Jenn-Air JFC2290VPR0, JFC2290VPY2, JFC2290VPR1, JFC2290VEP2, JFC2290VEM2 User Instructions

...

THANK YOU for purchasing this high-quality product. If you should experience a problem not covered in TROUBLESHOOTING,

please visit our website at www.jennair.com for additional information. If you still need assistance, call us at 1-800-536-6247. In

Canada, visit our website at www.jennair.ca or call us at 1-800-807-6777.

You will need your model and serial number, located on the inside wall of the refrigerator compartment.

Para obtener acceso a "lnstrucciones para el usuario del refrigerador" en espa_ol, o para obtener informaci6n adicional acerca de

su producto, visite: www.jennair.com.

Necesitara su nQmero de modelo y de serie, ubicado en el interior del compartimiento del refrigerador.

TableofContents/Tabledes mati6res

REFRIGERATOR SAFETY ..................................................................... 1

INSTALLATION INSTRUCTIONS ......................................................... 2

REFRIGERATOR USE ........................................................................... 7

REFRIGERATOR CARE ....................................................................... 10

TROUBLESHOOTING .......................................................................... 11

WATER FILTER CERTIFICATIONS .................................................... 13

PRODUCT DATA SHEETS .................................................................. 14

WARRANTY .......................................................................................... 16

SI_CURITI_ DU RI_FRIGI_RATEUR ..................................................... 17

INSTRUCTIONS D'INSTALLATION ................................................... 18

UTILISATION DU RI_FRIGI_RATEUR ................................................. 23

ENTRETIEN DU RI_FRIGI_RATEUR ................................................... 26

DI_PANNAGE ........................................................................................ 27

FEUlLLES DE DONNI_ES SUR LE PRODUlT .................................... 30

GARANTIE ............................................................................................ 32

REFRIGERATORSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10276070A

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your refrigerator, follow these basic precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before servicing.

• Replace all parts and panels before operating.

• Remove doors from your old refrigerator.

SAVE THESE INSTRUCTIONS

• Use nonflammable cleaner.

• Keep flammable materials and vapors, such as gasoline,

away from refrigerator.

• Use two or more people to move and install refrigerator.

• Disconnect power before installing ice maker (on ice maker

kit ready models only).

• Use a sturdy glass when dispensing ice (on some models).

• Do not hit the refrigerator glass doors (on some models).

Proper Disposal of Your Old Refrigerator

Suffocation Hazard

Remove doors from your old refrigerator.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are still dangerous

- even if they will sit for "just a few days." Ifyou are getting rid of

your old refrigerator, please follow these instructions to help

prevent accidents.

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install

refrigerator.

Failure to do so can result in back or other injury.

Before You Throw Away Your Old Refrigerator or Freezer:

• Takeoff the doors.

• Leave the shelves in place so that children may not easily

climb inside.

When Moving Your Refrigerator:

Your refrigerator is heavy. When moving the refrigerator for

cleaning or service, be sure to cover the floor with

cardboard or hardboard to avoid floor damage. Always pull

the refrigerator straight out when moving it. Do not wiggle or

"walk" the refrigerator when trying to move it, as floor

damage could occur.

Remove the Packaging

Remove tape and glue residue from surfaces before turning

on the refrigerator. Rub a small amount of liquid dish soap

over the adhesive with your fingers. Wipe with warm water

and dry.

Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your refrigerator. For

more information, see "Refrigerator Safety."

• Dispose of/recycle all packaging materials.

2

Clean Before Using

After you remove all of the packaging materials, clean the inside of

your refrigerator before using it. See the cleaning instructions in

"Refrigerator Care."

important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

/ _ _: _ _, 4/

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion, or fire.

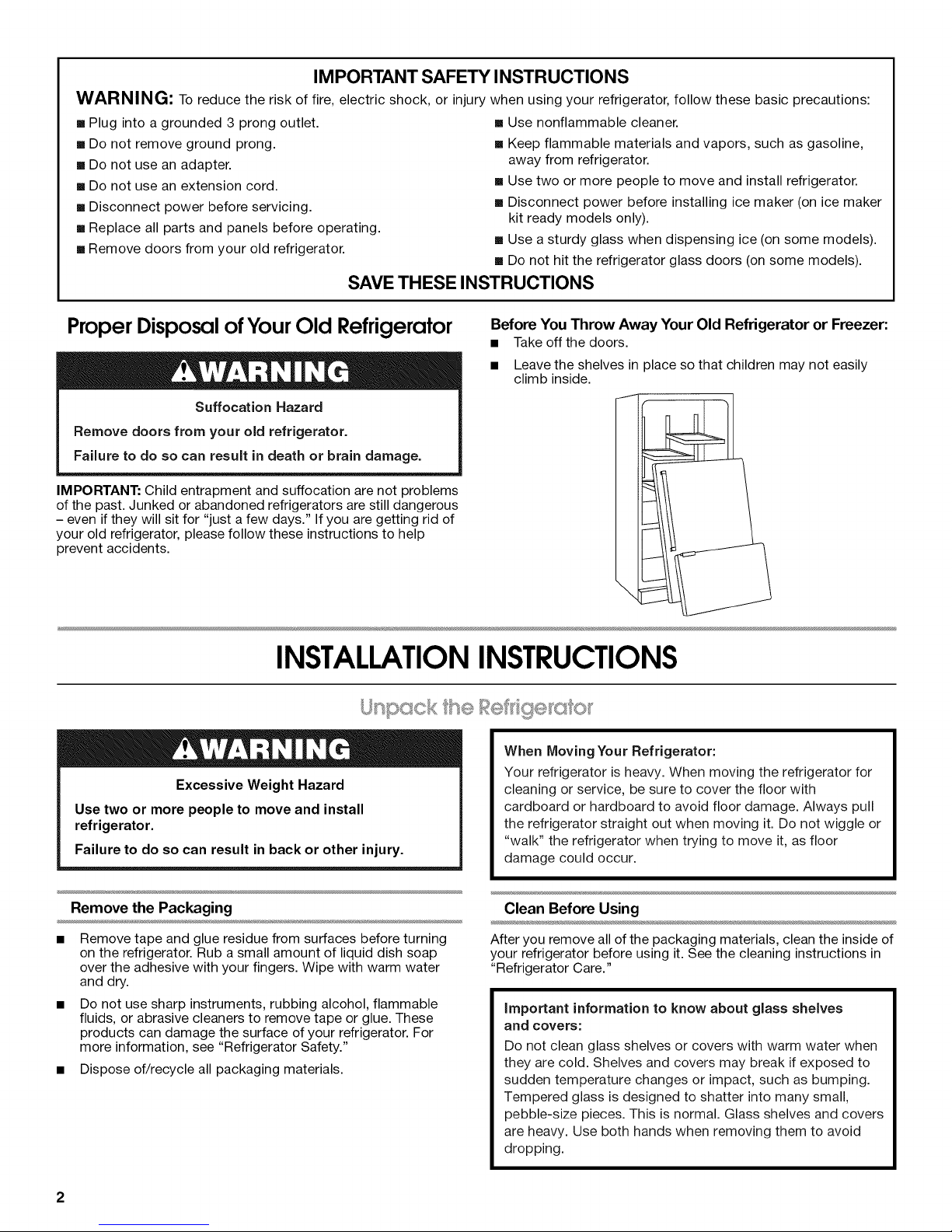

To ensure proper ventilation for your refrigerator, allow for a 1/2"

(1.25 cm) space at the top and behind the refrigerator. If your

refrigerator has an ice maker, allow extra space at the back for the

water line connections. When installing your refrigerator next to a

fixed wall, leave 21/2'' (6.3 cm) minimum on the hinge side (some

models require more) to allow for the door to swing open.

NOTE: It is recommended that you do not install the refrigerator

near an oven, radiator, or other heat source. Do not install the

refrigerator in a location where the temperature will fall below 55°F

(13°C).

/

1/2"(1.25cm)

II I

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 Volt, 60 Hz., AC only 15- or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your refrigerator be provided. Use an outlet

that cannot be turned off by a switch. Do not use an

extension cord.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, turn Cooling OFF, and then disconnect the

refrigerator from the electrical source. When you are finished,

reconnect the refrigerator to the electrical source and turn Cooling

ON. See "Using the Controls."

!_e S(s©© v _:'_÷ "

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

TOOLS NEEDED:

• Flat-blade screwdriver • 1A"Nut driver

• 7/le"and 1/_,,Open-end or two • 1A" Drill bit

adjustable wrenches • Cordless drill

21/2" (6.3 era) --

IMPORTANT:

• All installations must meet local plumbing code requirements.

• Do not use a piercing-type or ¾e" (4.76 mm) saddle valve

which reduces water flow and clogs more easily.

• Use copper tubing and check for leaks. Install copper tubing

only in areas where the household temperatures will remain

above freezing.

• For models with water filters, the disposable water filter

should be replaced at least every 6 months.

Wa_rPmssum

A cold water supply with water pressure of between 35 and

120 psi (241 and 827 kPa) is required to operate the water

dispenser and ice maker. Ifyou have questions about your water

pressure, call a licensed, qualified plumber.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of a

reverse osmosis system going to the water inlet valve of the

refrigerator needs to be between 35 and 120 psi (241 and

827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa):

• Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If your refrigerator has a water filter, it may further reduce the

water pressure when used in conjunction with a reverse

osmosis system. Remove the water filter. See "Water Filtration

System."

If you have questions about your water pressure, call a licensed,

qualified plumber.

6. Fasten the shutoff valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly inthe 1/4"drilled hole in

the water pipe and that the washer is under the pipe clamp.

Tighten the packing nut. Tighten the pipe clamp screws slowly

and evenly so the washer makes a watertight seal. Do not

overtighten.

7. Slip the compression sleeve and compression nut on the

copper tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not overtighten or

you may crush the copper tubing.

8. Place the free end of the tubing in a container or sink, and turn

ON the main water supply. Flush the tubing until water is clear.

Turn OFF the shutoff valve on the water pipe.

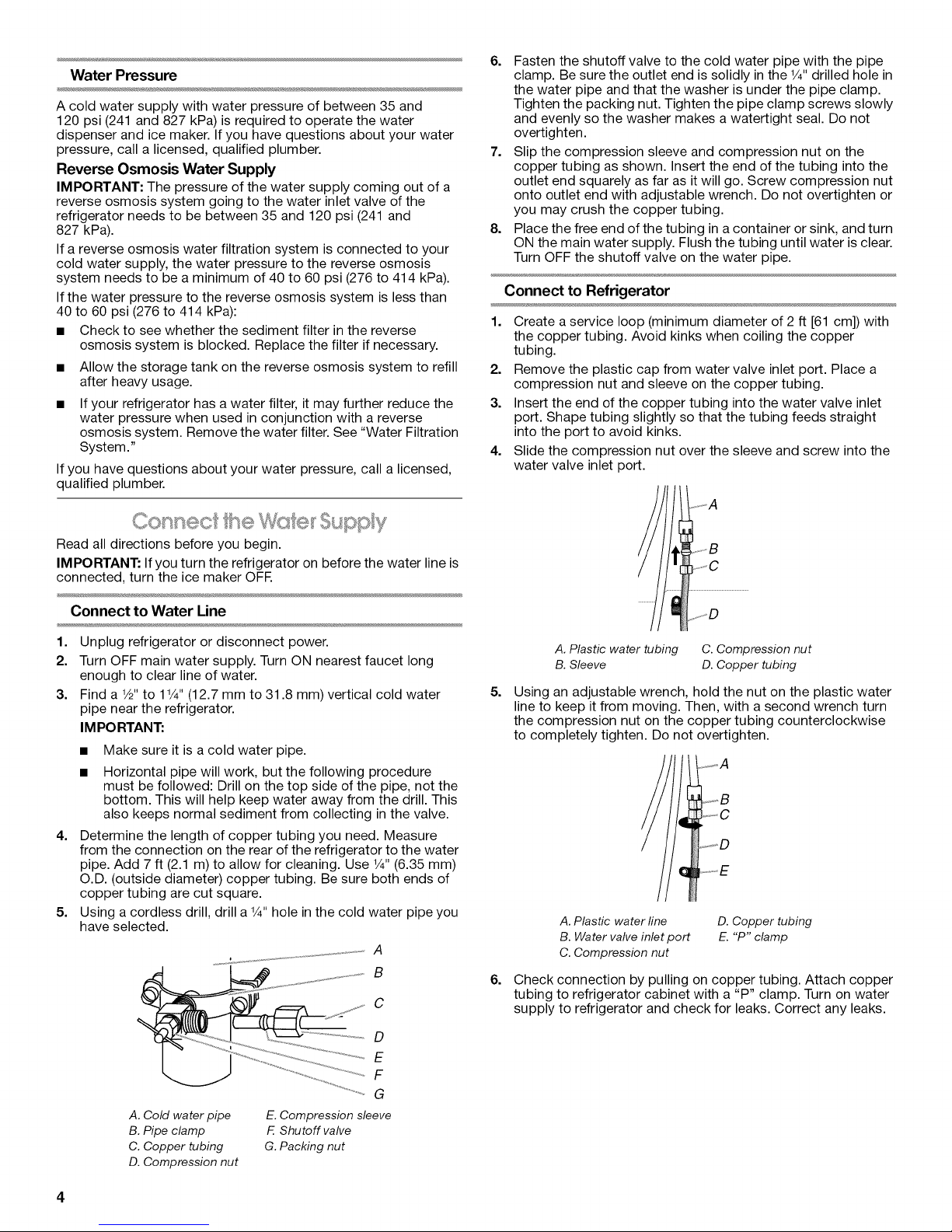

Connect to Refrigerator

1. Create a service loop (minimum diameter of 2 ft [61 cm]) with

the copper tubing. Avoid kinks when coiling the copper

tubing.

2. Remove the plastic cap from water valve inlet port. Place a

compression nut and sleeve on the copper tubing.

3. Insert the end of the copper tubing into the water valve inlet

port. Shape tubing slightly so that the tubing feeds straight

into the port to avoid kinks.

