Page 1

Professional 48²,36²,30²

Gas Range Models

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

(17663 Rev. B)

Retain this manual for future reference.

8101P601-60

(05-04-03)

Page 2

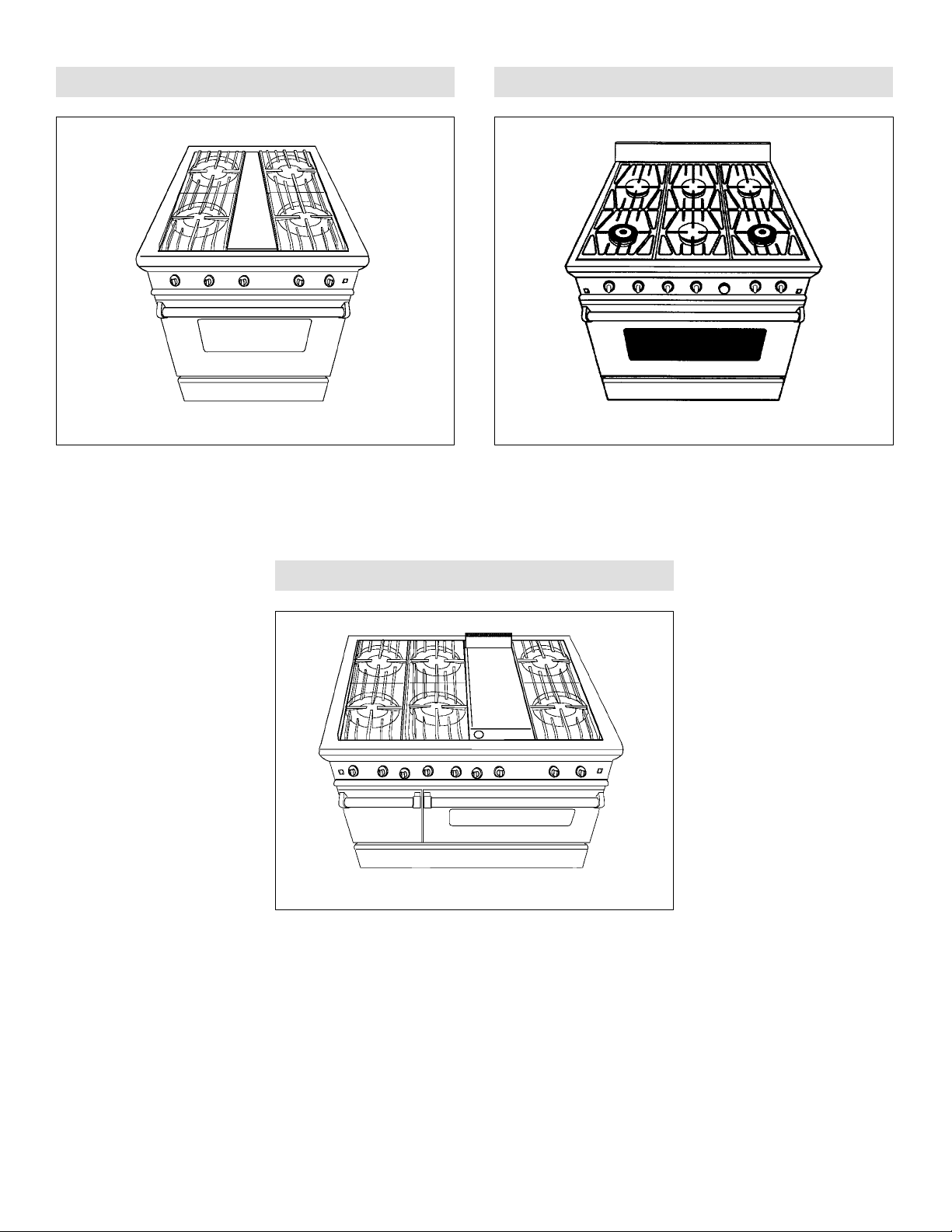

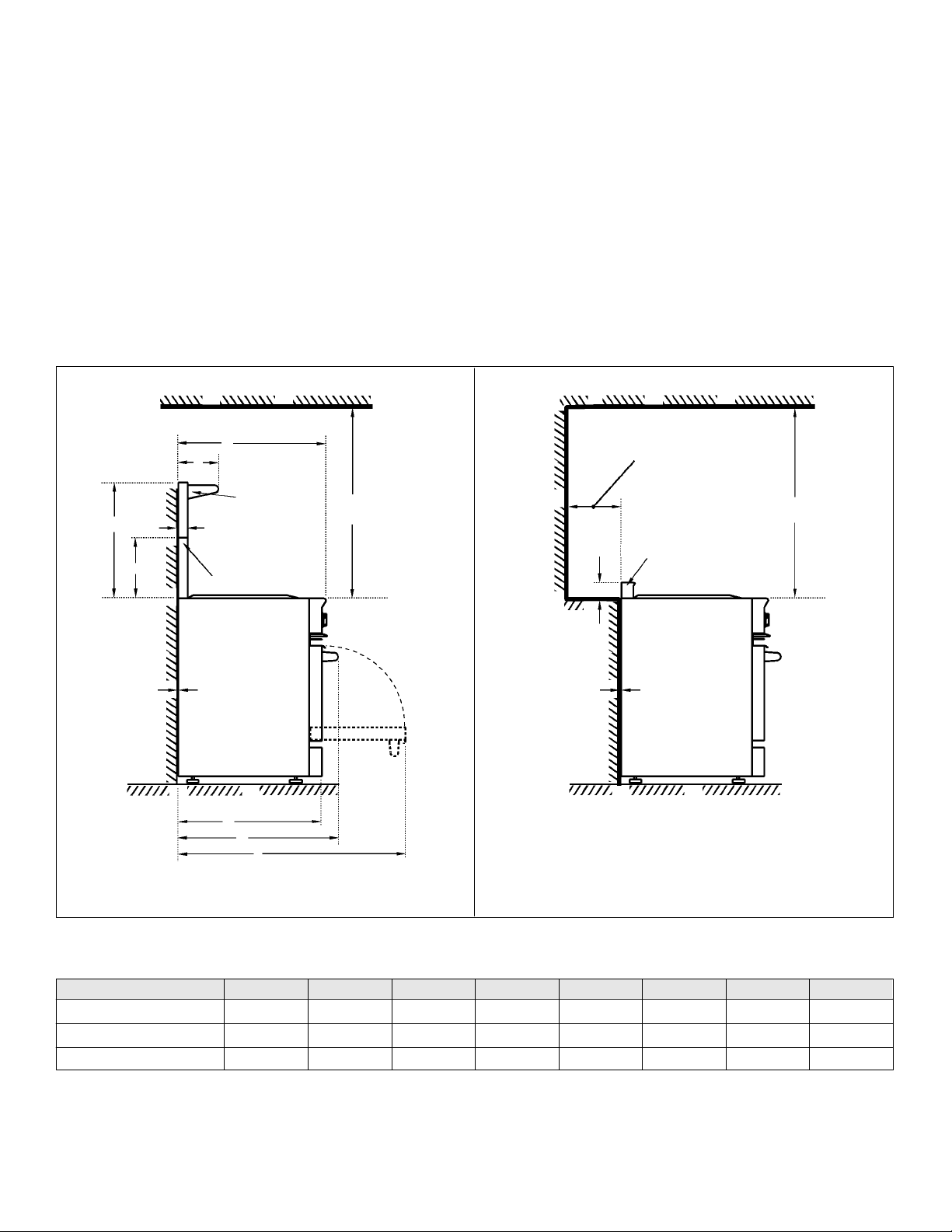

30² GAS RANGE MODEL 36² GAS RANGE MODEL

MODEL PRG3010 MODEL PRG3610

48² GAS RANGE MODEL

MODEL PRG4810

2

Page 3

T ABLE OF CONTENTS

INTRODUCTION

MODEL IDENTIFICATION 2........................

WARNING 3......................................

INTRODUCTION 3.................................

IMPORTANT INSTALLATION INSTRUCTIONS 4.....

STEP 1 - Ventilation Requirements 4................

STEP 2 - Cabinet Preparation 5-6..................

STEP 3 - Unpacking, Moving And Placing

The Range 7-8..........................

GRIDDLE ADJUSTMENTS 8.......................

ANTI-TIP INSTALLATION INSTRUCTIONS 9.........

STEP 4 - Electrical Connections 10.................

STEP 5 - Gas Requirements 10-11-12..............

STEP 6 - Backguard Installation 12.................

STEP 7 - Test And Adjustment 13-14...............

INSTALLER FINAL CHECK LIST 14.................

WIRING DIAGRAM

(PRG3010, PRG3610, PRG4810 Series) 15.........

SCHEMATIC DIAGRAM

(PRG3610, PRG4810, PRG3010 Series) 16.........

The features offered by the Jenn-Air professional series

of gas ranges are certain to make the cooking experience

more enjoyable and provide the novice or the experienced

chef with years of enjoyment. A large capacity gas oven

with a gas infrared broiler is included on the 30²,36² and

48² ovens. The PRG4810 (48²) range is also equipped

with a smaller 12² oven that is perfect for baking breads

and other small items while the larger items are being

prepared in the large capacity convection oven. Model

PRG3010 offers (4) 15,000 Btu/Hr. top burners, while the

36² and 48² models offer (6) 15,000 Btu/Hr. top burners.

All ranges are equipped with dual flow simmer burners

with a simmer turn down of 570-900 Btu/Hr, which can be

used for melting butter or chocolates. Model PRG3010

offers one simmer burner, while models PRG3610 and

PRG4810 offer two simmer burners each. In addition to

the large capacity oven and high output top burners, the

48² range also offers a stainless steel griddle. All range

models require installation of one of the three backguards

(this piece must be ordered separately) except the

PRG3010 model, which is shipped standard with a 9² low

back. See Figure 1.

If the information in this manual is not followed

exactly, a fire or explosion may result, causing

property damage, personal injury, or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS:

S Do not try to light any appliance.

S Do not touch any electrical switch, do not use

any phone in your building.

S Immediately call your gas supplier from a

neighbor’s phone. Followthe gas supplier’s

instruction.

S If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

FIGURE 1

3

Page 4

IMPORTANT INSTALLATION INSTRUCTIONS

STEP 1: VENTILATION REQUIREMENTS

Tested in accordance with ANSI Z21.1-1993 Standard for

Household Cooking Gas Appliances.

These ranges must be installed in conjunction with a

suitable overhead vent hood. (See Step: 1 for Ventilation

Requirements). Due to the professional high heat capacity

of this unit, particular attention should be paid to the hood

and duct work installation to assure it meets local building

codes. To eliminate risk of burns or fire by reaching over

heated surface units, cabinet storage located above the

surface units should be avoided.

Check local building codes for the proper method of range

installation. Local codes vary. Installation, Electrical

Connections, and Grounding must comply with all

applicable codes. In the absence of local codes, the range

should be installed in accordance with the National Fuel

Gas Code ANSI Z223.1-Latest Edition and National

Electrical Code ANSI / NFPA 70-Latest Edition.

Model numbers with suffix ‘NP’ are manufactured for use

with natural gas, while model numbers with suffix ‘LP’ are

for use with LP gas (propane).

A suitable exhaust hood must be installed above the

range. The following chart indicates the minimum blower

capacity recommended for hood ventilation. (Table 1).

CAUTION

Ventilation hoods and blowers are designed for use

with single wall ducting. However, some local building

codes or inspectors may require double wall ducting.

Consult local building codes and/or local agencies,

before starting, to assure that hood and duct

installation will meet local requirements.

Hood blower speeds should be variable to reduce noise

and loss of heated or air conditioned household air when

maximum ventilation is not required.

For best smoke elimination, the lower edge of the hood

should be installed a minimum of 30² to a maximum of

36² above the range cooking surface, see figure 3. If the

hood contains any combustible materials (i.e. a wood

covering) it must be a minimum of 36² above the cooking

surface.

Due to a high volume of ventilation air, a source of outside

replacement air is recommended. This is particularly

important for tightly sealed and insulated homes. A

reputable heating and ventilating contractor should be

consulted.

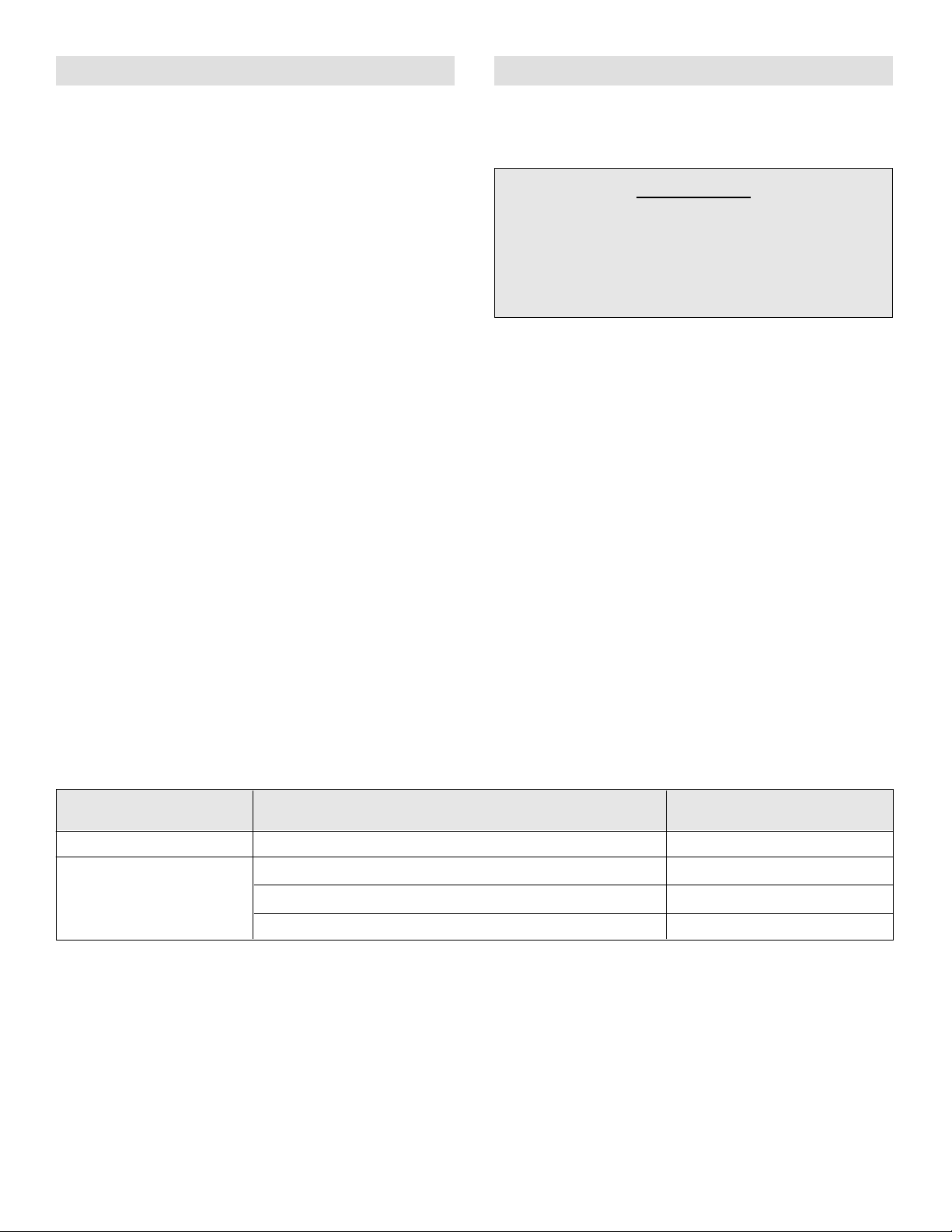

TABLE 1

VENTILATION UNIT

HOOD

BLOWER

STANDARD COUNTER INSTALLATION

RECOMMENDATIONS

(24² Deep x Unit Width)

48² RANGE - 800-1000 CFM

36² RANGE - 600-800 CFM

30² RANGE - 500 CFM

4

ISLAND INSTALLATION

RECOMMENDATIONS

(30² Deep x 36² At Bottom)

800-1000 CFM

600-800 CFM

500 CFM

Page 5

STEP 2: CABINET PREPARATION

1. The range is a free-standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown in

Figures 2A/B/C are required. The same clearances

apply to island installations.

