x 1/2" pan head wood screws (14)

Double sided adhesive tape

(for custom door panel)

Auxiliary grill kit

GETTING STARTED

†

Torx, T20 and T25 are trademarks of Acument Intellectual Properties, LLC.

GETTING STARTED | 5

GETTING STARTED

VACATION OR EXTENDED

TIME WITHOUT USE

When you will not be using the ice maker for

an extended period of time, turn off the water

and power supply to the ice maker.

Check that the water supply lines are insulated

against freezing conditions. Ice formations in

the supply lines can increase water pressure

and cause damage to your ice maker or home.

Damage from freezing is not covered by the

warranty.

UNPACK THE ICE MAKER

WARNING

Excessive Weight Hazard

Use two or more people to move and install

ice maker.

Failure to do so can result in back or other

injury.

REMOVING PACKAGING MATERIALS

Uncrate the ice maker. Remove tape and glue

from your ice maker before using.

To remove any remaining tape or glue

from the exterior of the ice maker,

rub the area briskly with your thumb.

Tape or glue residue can also be easily

removed by rubbing a small amount of

liquid dish soap over the adhesive with

your fingers. Wipe with warm water

and dry.

Do not use sharp instruments, rubbing

alcohol, flammable fluids, or abrasive

cleaners to remove tape or glue. Do not

use chlorine bleach on the stainless

steel surfaces of the ice maker. These

products can damage the surface of

your ice maker.

CLEANING BEFORE USE

After you remove all of the packaging materials,

clean the inside of your ice maker before using

it. For instructions on how to clean the ice

maker, refer to the cleaning instructions in the

“Ice Maker Care” section of Use and Care Guide.

OPTIONAL PERSONALIZATIONS

REVERSING THE DOOR

For instructions on how to reverse the door,

refer to the “Door Reversal” section.

CUSTOM PANEL INSTALLATION

For instructions on how to install a custom door

panel, refer to the “Custom Wood Door Panel”

section.

If you plan to install a custom overlay panel, you

will need to make the panel yourself or consult

a qualified cabinetmaker or carpenter.

IMPORTANT:

The thickness of the overlay panel must

be 3/4" (1.91 cm).

Overlay panel must not weigh more

than 8 lbs (3.62 kg).

Overlay panels weighing more than

recommended may cause damage to

your ice maker.

Countersink all the handle mounting

hardware.

Match wood grain direction with that of

adjacent cabinets.

Sand panel edges to provide a smooth

finish.

Use moisture sealer on both sides and

all edges of the panel to avoid damage

from moisture.

PARTS NEEDED:

Instructions, #8 x 1/2" pan head wood

screws (14)

Handle Kit (optional)

STAINLESS STEEL PANEL INSTALLATION

For instructions on how to install the Stainless

Steel Panel, refer to the instructions received

with the Stainless Steel Panel kit.

6 | GETTING STARTED

SITE PREPARATION

SITE PREPARATION

E

C

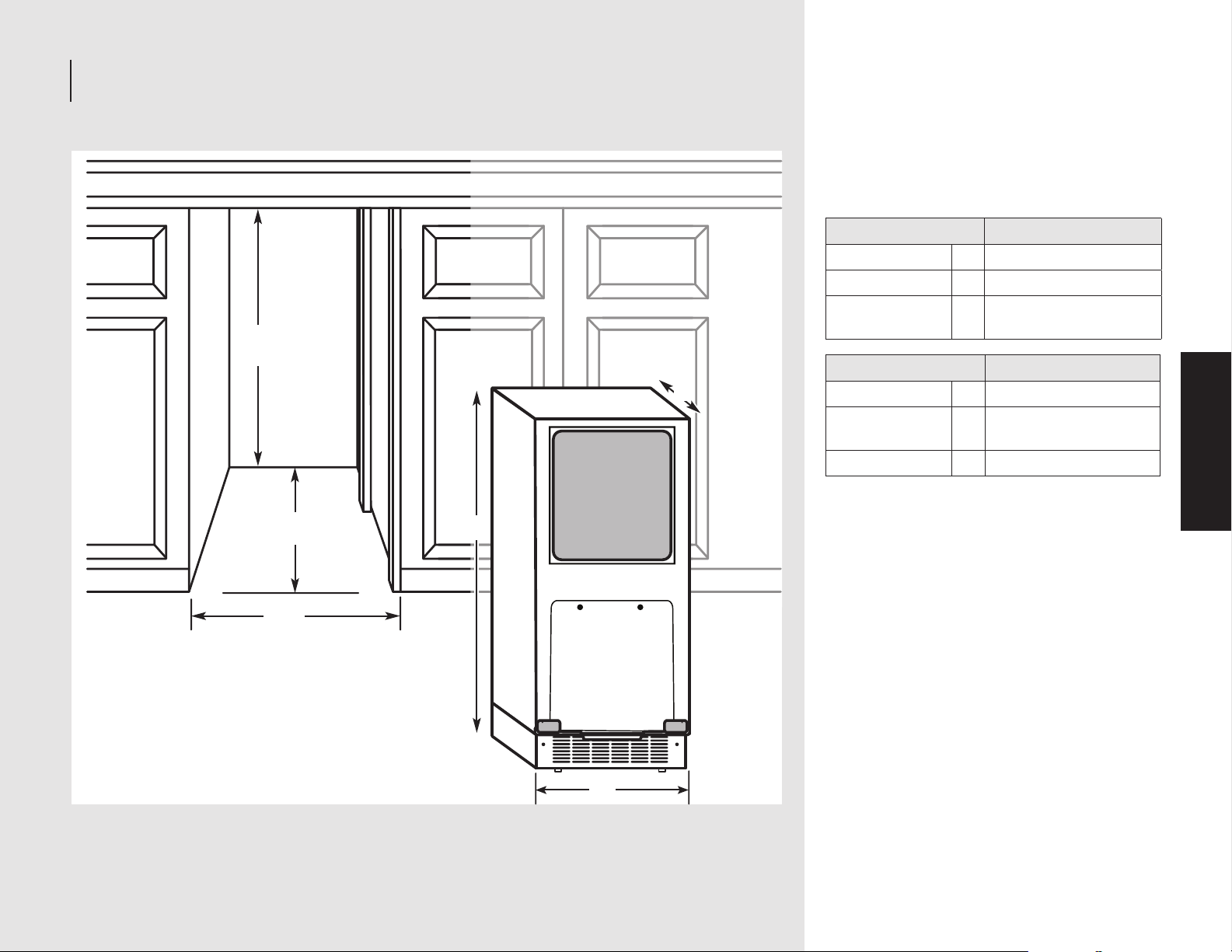

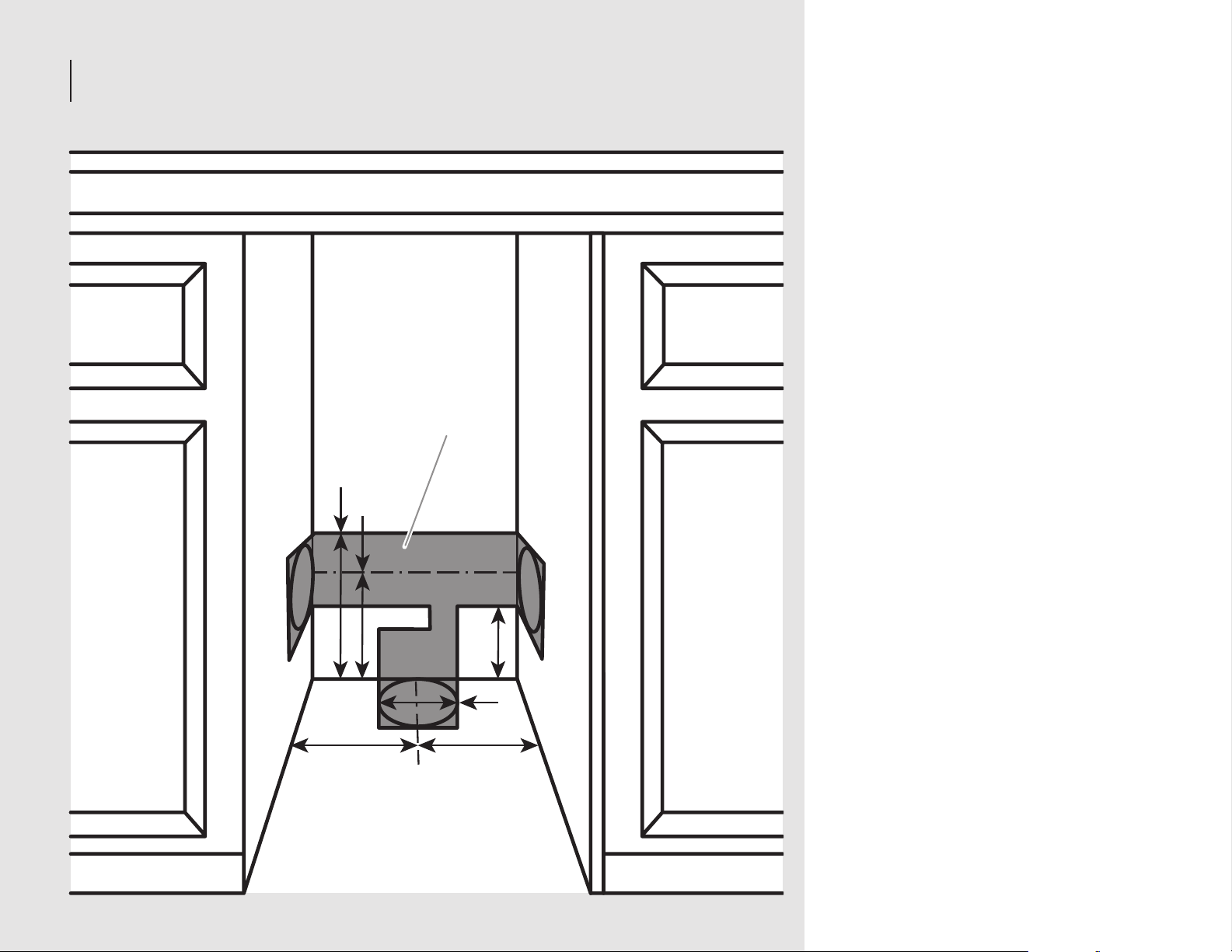

PRODUCT AND

OPENING DIMENSIONS

Product Dimensions

Product width A 147⁄8" (37.8 cm)

Product height B 333⁄4" (85.7 cm)

Product depth

(no door)

Opening Dimensions

Opening width D 15" (38.1 cm)

Opening height E

Opening depth F 24" (60.96 cm)

C 221⁄16" (56.1 cm)

34" min (86.4 cm)

341⁄2" max (87.6 cm)

SITE PREPARATION

7 | SITE PREPARATION

D

F

B

A

SITE PREPARATION | 7

C

D

A

B

SITE PREPARATION

SITE PREPARATION

7⁄" (19.05 cm) 7⁄" (19.05 cm)

Required zone for utility

hole/slot cutout location

LOCATION REQUIREMENTS

Installation must comply with all governing

codes and ordinances.

TEMPERATURE

It is recommended that you install the

ice maker in a well-ventilated area with

temperatures above 55°F (13°C) and below 110°F

(43°C). Best results are obtained between 70°F

and 90°F (21ºC and 32°C).

LOCATION

The ice maker must be installed in an area

sheltered from the elements, such as wind, rain,

or water spray.

To ensure proper ventilation for your ice

maker, the front side must be completely

unobstructed. The ice maker may be closed

in on the top and three sides, however the

installation should allow the ice maker to be

pulled forward for servicing if necessary.

The auxiliary grill kit provided can be used to

align the toe grill with the rest of the cabinets

while not obstructing ventilation of the ice

maker.