4. Slide the compression nut over the sleeve and screw into the

water valve inlet port.

, ,, _J _.,_,_ _j

Read all directions before you begin.

IMPORTANT: If you turn the refrigerator on before the water line is

connected, turn the ice maker OFF.

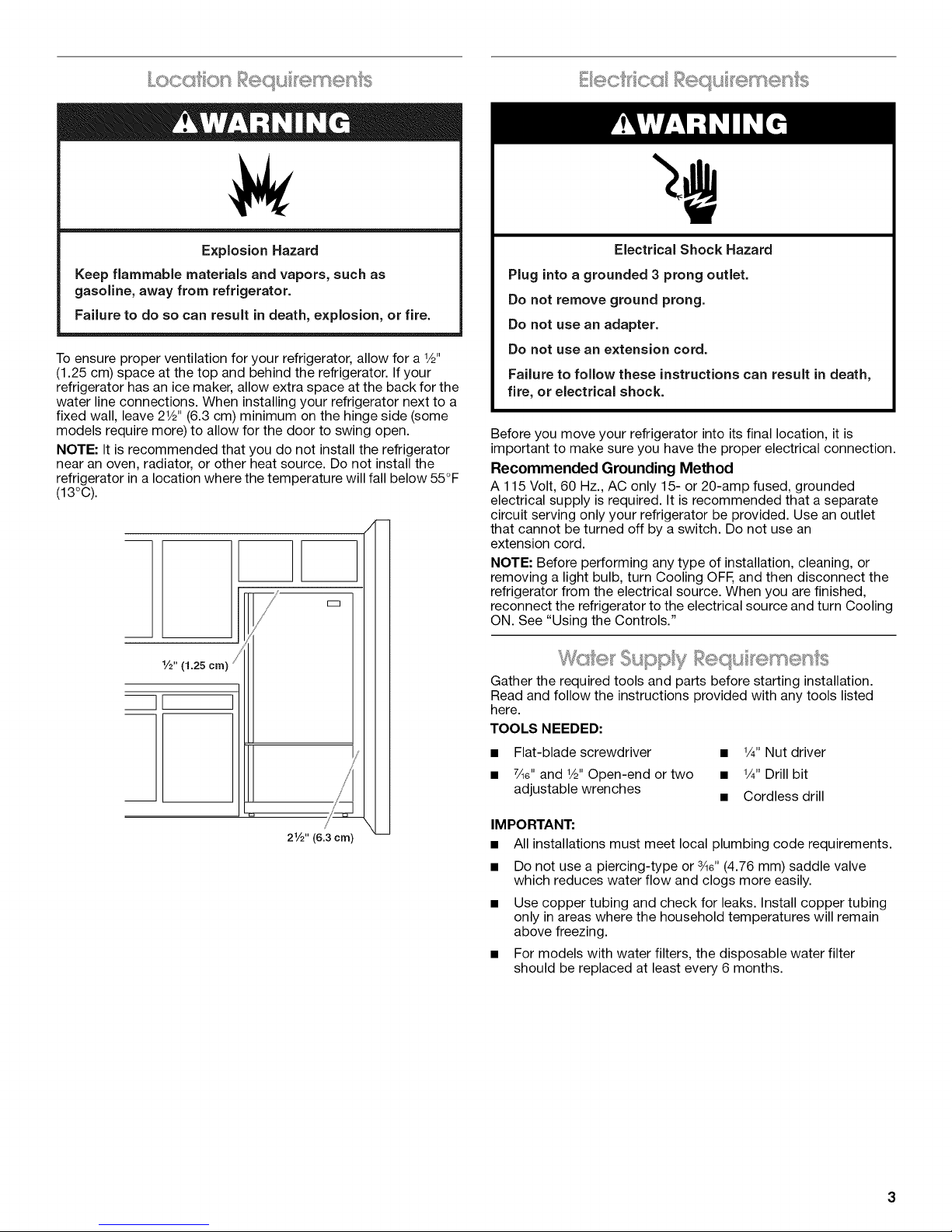

Connect to Water Line

1. Unplug refrigerator or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Find a 1/2"to 11/4"(12.7 mm to 31.8 mm) vertical cold water

pipe near the refrigerator.

IMPORTAN1"."

• Make sure it is a cold water pipe.

Horizontal pipe will work, but the following procedure

must be followed: Drill on the top side of the pipe, not the

bottom. This will help keep water away from the drill. This

also keeps normal sediment from collecting in the valve.

4. Determine the length of copper tubing you need. Measure

from the connection on the rear of the refrigerator to the water

pipe. Add 7 ft (2.1 m) to allow for cleaning. Use 1/4"(6.35 mm)

O.D. (outside diameter) copper tubing. Be sure both ends of

copper tubing are cut square.

5. Using a cordless drill, drill a V4"hole in the cold water pipe you

have selected.

B

C

D

E

F

G

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Compression nut

E. Compression sleeve

F. Shutoff valve

G.Packing nut

A. Plastic water tubing

B. Sleeve

5=

Using an adjustable wrench, hold the nut on the plastic water

C. Compression nut

D. Copper tubing

line to keep it from moving. Then, with a second wrench turn

the compression nut on the copper tubing counterclockwise

to completely tighten. Do not overtighten.

A. Plastic water fine

B. Water valve inlet port

C. Compression nut

6=

Check connection by pulling on copper tubing. Attach copper

D. Copper tubing

E. "P" clamp

tubing to refrigerator cabinet with a "P" clamp. Turn on water

supply to refrigerator and check for leaks. Correct any leaks.

Complete the Installation

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

NOTE: Allow 24 hours to produce the first batch of ice. Discard

the first three batches of ice produced. Allow 3 days to completely

fill the ice container.

Graphics are included later in this section.

Remove and Replace Handles

1. Using a3/32"or V8"Allen wrench, loosen the two setscrews

located on the side of each handle. See Graphics 1 and 2.

2. Pull the handle straight out from the door. Make sure you keep

the screws for reattaching the handles.

3. To replace the handles, reverse the directions.

Remove Doors and Hinges

IMPORTANT:

• Remove food and any adjustable door or utility bins from

doors.

• All graphics referenced in the following instructions are

included later in this section after "Final Steps."

TOOLS NEEDED: %e", 3/8",V4" hex-head socket wrench,

#2 Phillips screwdriver, and a flat-blade screwdriver.

1. Unplug refrigerator or disconnect power.

2. Keep the refrigerator doors closed until you are ready to lift

them free from the cabinet.

NOTE: Provide additional support for the refrigerator door

while the hinges are being removed. Do not depend on the

door gasket magnets to hold the door in place while you are

working.

3=

Starting with the right-hand side door, remove the parts for the

top hinge as shown inTop Hinge graphic. Lift the refrigerator

door from the bottom hinge pin.

NOTE: Remove the hinge pin cover from the bottom hinge pin

and keep it for later use. See Bottom Hinge graphic.

4. Before removing the left-hand side door, disconnect the wiring

plug located on top of the top hinge by wedging a flat-blade

screwdriver or your fingernail between the two sections. See

Wiring Plug graphic.

5. Remove the parts for the top hinge as shown in Top Hinge

graphic. Lift the left-hand side door from the bottom hinge pin.

NOTE: Remove the hinge pin cover from the bottom hinge pin

and keep it for later use. See Bottom Hinge graphic.

Replace Doors and Hinges

1=

Assemble the parts for the top hinge as shown in Top Hinge

graphic. Do not tighten the screws completely.

2.

Replace the parts for the bottom hinge as shown in Bottom

Hinge graphic. Tighten screws. Replace the refrigerator door.

NOTE: Provide additional support for the refrigerator door

while the hinges are being moved. Do not depend on the door

gasket magnets to hold the door in place while you are

working.

3. Align the door so that the bottom of the refrigerator door

aligns evenly with the top of the freezer drawer. Tighten all

screws.

4. Reconnect the wiring plug on top of the left-hand side

refrigerator door.

5. Replace the top hinge covers.

Remove and Replace Freezer Drawer Front

IMPORTANT: Two people may be required to remove and replace

the freezer drawer front. Graphics are included later in this

section.

Remove Drawer Front

1. Open the freezer drawer to full extension.

2. Loosen the four screws attaching the drawer glides to the

drawer front. See Drawer Front Removal graphic.

NOTE: Loosen screws three to four turns. Keep the screws in

the drawer front.

3. Lift drawer front upward and off the screws. See Drawer Front

Removal graphic.

Replace Drawer Front

1. Slide the drawer glides out of the freezer compartment. Insert

the screws in the top of the drawer front into the slots in the

drawer brackets. See Drawer Front Replacement graphic.

2. Pull the drawer brackets toward you to position the two

screws in the bottom of the drawer front into the brackets.

See Drawer Front Replacement graphic.

3. Completely tighten the four screws.

Final Steps

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to folow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

2. Return all removable door parts to doors and food to

refrigerator.

Top Hinges

::2:- B

A, Hinge Cover Screw

B, Top Hinge Cover

C, _6" Hex-Head Hinge Screws

D. Top Hinge

Bottom Hinges

A. Hinge Pin Cover

B, Bottom Hinge

C. Hinge Screws

Wiring Plug

C

\

\

@

A, Loosen 4 Door Bracket Screws

A. ½2" or _" Setscrews

A

A. ½2" or _" Setscrews

6

...... ..........e oot s

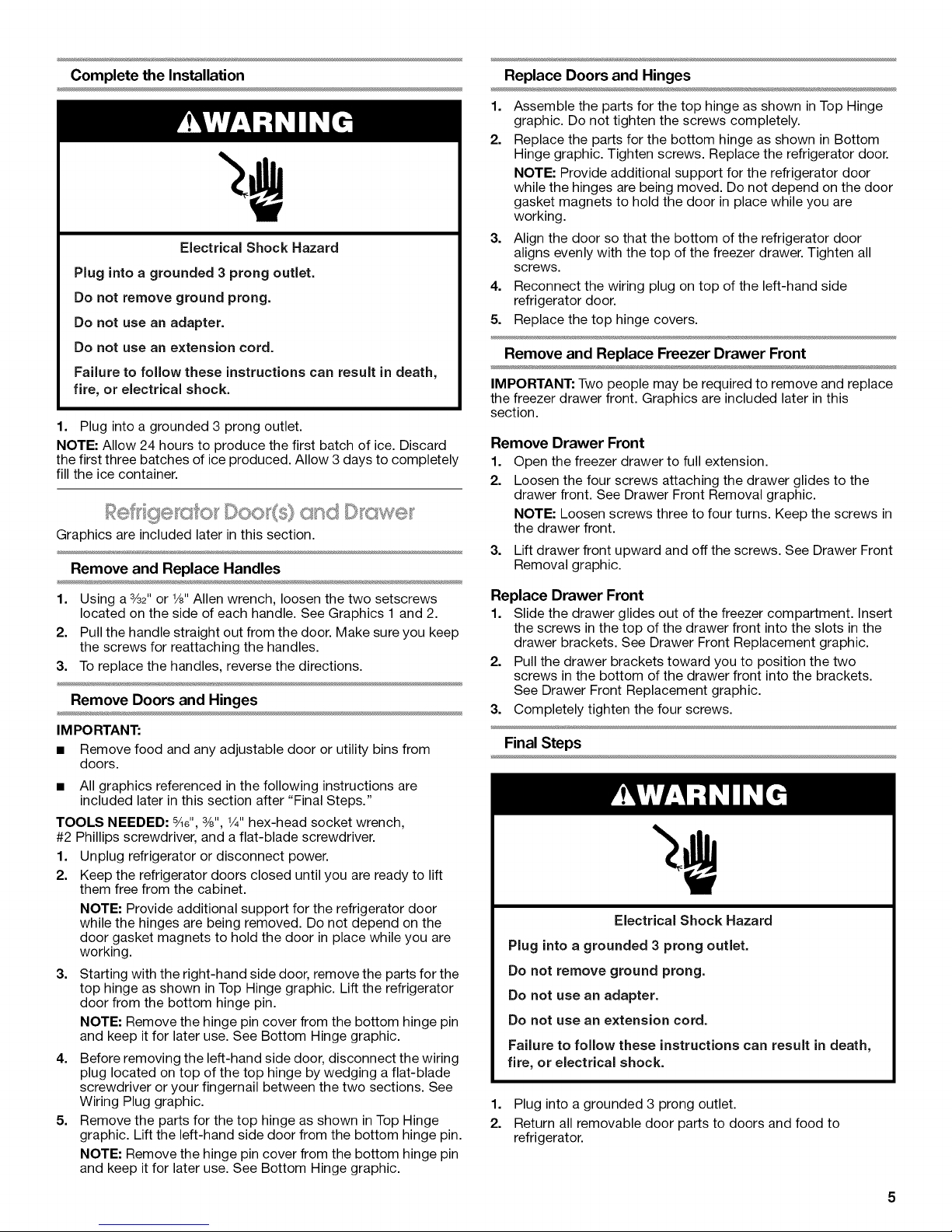

Your refrigerator has two adjustable, front leveling screws - one

on each side of the refrigerator base. If your refrigerator seems

unsteady or you want the door to close easier, use the instructions

below.

1. Remove the base grille. Grasp the grille firmly and pull it

toward you.

2. Raise or lower the cabinet.

Using a 1/4"hex driver, turn the leveling screw on each side to

raise or lower that side of the refrigerator.

NOTE: Having someone push against the top of the

refrigerator takes some weight off the leveling screws. This

makes it easier to turn the screws. It may take several turns of

the leveling screw to adjust the tilt of the refrigerator.

• To raise, turn the leveling screw clockwise.

• To lower, turn the leveling screw counterclockwise.