2. The range can be placed in various positions with

respect to the cabinet front, with the front either flush or

projecting, depending on the countertop depth. See

(PRG3010)

Figure 3A/B and Table 2 (side view of range) for

dimensions.

3. The gas and electrical supply should be within the

zones shown in Figures 2 and 4.

4. The maximum depth of over head cabinets installed on

either side of the hood is 13².

(PRG3610)

FIGURE 2A

FIGURE 2B

(PRG4810)

FIGURE 2C

5

Page 6

5. Any openings in the wall behind the range and in the

floor under the range must be sealed.

and Figure 3B indicate the space required for each

type of backguard.

6. When there is less than a 12² clearance between

combustible material and the back edge of the range,

(above the cooking surface) Jenn-Air Stub Back or

High Shelf Backguard must be installed. These parts

must be ordered separately, except for the PRG3010

which comes equipped with a Low Back. Figure 3A

F

G

High Shelf

D

C

H

Low Back

36² Min. To

Combustibles

7. Always keep the appliance area clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

8. Do not obstruct the flow of combustion and ventilation

air to the unit.

12² Min. To Combustibles

Without Backguard

36² Min. To

Combustibles

1-1/2²

Island Trim

TABLE 2

DIMENSIONS

PRG4810

PRG3610

PRG3010

0² Clearance 0² Clearance

A

E

B

FIGURE 3BFIGURE 3A

A

27-7/16²

27-7/16²

26-3/4²

B

44-11/16²

44-11/16²

44-1/4²

C

12²

12²

9²

D

21-1/4²

21-1/4²

21-1/4²

E

29-15/16²

29-15/16²

29-15/16²

F

28-3/16²

28-3/16²

28-3/16²

G

10²

10²

9-3/8²

H

2-1/2²

2-1/2²

1-3/4²

6

Page 7

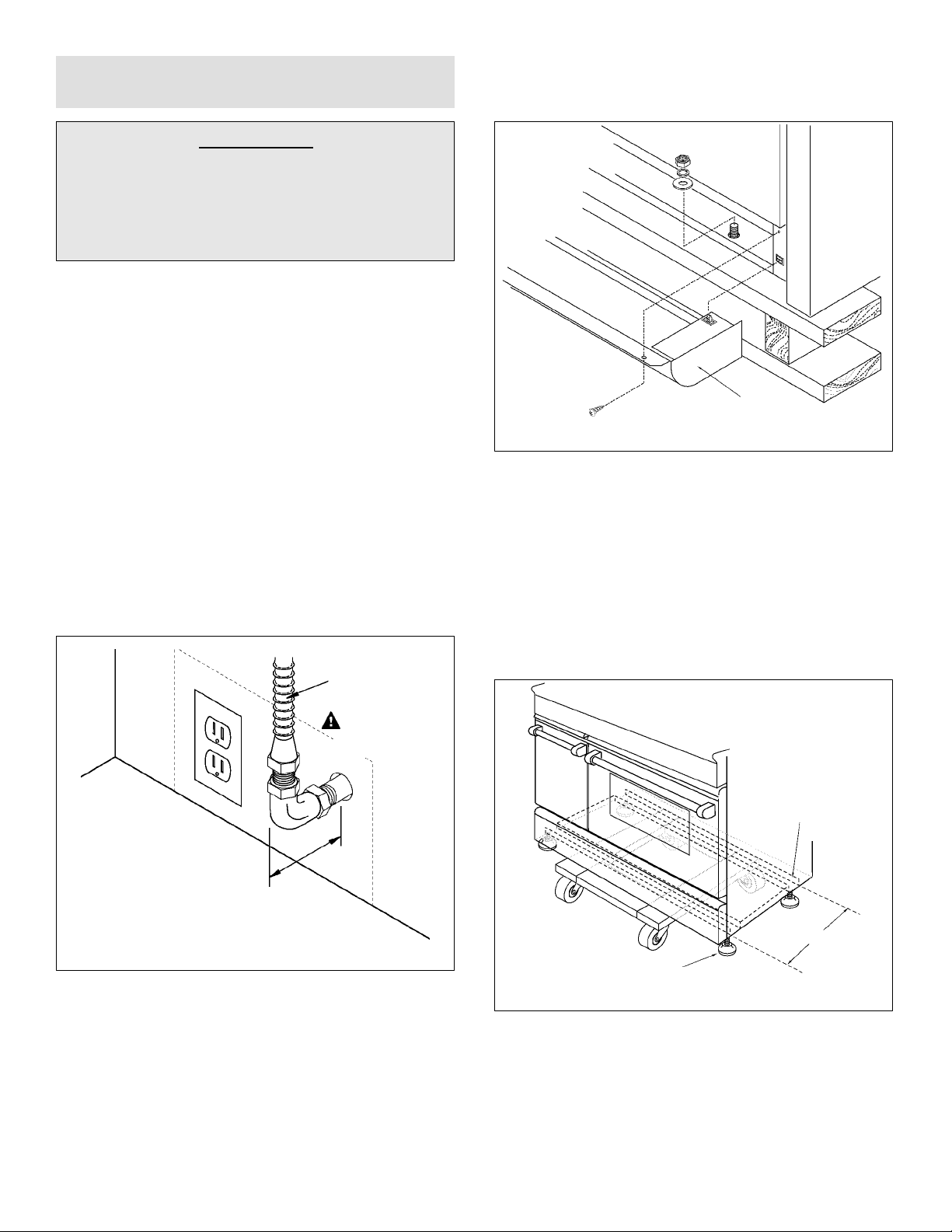

STEP 3: UNPACKING, MOVING AND

PLACING THE RANGE

CAUTION

PROPER EQUIPMENT AND ADEQUATE MANPOWER MUST BE USED IN MOVING THE

RANGE TO AVOID DAMAGE TO THE UNIT

OR THE FLOOR. THE UNIT IS HEAVY AND

RESTS ON ADJUSTABLE STEEL LEGS.

DO NOT LIFT THE RANGE BY THE

OVEN DOOR HANDLES!!

The 36² range has a shipping weight of approximately

408 pounds or 354 pounds after removal of packing

materials. It is recommended that the door, grates,

burners, front kick panel and drip pan (below knobs), be

removed to facilitate handling. This will reduce the weight

to about 230 pounds.

Kick Panel

FIGURE 5

DO NOT REMOVE THE GRIDDLE

ASSEMBLY

It may be necessary to remove the oven door and knobs

to pass through some doorways. With the doors and

knobs removed a 29-3/8² wide opening is required.

Without removing the door, a 30-13/16² wide opening is

required. See Figure 3A.

Flex Line to Range

Manual Shut-Off

Valve mus t b e

Easily Accessible

2² Maximum

Protrusion from Wall

for Gas Supply

Remove the outer carton and packing material from the

shipping base. Remove the kick panel (see Figure 5) by

removing two screws at the top and pulling forward. The

range is held to the skid by two bolts in the front behind

the kick panel (see Figure 5) and two L-brackets located

on bottom flange of the range back (see Figure 7). After

removing the bolts and brackets, the range must be lifted

and removed from the skid. Due to the weight, a dolly with

soft wheels should be used to move this unit. The weight

must be supported uniformly across the bottom (see

Figure 6).

Range Must

be Uniformly

Supported

on Braces

FIGURE 4

Leveling Legs

FIGURE 6

7

Page 8

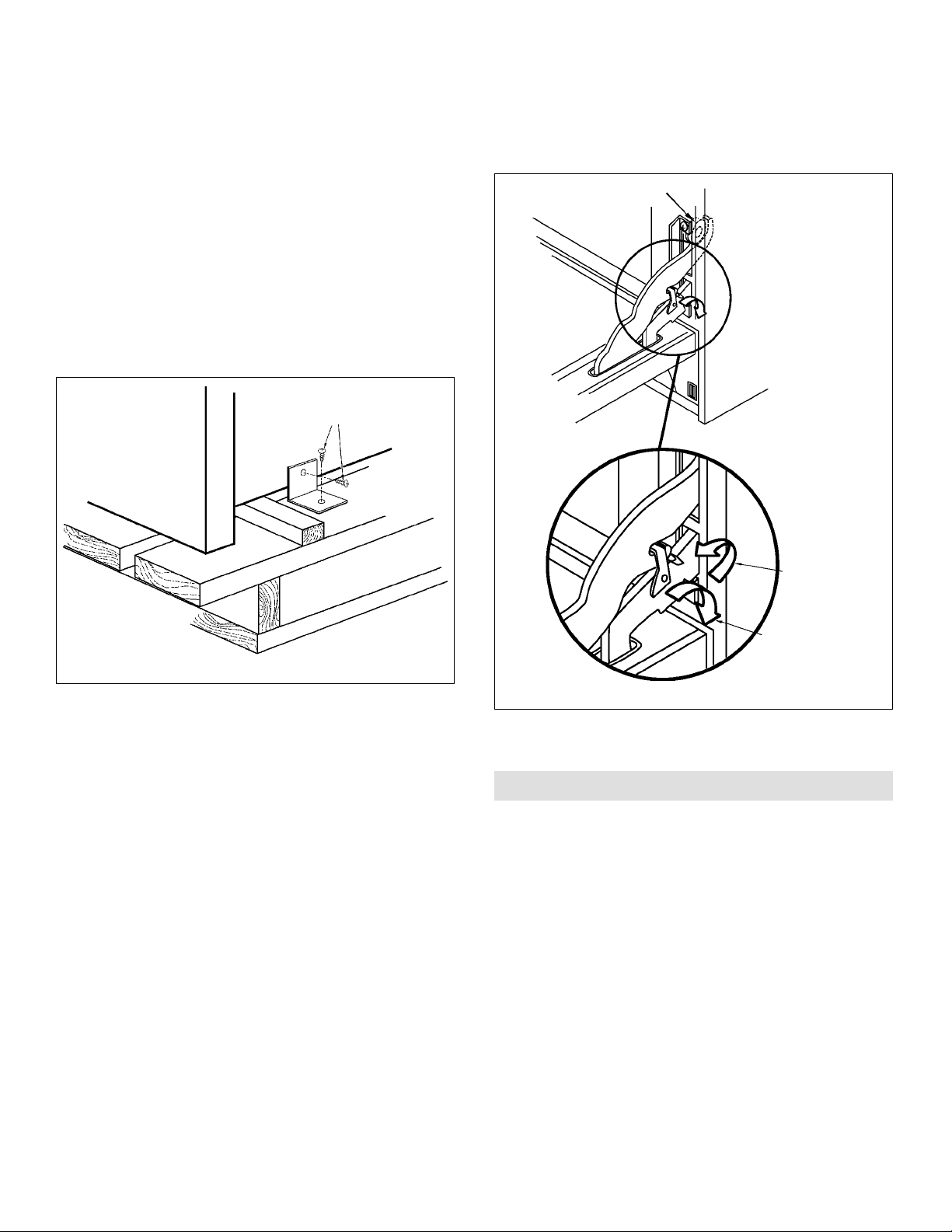

To remove the door, open the door and hold it all the way

open. Close the hinge latches (see Figure 8) and release

the door. The door can then be removed by gently lifting

and pulling the door, with the hinges up and out of the

frame. The hinges are assembled to the door and will be

removed from the frame when the door is lifted upward.

The professional range should be transported by a dolly

close to its final location. The range can be tipped back

and supported on the rear legs while the dolly is removed.

The floor under the legs should be protected (Wood

Strips, Carpet, Paneling, Etc.) before pushing the unit

back into position. Electric and gas connections should

be made (Steps 4 & 5) and the backguard installed (Step

6) before the range is placed in its final position.

Left Rear Shipping

Screws

It is important that the two screws retaining the kick

panel are secure to prevent accidental access to live

electrical components and wires (see Figure 5).

Door Hinge Roller

FIGURE 7

For proper performance, the professional range should be

level. To achieve a flush fit of the range to adjoining

countertops, it will be necessary to have level cabinets

(front to back, and left to right across the opening of the

range). After checking the countertops for level and

before sliding the range into place, measure the distance

from the floor to the top of the counter work surface in the

rear left and right corners. Adjust the corresponding rear

corner of the range to an equal height of the counter, as

the rear leveling legs are not accessible once the range is

pushed into place. Once the range is in place, the front

leg levelers can be accessed to level the front of the

range. Replace the kick panel and oven doors by

reversing the procedure described previously.

Lock (Close)

Un-Lock

FIGURE 8

GRIDDLE ADJUSTMENTS

The griddle section is fastened in place at the front with

screws. It is designed to be stationary and not meant to

be removed for cleaning.

The griddle has two leveling screws beneath the rear flue

cover which can be used to adjust the griddle to the

desired slope. The center screw is for shipping and

should be removed.