Floor must be able to support the ice maker’s

total weight, of more than 106 lbs (48.08 kg),

including door panels and contents of the

ice maker. It is important for the ice maker to

be level in order to work properly. If needed,

you can adjust the height of the ice maker by

changing the height of the leveling legs.

Check that the power supply cord, water supply

line, and drain line (on some models) are not

damaged, pinched, or kinked between the ice

maker and the cabinet.

8 | SITE PREPARATION

SITE PREPARATION

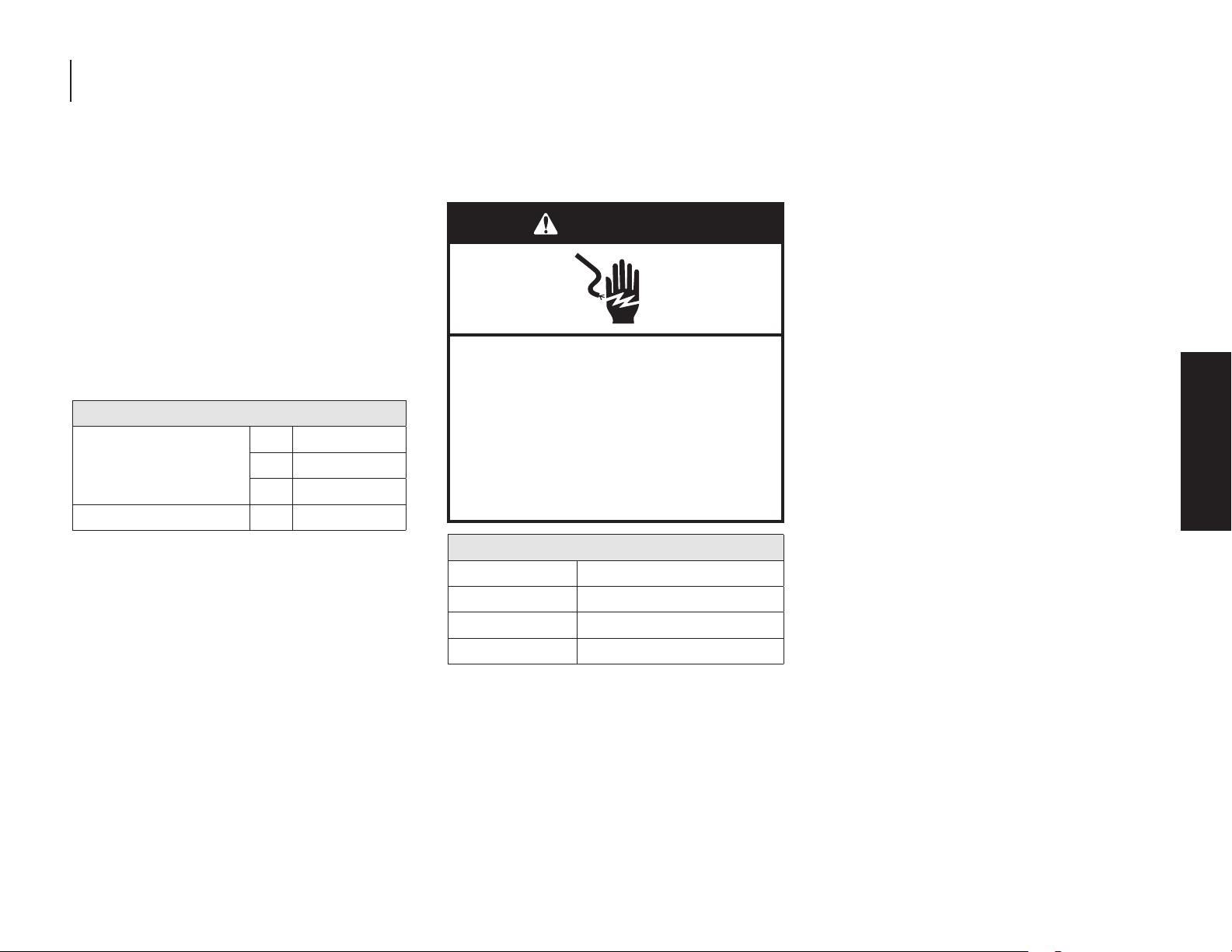

ELECTRICAL REQUIREMENTS

IMPORTANT:

■ This ice maker has been designed for flush

install in instances where the power supply,

water supply, and drain are located in a

cabinetry.

■ For installation of product with utilities

behind the ice maker, flush install may not

be achieved.

■ Refer “Location Requirement” illustration

and table below for utility slot/hole cutout

location.

Utility Slot/Cutout Location Zone

A 9" (22.9 cm)

Dimension

Diameter of the hole D 2" (5 cm)

B 8" (20.3 cm)

C 7" (17.8 cm)

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result

in death, fire, or electrical shock.

Electrical Requirements

Power Supply 115 V, 60Hz, AC only

Circuit Breaker 15 A to 20 A, fused

Receptacle 3 prong grounding-type

Outlet Non-GFCI

IMPORTANT:

■ Use an outlet that cannot be turned off by a

switch. Do not use an extension cord.

■ It is recommended that this product not be

connected to a GFCI (Ground Fault Circuit

Interrupter) protected outlet, as nuisance

tripping of the power supply may occur.

■ The ice maker must be grounded. The

ice maker is equipped with a power

supply cord having a grounded 3 prong

plug. The cord must be plugged into a

mating, grounded, 3 prong wall receptacle,

grounded in accordance with the National

Electrical Code and local codes and

ordinances. If a mating wall receptacle is

not available, it is the personal responsibility

of the customer to have a properly

grounded 3 prong wall receptacle installed

by a qualified electrician.

SITE PREPARATION

SITE PREPARATION | 9

SITE PREPARATION

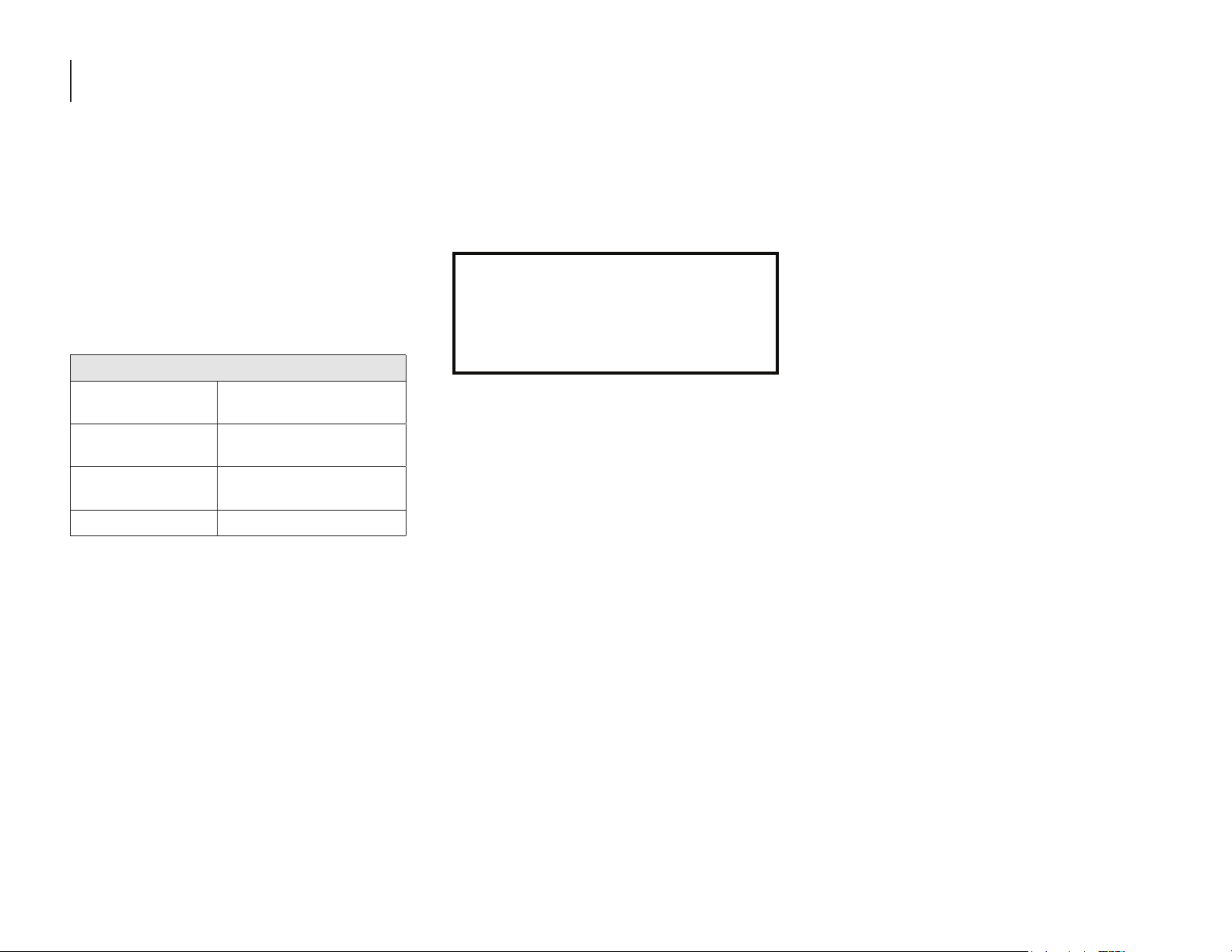

WATER SUPPLY REQUIREMENTS

Before connecting the ice maker, ensure that

the water supply lines are insulated against

freezing conditions. Ice formations in the

supply lines can increase water pressure and

damage the ice maker or home. Damage

from frozen supply lines is not covered by the

warranty.

Use new hoses supplied with the product. Do

not reuse old hoses.

Water Supply Requirements

Water Pressure

Excess Water Line

for Connection

Water Inlet Supply

Drain Pump With shut-off valve

1/4” (6.35 mm) OD soft

30 psi - 120 psi

(207 kPa - 827 kPa)

30" (76.2 cm)

copper tubing

IMPORTANT:

■ Connect to potable water supply only.

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction may be

used on disinfected waters that may contain

filterable cysts.

■ A reverse osmosis water filtration system is

not recommended for ice makers that have

a drain pump installed. Reverse osmosis

water filtration systems should be used for

gravity drain systems only.

■ Connect the ice maker drain to your drain

in accordance with the International

Plumbing Code and any local codes and

ordinance.

■ To achieve a flush installation, the water

shutoff valve should not be installed in the

wall behind the refrigerator, but in another

easily accessible location.

■ The drain pump discharge line must

terminate at an open-site drain.

■ Maximum rise 10 ft (3.1 m)

■ Maximum run 100 ft (30.5 m)

NOTE: If the drain hose becomes twisted and

water cannot drain, your ice maker will not

work.

REVERSE OSMOSIS WATER SUPPLY

A reverse osmosis system may be used if the

water pressure from the filtration system meets

the required water pressure requirements.

If a reverse osmosis system is desired, only a

whole-house capacity reverse osmosis system,

capable of maintaining the steady water supply

required by the ice maker, is recommended.

Faucet capacity reverse osmosis systems are

not able to maintain the steady water supply

required by the ice maker.

10 | SITE PREPARATION

SITE PREPARATION

DRAIN SUPPLY REQUIREMENTS

Connect the ice maker drain to your drain in

accordance with all state and local codes and

ordinances. Follow these guidelines when

installing drain lines. This will help avoid water

from flowing back into the ice maker storage

bin. Water flowing back into the ice maker can

potentially flow onto the floor and cause water

damage.

