Jenn-Air JJW3830DS Installation Manual

INSTALLATION INSTRUCTIONS

IMPORTANT:

Sa

IMPOR

À conser

.

30" (76.2 CM) ELECTRIC SINGLE AND

DOUBLE BUILT-IN OVEN

INSTRUCTIONS D’INSTALLATION

FOUR ÉLECTRIQUE ENCASTRÉ

30" (76,2CM) - SIMPLE ET DOUBLE

Table of Contents/Table des matières

BUILT-IN OVEN SAFETY ................................................................2

INSTALLATION REQUIREMENTS .................................................2

Tools and Parts .............................................................................2

Location Requirements ................................................................2

Electrical Requirements ...............................................................5

INSTALLATION INSTRUCTIONS ...................................................6

Prepare Built-In Oven ...................................................................6

Remove Oven Door(s) ..................................................................6

Replace Oven Door(s) ..................................................................7

Positioning Oven Feet for Multiple Cabinet Cutout Heights .......7

Make Electrical Connection .......................................................12

Install Oven .................................................................................13

Install Warming Drawer Deflector Kit

(Only for Ovens Installed Above Warming Drawers)..................15

Complete Installation .................................................................15

SÉCURITÉ DU FOUR ENCASTRÉ ..............................................16

EXIGENCES D’INSTALLATION ...................................................16

Outillage et pièces ......................................................................16

Exigences d’emplacement .........................................................17

Spécifications électriques ..........................................................20

INSTRUCTIONS D’INSTALLATION .............................................21

Préparation du four encastré .....................................................21

Dépose de la/des porte(s) du four .............................................21

Réinstallation la porte(s) du four ................................................22

Positionnement des pieds du four pour

des ouvertures d’encastrement de hauteur différente ..............23

Raccordement électrique ...........................................................27

Installation du four ......................................................................29

Installation de l’ensemble de déflecteur

du tiroir-réchaud (uniquement pour les fours

installés au-dessus d’un tiroir-réchaud) .....................................30

Achever l’installation ..................................................................31

ve for local electrical inspector's use.

W10790014C

TANT :

ver pour consultation par l'inspecteur local des installations électriques

BUILT-IN OVEN SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

INSTALLATION REQUIREMENTS

■ Flush Installation Kit (for Single and Double installed at flush

Tools and Parts

Gather the required tools and parts before starting

installation. Read and follow the instructions provided

with any tools listed here.

Tools Needed

■ Phillips screwdriver

■ Measuring tape

■ Hand or electric drill (for wall cabinet installations)

■ 1" (2.5 cm) drill bit (for wall cabinet installations)

■ Level

■ Flat-blade screwdriver

Parts Needed

■ UL listed or CSA approved conduit connector

■ UL listed wire connectors

■ Warming Drawer Deflector Kit (for ovens installed

above a warming drawer)

Order Part Number W10531010 for black 30" (76.2 cm) kit

Order Part Number W10536339 for stainless steel

30" (76.2 cm) kit

To order, see the “Assistance or Service” section

of the Use and Care Guide.

installation)

Order Part Number W10837578 for black 30" (76.2 cm) kit

Order Part Number W10837579 for stainless steel

30" (76.2 cm) kit

To order, see the “Assistance or Service” section

of the Use and Care Guide.

Parts Supplied

■ #8-14 x 1" screws - single ovens (2), double ovens (4)

■ #8-18 x

■ #8-18 x

■ #8-18 x

■ Bottom vent

■ Bottom vent trim

■ Rear feet - double oven (2)

■ Front feet - double oven (2)

Check local codes. Check existing electrical supply.

See “Electrical Requirements.”

It is recommended that all electrical connections

be made by a licensed, qualified electrical installer.

3

/8" screws - bottom vent (2)

1

/4" screws - bottom vent trim (4)

3

/8" screws - double oven feet (4)

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance with oven.

■ Recessed installation area must provide complete

enclosure around the recessed portion of the oven.

■ Grounded electrical supply is required. See

“Electrical Requirements” section.

follow

2

■ Electrical supply junction box should be located 3" (7.6 cm)

B

C

maximum below the support surface when the oven is

installed in a wall cabinet. A 1" (2.5 cm) minimum diameter

hole should have been drilled in the right rear or left rear

corner of the support surface to pass the appliance cable

through to the junction box.

NOTE: For undercounter installation, it is recommended

that the junction box be located in the adjacent right or

left cabinet. If you are installing the junction box on rear

wall behind oven, it is recommended that the junction box

be recessed and located in the upper center of the cabinet.

■ Oven support surface must be solid, level, and flush

with bottom of cabinet cutout.

■ Floor must be able to support a single oven weight

of 154 lb (70 kg) for 30" (76.2 cm) models.

■ Floor must be able to support a double oven weight

of 288 lbs (131 kg) for 30" (76.2 cm) models.

IMPORTANT: To avoid damage to your cabinets, check

with your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate, or sustain other

damage. This oven has been designed in accordance with

the requirements of UL and CSA International and complies

with the maximum allowable wood cabinet temperatures

of 194°F (90°C).

