Jenn-Air 41007605 User Manual

J ENN-AIR W INE C HILLER

TABLE OF C O NTENTS

Introduction..............................................................................1

Safety ........................................................................................2

Installation.........................................................................3–11

Operation................................................................................12

Features ..................................................................................13

Care and Cleaning..............................................................14

Before Calling for Service................................................15

Warranty..................................................................................17

Guide du propriétaire ........................................................18

Guía del Propietario............................................................35

OWNER’S

GUIDE

Form No. A/05/03 Part No. 41007605 Litho U.S.A.

1

DANGER – Immediate hazards which WILL result

in severe personal injury or death.

DANGER

WARNING – Hazards or unsafe practices which

COULD result in severe personal injury or death.

WARNING

CAUTION – Hazards or unsafe practices which

COULD result in minor personal injury.

CAUTION

What You Need to Know About

Safety Instructions

Warning and Important Safety Instructions appearing in

this manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating appliance.

Always contact your dealer, distributor, service agent or

manufacturer about problems or conditions you do not

understand.

Congratulations on the purchase of a Jenn-Air

Refrigerated Wine Chiller.

We appreciate your purchase decision and feel

confident you will be happy with this appliance for

years to come. For best results, please read this guide

carefully. You will find instructions on the proper

operation and maintenance.

Should you ever need our future assistance with your

wine chiller, a complete model and serial number

recorded in the spaces below will be extremely helpful.

These numbers are found on a data plate inside the

wine chiller located on the upper left side.

Model Number__________________________________

Serial Number __________________________________

Purchase Date __________________________________

Dealer Name ___________________________________

Dealer Address _________________________________

Dealer Phone ___________________________________

Before Calling for Service . . .

If something seems unusual, please check the “Before

Calling For Service” section, which is designed to help

solve basic problems before calling a servicer.

What if These Features are Different

from Mine?

This book is intended to show the variety of features

that are available in the product line. If you have

questions, write us (include your model number and

phone number) or call:

Jenn-Air Customer Assistance

P.O. Box 2370

Cleveland, TN 37320-2370

U.S.A and Canada 1-800-JENNAIR

(1-800-536-6247)

1-800-688-2080 (U.S.A. TTY for hearing

or speech impaired)

(Mon.-Fri., 8 a.m.-8 p.m. Eastern Time)

Internet: http://www.jennair.com

Introduction

Recognize Safety Symbols, Words,

Labels

2

Important Safety Instructions

•When using your appliance, always follow basic

precautions.

WARNING

•This appliance is designed to operate on a normal

115 volt, 15 amp, 60 cycle line. There should be a

separate, grounded circuit serving this appliance

only. Do not use an extension cord. Do not use

any device that will alter the electrical

performance of this appliance.

WARNING

• Use the wine chiller only for its intended purpose.

NOTE: This product is not intended for food storage.

•To prevent possibility of hazard due to electrical

shock, never plug the wine chiller into a receptacle

which has not been grounded adequately and in

accordance with the local and national electrical

codes. See warning and the grounding

instructions that follow.

• Disconnect the power cord to the wine chiller before

cleaning, servicing or replacing a light bulb.

• In case of power failure, minimize door openings.

• Any electrical service cord that becomes frayed or

damaged should be immediately repaired or

replaced. Never unplug your appliance by pulling on

the power cord.

•To prevent fire hazard, your wine chiller should not

be operated in the presence of gasoline or other

flammable vapors and liquids.

•To prevent injury, children should not climb, hang or

stand on this wine chiller.

IMPORTANT: Child entrapment and suffocation are

not problems of the past. Junked or abandoned

refrigeration products are still dangerous…even if they

will sit for “just a few days.” If you are getting rid of

your old refrigeration products, please follow the

instructions below to help prevent accidents.

•Take off the doors.

•Leave the shelves in

place so that children

may not easily climb

inside.

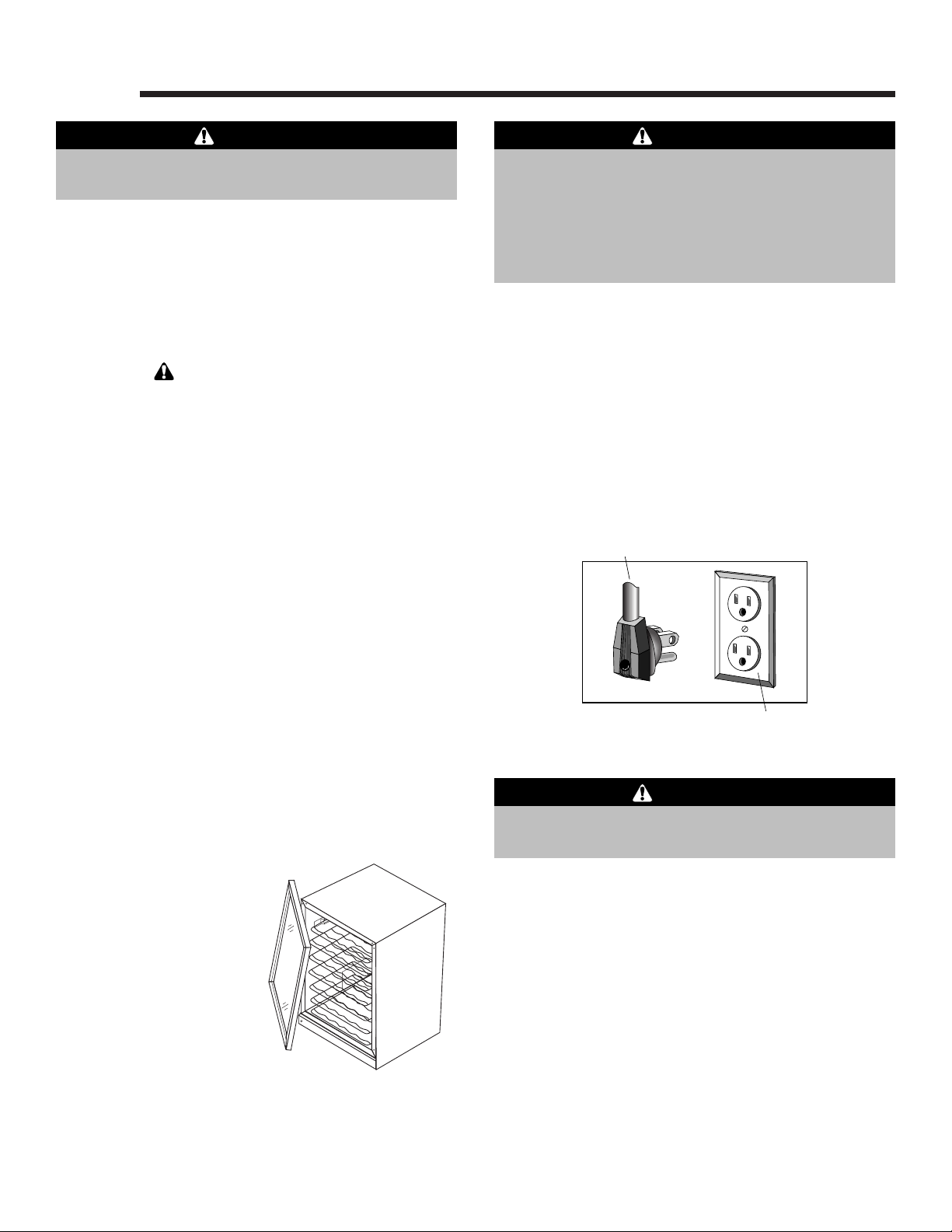

This appliance is equipped with a three-pronged

grounding plug for your protection against possible

electrical shock hazards. It must be plugged into a

grounding receptacle. Where a standard two-prong

wall receptacle is encountered, it is the personal

responsibility and obligation of the customer to have it

replaced with a properly grounded three-prong wall

receptacle. Do not under any circumstances, cut or

remove the third (ground) prong from the power cord.

Do not use an adapter plug.

Save These Instructions For Future Reference

Power supply cord with

three-prong grounding plug

Grounding type

wall receptacle

• This wine chiller should not, under any

circumstances, be ungrounded.

