Jenn-Air CVEX4100B19, CVEX4100W19, CVEX4270B, CVEX4270B19, CVEX4270W19 Installation Guide

...Page 1

ExpressionsConvertible I JENN-AIi;-

CooktopSeries ._WESTFO0..._TOEET,_'H.._ON,,.0

Models CVEX4100, CVEX4270 & CVEX4370

IMPORTANT

• Installation should be performed by a Jenn-Air authorized servicer or other qualified installer,

• Read Safety Precautions in the Use & Care manual before using this appliance.

INSTALLER

• Save installation instructions for local electrical inspector's use.

• Leave installation instructions with the appliance.

CONSUMER

° Retain installation instructions with the appliance.

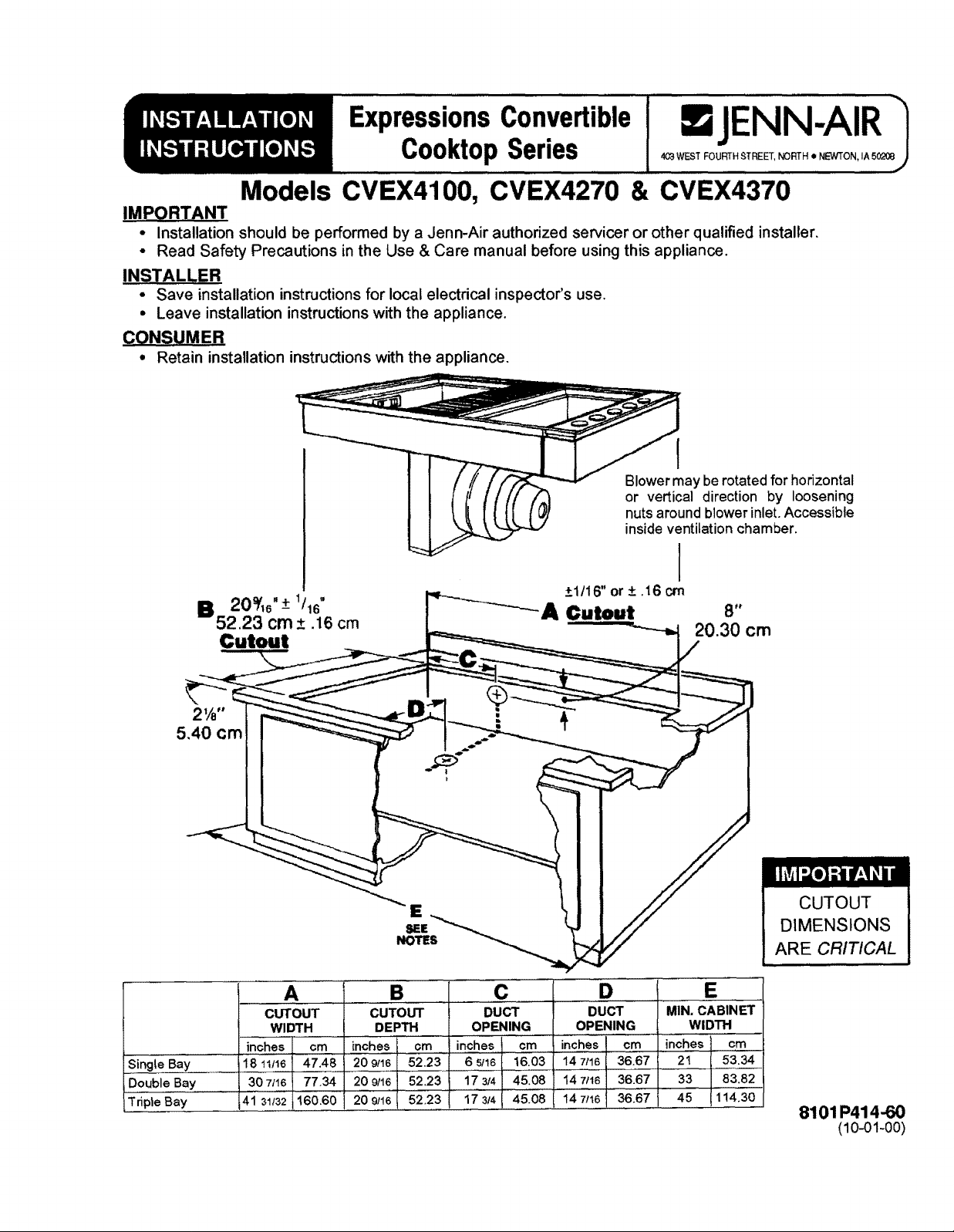

I

Blower may berotated for horizontal

or vertical direction by loosening

nuts around blower inlet. Accessible

inside ventilation chamber.

I

±1/16" or + .16 crn

A Cutout

Sir_j!____reBay

DoubleBaY

Tripte Bay

Cutout

5,40 cm

A ...........

CUTOUT

WIDTH

inches cm

18 11116 47.48

30 7/16 77.34

41 31132 160.60

E

SEE

NOTES

S ....

CUTOUT

DEPTH

inches cm

I 20 9/16 52,23

20 9/16 52,23

20 9/16 I 52.23 17 314

inches cm

6 _,116 16.03

17 3/4 45,08

C

DUCT

OPENING

45.08

D

DUCT

OPENING

inches cm

14 7/16 36.67

14 7/16 36.67

14 7116 36.67

CUTOUT

DIMENSIONS

ARE CRITICAL

MIN, CABINET

WIDTH

inches cm

21 53.34

33 83.82

45 1!4.30

8101 P414-60

(10-01-00)

Page 2

See side clearance--------)l

note below.

Min. I 1 I12.ol cm

Clearanoe ]J-----1_ *

Required ,._,, [] _ Grease

17 1/2" I II 1 I I Container

44"46cm [__,,_ LJSEENOT E

See side clearance_I _ _-

note below.

Min.

Clearance ,,.

Required

17 1/2"

