Page 1

IMPORTANT INFORMATION AND GLOSSARY

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

Thank you for selecting JELD-WEN® products. Attached are

JELD-WEN’s recommended installation instructions for hollow

and solid core bifold doors. Bifolds are designed for fast and

easy installation and adjustment using common tools.

Read these installation instructions thoroughly before beginning. They

are designed to work in most existing applications. However, existing

conditions may require changes to these instructions. If changes are

needed, they are made at the installer’s risk. For installations other than

indicated in these instructions, contact a building professional.

Note to Installer: Provide a copy of these instructions to the building

owner. By installing this product, you acknowledge the terms and

conditions of the limited warranty as part of the terms of the sale.

GLOSSARY

Finished Opening

The resulting opening after any trim work is completed. Measure these

dimensions for proper door tting.

Lead Door

The panel or section without the pivoting hardware. On four panel

assemblies, these are the two that meet in the middle.

Pivot Door

The panel or section that contains the pivoting hardware and supports

the weight of the door assembly.

SAFETY AND HANDLING

• Read and fully understand ALL manufacturers’ instructions before

beginning.

• Use safe lifting techniques.

• Wear protective gear (e.g. safety glasses, gloves, ear protection, etc.).

• Operate hand/power tools safely and follow manufacturer’s operating

instructions.

• Heed material manufacturers’ handling and application instructions.

• Store doors in a dry, well-ventilated building and on a at and level

surface.

• Do not subject interior doors to extremes of heat and/or humidity.

Prolonged exposure may cause damage. Buildings where humidity

and temperature are controlled provide the best storage facilities

(recommended conditions 30%-50% Relative Humidity and 50°F to

90°F).

• Do not install doors in buildings that have wet plaster or cement

unless they have been properly nished. Do not store doors in

buildings with excessive moisture content - HVAC systems should be

operating and balanced. Avoid sudden changes such as forced heat

to dry out a building. Doors should not be delivered to the job site

or installed until concrete oors, foundation, plaster or drywall are

cured.

• Doors should always be handled with clean hands or while wearing

clean gloves.

• Doors should be lifted and carried when being moved, not dragged

across one another.

• Finish all six sides (both sides and all four edges) of the door slab,

including cutouts for hardware. Failure to nish all six sides may

result in the denial of warranty claims for operational or performance

problems.

IF INJURY OCCURS, IMMEDIATELY SEEK MEDICAL ATTENTION!

12

1

½ hr

11

2

10

3

9

4

8

7

5

6

Estimated Install

Time

First Time: 1 hr

Experienced:

NEEDED MATERIALS AND TOOLS

FINISHING MATERIALS

Note! Follow all material manufacturers’ instructions for proper use

and compatibility.

• Rubber gloves

• Paint brush

• Sandpaper

• Drop cloth

• Paint (and primer for raw

wood doors) or stain and wood

conditioner

• Wood putty

TOOLS

• Hammer (applies only to certain hardware)

