INSTALLATION

INSTRUCTIONS

COOKTOP SERIES

CONVENTIONAL BURNER 3o3sSHADELANDINDIANAPOLIS,FNA2!-

GAS GRILL []iiUENN R1

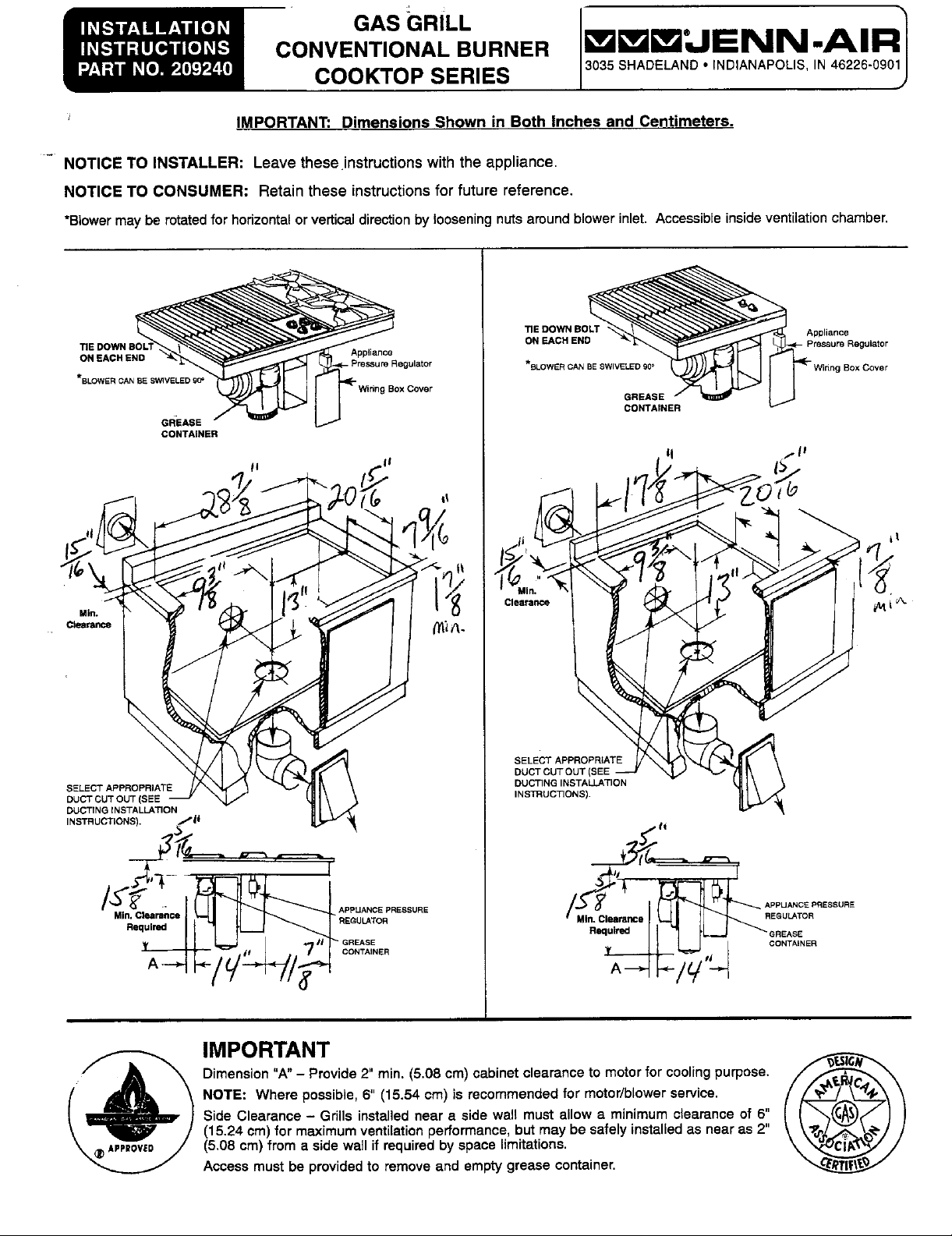

IMPORTANT:DimensionsShownin BothInchesand Centimeters.

- NOTICETOINSTALLER:Leavethese.instructionswiththeappliance.

NOTICETOCONSUMER:Retaintheseinstructionsforfuturereference.