44.46 cm

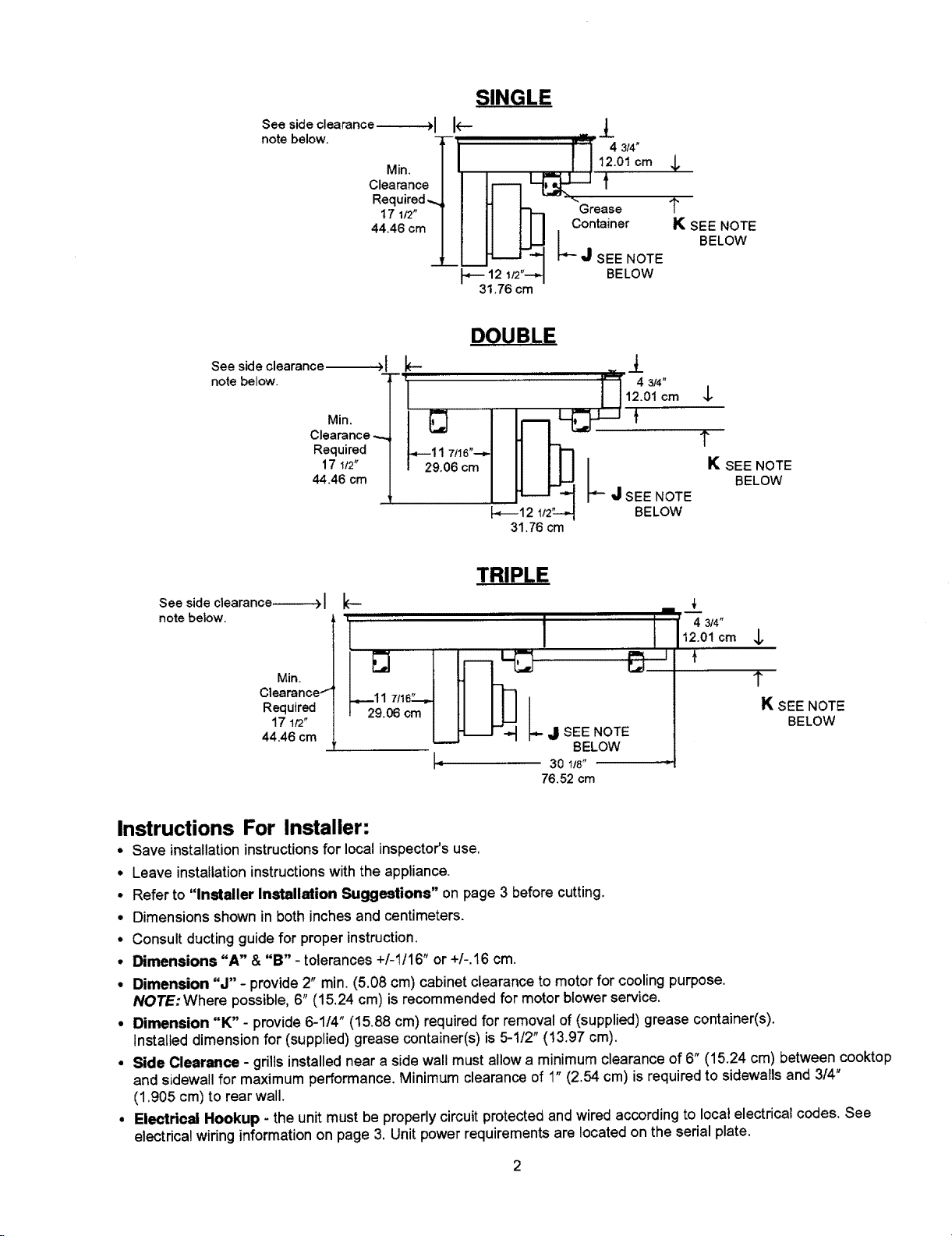

SINGLE

'" L ,,I, ,,

- ;- r-_ 4 3t4"

--_-- 12 1/2 -_ BELOW

31.76crn

DOUBLE

IIILli

I _fl _- J SEE NOTE

_12 1/2L-_ BELOW

31.76cm

4,

t"

K SEENOTE

BELOW

4,

1"

K SEE NOTE

BELOW

TRIPLE

See side clearancei-----) I

note below

.in

Clearance-" _-_11z116_._tl I IlL.

;,_::ircemd 2906cm17 1/2" i1_"m SEE NOTE

Instructions For Installer:

• Save installationinstructions for local inspector'suse.

° Leave installation instructions with the appliance.

• Refer to "installer Installation Suggestions" on page 3 before cutting.

• Dimensions shownin both inchesandcentimeters

• Consult ductingguidefor proper instruction,

• Dimensions "A" & "B" - tolerances+/-t/16" or +/-.16 cm.

• Dimension "J" - provide2" rain (5.08 cm)cabinetclearance to motorfor coolingpurpose.

NOTE:Where possible,6" (15,24 cm) is recommended for motor blower service.

• Dimension "K" - provide6-1/4" (15.88 cm) requiredfor removal of (supplied)greasecontainer(s).

Installed dimensionfor (supplied)grease container(s) is 5-1/2" (!3.97 cm)

• Side Clearance - grillsinstallednear a sidewall mustallowa minimum clearance of 6" (15.24 cm) between cooktop

and sidewallfor maximum performance.Minimum clearance of 1" (2.54 cm) is required to sidewallsand 314"

(1905 cm) to rear wall.