REFRIGERATORUSE

Jpe g ©oo s

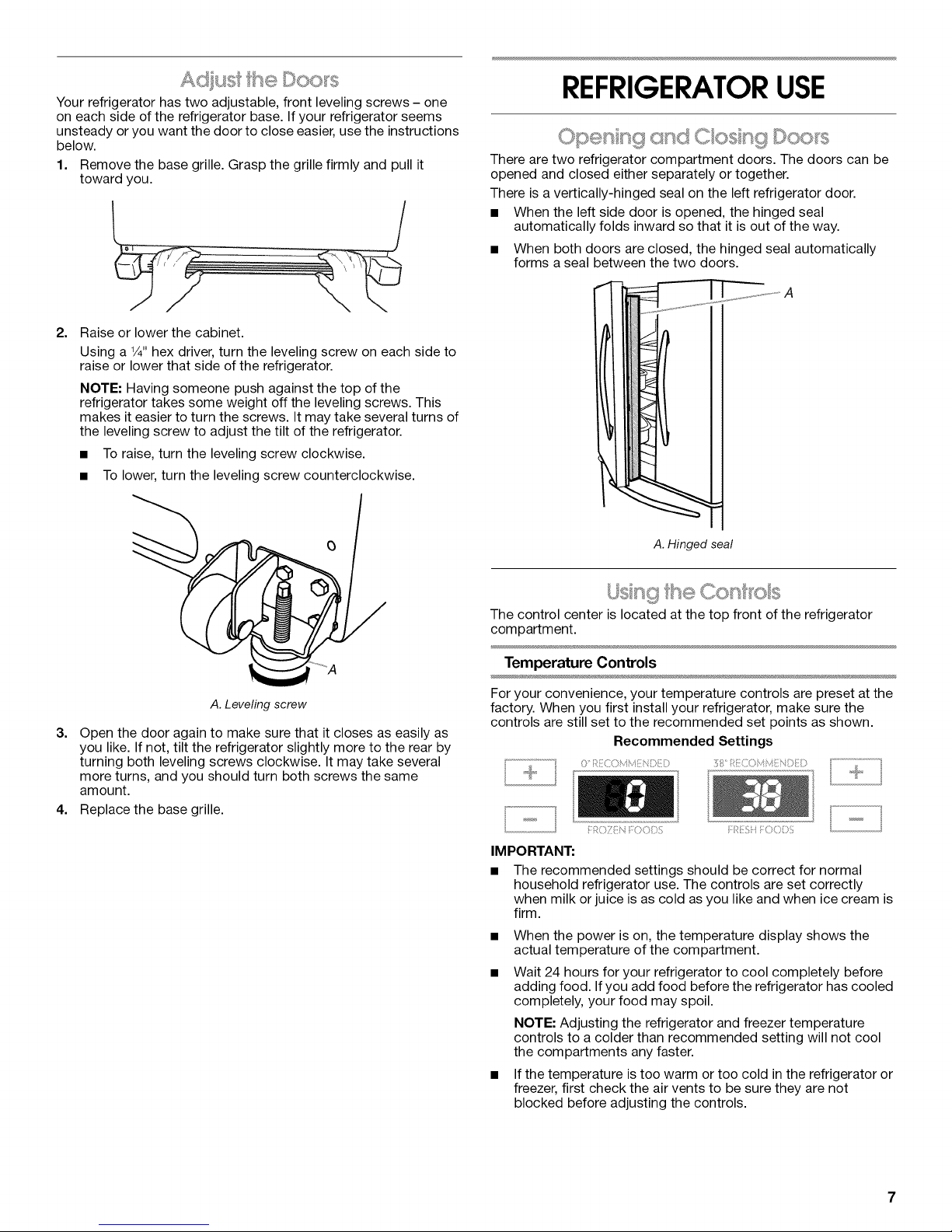

There are two refrigerator compartment doors. The doors can be

opened and closed either separately or together.

There is a vertically-hinged seal on the left refrigerator door.

• When the left side door is opened, the hinged seal

automatically folds inward so that it is out of the way.

• When both doors are closed, the hinged seal automatically

forms a seal between the two doors.

A

A. Leveling screw

3=

Open the door again to make sure that it closes as easily as

you like. If not, tilt the refrigerator slightly more to the rear by

turning both leveling screws clockwise. It may take several

more turns, and you should turn both screws the same

amount.

4. Replace the base grille.

A. Hinged seal

The control center is located at the top front of the refrigerator

compartment.

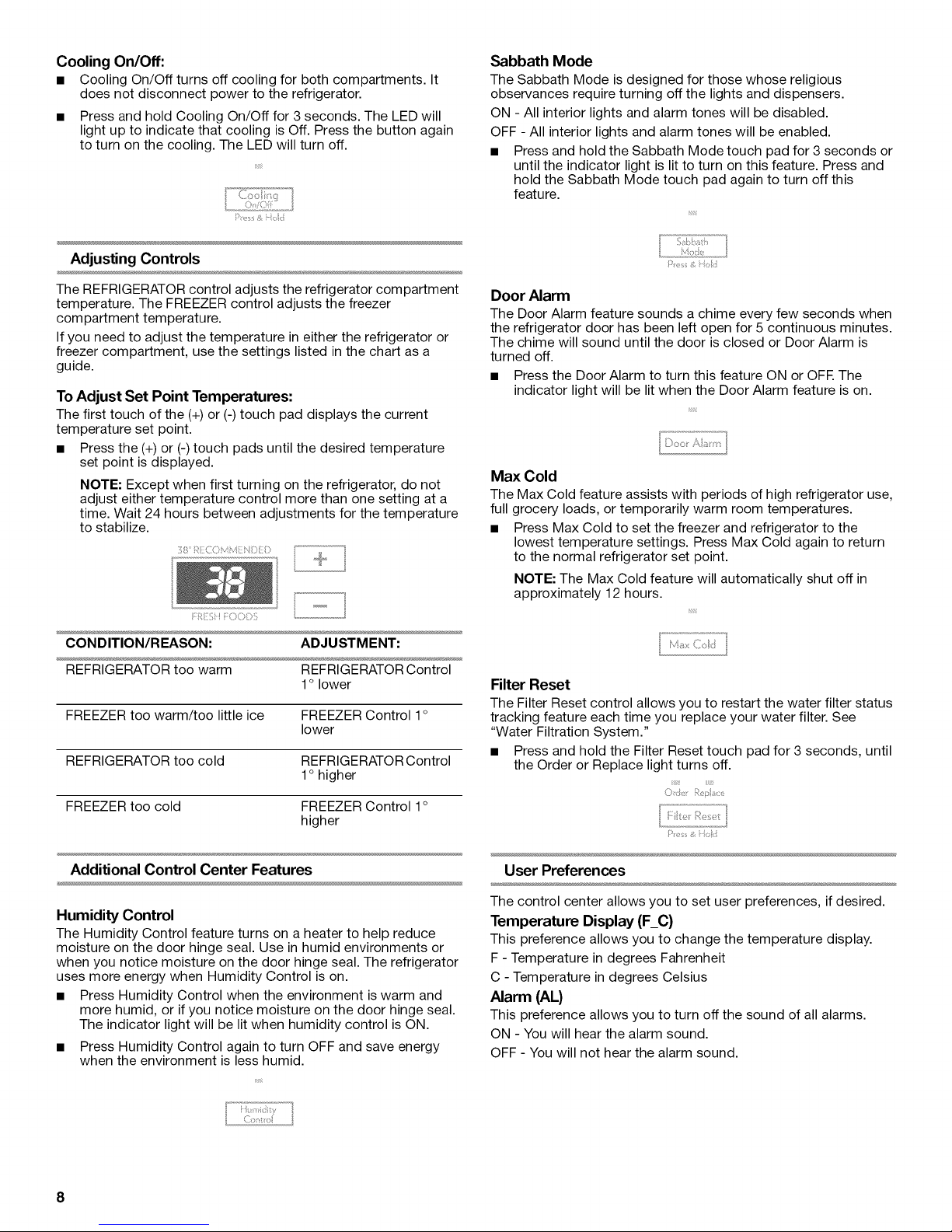

Temperature Controls

For your convenience, your temperature controls are preset at the

factory. When you first install your refrigerator, make sure the

controls are still set to the recommended set points as shown.

Recommended Settings

_,_ '_ _,_

:::R(7:'4 ::OODF; :: 7 }:

IMPORTANT:

The recommended settings should be correct for normal

household refrigerator use. The controls are set correctly

when milk or juice is as cold as you like and when ice cream is

firm.

When the power is on, the temperature display shows the

actual temperature of the compartment.

Wait 24 hours for your refrigerator to cool completely before

adding food. If you add food before the refrigerator has cooled

completely, your food may spoil.

NOTE: Adjusting the refrigerator and freezer temperature

controls to a colder than recommended setting will not cool

the compartments any faster.

If the temperature is too warm or too cold in the refrigerator or

freezer, first check the air vents to be sure they are not

blocked before adjusting the controls.

CoolingOn/Off:

• Cooling On/Off turns off cooling for both compartments. It

does not disconnect power to the refrigerator.

• Press and hold Cooling On/Off for 3 seconds. The LED will

light up to indicate that cooling is Off. Press the button again

to turn on the cooling. The LED will turn off.

Adjusting Controls

Sabbath Mode

The Sabbath Mode is designed for those whose religious

observances require turning off the lights and dispensers.

ON - All interior lights and alarm tones will be disabled.

OFF - All interior lights and alarm tones will be enabled.

• Press and hold the Sabbath Mode touch pad for 3 seconds or

until the indicator light is lit to turn on this feature. Press and

hold the Sabbath Mode touch pad again to turn off this

feature.

_ _i ¸ _

&

The REFRIGERATOR control adjusts the refrigerator compartment

temperature. The FREEZER control adjusts the freezer

compartment temperature.

If you need to adjust the temperature in either the refrigerator or

freezer compartment, use the settings listed in the chart as a

guide.

To Adjust Set Point Temperatures:

The first touch of the (+) or (-) touch pad displays the current

temperature set point.

• Press the (+) or (-) touch pads until the desired temperature

set point is displayed.

NOTE: Except when first turning on the refrigerator, do not

adjust either temperature control more than one setting at a

time. Wait 24 hours between adjustments for the temperature

to stabilize.

CONDITION/REASON: ADJUSTMENT:

REFRIGERATOR too warm REFRIGERATOR Control

1o lower

FREEZER too warm/too little ice FREEZER Control 1o

lower

REFRIGERATOR too cold REFRIGERATOR Control

1o higher

Door Alarm

The Door Alarm feature sounds a chime every few seconds when

the refrigerator door has been left open for 5 continuous minutes.

The chime will sound until the door is closed or Door Alarm is

turned off.

• Press the Door Alarm to turn this feature ON or OFF. The

indicator light will be lit when the Door Alarm feature is on.

Max Cold

The Max Cold feature assists with periods of high refrigerator use,

full grocery loads, or temporarily warm room temperatures.

• Press Max Cold to set the freezer and refrigerator to the

lowest temperature settings. Press Max Cold again to return

to the normal refrigerator set point.

NOTE: The Max Cold feature will automatically shut off in

approximately 12 hours.

Filter Reset

The Filter Reset control allows you to restart the water filter status

tracking feature each time you replace your water filter. See

"Water Filtration System."

• Press and hold the Filter Reset touch pad for 3 seconds, until

the Order or Replace light turns off.

FREEZER too cold FREEZER Control 1o

higher

Additional Control Center Features

Humidity Control

The Humidity Control feature turns on a heater to help reduce

moisture on the door hinge seal. Use in humid environments or

when you notice moisture on the door hinge seal. The refrigerator

uses more energy when Humidity Control is on.

• Press Humidity Control when the environment is warm and

more humid, or if you notice moisture on the door hinge seal.

The indicator light will be lit when humidity control is ON.

• Press Humidity Control again to turn OFF and save energy

when the environment is less humid.

8

User Preferences

The control center allows you to set user preferences, if desired.

Temperature Display (F C)

This preference allows you to change the temperature display.

F - Temperature in degrees Fahrenheit

C - Temperature in degrees Celsius

Alarm (AL)

This preference allows you to turn off the sound of all alarms.

ON - You will hear the alarm sound.

OFF - You will not hear the alarm sound.

To Access the User Preferences Menu:

1. Press and hold the Door Alarm touch pad for 3 seconds. The

preference name will appear in the Freezer display and the

preference status (F or C) or (ON or OFF) will appear in the

Refrigerator display.

2. Use the Freezer (+) or (-) touch pads to scroll through the

preference names. When the desired preference name is

displayed, press the Refrigerator (+) or (-) touch pads to

change the preference status.

3. Set your preferences by pressing and holding the Door Alarm

touch pad for 3 seconds, or by shutting the refrigerator

compartment door.

You can control the amount of humidity in the moisture-sealed

crisper. Depending on your model, adjust the control to any

setting between FRUIT and VEGETABLES or LOW and HIGH.

FRUIT / LOW (open) for best storage of fruits and vegetables with

skins.

VEGETABLES / HIGH (closed) for best storage of fresh, leafy

vegetables.

ce c o,e

Ice Production Rate

• The ice maker should produce a complete batch of ice

approximately every 3 hours.

• To increase ice production, lower the freezer and refrigerator

temperature. See "Using the Controls." Wait 24 hours

between adjustments.

Remember

Allow 24 hours to produce the first batch of ice. Discard the

first three batches of ice produced.

The quality of your ice will be only as good as the quality of the

water supplied to your ice maker. Avoid connecting the ice

maker to a softened water supply. Water softener chemicals

(such as salt) can damage parts of the ice maker and lead to

poor quality ice. If asoftened water supply cannot be avoided,

make sure the water softener is operating properly and is well

maintained.

Do not store anything on top of the ice maker or in the ice

storage bin.

Turning the Ice Maker On/Off

To turn the ice maker ON, simply lower the wire shutoff arm.

To manually turn the ice maker OFF, lift the wire shutoff arm to the

OFF (arm up) position and listen for the click.

NOTE: Your ice maker has an automatic shutoff. As ice is made,

the ice cubes will fill the ice storage bin and the ice cubes will

raise the wire shutoff arm to the OFF (arm up) position. Do not

force the wire shutoff arm up or down.

