Page 1

IMPORTANT INFORMATION AND GLOSSARY

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

Thank you for selecting JELD-WEN products. Attached are JELD-WEN’s

recommended installation instructions for Custom Lift and Slide doors.

Read these instructions thoroughly before beginning. They are designed

to work in most existing applications, however; existing conditions

may require use of alternative methods to these instructions. If changes

are needed, they are made at the installer’s risk. For installations other

than indicated in these instructions, contact a building professional. To

adequately protect your door, please refer to “Appropriate Protection for

Exterior Doors” for information on protection requirements at

www.jeld-wen.com.

Newer construction methods have led to an increase in air and water

tightness in buildings. This frequently leads to negative air pressure

inside the house, which can draw water through very small openings. Our

installation method seals the door to the weather barrier (typically building

wrap) and uses a sill pan to capture and drain incidental storm water from

under the door to the exterior.

Not all exterior door types may be installed into every wall condition

in all areas. See our Appropriate Protection document for overhang

requirements at www.jeld-wen.com. Consult your local building

code ofcial (or Authority having Jurisdiction) for applicable building

codes and regulations. Local building code requirements supersede

recommended installation instructions.

Please Note! Any door installation such that the sill is higher than

35 feet above ground level or into a wall condition not specically

addressed in these instructions must be designed by an architect or

structural engineer. We recommend that all non pre-nished wood or

berglass components be nished with an appropriate paint or stain

prior to installation. See our Finishing document for details at

www.jeld-wen.com. Failure to properly nish or install square, level

and plumb and on a at surface (without peak and valleys) could result

in denial of warranty claims for operational or performance problems.

Note to Installer: Provide a copy of these instructions to the building

owner. By installing this product, you acknowledge the terms and

conditions of the limited warranty as part of the terms of the sale.

GLOSSARY

Astragal

The vertical trim attached to one of the panels of a sliding patio door

that bridges the gap between the panels when closed and provides

weather protection.

Backer Rod (backing material)

A material (e.g. foam rod) placed into a joint primarily to control the

depth of the sealant.

Buck

A wood framework attached to the masonry inside a window or a door

rough opening.

Continuous Air Seal

Backer rod and sealant or low expansion foam applied to the interior

gap between the product and the building in a continuous fashion

used to block air ow between the interior and exterior of the building

envelope.

Interlock

A weatherstrip component that runs vertically along the stiles of

either horizontal sliding sashes or sliding patio door panels. When the

window/door is closed, the interlocks engage, locking together, to

create a weather barrier.

Pilot Hole

A drilled hole that is no larger than the body of the screw (minus the

threads).

Rough Opening

The framed opening in a wall where a door is to be installed.

Shiplap

The layering method in which each layer overlaps the layer below it so

that water runs down the outside.

Sill Pan

A ashing component installed in the sill of the rough opening

underneath the door. Sill pans have upturned walls along the interior

edge and at both ends, creating a three sided box. This component

serves as a collection device to drain incidental water to the exterior of

the building and should be properly sealed to the opening. The best sill

pan design has a positive slope to the exterior and offers continuous

support to the door's sill.

Please allow sufcient time to properly prepare the rough opening,

install the door, and ensure its proper operation.

Estimated Install

Time for New

Construction

First Time: 6 hr.

Experienced: 5 hr.

Professional: 4 hr.

12

1

11

2

10

3

9

4

8

7

5

6

LANDINGS

These instructions

cover two door

Step-Down Landing

sill conditions: the

step-down landing

and the continuous

slab landing. The

installation methods

vary slightly between

landing types.

Continuous

Slab

Landing

Page 2

ROUGH OPENINGS

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

This installation guide specically addresses masonry/block wall,

sheathed wall and open-stud construction.

MASONRY/BLOCK WALL CONSTRUCTION

This installation

assumes that a

building professional

has already properly

fastened and sealed

a framework of studs

(often called a buck)

to the concrete/

Buck

masonry wall.

SAFETY AND HANDLING

SAFETY

• Read and fully understand ALL manufacturers’ instructions before

beginning. Failure to follow proper installation and nishing

instructions may result in the denial of warranty claims for

operational or performance problems.

• Do not work alone. Two or more people are required. Use safe lifting

techniques.