*Blower may be rotated for horizontal or vertical direction by loosening nuts around blower inlet. Accessible inside ventilation chamber.

TIEDOWN BOLT Appliance

TIE DOWNBOLT Appliance

ONEACH E _- PressureRegulator *BLOWERCANBESWIVELED90_ Winng BoxCover

*BLOWERCANRESWlVELED90° _,-

BESW1GI_II_ _ ._J WiringBoxCover GREASE

CONTAINER

ii

it

ONEACH EN - PressureRegulator

CONTAINER

II

SELECT APPROPRIATE

SELECTAPPROPRIATE DUCTINGINSTALLATION

DUCTCUTOUT (SEE INSTRUCTIONS).

DUCTINGINSTALLATION

INSTRUCTIONS). ijt

DUCTOUT OUT (SEE

i "

...u,.< R..u,... ooo,..-%"_:%R

oo...,.ER A "1

IMPORTANT

NOTE: Where possible, 6" (15.54 cm) is recommended for motor/blower service. _,._J_

Side Clearance - Grills installed near a side wall must allow a minimum clearance of 6"

(15.24 cm) for maximum ventilation performance, but may be safely installed as near as 2" 1

(5.08 cm) from a side wall if required by space limitations.

_ Oimensiorl"A"-Provide2"min.(5.0Scm) cabinetclearancet°m°t°rf°rc°°lingpurpose" /__)

Access must be provided to remove and empty grease container.