Drain Requirements

Inside

Diameter

Drain

Lines

(2.54 cm drop per 122 cm of run) or

(6.35 mm drop per 30.48 cm of run)

Do not connect the outlet end of the drain tube

to a closed pipe system to avoid drain water

from backing up into the ice maker.

minimum 5/8" (15.88 mm)

Drain lines must have a

1" drop per 48" of run

1/4" drop per 12" of run

Drain pump modelGravity drain model

GRAVITY DRAIN SYSTEM

The ideal installation has a standpipe with a

1½" (3.81 cm) to 2" (5.08 cm) PVC drain reducer

installed directly below the outlet of the drain

tube as shown. You must maintain a 1" (2.54

cm) air gap between the drain hose and the

standpipe.

A

E

F

Gravity Drain System Dimensions

Drain Hose A

Air Gap B 1" (2.54 cm)

PVC Drain Reducer C

from front of door,

Center of Drain D

(1.9 cm) panel on

the door, centered

left to right (75⁄16"

either side of the

Bottom of Ice

Maker to top of PVC

E 17⁄8" (4.8 cm)

Drain Reducer

Depth to center of

PVC Drain Reducer

F 221⁄8" (56.2 cm)

B

C

D

2" to 11⁄2"

(5 cm - 3.8 cm)

221⁄8" (56.2 cm)

with or without

3/4"

[18.56 cm]) from

ice maker.

DRAIN PUMP SYSTEM

Drain pump maximum capability: For every

1 ft (0.31 m) of rise, subtract 10 ft (3.1 m) of

maximum allowable run.

IMPORTANT: A drain pump is necessary when

a floor drain is not available. A Drain Pump kit,

Part Number 1901A, is available for purchase at

jennair.com/accessories/details/1901A.

NOTE: It may be desirable to insulate the

drain line thoroughly up to the drain inlet. An

Insulation Sleeve kit, Part Number W10365792,

is available for purchase at

jennair.com/accessories/details/W10365792.

SITE PREPARATION | 11

SITE PREPARATION

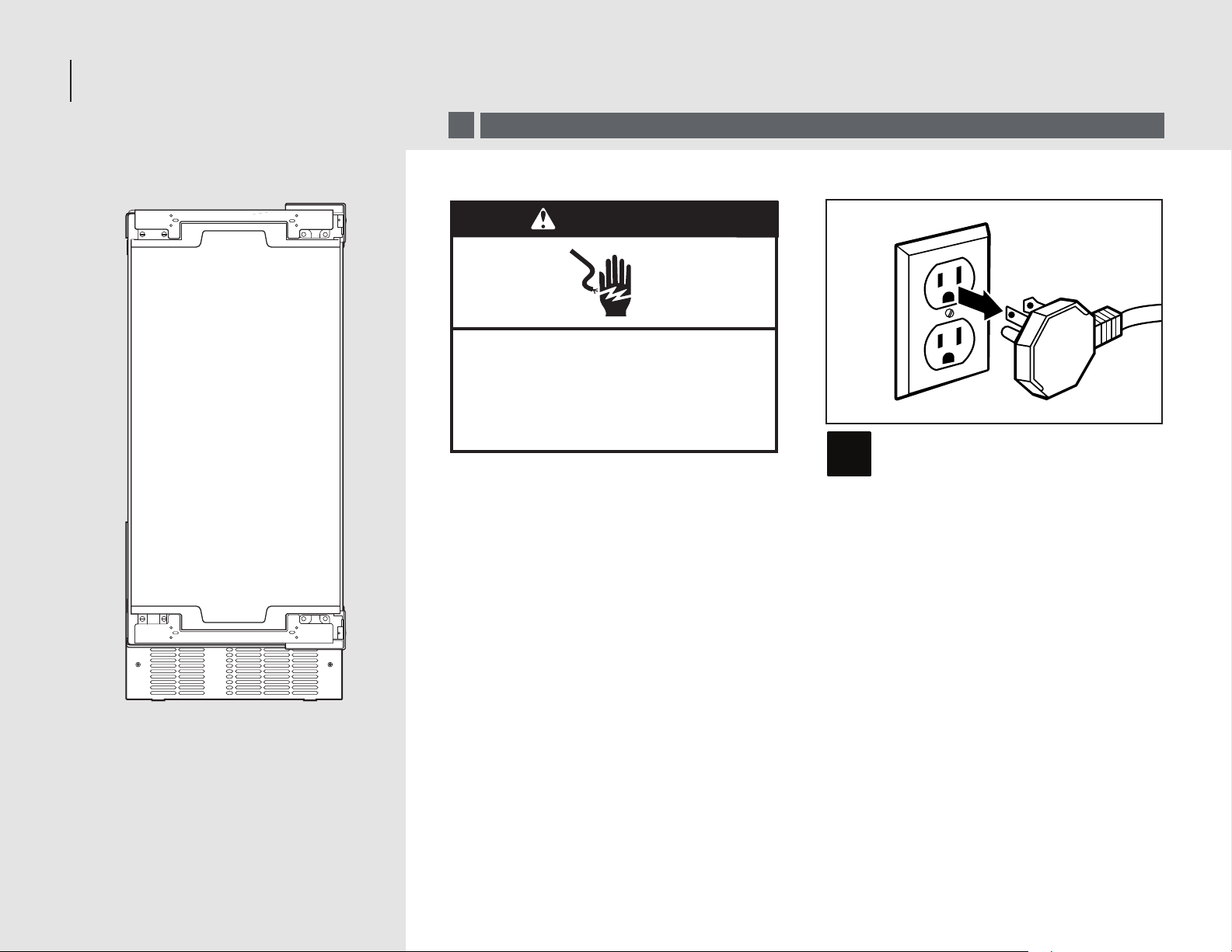

DOOR REVERSAL

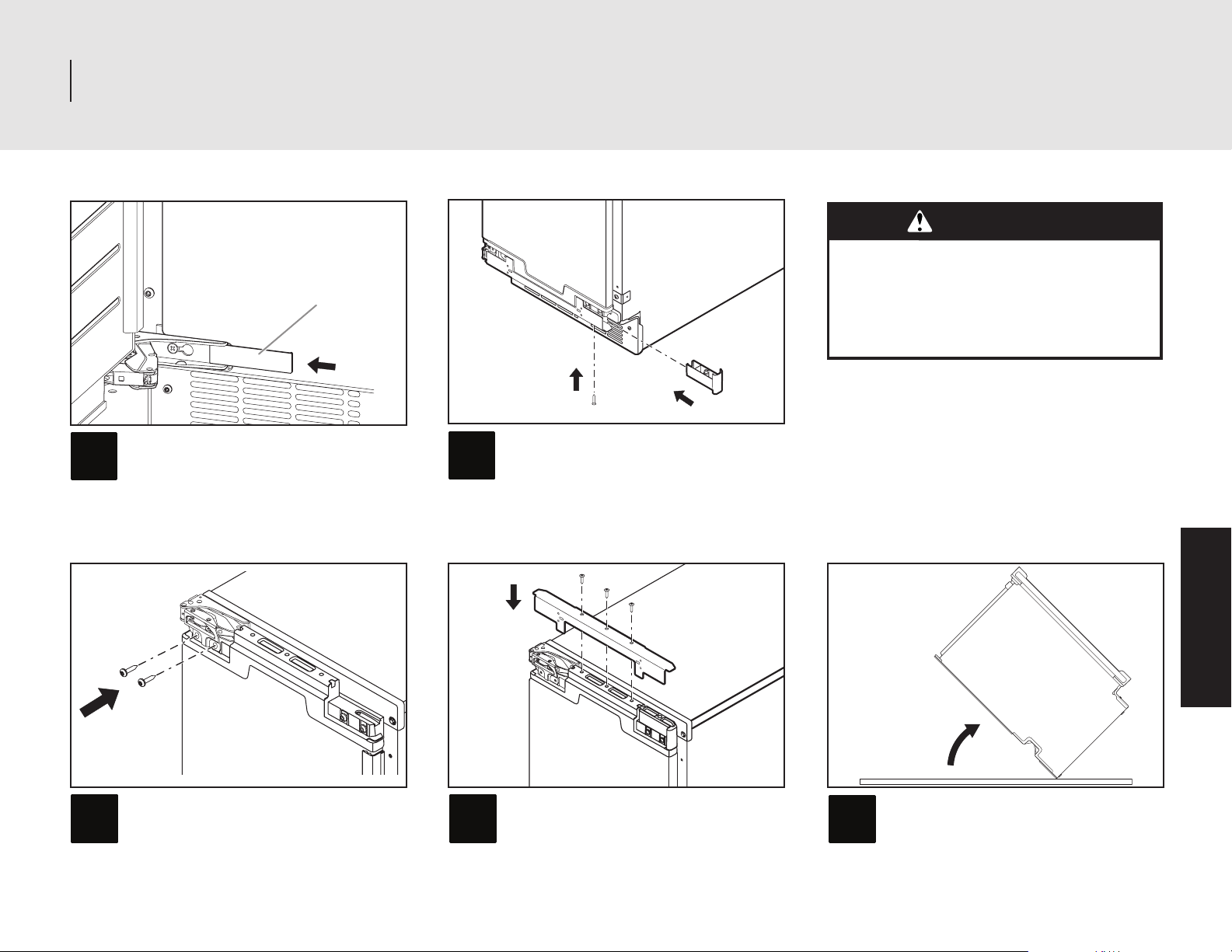

REMOVING HINGE COVERS

!

If door reversal is not needed, skip “Door Reversal” section.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Unplug the ice maker or disconnect

power.

1

12 | DOOR REVERSAL

DOOR REVERSAL

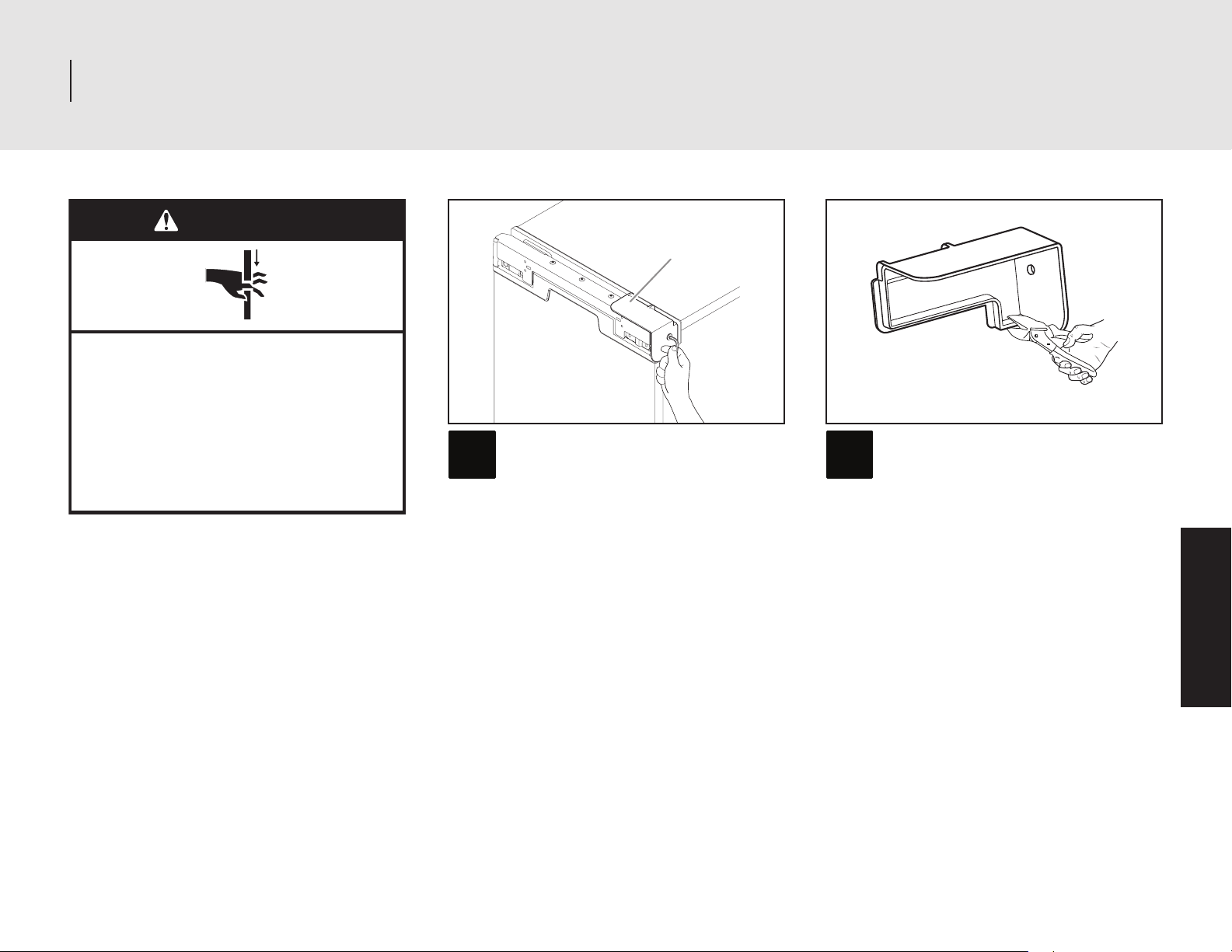

WARNING

Crush Hazard

Articulated hinges are self closing and many

pinch points exist prior to cabinet

installation.

