Page 1

IMPORTANT INFORMATION AND GLOSSARY

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

Thank you for selecting JELD-WEN products. Attached are

JELD-WEN’s recommended installation instructions for pocket

(replacement) double-hung, casement, awning, picture or transom

windows, designed to be installed into an existing window frame.

Pocket windows may be installed from either the exterior or

interior. Exterior detail work is needed in both installation types.

Read these installation instructions thoroughly before beginning. They

are designed to work in most existing applications. However, existing

conditions may require changes to these instructions. If changes are

needed, they are made at the installer’s risk. For installations other than

indicated in these instructions, contact a building professional.

Not all windows can be installed into every wall condition in all areas.

Consult your local building department for applicable building codes

and regulations (particularly regarding minimum egress requirements).

Local building code requirements supersede recommended installation

instructions.

The installation of a pocket window will not eliminate installation or

maintenance problems with an existing window. Problems such as wood

decay and water leaks around the existing frame must be investigated

and xed prior to installing a pocket window.

Please Note! Installation such that the window sill is higher than 35

feet above ground level or any window installation into a condition

not specically addressed in these instructions must be designed by an

architect or structural engineer.

Failure to install into a square, level and plumb condition could result in

denial of warranty claims for operational or performance problems.

Note to Installer: Provide a copy of these instructions to the building

owner.

By installing this product, you acknowledge the terms and conditions of

the limited product warranty as part of the terms of the sale.

The exterior trim (casing) around the existing window opening may

be painted a color of your choice. However, optional color matched

cladding to cover this trim is available for purchase and professional

installation. Discuss with your dealer.

Estimated Install

Time for New

Construction

Professional: 1.5 hr.

First Time: 4.0 hr.

Experienced: 2.5 hr.

12

11

10

9

8 4

7 5

6

1

2

3

GLOSSARY

Backer Rod (backing material)

A material (e.g. foam rod), placed into a joint primarily to control the

depth of the sealant.

Butt Joint

The joint of two square edges united without overlapping.

Check Rail

In a double-hung window, the bottom rail of the upper sash (upper

checkrail) and the upper rail of the lower sash, where the lock is

mounted (lower checkrail).

Clad

Pre-painted formed metal covering the exterior surface(s) of some

wood windows.

Double-Hung Window Balance System

A system of ropes and pulleys (older) or springs (newer) used to

counter-balance the weight of a sash.

Miter Joint

Joint made by joining two parts with 45° angles, to form a corner at a 90° angle.

Pilot Hole

A drilled hole that is no larger than the body of the screw (minus the

threads).

Sash

An assembly comprised of stiles (vertical pieces), rails (horizontal pieces)

and the window’s glass.

Transom

Typically a xed/picture window mounted above another window or door.

SAFETY AND HANDLING

SAFETY

• Read and fully understand ALL manufacturers’ instructions before

beginning.

• Do not work alone. Two or more people are required. Use safe lifting

techniques.

• Use caution when handling glass. Broken or cracked glass can cause

serious injury.

• Wear protective gear (e.g. safety glasses, gloves, ear protection, etc.).

• Operate hand/power tools safely and follow manufacturer’s operating

instructions.

• Use caution when working at elevated heights.

• Windows in older homes may be painted with lead-based paint. Take

precautions to minimize exposure to lead-based paints if removal

of existing sashes disturbs the paint. Your regional EPA (www.epa.

gov/lead) or Consumer Product Safety Commission ofces provide

information regarding regulations and lead protection.

IF INJURY OCCURS, IMMEDIATELY SEEK MEDICAL ATTENTION!

WINDOW HANDLING

• Handle in vertical position; do not carry at or drag on oor.

• Store window in dry, well-ventilated area in vertical, leaning position;

do not stack horizontally.

Page 2

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

INCLUDED PARTS, NEEDED MATERIALS AND TOOLS

PARTS INCLUDED

• 6 - 12 #8 x 3" installation screws (not all may be needed for any given

installation)

• 1 – jamb jack screw packet (includes 2 - #8 x 2" screws and instructions

for operating double-hung windows only)

• 1 – shim packet; 2 – shim packets for non-operating units

• Vinyl jambliner hole plugs if applicable (does not apply to Custom)

• Clad exterior cover strips (optional, based on order and product type)

• 1 – 14° aluminum sill adapter (all Premium clad products)

• 1 – Wood sill adapter. Premium wood double-hung only, will have a

14° and 10° adapter; Custom products will have a 0°, 8° or 14° adapter

or sill nose based on product order details.