• Electrical Hookup - the unit mustbe properlycircuitprotectedandwiredaccordingto localelectricalcodes, See

electrica!wiringinformationon page 3. Unit power requirementsare !ocated on the serialplate.

k-

i i ii

BELOW

30 t/8"

76.52 cm

-'_ 3/4"

12.01cm

{

$

1"

K SEE NOTE

BELOW

Page 3

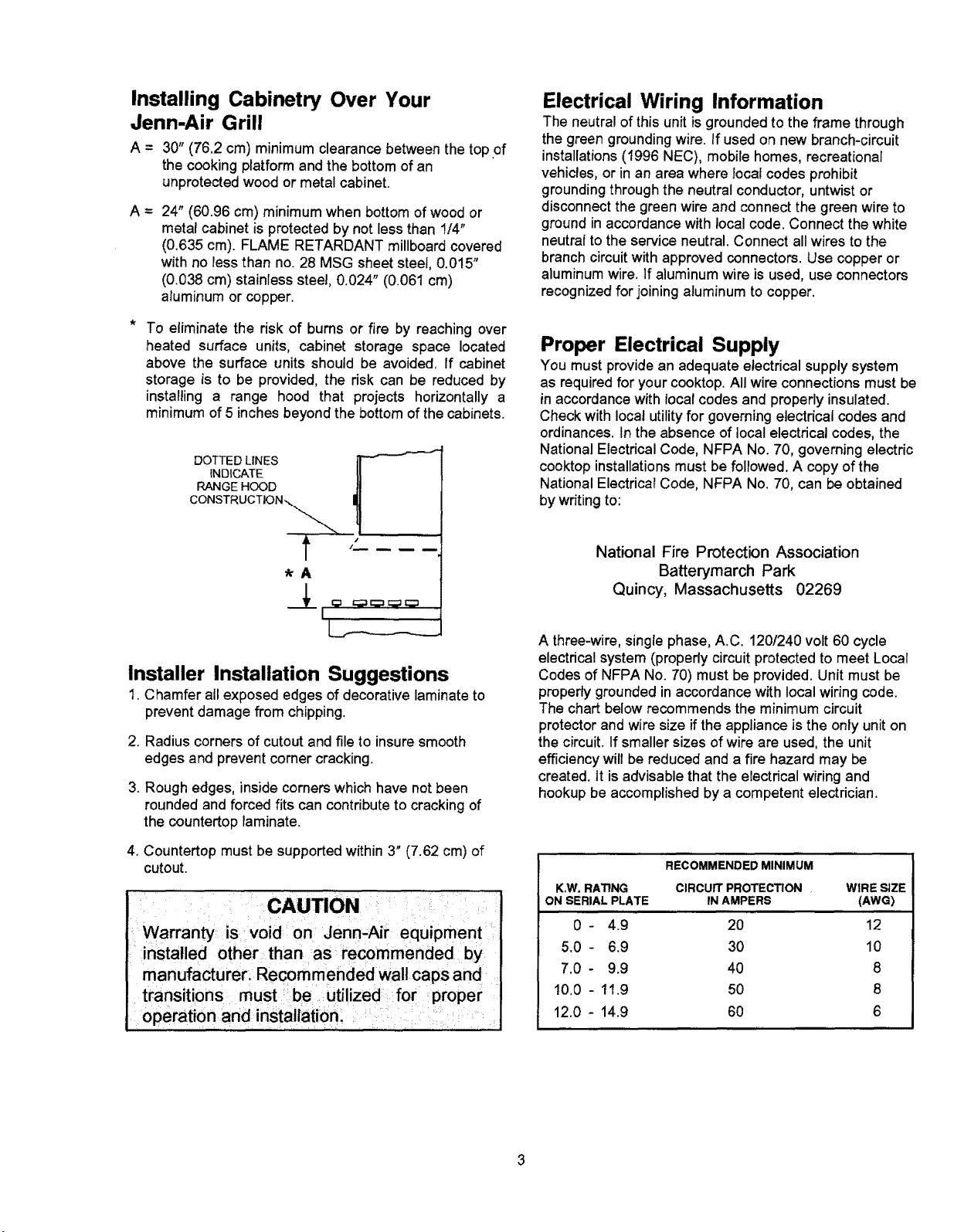

Installing Cabinetry Over Your

Jenn-Air Grill

A = 30" (76.2 cm) minimum clearance between the top of

the cooking platform and the bottom of an

unprotected wood or metal cabinet.