8

Page 9

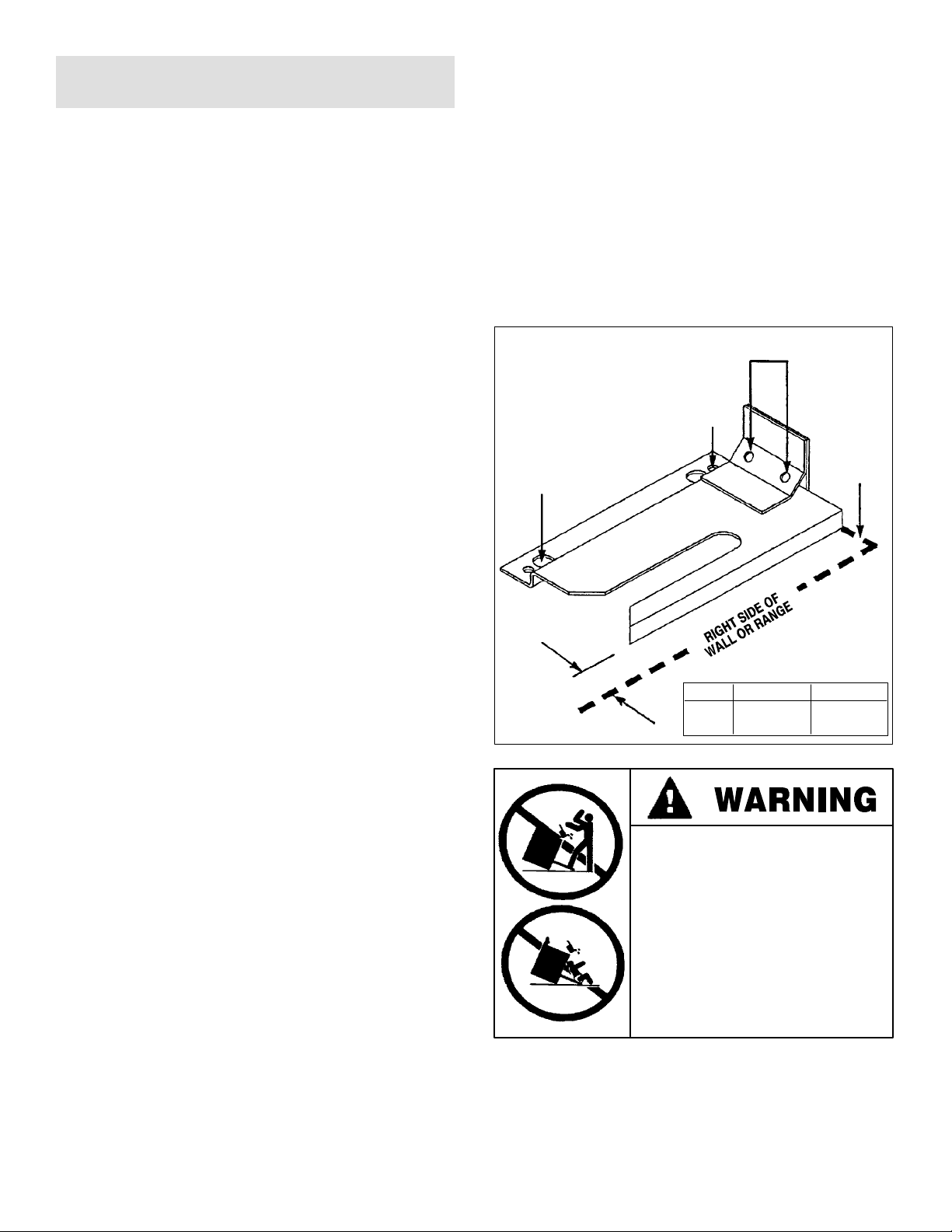

ANTI-TIP DEVICE INSTALLATION

INSTRUCTIONS

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the installation

instructions provided. The proper use of this device

minimizes the risk of TIP-OVER. In using the device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven door and/or kick plate as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall.

Included Parts

Included with this kit are: (4) #10 x 2² wood screws and

(1) Anti-tip bracket.

Wood Construction

Place the bracket against the back wall, into the right rear

corner where the range is to be located. Leave a gap

between the wall (or side of range) and the bracket per

dimension “A” (see chart). Drill (2) 1/8² diameter pilot

holes in the center of the small holes. A nail or awl may

be used if a drill is not available. Fasten the bracket

securely to the floor and wall (see illustration).

For SAFETY CONSIDERATIONS as well as optimum

performance adjust the range so that it is level. This may

be checked by placing a spirit level or a large pan of water

on the cooktop or the oven rack. Slide-in ranges require

total removal from cabinet before an adjustment can be

made.

To check the range for proper installation of the anti-tip

bracket: Use a flashlight and look underneath the bottom

of the range to see that one of the rear leveling legs is

engaged int eh bracket slot.

(2) Wood Screws into Back Wall

(ALL Installations)

(2) Small Holes For

Wood Installations

(2) Large Holes For

Concrete Installations

Back

Wall

Concrete Or Cement Construction

Hardware required: (2) sleeve anchors, lag bolts, and

washers (not provided). Locate the bracket as described

above. Drill the recommended size holes for the

hardware. Install the sleeve anchors into the holes and

then install the lag bolts through the bracket. The bolts

must be properly tightened as recommended for the

hardware. Fasten the bracket securely to the floor and

wall.

Range Installation

After the anti-tip bracket has been installed, complete

Steps 4-6 before sliding the range into position. Align

the range to its designated location and slide it back into

position. Make sure that the leveling foot is fully inserted

into and secured by the anti-tip bracket. To gain access to

the anti-tip bracket from the front of the range, remove the

kick plate by removing the (2) screws used to secure the

kick plate (Figure 5).

NOTE: Ensure that power is disconnected from the

range before the kick plate is removed.

DIMENSION A

A=

Model

Series

5/8²

PRG3610

PRG4810

· ALL RANGES CAN TIP AND

CAUSE INJURIES TO

PERSONS.

· INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

· FOLLOW ALL INSTALLATION

INSTRUCTIONS.

7/8²

PRG3010

9

Page 10

STEP 4: ELECTRICAL CONNECTIONS

STEP 5: GAS REQUIREMENTS

Power Requirements

120 VAC, 60 Hz., single phase.

PRG3010 - 4 Amp. Max.

PRG3610 - 7 Amp. Max.

PRG4810 - 13 Amp. Max.

(Use 15 Amp. Circuit)

Always disconnect electric supply cord from the wall outlet

or service disconnect before servicing this appliance.

Observe all governing codes and ordinances when

grounding, in the absence of which, observe National

Electrical Code ANSI/NFPA No. 70-1990.

Recommended Grounding Method

This appliance is factory equipped with a power supply

cord with a three-prong grounding plug (with polarized

parallel blades). It must be plugged into a mating

grounding type receptacle, and connected to a correctly

polarized 120 Volt circuit. If the circuit does not have a

grounding type receptacle, it is the responsibility and

obligation of the installer or user to have the existing

receptacle changed to a properly grounded and polarized

receptacle in accordance with all applicable local codes

and ordinances by a qualified electrician. In the absence

of local codes and ordinances the receptacle replacement

shall be in accordance with the National Electrical Code.

THIS THIRD GROUND PRONG SHOULD NOT, UNDER

ANY CIRCUMSTANCES, BE CUT OR REMOVED.

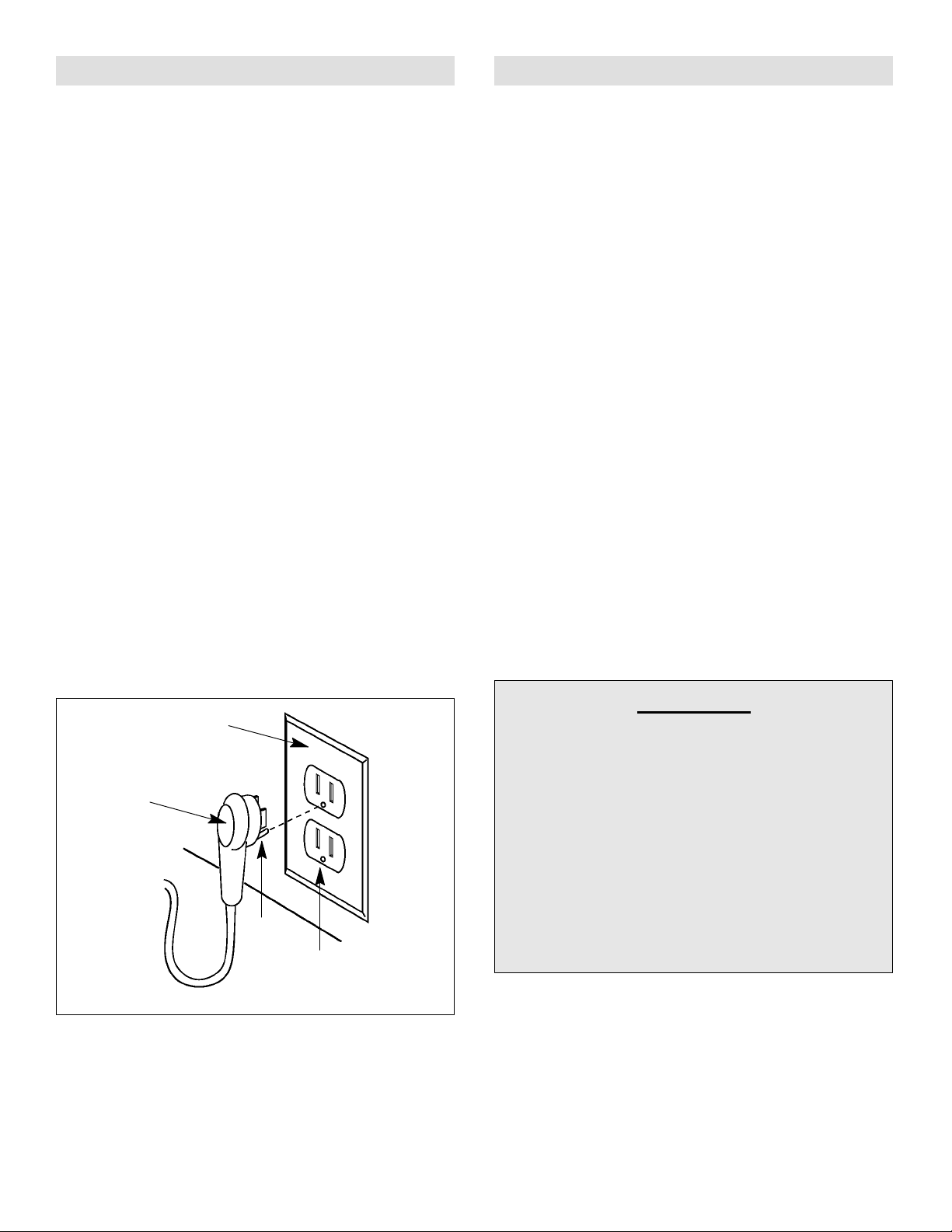

(SEE FIGURE 9)

Receptacle Box

Cover Plate

Three

Prong

Plug

Verify the type of gas supplied to the location.

The range is shipped from the factory set up and adjusted

for natural gas or LP gas (propane), depending on model

ordered.

Natural Gas Requirements

Connection: 1/2² N.P.T. Minimum 5/8² dia. flex line.

Pressure: 6² to 14² W.C.

LP Gas Requirements

Connection: 1/2² N.P.T., Minimum 5/8² dia. flex line.

Pressure: 11² to 14² W.C.

A regulator is required at the LP source to provide a

maximum of 14² W.C. to the range regulator.

Hook Up

A manual valve must be installed external to the

appliance, in a location accessible from the front for the

purpose of shutting off the gas supply. The supply line

must not protrude beyond the back of the unit. Make sure

the gas supply is turned off at the wall valve before

connecting the appliance.

The gas supply connections should be made by a

competent technician and in accordance with local codes

or ordinances. In the absence of a local code, the

installation must conform to the National Fuel Gas Code

ANSI 223.1-Latest Edition.

CAUTION

The appliance must be isolated from the building’s gas

supply piping system by closing its individual manual

shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less

than 1/2 psig (3.5kPa.).

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system

during any pressure testing of the system at the test

pressures in excess of 1/2 psig (3.5kPa.).

Ground

Prong

FIGURE 9

Three Prong

Receptacle

When checking the manifold gas pressure, the inlet

pressure to the regulator should be at least 7.0² W. C.

for natural gas.

** The flex line for the gas supply must be metal and be

approved by an approved certifying agency (AGA, CGA,

or U.L.). Never use a hose made of rubber or other

synthetic material, as the heat may cause the hose to

melt and develop leaks.

10

Page 11

STEP 6: BACKGUARD INSTALLATION

The backguard must be installed when there is less than

a12² clearance between combustibles and the back of

the range above the cooking surface (see Figure 3B).

RANGE BACKGUARD KITS

HIGH SHELF:

(22²) PRAG3022 - 30²

PRAG3622 - 36²

PRAG4822 - 48²

LOW SHELF:

(12²) PRAG3612 - 36²

PRAG4812 - 48²

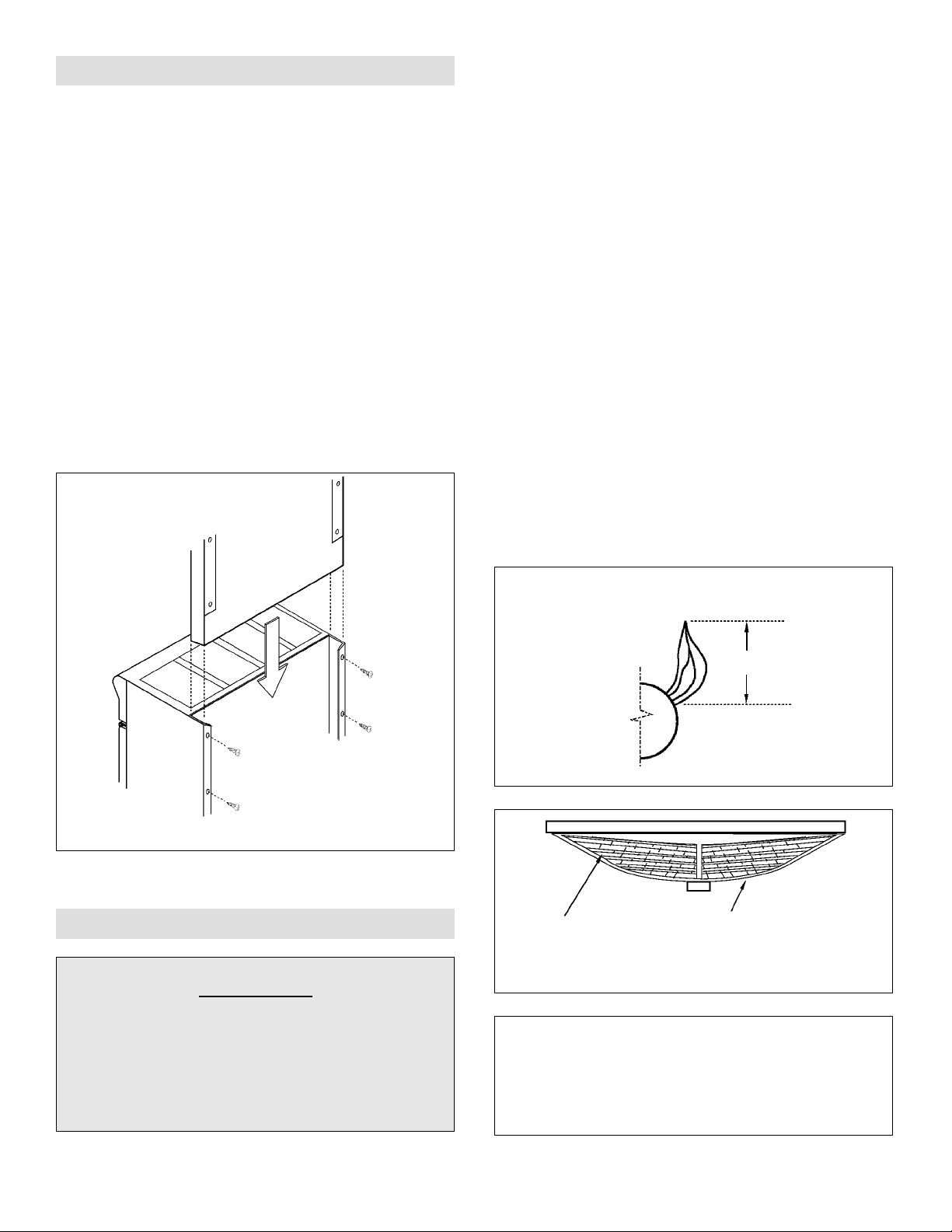

The backguard is inserted, as shown in Figure 12, into the

guide channels on the back of the range. Secure the

backguard with the (4) sheet metal screws provided.