• Use caution when handling glass. Broken or cracked glass can cause

serious injury.

• Wear protective gear (e.g. safety glasses, gloves, ear protection, etc.).

• Operate hand/power tools safely and follow manufacturer’s operating

instructions.

• Use caution when working at elevated heights.

• If disturbing existing paint, take proper precautions if lead paint is

suspected (commonly used before 1979). Your regional EPA (www.

epa.gov/lead) or Consumer Product Safety Commission ofces provide

information regarding regulations and lead protection.

FULLY SHEATHED WALL CONSTRUC TION

The wall framing is

covered by sheathing

Header

and the door will be

mounted inside of the

rough opening. This

installation assumes

building wrap is

properly installed

prior to installation.

King

stud

Trimmer

studs

Sill area

Sheathing

Building

wrap

MATERIALS AND DOOR HANDLING

• Heed material manufacturers’ handling and application instructions.

• Protect adhesive surfaces from dirt, moisture, direct sunlight and

folding over onto themselves.

• Handle in vertical position; do not drag on oor.

• Do not put stress on joints, corners or frames.

• Store door in dry, well-ventilated area in vertical, leaning position to

allow air circulation; do not stack horizontally.

• Protect from exposure to direct sunlight during storage.

• Install only into vertical walls and when conditions and sheathing

are dry.

IF INJURY OCCURS, IMMEDIATELY SEEK MEDICAL ATTENTION!

MATERIALS AND TOOLS

PARTS INCLUDED WITH PATIO DOOR

A

B

C

D

E

A #8 x 1 1/4" square drive screws

for frame assembly

B #10 X 2 1/2" square drive screws

for frame installation

C Head frame

D Sill track

E Left and right side frame

F Fixed panel keepers (if

applicable)

2

F

G

H

I

For pocketing systems only:

G Follower

H Post interlock

I Closure

Items not shown:

- Handle package

- Door panel(s)

- Astragal if applicable

- Corner seal pads

- Track caps

NEEDED MATERIALS

Note! Follow all material manufacturers’ instructions for proper use

and compatibility. When using ashing, spray adhesive/primer, sealant

and foam products, we recommend using the same manufacturer and

verifying compatibility.

• Sill: Wood Sub Floor: #8 x 1 1/4" corrosion-resistant, pan-head screws;

Concrete Sub Floor: 1/4" diameter self-tapping concrete screws

(Tapcon®, or equivalent); length of screw must penetrate at least 1

1/4" into the sub oor. Side Jambs: #10 x 2 1/2" corrosion-resistant,

at-head screws; Head jamb: #10 x 2 1/2" corrosion-resistant, panhead screws.

• Non-compressible or water degradable shims

• Sill pan: It is best practice to use a pre-formed, rigid, positively sloped,

PVC pan that provides continuous support. We recommend using

SureSill™ Sloped Sill Pan™ , manufactured by SureSill™, Ltd. An

alternative would be a non-sloped pre-formed sill pan or one can be

fabricated on site from metal or vinyl sheet material with the proper

tools.

• Sealant: We recommend OSI® QUAD® Max Sealant or equivalent. This

can be used in any application and can be painted or ordered in a

color matched product, if desired.

Page 3

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

MATERIALS AND TOOLS - CONTINUED

• Backer rod 1/8" larger than the widest portion of the gap (used in

conjunction with sealant bead).

• Polyurethane low expansion Window and Door foam: We recommend

OSI® QUAD® Foam or equivalent).

• 4", 6", or 9" (as required by local code and window conguration)

wide self-adhesive ashing: We recommend OSI® QUAD® Butyl

Flashing Tape or equivalent.

• Drip cap if required because of door location and exposure. Doors with

an adequate overhang (see our Appropriate Protection document at

www.jeld-wen.com) may not need a drip cap. In addition to sill pans,

SureSill™ also offers types of head ashing.

For installations into a Buck:

• Liquid applied ashing (Protecto Wrap LWM 200 or equivalent)

1

REMOVE PACKAGING

Remove shipping materials such as corner covers, shipping blocks

or pads.

INSPECT DOOR

• Cosmetic damage

• Included parts (See Parts List above)

• Correct product (size, color, grid pattern, handing, glazing, energyefciency requirements, etc.)