WARNING

3

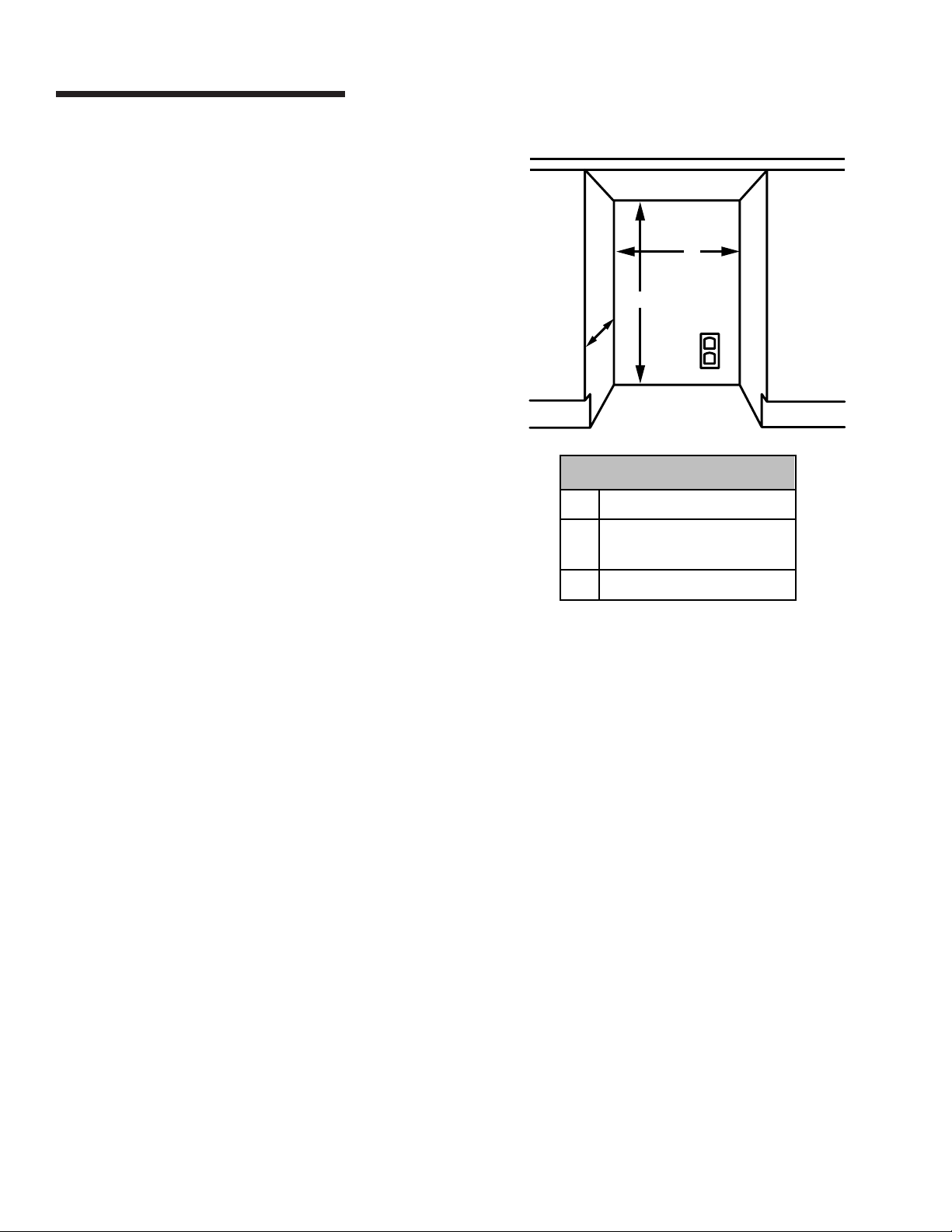

Installation

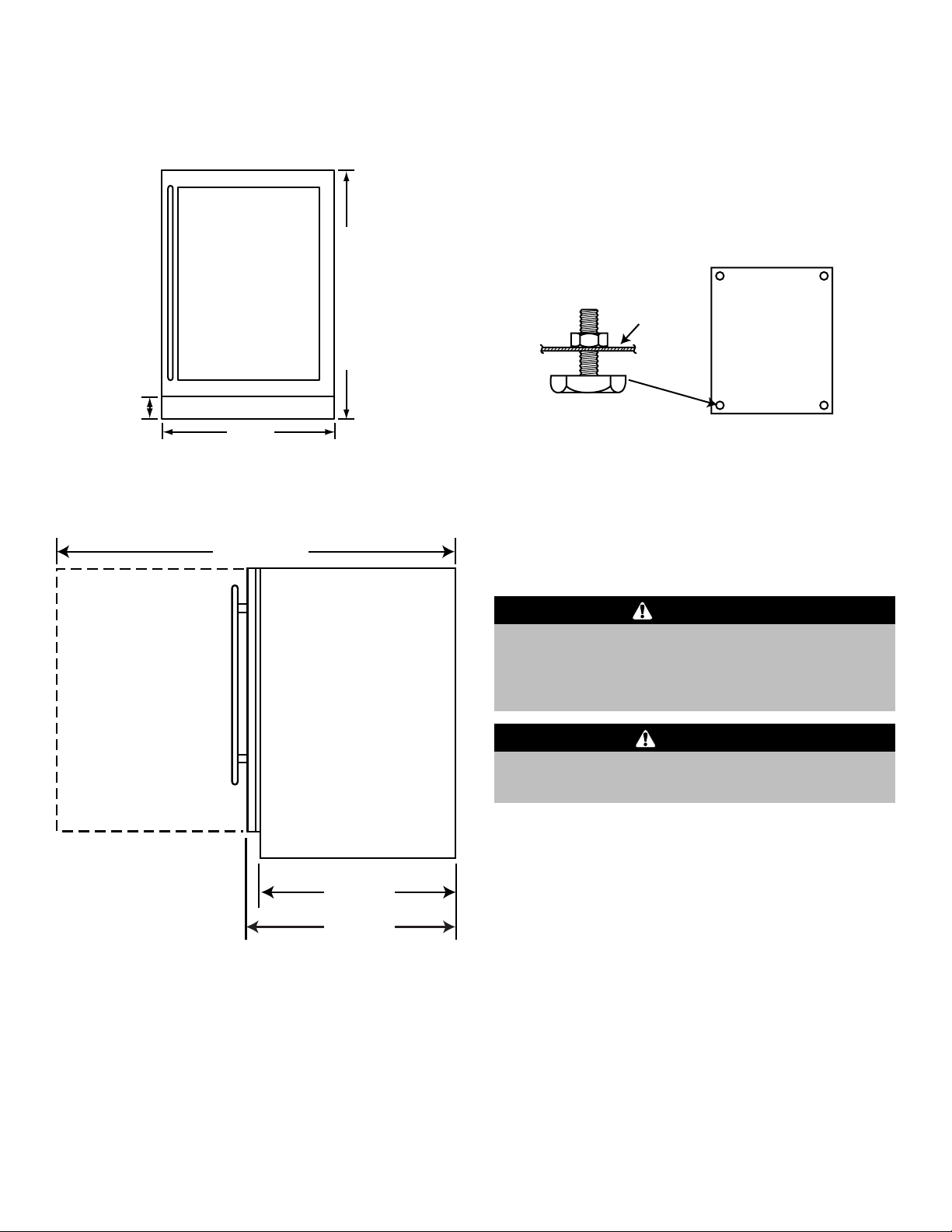

UNDER COUNTER CUTOUT

A 24" (61.0 cm)*

B Min. 34

1

⁄2" (87.6 cm)

Max. 35

1

⁄4

" (89.5 cm)

C 24

1

⁄8" (61.27 cm)

* If door is recessed between cabinets, cabinet cutout

must be 24

1

⁄4" (61.6 cm) in width.

Materials Needed

•

1

⁄8" Allen wrench

•

5

⁄16" socket

• Phillips screwdriver

•Putty knife

• Carpenter’s level

Select Location

The wine chiller was designed to be installed under the

counter. Its proper location will ensure peak

performance. Choose a location indoors, away from

heat and out of direct sunlight. Best performance will

be maintained when installed within the following

parameters:

Ideal Ambient

Temperature Range

Built-In........................................................65 - 80° F

(18 - 27° C)

Provisions for electricity should be determined before

placing the wine chiller in its final location (see page 2).

Cabinet Clearance

Ventilation is required from the bottom front section of

the wine chiller. Keep this area open and clear of any

obstructions.

The adjacent cabinets and counter top can be built

around the wine chiller as long as no top trim or

counter top is installed lower than the top of the hinge.

Installation should allow for the wine chiller to be

moved if service is ever required.

Cabinet Cutout Dimensions

A

B

C

4

•To prevent injury, one person should not attempt to

tilt the wine chiller by himself. Have someone else

assist to prevent the wine chiller from falling during

leveling leg installation.

WARNING

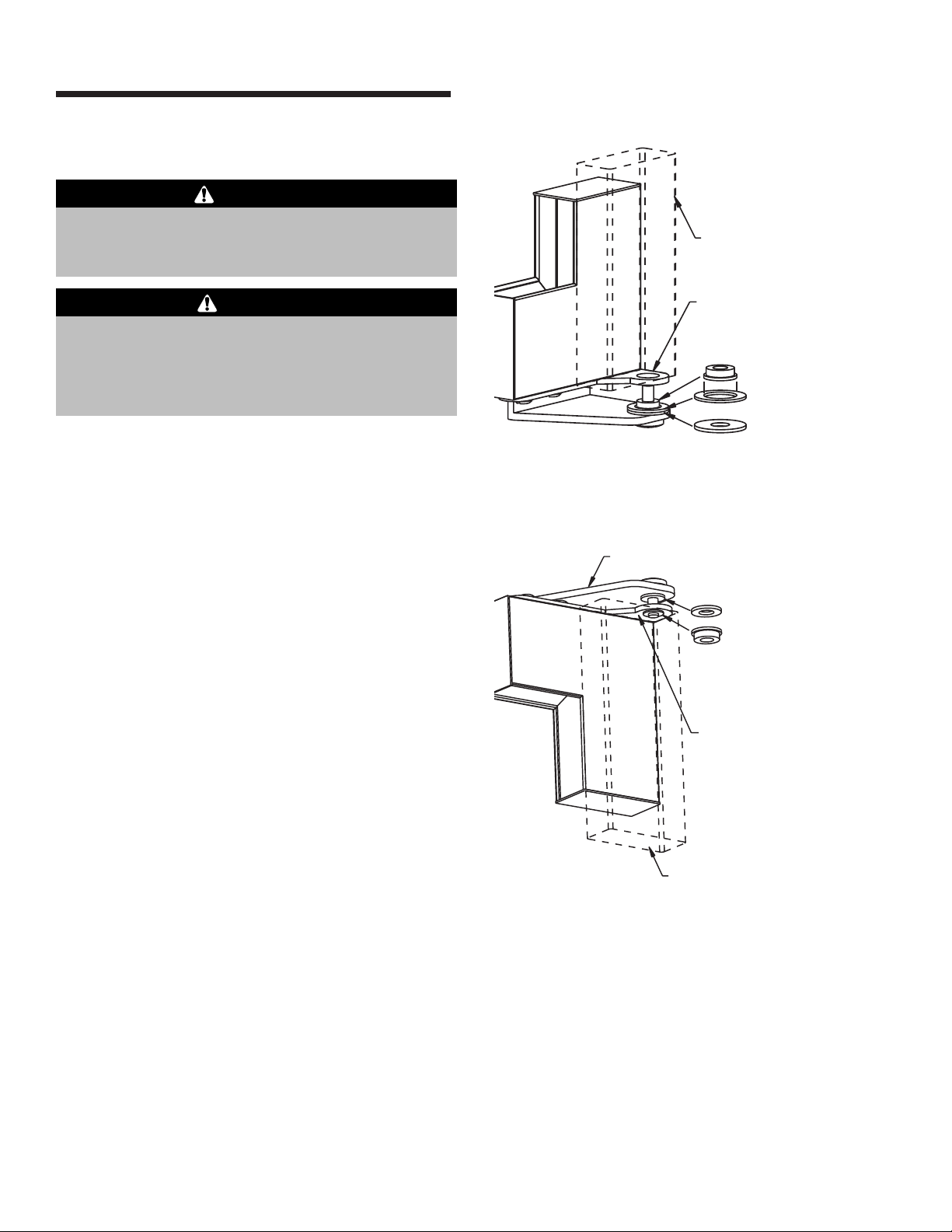

Dimensions Leveling Legs

Install leveling legs (located in literature pack):

•With at least two people, tip wine chiller backwards

until there is approximately 12" (31 cm) of clearance

between the floor and the wine chiller.