Oven and Griddle Burners

Check for the proper burner flame characteristics and

adjust air shutters if necessary (see figures 13 - 14). Each

valve and air shutter is individually tested and adjusted

prior to shipment. Normally adjustment is not required,

however, vibration during transit or variations in the local

gas supply may make minor adjustments necessary.**

Burner flames should be blue and stable with no yellow

tips, excessive noise or lifting of the flame from the

burner. (Slight yellow - tipping is normal with LP gas). If

any of these conditions exist, check that the air shutter or

burner ports are not blocked. If this condition persists,

adjust the air shutter as required.

If the flame is too yellow, indicating insufficient air, adjust

the shutter counterclockwise to increase air inlet.

If the flame is noisy or tends to lift away from the burner,

indicating too much air, turn the shutter clockwise to

reduce air.

The oven burner flames should be approximately 1-1/2²

high. The griddle burner flames should be 1-1/2² to 2²

(see figure 13).

FIGURE 12

STEP 7: TEST AND ADJUSTMENT

CAUTION

For Warranty coverage, Jenn-Air requires that burner adjustments be made by a qualified technician at

the time of installation. Extreme care should be used

when adjustments are made after installation.*

* Improper or lack of adjustments will void your

warranty.

Typical Section of Proper Flame (Approx.)

(Griddle / Oven)

1-1/2² -2²

FIGURE 13

Screen should

be glowing red

FIGURE 14

Flame should be

approximately 1/8²

thick and blue

** The oven infra-red broiler burner has no air shutter

and is not adjustable when used with natural gas. It is

necessary to operate the oven broiler for 45 minutes

to eliminate the harsh odor of the insulation binder.

This must be done before using the range for the

first time and with proper ventilation.

11

Page 12

Surface Burners

The surface burners are not adjustable. Proper operation is

achieved when the correct orifices for the gas supply are

installed at the factory, based on model ordered.

* If the top burner does not ignite, check the spark igniter

by listening for a clicking sound. If you do not hear the

igniter click, turn off the burner. Check for a tripped circuit

breaker, blown fuse, or poor wire connection to the igniter.

To Clean Exterior Surfaces

The stainless steel surfaces may be cleaned by wiping

with a damp soapy cloth. Any mild glass cleaner will

remove fingerprints and smears. Do not use steel wool as

it will scratch this surface. Small scratches may be

removed by lightly sanding, with the grain, using 120 grit

paper.

INSTALLER FINAL CHECK LIST

j Placement of unit.

j Specified clearance maintained to cabinet surfaces.

j Unit level - front to back, side to side.

j All packaging material and tie straps removed.

j Low back or high shelf backguard attached if there is

less than 12² clearance above the cooking surface to

combustibles behind unit.

Electrical

j Receptacle with 15 ampere over-current protection is

provided for service cord connection.

j Adequate ground connection.

j Kick panel in place and two (2) screws secure.

Gas Supply

j Connection: 1/2 NPT with a minimum 5/8² diameter

flex line.

j Site gas supply is compatible with range model, and

sufficient pressure is available (see Gas

Requirements on page 10).

j Manual gas shut off valve installed in an accessible

location.

j Unit tested and free of gas leaks.

Operation

j All internal packing materials removed. Check drip

drawers.

j Bezels centered on burner knobs and knobs turn

freely.

j Each burner lights satisfactorily, both individually and

with other burners on same side of unit operating.

j Griddle is level.

j Drip trays are properly in place and pull out freely.

j Oven door hinges seated and door opens and closes

properly.

j Burner grates correctly positioned, level, and do not

rock.