A = 24" (60.96 cm) minimum when bottom ofwoodor

metal cabinet is protected by not less than !/4"

(0.635 cm). FLAME RETARDANT millboard covered

with no less than no. 28 MSG sheet steel, 0.015"

(0.038 cm) stainless steel, 0.024" (0.061 cm)

aluminum or copper.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided, If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the cabinets.

INDICATE

RANGE HOOD

DOTTED LINES _-_

CONSTRUCTION_

Electrical Wiring Information

The neutralof thisunitisgrounded to the frame through

the green grounding wire. If used on new branch-circuit

installations (1996 NEC), mobile homes, recreational

vehicles, or in an area where local codes prohibit

grounding through the neutral conductor, untwist or

disconnect the green wire and connect the green wire to

ground in accordance with local code. Connect the white

neutral to the service neutral. Connect all wires to the

branch circuit with approved connectors. Use copper or

aluminum wire. If aluminum wire is used, use connectors

recognized for joining aluminum to copper.

Proper Electrical Supply

You must provide an adequate electrical supply system

as required for your cooktop. All wire connections must be

in accordance with focal codes and properly insulated.

Check with local utility for governing electrical codes and

ordinances. In the absence of local electrical codes, the

National Electrical Code, NFPA No. 70, governing electric

cooktop installations must be followed. A copy of the

National Electricat Code, NFPA No. 70, can be obtained

by writing to;

t '

*A

I

Installer Installation Suggestions

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking.

3. Rough edges, inside corners whichhave not been

rounded and forced fits can contribute to cracking of

the countertop laminate.

4. Countertop must be supportedwithin 3" (7.62 cm) of

cutout.

CAUTION

Warranty is void on Jenn-Air equipment

installed other than as recommended by

manufacturer. Recommended wall caps and

transitions must be utilized for proper

operation and installation.

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

A three-wire,single phase, A.C. 120/240 volt 60 cycle

electrical system (properly circuit protected to meet Local

Codes of NFPA No. 70) must be provided. Unit must be

properly grounded in accordance with local wiring code.

The chart below recommends the minimum circuit

protector and wire size if the appliance is the only unit on

the circuit. If smaller sizes of wire are used, the unit

efficiency will be reduced and a fire hazard may be

created, it is advisable that the electrical wiring and

hookup be accomplished by a competent electrician.

RECOMMENDED MINIMUM

K,W. RATING CIRCUIT PROTECTION • WIRE SIZE

ON SERIAL PLATE IN AMPERS (AWG)

0- 4.9 20 12

5.0- 6.9 30 10

7.0- 9.9 40 8

!0.0 - 11.9 50 8

12.0 - 14.9 60 6

Page 4

Preparing Unit For Assembly In Countertop

1, Unpack Unit.

2. Provide cutout for countertop and duct openings as

required per page 1.

3. Place unit in the cutout, and slide unit all the way to the

left hand side of cutout. (Figure 1).

4. HOLDING DOWN UNIT TO COUNTERTOP: Use the

hold down straps, provided in the hardware package, to

secure unit to the countertop. These straps may be

positioned on the left, front, and back sides of the unit.

(See figure 1A). To install, pre-thread the bolt into the

strap about 2 inches. With the unit positioned in the

cutout as desired, reach through the cabinet door

opening and push up along the wall of the burner box

flange. If it doesn't hook, pull strap down, move it left or

right about an inch and push up again. Once strap is

hooked, thread bolt into strap until it meets resistance

against bottom of countertop. Then tighten slowly until

unit top bottoms against countertop.

5. Connect outlet of blower housing to vent duct. Loosen

cap nuts inside plenum to rotate blower housing to

desired position.

6. Remove attachment screw and cover from junction

box. Connect BX Cable power supply to knockout in

side of box. Make wire connections, push wires into

box. Re-attach cover. Consult local codes for proper

power hookup. (Figure 2).

7. Test to insure electronic surface control operates all

elements properly.

FIGURE 1A FIGURE !