Do not remove hinge covers until product is

ready to be installed.

Failure to follow these instructions can result

in crush, cut, or pinch injuries.

Hinge cover

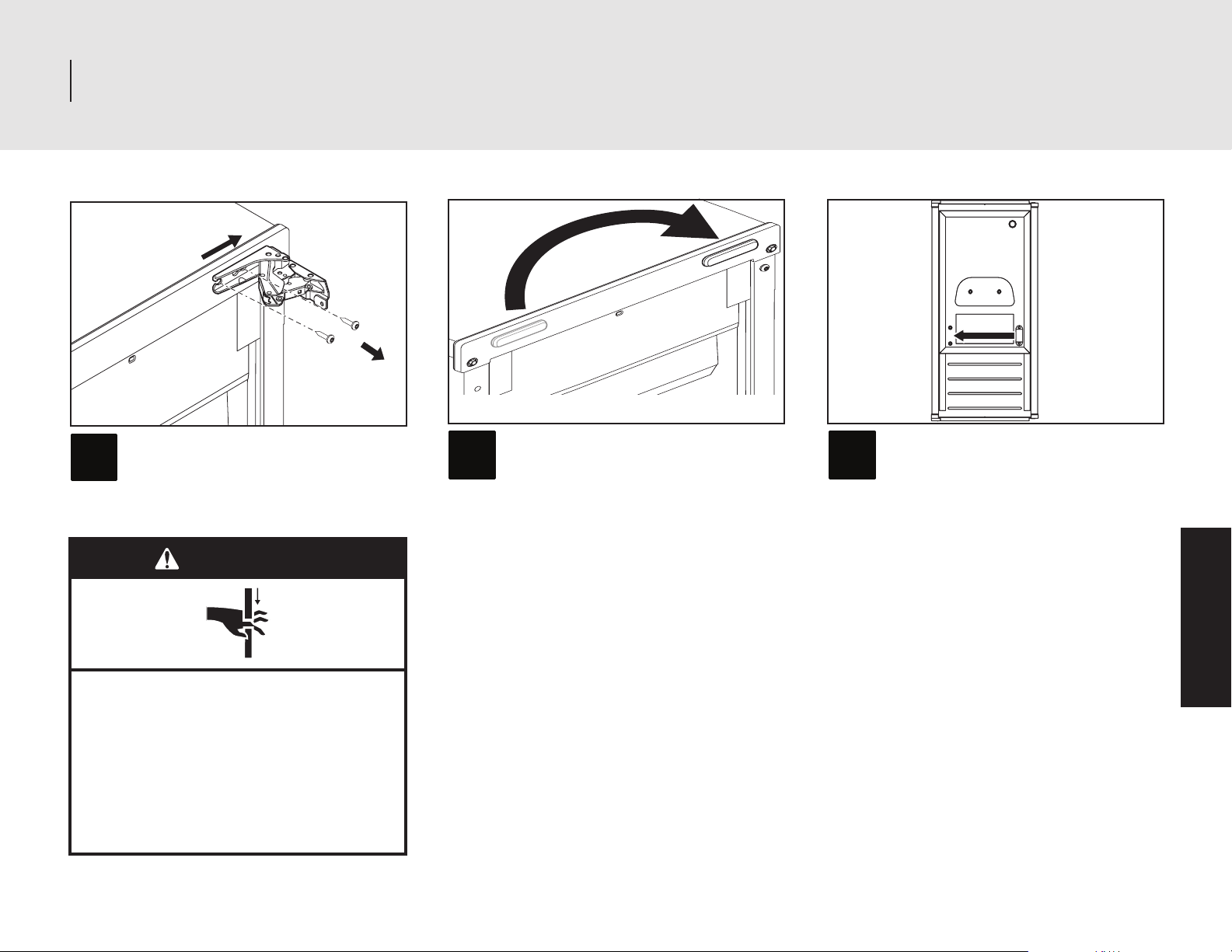

Remove the screws attaching top and

bottom hinge covers using an 3/16" hex

2

driver.

Using pliers, remove the hinge covers

from the top and bottom hinges.

3

NOTE: Save the hinge covers for

future use. Reinstall the hinge covers

if product is removed from cabinet

installation.

DOOR REVERSAL

DOOR REVERSAL | 13

DOOR REVERSAL

REMOVING THE HINGES

WARNING

Excessive Weight Hazard

Use two or more people to move and install

ice maker.

Failure to do so can result in back or other

injury.