12

Page 13

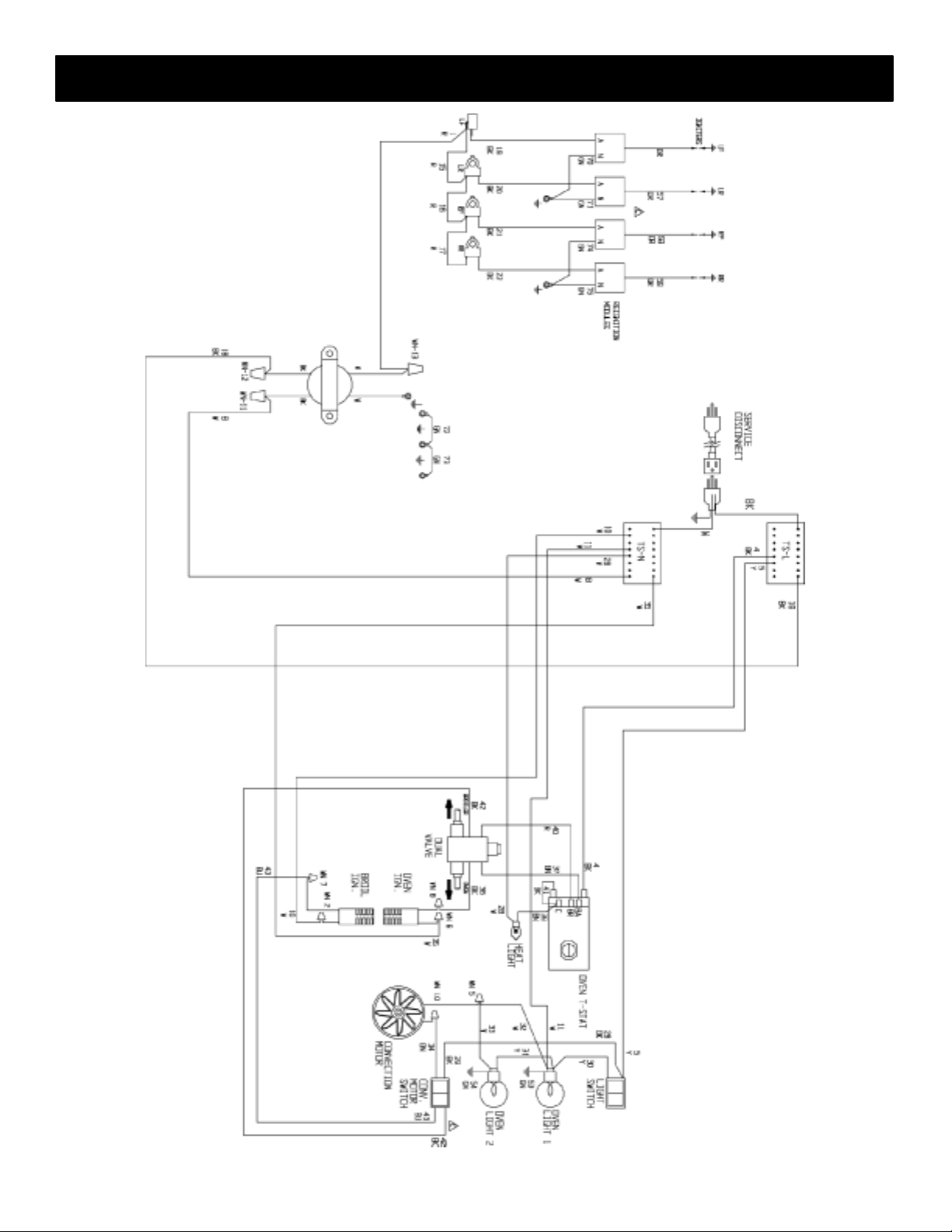

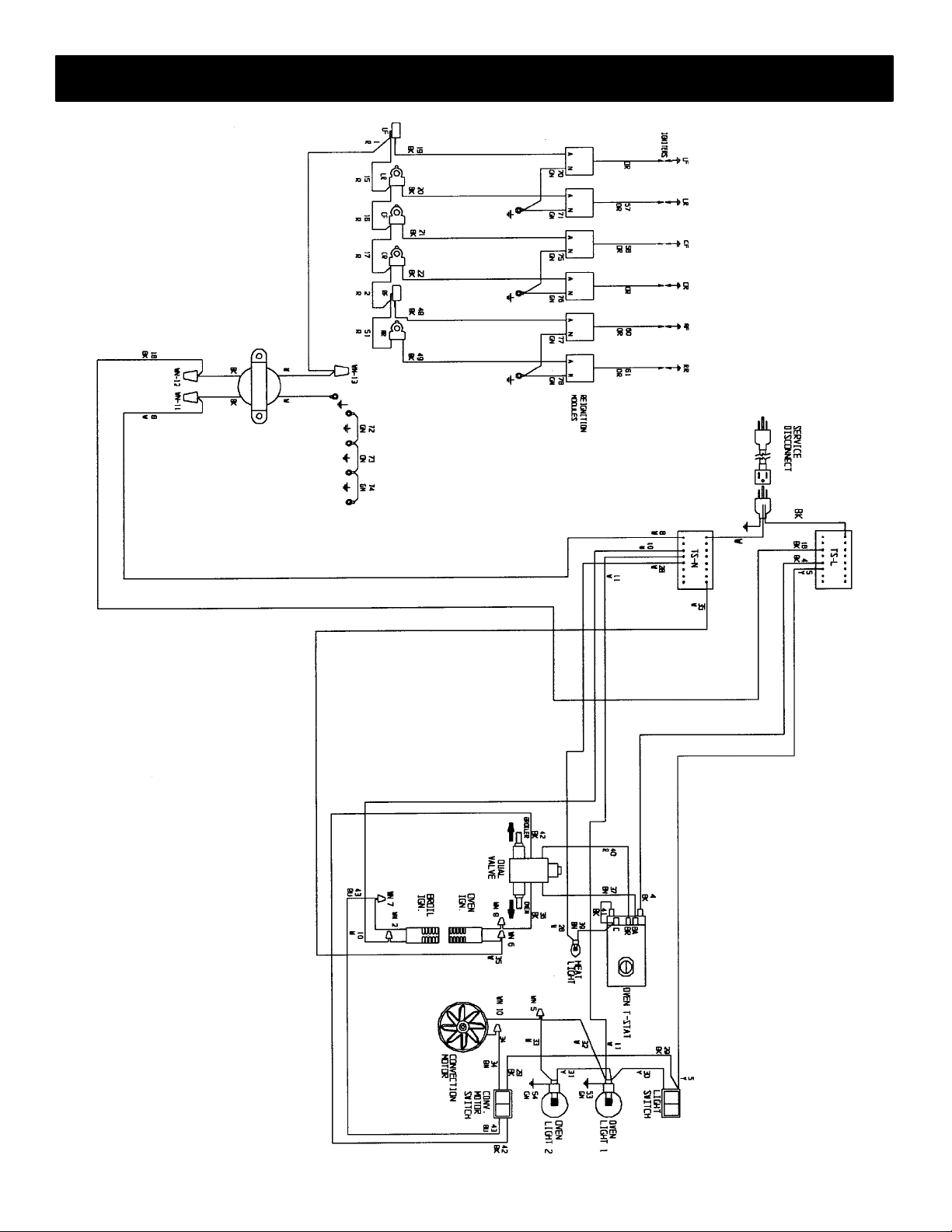

JENN-AIR PRG3010 WIRING DIAGRAM

Part No.: 16565-50 12/03 Rev. C

13

Page 14

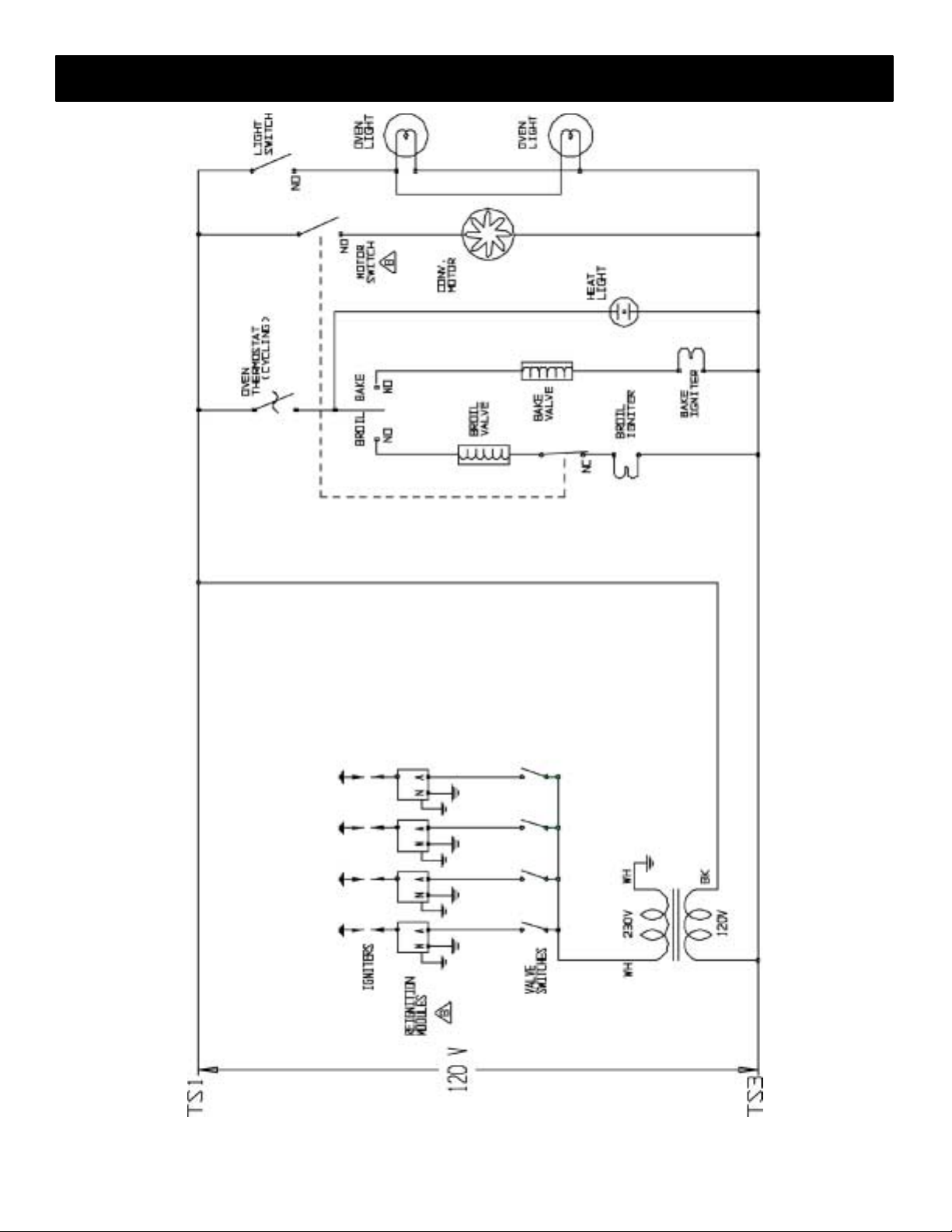

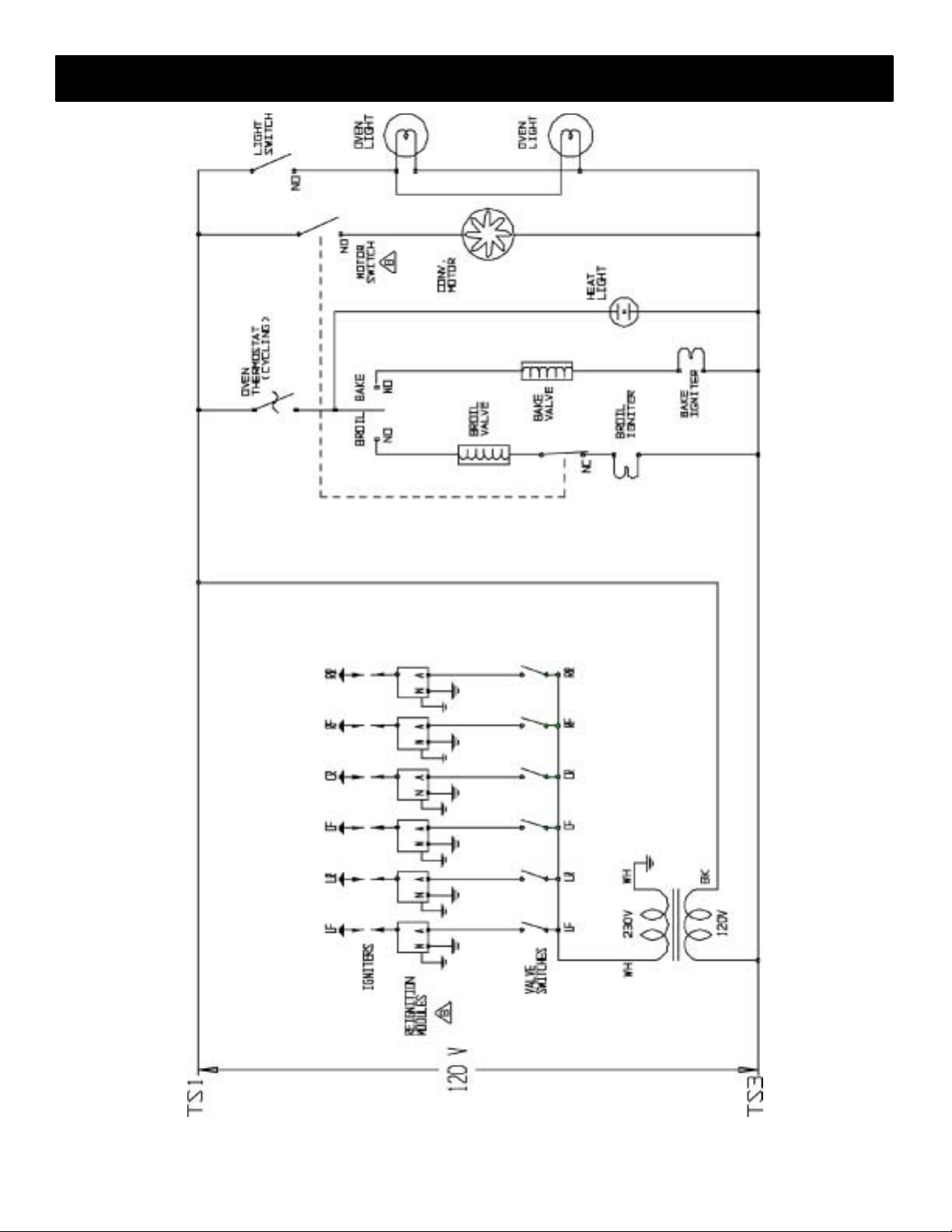

JENN-AIR PRG3010 WIRING SCHEMATIC

Part No.: 16565-50 12/03 Rev. C

RR

RF

LF LR

RR

RF

LF LR

14

Page 15

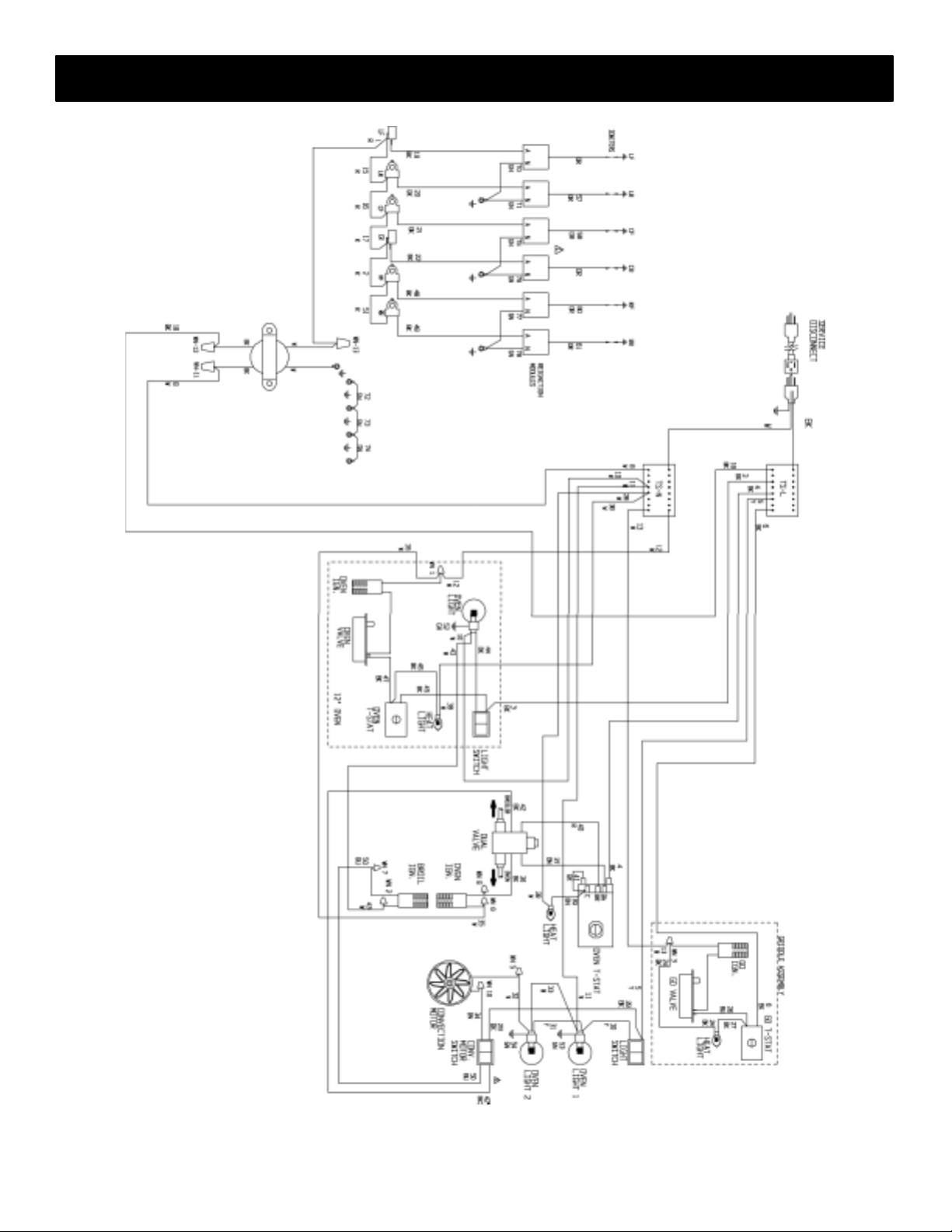

JENN-AIR PRG3610 WIRING DIAGRAM

Part No.: 16560-50 12/03 Rev. C

15

Page 16

JENN-AIR PRG3610 WIRING SCHEMATIC

Part No.: 16560-50 12/03 Rev. C

16

Page 17

JENN-AIR PRG4810 WIRING DIAGRAM

Part No.: 16561-50 12/03 Rev. C

17

Page 18

JENN-AIR PRG4810 WIRING SCHEMATIC

Part No.: 16561-50 12/03 Rev. C

18

Page 19

MISE EN

SERVICE

Cuisinières à gaz

professionnelles

de 121,9, 91,4 et 76,2 cm

WEST FOURTH STREET, NORTH · NEWTON, IA 50208,

ÉTATS- UNIS

Veuillez conserver ce manuel pour référence ultérieure.

Page 20

MODÈLE DE CUISINIÈRE À GAZ DE 76,2 CM MODÈLE DE CUISINIÈRE À GAZ DE 91,4 CM

MODÈLE PRG3010 MODÈLE PRG3610

MODÈLE DE CUISINIÈRE À GAZ DE 121,9 CM

MODÈLE PRG4810

2

Page 21

TABLE DES MATIÈRES

INTRODUCTION

IDENTIFICATION DU MODÈLE 2...................

AVERTISSEMENT 3...............................

INTRODUCTION 3.................................

CONSIGNES IMPORT ANTES DE MISE EN SERVICE 4

ÉTAPE 1 - Besoins en évacuation et apport d’air 4.....

ÉTAPE 2 - Préparation de l’armoire 5-6..............

ÉTAPE 3 - Déballage, déplacement et placement

de la cuisinière 7- 8.....................

RÉGLAGES DU GRIL 8............................

MISE EN PLACE DU DISPOSITIF

DE STABILISATION 9.............................

ÉTAPE 4 - Raccordement à l’électricité 10............

ÉTAPE 5 - Alimentation en gaz 10-11................

ÉTAPE 6 - Pose du dosseret 11.....................

ÉTAPE 7 - Vérification et réglage 12-13..............

LISTE DE VÉRIFICATION DE L’INSTALLATEUR 13..

SCHÉMA DE CÂBLAGE

(série PRG3010, PRG3610, PRG4810) 14..........

SCHÉMA DE CÂBLAGE

(série PRG3610, PRG4810, PRG3010) 15..........

Les caractéristiques des cuisinières à gaz

professionnelles Jenn-Air ne manqueront pas de rendre

vos activités culinaires encore plus agréables et

d’apporter au novice comme au cordon bleu des années

d’agrément. Les fours de 76,2, 91,4 et 121,9 cm

comportent un four de grande capacité avec gril à gaz à

infrarouges. La cuisinière PRG4810 (121,9 cm) est

également équipée d’un four plus petit, de 30,5 cm,

parfait pour la cuisson de pain et d’autres articles de

petites dimensions pendant que de plus gros articles sont

en préparation dans le grand four à chaleur tournante de

grande capacité. Le modèle PRG3010 a une surface de

cuisson comportant 4 brûleurs de 15 000 Btu/h, tandis

que celles de 91,4 et de 121,9 cm sont équipées de 6

brûleurs de 15 000 Btu/h. Toutes les cuisinières sont

équipées de brûleurs de mijotage à écoulement double

qui peuvent être baissés à 570-900 Btu/h pour faire

fonder du beurre ou du chocolat. Le modèle PRG3010 a

1 brûleur de mijotage, pendant que les modèles PRG3610

et PRG4810 ont 2 brûleurs de mijotage chacun. En plus

d’un four d’une grande capacité et de brûleurs d’une

grande puissance de chauffe, la cuisinière de 121,9 cm

est aussi équipée d’un gril en acier inoxydable. Tous les

modèles de cuisinière exigent la pose d’un des trois

dosserets (cet element doit être commandé séparément),

sauf le modèle PRG3010, qui est expédié de l’usine avec

un petit dosseret de 22,9 cm. Voir la figure 1.

AVERTISSEMENT

Si les indications fournies dans ce manuel ne sont

pas observées scrupuleusement, cela pourra

provoquer une explosion ou un incendie et des

dégâts matériels, des blessures, voire le décès.

Ne pas conserver ni utiliser d’essence ou autres

vapeurs ou liquides inflammables à proximité de

cet appareil ou de tout autre appareil électrique.

QUE FAIRE EN CAS D’ODEUR DE GAZ :

S Ne pas allumer d’appareil électrique.

S N’actionner aucun commutateur électrique, ne

pas utiliser le téléphone dans votre bâtiment.

S Appeler immédiatement votre fournisseur de

gaz de chez un voisin. Suivre les consignes du

fournisseur de gaz.

S S’il n’est pas possible de contacter le

fournisseur de gaz, appeler les pompiers.

La mise en service et les réparations doivent être

effectuées par un installateur qualifié, un

prestataire de service après-vente ou le

fournisseur de gaz.

FIGURE 1

3

Page 22

CONSIGNES IMPORTANTES DE MISE EN

SERVICE

ÉTAPE 1 : BESOINS EN ÉVACUATION ET

APPORT D’AIR

Fonctionnement vérifié conformément à la norme ANSI

Z21.1-1993 pour les appareils de cuisson ménagers

fonctionnant au gaz.

La mise en service de ces cuisinières doit comporter une

hotte d’évacuation de puissance appropriée. (Voir l’étape

1 pour les besoins en évacuation d’air. En raison de la

forte capacité de chauffe, de niveau professionnel, de cet

appareil, une attention particulière devra être accordée à

la pose d’une hotte et de conduits d’évacuation, de façon

à ce qu’elle soit conforme aux codes locaux de la

construction. Pour éliminer tout risque de brûlure ou

d’incendie en essayant d’atteindre un objet placé

au-dessus d’éléments brûlants, éviter d’avoir un espace

de rangement au-dessus de la surface de cuisson.

Vérifier dans les codes de la construction locaux la

méthode qui convient pour la mise en service de la

cuisinière. Les codes locaux varient. La mise en service,

le raccordement à l’électricité et la mise à la terre doivent

être conformes à tous les codes en vigueur. En l’absence

de tels codes, la mise en service doit être conforme à la

norme ANSI Z223.1, dernière édition, du National Fuel

Gas Code et à la norme ANSI / NFPA 70, dernière

édition, du National Electrical Code.

Les numéros de modèle qui se terminent en le suffixe

”PS” sont fabriqués pour l’usage avec le gaz naturel,

pendant que les numéros de modèle avec le suffixe ”LP”

s’utilisent avec le gaz GPL (propane).

Une hotte d’évacuation appropriée doit être posée

au-dessus de la cuisinière. Le tableau suivant indique la

capacité recommandée pour le ventilateur (voir le

tableau 1).

ATTENTION

Les hottes et les ventilateurs d’évacuation sont conçus

pour être raccordés à un conduit mural simple.

Toutefois, certains inspecteurs et certains codes de la

construction peuvent exiger l’utilisation d’un conduit

double. Vérifier dans les codes locaux de la

construction et/ou auprès des organismes compétents

locaux avant de commencer la mise en service, afin

de faire le nécessaire pour que la mise en service de

la hotte et du ou des conduits satisfassent aux

règlements locaux.

Le ventilateur de la hotte doit être à vitesse variable pour

réduire le bruit et la perte d’air chauffé ou climatisé de

l’habitation lorsqu’une évacuation d’air maximum n’est

pas nécessaire.

Pour une élimination optimum de la fumée, la partie

inférieure de la hotte doit être à une distance minimum de

76,2 cm et maximum de 91,4 cm au-dessus de la surface

de cuisson de la cuisinière (voir la figure 3). Si la hotte

contient des matériaux combustibles, (par ex. un

habillage en bois), elle doit être à une distance minimum

de 91,4 cm de la surface de cuisson.