JUNCTION BOX

\

FIGURE 2

Page 5

C_.stomer SeP:ic_

Z40EawardsSLreet,SE

C1eve!and,Tennessee37311

Tei:_22-472-3333

Fax:_23-478-6710

I0.

FLOOR VENT CUTOUT (JOISTS AS SHOWN)

- Check the direction of the floor joists (see illustration), tf the joists' direction is as shown, locate

the cutout on the '7" as illustrated. The cutout must miss the floarjoists!

- Cutout may be moved from side to side on line to clear floor joist.

- Recheck your dimensions and make the cutout.

11. FLOOR VENT CUTOUT (JOISTS AS SHOWN)

- Check the direction of the floor joists (see illustration). If the joists' direction is as shown, locate

the cutout on the T as illustrated. The cutout must miss the floor joist!!

- Cutout may be moved from front to back on line to clear floor joist.

- Recheck your dimensions and make the cutout.

!

12. WALL VENT CUTOUT

- Locate the vertical studs in the rear wall. Studs are usually t6 _ (40.64 cm) center to center.

- Wil! the vent duct be 6" (15.24 cm) round throug.h the wall or 3 1t4" x 10" (8.26 cm x 25.4 era)

rectangle, vertically inside the wall?

- See Ducting Instructions for rear duct inside the wall. NOTE: Cutout in walt must clear 3 1/4" x

10" (8.26 cm x 25.4 era) transition elbow.

- Locate the closest stud to your proposed vent hole location. Use the following chart to figure the

_X" dimension. See the illustration for the other dimensions.

) "X" MINIMUM

- A 1" (2.54 cm) length of duct must protrude through the wall for connection to the Blower.

6" Round (15.24 era) 3¼" x 10"

i VERTICAL DUCT INSIDE WALL

}. 4" (10.16 cm) 6" (15.24 era)

(8-26 cm x 25.4 era)

{ _ |c:.os_sTt

8'h" 61t_-

t43._ crop q

._4,_,'/I,\G Admiral 7! -'ttvl'_jl::NN-.A;l::t "_iI!,1_i€ C,_.e_

Page 6

2J-gEawa_dsStreeLSE

C;eveiand,Tennessee37311

Tel:423-477.-;333

Fax:'_23-J-78-67!0

13.

INSTALL BLOWER (PRIOR TO INSTALLING RANGE)

- Refer to your vent plan. It may be desirable to attach part of the ducting to the blower before it

is installed.

- Position the blower (see illustration) and attach it to the floor with at least two (2) screws.

- Apply duct tape around blower exhaust/duct joint.

THROUGH THROUGH

OUTSIDE WALl. THE FLOOR

r It .---.

rfZfTflVfl_l/ ff¢ ffJ'--J_ E.Z .."

14.

INSTALL ELECTRICAL oucr TAPE

METAL DUCT

- NOTE: Observe all local electrical codes.

- CAUTION: Make sure power to cable is OFF:

- Locate the electric power supply in the floor or wall, any place in the shaded areas which will

clear the blower.

- Direct Connect. Pull through 5' (152.4 cm) of electrical cable.

- Use three or four conductor copper stranded power cable (see front cover for proper wire size). If

four conductor wire is used, see #16 for connection to range.

- See front cover for proper supply connection. . _1"[ _eTRIC,_t.k

I5.

CONNECT ELECTRICAL (THREE CONDUCTOR WIRE)

- CAUTION: Make sure power to cable is OFF.

- Remove the range electrical service cover, located on the back, lower lefthand corner.

- [nstatl a 3/4" (I.91 cm) clamp in the hole provided below the terminal block.

- Strip 3" (7.62 cm) of outer insulation from the cable.

- Strip It2" (I .27 era) of insulation from each wire.

- Pull the cable through the cable clamp. Attach the BLACK, RED, and WHITE wires (see

illustration). Tighten the terminal block nuts and the cable clamp and install cover.

j I

I \I

4,/,"(_1._=_ SHADEDAREA \ i

---,4 ----- V

/ i _L_,._ _._ :-o_.tt . 1 $" (782 ¢m}

1 I

ELECTRICAL CAI_

Page 7

2_0Eawar_sE,tr_e[ %

C'.m:e,anaTe.nr_z_ee_7._11

Fax_2._-478-_70

16. CONNECT ELECTRICAL (FOUR CONDUCTOR WIRE)

- CAUTION: Make sure power to cable is OFF.