• Drill with bits

• Screwdrivers

• Safety glasses

• Tape measure

Page 2

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

INSPECT FINISHED OPENING, REMOVE PACKAGING AND INSPECT DOOR

INSPECT FINISHED OPENING

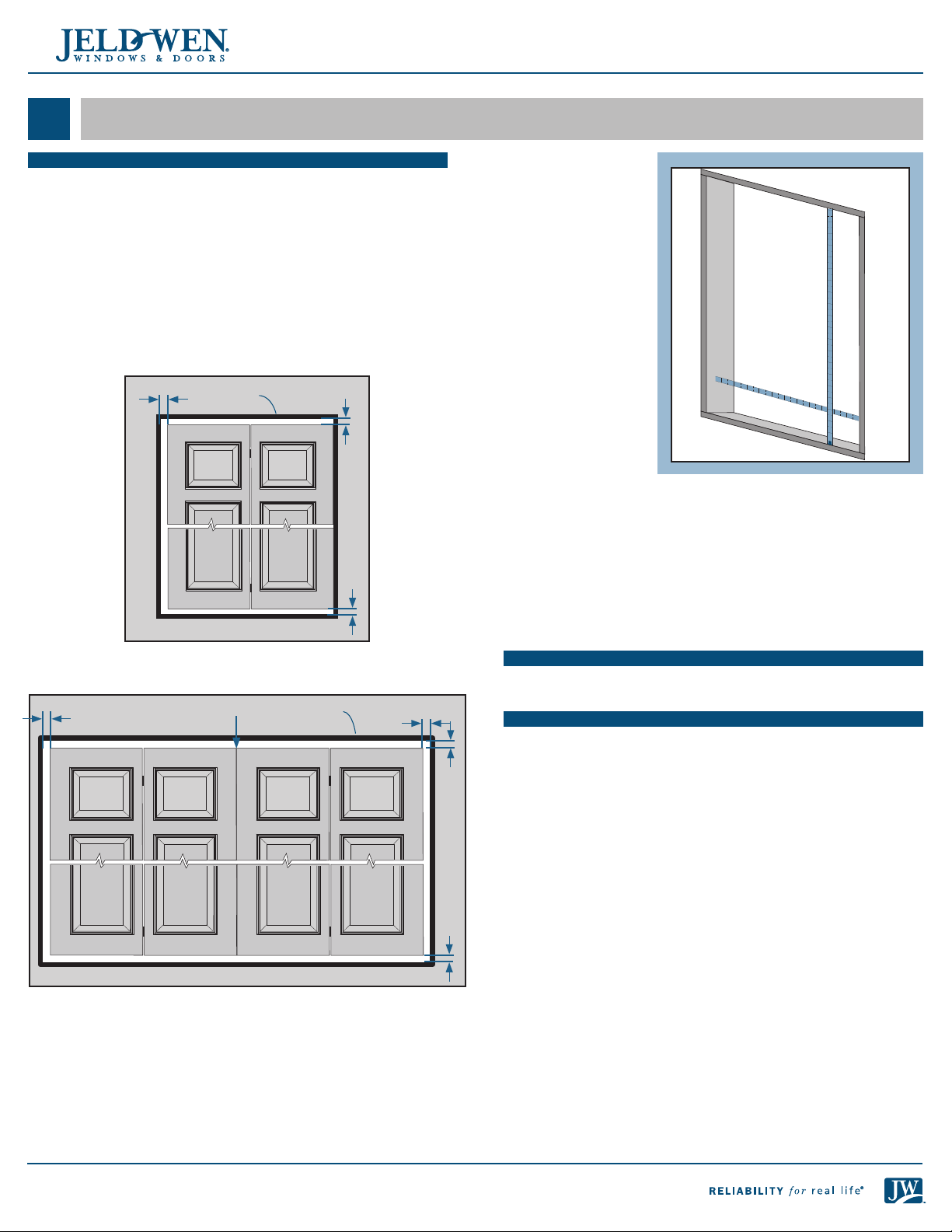

• The width size specication (nished opening size) shown on the

bifold packaging is 1/2" larger than the bifold set to allow for at least

a 1/4" gap between the side jamb and pivot door (door secured to

the oor and head jamb). Double units should have at least 1/4" gap

between both side jambs and no gap between the doors that meet in

the middle.

• The height size specication (nished opening size) shown on the

bifold packaging is 1 1/2" larger than the bifold set to allow for

the track to be installed above the door set and the lower bracket

installed below the door set.

Single Bifold Set

Double Bifold Set

1/4"

min.

Pivot

door

Wall

Wall

1/4"

min.

Pivot

door

Finished

opening

No gap

3/4"

min.

Finished

opening

1/2"

min.

1/4"

min.

Pivot

door

3/4"

min.

• Measure height and

width of nished

wall opening and

verify it is no more

than 1/4" larger or

smaller than the

stated opening size

on the packaging.

• Once the door

set(s) are installed,

there is an

additional hardware

adjustment of up to

3/8" to center the

sets in the nished

opening.

• If the nished

opening is too large,

ller material, such

as a 1" x 6" piece

of pine trim can be

tacked into the opening to bring it to the correct size.