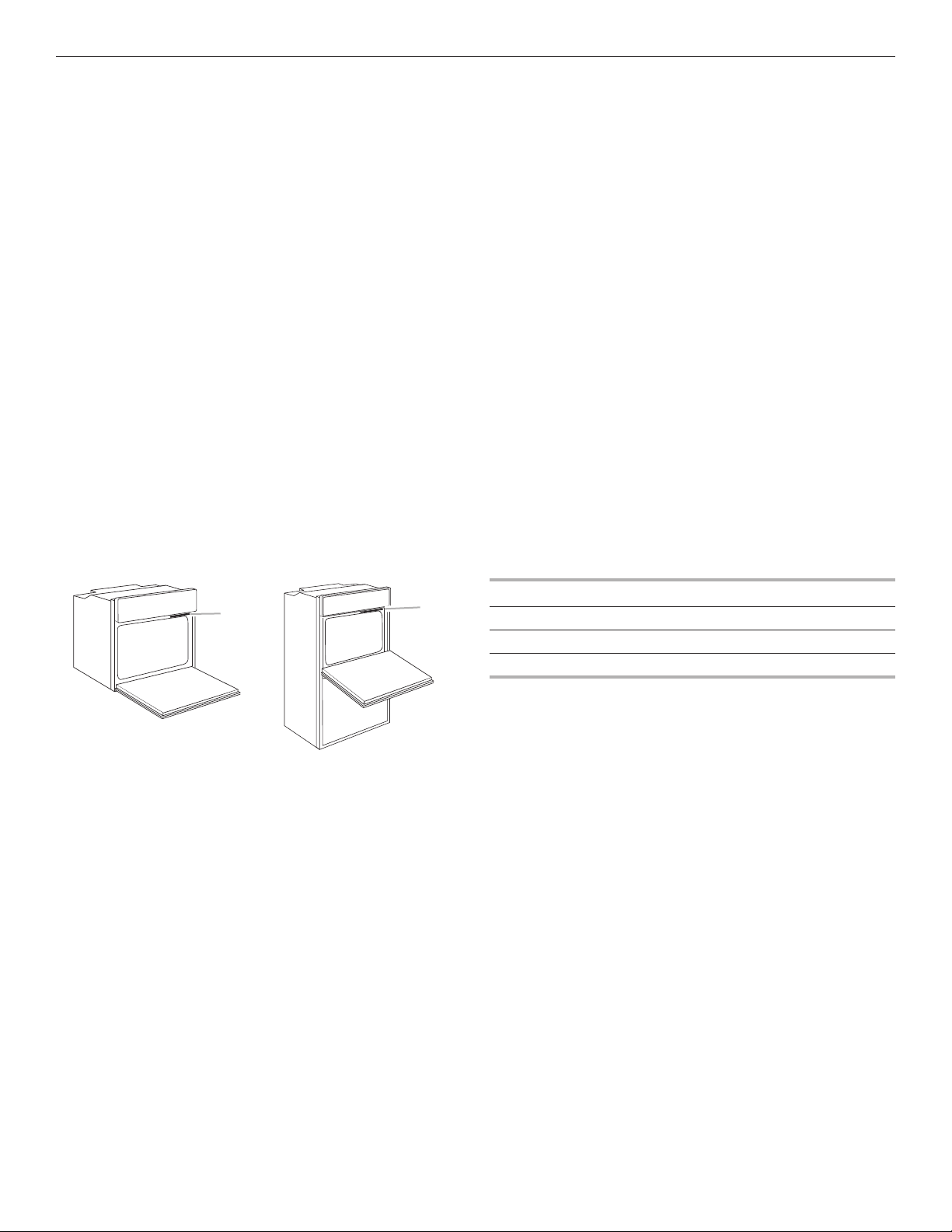

Undercounter Installation (with Cooktop Installed Above):

Ovens approved for this type of installation have an approval

label located on the top of the oven. Refer to Cutout Dimensions

for Ovens Installed Under Cooktop (separate sheet).