• Screw one front leveling leg into the screw

impression found in each corner. Leveling legs

should be screwed in until snug.

• Repeat the above procedures to install the rear

leveling legs.

•The wine chiller should remain upright at least

30 minutes prior to plugging it in.

CAUTION

Level the Wine Chiller

Using a carpenter’s level, check to be sure the wine

chiller is level from side to side and from front to back.

Leveling adjustments can be made by turning the

leveling legs counter-clockwise to increase height and

clockwise to reduce height.

NOTE: The wine chiller should not wobble. Use shims

to add stability when needed.

3"

(7.6 cm)

min. 34"

(86.4 cm)

max. 35"

(88.9 cm)

with

leveling

legs fully

extended

47

1

⁄4

"

(120.0 cm)

Side

22"

(55.9 cm)

24

1

⁄

4"

(61.6 cm)

Bottom of

wine chiller

Weldnut

(each bottom

corner of unit)

Leveling leg

(4 per wine chiller)

23

7

⁄8"

(60.6 cm)

Front

5

Installation, cont.

The wine chiller door can have a left or right hand

swing. Typically the door is installed on the wine

chiller with a right hand swing configuration. To

change to a left hand swing, follow the instructions

listed below.

Materials Needed

•

1

⁄8" Allen wrench

• Phillips screwdriver with magnetic tip

• Needle-nose pliers

•

5

⁄16" nut driver

• Small flat-blade screwdriver

Black or white framed model:

• 15 mm deep-well socket and wrench

Custom wood frame or stainless steel frame overlay model:

• 15 mm open-end wrench

1. Note the thermostat control knob setting so you

can reset the thermostat knob to its proper setting

after the door reversal is complete.

2. Turn the thermostat control knob counterclockwise

until the “OFF” setting is at the 12:00 position. The

wine chiller’s refrigeration system will shut off.

3. Using the

1

⁄8" Allen wrench, remove the screw from

the top hinge of the wine chiller. Be sure to

support the door so that it does not fall. Lift the

door gently up and away from the bottom hinge.

4. Lay the glass door face down on a smooth, nonabrasive surface protected by towels or rugs to

avoid accidental damage.

5. Using the

5

⁄16" nut driver, remove the 5⁄16" hex head

screws which are holding the top and bottom

hinges. Set screws and hinges aside for later.

6. Using the Phillips screwdriver, remove the Phillips

head hinge pin from the bottom hinge. Set the

hinge, hinge pin and plastic washer aside for later.

For custom wood frame model, skip to step 12.

7. Pull the door gasket out of the door’s back frame,

enough to allow access to the screw holes and the

back of the door lock.

8. Using the Phillips screwdriver, remove the Phillips

screw at the end of the door lock. Set the Phillips

screw lock washer, lock cam and lock/cam

extension pieces aside for later.

9. Stainless steel frame overlay model only: Remove

the ten screws that secure the stainless steel frame

overlay to the glass door. Set the screws aside for

later.

10. Black or white framed model: Use the 15 mm

deep-well sock and wrench.

Stainless steel frame overlay model: use the 15 mm

open-end wrench.

Loosen the retaining nut that secures the lock to

the door frame. If the nut falls back into the door

frame, use the needle-nose pliers to retrieve it and

set the nut aside for later.

11. Gently lift the door end up where the lock is

currently located and let the lock fall out and away

from the door. Set the lock aside for later.

12. Using the Phillips screwdriver, remove the two

screws holding the light striker plate to the back

side of the door.

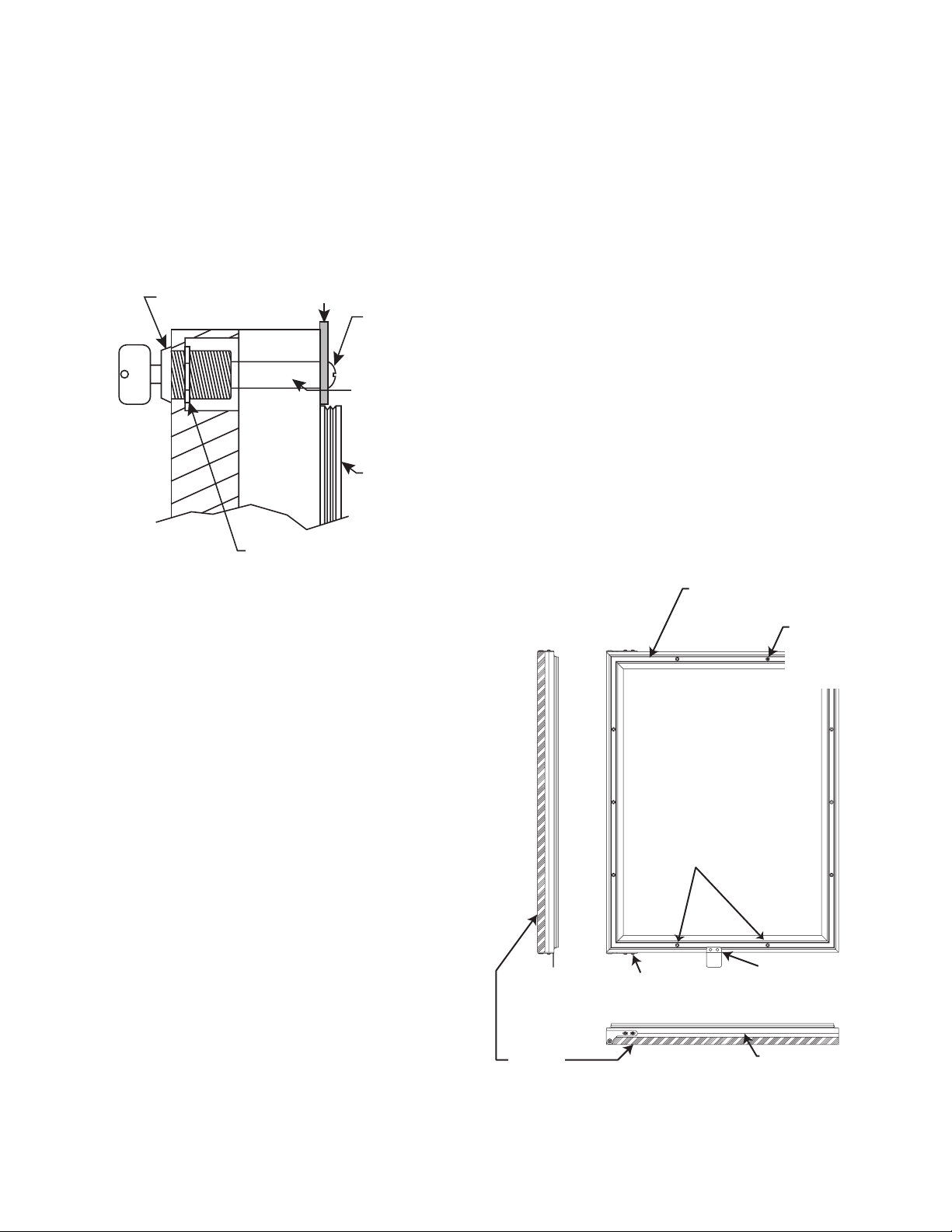

The following graphic shows the striker plate hole

locations when changing to a left hand door swing.

Remove the light switch striker from the bottom of

the right hand swing door and install the striker

plate in the holes as shown.

• To avoid electrical shock which can cause personal

injury or death, disconnect power to the wine chiller

before reversing the door.

WARNING

Reversing the Glass Door

Lock body

Key

Lock cam

Phillips

screw

Door

gasket

Glass

door

Panel

Lock

extension

Lock retainer nut

5

⁄

32" (0.4 cm) diameter

two holes, striker plate

Door

gasket

(Back view of glass door)

6

13. Relocate the light striker plate to the opposite end of

the door, lining up the two holes in the striker plate,

with the two holes at the opposite center of the

door. Remove the two hole plugs (select models)

and resecure the striker plate with the two screws.

For custom wood frame model, skip to step 21.

14. Lift the door or stainless steel frame overlay end

up, opposite of where the door lock was previously

located and insert the lock from the front side.

Hold the lock in place and gently lower the door or

stainless steel frame overlay back down.

Black or white framed model: Use the 15 mm

deep-well socket and wrench.

Stainless steel frame overlay: 15 mm open-end

wrench.

Reassemble the door lock’s retaining nut to the

lock. Follow step 15 before tightening the door

lock’s nut.