If any of the above conditions represent a concern, or if you expect

environmental conditions to exceed the door's performance rating,

do not install the door. Contact your dealer or distributor for

recommendations.

REMOVE PACKAGING AND INSPECT DOOR

NEEDED TOOLS

• Hacksaw (SureSill sill pan)

Cutting shears (fabricated sill

pan)

• Tape measure

• Utility knife

• Level (6' recommended)

• J-roller

• Caulking gun

• Drill with bits

• Screwdrivers

• Hammer drill and masonry bits

for masonry applications

2

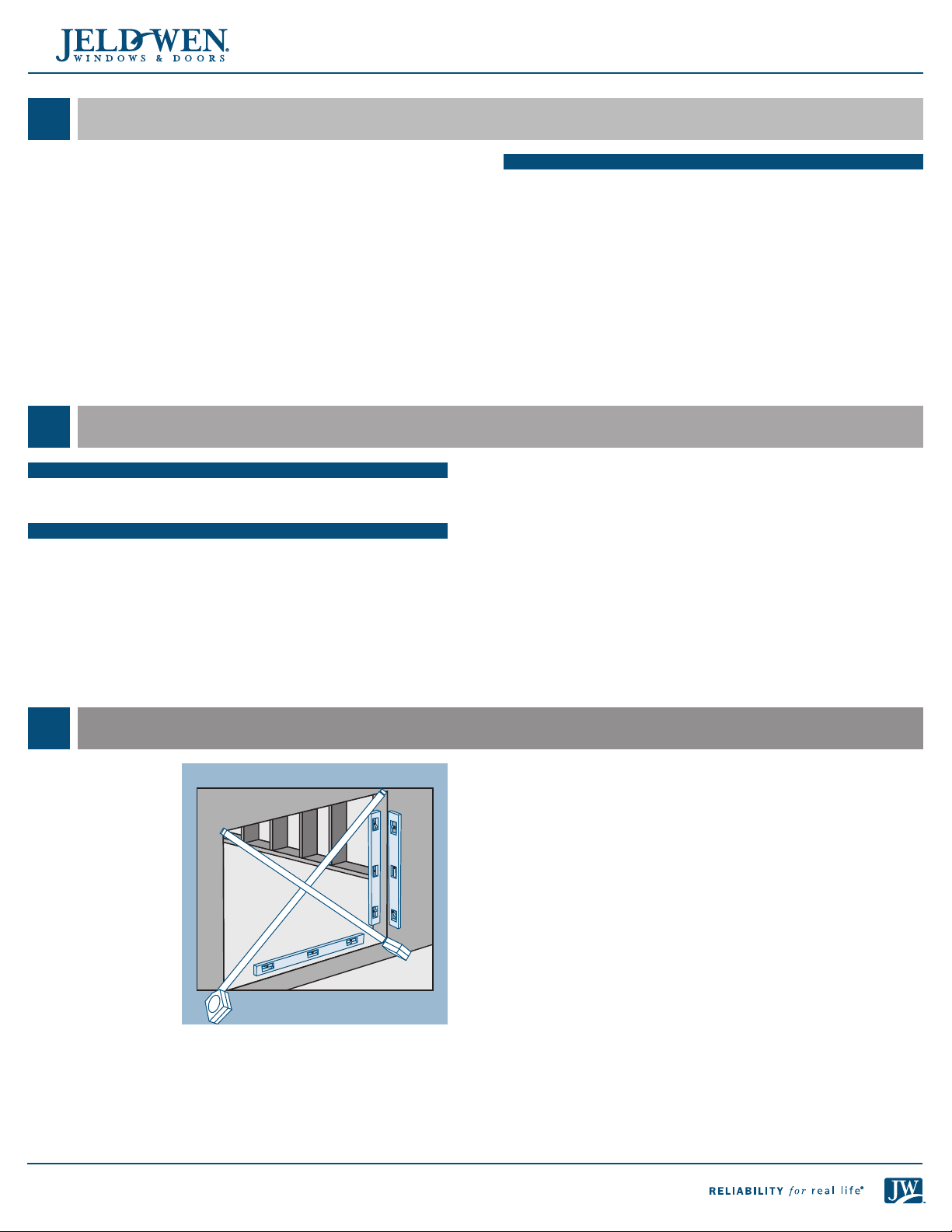

• Verify the rough

opening (inside the

buck) is no larger than

1" wider and 1/2" taller

than the patio door

frame.