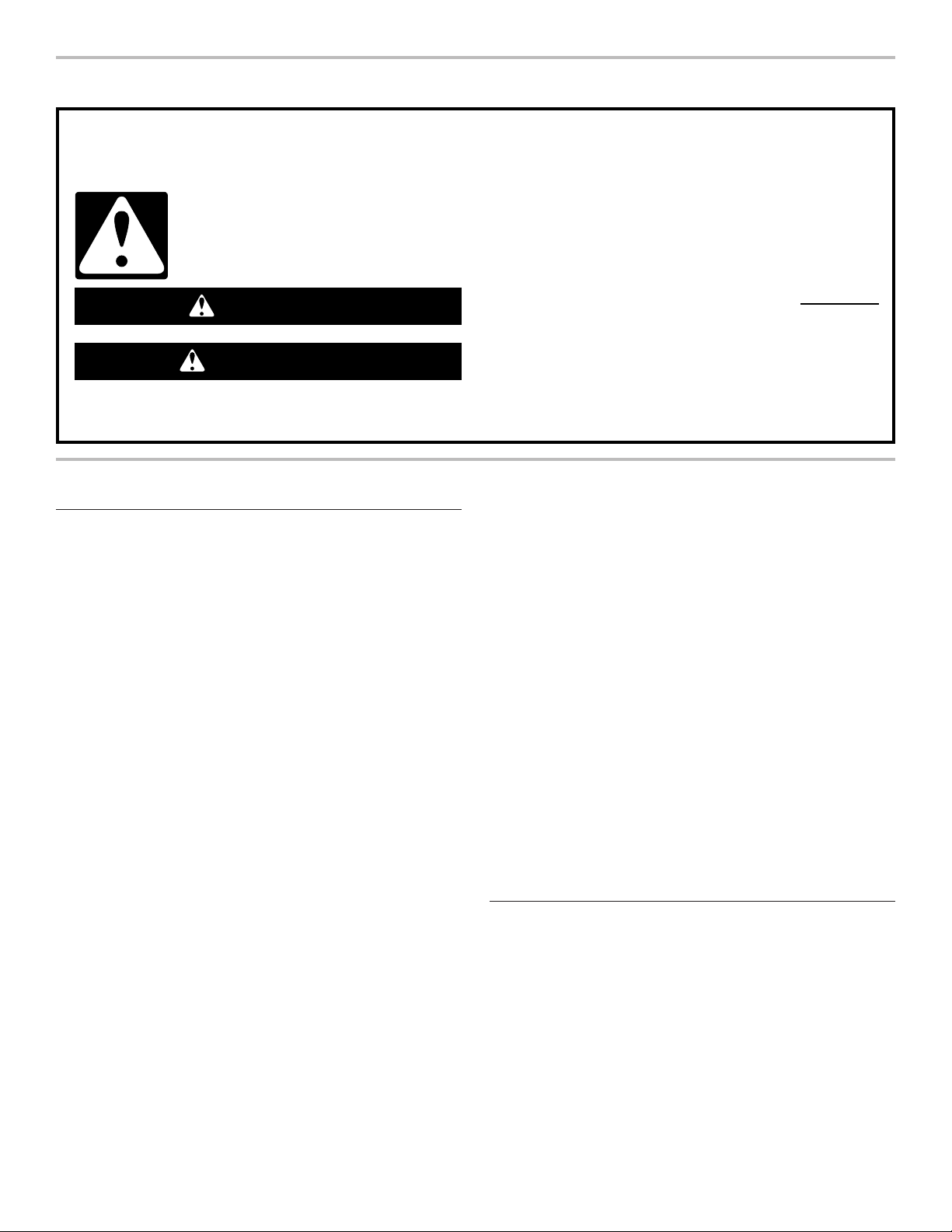

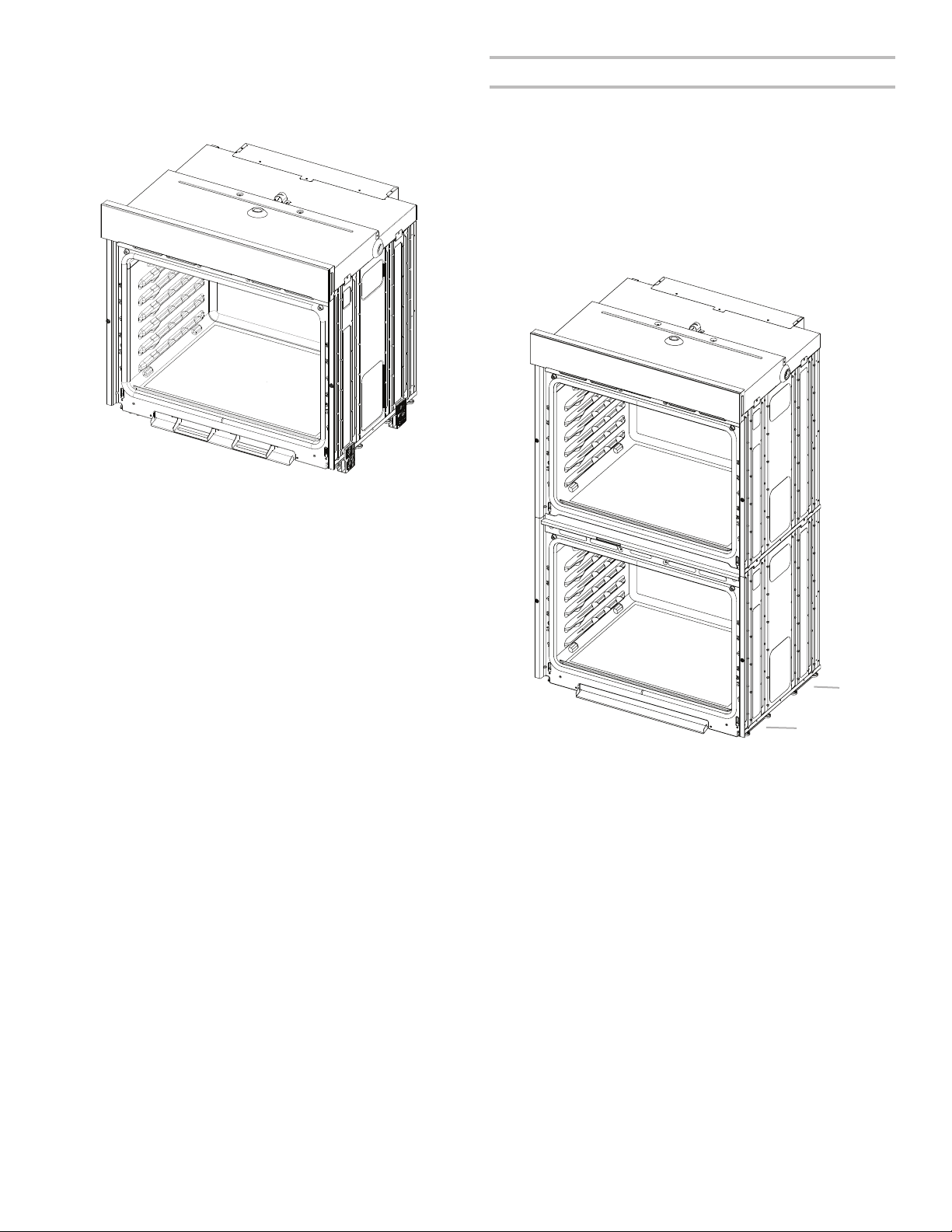

Cabinet Dimensions - Single Ovens

Single Oven Undercounter (Without Cooktop Installed Above)

A

E

D

A. 30" (76.2 cm) min. cabinet width

1

B. 1

/2" (3.8 cm) min. top of cutout to underside of countertop

1

C. 5

/4" (13.3 cm) bottom of cutout to floor

1

D. 28

/2" (72.4 cm) cutout width

E. 28" (71.2 cm) min. cutout height

Single Ovens Installed in Cabinet

A

Product Dimensions - Single Ovens

B

G

F

A

E

A. 297/8" (75.8 cm) max. overall height

7

B. 28

/16" (72.2 cm) max. recessed width

3

C. 27

/16" (69 cm) recessed height

1

D. 23

/4" (59.1 cm) max. recessed depth

E. 30" (76.2 cm) overall width

F. 12" (30.5 cm) from back of control panel to start of strain relief

G. 48" (121.9 cm) flexible conduit length

C

D

B

D

F

G

E

C

A. 30" (76.2 cm) min. cabinet width

3

B. 2

/16" (5.5 cm) top of cutout to bottom of upper cabinet door

C. 32" (81.3 cm) bottom of cutout to floor

1

D. 28

/2" (72.4 cm) cutout width

1

E. 1

/2" (3.8 cm) min. bottom of cutout to top of cabinet door

F. 28" (71.2 cm)* recommended cutout height

G. 24" (60.7 cm) cutout depth

* NOTE: The cutout height can be between 2615/16" and 297/16"

(68.4 cm and 74.8 cm) for single ovens.