15. Reassemble the Phillips screw, lock washer and

lock cam back into the lock in the order they were

removed. Position the door lock’s cam so that it

projects upward from the top of the door. Make

sure the key slot on the front is aligned vertically,

from top to bottom. Lightly tighten the Phillips

screw to secure the lock assembly. Now tighten

the door lock’s retaining nut.

Stainless steel frame overlay model: Now tighten

the retaining nut.

Black or white framed model: Mark the alignment

of the door lock and then remove the Phillip’s

screw and lock cam. Now tighten the retaining

nut, then reassemble the lock cam and Phillip’s

screw.

Steps 16 – 19 are needed for stainless steel frame

overlay model only. If reversing the door on a

black or white framed model, skip to step 20.

16. Using the Phillips head screwdriver, remove the

door lock’s Phillips screw at the end of the door

lock’s extension and remove the lock cam. Set the

lock cam aside for reassembly later. Resecure the

lock extension to the lock with the Phillips screw.

17.Lay the stainless steel frame overlay face down on

a smooth surface. Align the glass door directly

over the stainless steel frame overlay so that the

lock extension will go through the hole in the glass

door that is on the opposite end of where the lock

was originally located. Look for the mounting

holes in the glass door and align these holes with

the threaded weld nuts in the overlay. Use the ten

screws removed in step 9 to resecure the stainless

steel frame overlay to the glass door.

18. Remove the door lock’s Phillips screw and reassemble

the lock cam to the lock extension and resecure.

19. Check to see that the lock easily turns a quarter

turn from vertical to horizontal.

20. Reinstall the door gasket by pressing it back into

the door channel. Make certain the door gasket is

secure and sealed. If necessary, use the small flatblade screwdriver to help push the arrowhead,

section of the door gasket into the gasket channel.

21. Locate the two hinges that were removed from the

right-hand side of the wine chiller. Insert the hinge

pin screw into the hinge that was on top and

tighten securely. This hinge will be the bottom

hinge on the left side of the cabinet.

22. Remove the six plastic hole plugs from the left

hand side hinge mounting holes.

23. Using the

5

⁄16" nut driver, mount the hinges on the

left side of the wine chiller using the six set-aside

5

⁄16" hex screws. Tighten screws securely.

24. Install custom wood frame panel (select models,

refer to page 7).

25. Gently lift the door up and place the door on the

bottom hinge/hinge pin assembly. Make sure the

plastic washer is installed on the bottom hinge

before placing the door on it.

26. Using the

1

⁄8" Allen wrench, secure the door to the

top hinge with the Allen hinge pin screw.

27. Make certain that the door swings freely, the door

gasket seals properly and the interior light goes on

and off as the door opens and closes.

28. Confirm that door lock turns a quarter turn from

vertical to horizontal and that this locks the door

closed.

29. Replace all hole plugs.

30. Reconnect the power to the wine chiller. Return

the control knob to its previous setting.

7

Installation, cont.

Prepare the Custom Door

Wood Frame

Custom Handle

1. A custom handle (not supplied) must be installed.

2. Drill pilot holes through the custom panel to match

the handle. Countersink the holes in the back of

the panel.

3. Attach the custom handle to the front door panel

assembly.

NOTE: The custom handle screws should be installed

through custom panel and into the custom handle.

The screw heads should be countersunk so the inside

panel surface can be installed flush with the wine

chiller door.

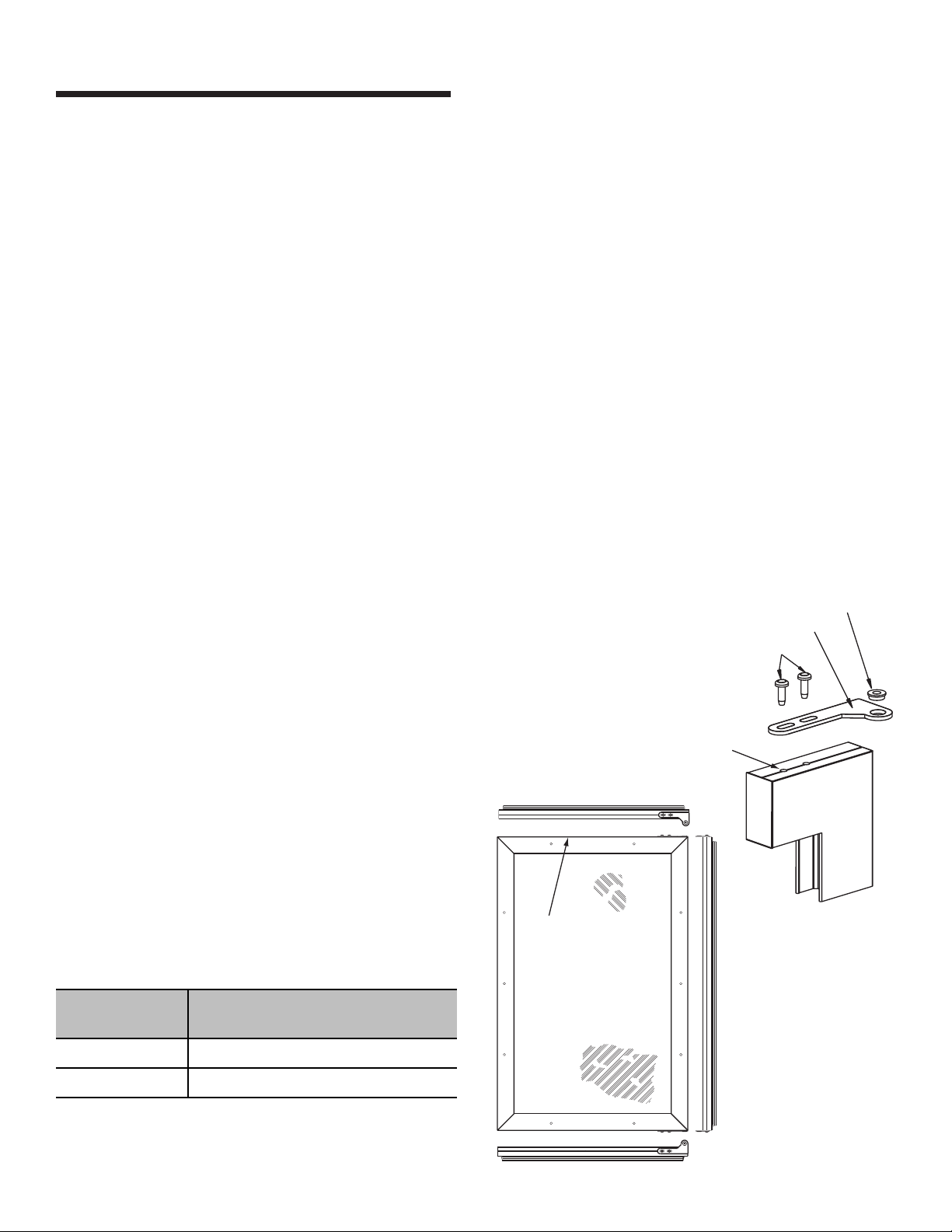

Door Wood Frame Dimensions

Overall width:.....................................................23

7

⁄16

" (59.5 cm)

3

1

⁄2" (8.9 cm) toe kick height: ..........................305⁄16" (77 cm)

4" (10.2 cm) toe kick height: ......................29

13

⁄16" (75.7 cm)

Door frame minimum width

to cover door extrusion:...................................1

23

⁄32" (4.4 cm)

Thickness:.......................

5

⁄8" to 3⁄4" (1.6 to 1.9 cm) maximum

Wood Screws

1. #8 pan head wood screws are recommended to

properly secure the custom wood panel to the

wine chiller door.

2. A total of ten screws will be needed for a 3

1

⁄2" (8.9 cm)

toe kick or eight screws for a 4" (10.2 cm) toe kick.

3. Use only pan head screws.

4. Be sure the screw length is NOT longer than the

wood thickness at the screw locations.

5. Use the following pilot hole drill sizes for the frame

material.

Type of Pilot Hole Drill Size for

Wood #8 Pan Head Wood Screws

Hardwood

3

⁄32" (0.24 cm)

Softwood

5

⁄64" (0.20 cm)