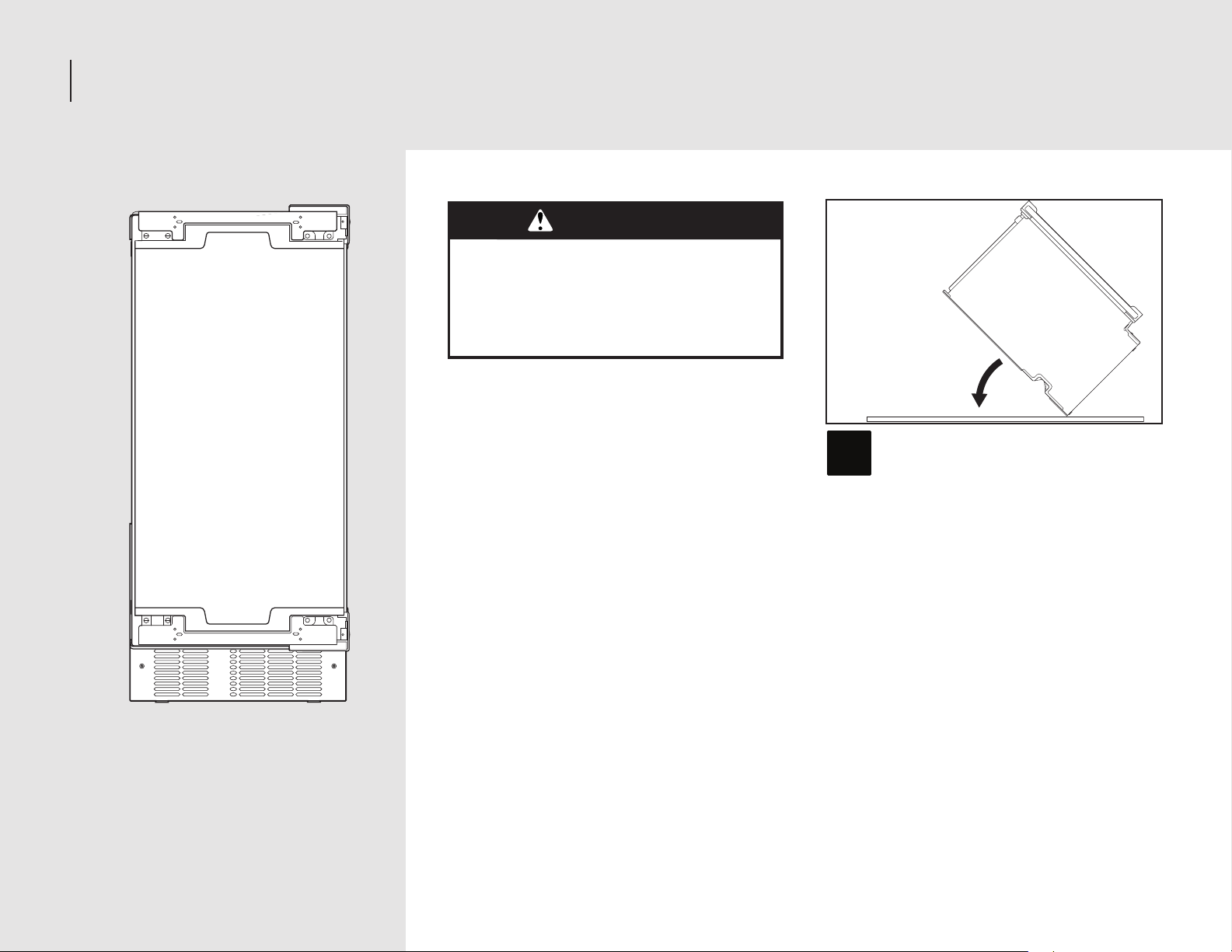

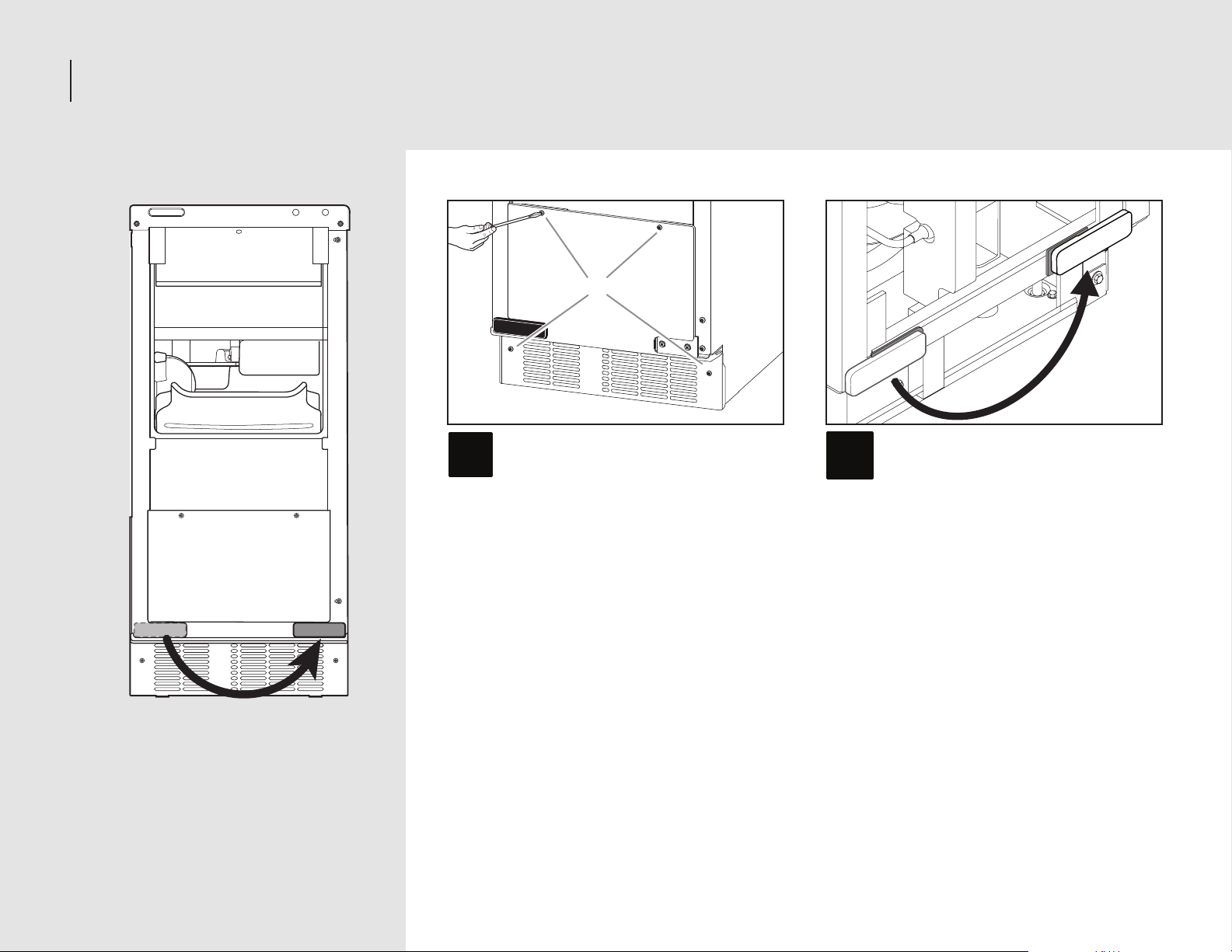

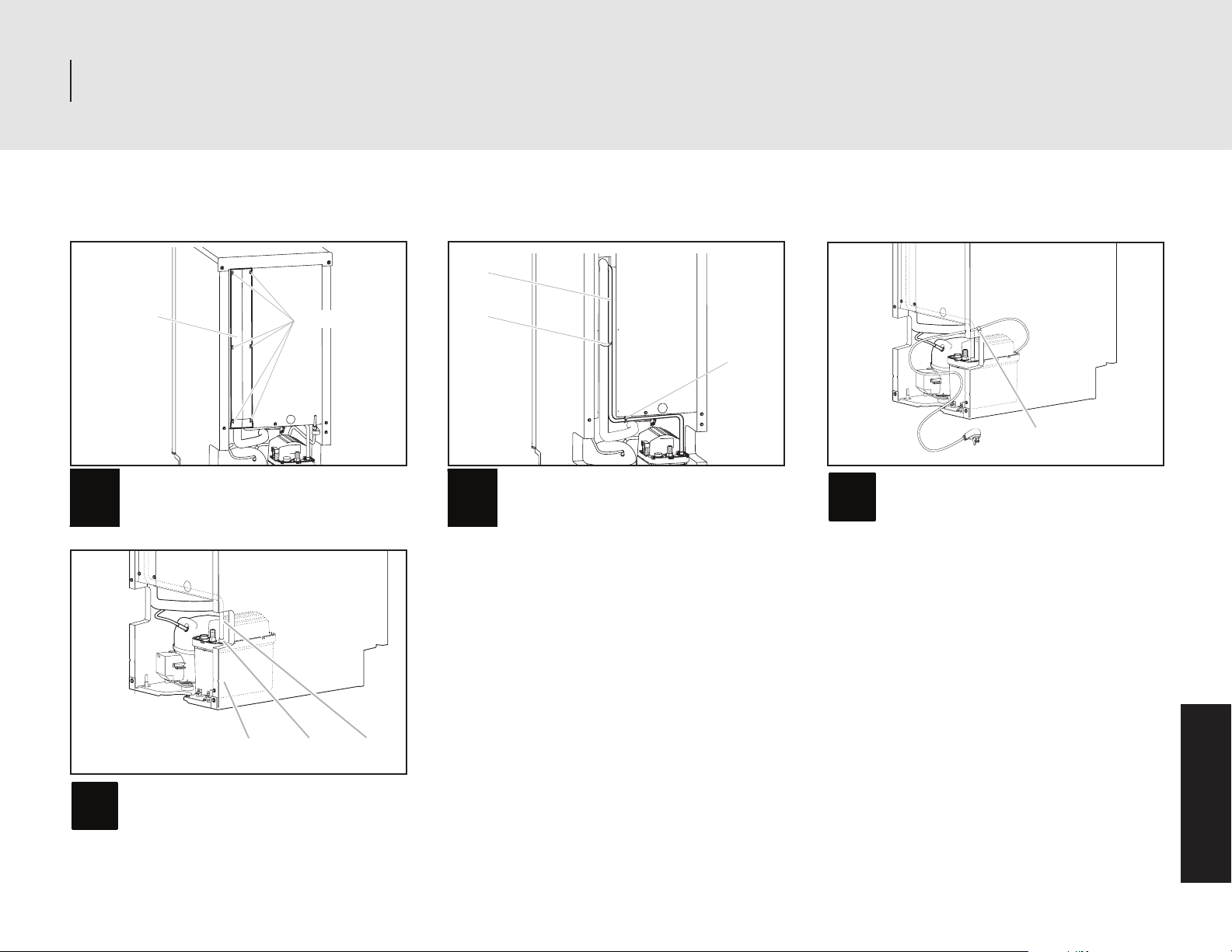

Lay down the ice maker as shown in

the illustration. Be sure to cover the

1

floor with cardboard or hardboard to

avoid damaging it.

14 | DOOR REVERSAL

DOOR REVERSAL

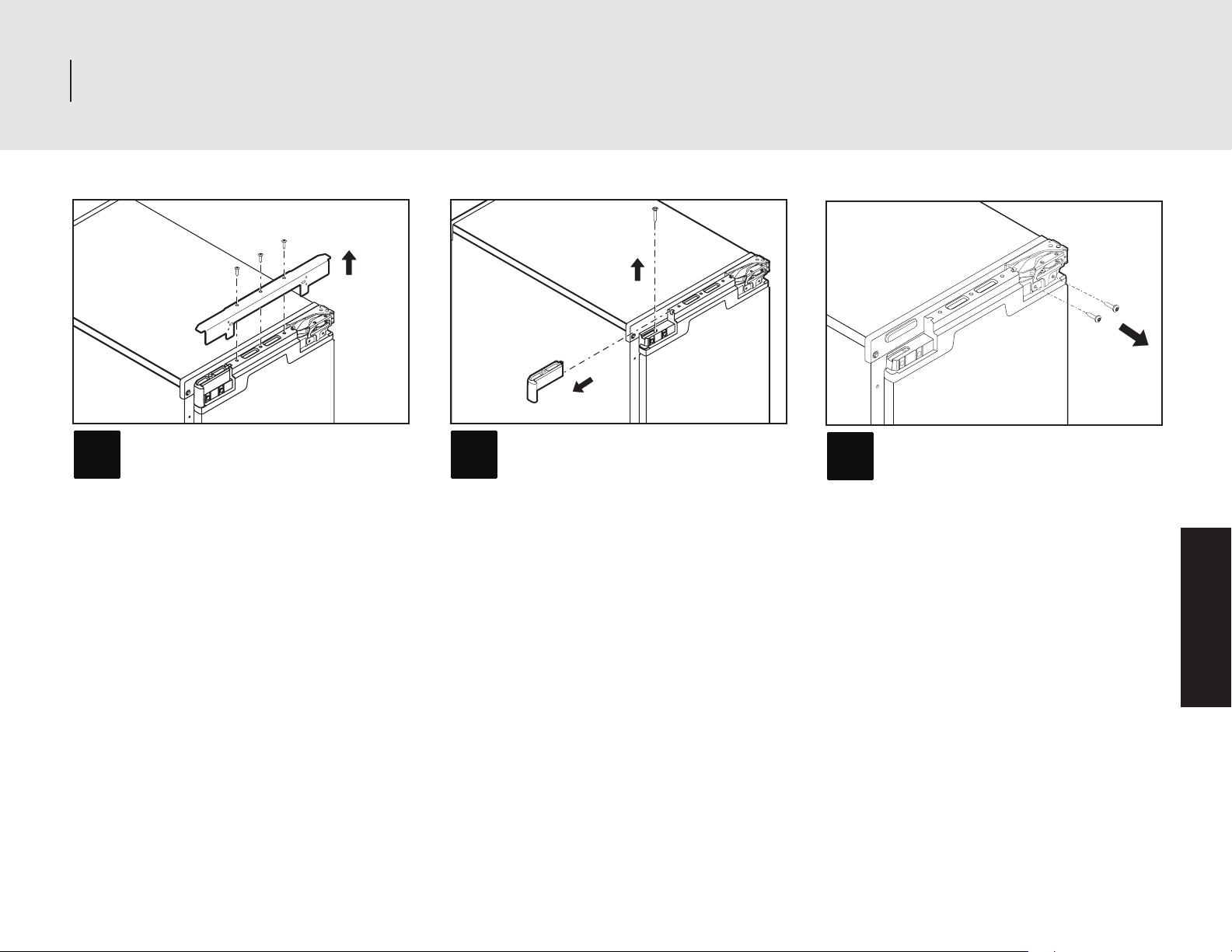

Remove the screws and the top metal

bracket using the Phillips screwdriver.

2

Place them aside.

Remove the screw from the top and

bottom end caps using the Phillips

3

screwdriver. Remove and place them

aside.

Using Torx T25 screwdriver unscrew

the door hinge screws completely

4

from the top and bottom hinges and

place them aside.

DOOR REVERSAL

DOOR REVERSAL | 15

DOOR REVERSAL

REMOVING THE HINGES CONT.

Remove the door and place it aside.

Swap the hinge screws to the opposite

5

side.

Remove the plastic screw cover from

the inside of the hinges and place

6

them aside.

16 | DOOR REVERSAL

DOOR REVERSAL

Remove the screws and hinges

from the cabinet with the Torx T25

7

screwdriver and place them aside.

WARNING

Crush Hazard

Articulated hinges are self closing and many

pinch points exist prior to cabinet

installation.

Do not operate, or close, the hinges while

they are removed from the ice maker.

Failure to follow these instructions can

result in crush, cut, or pinch injuries.

Remove the screw cap cover and

replace on the other side.

8

Swap the magnetic door catch to other

side.