TABLEAU 1

APPAREIL

D’ÉVACUATION

HOTTE

VENTILATEUR

En raison du volume important d’air pouvant être évacué,

une prise d’air sur l’extérieur est recommandée. Ceci est

particulièrement important dans les logements

hermétiquement fermés et bien isolés. Il est recommandé

de consulter une entreprise locale sérieuse de chauffage

et de ventilation.

RECOMMANDATIONS POUR

UN COMPTOIR STANDARD

(61 cm de prof. x largeur de l’appareil)

CUISINIÈRE DE 121,9 CM - 22,6 À 22,3 M

CUISINIÈRE DE 91,4 CM - 17 À 22,6 M

3

CUISINIÈRE DE 76,2 CM - 14,1 M

/MN

3

/MN

3

/MN

RECOMMANDATIONS POUR

UN ÎLOT DE CUISINE

(76,2 cm de prof. x 91,4 cm au bas)

3

3

/MN

3

/MN

/MN

22,6 À 22,3 M

17 À 22,6 M

14,1 M

4

Page 23

ÉTAPE 2 : PRÉPARATION DE L’ARMOIRE

1. La cuisinière est amovible. Si elle doit être placée

adjacente à des armoires, les dégagements indiqués à

la figures 2A/B/C sont exigés. Les mêmes

dégagements sont exigés dans le cas d’îlots de

cuisine.

2. La cuisinière peut être placée de différentes façons par

rapport à l’avant de l’armoire, avant l’avant qui dépasse

de l’armoire ou complètement encastré, en fonction de

hotte de 76,2 cm

(30 po) min. de large

(PRG3010)

30,5 cm (12 po) min. de

tout matériau combustible

D de chaque côté

surface de

cuisson

alimentation en gaz

et en électricité

ATTENTION :

91,4 cm (36 po)

min. de tout

matériau

combustible

[symbol] à partir

de la surface de

cuisson

la profondeur du comptoir. Voir la figure 3A/B et le

tableau 2 (vue du côté de la cuisinière) pour les

dimensions.

3. L’alimentation en électricité et en gaz doit être dans les

zones indiquées aux figures 2 et 4.

4. La profondeur maximum d’armoires en hauteur posées

de chaque côté de la hotte d’évacuation doit être de

33 cm.

hotte de 91,4 cm

(36 po) min. de large

(PRG3610)

30,5 cm (12 po) min. de

tout matériau combustible

D de chaque côté

surface de

cuisson

alimentation

alimentation

en électricité

en gaz

ATTENTION :

91,4 cm (36 po)

min. de tout

matériau

combustible

[symbol] à partir

de la surface de

cuisson

89,9 cm (35 3/8 po) max. pour la surface du comptoir,

93,3 cm (36 3/4 po) max. avec les pieds réglables relevés

à fond

FIGURE 2A

D Tel que défini par le

« National Fuel Gas Code »

(ANSI Z223.1, dernière édition).

Les surfaces horizontales de la garniture du dessus

de la cuisinière (surface de cuisson) ne doivent pas

être plus basses que la surface du comptoir.

N) 45,7 cm (18 po) min.

O) 40,6 cm (16 po)

P) 10,2 cm (4 po)

Q) 5,1 cm (2 po)

R) 33 cm (13 po) max.

(48 po) min. de large

30,5 cm (12 po) min. de

tout matériau combustible

alimentation

en électricité

89,9 cm (35 3/8 po) max. pour la surface du comptoir,

93,3 cm (36 3/4 po) max. avec les pieds réglables relevés

à fond

D Tel que défini par le

« National Fuel Gas Code »

(ANSI Z223.1, dernière édition).

Les surfaces horizontales de la garniture du dessus

de la cuisinière (surface de cuisson) ne doivent pas

être plus basses que la surface du comptoir.

hotte de 121,9 cm

(PRG4810)

D de chaque côté

surface de

cuisson

alimentation

en gaz

FIGURE 2B

ATTENTION :

91,4 cm (36 po)

min. de tout

matériau

combustible

[symbol] à partir

de la surface de

cuisson

P) 30,5 cm (12 po)

Q) 30,5 cm (12 po)

R) 45,7 cm (18 po) min.

S) 10,2 cm (4 po)

T) 33 cm (13 po) max.

U) 8,3 cm (3--1/4 po)

V) 8,9 cm (3--1/2 po)

89,9 cm (35 3/8 po) max. pour la surface du comptoir,

93,3 cm (36 3/4 po) max. avec les pieds réglables relevés

à fond

D Tel que défini par le« National

Fuel Gas Code » (ANSI Z223.1,

dernière édition).

Les surfaces horizontales de la garniture du dessus

de la cuisinière (surface de cuisson) ne doivent pas

être plus basses que la surface du comptoir.

FIGURE 2C

5

P) 40,6 cm (16 po)

Q) 30,5 cm (12 po)

R) 45,7 cm (18 po) min.

S) 20,3 cm (8 po)

T) 33 cm (13 po) max.

U) 8,3 cm (3--1/4 po)

V) 8,9 cm (3--1/2 po)

Page 24

5. Toute ouverture dans le mur à l’arrière de la cuisinière

et dans le plancher sous la cuisinière doit être

bouchée.

est déjà équipé d’un dosseret court. Les figures 3A et

3B indiquent l’espace requis pour chaque type de

dosseret.

6. S’il y a moins de 30,5 cm entre un matériau

combustible et le bord arrière de la cuisinière

(au-dessus de la surface de cuisson), il faut poser un

dosseret extra court ou un dosseret Jenn-Air avec

tablette. Ces éléments doivent être commandés

séparément, sauf dans le cas du modèle PRG3010 qui

F

G

Tablette en

D

C

hauteur

H

Dosseret court

91,4 cm min. par rapport à

des matériauxcombustibles

7. Toujours garder l’appareil et sa proximité dégagés et

libre de tout matériau combustible, d’essence et de

tout autre liquide ou vapeur inflammable.

8. Ne pas bloquer l’apport d’air nécessaire à la

combustion et à l’évacuation d’air de l’appareil.

30,5 cm min. par

rapport à des

matériaux

combustibles

sans dosseret

91,4 cm min.par rapport à

des matériaux combustibles

3,8 cm

Garniture

pour îlot

TABLEAU 2

DIMENSIONS

PRG4802P

PRG3601P

PRG3000P

Dégagement

de0cm

A

E

B

69,7 cm

69,7 cm

67,9 cm

Dégagement

de0cm

FIGURE 3BFIGURE 3A

A

B

113,5 cm

113,5 cm

112,4 cm

C

30,5 cm

30,5 cm

22,9 cm

D

54 cm

54 cm

54 cm

E

76,1 cm

76,1 cm

76,1 cm

F

71,6 cm

71,6 cm

71,6 cm

G

25,4 cm

25,4 cm

23,8 cm

H

6,4 cm

6,4 cm

4,4 cm

6

Page 25

ÉTAPE 3 : DÉBALLAGE, DÉPLACEMENT ET

PLACEMENT DE LA CUISINIÈRE

ATTENTION

IL FAUT UTILISER L’ÉQUIPEMENT APPROPRIÉ

ET AVOIR DU PERSONNEL SUFFISANT POUR

DÉPLACER LA CUISINIÈRE AFIN D’ÉVITER

D’ABÎMER L’APPAREIL OU LE PLANCHER.

L’APPAREIL EST LOURD ET REPOSE SUR DES

PIEDS RÉGLABLES EN ACIER.

NE PAS SOULEVER LA CUISINIÈRE EN LA

TENANT PAR LES POIGNÉES DU FOUR !!

Le poids d’expédition de la cuisinière de 91,4 cm est

d’environ 185 kg avec l’emballage et de 161 kg une fois

les matériaux d’emballage enlevés. Il est recommandé

d’enlever la porte, les grilles, les brûleurs, le panneau

inférieur avant et la cuve à eau (sous les boutons) pour

faciliter les manipulations. Ceci réduira le poids de la

cuisinière pour l’amener à environ 104 kg.

NE PAS ENLEVER LE GRIL

Il pourra être nécessaire d’enlever la porte du four et les

boutons pour faire passer l’appareil dans les embrasures

de portes. Lorsque les portes et les boutons sont retirés, il

faut une ouverture minimum de 74,6 cm pour passer. S’ils

ne sont pas retirés, il faut une ouverture minimum de 78,3

cm pour passer. Voir la figure 3A.

Conduite flexible

vers la cuisinière

Le robinet d’arrêt

doit être d’un

accès facile

Panneau inférieur

FIGURE 5

Retirer le carton extérieur et les matériaux d’emballage du

socle d’expédition. Enlever le panneau inférieur (voir la

figure 5). Pour cela, enlever les deux vis du haut et tirer

vers soi. La cuisinière est fixée à la palette par deux

boulons à l’avant, derrière le panneau inférieur (voir la

figure 5), et deux supports en L situés sur le rebord

inférieur de l’arrière de la cuisinière (voir la figure 7). Une

fois les boulons et les supports enlevés, la cuisinière doit

être soulevée et retirée de la palette. En raison du poids

de l’appareil, il est recommandé d’utiliser un chariot de

déménagement à roues souples pour le déplacer. Le

poids doit être supporté uniformément sur tout le fond

(voir la figure 6).

La cuisinière doit

être supportée de

façon uniforme

par des supports

Dépassement maximum

de 5,1 cm du mur pour

l’alimentation en gaz

FIGURE 4

Pieds réglables

FIGURE 6

7

Page 26

Pour enlever la porte, l’ouvrir et la maintenir

complètement ouverte. Fermer les verrous de charnière

(voir la figure 8) et dégager la porte. La porte peut

maintenant être enlevée en tirant doucement pour la

soulever jusqu’à ce que les charnières soient sorties de

l’encadrement. Les charnières sont fixées à la porte et

s’enlèvent de l’encadrement quand la porte est soulevée

et retirée de l’encadrement.

La cuisinière professionnelle doit être transportée sur un

chariot de déménagement et amenée à proximité de son

emplacement final. Elle peut être basculée vers l’arrière

pour reposer sur ses pieds arrière et permettre de retirer

le chariot une fois sur place. Placer des morceaux de

bois, de moquette, de contreplaqué, etc. sous les

pieds pour protéger le plancher avant de pousser la

cuisinière en place. Faire les raccordements au gaz et à

l’électricité (étapes 4 et 5) et poser le dosseret (étape 6)

avant de mettre la cuisinière à son emplacement final.

Vis d’expédition

arrière gauches

réglables avant pour mettre l’avant de la cuisinière de

niveau. Remettre le panneau inférieur et les portes du

four en place en reprenant à l’inverse la méthode décrite

précédemment.

Il est important que les deux vis qui retiennent le

panneau inférieur en place soient bien serrées pour

éviter l’accès accidentel à des composants et des fils

électriques sous tension (voir la figure 5).

Galet de la charnière de la porte

FIGURE 7

Pour donner de bons résultats à la cuisson, la cuisinière

professionnelle doit être de niveau. Pour que la cuisinière

affleure parfaitement par rapport aux dessus de comptoir

adjacents, les armoires doivent être de niveau (d’avant en

arrière et d’un côté à l’autre de l’ouverture prévue pour la

cuisinière). Une fois le bon niveau des comptoirs vérifié et

avant de glisser la cuisinière en place, mesurer la

distance du plancher au dessus de la surface de travail

du comptoir dans les coins arrière gauche et droit. Régler

le pied du coin arrière correspondant de la cuisinière à la

hauteur du comptoir de chaque côté car les pieds

réglables de l’arrière de la cuisinière ne seront pas

accessibles une fois la cuisinière poussée en place. Une

fois celle-ci en place, il est possible d’accéder aux pieds

Verrouiller

(fermé)

Déverrouiller

FIGURE 8

RÉGLAGE DU GRIL

Lapartiegrilestfixéeenplaceàl’aidedevisàl’avant.Le

gril est conçu pour rester en place et il n’est pas prévu

pour être retiré aux fins d’entretien.

Le gril est doté de deux vis de mise à niveau, sous le

couvre-carneau arrière, qui peuvent être utilisées pour

régler la pente du gril. La vis centrale sert uniquement

pour le transport et doit être enlevée.

8

Page 27

MISE EN PLACE DU DISPOSITIF DE

STABILISATION

REMARQUE : La cuisinière risque de basculer si elle

n’est pas mise en place conformément aux consignes de

mise en service fournies. Si le dispositif de stabilisation

est utilisé correctement, il réduit le risque que la cuisinière

ne - BASCULE. Même si le dispositif est utilisé

correctement, le consommateur doit observer les

précautions indiquées dans le MANUEL D’UTILISATION

ET D’ENTRETIEN et éviter d’utiliser la porte du four et/ou

le panneau inférieur comme un tabouret.

Les instructions sont prévues pour un plancher ou un mur

en bois ou en ciment. Un autre matériau pourra requérir

des techniques spéciales, qu’il conviendra de déterminer,

pour assurer la fixation du SUPPORT DE

STABILISATION au mur ou au plancher.

Pièces comprises

Ce nécessaire comprend : 4 vis à bois de 10 x 2 po et un

(1) support de stabilisation.

Bois :

Mettre le support contre le mur arrière, dans le coin

arrière droit de l’emplacement où sera mise la cuisinière.

Laisser un espace entre le mur (ou le côté de la

cuisinière) et le support en suivant la dimension A (voir le

tableau). Percer 2 avant-trous de 3 mm dans le centre

des petits trous. On pourra utiliser un clou ou un poinçon

si une mèche n’est pas disponible. Fixer solidement le

support au plancher et au mur (voir l’illustration).

Pour des RAISONS DE SÉCURITÉ et pour obtenir des

résultats optimums à la cuisson, régler la cuisinière de

façon à ce qu’elle soit de niveau. Pour vérifier le niveau,

mettre un niveau à bulle ou une grande casserole d’eau

sur la surface de cuisson ou sur la grille du four. La

cuisinière encastrée doit être complètement retirée de

l’ouverture dans l’armoire avant que le réglage ne puisse

être fait.

Pour vérifier si le support de stabilisation est bien en

place : Regarder sous la cuisinière à l’aide d’une lampe

électrique et vérifier que l’un des pieds arrière de mise à

niveau est bien inséré dans la fente du support.

2visàboisdanslemurarrière

(TOUS types de p ose)

2 petits trous pour

la pose sur du bois

2 grands trous pour

la pose sur du ciment

CÔTÉ DROIT DU MUR

OU DE LA CUISINIÈRE

Mur

arrière

Bétonouciment

Matériel requis : 2 ancres à manchon, tire-fonds et

rondelles (non fournis) Repérer l’emplacement du

support tel que décrit ci-dessus. Percer les trous des

dimensions recommandées pour la visserie. Poser les

ancres à manchons dans les trous, puis poser les

tire-fonds dans le support. Les boulons doivent être

serrés correctement, tel que recommandé pour la

visserie. Fixer solidement le support au plancher et au

mur.

Mise en place de la cuisinière

Une fois le support de stabilisation posé, compléter les

étapes4à6avant de pousser la cuisinière en place.