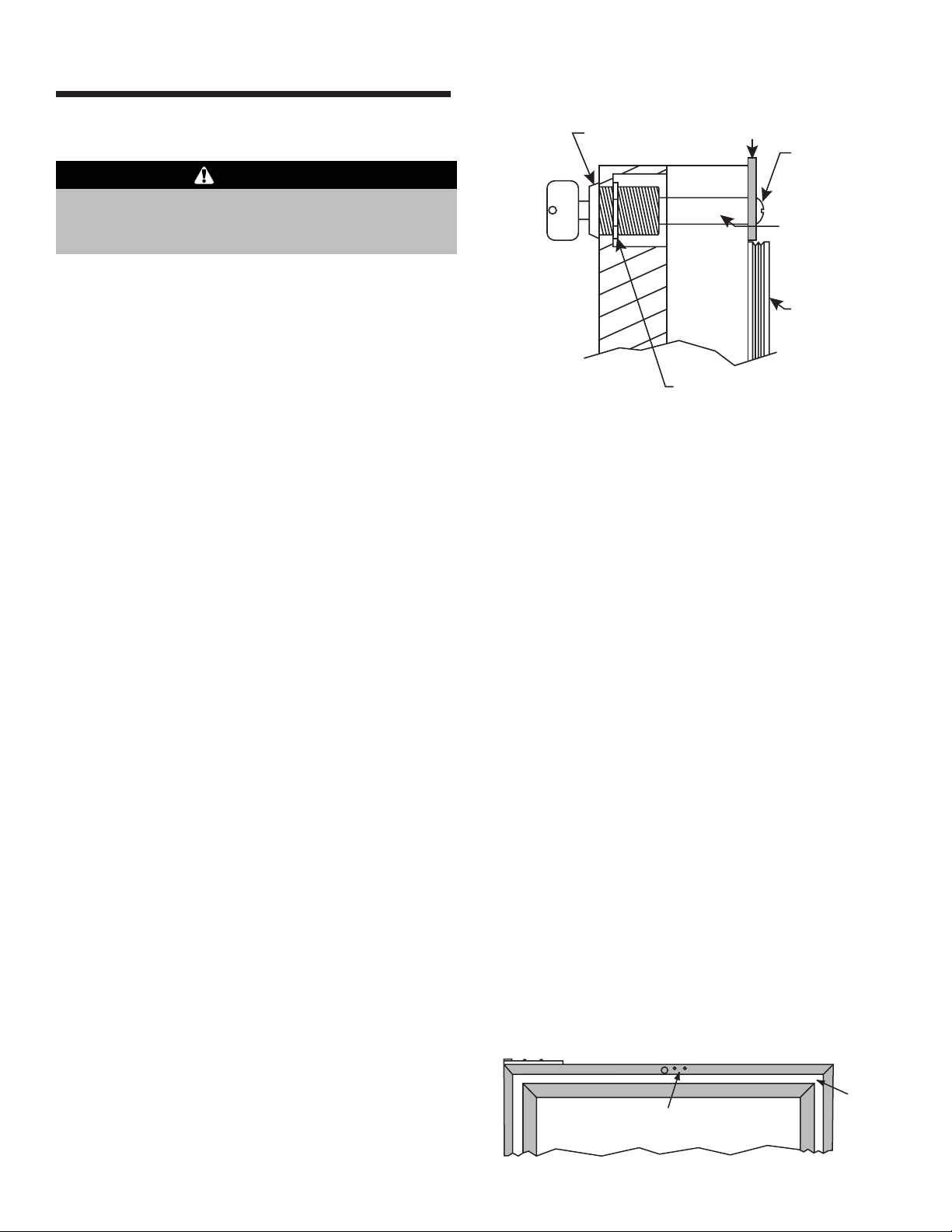

Assemble Door Hinge Brackets

NOTE: Skip this step if hinges are already attached.

1. Attach the top and bottom door hinges to the door

with the 10-32 machine screws and a

1

⁄8" Allen

head driver as shown in the following figure.

2. Press in the shoulder bushings to the top and

bottom door hinges. Make certain that the

shoulder is to the outside of the door as shown in

the following figure.

3. Test fit the door to the wine chiller to make certain

door will hang correctly. The door is hung correctly

when the top of the door is parallel to the top of

the wine chiller. Adjustments can be made by

loosening the door hinge machine screws and

moving the door hinge on the door.

4. Tighten all four machine screws after adjustments

have been made.

5. Remove the door from the wine chiller by removing

the top hinge set screw and angling the door off

the bottom hinge pin.

Right

hand

swing

door

This surface parallel

to the wine chiller.

Door front

surface

Typical top and

bottom door hinge

assembly.

Shoulder bushing

Door hinge

Door hinge

screw holes

10-32 machine

screws

8

Prepare the Wood Frame

Lock Hole Detail

For a 3

1

⁄2

" (8.9 cm) toe kick

(covers the entire door extrusion)

Optional for a 4" (10.2 cm) toe kick

(to match existing cabinetry toe kick height)

1

⁄4" (0.6 cm) x 3⁄8" (1.0 cm) deep hinge screw clearance

hole. Locate and drill using door hinge hole after the

door has been aligned to the wine chiller and when

the wood is positioned on door.

Mounting surface

(non-face) side

Mounting surface

(non-face) side

1

⁄

4" (0.6 cm) x

3

⁄

8" (1.0 cm) deep hinge screw clearance

hole. Locate and drill using door hinge hole after the

door has been aligned to the wine chiller and when

the wood is positioned on door.

Mounting surface

(non-face) side

Mounting surface

(non-face) side

Pre-drilled pilot holes

10 places do not drill

through wood frame

Back side of door

Back view

Pre-drilled pilot holes

8 places do not drill

through wood frame

Back view

30

5

⁄16"

(77.0 cm)

29

13

⁄16"

(75.7 cm)

22

1

⁄2"

(57.1 cm)

22

1

⁄2"

(57.1 cm)

15

5

⁄

32"

(38.5 cm)

7

13

⁄16

"

(19.8 cm)

15

5

⁄

32"

(38.5 cm)

7

13

⁄16

"

(19.8 cm)

23

⁄32"

(1.8 cm)

23

⁄32"

(1.8 cm)

23

⁄32"

(1.8 cm)

23

⁄32"

(1.8 cm)

15

5

⁄8"

(39.7 cm)

7

13

⁄16"

(19.8 cm)

15

5

⁄8"

(39.7 cm)

7

13

⁄16"

(19.8 cm)

11

23

⁄32"

(29.8 cm)

23

7

⁄16"

(59.5 cm)

Thickness:

5

⁄8" to 3⁄4"

(1.6 to 1.9 cm)

15

⁄32" (1.2 cm)

diameter through hole

Mounting surface

(non-face) side of

wood frame

Back view of overlay

wood frame panel

Center Line

13

⁄16" (2.1 cm)

diameter counterbore

7

⁄16" (1.1 cm) deep

1

23

⁄32" (4.4 cm)

width to cover

door extrusion

15

⁄32" (1.2 cm)

9

Installation, cont.

•To avoid electrical shock which can cause severe

personal injury or death, disconnect power to wine

chiller before installing wood frame.

WARNING

Attach the Wood Panel to the Wine

Chiller Door

1. If the door is attached to the wine chiller, remove it

by unscrewing the top Allen head set screw at the

top hinge. Remove the door by angling the door

off of the bottom hinge pin.

Wood frame

Door hinge

Shoulder bushing

Washer

Washer

• Door can become disengaged if washers are not

installed.

• Door may not swing properly if all nylon

components are not installed as shown.

CAUTION

Bottom Hinge Corner

Wood frame

Cabinet hinge

Door hinge

Shoulder bushing

Washer

Top Hinge Corner

10

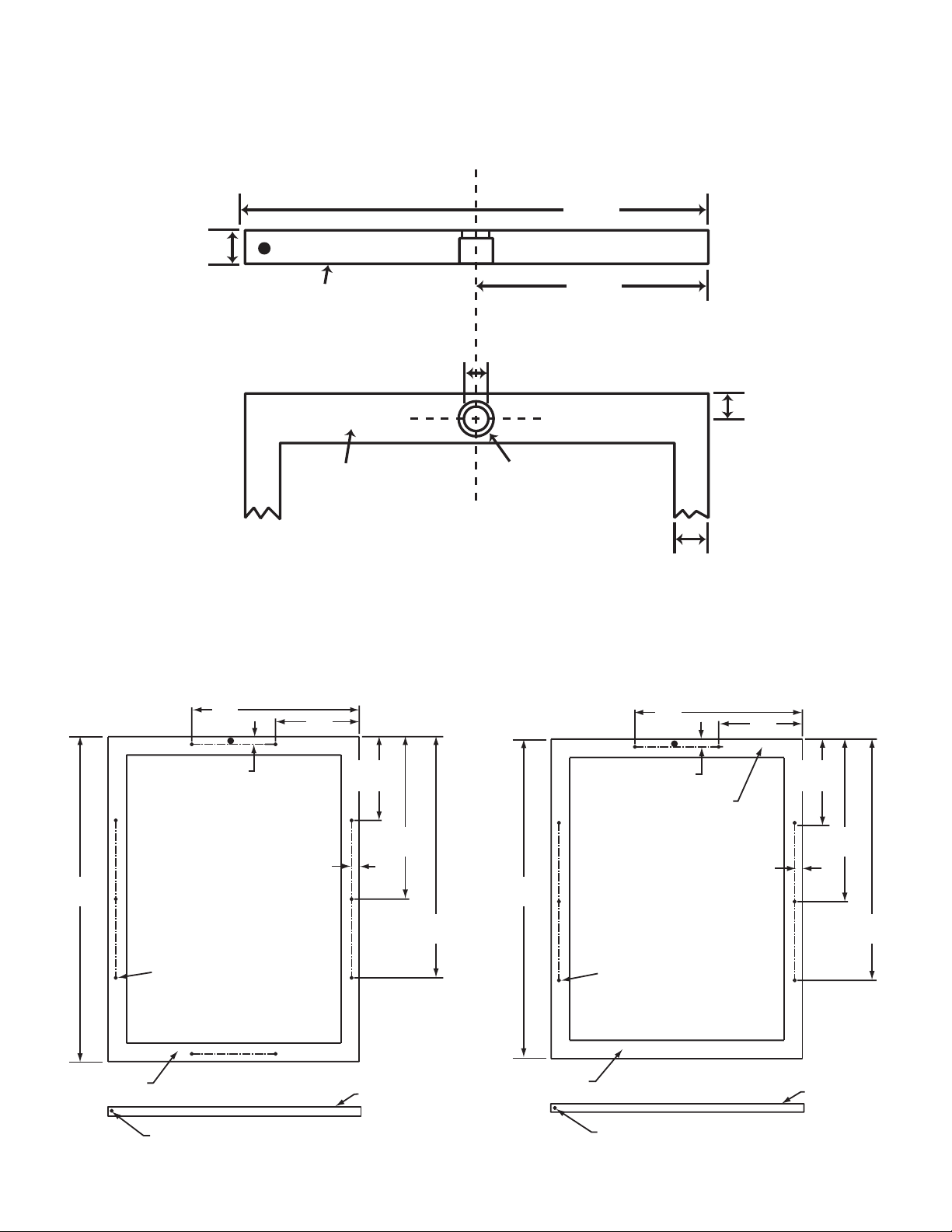

3. Peel back door gasket on the glass door to provide

access to the screw holes used to mount the

wooden frame and the hole for the lock’s extension

section at the top of the door.