9

DOOR REVERSAL

DOOR REVERSAL | 17

DOOR REVERSAL

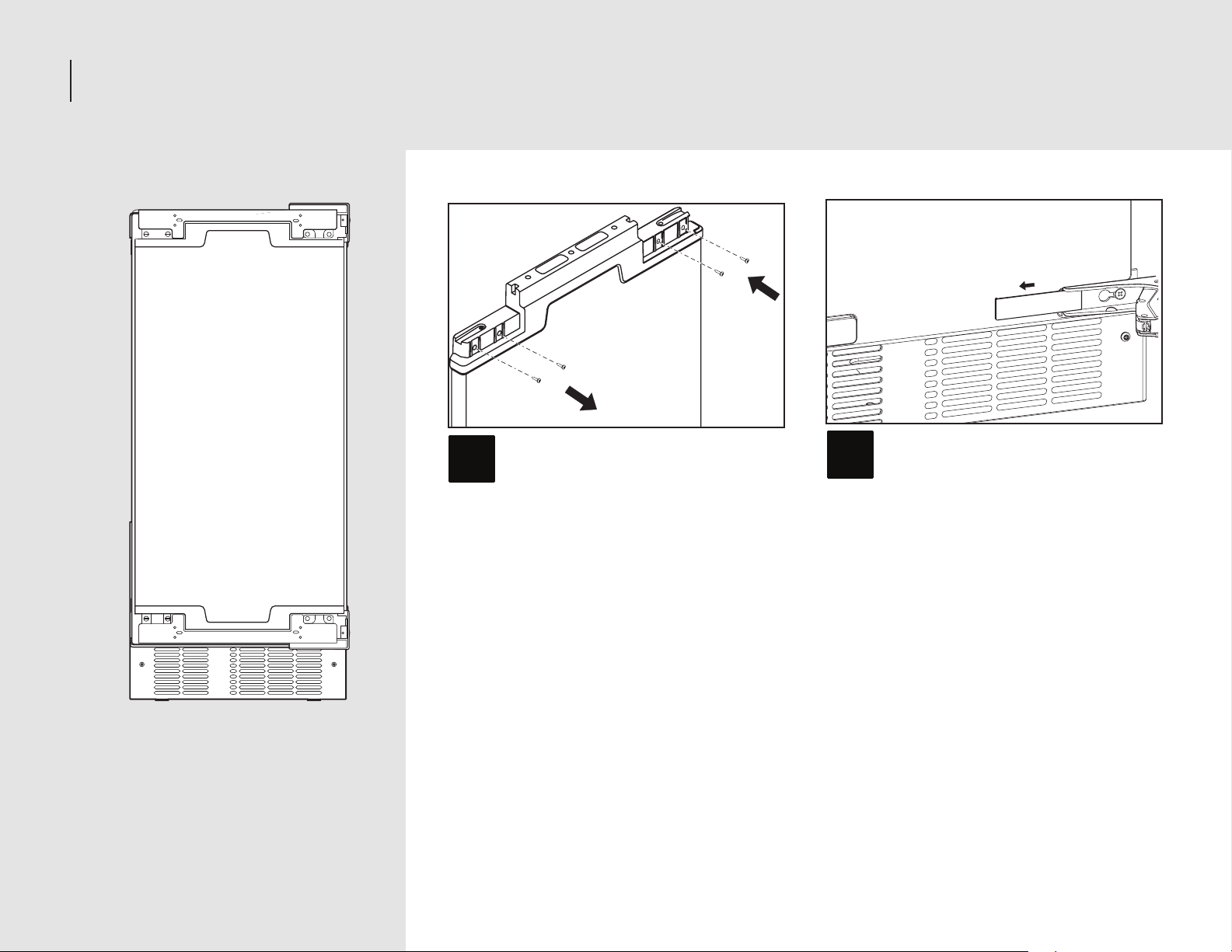

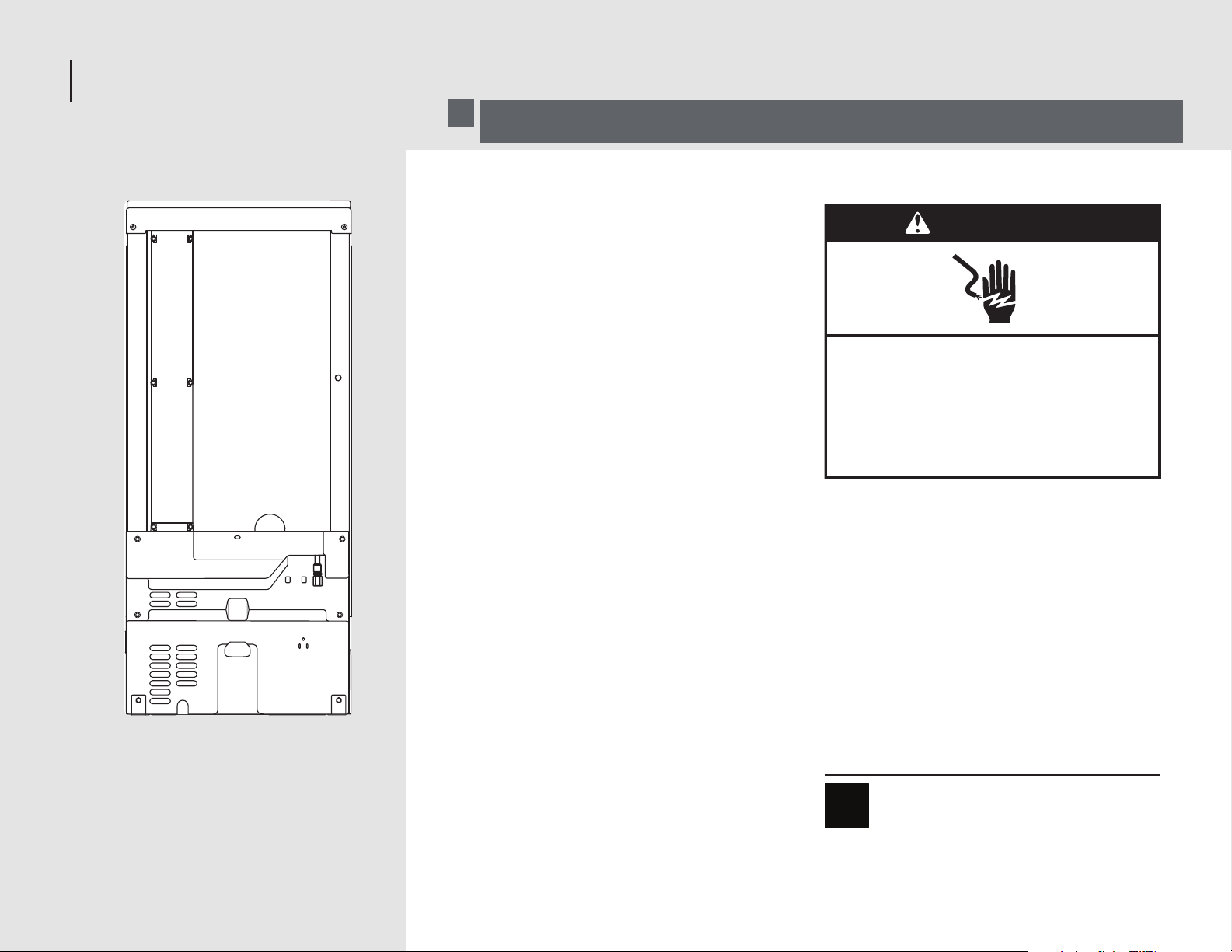

PREPARING THE BOTTOM HINGES

Grill cover screws

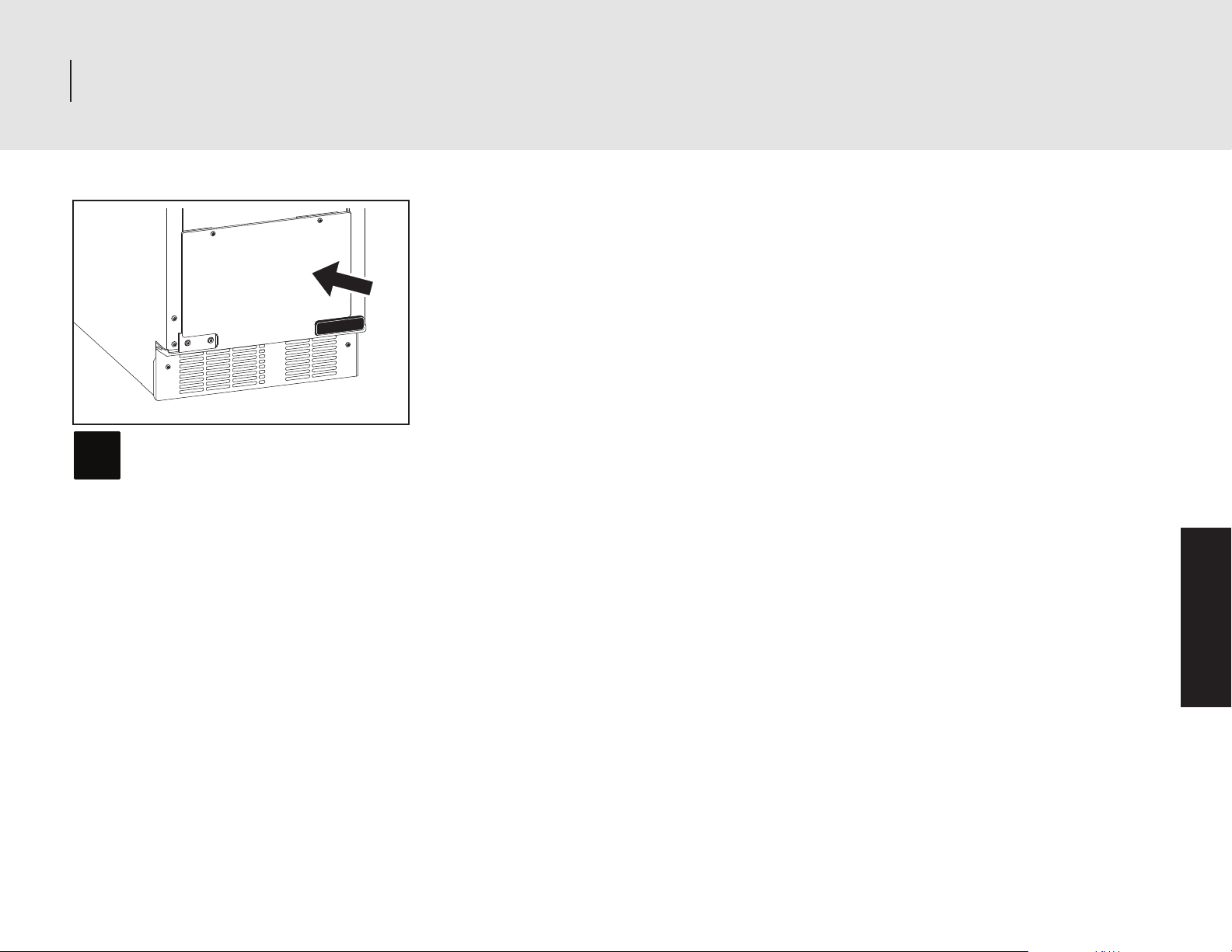

Unscrew and remove the grill cover

using a TORX T20 screwdriver. Place

1

them aside.

Remove the screw cover and place

it on the other side as shown in the

2

illustration.

18 | DOOR REVERSAL

DOOR REVERSAL

Reinstall the grill cover.