Placer la cuisinière de façon à ce qu’elle puisse entrer

dans l’ouverture où elle sera encastrée et la pousser en

place. S’assurer que le pied de réglage est inséré à fond

dans le support de stabilisation et que celui-ci le retient

bien. Pour accéder au support de stabilisation à partir de

l’avant de la cuisinière, enlever le panneau inférieur. Pour

cela, enlever les 2 vis qui retiennent le panneau inférieur

en place (figure 5).

REMARQUE : S’assurer que la cuisinière est

débranchée du secteur avant d’enlever le panneau

inférieur.

A=

DIMENSION A

Modèle

Série

PRG3610

PRG4810

AVERTISSEMENT

· TOUTES LES CUISINIÈRES

PEUVENT BASCULER ET

PROVOQUER DES BLESSURES.

· POSER LES DISPOSITIFS DE

ST ABILISATION FOURNIS A VEC

CETTE CUISINIÈRE.

· SUIVRE TOUTES LES

CONSIGNES DE MISE EN

SERVICE.

5/8²

7/8²

PRG3010

9

Page 28

ÉTAPE 4 : RACCORDEMENT À

L’ÉLECTRICITÉ

ÉTAPE 5 : ALIMENTATION EN GAZ

Vérifier le type de gaz fourni.

Installation électrique nécessaire

120 VAC, 60 Hz., monophasé.

PRG3010 - 4 A max.

PRG3610 - 7 A max.

PRG4810 - 13 A max.

(Utiliser un circuit de 15 A.)

Toujours débrancher le cordon d’alimentation de la prise

murale ou couper l’appareil du secteur avant toute

intervention.

Observer les codes et règlements en vigueur pour la mise

à la terre ; en leur absence, observer la norme

ANSI/NFPA n 70-1990 du National Electrical Code.

Méthode de mise à la terre recommandée

Cet appareil est équipé en usine d’un cordon

d’alimentation à trois broches (avec lames parallèles

polarisées) pour permettre la mise à la terre. Ce cordon

doit être branché dans une prise murale adaptée et

raccordée à un circuit de 120 V correctement polarisé. Si

le circuit n’est pas équipé d’une prise reliée à la terre, la

responsabilité et l’obligation reviennent à l’installateur ou à

l’utilisateur de faire changer la prise existante par un

électricien qualifié pour en poser une correctement reliée

à la terre et polarisée conformément aux codes et

règlements locaux en vigueur. En l’absence de codes et

règlements locaux, le remplacement de la prise murale

sera fait conformément au National Electric Code.

CETTE TROISIÈME BROCHE NE DOIT EN AUCUN

CAS ÊTRE COUPÉE OU ENLEVÉE

(VOIR LA FIGURE 9).

Couvre-boîtier

de la prise

Fiche

àtrois

broches

Cet appareil a été expédié de l’usine réglé sur le gaz

naturel ou le gaz GPL (propane) selon le modèle

commandé.

Caractéristiques de l’alimentation en gaz

naturel

Raccordement : conduite flexible 1/2 NPT de 1,5 cm de

diam. min. Pression : 1,5 à 3,5 kPa

Caractéristiques de l’alimentation en gas

GPL :

Raccordement : conduite flexible ½ NPT de 1,5 cm de

diam. min. Pression : 2,75 à 3,5 kPa

Un détendeur est nécessaire à la source du gaz GPL afin

de fournir un maximum de 3,5 kPa au détendeur de

l’appareil.

Branchement

Un robinet d’arrêt doit être posé à l’extérieur de l’appareil,

dans un endroit accessible de l’avant, pour permettre de

couper l’alimentation en gaz. Le conduit d’alimentation ne

doit pas dépasser de l’arrière de l’appareil. S’assurer que

l’alimentation en gaz est bien fermée au niveau du robinet

d’arrêt avant d’effectuer le raccordement de l’appareil.

Les raccords dans l’alimentation de gaz doivent être

réalisés par un technicien compétent et conformément

aux codes ou règlements locaux. En l’absence de tels

codes, l’installation doit être conforme à la norme ANSI

223.1 du National Fuel Gas Code, dernière édition.

ATTENTION

L’appareil à gaz doit être isolé des conduites de gaz

de l’habitation en fermant le robinet d’arrêt manuel

pendant toute vérification de la pression dans les

conduites de gaz à des pressions égales ou

inférieures à 3,5 kPa.

Broche

de terre

FIGURE 9

Prise à

3 broches

L’appareil à gaz et son robinet d’arrêt doivent être

désolidarisés des conduites de gaz pendant toute

vérification de la pression à des pressions supérieures

à3,5kPa.

Lors de la vérification de la pression de la rampe, la

pression à l’arrivée du détendeur doit être d’au moins

1,75 kPa pour le gaz naturel.

** La conduite flexible d’alimentation en gaz doit être en

métal et homologuée par un organisme de certification

homologué (AGA, ACG ou U.L.). Ne jamais utiliser de

flexible en caoutchouc ou autre matériau synthétique car

la chaleur pourrait le faire fondre et provoquer des fuites.

10

Page 29

ÉTAPE6:POSEDUDOSSERET

La pose du dosseret est réalisée une fois le raccordement

au gaz effectué. Un dosseret doit être posé lorsqu’il y a

une distance inférieure à 30,5 cm entre des matériaux

combustibles et l’arrière de la cuisinière au-dessus de la

surfacedecuisson(voirlafigure3B).

NÉCESSAIRES DE POSE DE DOSSERET

DE CUISINIÈRE

TABLETTE HAUTE :

(55,9 cm ) PRAG3022 - 76,2 cm

PRAG3622 - 91,4 cm

PRAG4822 - 121,9 cm

TABLETTE BASSE :

(30,5 cm) PRAG3622 - 76,2 cm

PRAG4812 - 121,9 cm

Le dosseret est inséré dans les gouttières à l’arrière de la

cuisinière, tel qu’indiqué à la figure 12. Fixer le dosseret

en place à l’aide des 4 vis à tôle fournies.

Brûleurs du four et du gril

S’assurer que la flamme du brûleur présente bien les

caractéristiques désirées et régler les obturateurs d’air s’il

y a lieu (voir les figures 13 à 14). Chaque bouton de

commande et chaque obturateur est testé

individuellement et ajusté avant l’expédition.

Normalement, aucun réglage n’est nécessaire ; toutefois,

les vibrations au cours du transit ou des variations dans

l’alimentation en gaz local peuvent rendre des réglages

mineurs nécessaires.**

Les flammes des brûleurs devraient être bleues et stables

sans bouts jaunes, du bruit excessif ou une flamme qui se

soulève du brûleur. (Des bouts qui sont légèrement

jaunes sont normaux avec le gaz GPL.) Si un

quelconque de ces conditions existent, vérifier que

l’obturateur d’air ou les ports du brûleur ne sont pas

bloqués. Si cette condition persiste, ajuster l’obturateur

d’air comme requis.

Si la flamme est trop jaune, indiquant un apport d’air

insuffisant, tourner l’obturateur dans le sens contraire à

celui des aiguilles d’une monte pour augmenter l’arrivée

d’air.

Si la flamme est bruyante ou a tendance à se soulever du

brûleur, indiquant un trop grand apport d’air, tourner

l’obturateur dans le sens des aiguilles d’une montre pour

réduire l’apport d’air.

FIGURE 12

ÉTAPE 7 : VÉRIFICATION ET RÉGLAGE

ATTENTION

Jenn-Air exige, dans le cadre de la garantie, que tous

réglages sur les brûleurs soient réalisés par un

technicien qualifié au moment de la mise en service.

Tout réglage après la mise en service devra être

effectué avec le plus grand soin.*

* Des réglages qui ne sont pas faits ou qui ne

sont pas correctement faits annulent la garantie.

Les flammes du brûleur du four devraient être d’environ

3,8 cm (1,5 po) de haut. Les flammes du brûleur du gril

devraientêtrede3,8à5cm(de1,5poà2po)(voirla

figure 13).

Section type d’une flamme correcte

(approximativement)

(gril/four)

4à5cm

FIGURE 13

L’écran doit être d’un

rouge incandescent

La flamme doit être

d’approximativement 3 mm,

épaisse et bleue

FIGURE 14

** Le brûleur à infrarouges du gril du four n’a pas

d’obturateur d’air et n’est pas réglable lorsqu’il est utilisé

avec du gaz naturel. Il est nécessaire de faire

fonctionner le gril du four pendant 45 minutes pour

éliminer l’odeur désagréable du liant de l’isolation. Ceci

doit être fait avant d’utiliser la cuisinière pour la

première fois et avec une ventilation appropriée.

11

Page 30

Brûleurs de la su rface de cuisine

Les brûleurs de la surface de cuisine ne sont pas réglables.

Les brûleurs functionnent correctement quand les orifices

convenables à alimentation de gaz sont installés en usine

selon le modèle commandé.

*Si l’un des brûleurs de la surface de cuisine ne s’allume

pas, détecter à l’oreille un bruit cliquetant pour vérifier le

dispositif d’allumage. S’il n’y a pas de bruit cliquetant,

éteigner le brûleur. Vérifiez un disjoncteur déclenché, un

fusible sauté, ou un raccordement faible de fil au dispositif

d’allumage.

Nettoyage des surfaces extérieures

Les surfaces en acier inoxydable se nettoient avec un

linge humidifié d’eau savonneuse. Tout nettoyeur pour

vitres doux éliminera les traces de doigts et les traînées.

Ne pas utiliser de laine d’acier qui éraflerait la surface.

Les petites éraflures peuvent s’enlever en ponçant

légèrement dans le sens du grain avec du papier de verre

n 120.

LISTE DE VÉRIFICATION DE L ’INSTALLATEUR

j Placement de la cuisinière.

j Dégagement spécifié maintenu par rapport aux

surfaces des armoires.

j Appareil de niveau - d’avant en arrière et d’un côté à

l’autre.

j Tous matériaux d’emballage et sangles enlevés.

j Dosseret court ou dosseret à tablette élevée en place

s’il y a un espace inférieur à 30,5 cm par rapport à

des parois combustibles à l’arrière de la cuisinière

au-dessus de la surface de cuisson.

Électricité

j Prise avec protection de surcharge de 15 A fournie

pour le raccordement du cordon d’alimentation.

j Connexion à la terre suffisante.

j Panneau inférieur en place et fixé par 2 vis.

Alimentation en gaz

j Branchement : 1/2 NPT avec une conduite flexible

d’un minimum de 15 mm de diamètre.

j L’alimentation de gaz de l’emplacement est

convenable au modèle de cuisinière, et une pression

suffisante est disponible (voir ”Alimentation en gaz” à

la page 10).

j Un robinet d’arrêt de gaz a été posé dans un endroit

accessible.

j Appareil vérifié et sans fuites.

Fonctionnement

j Les matériaux d’emballage ont été enlevés. Vérifier

les tiroirs de gouttes.

j Les plaques indicatrices sont centrées sur les

boutons des brûleurs et les boutons tournent

librement.

j Tous les brûleurs s’allument correctement, à la fois

individuellement et pendant que d’autres brûleurs

fonctionnent du même côté.

j Le gril est de niveau.

j Les bacs à graisse sont correctement en place et

coulissent librement.

j Les charnières du four sont en place et la porte

s’ouvre et se ferme correctement.

j Les grilles des brûleurs sont correctement en place,

de niveau et ne basculent pas.

12

Page 31

SCHÉMA DE CÂBLAGE PRG3010 JENN-AIR

DISP.

AVG

ALLUMAGE

19

NR

ARG

IT

20

NR

AVD ARD

21

NR

22

NR

18

NR

NR

NR

NR

BC

BCBC

72

VE

73

VE

70

VE

71

VE

74

VE

75

VE

MODULES DE

RÉALLUMAGE

AVG

ARG

AVD ARD

DÉBRANCHEMT

RÉSEAU

NR

10

BC

11

BC

B--N

28

J

8

BC

35

BC

BC

4

NR

B--L

5

J

18

NR

10

BC

Référence : 16565-50 12/03 Rév. C

GRIL FOUR

42

NR

ROBINET

DOUBLE

37

ALLUM.

FOUR

BROIL

IGN.

ALLUM.

GRIL

36

NR

28

BC

35

BC

BR

NR

39

NR

TÉMOIN

CHAUFF.

4

NR

TSTAT FOUR

11

CHALEUR TOURN.

BC

32

BC

33

BC

34

BR

MOTEUR

CHAL. TRN.

29

NR

COMMUT.

MOTEUR

54

VE

42

NR

31

J

53

VE

ÉCLAIR.

FOUR 1

ÉCLAIR.

FOUR 2

29

NR

5

J

30

J

COMMUT.

ÉCLAIR.

13

Page 32

SCHÉMA DE BRANCHEMENT PRG3010 JENN-AIR

COMMUT.

THERMOSTAT

ÉCLAIR.

FOUR

(CYCLES)

ÉCLAIRAGE

FOUR

COMMUT.

MOTEUR

FOUR

GRIL

MOT.

CHAL.

TOURN.

BOUTON

ÉCLAIRAGE

FOUR

TÉMOIN

CHAUFF.

DISP.

ALLUM.

FOUR

GRIL

BOUTON

FOUR

NF

DISP.

ALLUM.

GRIL

Référence : 16565-50 12/03 Rév. C

ARD

AVD

ARG

AVG

ARD

AVD

ARG

AVG

BOUTONS

RÉGLAGE

DISP. ALLUMAGE

MODULES DE

RÉALLUMAGE

BC

BC

NR

14

Page 33

SCHÉMA DE CÂBLAGE PRG3610 JENN-AIR

DISP.

AVG

19

NR

ARG

20

NR

70

VE

ALLUMAGE

AVG

AVC

21

NR

ARC

22

NR

AVD

48

NR

ARD

49

NR

71

VE

AVC

75

VE

ARC

76

VE

AVD

77

VE

ARDARG

78

VE

MODULES DE

RÉALLUMAGE

Référence : 16560-50 12/03 Rév. C

15

Page 34

SCHÉMA DE BRANCHEMENT PRG3610 JENN-AIR

COMMUT.

THERMOSTAT

ÉCLAIR.

FOUR

(CYCLES)

ÉCLAIRAGE

FOUR

COMMUT.

MOTEUR

FOUR

GRIL

MOT.

CHAL.

TOURN.

BOUTON

ÉCLAIRAGE

FOUR

TÉMOIN

CHAUFF.

DISP.

ALLUM.

FOUR

GRIL

BOUTON

FOUR

NF

DISP.

ALLUM.

GRIL

ARD

AVD

ARC

AVC

ARG

AVG

ARD

AVD

ARC

AVC

ARG

AVG

BOUTONS

RÉGLAGE

MODULES DE

DISP. ALLUMAGE

RÉALLUMAGE

BC

BC

NR

Référence : 16560-50 12/03 Rév. C

16

Page 35

SCHÉMA DE CÂBLAGE PRG4810 JENN-AIR

DISP.