4. Place the custom wood panel on a non-abrasive

surface, protected by towels or rugs, to avoid

accidental damage to the door finish.

5. Set the wood frame flush to the front of the door in

the desired location clamp wood frame to the door

if necessary. Check to see that the back of the

lock in the wood frame lines up with the hole in

the door.

6. Insert the wood screws through the back of the

door into the pilot holes in the wood frame and

tighten.

7. Assemble the door lock Phillips screw, lock

extension, lock cam and mount them to the back of

the lock body. Position the door lock cam so that it

projects upward from the top of the door. Tighten

the Phillips screw to secure the lock assembly.

2. Install the supplied lock body into the wood panel.

The lock and key assembly is supplied with your

wine chiller. Secure the lock body by using the

supplied 15 mm lock retaining nut and screwing it

on the lock body’s threaded section. Make sure

that the lock’s key slot is vertical, then tighten the

15 mm nut with a 15 mm deep-well socket.

Magnetic door gasket

Rear of door

Light door

striker plate

Bottom of door

1

⁄8" Allen head screws for

hinge adjustment (top

and bottom of door).

3

⁄8" (1.0 cm)

clearance

holes for wood

frame wood

screws

Attached

wood

Frame

Lock body

Key

Lock cam

Phillips

screw

Door

gasket

Glass

door

Wood

panel

Lock

extension

Lock retainer nut

8. Reinstall the door gasket by pressing into door

channel. Make certain the corners are inserted

fully. Insert the key into the lock and make sure

the lock operates properly.

9. Install the door to the wine chiller. Use the

washers (if provided) as shown on page 9.

10. Realigning the door may be necessary. Final door

adjustments can be made using a

1

⁄8" Allen wrench

to adjust the door hinges (see figure below).

11. Attach the door to the wine chiller by reversing

step number one above.

12. Make certain that the glass door swings freely, the

door gasket seals properly and the interior light

goes on and off as the door opens and closes.

13. Confirm that door lock turns a quarter turn from

vertical to horizontal and that this locks the door

closed.

14. Reconnect the power to the wine chiller. Return

the control knob to its previous setting.

Not required

for 4" toe kick

11

Installation, cont.

Wine Racks

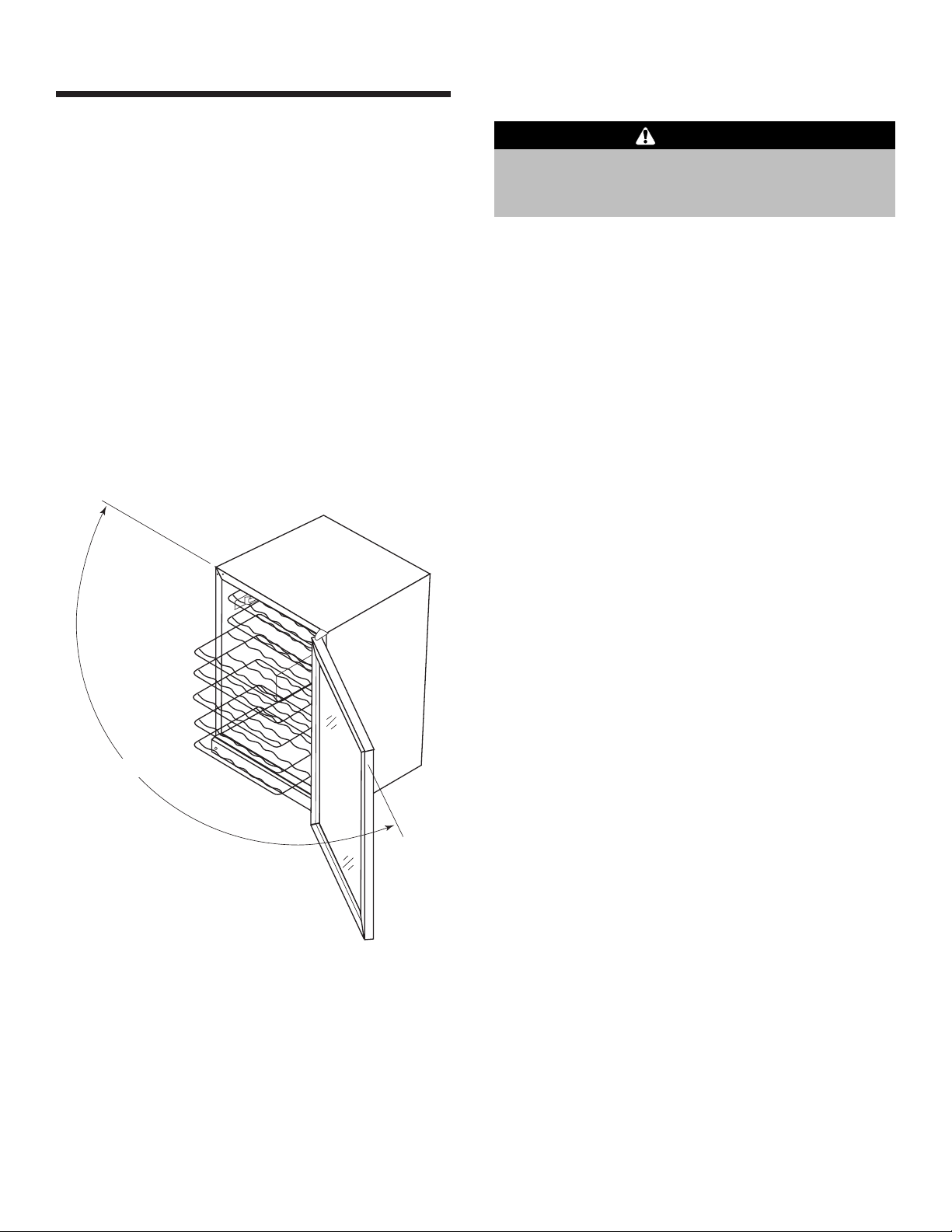

The wine chiller features slide out racks at the mid and

lower level. The upper two racks are fixed.

To be able to pull the wine racks out from the wine

chiller, the door from a closed position must be opened

a minimum of 150°.

Verify before completing installation of your wine

cooler at it’s proposed location will allow the door to

open sufficiently so that the wine racks can be pulled

out, if desired. As a possible solution, reversing the

door swing may provide enough door swing to pull out

the wine racks.

You may also alleviate the door swing situation, by

keeping the wine chiller’s door pulled out further than

the cabinet fronts.

• Do not attempt to remove a rack while it has wine

bottles stored. Always empty the rack prior to

removing it from the cabinet.

CAUTION

150°

12

O

F

F

7

6

5

4

3

2

1

C

O

L

D

E

R

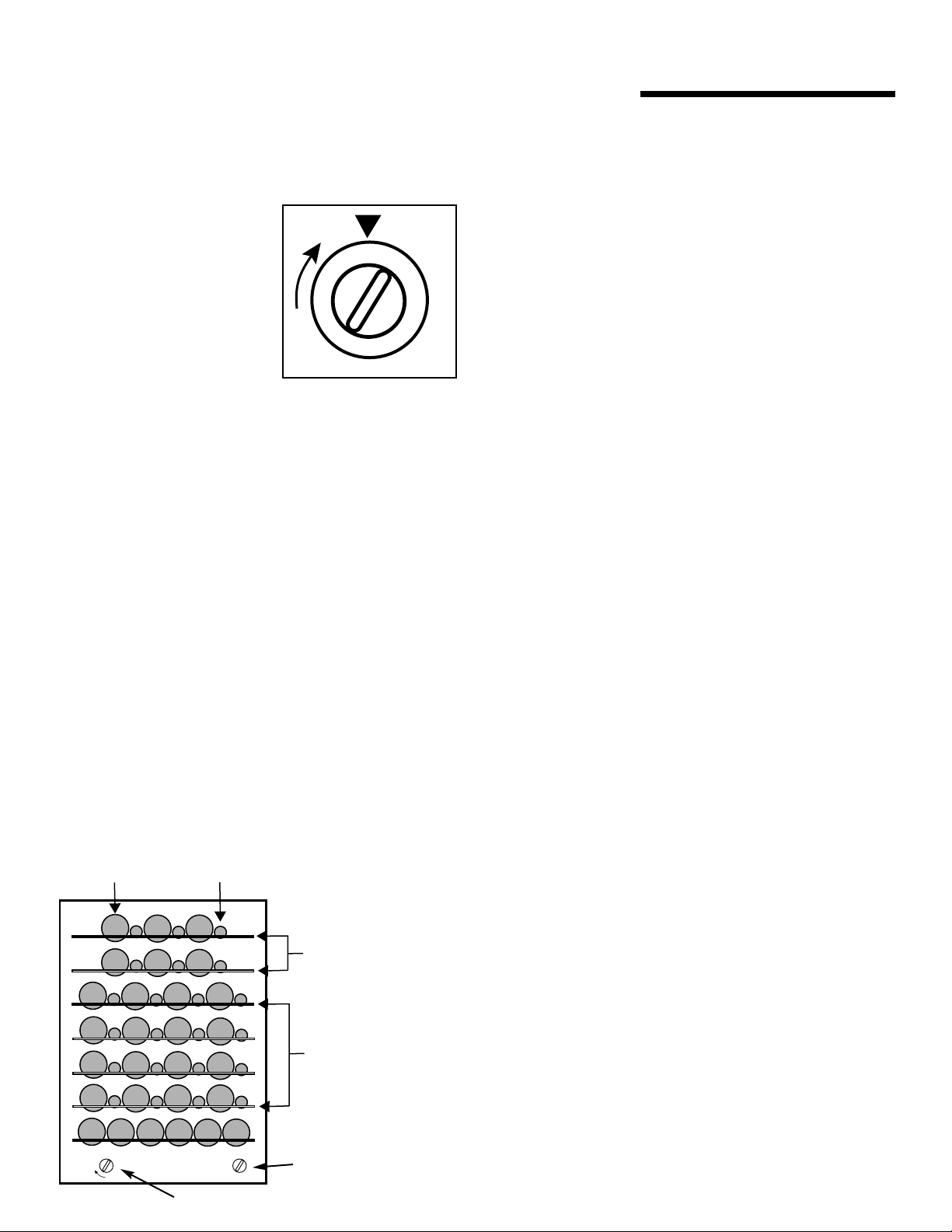

1. Setting the Control:

The available settings of 1 through 7 provide a

temperature range in the wine chiller from the low

forties to the mid sixties.