- Remove the range electrical service cover located on the back, lower left-hand corner. Remove the

ground strapscrew and bend the strap up as shown.

- [nstall a 3/4 (1.19 cm) cable clamp in the hole provided, below the terminal block.

- Strip 3" (7.62 cm) of outer insulation from the cable.

- Strip lt2" (1.27 era) of insulation from each wire.

- Pull the cable through the cable clamp.

- Make a loop in the bare ground wire and attach it to the range with the screw that held the _m'ound

strap.

- Attach the BLACK, RED, and WHITE wires (see #15). Tighten the terminal block nuts and the

cable clamp.

- Tape the ground strap to the WHITE wire as shown. Installelectrical cover.

17. INSTALL Ot_IONS

- If a backsplash or side panels are to be used, install according to instructions included with those

accessories.

18. POSITION RANGE

- Free-Standing: Adjust the range feet so the range and cabinet height wil! be approximately the

same. Slide the range into place, taking care not to damage floor coventlg.

- Slide-In: Carefully lift and place the range on the cabinet top.

.==,=,=.,=_ \

, _ 'WlRI::

a

i

|

J

Page 8

Cus[ome r _ePdc_

2_0EdwardsStreet,SE

Ceveian_.Tennessee373I I

Te!:a22-'72-3333

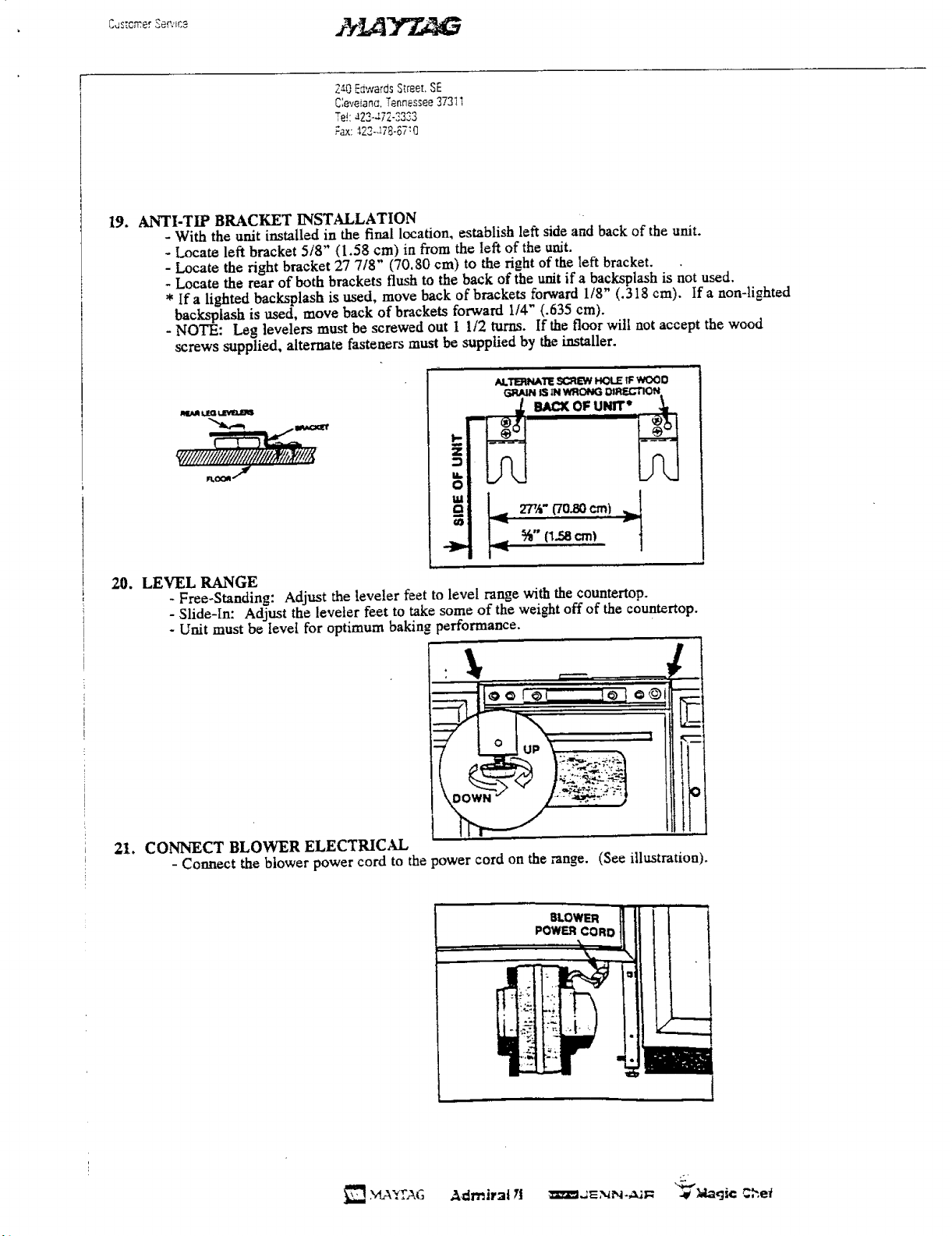

t9. ANTI-TIP BRACKET INSTALLATION

- With the unit installed in the final location, establish left side and back of the unit.

- Locate left bracket 5/8" (1.58 cm) in from the left of the unit.

- Locate the right bracket 27 718" (70.80 cm) to the right of the left bracket.

- Locate the rear of both brackets flush to the back of the unit if a backsplash is not used.

* Ira lighted backsptash is used, move back of brackets forward 1/8" (.3t8 cm). Ira non-lighted