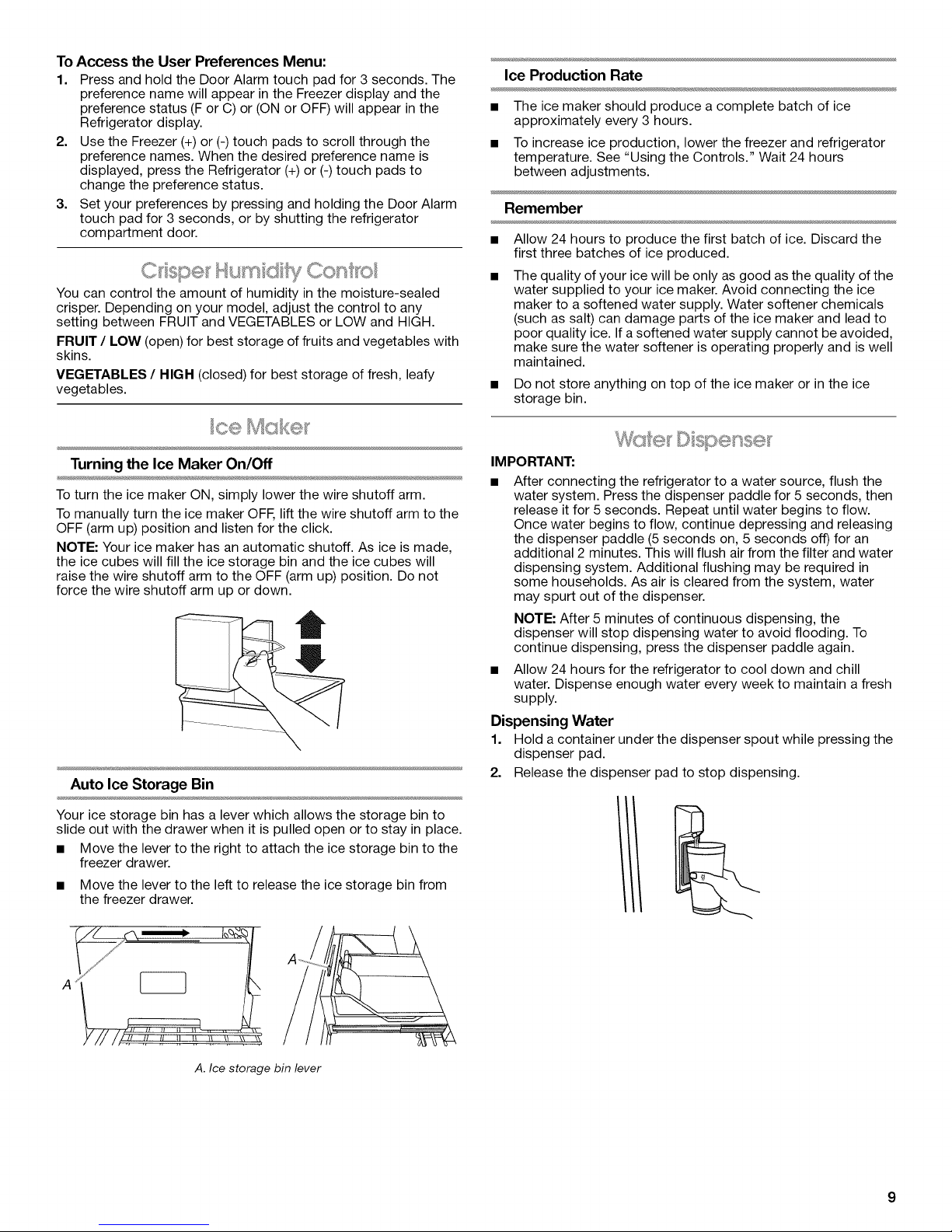

Auto Ice Storage Bin

Your ice storage bin has a lever which allows the storage bin to

slide out with the drawer when it is pulled open or to stay in place.

• Move the lever to the right to attach the ice storage bin to the

freezer drawer.

• Move the lever to the left to release the ice storage bin from

the freezer drawer.

IMPORTANT:

After connecting the refrigerator to a water source, flush the

water system. Press the dispenser paddle for 5 seconds, then

release it for 5 seconds. Repeat until water begins to flow.

Once water begins to flow, continue depressing and releasing

the dispenser paddle (5 seconds on, 5 seconds off) for an

additional 2 minutes. This will flush air from the filter and water

dispensing system. Additional flushing may be required in

some households. As air is cleared from the system, water

may spurt out of the dispenser.

NOTE: After 5 minutes of continuous dispensing, the

dispenser will stop dispensing water to avoid flooding. To

continue dispensing, press the dispenser paddle again.

• Allow 24 hours for the refrigerator to cool down and chill

water. Dispense enough water every week to maintain a fresh

supply.

Dispensing Water

1. Hold a container under the dispenser spout while pressing the

dispenser pad.

2. Release the dispenser pad to stop dispensing.

1

A

// // // ii 11 in u _1 \_ \\ \\

A. Ice storage bin lever

The water filter is located in the upper right-hand corner of the

refrigerator compartment.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

Water Filter Status Lights

The water filter status lights will remind you when it is time to

order and replace your water filter. When the yellow (Order) light is

on, it is almost time to change the water filter. When the red

(Replace) light is on, a new water filter should be installed. The

disposable water filter should be replaced at least every 6 months

OR earlier if the flow of water to your water dispenser or ice maker

decreases noticeably.

After replacing the water filter, press and hold Reset Filter or Filter

Reset (depending on your model) for 3 seconds. The Order and

Replace indicator lights will blink and then go off when the system

is reset. See "Using the Controls."

Replacing the Water Filter

To purchase a replacement water filter, model UKF8001AXX-750

or UKF8001AXX-200, contact your dealer or call 1-877-232-6771

U.S.A. or 1-800-807-6777 Canada.

IMPORTANT: Air trapped inthe water system may cause water

and filter to eject. Always dispense water for at least 2 minutes

before removing the filter or blue bypass cap.

1. Turn filter counterclockwise to remove.

2. Remove sealing label from replacement filter and insert the

filter end into the filter head.

3. Turn the filter clockwise until it stops. Snap the filter cover

closed.

NOTE: The dispenser feature may be used without a water filter

installed. Your water will not be filtered. Ifthis option is chosen,

replace the filter with the blue bypass cap.

REFRIGERATORCARE

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Both the refrigerator and freezer sections defrost automatically.

However, clean both sections about once a month to avoid

buildup of odors. Wipe up spills immediately.

IMPORTANT: Because air circulates between both sections, any

odors formed in one section will transfer to the other. You must

thoroughly clean both sections to eliminate odors. To avoid odor

transfer and drying out of food, wrap or cover foods tightly.

To Clean Your Refrigerator:

NOTE: Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning waxes,

concentrated detergents, bleaches or cleansers containing

petroleum products on plastic parts, interior and door liners or

gaskets. Do not use paper towels, scouring pads, or other harsh

cleaning tools.

1. Unplug refrigerator or disconnect power.

2. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

3. Clean the exterior surfaces.

Broken Glass Hazard

Do not hit refrigerator glass doors.

Protect glass surface and edges during installation or

removal of doors.

Failure to do so can result in serious eye injury or

minor cuts.

Glass door panels: Wash glass door panels with a clean

sponge or soft cloth and a mild detergent in warm water.

NOTE: Do not hit the glass with pots, pans, furniture, toys, or

other objects. Scratching, hitting, jarring or stressing the glass

may weaken its structure, causing an increased likelihood of

breakage at a later date.

Painted metal and stainless steel: Wash stainless steel and

painted metal exteriors with a clean sponge or soft cloth and a

mild detergent in warm water.

To keep your stainless steel refrigerator looking like new

and to remove minor scuffs or marks, it is suggested that

you use the manufacturer's approved Stainless Steel

Cleaner and Polish, Part Number 20000008. To order the

cleaner, call 1-877-232-6771 U.S.A. or 1-800-807-6777

Canada.

IMPORTANT: This cleaner is for stainless steel parts only!

Do not allow the Stainless Steel Cleaner and Polish to come

into contact with any plastic parts such as the trim pieces,

dispenser covers or door gaskets. If unintentional contact

does occur, clean plastic part with a sponge and mild

detergent in warm water. Dry thoroughly with a soft cloth.

4=

There is no need for routine condenser cleaning in normal

home operating environments. If the environment is

particularly greasy or dusty, or there is significant pet traffic in

the home, the condenser should be cleaned every 2 to

3 months to ensure maximum efficiency.

If you need to clean the condenser:

• Remove the base grille.

• Use a vacuum cleaner with a soft brush to clean the grille,

the open areas behind the grille and the front surface area

of the condenser.

• Replace the base grille when finished.

5.

Plug in refrigerator or reconnect power.

10

_° _'_C_ _ _ ' B_ '_¸¸

NOTE: Not all appliance bulbs will fit your refrigerator. Be sure to

replace the bulb with an appliance bulb of the same size, shape,

and wattage (no greater than 40 watts).

Changing the Refrigerator Light Bulb

1. Unplug the refrigerator or disconnect power.

2. Slide the light shield toward the back of the compartment to

release it from the light assembly.

TROUBLESHOOTING

First try the solutions suggested here or visit our website and reference FAQs (Frequently Asked Questions)

to possibly avoid the cost of a service call.

In the U.S.A., www.jennair.com In Canada, www.jennair.ca

3.

Replace burned-out bulb(s) with appliance bulb(s) no greater

than 40 watts.

4.

Replace the light shield by inserting the tabs on the shield into

the liner holes on each side of light assembly. Slide the shield

toward the front until it locks into place.

NOTE: To avoid damaging the light shield, do not force the

shield beyond the locking point.

5. Plug in refrigerator or reconnect power.

Changing the Freezer Light Bulb

1. Unplug refrigerator or disconnect power.

2. Remove the burned-out bulb and replace it with an appliance

bulb no greater than 40 watts.

3. Plug in refrigerator or reconnect power.

The refrigerator will not operate

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Power cord unplugged? Plug into a grounded 3 prong outlet.

Is outlet working? Plug in a lamp to see if the outlet is

working.

Household fuse blown or circuit breaker tripped? Replace

the fuse or reset the circuit breaker. If the problem continues,

call an electrician.

Are controls on? Make sure the refrigerator controls are on.

See "Using the Control(s)."

New installation? Allow 24 hours following installation for the

refrigerator to cool completely.

NOTE: Adjusting the temperature controls to coldest setting

will not cool either compartment more quickly.

The motor seems to run too much

Your new refrigerator may run longer than your old one due to its

high-efficiency compressor and fans. The unit may run even

longer if the room is warm, a large food load is added, doors are

opened often, or if the doors have been left open.

The refrigerator seems noisy

Refrigerator noise has been reduced over the years. Due to this

reduction, you may hear intermittent noises from your new

refrigerator that you did not notice from your old model. Below are

listed some normal sounds with explanations.

• Buzzing - heard when the water valve opens to fill the ice

maker

Pulsating - fans/compressor adjusting to optimize

performance

Hissing/Rattling - flow of refrigerant, movement of water

lines, or from items placed on top of the refrigerator

Sizzling/Gurgling - water dripping on the heater during

defrost cycle

Popping - contraction/expansion of inside walls, especially

during initial cool-down

Water running - may be heard when ice melts during the

defrost cycle and water runs into the drain pan

Creaking/Cracking - occurs as ice is being ejected from the

ice maker mold.

The doors will not close completely

• Door blocked open? Move food packages away from door.

• Bin or shelf in the way? Push bin or shelf back in the correct

position.

11

The doors are difficult to open

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Freezer door closed completely? Firmly close the freezer

compartment door. If the freezer compartment door will not

close all the way, see "The doors will not close completely,"

earlier in this section.

Large amount of ice recently removed? Allow 24 hours for

ice maker to produce more ice.

Ice cube jammed in the ice maker ejector arm?

Remove ice from the ejector arm with a plastic utensil.

Water filter installed on the refrigerator? Remove filter and

operate ice maker. If ice volume improves, then the filter may

be clogged or incorrectly installed. Replace filter or reinstall it

correctly.

Reverse osmosis water filtration system connected to

your cold water supply? This can decrease water pressure.

See "Water Supply Requirements."

• Gaskets dirty or sticky? Clean gaskets and contact surfaces

with mild soap and warm water. Rinse and dry with soft cloth.

_s_ _'_,_:_::_f",' _ ,_+,_+1._÷4__s_>_,_t_ _

Temperature is too warm

• New installation? Allow 24 hours following installation for the

refrigerator to cool completely.

• Door(s) opened often or left open? Allows warm air to enter

refrigerator. Minimize door openings and keep doors fully

closed.

Large load of food added? Allow several hours for

refrigerator to return to normal temperature.

Controls set correctly for the surrounding conditions?

Adjust the controls a setting colder. Check temperature in

24 hours. See "Using the Control(s)."

There is interior moisture buildup

NOTE: Some moisture buildup is normal.

• Humid room? Contributes to moisture buildup.

• Door(s) opened often or left open? Allows humid air to enter

refrigerator. Minimize door openings and keep doors fully

closed.

The ice maker is not producing ice or not enough ice

• Refrigerator connected to a water supply and the supply

shutoff valve turned on? Connect refrigerator to water

supply and turn water shutoff valve fully open.

• Kink in the water source line? A kink in the line can reduce

water flow. Straighten the water source line.

• Ice maker turned on? Make sure wire shutoff arm or switch

(depending on model) is in the ON position.

• New installation? Wait 24 hours after ice maker installation

for ice production to begin. Wait 72 hours for full ice

production.

The ice cubes are hollow or small

NOTE: This is an indication of low water pressure.

• Water shutoff valve not fully open? Turn the water shutoff

valve fully open.

Kink in the water source line? A kink in the line can reduce

water flow. Straighten the water source line.

Water filter installed on the refrigerator? Remove filter and

operate ice maker. If ice quality improves, then the filter may

be clogged or incorrectly installed. Replace filter or reinstall it

correctly.