• Verify the rough

opening is square.

The (A) and (B)

measurements should

be the same. Maximum

allowable deviation

from square is 1/4".

INSPECT ROUGH OPENING

Verify Square, Level, and Plumb

A

B

D

• Verify the rough opening is level and plumb (C). The maximum

allowable deviation is 1/8".

• The rough opening sill must not be crowned or sagged (D). A 5 degree

sloped sill is recommended.

• The exterior face of the rough opening must be in a single plane (E)

with less than 1/8" twist from corner to corner.

C

E

• In wood frame construction, the header must be supported by

trimmer studs and designed to ensure that no load is transferred to

patio door unit.

• Correct any deviations before installing the patio door. Consult a

building professional as needed.

• Verify the rough opening is clean and dry.

3

Page 4

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

3

The sill can be prepared using one of two methods: We recommend

SureSill™ Sloped Sill Pan™ available from SureSill at www.suresill.com,

building supply stores, and some manufacturing locations or fabricate a

sill pan on site. Note! Sills wider than 7" will not allow a pre-formed

sill pan to be used, follow the instructions for the job site fabricated

sill pan instead. If installing a SureSill™ sill pan, follow SureSill™'s

instructions for installation and skip to section 4 “PREPARE BUCK“, or to

section 5, “PREPARE STUD-FRAMED WALL“ as it applies to your situation.

If fabricating a sill pan on the job site, follow the instructions below.

JOBSITE FABRICATED SILL PAN

1. Cut a piece of sheet

2. Lightly crease folding

3. Measure the width

4. Take this distance

5. For step-down

6. For continuous slab, cut across the folding line.

INSTALL SILL PAN

material to the

length shown.

lines 1/2" in from the

two short sides and

one long side.

of the frame and

add 9/16".

from the back edge

and lightly crease a

folding line across

the sheet material.

landings, cut 1/2" in

at this line on both

sides of the sheet

material.

Length of rough opening sill plus 1"

Frame

width

+9/16"

Folding Line

1/2"

Fold sides and back up

Fold corner

forward

Fold front

ap down

1/2"

7. Fold the three back

sides up to make a

3-sided box, and,

for step-down

landings, fold the

front ap down.

INSTALL SILL PAN

1. Set the sill pan

in the rough

opening, aligning

the front edge (for

continuous slab) or

folded down edge

(for step down)

with the exterior of

the rough opening.

2. Mark a line across

the front and back

of the sill pan.

3. Apply three 3/8"

beads of sealant

between the lines.

4. Place the sill pan in

the rough opening.

Firmly press the sill

pan into the sealant

with a J-roller.

Remove for

continuous slab

Sealant

4

Note! This section applies to installations into a buck only. For

installations into a stud-framed wall, begin with section 5, “PREPARE

STUD-FRAMED WALL.”

1. Seal any joint larger than 1/16" in the buck and between the buck

and the concrete/masonry with sealant.

2. Cover the buck and the surrounding concrete/masonry at the head

and jambs (apply over sill pan if installing a job site fabricated sill

pan) with liquid applied ashing per manufacture's instructions as

shown.

END of Buck Instructions, SKIP to section 6, “INSTALL DOOR.”

PREPARE BUCK

Liquid applied

ashing

Sealant joints

4

Page 5

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

5

PREPARE STUD - FRAMED WALL

FOR RETROFIT INSTALLATIONS

Completely remove the old door unit. Verify rough opening is

structurally sound.

PREPARE BUILDING WRAP

Verify these steps are allowed by the building wrap manufacturer.

1. Trim building wrap

ush with the

edges of the rough

opening.

2. If the door extends

beyond the exterior

plain of the

6"

building and a drip

cap is desired, at the

head, slit building

45˚

wrap 6" at 45°.

Tape up as shown.

We recommend

installing a drip cap

because this integrates the building wrap and drip cap to protect

the structure and the product from incidental water.

3. Trim the sides sufciently to allow the nailing n to be mounted

against the sheathing.