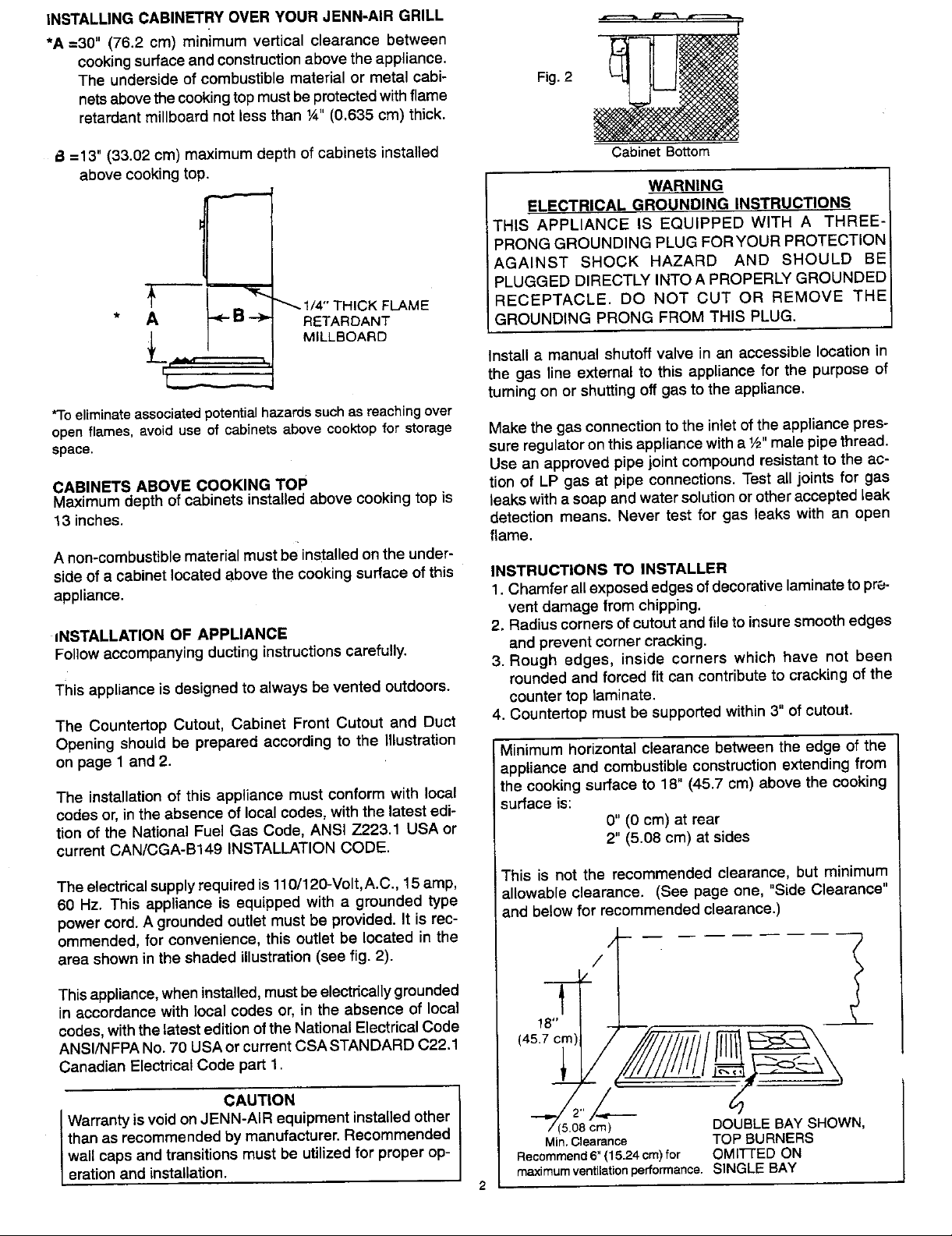

INSTALLINGCABINETRYOVERYOURJENN-AIRGRILL _ _ ._ _,,_ _ ,

*A=30" (76.2 cm) minimum vertical clearance between T-_---_ i_ I

cookingsurfaceandconstructionabovetheappliance.

The undersideof combustiblematerialor metalcabi- Fig.2

netsabovethecookingtopmustbeprotectedwithflame

retardantmillboardnot lessthan 1/_,,(0.635cm) thick.

,-1=13"(33.02cm) maximumdepth ofcabinetsinstalled CabinetBottom

abovecookingtop.

WARNING,wl

THIS APPLIANCE IS EQUIPPED WITH A THREE-

PRONGGROUNDINGPLUGFORYOURPROTECTION

AGAINST SHOCK HAZARD AND SHOULD BE

ELECTRICALGROUNDINGINSTRUCTIONS

PLUGGEDDIRECTLYINTOA PROPERLYGROUNDED

_I/4"THICK FLAME RECEPTACLE. DO NOT CUT OR REMOVE THE

* A B --_ RETARDANT GROUNDING PRONG FROM THIS PLUG.

,_,--.... _ Installa manualshutoff valve in an accessiblelocation in

k MILLBOARD

[ __ __ the gas line external to this appliancefor the purposeof

-- -- turningon orshuttingoff gasto theappliance.

*Toeliminateassociatedpotentialhazardssuchasreachingover

openflames,avoiduseof cabinetsabovecooktopfor storage Makethe gasconnectionto the inletofthe appliancepres-

space, sure regulatoronthisappliancewith a1/2"malepipethread.

Usean approvedpipe joint compoundresistantto the ac-

CABINETSABOVECOOKINGTOP tion of LP gas at pipe connections.Test alljoints for gas

Maximumdepthof cabinetsinstalledabovecookingtopis leakswitha soapandwatersolutionorotheracceptedleak

13inches, detectionmeans.Nevertest forgas leakswithan open

flame.

A non-combustiblematerialmustbeinstalledontheunder-

sideofacabinetlocatedabovethe cookingsurfaceof this INSTRUCTIONSTO INSTALLER

appliance. 1,Chamferallexposededgesofdecorativelaminateto pra.

ventdamagefromchipping.

iNSTALLATIONOF APPLIANCE 2. Radiuscornersofcutoutandfiletoinsuresmoothedges

Followaccompanyingductinginstructionscarefully, andpreventcornercracking.

Thisapplianceisdesignedto alwaysbeventedoutdoors, roundedandforcedfit cancontributeto crackingofthe

3. Rough edges, inside corners which have not been

countertoplaminate.

The CountertopCutout,CabinetFrontCutoutand Duct 4. Countertopmustbesupportedwithin3" ofcutout.