• If the nished opening is too small (1/2" or less), 1 3/8" thick hollow

or solid core molded and ush doors may be trimmed 1/4" on each

side as necessary. Trimming any other bifold type is not recommend.

• If the opening is too far out of specication, or if you are

not condent trimming, you can order custom sizes from our

manufacturing locations to t the nished opening, or contact a

building professional for assistance. Contact us or a dealer/distributor

for options.

REMOVE PACKAGING

Remove shipping materials such as corner covers, shipping blocks or

pads.

INSPECT DOOR

• Cosmetic damage

• Correct product (size, color, design, etc.)

1/2"

min.

2

Page 3

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

2

Open the hardware pack and compare the contents to the images on this page. They do not show everything in the hardware pack, but only what is

necessary to properly identify a speci c type of hardware. Go to the page number for the pictured hardware type that matches the contents of the

hardware pack that came with the door and follow the installation instructions.

Type A1 - Page 4

Type A2 - Page 4

IDENTIFY HARDWARE TYPE

Type B - Page 5

Type C - Page 6

Type A3 - Page 4

Type A4 - Page 4

Type D - Page 7

Type E - Page 8

3

Page 4

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

3

INSTALLATION FOR TYPE A1 - A4

PARTS INCLUDED

A. Upper pivot pin

B. Guide for track

C. Snugger or slide guide

D. Lower pivot pin

E. Lower bracket

A B

OR

C

OR

F

I

1. Using a hammer, gently tap

pivot pins and guide into

the pre-drilled holes in the

locations shown.

2. Position overhead track

in the opening with the

open side down and the

bracket end toward the

jamb. Center the track, or

allow at least 3/4" between

the track and the front of

the opening. Secure the

track with the long pan

head screws through the

pre-drilled holes until snug.

If installing four panels

with two tracks, use a track

bracket between the two

ends in the center.

3. Position the lower bracket

on the oor in line with

overhead track. The

bottom of the bracket

must rest securely on the

oor or carpet. Fasten to

the jamb and oor with

a long at head screw

through each hole.

F. Track slide (optional)

G. Knob

H. Aligner

I. Track

J. Track bracket

Screws (not shown)

OR

D E

G

Upper

pivot pin

Jamb

side

Lower

pivot pin

OR

H

Guide

OR

Lower

bracket

4. Place the upper pivot

pin in the hole in

the bracket and the

guide in the track (or

in the middle of the

slide guide between

the springs). Lift

the door assembly

slightly and drop the

lower pin into the

1/4"

Bracket

Pin

lower bracket slot.

5. Verify there is a 1/4"

clearance between

the pivot door and

the jamb. Four panel

assemblies should be snug at the middle. If adjustments are necessary,

door panels should be folded, in some cases removed, to gain access

to the adjustment screws.

To adjust horizontally:

6. At the top, loosen

the screw in the top

pivot bracket and

move toward or

away from the jamb

until there is 1/4"

clearance. Retighten.

7. At the bottom, lift

J

assembly and move

the adjusting wheel

toward or away from

Horizontal

adjustment

screw

the jamb until doors

are plumb with jamb,

then lower into

bracket.

To adjust vertically:

8. Lift assembly slightly

until the adjustment

wheel clears the

slot in the lower

bracket. Rotate the

adjustment wheel to

the left to raise doors

or to the right to

lower them. Be sure

Adjusting

wheel

the teeth lock rmly

into bracket when

nished.

Snugger

9. Snap the snugger

or slide guide into

the lead door end of

the track as shown,

or in the center of

the track between

guides in a four door

installation. If using

Slide guide

a slide guide, seat

lead door guide pin

between the two

springs in the guide

as shown.

SKIP to Section

8, “COMPLETE

INSTALLATION.”

4

Page 5

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

4

INSTALLATION FOR TYPE B

PARTS INCLUDED

A. Upper pivot pin

B. Guide for track

C. Snugger

D. Knob

E. Lower pivot pin

A

E

H

1. Position the guide,

upper pivot pin and

lower pivot pin on

the door assembly

in the locations and

orientations shown.

2. Measure in 5/8"

from the end of

each panel and

center each pin on

the panel.