Use a coin to initially turn

the control clockwise to

the middle thermostat

setting (4). Allow at least

48 hours for the wine

chiller to stabilize before

making any adjustments to

the initial setting.

The mid setting on the control (4) provides

approximately 55° F (13° C) which is the

appropriate temperature for long term storage of

all types of wine.

The coldest setting (7) provides a storage

temperature of approximately 45° F (7° C) which is

the serving temperature for white wine.

The temperature can be adjusted by turning the

control clockwise for a colder temperature or

counterclockwise for a warmer temperature.

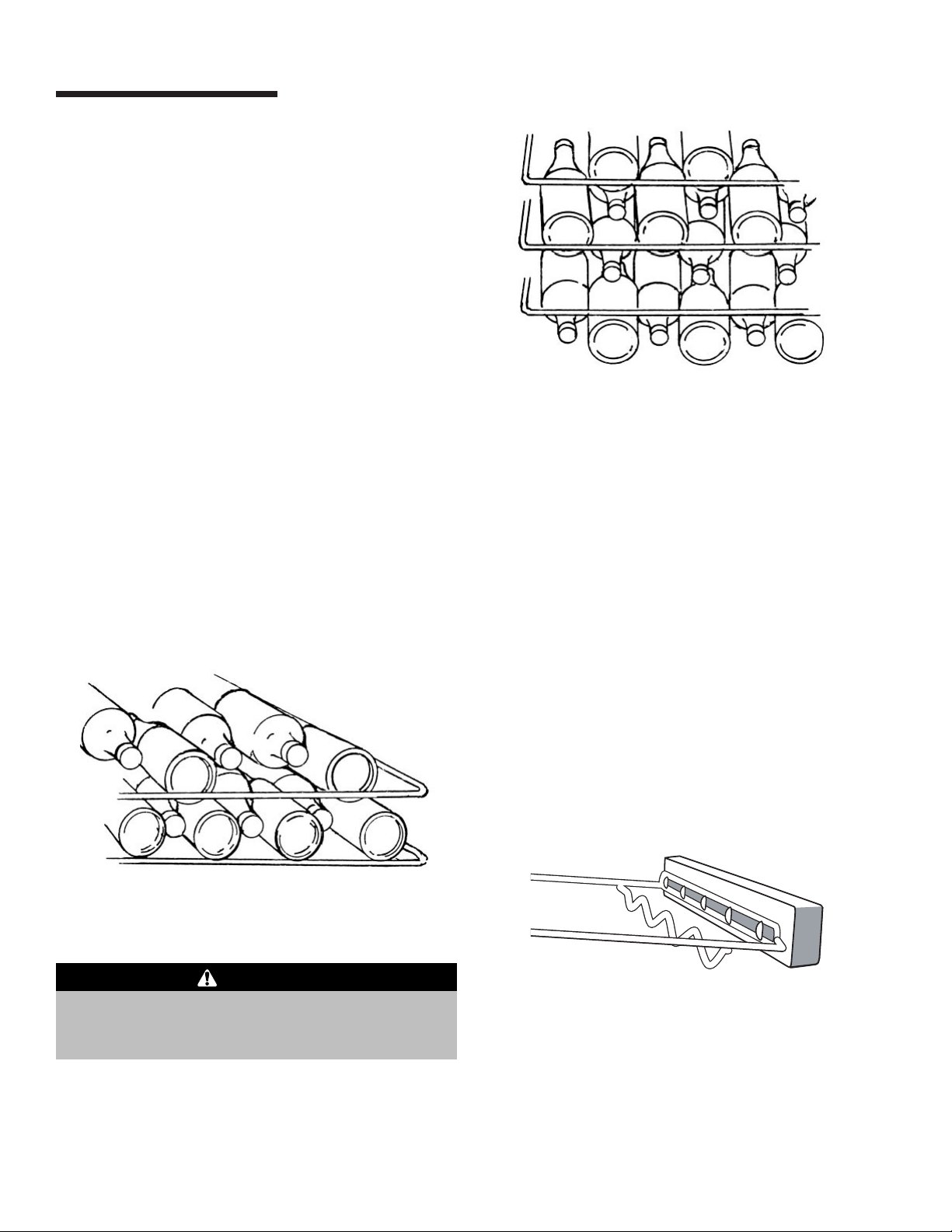

2. Insert Wine Bottles: The top two racks each hold

six bottles, with the necks alternating front (rear

bottles) to back (front bottles). The middle four

racks each hold eight bottles, with necks

alternating front (rear bottles) to back (front

bottles). The bottom rack holds six bottles and are

loaded with necks facing the rear. Tall bottles

should not be loaded on the bottom rack because

they may prevent the door from closing.

Front bottles

(necks facing

rear)

Rear bottles

(necks facing

front)

Loading Tips and Suggestions:

1. As with most refrigeration products, there is a

slight temperature variance at different locations

within the wine chiller.

The coolest areas will be at the rear of the four

middle racks. The front locations on these racks

are generally a few degrees warmer than the rear

locations.

The overall warmest storage location in the wine

chiller will be the upper two racks. This location in

the wine chiller is approximately 3° to 7° F (-1.5° to

-4° C) warmer.

2. Position white wines on the middle or lower racks

and red wines on the upper racks.

3. Turn off the light when it is not needed, as bottles

directly under the light will be exposed to a slightly

higher temperature when the light is on.

4. Place wines that are being stored for aging or long

term at the rear of the racks.

5. Place wines that will be used sooner on the front

half of the racks where labels are more readily

visible.

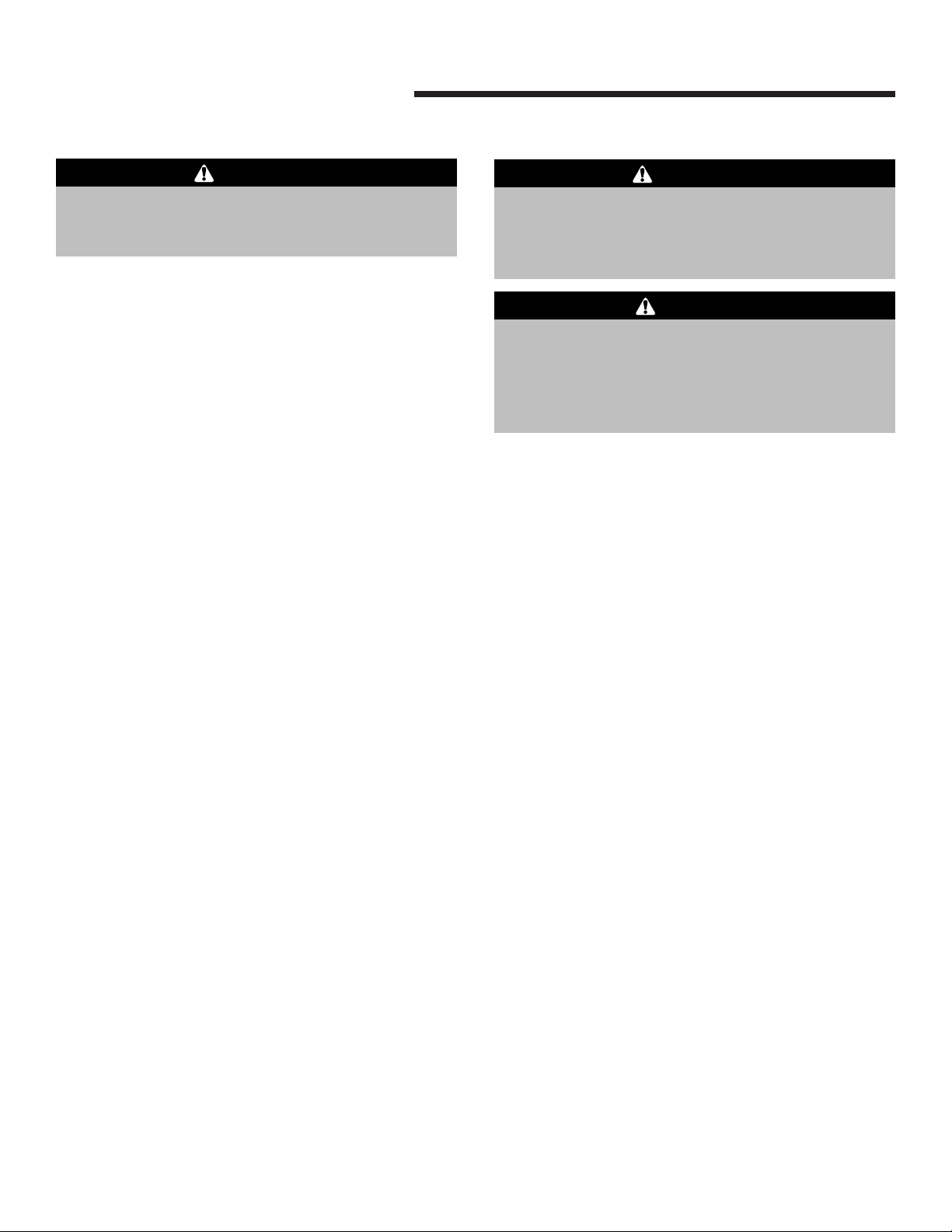

6. Magnums and other large bottles can be stored on

the upper right and left positions of the wine chiller

or on any of the middle racks, by removing the

rack directly above them.