3

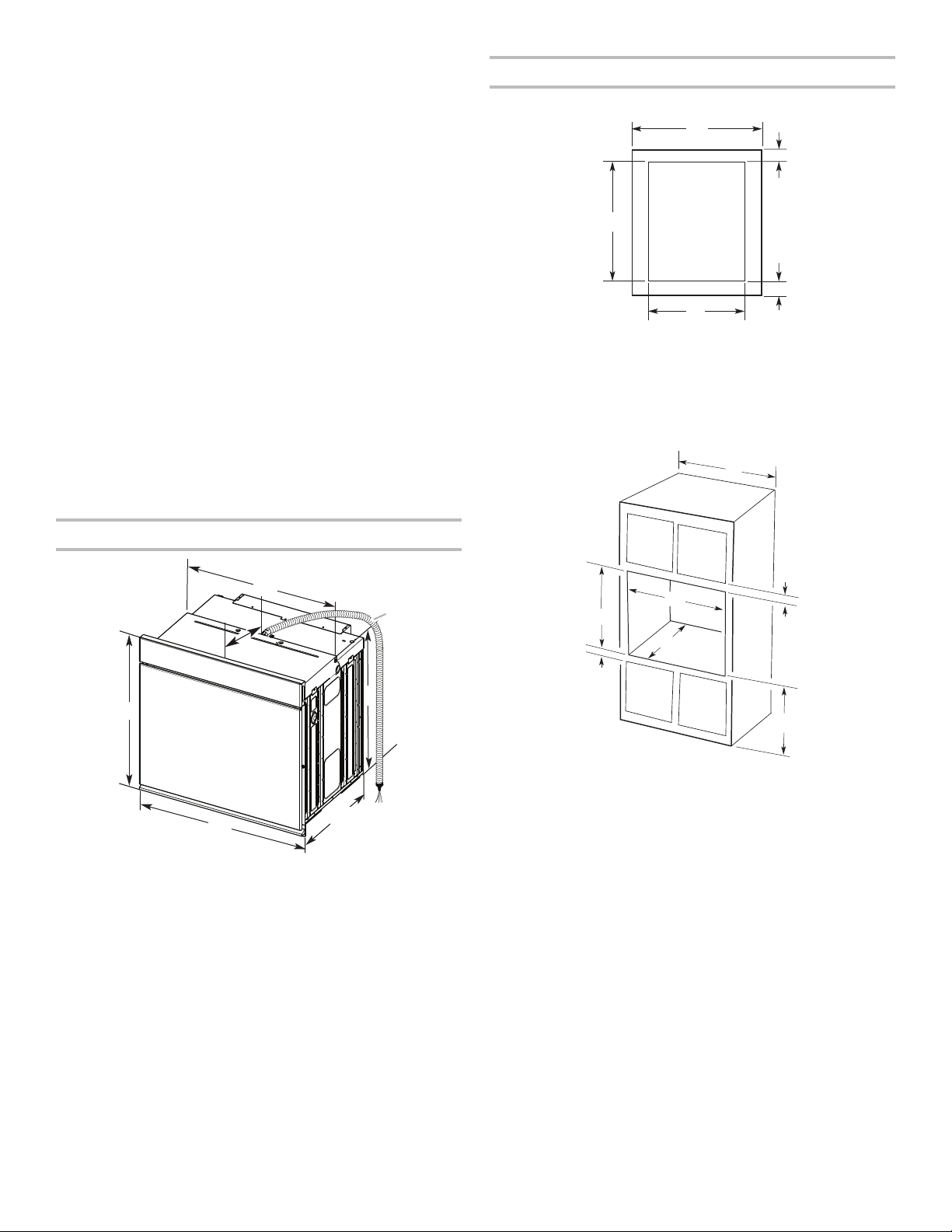

Product Dimensions - Double Ovens Cabinet Dimensions - Double Ovens

G

B

F

A

E

A. 523/8" (133 cm) max. overall height

7

B. 28

/16" (72.2 cm) max. recessed width

1

C. 49

/4" (125.1 cm) recessed height

1

D. 23

/4" (59.1 cm) max. recessed depth

E. 30" (76.2 cm) overall width

F. 12" (30.5 cm) from back of control panel to start of strain relief

G. 66" (167.6 cm) flexible conduit length

C

D

Double Ovens Installed in Cabinet

A

B

D

F

G

E

C

A. 30" (76.2 cm) min. cabinet width

3

B. 2

/16" (5.5 cm) top of cutout to bottom of upper cabinet door

3

C. 14

/4" (37.5 cm) bottom of cutout to floor is recommended.

4"-143/4" (10.2-37.5 cm) bottom of cutout to floor is acceptable.

1

D. 28

/2" (72.4 cm) cutout width

1

E. 1

/2" (3.8 cm) min. bottom of cutout to top of cabinet door

1

F. 50

/4" (127.6 cm)* recommended cutout height

G. 24" (60.7 cm) cutout depth

* NOTE: The cutout height can be between 491/2" and 523/16"

(125.2 cm and 132.6 cm) for double ovens.

4

Electrical Requirements

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine

that the ground path and the wire gauge are in accordance

with local codes.

Check with a qualified electrical installer if you are not

sure the oven is properly grounded.