3. Secure with a 1" at

head screw through

each hole.

4. Position overhead

track in the opening

with the open

side down and

the bracket end

toward the jamb.

Allow 3/4" between

the front of the

opening and the

track and drive the

1 1/4" pan head

screws through the

pre-drilled holes

until snug. Position

the lower bracket

B

F

Upper

pivot pin

Jamb

side

Lower

pivot pin

5/8"

5/8"

F. Lower bracket

G. Aligner

H. Track

I. Adjustment wrench

Screws (not shown)

C

G

Pivot door

Bottom of

pivot door

3/4"

Jamb

Lead door

Head

Center

Guide

Track

Lower

bracket

on the oor in line with overhead track. Fasten to the jamb with a

1 1/4" at head screw through only the middle of the top slotted

hole.

5. Unlock the track

pivot latch by

pulling the latch

away from the

jamb. With the door

assembly folded,

D

place the guide in

the track and then

Track

pivot

Track

pivot latch

unlocked

position the upper

pivot pin next to

the track pivot.

Slide the pin away

from the jamb into

the track pivot.

Slide the latch

I

toward the jamb to

lock the pivot pin in

Track

pivot

Track

pivot latch

locked

place. Verify the pin

is secure.

6. On the bottom,

depress the arm

on the lower

bracket and insert

the lower pivot

pin. If installing a

Horizontal

adjustment

screw

Lower

pin

four door system,

repeat for the other

assembly. Check

positioning and

operation.

To adjust horizontally:

Gap

Bracket

arm

7. At the top, loosen

the screw in the

top pivot bracket

and move toward

or away from the

5/8"

jamb until there

is 1/4" clearance.

Retighten. Repeat

the process for the

1/4"

Horizontal

adjustment

screw

lower bracket.

To adjust vertically:

8. There should be a

slight gap between

the lower pin and

the bracket. If there is no gap or the gap is too large and allows the

pin to come out of the bracket, loosen the single screw in the bracket

and adjust up or down until there is a small gap (shown above) and

the pin is engaged in the bracket. When the bracket is properly

adjusted, install the remaining two screws and tighten.

9. Loosen the screw on the snugger and close doors. Move the snugger

until it contacts the guide pin. Open doors and move the snugger an

additional 1/8" toward doors and tighten screw. Doors should slightly

“snap” shut, but reopen easily with a tug on the knob.

SKIP to Section 8, “COMPLETE INSTALLATION.”

5

Page 6

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

5

INSTALLATION FOR TYPE C

PARTS INCLUDED

A. Upper pivot pin

B. Hanger with T-nut

C. Snugger

D. Top pivot bracket

F. Lower bracket

G. Adjustment wrench

H. Track

Screws (not shown)

E. Lower pivot pin

A

B

F

C

G

D

E

1. If holes are not

drilled in panels,

pre-drill one hole

on each outside

corner of the

assembly 7/16" in

diameter and at

1 1/4"

Pivot door

Bottom of

pivot door

Pivot hole

Lead door

least 1 1/2" deep

in the locations

shown.

T nut

2. Tap pivots into

holes with light

hammer blows as

Upper

pivot pin

shown. Secure T-nut

by driving a

#8 x 1" pan head

screw through both

holes.

3. Trim track to t

Jamb

side

Lower

pivot pin

nished opening if

necessary.

4. Insert the hanger

into one end of the

track. Loosen the

screw on the top

pivot bracket and

position on track

with the screw

toward the jamb.

Top pivot

bracket

Hanger

Snugger

Snap the snugger

onto the track next

to the hanger, opposite the top pivot bracket as shown.

5. Secure the track to the head jamb with the provided #8 x 1" pan

head screws through the pre-drilled holes. Move the top pivot

bracket back toward the track end until it is 1/4" from the jamb and

tighten the screw.

H

7/8"

6. Position the lower

bracket in the jamb,

centered with the

track, and secure

with the provided

#8 x 3/4" at head

Lower

bracket

screws.

7. Fold the door

assembly and

position the T-nut

to the hanger.