AVG AVD ARD

19

NR

ARG

20

NR

AVC

21

NR

ARC

22

NR

48

NR

18

NR

NR

BC

NR

NR

BC

BC

72

VE

73

VE

74

VE

49

NR

35

BC

70

VE

71

VE

75

VE

76

VE

77

VE

78

VE

MODULES DE

RÉALLUMAGE

ALLUMAGE

AVG

ARG AVC

ARC

AVD ARD

8

BC

10

BC

11

BC

28

BC

38

BC

13

BC

DÉBRANCHEMT

RÉSEAU

BC

NR

18

NR

3

B--N

12

BC

NR

B--L

4

NR

5

J

6

NR

Référence : 16561-50 12/03 Rév. C

COMMUT.

ÉCLAIR.

GRIL

42

NR

ROBINET

DOUBLE

37

FOUR

36

NR

BC

BC33BC

54

VE

FOUR 2

NR

NR

28

39

NR

TÉMOIN

CHAUFF.

31

J

53

VE

ÉCLAIR.

4

NR

GRIL DE SURFACE

TSTAT

FOUR

5

J

11

BC

29

NR

30

J

COMMUT.

ÉCLAIR.

ÉCLAIR.

FOUR 1

ALLUM.

FOUR

ALLUM.

GRIL

43

BC

35

BC

MOTEUR

CHALEUR

TOURN.

34

BR

29

NR

COMMUT.

MOTEUR

CHAL. TRN.

42

NR

17

Page 36

SCHÉMA DE BRANCHEMENT PRG4810 JENN-AIR

COMMUT.

ÉCLAIR.

THERMOSTAT

FOUR(CYCLES)

ÉCLAIRAGE

FOUR

MOT.

COMMUT.

FOUR

GRIL

CHAL.

MOTEUR

TOURN.

ÉCLAIRAGE

FOUR

TÉMOIN

CHAUFF.

BOUTON

GRIL

BOUTON

FOUR

NF

DISP.

DISP.

ALLUM.

ALLUM.

FOUR

GRIL

GRIL DE SURFACEFOUR 30 CM (12 PO)

ARD

AVD

ARC

AVC

ARG

AVG

DISP.

(SANS GRIL)

ARD

ARC

AVC AVD

BC

ARG

AVG

BC

BOUTONS

ALLUMAGE

MODULES DE

RÉALLUMAGE

RÉGLAGE

NR

NR

Référence : 16561-50 12/03 Rév. C

18

Page 37

MANUAL DE

INSTALACIÓN

Modelos profesionales

de estufas de gas

de 48”, 36” y 30”

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

EE.UU.

Conserve este manual como referencia futura.

Page 38

MODELO DE ESTUF A DE GAS DE 30²²²² MODELO DE ESTUFA DE GAS DE 36²

MODELO PRG3010 MODELO PRG3610

²

²²

MODELO DE ESTUFA DE GAS DE 48²

MODELO PRG4810

²

²²

2

Page 39

ÍNDICE

INTRODUCCIÓN

IDENTIFICACIÓN DEL MODELO 2.................

ADVERTENCIA 3..................................

INTRODUCCIÓN 3................................

INSTRUCCIONES IMPORTANTES

DE INSTALACIÓN 4..............................

PASO 1 - Requisitos de ventilación 4................

PASO 2 - Preparación del gabinete 5-6.............

PASO 3 - Desempacado, transportación y

colocación de la estufa 7-8..........................

AJUSTES DE LA PLANCHA DE LA ESTUFA 8......

INSTRUCCIONES DE INSTALACIÓN DEL

DISPOSITIVO ESTABILIZADOR 9..................

PASO 4 - Conexiones eléctricas 10.................

PASO 5 - Requisitos de gas 10-11..................

PASO 6 - Instalación del protector posterior 11........

PASO 7 - Prueba y ajuste 12-13....................

LISTA DE VERIFICACIÓN FINAL

DEL INSTALADOR 13.............................

DIAGRAMA DE CABLEADO

(Series PRG3010, PRG3610, PRG4810) 14.........

DIAGRAMA ESQUEMÁTICO

(Series PRG3610, PRG4810, PRG3010) 15.........

Las características que ofrecen las estufas de gas de la

serie profesional de Jenn-Air harán que la experiencia de

cocinar sea más placentera y le darán al principiante o al

cocinero experimentado muchos años de servicio fiel. Los

hornos de 30”, 36” y 48” se incluyen un horno de gas de

gran capacidad y un asador infrarrojo de gas. La estufa

PRG4810 (48²) también está equipada con un horno más

pequeño de 12” el cual es perfecto para hornear panes y

otros artículos pequeños mientras los artículos grandes

se preparan en el horno de convección de capacidad

grande. El modelo PRG3010 ofrece (4) quemadores de

superficie abierta de 15,000 Btu/hr, mientras que los

modelos de 36” y 48” ofrecen (6) quemadores superiors

de 15,000 Btu/hr. Todas las estufas están équipadas con

quemadores a flujo doble para cocinar a fuego lento con

una llama de menor intensidad de 570 a 900 Btu/hr. lo

cual se usa para derretir mantequilla o chocolate. El

modelo PRG3010 ofrece (1) quemador para cocinar a

fuego lento, mientras que los modelos PRG3610 y

PRG4810 ofrecen (2) quemodores para cocinar a fuego

lento cada uno. Además del horno de gran capacidad y

quemadores superiores de alto rendimiento, el modelo de

48” ofrece también una plancha de acero inoxidable.

Todos los modelos de estufa requieren la instalación de

uno de los tres protectors (esta pieza tiene que pedirse

por separado) excepto en el modelo PRG3010, el cual se

embarca de fábrica con un protector bajo de 9”. Vea la

figura 1.

ADVERTENCIA

Si no se sigue exactamente la información de

este manual, podría suceder un incendio o

explosión, que podrían causar daños materiales,

lesiones personales o la muerte.

No almacene ni use gasolina ni otros vapores o

líquidos inflamables cerca de éste u otro

electrodoméstico.

QUÉ HACER SI HUELE A GAS:

S No trate de encender ningún electrodoméstico.

S No toque ningún interruptor eléctrico, no use

ningún teléfono del edificio.

S Llame inmediatamente al proveedor de gas

desde la casa de un vecino. Siga las

instrucciones que le dé el proveedor de gas.

S Si no puede comunicarse con el proveedorde

gas, llame a los bomberos.

La instalación y el servicio debe realizarlo un

instalador calificado, una agencia de servicio o el

proveedor de gas.

FIGURA 1

3

Page 40

INSTRUCCIONES IMPORTANTES DE

INSTALACIÓN

Pruebas realizadas en conformidad con Estándar ANSI

Z21.1-1993 para electrodomésticos de gas para cocinar.

Estas estufas deben instalarse en conjunto con una

campana superior de ventilación apropiada. (Vea el Paso

1: Requisitos de ventilación). Debido a la alta capacidad

de calor profesional de esta unidad, debe prestarse

atención especial al trabajo de instalación de la campana

y los ductos para garantizar que cumpla con los códigos

locales de construcción. Para eliminar el riesgo de

quemaduras o incendios por atravesarse sobre las

unidades superficiales calientes, debe evitarse el

almacenaje en los gabinetes localizados encima de las

unidades superficiales.

Revise los códigos locales de construcción para obtener

el método apropiado para la instalación de la estufa. Los

códigos locales varían. La instalación, las conexiones

eléctricas y la de tierra deben estar en conformidad con

todos los códigos correspondientes. Si no existieran

códigos locales, la estufa deberá instalarse de acuerdo

con la última edición del Código Nacional de Gas

Combustible ANSI Z223.1- ANSI / NFPA 70-Última

edición.

Los números de modelo que terminan en el sufijo ”SP”

son fabricados para el uso con el gas natural, mientras

que los números de modelo con el sufijo ”LP” se usan con

el gas del LP (propano).

PASO 1: REQUISITOS DE VENTILACIÓN

Debe instalarse encima de la estufa una campana de

escape apropiada. La tabla siguiente indica la capacidad

mínima de ventilación que se recomienda para la

ventilación con campana. (Tabla 1).

PRECAUCIÓN

Las campanas de ventilación y los ventiladores están

diseñados para usarse con ductos sencillos de pared.

Sin embargo, algunos códigos o inspectores locales

de construcción podrían requerir ductos dobles de

pared. Consulte los códigos locales de construcción o

las agencias locales antes de comenzar la instalación

para garantizar que la campana y los ductos cumplan

con los requisitos locales.

Las velocidades del ventilador de la campana deben ser

variables para reducir el ruido y la pérdida de aire de

calefacción o acondicionado cuando no se requiera la

máxima ventilación.

Para obtener una mejor eliminación de humo, el borde

inferior de la campana debe instalarse cuando menos a

30” y a un máximo de 36” por encima de la superficie

para cocinar de la estufa, vea la figura 3. Si la campana

contiene materiales combustibles (por ejemplo, un

recubrimiento de madera) debe estar cuando menos a

36” por encima de la superficie para cocinar.

TABLA 1

UNIDAD DE

VENTILACIÓN

CAMPANA

VENTILADOR

Debido al alto volumen de aire de ventilación, se

recomienda una fuente exterior de reemplazo de aire.

Esto es especialmente importante en las casas

firmemente selladas y aisladas. Debe consultarse a un

contratista de ventilación y calefacción reconocido.

RECOMENDACIONES DE INSTALACIÓN

EN GABINETES ESTÁNDAR

(24² profundidad x ancho de la unidad)

ESTUFA DE 48” - 800-1000 CFM

ESTUFA DE 36” - 600-800 CFM

ESTUFA DE 30” - 500 CFM

RECOMENDACIONES DE

INSTALACIÓN EN ISLAS

(30² de profundidad x 36² al fondo)

800-1000 CFM

600-800 CFM

500 CFM

4

Page 41

PASO 2: PREPARACIÓN DEL GABINETE

1. La estufa es una unidad independiente. Si se colocará

adyacente a los gabinetes, se requerirán los espacios

libres que se muestran en la figuras 2A/B/C. Los

mismos espacios libres se aplican a las instalaciones

en islas.

2. La estufa puede colocarse en varias posiciones con

respecto al frente del gabinete, con el frente al ras o

30” (76.2 cm) mín. de

ancho de campana

(PRG3010)

12” (30.48cm) mín. a los

materiales combustibles,

en cada lado

superficie para

cocinar

suministro

eléctrico y de gas

PRECAUCIÓN:

36” (91.44cm)

mín. a los

materiales

combustibles,

de la superficie

para cocinar

realzado, dependiendo de la profundidad del

mostrador. Vea la figura 3A/B y la tabla 2 (vista lateral

de la estufa) para encontrar las dimensiones.

3. El suministro de gas y eléctrico deberán estar dentro

de las zonas que se indican en las figuras 2 y 4.

4. La profundidad máxima de los gabinetes superiores

instalados a cada lado de la campana es de 13”.

36” (91.44 cm) mín.

de ancho de campana

(PRG3610)

12” (30.48cm) mín. a los

materiales combustibles,

suministro

superficie para

cocinar

eléctrico

en cada lado

suministro

de gas

PRECAUCIÓN:

36” (91.44cm)

mín. a los

materiales

combustibles,

de la superficie

para cocinar

89.86 cm (35 3/8”) máx. para el mostrador nivelado

93.3cm (36 3/4”) máx. con las patas niveladoras de

la estufa completamente extendidas

FIGURA 2A

D Según se describe en el “Código

nacional de gas combustible”

(ANSI Z223.1 última edición).

Las superficies horizontales del adorno de la parte

superior de la estufa (superficie para cocinar) no

deben estar por debajo del nivel del mostrador.

N) 45.72 cm (18”) mín.

O) 40.64 cm (16”)

P) 10.16 cm (4”)

Q) 5.08 cm (2”)

R) 33.02 cm (13”) máx.

de ancho de campana

12” (30.48cm) mín. a los

materiales combustibles,

suministro

eléctrico

89.86 cm (35 3/8”) máx. para el mostrador nivelado

93.3cm (36 3/4”) máx. con las patas niveladoras de

la estufa completamente extendidas

D Según se describe en el “Código

nacional de gas combustible”

(ANSI Z223.1 última edición).

Las superficies horizontales del adorno de la parte

superior de la estufa (superficie para cocinar) no

deben estar por debajo del nivel del mostrador.

48” (121.9 cm) mín.

(PRG4810)

en cada lado

superficie

para cocinar

suministro

de gas

FIGURA 2B

PRECAUCIÓN:

36” (91.44cm)

mín. a los

materiales

combustibles,

de la superficie

para cocinar

P) 30.5 cm (12”)

Q) 30.5 cm (12“)

R) 45.7 cm (18“) mín.

S) 10.2 cm (4“)

T) 33 cm (13“) máx.

U) 8.3 cm (3- -1/4“)

V) 8.9 cm (3--1/2“)

89.86 cm (35 3/8”) máx. para el mostrador nivelado

93.3cm (36 3/4”) máx. con las patas niveladoras de

la estufa completamente extendidas

FIGURA 2C

D Según se describe en el “Código

nacional de gas combustible”

(ANSI Z223.1 última edición).

Las superficies horizontales del adorno de la parte

superior de la estufa (superficie para cocinar) no

deben estar por debajo del nivel del mostrador.

5

P) 40.6 cm (16”)

Q) 30.5 cm (12“)

R) 45.7 cm (18“) mín.

S) 20.3 cm (8“)

T) 33 cm (13“) máx.

U) 8.3 cm (3- -1/4“)

V) 8.9 cm (3--1/2“)

Page 42

5. Deben sellarse las aberturas en la pared posterior y en

el piso debajo de la estufa.

6. Cuando haya menos de 12” de espacio libre entre el

material combustible y el borde posterior de la estufa,

(por encima de la superficie para cocinar), debe

instalarse un protector posterior corto o uno con repisa

alta de Jenn-Air. Estas piezas deben pedirse por

separado, excepto en el modelo PRG3010, el cual

F

G

Repisa alta

D

C

H

Protector

posteriorbajo

36² Mín. a materiales

combustibles

viene equipado con el protector posterior bajo. Las

figuras 3A y 3B indican el espacio que se requiere

para cada tipo de protector posterior.

7. Siempre mantenga el área del electrodoméstico limpia

y libre de materiales combustibles, gasolina y otros

vapores y líquidos inflamables.

8. No obstruya el flujo de aire de combustión y ventilación

de la unidad.

12² Mín. a materiales

combustibles sin protector

posterior

36² Mín. a materiales

combustibles

1-1/2²

Adorno

de la isla

TABLA 2

DIMENSIONES

PRG4810

PRG3610

PRG3010

0² de espacio

libre

A

E

B

A

27-7/16²

27-7/16²

26-3/4²

B

44-11/16²

44-11/16²

44-1/4²

C

12²

12²

9²

D

21-1/4²

21-1/4²

21-1/4²

E

29-15/16²

29-15/16²

29-15/16²

0² de espacio

libre

FIGURA 3BFIGURA 3A

F

28-3/16²

28-3/16²

28-3/16²

G

10²

10²

9-3/8²

H

2-1/2²

2-1/2²

1-3/4²

6

Page 43

PASO 3: DESEMPACADO, TRANSPORTACIÓN

Y COLOCACIÓN DE LA ESTUFA

PRECAUCIÓN