This oven must be connected to a grounded metal,

permanent wiring system.

Be sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical

Code, ANSI/NFPA 70-latest edition or CSA Standards C22.

1-94, Canadian Electrical Code, Part 1 and C22.2 No.

O-M91-latest edition, and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Electrical Connection

To properly install your oven, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

■ Oven must be connected to the proper electrical voltage and

frequency as specified on the model/serial/rating plate. The

model/serial/rating plate is located under the control panel

on single ovens and under the control panel on the upper

oven cavity on double ovens. See the following illustrations.

■ Models rated from 7.3 to 9.6 kW at 240 volts (5.4 to 7.4

kW at 208 volts) require a separate 40-amp circuit. Models

rated at 4.8 kW and below at 240 volts (3.6 kW and below

at 208 volts) require a separate 20-amp circuit.

■ A circuit breaker is recommended.

■ Connect directly to the circuit breaker box (or fused

disconnect) through flexible, armored, or nonmetallic

sheathed, copper cable (with grounding wire). See

“Make Electrical Connection” section.

■ Flexible conduit from the oven should be connected

directly to the junction box.

■ Fuse both sides of the line.

■ Do not cut the conduit. The length of conduit provided

is for serviceability of the oven.

■ A UL listed or CSA approved conduit connector

must be provided.

■ If the house has aluminum wiring, follow the

procedure below:

1. Connect a section of solid copper wire to the ends

of the flexible conduit leads.

2. Connect the aluminum wiring to the added section

of copper wire, using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer’s recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

For power requirements for models JJW3430D and JJW3830D,

refer to the following table.

Single Oven

A. Model/serial/rating plate

A

Double Oven

A. Model/serial/rating plate

A

Model kW Amps kW Amps

JJW3430D

JJW3830D

4.2 18.3 3.2 16.1

8.4 36.6 6.4 32.1

240 VAC 208 VAC

5

INSTALLATION INSTRUCTIONS

Prepare Built-In Oven

1. Decide on the final location for the oven. Avoid drilling

or cutting into house wiring during installation.

WARNING

Excessive Weight Hazard

Use two or more people to move and install oven.

Failure to do so can result in back or other injury.

2. To avoid floor damage, set the oven onto cardboard prior

to installation. Do not use handle or any portion of the front

frame for lifting.

3. Remove the shipping materials and tape from the oven.

Remember to keep the corner posts and other materials

that may be needed for installation.

4. Remove the hardware package from inside the bag

containing literature.

5. Remove and set aside racks and other parts from

inside the oven.

6. Move oven and cardboard close to the oven’s final location.

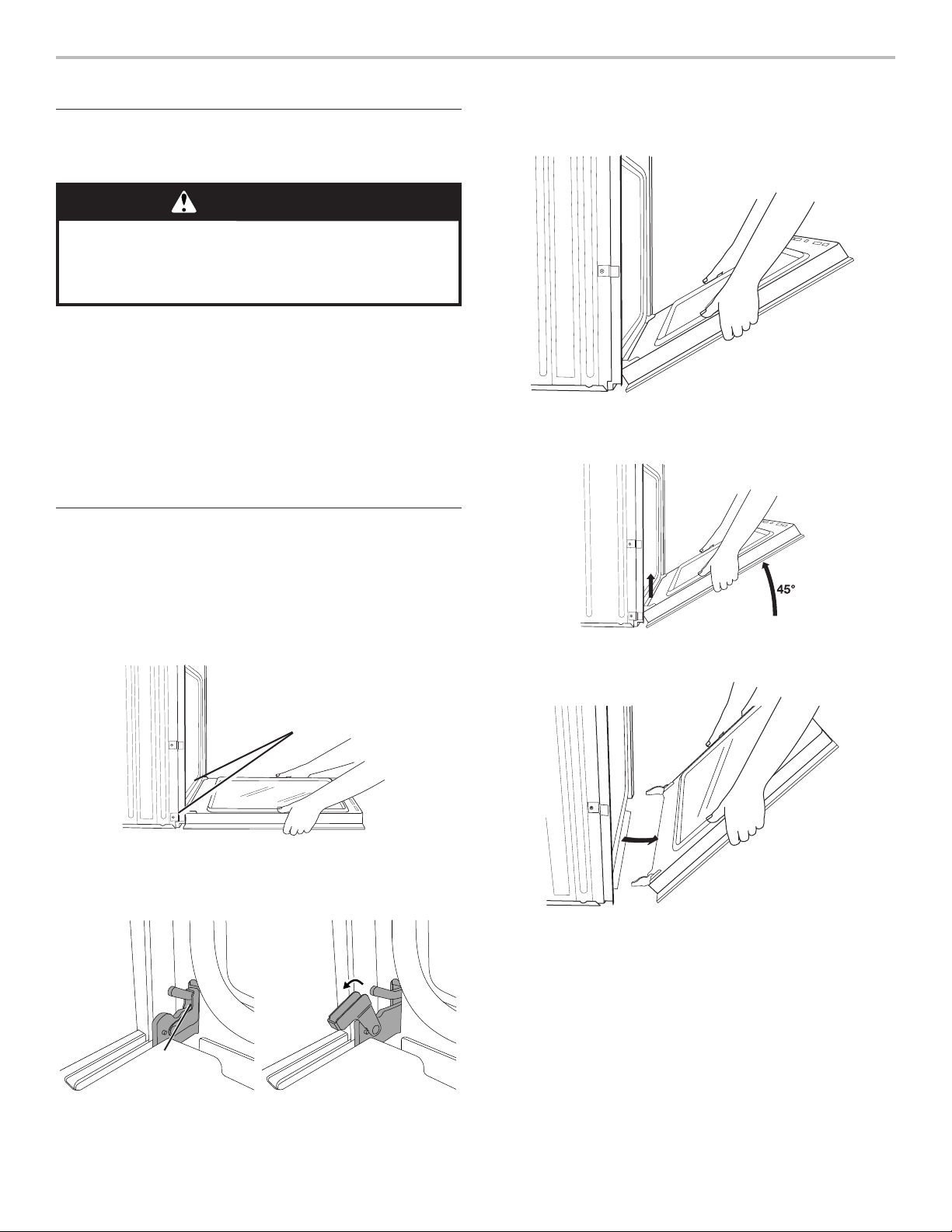

Remove Oven Door(s)

IMPORTANT: Use two hands to remove oven door. For double

ovens, repeat the process for each door.