Note! The rest of the steps in this section only apply to a job site

fabricated sill pan. If installing a sill pan that you have purchased,

follow manufacturer's instructions for installation and skip to section 6,

“INSTALL DOOR.”

4. If installing a metal sill pan on concrete, cut a piece of self-adhesive

ashing the length of the sill pan and adhere it to the entire bottom

surface where the pan will sit on the concrete.

5. Apply spray adhesive/primer to the sill pan and surrounding area.

Follow manufacturer’s instructions for application methods.

6. Cut a piece of selfadhesive ashing

the length of the sill

and apply over the

entire sill pan. For

step down landings,

fold ashing down

as shown. For

continuous slabs,

trim ush with

rough opening.

7. Cut two pieces

of self-adhesive

ashing 6" wide by

the sill pan width +

3" long.

a. For continuous

slab landings

only, cut out the

inside corner.

b. Adhere the

pieces of

ashing to the

inside corners.

Stretch ashing

as needed to

cover corners

and lay at.

8. Smooth gaps or

bubbles beneath

self-adhesive

ashing with a

J-roller (remove

and replace if

necessary).

9. Seal back corners

of sill pan with

sealant.

End of Stud-Framed

Wall Instructions,

continue with section

6, “INSTALL DOOR.”

Sill pan

width

3"

continuous

Sill pan

width

Continuous Slab

Sealant

Discard

(for

slab only)

3"

Landing

6"

Step-Down

3"

Landing

Sill pan

width

3"

3"

5

Page 6

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

6

INSTALL DOOR

ASSEMBLE FRAME

1. On a clean and at

surface, lay out

frame head, sill and

side jambs with

Depth of

pocket

the exterior side

up. If installing a

pocketing system,

Frame

Post

interlock

there will be post

interlock(s) for each

end that pockets

Exterior side

shown

used instead of a

side jamb piece.

Post interlock(s) do

not install on the

extreme end of the

head and sill tracks,

but will install to

the side where

the pre drilled

holes are located

(approximately the

width of one panel

from the end of the

head and sill tracks).

2. If gaskets are

provided, adhere

to both ends of

the sill. Run a bead

of silicone on all

surfaces of the sill

as shown. Repeat

silicone application

Sill

Jamb

Screw

holes

for the head where

the ends will

contact the jambs.

3. Clamp the frame

corners as needed

to ensure that the

frame sections t

together ush and

using the supplied 1

1/4" screws, fasten

the sill to the right and left jamb frame parts. The pre-drilled holes in

the jamb will line up with the screw bosses in the sill. Make sure the

attached gasket lies at and the screws are inserted properly into the

screw bosses.

4. Using the supplied 1 1/4" screws, fasten the header to the right and

left jamb frame parts through the pre-drilled holes in the jambs.

5. Seal the screw heads and the outside of each corner joint with

sealant.

INSTALL FRAME

Warning! To avoid injury, use at least two people to install.

1. If installing a preformed sill pan,

follow manufacturer's

instructions and skip

this step. If installing a

job site fabricated sill

Sealant

pan, run a continuous

3/8" bead of sealant

along the sill pan back

dam. When the frame

is installed, make

sure the frame makes

solid contact with the

sealant. Add more

sealant if necessary.

2. Tilt the frame into the rough opening. Adequately support the frame

until fully installed.

3. Align the exterior of the frame, or applied nailing n, with the most

exterior surface of the structure (the exterior face of the concrete

wall, framing or sheathing).

SHIM THE JAMBS

Note! Secure all shims with sealant.

1. From the interior,

shim the side jambs at

each pre-drilled hole.

Shim head track next

to pre-drilled holes.

6"

Also shim at the strike

plate(s) if applicable so

that strike plate screws

(installed later) will

each penetrate a shim.

2. Inspect the frame for

square, level, and

plumb (remove and

reinstall if necessary).

Interior

6"

FASTEN FRAME

1. To secure the head, fasten through each pre-drilled hole using #10 x 2

1/2" screws. Fastener holes should not go through, but next to shims.

Move shims accordingly to be next to fastener holes if necessary.

2. To secure the sill, put a generous amount of silicone sealant in each

pre-drilled hole and drive a #10 x 2 1/2" screw through each hole.