Using the provided

wrench, screw

hanger into T-nut as

far as possible.

8. Place the upper

pivot pin into the

hole in the top

pivot bracket. Lift

the assembly and

place the lower

pivot pin into the

hole in the lower

Pin

Bracket

bracket. If installing

a four door system,

repeat for the other

assembly. Check

positioning and

operation.

Verify there is a 1/4"

clearance between

the pivot door and

the jamb. Four panel

assemblies should be

snug at the middle.

If adjustments are

1/4"

Horizontal adjustment

screw

necessary, door panels

should be folded to

gain access to the

adjustment screws.

To adjust horizontally:

9. At the top, loosen

the screw in the

top pivot bracket

and move toward

or away from the

Horizontal

adjustment

screw

jamb until there

is 1/4" clearance.

Retighten.

10. At the bottom,

loosen the

adjustment screw

and move toward

Bracket

Vertical

adjustment

screw

or away from the

jamb until doors

are plumb with jamb, then retighten the screw.

To adjust vertically:

11. Lift assembly slightly and rotate the adjustment screw to the right to

raise doors, and to the left to lower them.

12. Slide the snugger until it is against the jamb opposite the top pivot

bracket, or place between hangers in four door sets.

SKIP to Section 8, “COMPLETE INSTALLATION.”

6

Page 7

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

6

INSTALLATION FOR TYPE D

PARTS INCLUDED

A. Upper pivot pin

B. Guide for track

C. Snugger

D. Knob

E. Lower pivot pin

A

E

H

1. If holes are not

drilled in panels,

pre-drill 7/16" in

diameter holes at

least 1 3/8" deep,

1 1/4" from edges

as shown. Tap pivots

into holes with light

hammer blows as

shown.

2. Trim track to t

nished opening

length if necessary.

3. Secure the track to

the head jamb with

the provided

#8 x 1" pan head

screws through the

pre-drilled holes.

4. Position the lower

bracket in the jamb,

centered with the

track, and secure

with the provided

#8 x 3/4" at head

screws.

B

1 1/4"

pivot pin

F. Lower bracket

G. Aligner

H. Track

I. Adjustment wrench

Screws (not shown)

F

Lead door

Pivot hole

Upper

pivot pin

Jamb

side

Lower

C

G

Pivot door

Bottom of

pivot door

Guide

D

I

1 1/4"

Lower

bracket

5. Place the upper pivot

pin into the hole in

the top pivot bracket

and the guide pin

into the track. Lift

the assembly and

place the lower pivot

pin into the lower

bracket. If installing

a four door system,

1/4"

Pin

Bracket

repeat for the other

assembly. Check

positioning and

operation.

Two and four panel

assemblies should have 1/4" clearance between the pivot doors and

each jamb. Four panel assemblies should be snug at the middle.

Door panels should be folded to gain access to the adjustment screws.

In some cases, the doors may need to be removed to properly access the

adjustment screws.

To adjust horizontally:

6. At the top, loosen

the screw in the top

pivot bracket and

move toward or

away from the jamb

until there is 1/4"

clearance. Retighten.

7. At the bottom,

loosen the

adjustment screw

and move toward or

Horizontal

adjustment

screw

away from the jamb

until doors are plumb

with jamb, then

retighten the screw.

To adjust vertically:

8. Lift assembly slightly

and rotate the

adjustment screw

ange to the right

Horizontal

adjustment

screw

to raise doors, and

to the left to lower

them.

9. Loosen the screw

Vertical

adjustment

screw ange

on the snugger and

close doors. Move

the snugger until it

Bracket

contacts the guide

pin. Open doors and

move the snugger an additional 1/8" toward doors and tighten screw.

Doors should slightly “snap” shut, but reopen easily with a tug on the

knob.

SKIP to Section 8, “COMPLETE INSTALLATION.”

7

Page 8

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

7

INSTALLATION FOR TYPE E

PARTS INCLUDED

A. Upper pivot plate (2)

B. Hanger

C. Snugger

D. Knob

E. Lower pivot pin

G. Top pivot bracket

H. Aligner

I. Track

J. Adjustment wrench

Screws (not shown)

F. Lower bracket

A

E

I

B

F

C

D

G

H

J

1. Fasten the pivot

plates to each

7/8"

door panel with

the 1 1/4" pan

head screws in the

locations shown.