1. Prior to removing the oven door, prepare a surface where

you will place it. This surface should be flat and covered

with a soft blanket, or use the corner posts from your

packaging material.

2. Fully open the oven door.

4. Gently start to close the door. The door will stop at a partially

closed position.

5. Using two hands, grasp the edges of the oven door. Close

the oven door slightly past the stop position to take the

weight off of the door hinges, and then pull the oven door up.

6. Pull the oven door toward you, and then remove. You may

need to gently shift door from side to side as you pull.

Door

Hinges

3. Locate the oven door hinge locks in both corners of the

oven door, and rotate the hinge locks toward the oven door

to the unlocked position. If the door hinge lock is not rotated

fully (see illustration B), the door will not remove properly.

Locked

position

Grip here

to rotate

A. Oven door hinge lock in

lockedposition

Unlocked

position

B. Oven door hinge lock in

partially unlocked position

7. Set the oven door aside on the prepared covered work

surface with the oven door resting on its handle.

8. To continue with the oven installation, go to the

“Positioning Oven Feet” section.

6

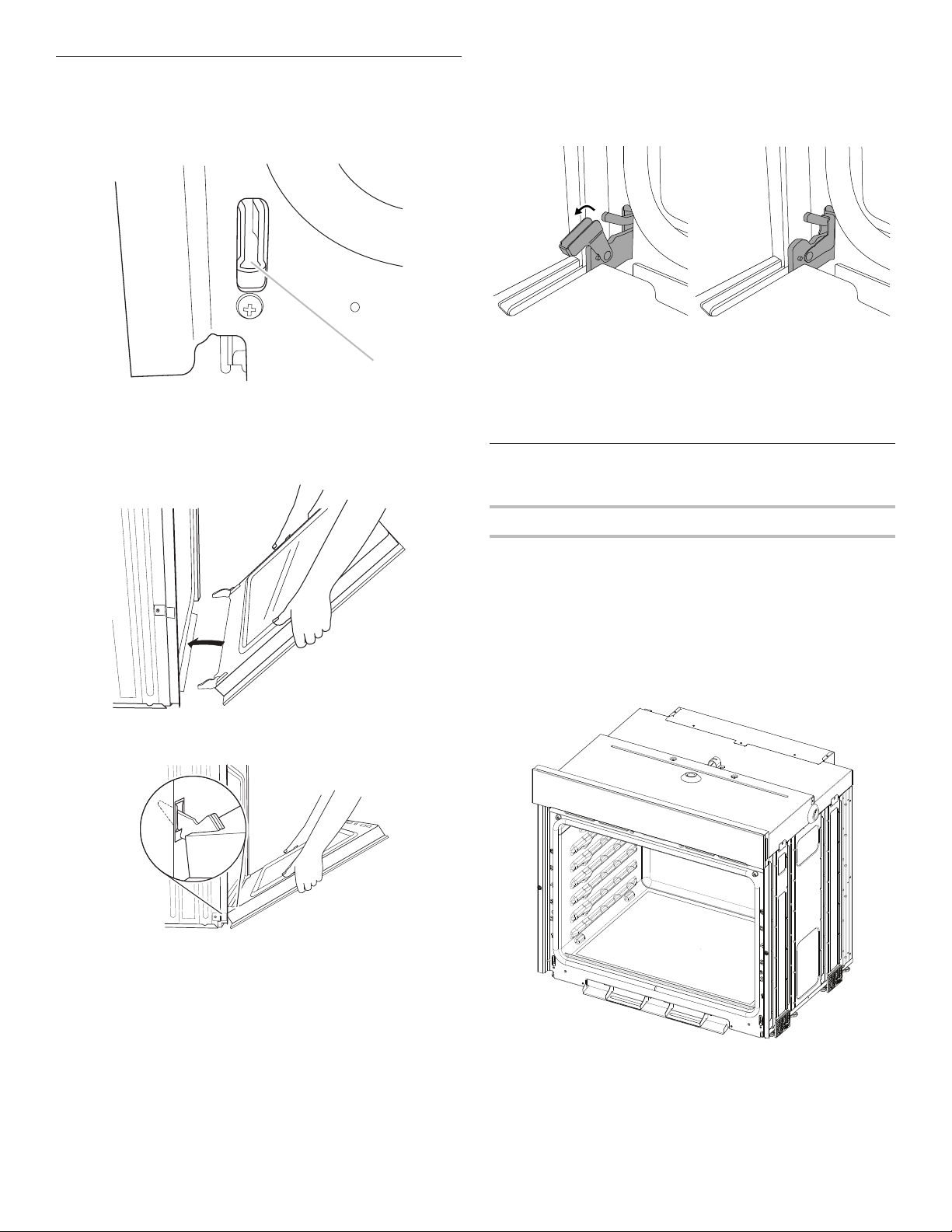

Replace Oven Door(s)

1. Using two hands, grasp side edges of door at the midpoint.

Face the oven cavity.

2. Locate the slots on each side of the oven front frame for

the door hinge locks.

A

A. Slot in the oven cavity for door hinge lock

3. Using two hands, grasp the edges of the oven door. At a 45°

angle, insert the hinges at the same time, and push the oven

door into the oven cavity slot to replace. You may need to

gently shift the door from side to side as you push.