Reverse osmosis water filtration system connected to

your cold water supply? This can decrease water pressure.

See "Water Supply Requirements."

Questions remain regarding water pressure? Call a

licensed, qualified plumber.

Off-taste, odor or gray color in the ice

New plumbing connections? New plumbing connections

can cause discolored or off-flavored ice.

Ice stored too long? Discard ice. Wash ice bin. Allow

24 hours for ice maker to make new ice.

Odor transfer from food? Use airtight, moisture proof

packaging to store food.

Are there minerals (such as sulfur) in the water? A water

filter may need to be installed to remove the minerals.

Water filter installed on the refrigerator? Gray or dark

discoloration in ice indicates that the water filtration system

needs additional flushing. Flush the water system before using

a new water filter. Replace water filter when indicated. See

"Water Filtration System."

The water dispenser will not operate properly

• Refrigerator connected to a water supply and the supply

shutoff valve turned on? Connect refrigerator to water

supply and turn water shutoff valve fully open.

• Kink in the water source line? Straighten the water source

line.

• New installation? Flush and fill the water system. See "Water

Dispenser."

12

Is the water pressure at least 35 psi (241 kPa)? The water

pressure to the home determines the flow from the dispenser.

See "Water Supply Requirements."

Water filter installed on the refrigerator? Remove filter and

operate dispenser. If water flow increases, the filter may be

clogged or incorrectly installed. Replace filter or reinstall it

correctly.

Refrigerator door closed completely? Close the door firmly.

If it does not close completely, see "The doors will not close

completely," earlier in this section.

Recently removed the doors? Make sure the water

dispenser wire/tube assembly has been properly reconnected.

See "Refrigerator Door(s) and Drawer."

Reverse osmosis water filtration system connected to

your cold water supply? This can decrease water pressure.

See "Water Supply Requirements."

Water is leaking from the dispenser system

NOTE: One or two drops of water after dispensing is normal.

• Glass not being held under the dispenser long enough?

Hold the glass under the dispenser 2 to 3 seconds after

releasing the dispenser lever.

WATERFILTERCERTIFICATIONS

New installation? Flush the water system. See "Water

Dispenser."

Recently changed water filter? Flush the water system. See

"Water Dispenser."

Water on the floor near the base grille? Make sure the water

dispenser tube connections are fully tightened. See

"Refrigerator Door(s) and Drawer."

Water from the dispenser is warm

NOTE: Water from the dispenser is only chilled to 50°F (10°C).

• New installation? Allow 24 hours after installation for the

water supply to cool completely.

• Recently dispensed large amount of water? Allow 24 hours

for water supply to cool completely.

• Water not been recently dispensed? The first glass of water

may not be cool. Discard the first glass of water.

• Refrigerator connected to a cold water pipe? Make sure

the refrigerator is connected to a cold water pipe. See "Water

Supply Requirements."

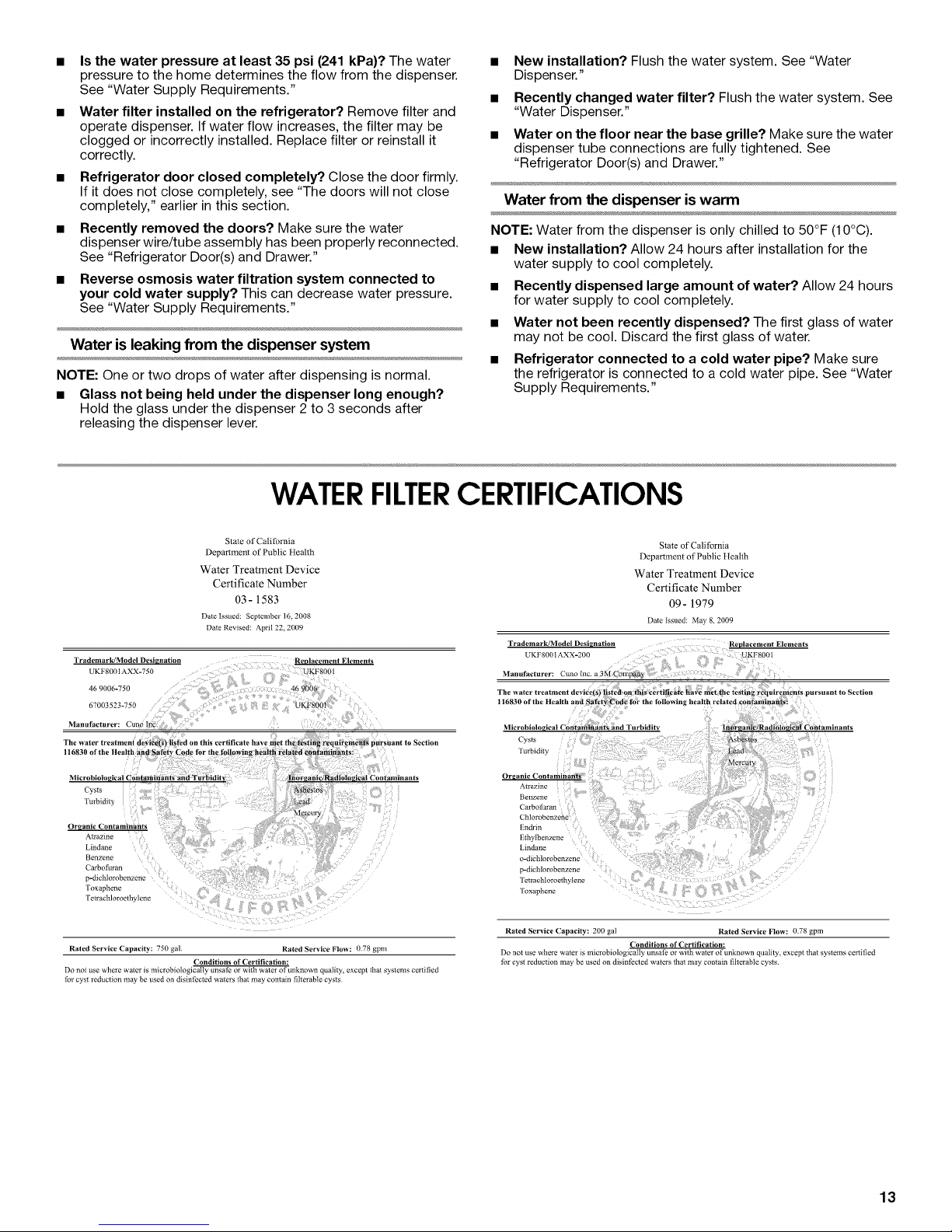

State of California

Department of Public Health

WaterTreatment Device

CertificateNumber

03- 1583

Dat_ Issued: September 16, 2008

Date Revised: April 22, 2009

Trademark/Model Designation

UKI:8001 AXX-750

469006-750

67003523-750

Manufacturer: Cuno

Cysts

Turbidity

Organic Contaminahts

Atrazine

Lindane

Carbofuran

p-dichlorobenzene ,

Toxaphene

Tetrachloroethylene

Rated Service CapaciD': 750 gal. Rated Service Flow: 0.78 gpm

Do ilo(use where water is microbiologically unsalb or wilh water o[" ur&nown quality, except that systems certified

lbl cys_ reduction may be used on disJnl_ctcd waters that may contain Iilterable cysts

Conditions of Certification:

State of California

Department of Public tlealtb

Water Treatment Device

CertificateNumber

09- 1979

Date Issued: May 8, 2009

Trademark/Model Designation Replacement Etenlents

UKF8001 AXX-200 UK F800

Manufacturer: ('uno In_ a3M ('ompally

The _vater treatment device(s) )isted on this e_rtfficate |la_e met the testing _:equire)gnents pursuant to Section

116830 of the Health and Safety _}ode lor the |Mlowin8 health related eontaminanI_:

Microbiological Contaminants and "1urbiditv

Cyst_

Turbidity

Organic Contaminants

Atrazine

Benzene

Carbofuran

Chlorobenzene

Endrm

Ethy/bcnzene

Lindane

o-dichlorobenzcnc

p-dichlorobenzcne

TetrachIoroethylcne

I'oxaphcne

Rated Service Capacity: 200 gal Rated Service Flow: 0.78 gpm

Do not use where water is microbiologically unsali_ or with watel of unknown qua]fly, except that systems certil_cd

for cyst reduction may be used on disinfected waters that may contain fiherabIe cysts•

Conditions of Certification:

13

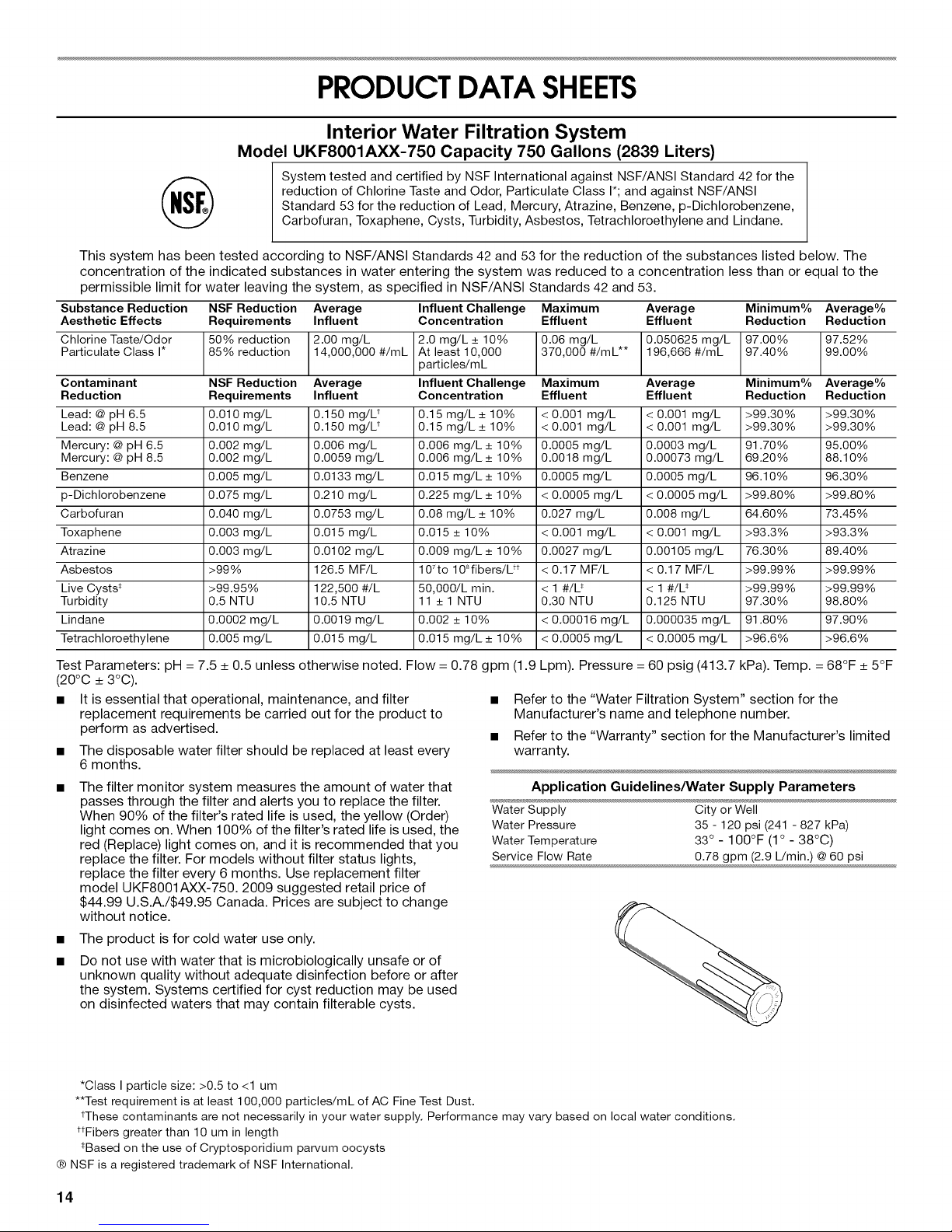

PRODUCTDATASHEETS

Interior Water Filtration System

Model UKF8001AXX-750 Capacity 750 Gallons (2839 Liters)

System tested and certified by NSF International against NSF/ANSI Standard 42 for the

reduction of Chlorine Taste and Odor, Particulate Class I*; and against NSF/ANSI

Standard 53 for the reduction of Lead, Mercury, Atrazine, Benzene, p-Dichlorobenzene,

Carbofuran, Toxaphene, Cysts, Turbidity, Asbestos, Tetrachloroethylene and Lindane.