NEEDED MATERIALS

• Sealant: We recommend OSI® QUAD® Max Sealant or equivalent. This

can be used in any application and can be painted or ordered in a

color matched product, if desired.

1

REMOVE PACKAGING AND INSPECT WINDOW

REMOVE PACKAGING

Remove packaging materials such as corner covers, shipping blocks

or pads.

INSPECT WINDOW

• Cosmetic damage

• Included parts

• Correct product (size, color, grid pattern, glass type, energy-efciency

requirements, etc.)

If any of the above represents a concern, BEFORE installing, contact

your dealer or distributor for recommendations.

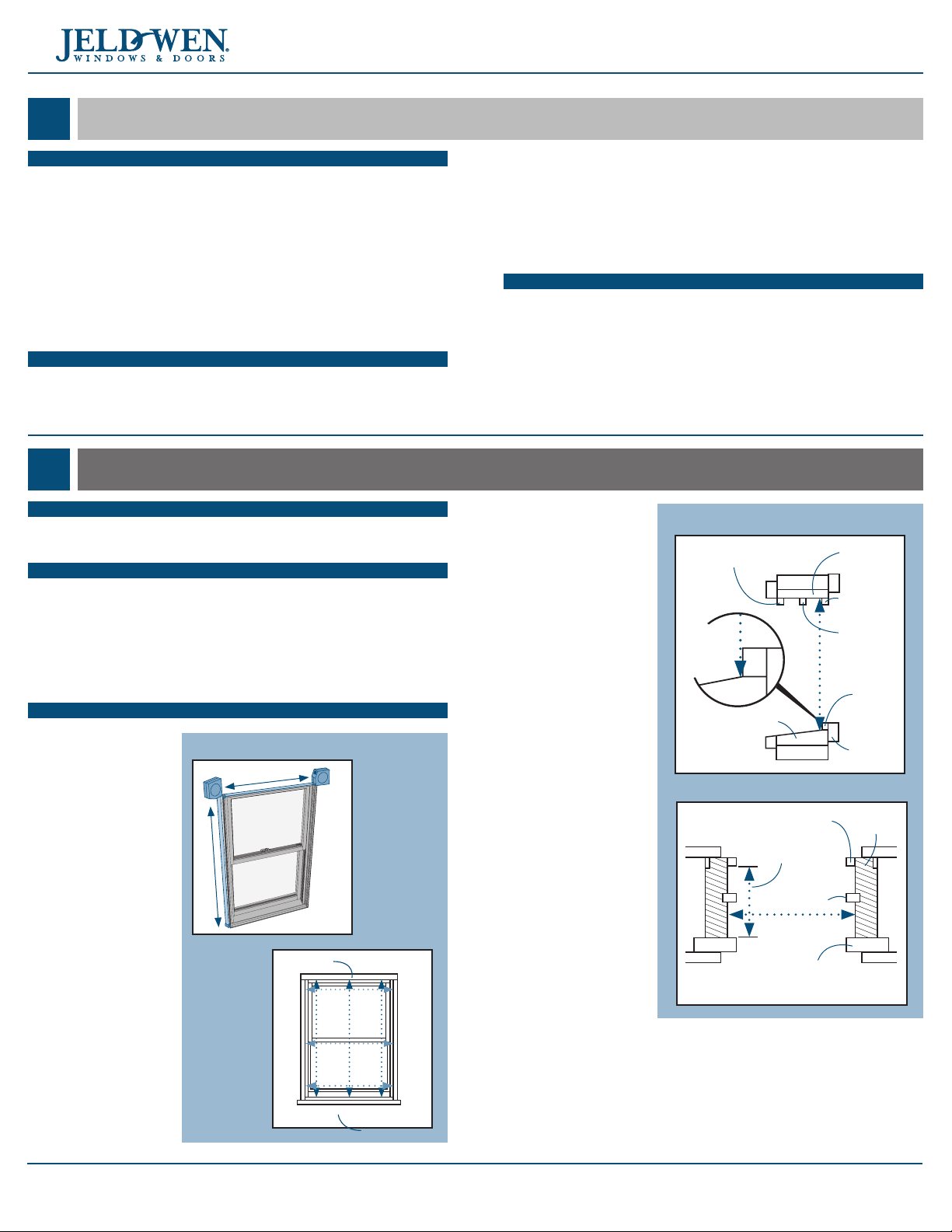

CONFIRM MEASUREMENTS

• Conrm the

replacement unit

Replacement Window

will t properly.