Use the 1" at head

screws on the lower

pivot pin. Center

Pivot door

Bottom of

pivot door

5/8"

Lead door

each plate on the

panel.

2. Trim track to t

nished opening.

2 1/4"

Top pivot

bracket

Snugger

3. Install top pivot

bracket into one

end of the track with the pin toward the end and 2 1/4" in. From

the other end, install the hanger and snugger (with rubber bumper

toward hanger) into track.

4. Position overhead

track in the opening

with the open

side down and

Head

the bracket end

toward the jamb.

Allow 3/4" between

3/4"

Track

the front of the

opening and the

track and drive the

Jamb

Center

provided 1 1/4"

pan head screws

through the pre-

Lower

bracket

drilled holes until

snug. Position the

lower bracket on

the oor in line with overhead track. Fasten to the jamb with a 1 1/4"

at head screw through the middle of the top slotted hole.

7/8"

5. Unlock the track

pivot plate by

pulling the latch

Unlock

away from the

bracket. With the

door assembly

Lock

folded, place the

pin from the top

pivot bracket into

the pivot plate on

the pivot door. Slide

the pin into the

pivot plate and slide

the latch to lock the

pivot plate to the

bracket. Verify the

pin is secure. In the

same manner, lock

the hanger into the

pivot plate on the

lead door.

Horizontal

adjustment

screw

Lower

pin

6. On the bottom,

depress the arm on

the lower bracket

and insert the lower

pivot pin.

To adjust horizontally:

Gap

Bracket

arm

7. At the top, loosen

the screw in the

top pivot bracket

and move toward

or away from the

jamb until there

is 1/4" clearance.

Retighten. Repeat

the process for the

Horizontal adjustment

screw

lower bracket.

To adjust vertically:

8. There should be a

slight gap between

the lower pin and

the bracket. If there is no gap or the gap is too large and allows the

pin to come out of the bracket, loosen the single screw in the bracket

and adjust up or down until there is a small gap and the pin is

engaged in the bracket. When the bracket is properly adjusted, install

the remaining two screws and tighten.

9. Loosen the screw on the snugger and close doors. Move until the

snugger contacts the guide pin. Open doors and move an additional

1/8" and tighten screw. Doors should slightly “snap” shut, but reopen

easily with a tug on the knob.

10. Adjust the snugger by closing doors, loosen screw and slide against

guide in track. Open doors and move snugger 1/8" closer to panels

and tighten screw.

Continue with Section 8, “COMPLETE INSTALLATION.”

8

Page 9

INSTALLATION INSTRUCTIONS

for Bifold Doors (JII103)

8

For four door

congurations, mount

an aligner as shown

on the back side of

each lead door.

COMPLETE INSTALLATION

Back side

of door

Back side

of door

For best operational

performance and

aesthetic appeal,

install the door knob

in the center of the

middle rail of the lead

door(s) (panel without

pivot hardware). The

knob, however, can

also be installed in any

other location on the

lead door if desired.

Drill a hole slightly

smaller than the screw

and attach knob.

Note! Unless drilling the knob attachment hole close to an edge on a

hollow core door, it will likely be in a hollow part of the door. This does

not cause problems and the door material is sufciently strong if the

screw is snug but not over tightened.

Knob

Please visit jeld-wen.com for warranty, nishing instructions and

care and maintenance information.

Thank you for choosing

©2012 JELD-WEN, inc.; This publication and its contents are owned by JELD-WEN, inc. and are protected under the U.S. Copyright Act and other intellectual

property laws. All trademarks, service marks, logos and the like (whether registered or unregistered) are owned or controlled by JELD-WEN, inc. or others.

Unauthorized use or duplication of JELD-WEN intellectual property is prohibited.

JELD-WEN reserves the right to change product specications without notice. Please check our website, jeld-wen.com, for current information.

9

(08/12)

Loading...

Loading...