Openingshouldbe preparedaccordingto the Illustration

onpage1 and2. Minimumhorizontalclearancebetweenthe edgeof the

applianceandcombustibleconstructionextendingfrom

The installationof thisappliancemustconformwithlocal thecookingsurfaceto 18"(45.7 cm)abovethecooking

codesor,intheabsenceoflocalcodes,withthelatestedi- surfaceis:

tion ofthe NationalFuelGas Code,ANSIZ223.1 USAor 0" (0 cm) at rear

currentCAN/CGA-B149INSTALLATIONCODE. 2" (5.08cm) at sides

Theelectricalsupplyrequiredis110/120-Volt,A.C.,15amp, This is not the recommendedclearance,but minimum

60 Hz. Thisapplianceis equippedwith a groundedtype allowableclearance. (See pageone,"SideClearance"

powercord.Agroundedoutletmustbe provided.It isrec-

andbelowforrecommendedclearance.)

ommended,for convenience,this outletbe locatedinthe

areashowninthe shadedillustration(seefig. 2). / _,

Thisappliance,wheninstalled,mustbeelectricallygrounded

inaccordancewithlocalcodesor,intheabsenceof local

codes,withthelatesteditionoftheNationalElectricalCode 18"

ANSI/NFPANo.70 USAorcurrentCSASTANDARDC22.1 (45.7cml _/_'_ _'__ _"

CanadianElectricalCode part1. _ /

WarrantyisvoidonJENN-AIRequipmentinstalledother -"

thanas recommendedby manufacturer.Recommended 8cm'_) DOUBLEBAYSHOWN,

CAUTION _ /

Min.Clearance TOP BURNERS

wall capsand transitionsmust beutilizedfor proper op- Recommend6"(15.24cm)for OMITFEDON