3

DOOR REVERSAL | 19

DOOR REVERSAL

DOOR REVERSAL

REVERSING THE HINGES

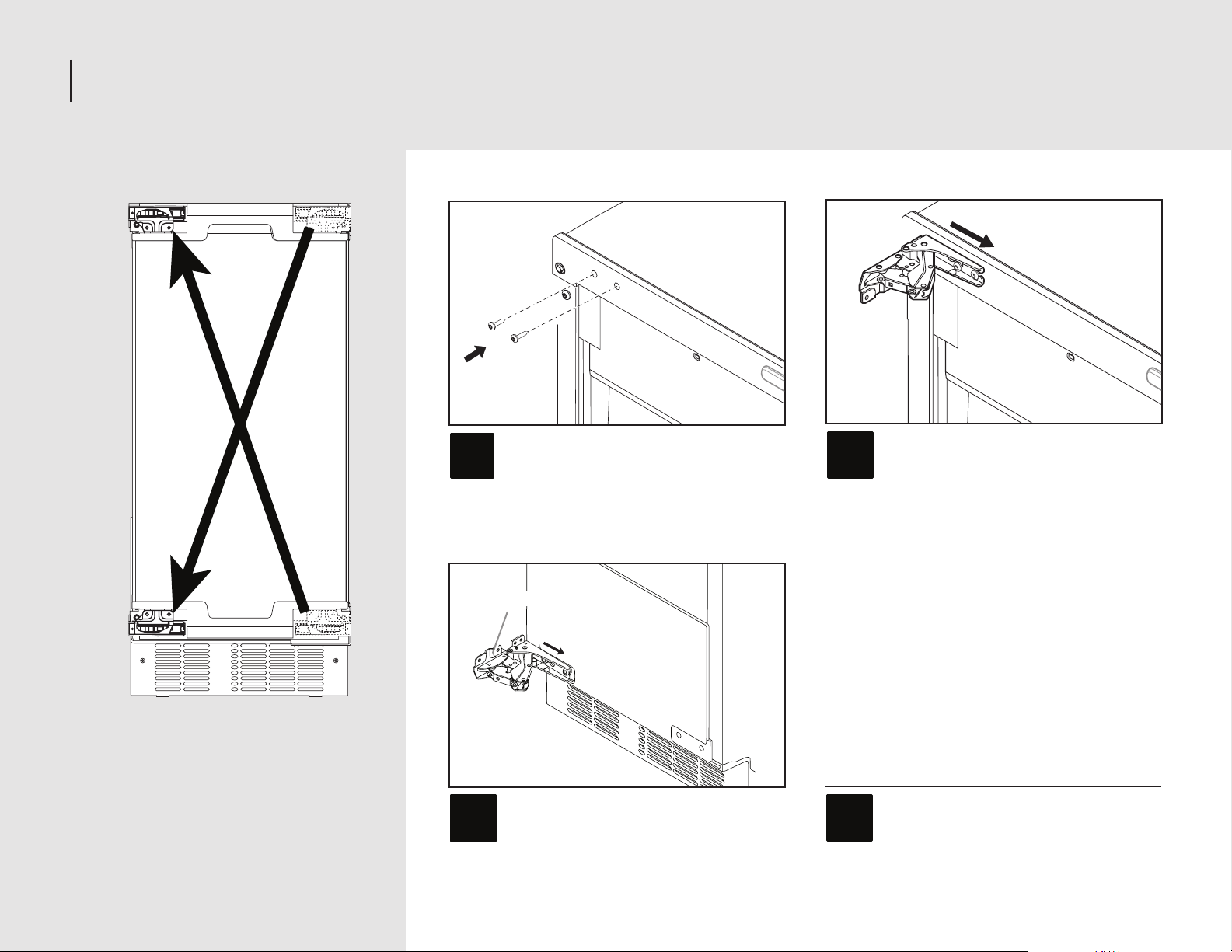

Install the hinge screws (placed aside

in step 7 of “Preparing the Bottom

1

Hinges”) half way on the desired side of

the cabinet.

Hinge tab

Take the original top hinge, flip it

and place it in the bottom hinge

2

position on the opposite side. Slide

onto the cabinet hinge screws. The

hinge tabs on the hinges should

always face towards each other.

Take the original bottom hinge, flip it

and place it in the top hinge position

3

on the opposite side. Slide onto the

cabinet hinge screws.

Fully tighten the top and bottom hinge

screws.

4

20 | DOOR REVERSAL

DOOR REVERSAL

Plastic screw cover

WARNING

Excessive Weight Hazard

Use two or more people to move and install

ice maker.

Failure to do so can result in back or other

injury.

Reinstall the plastic screw cover to

original locations on the hinges.

5

Slide the door onto the hinges. Using

Torx T25 screwdriver install the screws

6

(removed in the step 6 of “Removing

the Hinges” section) onto the door.

Reinstall the top and bottom end caps

on the door (the top right end cap is

7

now the bottom left end cap and vice

versa).

NOTE: For custom wood install skip

this step.

Reinstall the top metal bracket on the

door.

8

NOTE: For stainless steel panel install

skip this step.

Return the ice maker back to upright

position.

9

DOOR REVERSAL

DOOR REVERSAL | 21

INSTALLATION

If ice maker is not connected to the water supply, skip this section and

!

go to “Installing the Drain Pump and Drain Hose” section.

INSTALLING THE DRAIN PUMP

SITE PREPARATION

NOTES:

■ Connect drain pump to your drain in

accordance with all state and local codes and

ordinances.

■ It may be desirable to insulate drain tube

thoroughly up to drain inlet to minimize

condensation on the drain tube. Insulated

tube kit Part Number W10365792 is available

for purchase.

■ Drain pump is designed to pump water to

a maximum height of 10 ft (3 m). Use only

Whirlpool approved drain pump kit Part

Number 1901A.

■ Do not connect the outlet end of the drain

tube to a closed pipe system to avoid drain

water from backing up into the ice maker.

Kit Contains:

■ Drain pump kit Part Number 1901A

■ 5/8" I.D. x 51/8" drain tube (ice maker bin to

drain pump reservoir inlet)

■ 1/2" I.D. x 10 ft (3 m) drain tube hose (drain

pump discharge to household drain)

■ 5/16" I.D. x 32" (81 cm) vent tube (drain pump

reservoir vent to ice maker cabinet back)

■ Cable tie (secures vent tube to suction tube)

(1)

■ #8-32 x 3/8" pump mounting screws (secures

drain pump to baseplate and clamps to back

of ice maker) (5)

■ 5/8" small adjustable hose clamp (secures

vent to drain pump)

■ 7/8" large adjustable hose clamp, (secures

drain tube to ice maker bin and drain pump

reservoir inlet) (3)

■ Instruction sheet

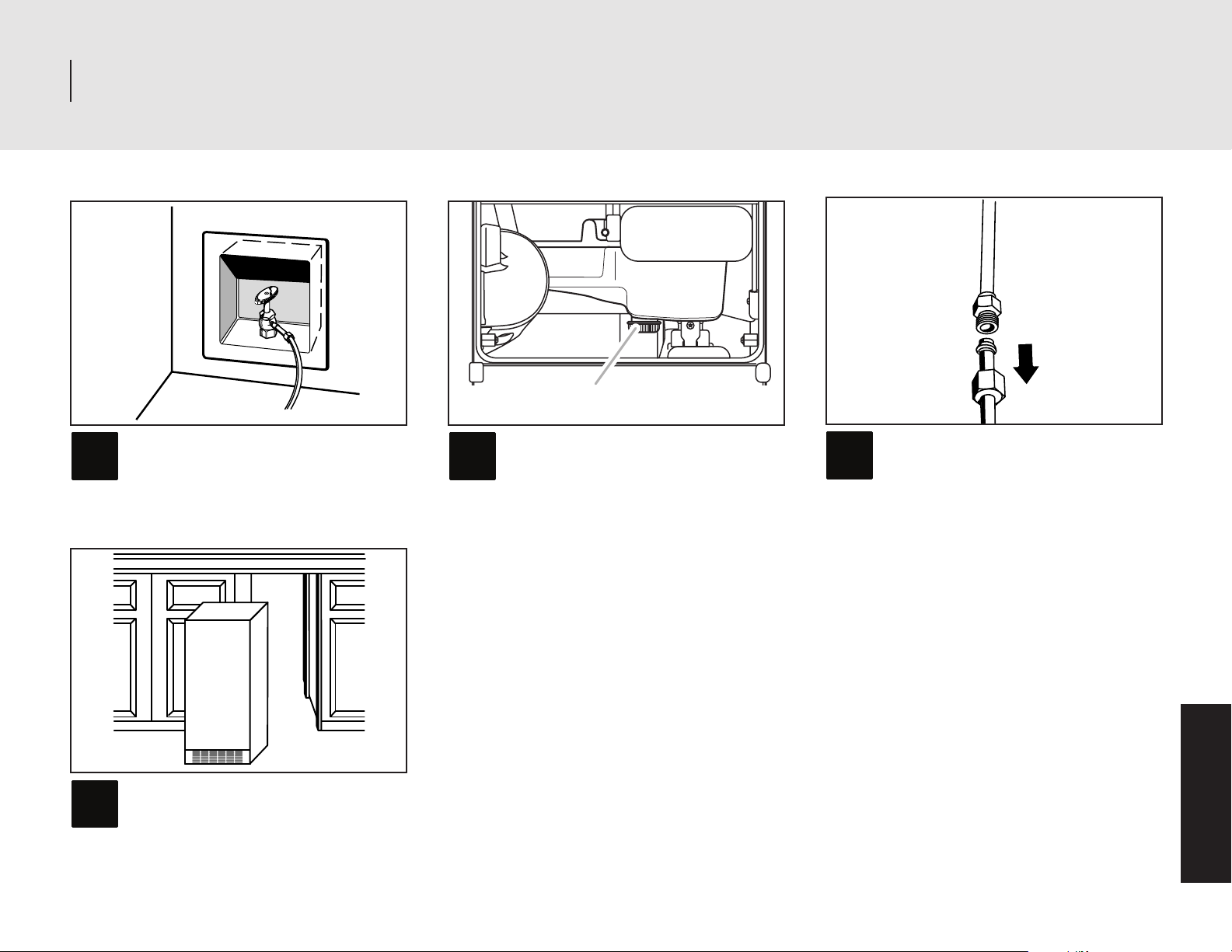

If Ice Maker is Currently Installed

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Press the OFF button to Stop ice

production. Then unplug the ice maker

1

or disconnect power.

22 | INSTALLATION

INSTALLATION

Drain cap

Turn off water supply. Wait 5 to 10

minutes for the ice to fall into the

2

storage bin. Remove all ice from bin.

If ice maker is built into cabinets, pull

ice maker out of the opening.

3

Unscrew the drain cap from the

bottom of the water pan located inside

4

the storage bin. Allow water to drain

completely.

Disconnect water supply line.

5

INSTALLATION

INSTALLATION | 23

INSTALLATION

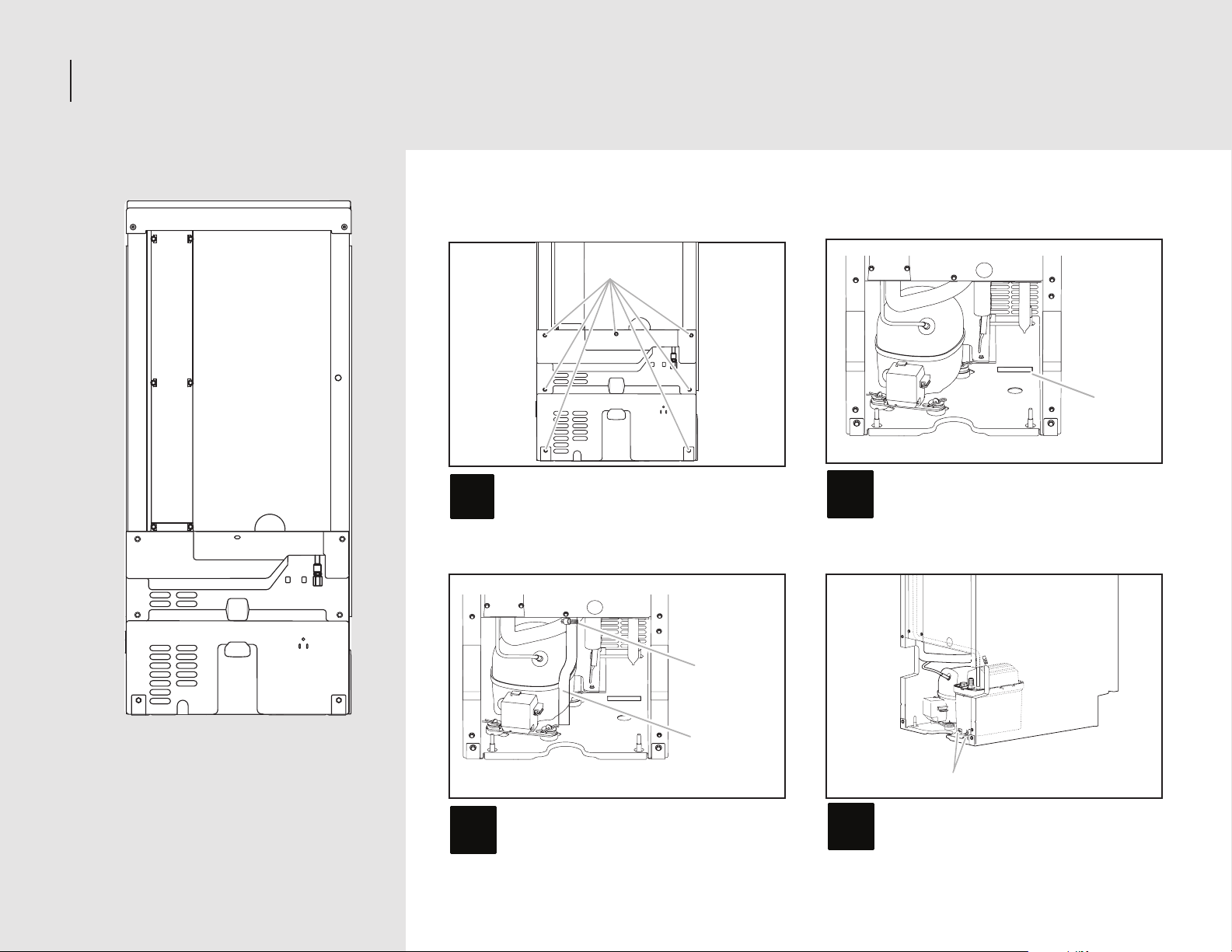

INSTALLING THE DRAIN PUMP

AND DRAIN HOSE

NOTE: Do not kink, smash or damage tubes or

wires during installation.