backsp|ash is used, move back of brackets forward 1/4" (.635 cm).

- NOTE: I._g levelers must be screwed out I I/2 turns. If the floor will not accept the wood

screws supplied, alternate fasteners must be supplied by the installer.

mt_ot t.zQ_

AL_TE SCREW_t.E TFWCX_0

GRAINIS1NWRONGOII_.b'-I'IQN

_ii/iii/iiiiiiiiltli!/i/#il#'i//_ti7!&

20.

LEVEL RANGE

- Free-Standing: Adjust the leveler feet to level range with the countertop.

- Slide-in: Adjust the leveler feet to take some of the weight off of the countertop.

- Unit must be level for optimum baking _erformance.

21. CONNECT BLOWER ELECTRICAL

- Connect the blower power cord to the power cord on the range. (See illustration).

z

0

£ 2-,",/,-ffo.8o_m) _!

_),. %" (1.5_1cm)

. , J ,_

Page 9

22. INSTALL FLEX DUCT

- Attach the flex duet to the blower and range (See illustration), Using a screwdriver, securely tighten

duet clamp at each connection.

3. CHECK OPERATION

- Unpack and in,stall grill element in one side and cooking cartridge in other side.

- Be sure to remove all packaging materials from unit prior to applying power.

- Switch the electrical circuit breaker to the ON position.

- Consult Owner's Manual for operation.

- Check range top elements, Fan comes on automatically when grill is turned on, cooking

cartridge does not energize fan automatically.

- Check oven.

- Check vent fan.

- With vent fan on, cheek all vent duct connections to the outside to make sure there are no airleaks.

240EdwardsS_r_e[.SE

C[eveiane,Tennessee3731;

Tei:423.47Z-,_333

F,a×:422-47_,-3710

24. INSTALL LOWER DOOR

- After'check for air leaks at duct connections, install the lower range door,

CHECX HEAT '

AIR

CONTROLS

HEAT

[

-\

3,UV_L'_G Idrn|ral ?1 =,_E_'4N-AIR wia¢, qi¢ C."_f

Loading...

Loading...