Measure the height

Width

and width of the

replacement unit.

• Check existing frame

measurements.

Measure the width

between the side

jambs at the top,

middle and bottom

(remove jambliner if

necessary). Measure

the height between

the head and sill at

Height

Measuring

Locations

Head

the left side, middle

and right side. Note

measurements

to compare with

replacement unit in

next step.

• Polyurethane low expansion Window and Door foam: We recommend

OSI® QUAD® Foam or equivalent).

• Backer rod 1/8" larger than the widest portion of the gap (used in

conjunction with sealant bead).

• Wood trim pieces, milled on site to t on exterior side of window

between replacement window and existing window frame

• 4d exterior nish nails

NEEDED TOOLS

• Tape measure

• Level

• Hammer

• Utility knife

• Screwdrivers (driver with #2

• Putty knife

• Drill with bits

• Reciprocating saw (for exterior

install)

• Caulk gun

Phillips and at blade)

Unless the unit was

ordered as ”build to

specied dimension“

ensure that:

Height Measurement

Exterior blindstop

Head jamb

• The replacement

unit is 1/2" narrower

than the smallest

existing frame width

measurement.

• The replacement

unit (with applied

sill adapter)is at least

1/4" shorter than

the smallest existing

Measure

directly

behind

sill stop

Sill

Interior

trim stop

Head

parting

stop

Sill stop

frame height

measurement.

• The existing

frame jamb depth

(“pocket”) must be

3 1/4" or greater

Width Measurement

Interior trim stop

Jamb depth

Stool

Wood

side jamb

for all windows

except the Premium

casement, which

Parting stop

requires at least a 4"

pocket.

Note! These

instructions assume

Exterior blindstop

an installation from

the exterior (most

common). Alternate

instruction steps for

installation from the interior are shown in italic type.

Sill

2

Page 3

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

2

REMOVE EXISTING SASH AND PREPARE OPENING

EXTERIOR/INTERIOR INSTALLATION

For non-operating

units, remove and

dispose of wood stops

Exterior Install

Head

and sash or glass.

Exterior Installation:

Remove or cut exterior

blindstops at head and

sides ush with jambs.

Do not remove

interior trim stops or

sill stop.

Interior Installation:

Remove or cut any

interior trim stops

at head or sides

ush with jambs.

Interior trim stops

may be reused if not

damaged.

Do not remove

interior sill stop or

exterior blindstops at

head and sides.

Remove

blindstops

Interior Install

Jamb

Remove

trim stops

Head

Exterior/Interior

Installation:

Apply 100%

polyurethane sealant

to sill/sill stop and sill/

jamb joints.

Interior Installation:

Also apply a 1/4"

bead of sealant

to interior side of

exterior blindstops

on sides and head.

Both Installs/Exterior View

Sill/

sill stop

joint

Sill/jamb joint

Interior Install

Exterior

blind

stop

Exterior

blind

stop

Exterior/Interior

Installation:

For operating units,

remove and dispose

of existing sash,

balance system (e.g.,

cut balance cords and

unscrew pulleys), head

and jamb parting

stops.

Do not remove

sill stop

Both Installs/Interior View

Remove old

balance system

Both Installs/Exterior View

Remove

parting stops

3

Page 4

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

3

INSTALL WINDOW AND SEAL

Exterior/Interior

Installation:

1. Operating Double

hung windows will

have installation holes

pre-drilled through the

jamb liners. Remove

screen from the

Premium operating

casement windows.

For all other products,

remove the interior

trim or sash stop to

gain access to fastener

holes.

2. Slide replacement

window into the

opening until tight

against existing trim

stops. Be sure to hold

window in place until

fully secured.

Exterior Installation:

For custom doublehung windows only,

position sill adapter

all the way to the

interior. For custom

Casement/Awning/

Picture windows, tack

sill adapter 1 7/32" from

the interior and set

window into place.

Interior Installation:

For custom doublehung windows only, lift

window and slide sill

adapter underneath sill

positioned all the way to

the interior.

Both Installations:

3. Drill a pilot hole

through the lower

right installation hole

in the double hung

vinyl jambliner or in

interior wood stop

installation hole on

Premium casement,

Premium awning, or

xed windows. Install

one of the installation

screws, but do not

fully tighten.

4. Shim unit and verify

window is square,

level, and plumb.