Warmest locations

(better for red wine

storage)

Coldest locations

are at the rear of

these shelves

(better for white

wine storage)

Operation

Temperature control knob

Light control knob

F

F

O

1

2

3

7

6

D

5

L

4

O

C

R

E

13

Features

• Adjustable Temperature Control: The temperature

control is adjustable from the low forties to the mid

sixties. The temperature range allows flexibility for

storage temperature preferences and accommodates

storage of a variety of red, white and sparkling wines.

• Interior Light: The light control knob is located on

the lower right front of the wine chiller, in the toe

kick area.

The light automatically illuminates to full intensity any

time the door is opened, to make it easier to view the

wine labels.

To view the display of your wine collection, while the

door is closed, turn the light control knob (see page

12).

NOTE: When the knob is turned fully counter-

clockwise, the light is off when the door is closed.

In the full clockwise position, the light remains on

continuously. The knob can be set at any position in

between to achieve the desired level of light intensity.

The dimming feature only affects the light when the

door is closed. The light is always at full intensity

when the door is open.

Remember to turn off the light when it is no longer

needed.

• Pull-out Racks: The middle four racks may be

pulled out approximately 6" (15 cm) to facilitate

adding or removing bottles

• Single Bottle Racks: Because bottles are not

stacked on top of each other, you can easily view

and access your inventory without disturbing other

bottles.

• Lock: To secure your wine collection, the wine

chiller can be locked. Use the ejectable key that has

been shipped with your appliance to securely lock

the door.

NOTE: Lock is designed so key cannot stay inserted

into the lock.

• Wood Rack Fronts: There are four unfinished solid

maple rack fronts packed with your wine chiller.

These can be finished to match the surrounding

cabinetry in your home. Follow the finishing

instructions provided by the stain manufacturer.

NOTE: In many cases stains and/or finishes have

odors that may be objectionable in an enclosed area.

To Install: Place one rack front on each of the

middle four racks. Align the holes in the wood up to

rack front and gently tighten down.

• Do not attempt to remove a rack while it has wine

bottles stored. Always empty the rack prior to

removing it from the cabinet.

CAUTION

14

Care and Cleaning

Cleaning Light Bulb Replacement

• Condenser: The condenser tubing inside the wine

chiller does not require frequent cleaning; however,

satisfactory cooling depends on adequate ventilation

over the coils. Be sure that nothing obstructs the

required air flow openings in front of the wine chiller.

At least twice a year brush or vacuum lint and dirt

from the condenser for efficient performance by

unscrewing the grille on the bottom front of the wine

chiller.

• Wine Chiller: The painted cabinet can be washed

with mild detergent and water and thoroughly rinsed

with clear water. Never use abrasive scouring

powders.

• Stainless Steel Door Frame: Use a soft cloth or

sponge and wipe with the grain of the stainless steel.

Use mild detergent and water for light soil, Bon Ami*

for more moderate soil and Cameo Stainless Steel

Cleaner* for discoloration. Do not use chlorine

bleach or products containing chlorine bleach on

stainless steel.

After cleaning, rinse and dry. To restore luster and

remove streaks, follow with Stainless Steel Magic

Spray* (Jenn-Air model A912, part number

20000008).

• Interior: Wash interior compartment with mild

detergent and water. Do not use an abrasive

powder, solvent, polish cleaner or undiluted

detergent.

• Glass Door: Use a glass cleaner or mild detergent

and water and soft cloth to clean the glass door. Do

not use abrasive powders.

• Door Gasket: The vinyl gasket may be cleaned

with mild detergent and water, or a solution of

2 tablespoons baking soda to 1 quart warm water.

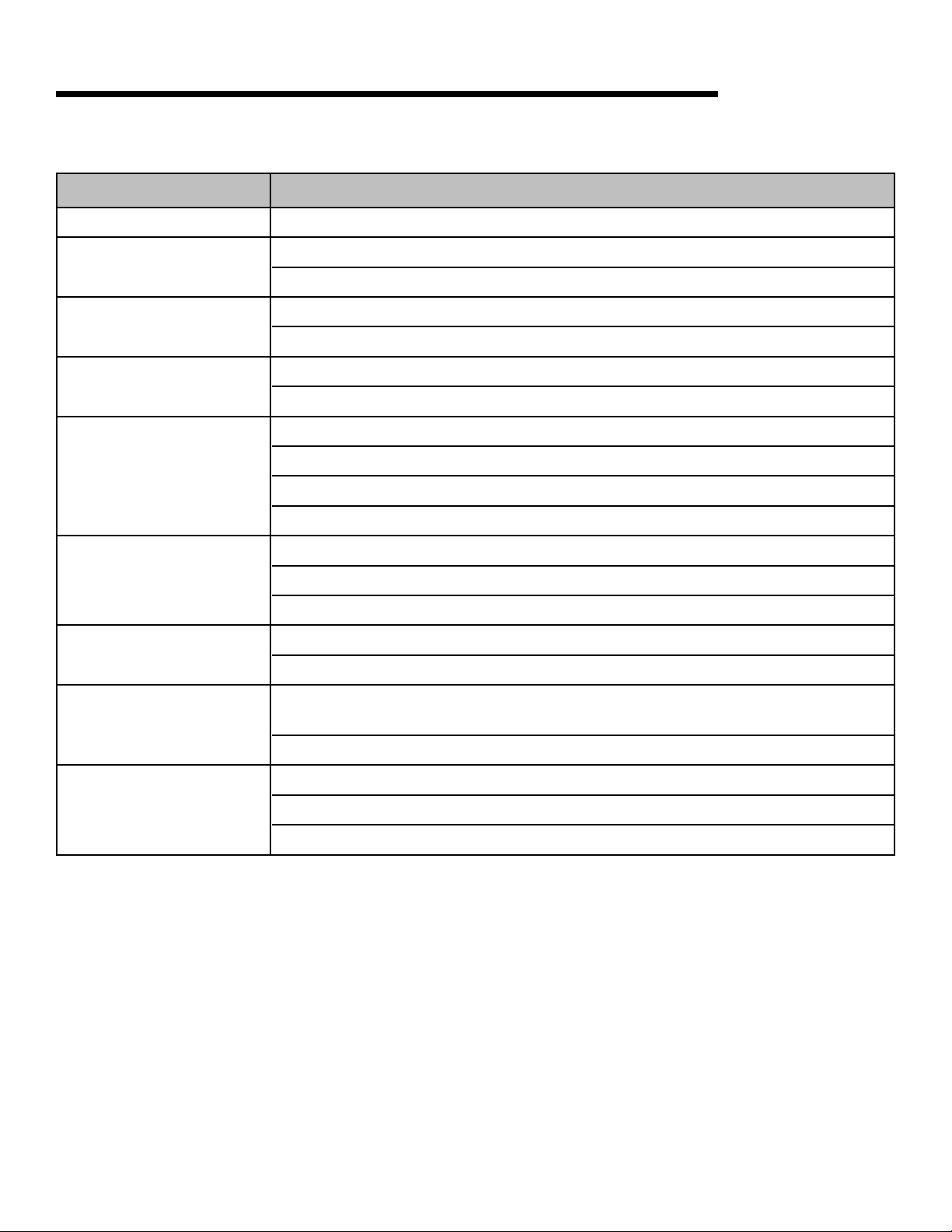

The wine chiller uses a 15 watt, intermediate base bulb

and is located inside the light shield. The light shield is

on the ceiling of the wine chiller and is held in place by

three screws. Remove the three screws and light

shield to remove the light bulb. Do not use a

replacement light bulb greater than 15 watts.

In the Event of a Power Failure

If the power fails, open the door as infrequently as

possible to maintain the temperature. A gradual rise in

temperature should not have any adverse effect on the

wine.

If it is extremely hot, you may want to move the wine to

the coolest location you can find until power is

restored.

* Brand names for cleaning products are registered trademarks of the respective manufacturers.

To avoid personal injury or property damage,

observe the following:

• Allow light bulb to cool.

•Wear gloves when replacing light bulb.

CAUTION

•To avoid electrical shock which can cause severe

personal injury or death, disconnect power to the

wine chiller before cleaning.

WARNING

•To avoid electrical shock which can cause severe

personal injury or death, disconnect power to the

wine chiller before replacing light bulb. After

replacing light bulb, connect power.

WARNING

15

Before calling for service check the troubleshooting table below. This table lists possible problems that you can

remedy without difficulty to avoid an unnecessary service call.

Before Calling for Service

PROBLEM POSSIBLE CAUSE/SOLUTIONS

Odor in wine chiller • Interior needs cleaning.

Noisy operation • Wine chiller not level.

•Weak floor.

Wine chiller vibrates • Wine chiller not level.

•Weak floor.

Wine chiller light not • Bulb burned out.

working

• No power at outlet.

Appliance will not run • Temperature control turned to “OFF”.

•Line cord not plugged in.

• No power at electrical outlet.

• House fuse blown or circuit breaker open.

Appliance runs long • Prolonged door openings.

• Control set too cold.

• Condenser needs cleaning.

Moisture collects inside • Too many door openings.

• Hot, humid weather increases condensation.

Moisture collects on • Hot, humid weather increases condensation.

outside surface As humidity decreases, moisture will disappear.

• Control improperly set.

Interior too hot/too cold • Control improperly set.

•Temperature is being checked with a faulty thermometer.

• Move the thermometer to center of wine chiller and recheck.

If you do need service, contact your dealer or the manufacturer. In any correspondence, refer to the model number

and serial number of your wine chiller which is located inside the wine chiller, on the upper left side. Retain your

proof of purchase. Record these numbers in the space provided on page 1.

Loading...

Loading...