5. Lower the oven door to the fully open position. If the oven

door does not open to a full 90°, repeat steps 1 through 3.

6. Locate the oven door hinge locks in the corners of the oven

door, and rotate the hinge locks toward the oven cavity to

the locked position.

Unlocked

position

7. After the door hinges have been locked, gently swing the

door upward to close. The door should not be forced closed.

8. When the hinges are properly installed and the door is

closed, there should be an even gap between the door and

the control panel. If one side of the oven door is lower than

the other, the hinge on that side is not properly installed.

See “Remove Oven Door” and “Replace Oven Door.”

Locked

position

Positioning Oven Feet for Multiple

Cabinet Cutout Heights

4. Make sure the door hinge notch is engaged on the bottom

of the oven cavity slot.

IMPORTANT: Do not close the door at this step or damage

may occur to the door hinge.

Single Ovens

The positioning of the oven feet allow a single oven to be

installed in a cutout height between 2615/16" and 297/16" (68.4 cm

and 74.8 cm). Refer to the following instructions to position the

feet for the size of your cabinet cutout.

Cutout Height Is Between 275/8" and 285/8"

(70.2 cm and 72.7 cm)

The oven feet do not need to be changed. They are

positioned correctly as received.

Go to the “Make Electrical Connection” section.

7

Cutout Height Is Between 2615/16" and 2711/16"

(68.4 cm and 70.3 cm)

1. Using 2 or more people, place the oven on its back

on a covered surface.

Cutout Height Is Between 2811/16" and 297/16"

(72.8 cm and 74.8 cm)

1. Using 2 or more people, place the oven on its back

on a covered surface.

2. Remove the foot from the right front spacer by removing

the #8-18 x 3/8" screw.

NOTE: Do not remove the spacer.

A

B

C

A. Spacer

B. Foot

C. #8-18 x

3

/8" screw

3. In the same manner, remove the feet on the right rear,

left front, and left rear of the oven.

4. Using 2 or more people, place the oven in its upright position.

2. Remove the foot from the right front spacer by removing

the #8-18 x 3/8" screw.

NOTE: Do not remove the spacer.

A

B

C

A. Spacer

B. Foot

C. #8-18 x

3

/8" screw

3. Rotate the foot 90°, so the short side of the foot

is positioned toward the top of the oven.

5. Go to the “Make Electrical Connection” section.

8

4. Reinstall the foot to the spacer using the #8-18 x 3/8"

A

A

screw previously removed.

5. In the same manner, remove, rotate, and reinstall the

feet on the right rear, left front, and left rear of the oven.