This system has been tested according to NSF/ANSI Standards 42 and 53 for the reduction of the substances listed below. The

concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the

Substance Reduction NSF Reduction Average Influent Challenge Maximum Average Minimum% Average%

Aesthetic Effects Requirements Influent Concentration Effluent Effluent Reduction Reduction

Chlorine Taste/Odor 50% reduction 2.00 mg/L 2.0 mg/L + 10% 0.06 mg/L ** 0.050625 mg/L 97.00% 97.52%

Particulate Class I* 85% reduction 14,000,000 #/mL Atparticles/mLleast10,000 370,000 #/mL 196,666 #/mL 97.40% 99.00%

Contaminant NSF Reduction Average Influent Challenge Maximum Average Minimum% Average%

Reduction Requirements Influent Concentration Effluent Effluent Reduction Reduction

Lead: @ pH 6.5 0.010 mg/L 0.150 mg/U 0.15 mg/L + 10% < 0.001 mg/L < 0.001 mg/L >99.30% >99.30%

Lead: @ pH 8.5 0.010 mg/L 0.150 mg/U 0.15 mg/L _+10% < 0.001 mg/L < 0.001 mg/L >99.30% >99.30%

Mercury: @ pH 6.5 0.002 mg/L 0.006 mg/L 0.006 mg/L + 10% 0.0005 mg/L 0.0003 mg/L 91.70% 95.00%

Mercury: @ pH 8.5 0.002 mg/L 0.0059 mg/L 0.006 mg/L _+10% 0.0018 mg/L 0.00073 mg/L 69.20% 88.10%

Benzene 0.005 mg/L 0.0133 mg/L 0.015 mg/L _+10% 0.0005 mg/L 0.0005 mg/L 96.10% 96.30%

p-Dichlorobenzene 0.075 mg/L 0.210 mg/L 0.225 mg/L _+10% < 0.0005 mg/L < 0.0005 mg/L >99.80% >99.80%

Carbofuran 0.040 mg/L 0.0753 mg/L 0.08 mg/L _+10% 0.027 mg/L 0.008 mg/L 64.60% 73.45%

Toxaphene 0.003 mg/L 0.015 mg/L 0.015 _+10% < 0.001 mg/L < 0.001 mg/L >93.3% >93.3%

Atrazine 0.003 mg/L 0.0102 mg/L 0.009 mg/L _+10% 0.0027 mg/L 0.00105 mg/L 76.30% 89.40%

Asbestos >99% 126.5 MF/L 107to 108fibers/L tt < 0.17 MF/L < 0.17 MF/L >99.99% >99.99%

Live Cysts _ >99.95% 122,500 #/L 50,000/L min. < 1 #/U < 1 #/U >99.99% >99.99%

Turbidity 0.5 NTU 10.5 NTU 11 _+1 NTU 0.30 NTU 0.125 NTU 97.30% 98.80%

Lindane 0.0002 mg/L 0.0019 mg/L 0.002 _+10% < 0.00016 mg/L 0.000035 mg/L 91.80% 97.90%

Tetrachloroethylene 0.005 mg/L 0.015 mg/L 0.015 mg/L _+10% < 0.0005 mg/L < 0.0005 mg/L >96.6% >96.6%

system, as specified in NSF/ANSI Standards 42 and 53.

Test Parameters: pH = 7.5 _+0.5 unless otherwise noted. Flow = 0.78 gpm (1.9 Lpm). Pressure = 60 psig (413.7 kPa). Temp. = 68°F _+5°F

(20°0 _+3°0).

• It is essential that operational, maintenance, and filter •

replacement requirements be carried out for the product to

perform as advertised.

• The disposable water filter should be replaced at least every

6 months.

The filter monitor system measures the amount of water that

passes through the filter and alerts you to replace the filter.

When 90% of the filter's rated life is used, the yellow (Order)

light comes on. When 100% of the filter's rated life is used, the

red (Replace) light comes on, and it is recommended that you

replace the filter. For models without filter status lights,

Refer to the "Water Filtration System" section for the

Manufacturer's name and telephone number.

Refer to the "Warranty" section for the Manufacturer's limited

warranty.

Application Guidelines/Water Supply Parameters

Water Supply City or Well

Water Pressure 35 - 120 psi (241 - 827 kPa)

Water Temperature 33 ° - 100°F (1o _ 38oc)

Service Flow Rate 0.78 gpm (2.9 L!min.) @60 psi

replace the filter every 6 months. Use replacement filter

model UKF8001AXX-750.2009 suggested retail price of

$44.99 U.S.A./S49.95 Canada. Prices are subject to change

without notice.

The product is for cold water use only.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system. Systems certified for cyst reduction may be used

on disinfected waters that may contain filterable cysts.

*Class I particle size: >0.5 to <1 um

**Test requirement is at least 100,000 particles/mL of AC Fine Test Dust.

tThese contaminants are not necessarily in your water supply. Performance may vary based on local water conditions.

ttFibers greater than 10 um in length

_Based on the use of Cryptosporidium parvum oocysts

® NSF is a registered trademark of NSF International.

14

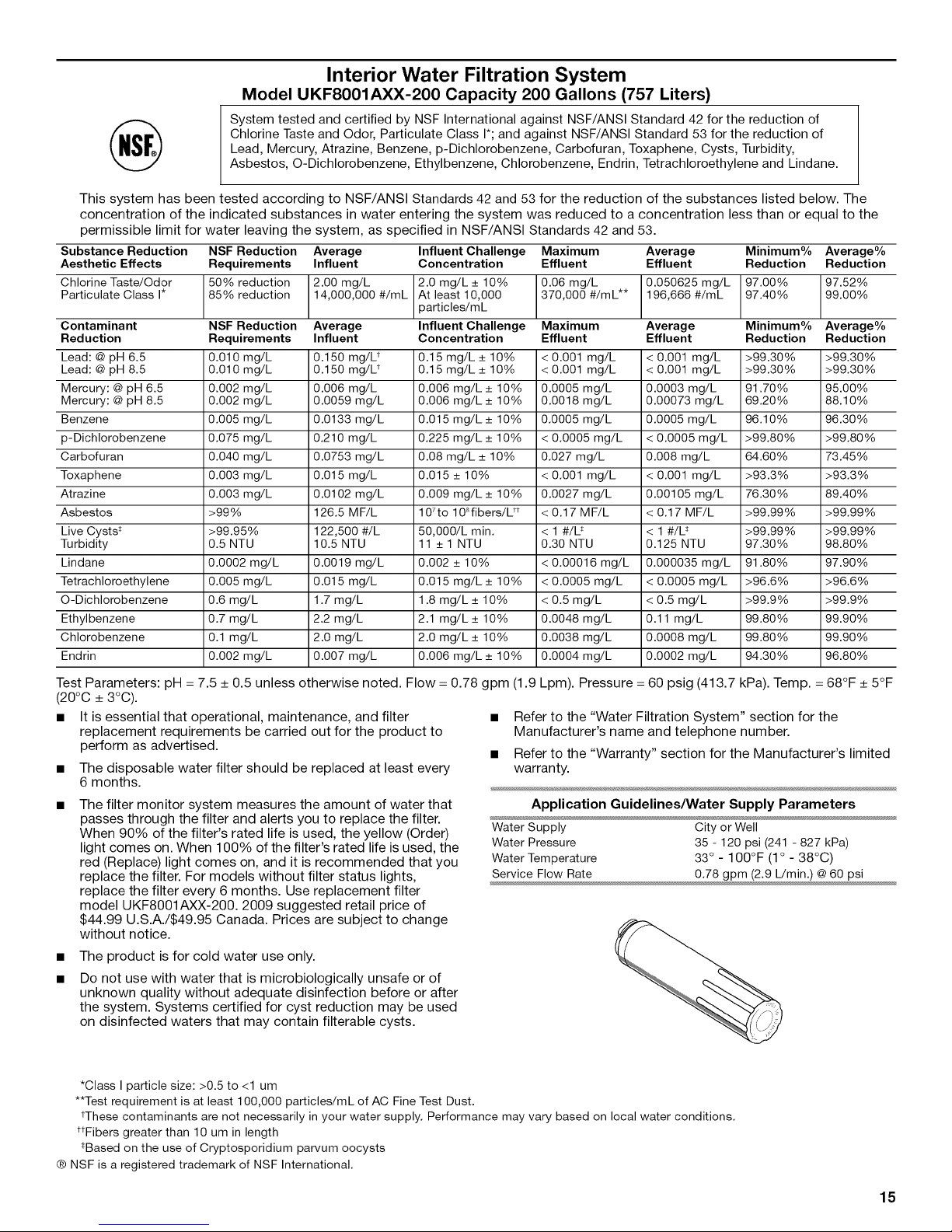

Interior Water Filtration System

Model UKF8001AXX-200 Capacity 200 Gallons (757 Liters)

Chlorine Taste and Odor, Particulate Class I*; and against NSF/ANSI Standard 53 for the reduction of

Lead, Mercury, Atrazine, Benzene, p-Dichlorobenzene, Carbofuran, Toxaphene, Cysts, Turbidity,

System tested and certified by NSF International against NSF/ANSI Standard 42 for the reduction of

Asbestos, O-Dichlorobenzene, Ethylbenzene, Chlorobenzene, Endrin, Tetrachloroethylene and Lindane.

This system has been tested according to NSF/ANSI Standards 42 and 53 for the reduction of the substances listed below. The

concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system, as specified in NSF/ANSI Standards 42 and 53.

Substance Reduction NSF Reduction Average Influent Challenge Maximum Average Minimum% Average%

Aesthetic Effects Requirements Influent Concentration Effluent Effluent Reduction Reduction

Chlorine Taste/Odor 50% reduction 2.00 mg/L 2.0 mg/L _+10% 0.06 mg/L ** 0.050625 mg/L 97.00% 97.52%

Particulate Class I* 85% reduction 14,000,000 #/mL At least 10,000 370,000 #/mL 196,666 #/mL 97.40% 99.00%

Contaminant NSF Reduction Average Influent Challenge Maximum Average Minimum% Average%

Reduction Requirements Influent Concentration Effluent Effluent Reduction Reduction

Lead: @ pH 6.5 0.010 mg/L 0.150 mg/U 0.15 mg/L + 10% < 0.001 mg/L < 0.001 mg/L >99.30% >99.30%

Lead: @ pH 8.5 0.010 mg/L 0.150 mg/U 0.15 mg/L _+10% < 0.001 mg/L < 0.001 mg/L >99.30% >99.30%

Mercury: @ pH 6.5 0.002 mg/L 0.006 mg/L 0.006 mg/L + 10% 0.0005 mg/L 0.0003 mg/L 91.70% 95.00%

Mercury: @ pH 8.5 0.002 mg/L 0.0059 mg/L 0.006 mg/L _+10% 0.0018 mg/L 0.00073 mg/L 69.20% 88.10%

Benzene 0.005 mg/L 0.0133 mg/L 0.015 mg/L _+10% 0.0005 mg/L 0.0005 mg/L 96.10% 96.30%

p-Dichlorobenzene 0.075 mg/L 0.210 mg/L 0.225 mg/L _+10% < 0.0005 mg/L < 0.0005 mg/L >99.80% >99.80%

Carbofuran 0.040 mg/L 0.0753 mg/L 0.08 mg/L _+10% 0.027 mg/L 0.008 mg/L 64.60% 73.45%

Toxaphene 0.003 mg/L 0.015 mg/L 0.015 _+10% < 0.001 mg/L < 0.001 mg/L >93.3% >93.3%

Atrazine 0.003 mg/L 0.0102 mg/L 0.009 mg/L _+10% 0.0027 mg/L 0.00105 mg/L 76.30% 89.40%

Asbestos >99% 126.5 MF/L 107to 108fibers/L t_ < 0.17 MF/L < 0.17 MF/L >99.99% >99.99%

Live Cysts _ >99.95% 122,500 #/L 50,000/L min. < 1 #/U < 1 #/U >99.99% >99.99%

Turbidity 0.5 NTU 10.5 NTU 11 _+1 NTU 0.30 NTU 0.125 NTU 97.30% 98.80%

Lindane 0.0002 mg/L 0.0019 mg/L 0.002 _+10% < 0.00016 mg/L 0.000035 mg/L 91.80% 97.90%

Tetrachloroethylene 0.005 mg/L 0.015 mg/L 0.015 mg/L _+10% < 0.0005 mg/L < 0.0005 mg/L >96.6% >96.6%

O-Dichlorobenzene 0.6 mg/L 1.7 mg/L 1.8 mg/L _+10% < 0.5 mg/L < 0.5 mg/L >99.9% >99.9%

Ethylbenzene 0.7 mg/L 2.2 mg/L 2.1 mg/L _+10% 0.0048 mg/L 0.11 mg/L 99.80% 99.90%

Chlorobenzene 0.1 mg/L 2.0 mg/L 2.0 mg/L _+10% 0.0038 mg/L 0.0008 mg/L 99.80% 99.90%

Endrin 0.002 mg/L 0.007 mg/L 0.006 mg/L _+10% 0.0004 mg/L 0.0002 mg/L 94.30% 96.80%

Test Parameters: pH = 7.5 _+0.5 unless otherwise noted. Flow = 0.78 gpm (1.9 Lpm). Pressure =

(20°C _+3°C).

• It is essential that operational, maintenance, and filter •

replacement requirements be carried out for the product to

perform as advertised.

• The disposable water filter should be replaced at least every

6 months.

The filter monitor system measures the amount of water that

passes through the filter and alerts you to replace the filter.

When 90% of the filter's rated life is used, the yellow (Order)

light comes on. When 100% of the filter's rated life is used, the

red (Replace) light comes on, and it is recommended that you

replace the filter. For models without filter status lights,

replace the filter every 6 months. Use replacement filter

model UKF8001AXX-200.2009 suggested retail price of

$44.99 U.S.A./S49.95 Canada. Prices are subject to change

without notice.

The product is for cold water use only.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system. Systems certified for cyst reduction may be used

on disinfected waters that may contain filterable cysts.

particles/mL

60 psig (413.7 kPa). Temp. = 68°F _+5°F

Refer to the "Water Filtration System" section for the

Manufacturer's name and telephone number.

Refer to the "Warranty" section for the Manufacturer's limited

warranty.

Application Guidelines/Water Supply Parameters

Water Supply City or Well

Water Pressure 35 - 120 psi (241 - 827 kPa)

Water Temperature 33 ° - 100°F (1° - 38°C)

Service Flow Rate 0.78 gpm (2.9 L!min.) @60 psi

*Class I particle size: >0.5 to <1 um

**Test requirement is at least 100,000 particles/mL of AC Fine Test Dust.

tThese contaminants are not necessarily in your water supply. Performance may vary based on local water conditions.

ttFibers greater than 10 um in length

_Based on the use of Cryptosporidium parvum oocysts

® NSF is a registered trademark of NSF International.

15

JENN-AII REFRIGERATORWARRANTY

LIMITED WARRANTY

For one year from the date of purchase, when this major appliance is operated and maintained according to instructions attached to or furnished

with the product, Jenn-Air brand of Whirlpool Corporation or Whirlpool Canada LP (hereafter "Jenn-Air") will pay for factory specified parts and

repair labor to correct defects in materials or workmanship that existed when this major appliance was purchased. Service must be provided by

a Jenn-Air designated service company. YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT

REPAIR AS PROVIDED HEREIN. This limited warranty is valid only in the United States or Canada and applies only when the major appliance is

used in the country in which it was purchased. Proof of original purchase date is required to obtain service under this limited warranty.