Screws

Mounting

tab slot

24 | INSTALLATION

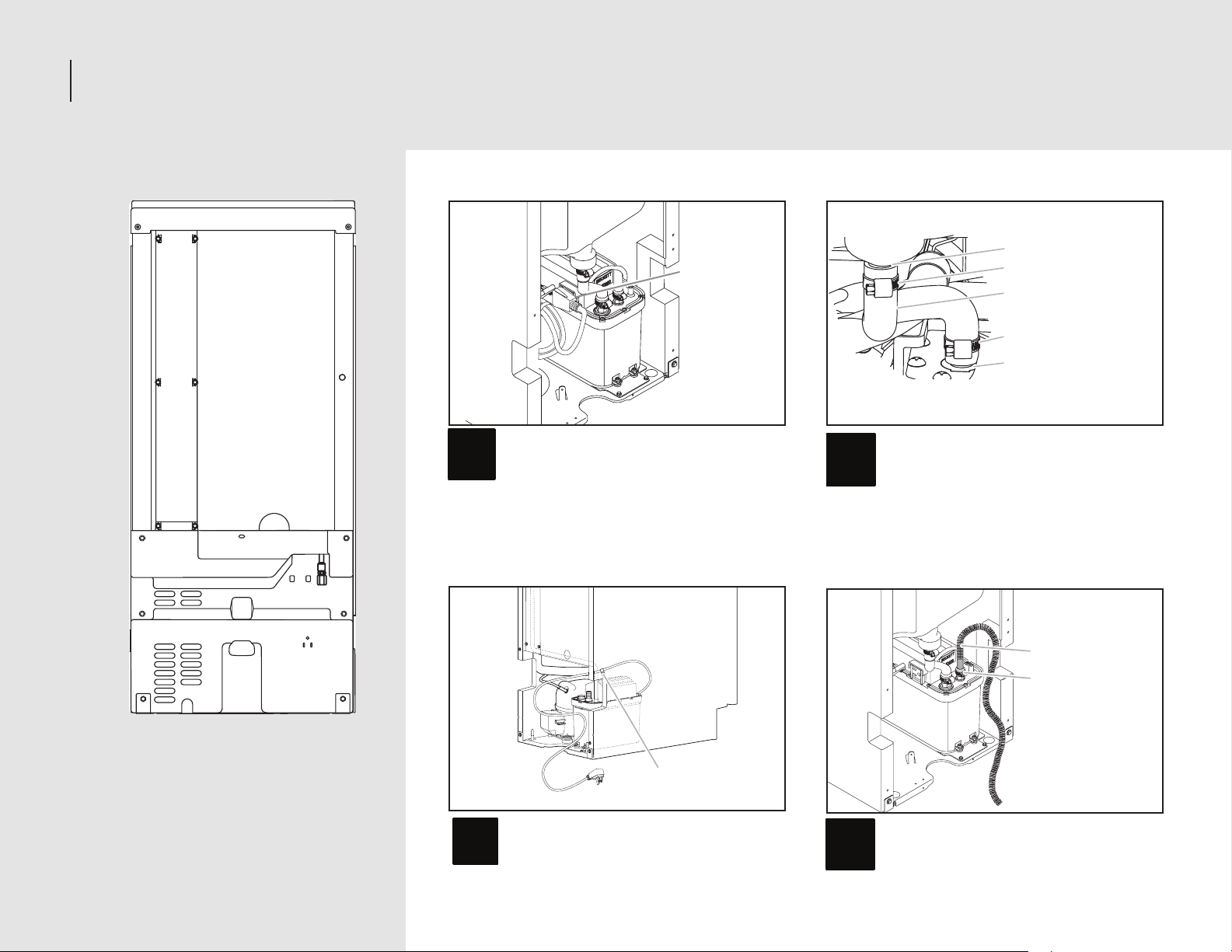

Unscrew the screws attaching rear

panel to ice maker. Remove the screws

1

and rear panel, place them aside. For

pump models, skip to step 12.

Remove the old drain tube and clamp

attached to the ice maker bin.

2

NOTE: Discard old drain tube and

clamp.

Clamp

Old drain

tube

Install the drain pump on the right side

of the ice maker base. Tip the drain

3

pump slightly to slide the mounting

tab into the mounting tab slot.

#8-32 x 3/8" pump mounting screws

Align the two screw holes at the rear

of the pump. Use the two #8-32 x 3/8"

4

screws supplied to attach the pump to

the ice maker base.

INSTALLATION

5

7

Vent

tube

Wiring

cover

Unscrew the screws attaching wiring

cover to the ice maker and remove

the wiring cover. Place the screws and

wiring cover aside.

Drain

pump

Screws

5/8" hose

clamp

Vent

tube

Cable

tie

Plastic

retainer

Route the vent tube through the

plastic retainer as shown in the

illustration. Using a cable tie, tie the

vent tube to the suction tube and

wires located behind the wiring cover.

Reinstall the wiring cover and screws.

NOTE:

■ Do not overtighten the vent tube, it

may block the airflow through tube.

Ice maker power cord,

clamp and screw

Unscrew and remove the power cord

clamp mounted to the ice maker side

8

wall from the ice maker power cord.

INSTALLATION

Install vent tube [5/16" I.D. x 32" (81 cm)]

to drain pump reservoir vent. Use one

6

of the supplied 5/8" small adjustable

clamp.

NOTE:

■ Do not block air flow through the

vent tube by over tightening the

cable tie.

INSTALLATION | 25

INSTALLATION

10

11

INSTALLING THE DRAIN PUMP

AND DRAIN HOSE CONT.

Coil the ice maker power cord into a 4"

(10.2 cm) diameter coil. Restrain the

9

coil with electrical tape or cable ties.

Place the coiled power cord as shown

in the illustration and plug it into the

receptacle on the drain pump.

Receptacle of the

drain pump

Ice bin outlet

7/8" adjustable hose clamp

Drain tube (ice bin to drain

pump)

7/8" adjustable hose clamp

Drain pump reservoir inlet

New drain tube is provided in the

drain pump kit. Install new drain tube

to both the ice bin outlet and the

drain pump reservoir inlet using new

adjustable clamps.

NOTES:

■ Do not kink.

■ Trim tube length if required.

Drain tube

Clamp

26 | INSTALLATION

Drain pump power

cord, clamp and screw

Attach the drain pump power cord to

the ice maker side wall with the clamp

and screw (removed in step 7).

12

Attach the drain tube to pump

discharge tube using a clamp

provided.

INSTALLATION

15

Cable tie

Holes to

fix the

cable tie

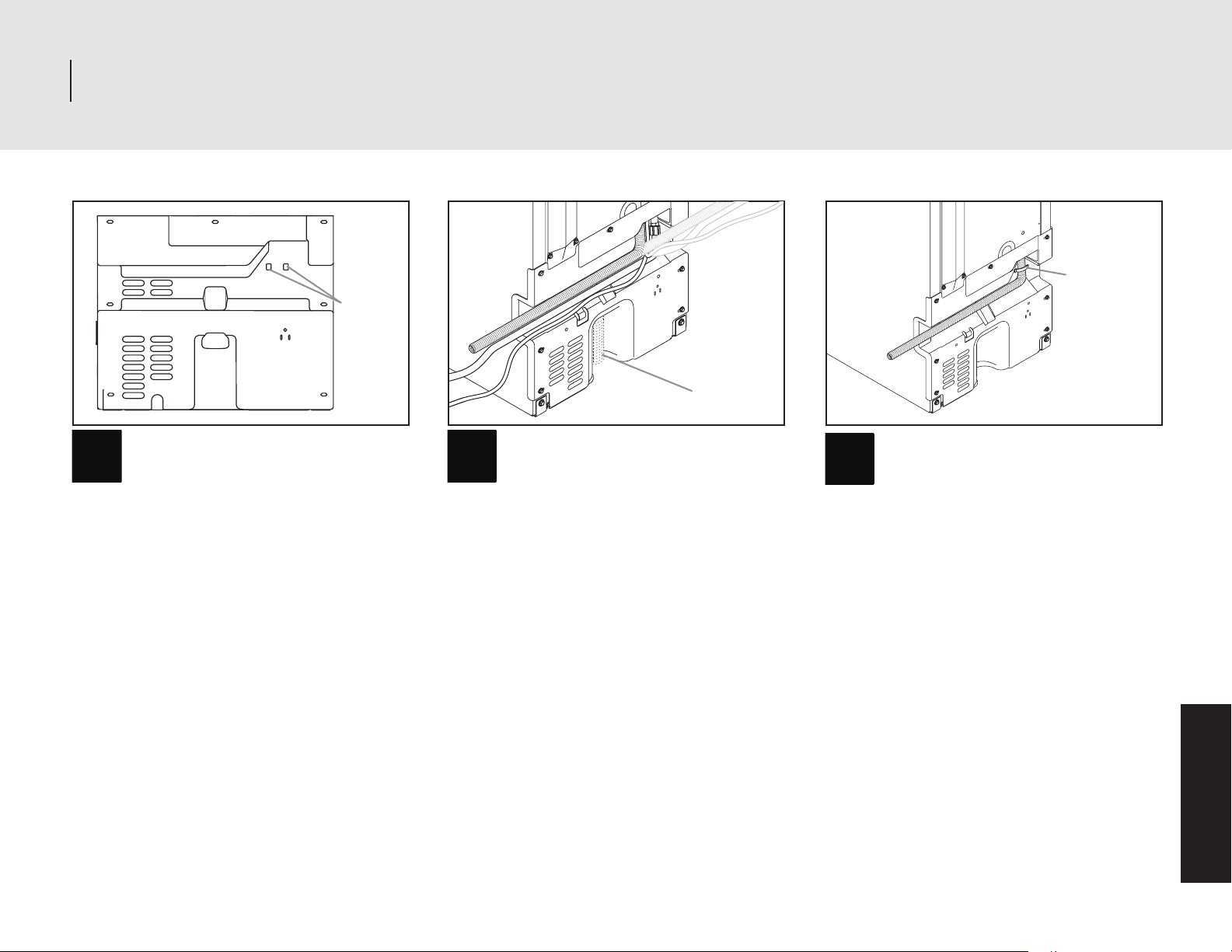

For floor applications, drain

tube can be routed this way

13

Install the cable tie on the rear panel

using two holes provided on the rear

panel.

14

Route the drain pump discharge tube,

power cord, and water inlet through

the slot in the ice maker back panel.

Replace the rear panel and screws.

Using a cable tie, fix the drain tube to

rear panel as shown in the illustration.

INSTALLATION

INSTALLATION | 27

Loading...

Loading...