6. Using 2 or more people, place the oven in its upright position.

7. Go to the “Make Electrical Connection” section.

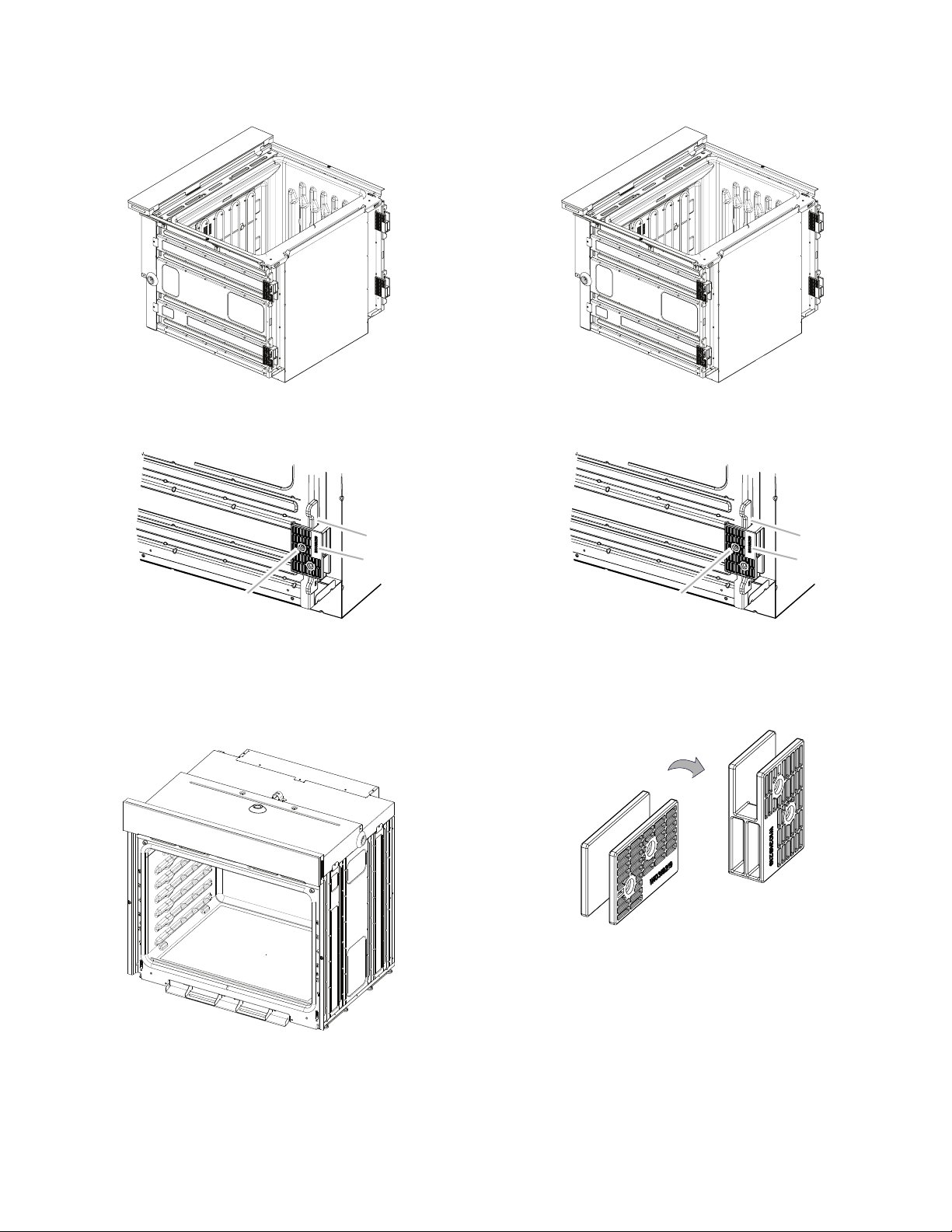

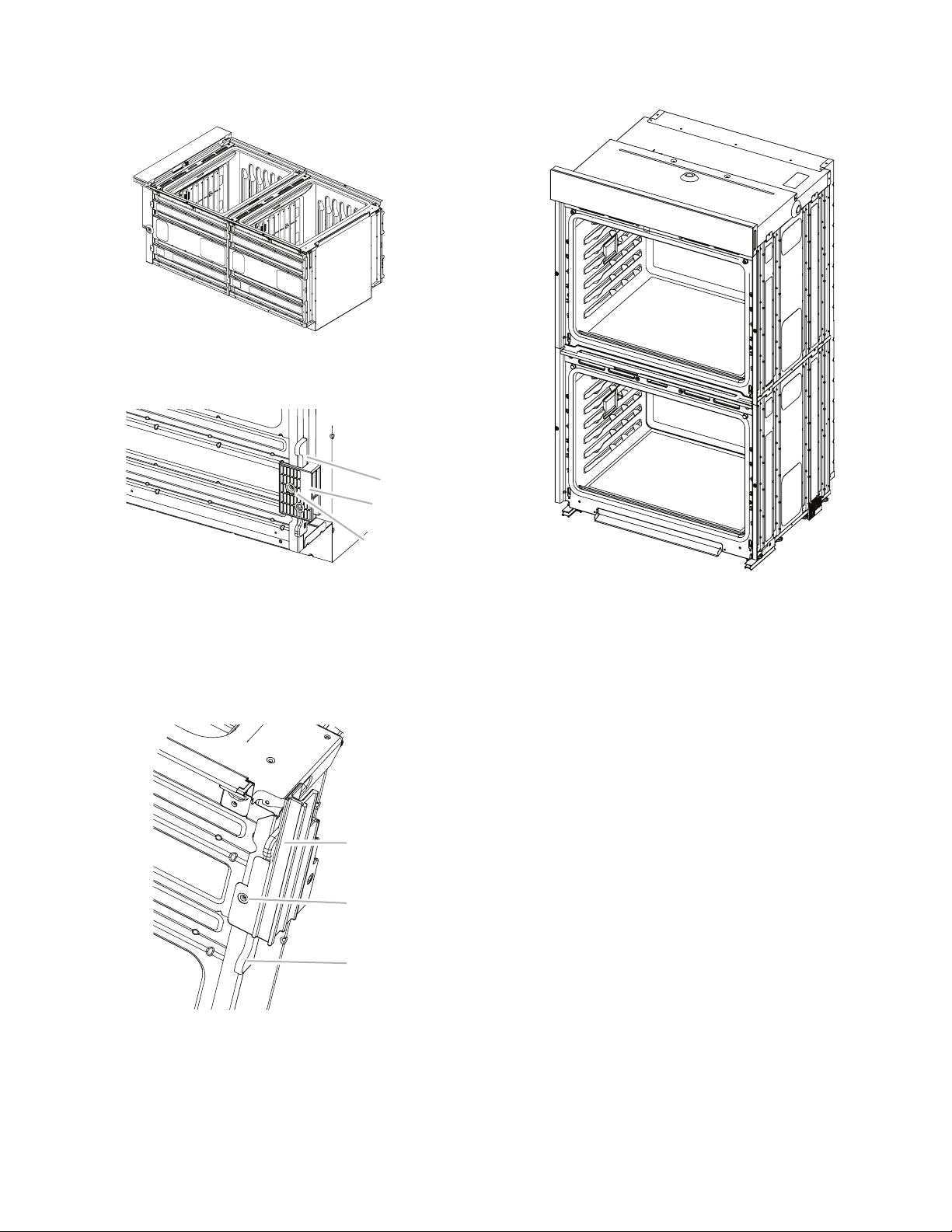

Double Ovens

The positioning of the oven feet allow a double oven to be

installed in a cutout height between 487/8" and 523/16" (124.1 cm

and 132.6 cm). Refer to the following instructions to position

the feet for the size of your cabinet cutout.

Cutout Height Is Between 487/8" and 507/16"

(124.1 cm and 128.1 cm)

The oven feet do not need to be installed. The oven

is configured correctly as received.

NOTE: Do not remove the spacers.

Go to the “Make Electrical Connection” section.

A. Spacers

9

Cutout Height Is Between 501/2" and 511/8"

A

A

(128.2 cm and 129.9 cm)

1. Using 2 or more people, place the oven on its back

on a covered surface.

2. Install a foot on the left rear spacer using a #8-18 x 3/8" screw.

NOTE: Position the foot so the long side of the foot is facing

toward the top of the oven.

B

5. In the same manner, install a front foot on the right front

of the oven.

6. Using 2 or more people, place the oven in its upright position.

C

A. Spacer

B. Foot

C. #8-18 x

3

/8" screw

3. In the same manner, install a foot on the right rear of the oven.

4. Install a front foot on the left front spacer using a #8-18 x 3/8"

screw.

NOTE: Position the foot so the long side of the foot is facing

toward the inside of the oven.

B

C

7. Go to the “Make Electrical Connection” section.

10

A. Front foot

B. #8-18 x

C. Spacer

3

/8" screw

Loading...

Loading...