On models with a water filter: 30 day limited warranty on water filter. For 30 days from the date of purchase, when this filter is operated and

maintained according to instructions attached to or furnished with the product, Jenn-Air will pay for a replacement water filter to correct defects

in materials and workmanship.

SECOND THROUGH FIFTH YEAR LIMITED WARRANTY ON CAVITY LINER AND SEALED REFRIGERATION SYSTEM

In the second through fifth years from the date of purchase, when this major appliance is operated and maintained according to instructions

attached to or furnished with the product, Jenn-Air will pay for replacement or repair of the refrigerator/freezer cavity liner (including labor costs)

if the part cracks due to defective materials or workmanship. Also, in the second through fifth year from the date of purchase, when this major

appliance is operated and maintained according to instructions attached to or furnished with the product, Jenn-Air will pay for factory specified

parts and repair labor for the following components to correct defects in materials or workmanship in the sealed refrigeration system that existed

when this major appliance was purchased: compressor, evaporator, condenser, dryer, and connecting tubing.

ITEMS EXCLUDED FROM WARRANTY

This limited warranty does not cover:

1. Replacement parts or repair labor if this major appliance is used for other than normal, single-family household use or when it is used in a

manner that is inconsistent to published user or operator instructions and/or installation instructions.

2. Service calls to correct the installation of your major appliance, to instruct you on how to use your major appliance, to replace or repair house

fuses, or to correct house wiring or plumbing.

3. Service calls to repair or replace appliance light bulbs, air filters or water filters. Consumable parts are excluded from warranty coverage.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, installation not in accordance with

electrical or plumbing codes, or use of products not approved by Jenn-Air.

5. Cosmetic damage, including scratches, dents, chips or other damage to the finish of your major appliance, unless such damage results from

defects in materials or workmanship and is reported to Jenn-Air within 30 days from the date of purchase.

6. Any food or medicine loss due to refrigerator or freezer product failures.

7. Pickup and delivery. This major appliance is intended to be repaired in your home.

8. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

9. Expenses for travel and transportation for product service if your major appliance is located in a remote area where service by an authorized

Jenn-Air servicer is not available.

10. The removal and reinstallation of your major appliance if it is installed in an inaccessible location or is not installed in accordance with Jenn-

Air's published installation instructions.

11. Replacement parts or repair labor on major appliances with original model/serial numbers that have been removed, altered or cannot be

easily determined.

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do not

allow limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you

specific legal rights, and you also may have other rights that vary from state to state or province to province.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. JENN-AIR

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the exclusion or limitation

of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights,

and you also may have other rights that vary from state to state or province to province.

If outside the 50 United States and Canada, contact your authorized Jenn-Air dealer to determine if another warranty applies. 6/08

For additional product information, in the U.S.A., visit www.jennair.com

In Canada, visit www.jennair.ca

If you do not have access to the Internet and you need assistance using your product or you would like to schedule service, you may

contact Jenn-Air at the number below.

Have your complete model number ready. You can find your model number and serial number on the label, located on the inside wall of

the refrigerator compartment.

For assistance or service in the U.S.A., call 1-800-536-6247. In Canada, call 1-800-807-6777.

If you need further assistance, you can write to Jenn-Air with any questions or concerns at the address below:

In the U.S.A.: In Canada:

Jenn-Air Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence.

Please keep these User Instructions and the model number information for future reference.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

Jenn-Air Brand Home Appliances

Customer eXperience Centre

1901 Minnesota Court

Mississauga, Ontario L5N 3A7

16

NousvousREMERCIONSd'avoiracheteceproduitdehautequalite.Sivousrencontrezunproblemenonmentionne

danslasectionDI_PANNAGE,veuillezvisiternotresiteWebwww.jennair.compourdesinformationssupplementaires.Si

vousaveztoujoursbesoind'assistance,veuilleznoustel6phonerau1-800-536-6247.AuCanada,visiteznotresiteWeb

www.jennair.caoutel6phonez-nousau1-800-807-6777.

Vousaurezbesoindevosnum@osdemodeleetdes@iesituessurlaparoiinterneducompartimentderefrig@ation.

SECURITEDU REFRIGERATEUR

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves a vous

eta d'autres.

Voici le symbole d'alerte de s_curit_.

Tous les messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

IMPORTANTES INSTRUCTIONS DE SI_CURITI_

AVERTISSEMENT : Pour reduire les risques d'incendie, de choc electrique ou des blessures Iors de I'utilisation du

refrig6rateur, prendre quelques precautions fondamentales, y compris les suivantes :

• Brancher I'appareil sur une prise a 3 alveoles reliee a la terre. • Garder les materiaux et les vapeurs inflammables, telle

• Ne pas enlever la broche de liaison a la terre, que I'essence, loin du r6frigerateur.

• Ne pas utiliser un adaptateur. • Utiliser deux ou plus de personnes pour deplacer et

Ne pas utiliser un cable de rallonge.

Debrancher la source de courant electrique avant I'entretien.

• machine a glagons (seulement pour modeles pr_ts

Replacer pieces et panneaux avant de faire la remise en marche.

• recevoir une machine a glagons).

Enlever les portes de votre vieux r6frigerateur.

• • Utiliser un verre robuste pour prendre des glagons (sur

• certains modeles).

Utiliser un produit de nettoyage ininflammable.

installer le refrig6rateur.

• Debrancher le refrig6rateur avant I'installation de la

• Ne pas heurter les portes en verre du r6frigerateur (sur

certains modeles).

CONSERVEZ CES INSTRUCTIONS

17

Mise au rebut ad( cjuate de

votre vieux refrigerateur

Risque de suffoquer

Enlever les portes de votre vJeux r_frig_rateur.

Le non=respect de cette instruction peut causer

un d_c_s ou des I_sions c_r_brales.

IMPORTANT : L'emprisonnement et I'etouffement des enfants ne

sont pas un probleme du passe. Les refrigerateurs jetes ou

abandonnes sont encore dangereux, m_me s'ils sont laisses

abandonnes pendant "quelques jours seulement". Si vous vous

debarrassez de votre vieux refrigerateur, veuillez suivre les

instructions suivantes pour aider & eviter les accidents.

INSTRUCTIONSD'INSTALLATION

Risque du poids excessif

Utiiiser deux ou plus de personnes pour d_placer et

installer le r_frig_rateur.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

Enl_vement des mat_riaux d'emballage

• Enlever le ruban adhesif et la colle des surfaces du

refrigerateur avant de le mettre en marche. Frotter une petite

quantite de savon liquide pour la vaisselle sur I'adhesif avec

les doigts. Rincer a I'eau tiede et essuyer.

Ne pas utiliser d'instruments coupants, d'alcool &friction, de

liquides inflammables ou de nettoyants abrasifs pour enlever

le ruban adhesif ou la colle. Ces produits peuvent

endommager lasurface de votre refrigerateur. Pour plus de

renseignements, voir "Securite du refrigerateur".

• Jeter ou recycler tousles materiaux d'emballage.

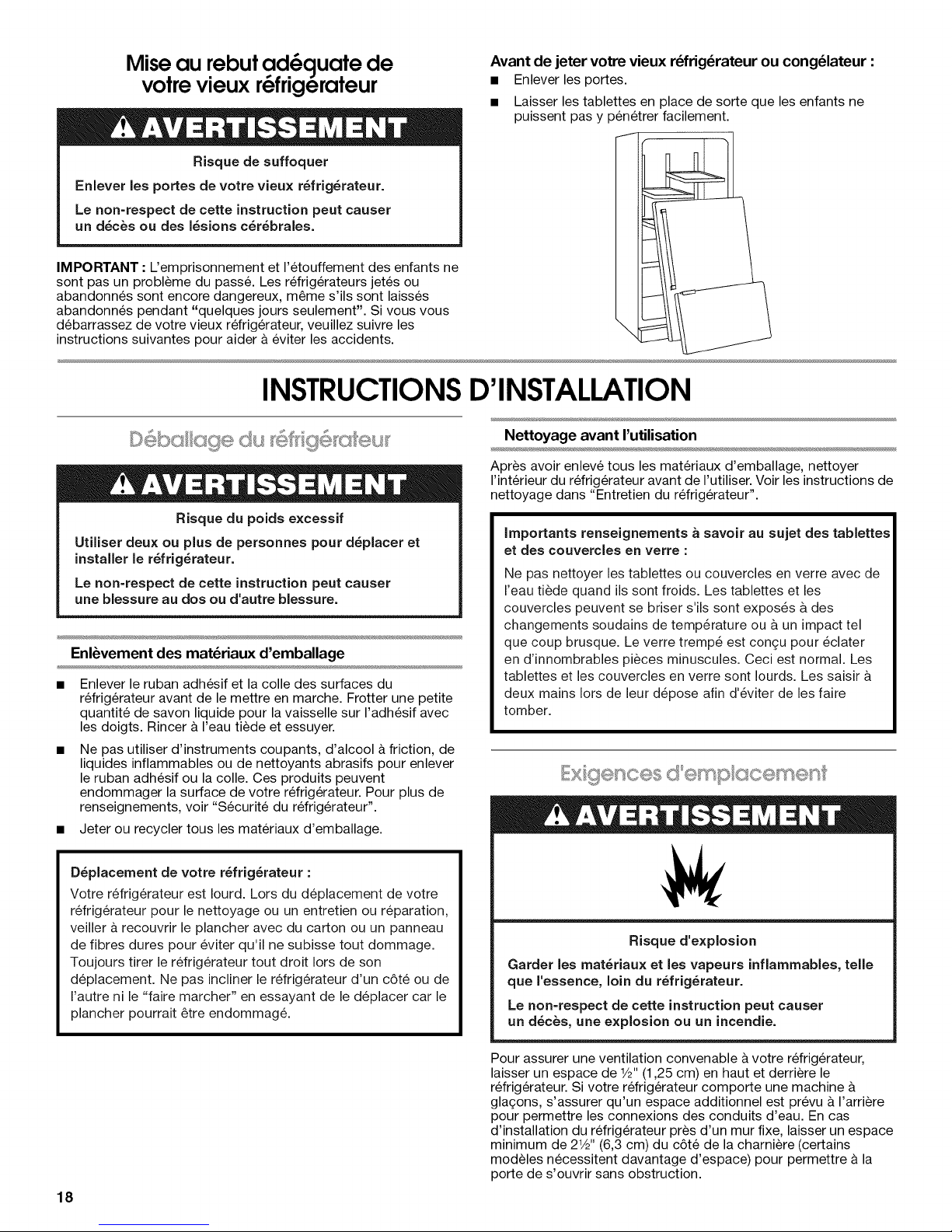

Avant de jeter votre vieux r_frig_rateur ou cong_lateur :

• Enlever les portes.

• Laisser les tablettes en place de sorte que les enfants ne

puissent pas y pen6trer facilement.

Nettoyage avant I'utilisation

Apres avoir enleve tousles materiaux d'emballage, nettoyer

I'interieur du refrigerateur avant de I'utiliser. Voir les instructions de

nettoyage dans "Entretien du refrigerateur".

Jmportants renseignements a savoir au sujet des tablettes

et des couvercles en verre :

Ne pas nettoyer les tablettes ou couvercles en verre avec de

I'eau tiede quand ils sent froids. Les tablettes et les

couvercles peuvent se briser s'ils sont exposes a des

changements soudains de temp@ature ou & un impact tel

que coup brusque. Le verre tremp_ est con£u pour _clater

en d'innombrables pieces minuscules. Ceci est normal. Les

tablettes et les couvercles en verre sont Iourds. Les saisir

deux mains Iors de leur d_pose afin d'_viter de les faire

tomber.

D_placement de votre r6frig6rateur :

Votre refrig6rateur est Iourd. Lors du deplacement de votre

refrig6rateur pour le nettoyage ou un entretien ou reparation,

veiller & recouvrir le plancher avec du carton ou un panneau

de fibres dures pour eviter qu'il ne subisse tout dommage.

Toujours tirer le r6frigerateur tout droit Iors de son

deplacement. Ne pas incliner le refrig6rateur d'un c6te ou de

I'autre ni le "faire marcher" en essayant de le deplacer car le

plancher pourrait _tre endommag&

18

Risque d'explosion

Garder les mat_riaux et les vapeurs inflammables, telle

que ressence, loin du r6frig_rateur.

Le non=respect de cette instruction peut causer

un d_c_s, une explosion ou un incendie.