erationandinstallation, maximurnventilationperformance.SINGLEBAY

2

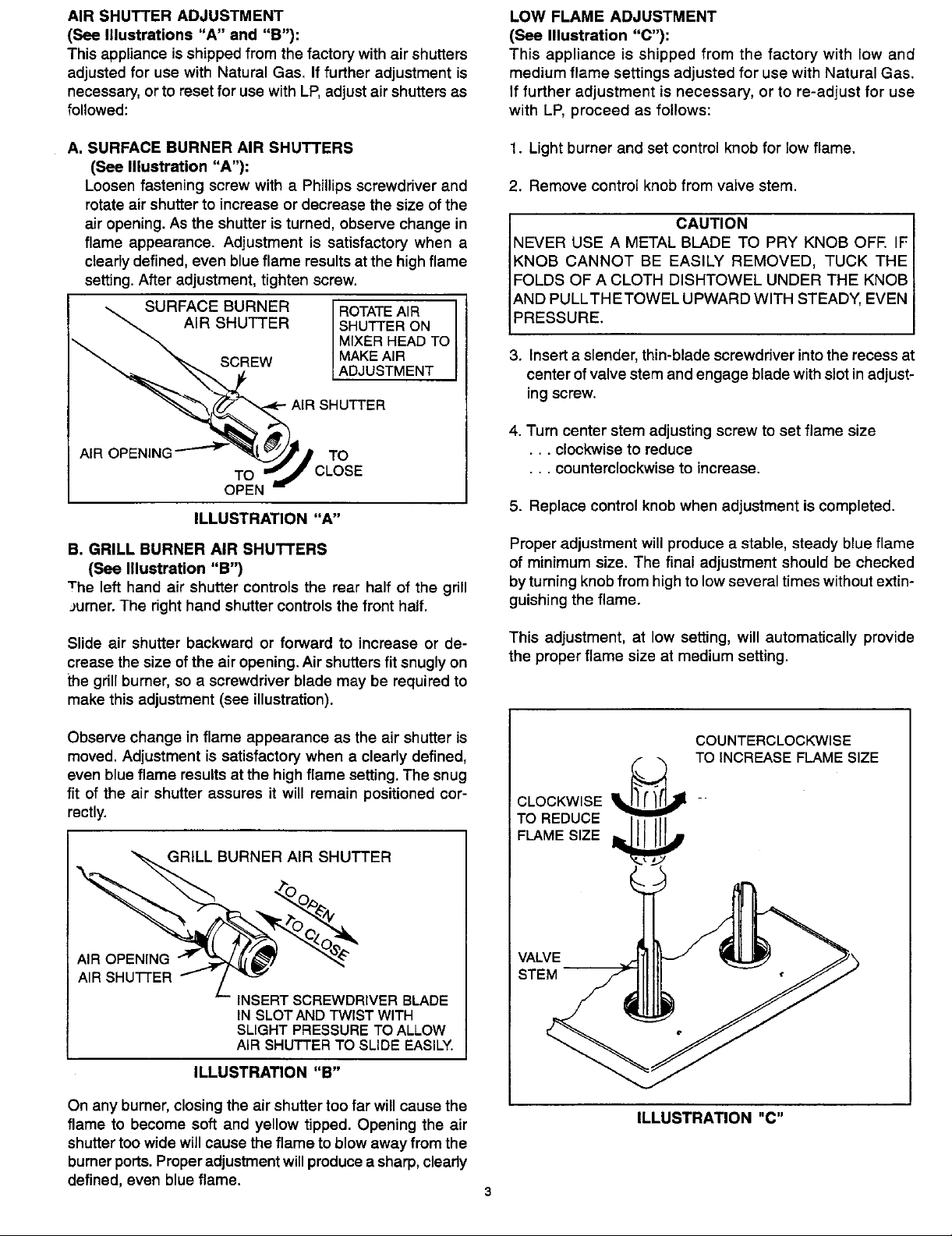

AIR SHUTTER ADJUSTMENT LOW FLAME ADJUSTMENT

(See Illustrations "A" and "B"): (See Illustration "C"):

This appliance is shipped from the factory with air shutters This appliance is shipped from the factory with low and

adjusted for use with Natural Gas. If further adjustment is medium flame settings adjusted for use withNatural Gas.

necessary, orto resetfor use with LP,adjustair shuttersas If further adjustment is necessary, or to re-adjust for use

followed: with LP, proceed as follows:

A. SURFACE BURNER AIR SHUTTERS 1. Lightburner andset control knob forlow flame.

(See Illustration "A"):

Loosen fastening screw with a Phillipsscrewdriverand 2. Remove control knobfrom valve stem.

rotate air shutterto increase or decrease the size of the

air opening.As the shutter isturned, observe change in CAUTION IF

flame appearance. Adjustment is satisfactory when a NEVER USE A METAL BLADE TO PRY KNOB OFF.

clearly

defined, even blue flame results atthe high flame KNOB CANNOT BE EASILY REMOVED, TUCK THE I

setting. After adjustment, tighten screw. FOLDS OF A CLOTH DISHTOWEL UNDER THE KNOB

SURFACE BURNER ROTATEAIR AND PULLTHETOWEL UPWARD W TH STEADY, EVENAIR SHUTTER SHUTTERON PRESSURE.

_ MIXERHEADTO

_ _C..RFW MAKEAIR 3. Insert aslender, thin-blade screwdriver into the recess at

",._ _ --_-- ADJUSTMENT center of valve stemand engage blade with slot in adjust-

AIR SHUTTER ing screw.

"__'_ 4. Turncenterstemadjustingscrewtosetflamesize

AIR OPENI_'_JlB TO ...clockwise to reduce

TO _" CLOSE ... counterclockwise to increase.

OPEN --

ILLUSTRATION "A"

5. Replace control knob when adjustment is completed.

B. GRILL BURNER AIR SHUTTERS Proper adjustment will produce a stable, steady blue flame

(See Illustration "B") of minimum size. The final adjustment should be checked

The left hand air shutter controls the rear half of the grill bytuming knob from highto Iowseveral times without extin-

Jurner.The right hand shuttercontrolsthe front half. guishing the flame.

Slide air shutter backward or forward to increase or de- This adjustment, at low setting, will automatically provide

crease the size of the air opening. Air shuttersfitsnuglyon the proper flame size at medium setting.

the grillburner, so a screwdriver blade may be requiredto

make thisadjustment (see illustration).

Observe change in flame appearance as the air shutter is COUNTERCLOCKWISE

moved. Adjustment is satisfactory when a clearly defined, f -_ TO INCREASEFLAMESIZE

even blue flame results at the high flame setting. The snug

fit of the air shutter assures it will remain positioned cor- CLOCKWISE

rectly. TO REDUCE

_GRtLL BURNER AIR SHUTTER

FLAME SIZE _ _

A,ROPEN,NG VALVE

AIR SHUTTER "'- / _ STEM

/

INSERTSCREWDRIVERBLADE

IN SLOTANDTWIST WITH

SLIGHTPRESSURETOALLOW

AIR SHUTTER TO SLIDE EASILY.

ILLUSTRATION "B"

On any burner,closing the air shutter too far will cause the

flame to become soft and yellow tipped. Opening the air ILLUSTRATION "C"

shutter too wide willcause the flame to blow away from the

burnerports.Properadjustmentwill producea sharp,clearly

defined,even blue flame.

3

Loading...

Loading...