3. Secure the side jambs through each pre-drilled hole.

6. Verify the unit is square by re-measuring on the diagonals.

7. Verify the unit is plumb and level.

8. Use a level (4 foot recommended) to ensure there are no bows in the

framing.

9. Adjust screws and re-shim as needed to correct any bows.

6

Page 7

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

6

INSTALL DOOR - CONTINUED

INSTALL PANELS

Note! To avoid damage to the rollers, clean all debris from the main

roller track in the sill.

1. Study the overall door conguration before installation. Each panel

will be labeled with a number indicating the order of installation

into the frame and will contain an elevation drawing of the entire

unit. Refer to these drawings and the sections below for detailed

instructions on installing each panel into the frame. Note! Panels are

not reversible or interchangeable. Two panel doors are shown, but

also apply to three or more panels.

2. If installing a

xed panel, install

keepers in the

jamb by driving

the provided #10

Jamb

Fixed

panel

keeper

x 2 1/2 at head,

square drive screws

(remove keepers

and use #10 x 2

1/2 screws if preinstalled) through

the keeper, predrilled holes in the

frame and into the

rough opening.

3. Working from

the outside, align

the panel marked

number 1 next

to the frame end

with the interlock

facing the interior.

Place the top of the

rst panel into the

exterior most head

track directly over

the corresponding

sill location.

4. Raise the panel and

swing the bottom

in so the wheels are

properly located on

the sill track.

5. Push the panel fully

into the pocket (for

pocketing systems)

Jamb

Fixed panel

lock mechanism

drive

or to the xed panel

jamb (for stacking

systems).

6. If installing a xed

panel, use either

a handle or 3/8"

ratchet to rotate the

locking mechanism

180 degrees to

secure the xed

panel to the jamb.

7. Repeat for all remaining panels in sequential order.

FOLLOWER AND POCKET CLOSURE (POCKETING SYSTEMS ONLY)

1. From interior side

of system, slide the

follower over the

bolt heads located

at the back edge

of the last panel

Panel

and align so that

the weatherstrip is

tight against the

exterior surface of

Access

hole

Follower

the panel. Tighten

the bolts with a 1/2"

wrench to secure

Access

hole

the follower.

Panel

Fixed panel

lock mechanism

drive

2. Attach the pocket

closure to the

follower using the

screws supplied

Panel

in the “Follower/

Pocket Closure”

screw package.

Closure

Pocket

closure

Panel

Fixed

panel lock

mechanism

drive

7

Page 8

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for Custom Clad Lift and Slide Door Systems (JII040)

7

FINISH INSTALLATION

1. Refer to the manufacturer’s instructions supplied in the handle

package.

2. Install track covers.

3. Install astragal if applicable.

4. If the door unit has a strike jamb against a rough opening jamb, drive

#10 x 2 1/2" screws through the screw holes in the strike plate. Replace

existing screws if necessary. This will secure the door frame to the structure.

5. Install drip cap if required or desired. Fold the building wrap

(previously taped up) down over the drip cap and seal the cut ends

with self-adhesive ashing or building wrap tape.

CONTINUOUS AIR SEAL

On the interior, create a continuous air seal between the rough opening

and the door frame with backer rod and sealant or low expansion foam.

COMPLETE INSTALLATION

AFTER INSTALLATION

1. Maintain gap of 1/4"- 3/8" between door frame and nal exterior

wall surface (siding, stucco, etc.).

2. Seal this gap on the

sides with backer

rod and sealant. Do

not apply sealant on

top of the drip cap

if present.

3. Protect recently

installed units

from damage from

plaster, paint, etc.

by covering the unit

with plastic.

4. Remove labels or

other materials

adhered to glass

within 30 days after

installation.

Sealant

joint

Gap

Backer

rod

Please visit jeld-wen.com for warranty and care and maintenance information.

Thank you for choosing

©2014 JELD-WEN, inc.; This publication and its contents are owned by JELD-WEN, inc. and are protected under the U.S. Copyright Act and other intellectual property laws. All trademarks, service marks,

logos and the like (whether registered or unregistered) are owned or controlled by JELD-WEN, inc. or others. Unauthorized use or duplication of JELD-WEN intellectual property is prohibited.

JELD-WEN reserves the right to change product specications without notice. Please check our website, jeld-wen.com, for current information.

(05/14)

8

Loading...

Loading...