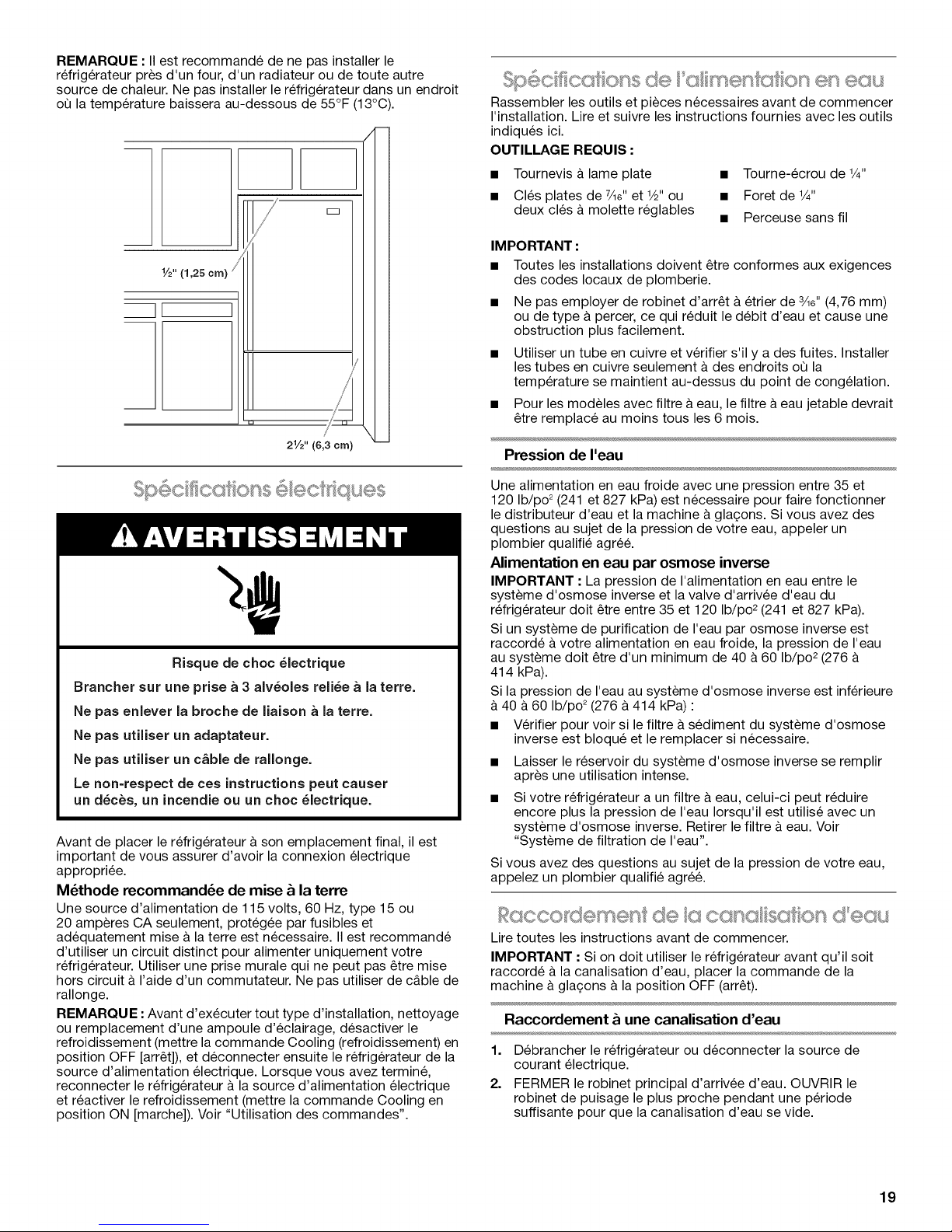

Pour assurer une ventilation convenable a votre refrigerateur,

laisser un espace de 1/2"(1,25 cm) en haut et derriere le

refrigerateur. Si votre refrigerateur comporte une machine &

glagons, s'assurer qu'un espace additionnel est prevu & I'arriere

pour permettre les connexions des conduits d'eau. En cas

d'installation du refrigerateur pres d'un mur fixe, laisser un espace

minimum de 2W' (6,3 cm) du c6te de la charniere (certains

modeles necessitent davantage d'espace) pour permettre a la

porte de s'ouvrir sans obstruction.

REMARQUE:IIestrecommandedenepasinstallerle

refrig6rateurpresd'unfour,d'unradiateuroudetouteautre

sourcedechaleur.Nepasinstallerlerefrigerateurdansunendroit

oQlatemperaturebaisseraau-dessousde55°F(13°C).

1/2"(1,25cm)

II

21/2" (6,3 Cm) --

Risque de choc _lectrique

Brancher sur une prise a 3 alv_oles reli_e a la terre.

Ne pas enlever la broche de liaison a la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c&ble de rallonge.

Le non=respect de ces instructions peut causer

un d_c_s, un incendie ou un choc _lectrique.

Avant de placer le refrigerateur & son emplacement final, il est

important de vous assurer d'avoir la connexion electrique

appropriee.

M_thode recommand_e de mise _ la terre

Une source d'alimentation de 115 volts, 60 Hz, type 15 ou

20 amperes CA seulement, protegee par fusibles et

adequatement mise a la terre est necessaire. II est recommande

d'utiliser un circuit distinct pour alimenter uniquement votre

refrigerateur. Utiliser une prise murale qui ne peut pas _tre mise

hors circuit & I'aide d'un commutateur. Ne pas utiliser de c&ble de

rallonge.

REMARQUE : Avant d'executer tout type d'installation, nettoyage

ou remplacement d'une ampoule d'eclairage, desactiver le

refroidissement (mettre la commande Cooling (refroidissement) en

position OFF [arr_t]), et deconnecter ensuite le refrigerateur de la

source d'alimentation electrique. Lorsque vous avez termine,

reconnecter le refrigerateur & la source d'alimentation electrique

et reactiver le refroidissement (mettre la commande Cooling en

position ON [marche]). Voir "Utilisation des commandes".

Rassembler les outils et pieces necessaires avant de commencer

I'installation. Lire et suivre les instructions fournies avec les outils

indiques ici.

OUTILLAGE REQUIS :

• Tournevis a lame plate

• Cles plates de 7_e"et V_"ou

deux cles a molette reglables

IMPORTANT :

• Toutes les installations doivent _tre conformes aux exigences

des codes Iocaux de plomberie.

Ne pas employer de robinet d'arr_t & etrier de 3/le"(4,76 mm)

ou de type & percer, ce qui reduit le debit d'eau et cause une

obstruction plus facilement.

Utiliser un tube en cuivre et verifier s'il y a des fuites. Installer

les tubes en cuivre seulement & des endroits oQ la

temperature se maintient au-dessus du point de congelation.

Pour les modeles avec filtre & eau, le filtre & eau jetable devrait

_tre remplace au moins tous les 6 mois.

• Tourne-ecrou de V4"

• Foret de V4"

• Perceuse sans fil

Pression de I'eau

Une alimentation en eau froide avec une pression entre 35 et

120 Ib/po _(241 et 827 kPa) est necessaire pour faire fonctionner

le distributeur d'eau et la machine & gla£_ons.Si vous avez des

questions au sujet de la pression de votre eau, appeler un

plombier qualifie agree.

Alimentation en eau par osmose inverse

IMPORTANT : La pression de I'alimentation en eau entre le

systeme d'osmose inverse et la valve d'arrivee d'eau du

refrigerateur dolt @treentre 35 et 120 Ib/po 2(241 et 827 kPa).

Si un systeme de purification de I'eau par osmose inverse est

raccorde &votre alimentation en eau froide, la pression de I'eau

au systeme dolt @tred'un minimum de 40 & 60 Ib/po 2(276 &

414 kPa).

Si la pression de I'eau au systeme d'osmose inverse est inferieure

&40 a 60 Ib/po _ (276 a 414 kPa) :

• Verifier pour voir si lefiltre & sediment du systeme d'osmose

inverse est bloque et le remplacer si necessaire.

• Laisser le reservoir du systeme d'osmose inverse se remplir

apres une utilisation intense.

Si votre refrigerateur a un filtre & eau, celui-ci peut reduire

encore plus la pression de I'eau Iorsqu'il est utilise avec un

systeme d'osmose inverse. Retirer le filtre a eau. Voir

"Systeme de filtration de I'eau".

Si vous avez des questions au sujet de la pression de votre eau,

appelez un plombier qualifie agree.

Lire toutes les instructions avant de commencer.

IMPORTANT : Si on dolt utiliser le refrigerateur avant qu'il soit

raccorde &la canalisation d'eau, placer la commande de la

machine a gla£_onsa la position OFF (arr_t).

Raccordement _ une canalisation d'eau

1. Debrancher le refrigerateur ou deconnecter la source de

courant electrique.

2. FERMER le robinet principal d'arrivee d'eau. OUVRIR le

robinet de puisage le plus proche pendant une periode

suffisante pour que la canalisation d'eau se vide.

19

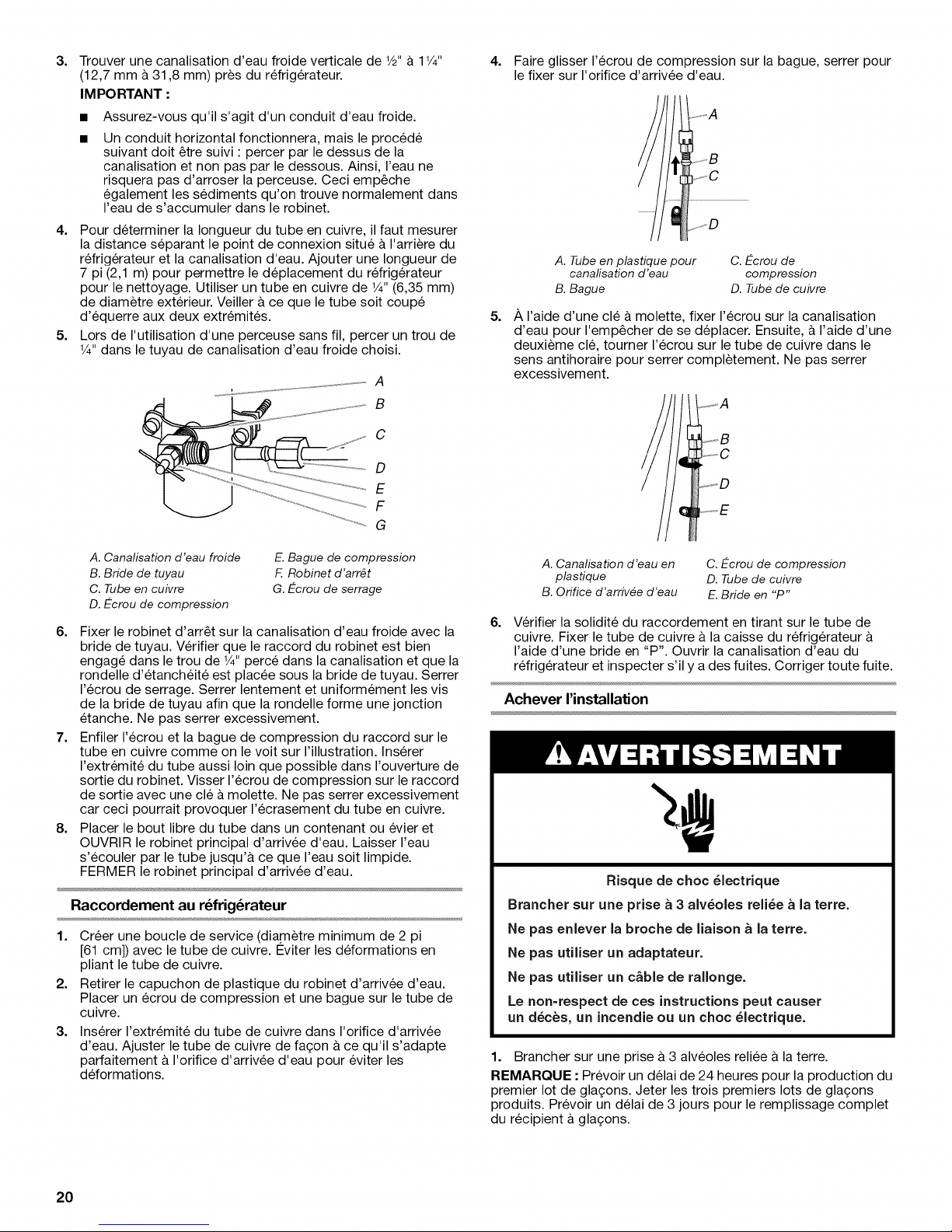

Trouver une canalisation d'eau froide verticale de 1/2"& 11/4"

3. 4. Faire glisser I'ecrou de compression sur la bague, serrer pour

(12,7 mm & 31,8 mm) pres du refrigerateur.

le fixer sur I'orifice d'arrivee d'eau.

IMPORTANT :

Assurez-vous qu'il s'agit d'un conduit d'eau froide.

Un conduit horizontal fonctionnera, mais le procede

suivant dolt 6tre suivi : percer par le dessus de la

canalisation et non pas par le dessous. Ainsi, I'eau ne

risquera pas d'arroser la perceuse. Ceci emp6che

egalement les sediments qu'on trouve normalement dans

I'eau de s'accumuler dans le robinet.

4. Pour determiner la Iongueur du tube en cuivre, il faut mesurer

la distance separant le point de connexion situe & I'arriere du

refrigerateur et la canalisation d'eau. Ajouter une Iongueur de

7 pi (2,1 m) pour permettre le deplacement du refrigerateur

pour le nettoyage. Utiliser un tube en cuivre de 1/4"(6,35 mm)

A. Tube en p_stique pour

canafisafion d_au

B. Bague

C. E-crou de

compression

D. Tube de cuivre

de diametre exterieur. Veiller & ce que le tube soit coupe

d'equerre aux deux extremites.

5. Lors de I'utilisation d'une perceuse sans ill, percer un trou de

1/4"dans le tuyau de canalisation d'eau froide choisi.

5=

A I'aide d'une cle & molette, fixer I'ecrou sur la canalisation

d'eau pour I'emp6cher de se deplacer. Ensuite, & I'aide d'une

deuxieme cle, tourner I'ecrou sur le tube de cuivre dans le

sens antihoraire pour serrer completement. Ne pas serrer

excessivement.

B

C

D

E

F

G

A. Canalisation d'eau froide

B. Bride de tuyau

C. Tube en cuivre

D. E-crou de compression

E. Bague de compression

F. Robinet d'arr6t

G. E-crou de serrage

6. Fixer le robinet d'arr6t sur la canalisation d'eau froide avec la

bride de tuyau. Verifier que le raccord du robinet est bien

engage dans le trou de 1/4"perce dans la canalisation et que la

rondelle d'etancheite est placee sous la bride de tuyau. Serrer

I'ecrou de serrage. Serrer lentement et uniformement les vis

de la bride de tuyau afin que la rondelle forme une jonction

etanche. Ne pas serrer excessivement.

7. Enfiler I'ecrou et la bague de compression du raccord sur le

tube en cuivre comme on le volt sur I'illustration. Inserer

I'extremite du tube aussi loin que possible dans I'ouverture de

sortie du robinet. Visser I'ecrou de compression sur le raccord

de sortie avec une cle & molette. Ne pas serrer excessivement