Exterior Install

3

1

2

Interior

Install

Interior

trim stop

Interior Install

Shims

Exterior blind stop

Exterior

Install

Shims

5. For Custom Casement/

Awning/Picture

Both Installs/Exterior View

windows only, gently

pry out and remove

the interior trim

(screen stops, operator

cover etc.) from the

head, sill, and sides for

access to installation

holes. Drill pilot holes

into existing frame

through pre-drilled

installation holes

in the replacement

window jambs.

6. Install screws in every

Both Installs/Interior View

pre-drilled hole and

tighten all screws

appropriately. Reapply all previously

removed interior

trim and sash stops.

Premium double-hung

operating units are

Remove

band

supplied with colormatched vinyl caps. For

casement windows,

natural wood caps

are available through

dealers. Install caps into

the installation holes as

(Shims not

shown for clarity)

desired.

7. On double hung

Jamb Jack

operating windows,

remove the band

securing the jambs

at the check rail and

remove the lower

sash.

8. On double hung

operating units only,

jamb jack hardware

is mounted in the

middle installation

holes to allow

for some jamb

adjustment. Install

jamb jack screws until

Turn clockwise to

rst click and adjust

as needed

captured (rst ‘click’),

the screw may then be

screwed in or out to

adjust the jamb as needed. Replace lower sash.

Screws

Screws

Verify

square,

level, &

plumb

4

Page 5

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

3

INSTALL WINDOW AND SEAL - CONTINUED

Exterior Installation:

On the exterior, insulate

between the existing

frame and replacement

window frame with low

expansion foam. Seal

with backer rod and

sealant at only the head

and side jambs.

Interior Installation:

On the interior, insulate

between the existing

frame and pocket

window frame with

low expansion foam.

Seal with backer rod

and sealant all the way

around the window.

Exterior View

Gap

Backer

rod

Backer rod

Sealant

joint

Exterior Installation:

• Metal clad double-hung,

xed and casement

windows, installer must

supply and mill four wood

trim pieces to t on the

exterior front between

Milled

wood

trim

replacement window

frame and existing frame.

Tack into place.

• Wood double-hung and

xed windows, installer

must supply and mill

three (for head and side

jambs only) to t on the

exterior front between

replacement window

frame and existing

frame. Tack into place.

• For all wood products, if

not previously installed,

tack the provided sill

adapter into place

between the jamb trim

pieces (cut to length if

necessary).

Sill

Milled

wood trim

Interior Installation:

• For Premium clad

products, installer must supply and mill a wood sill piece. For all wood

products, tack the provided sill adapter into place between the jamb

trim pieces (cut to length if necessary).

• Reuse previously removed interior trim, or mill new pieces to cover

interior joint between replacement window frame and existing frame.

Tack into place.

4

COMPLETE INSTALLATION

Note! If the existing exterior trim (casing) is to be wrapped with color-

matched aluminum cladding, this cladding MUST be professionally

installed prior to the installation of the clad exterior cover strips. The

following instructions are for a simple butt joint application. A miter

joint application is feasible at the installer’s risk; be sure to allow for a

weep gap.

1. On metal clad

double-hung and

Both Installs/Exterior View

casement windows,

cut and apply clad

exterior cover strips.

1/16"

1/8"

1/16"

Clad exterior

cover strips

1/16"

Weep

gap

1/16"

1/16"

Existing

trim

1/8"

a. Measure the

distance between

Head Detail End View

the existing side

jamb trim pieces

and subtract 1/8".

Cut the head clad

exterior cover

strip to length.

Clad exterior

cover strip

Milled

wood trim

Center and tap

the head strip

into the accessory

groove.

b. Cut two side

jamb clad exterior

Accessory

groove

cover strips,

leaving a 1/8"

weep gap at the

sill. Tap the strips into the accessory groove.

c. Cut the sill clad exterior cover strip (for Premium windows only,

a 14° sill adaptor may be used in place of cladding strip) to t

between the two side jamb strips, leaving a 1/16" gap above the

sill. Tap into the accessory groove.

5

Page 6

INSTALLATION INSTRUCTIONS

for Custom and Premium Pocket Windows (JII022)

4

COMPLETE INSTALLATION - CONTINUED

Exterior Installation:

Seal the interior

joint between the

existing frame and

the replacement

window with 100%

polyurethane sealant.

Interior Installation:

Skip this step.

Exterior Install ONLY/Interior View

Seal

interior

joint

Exterior/Interior

Installation:

Both Installs/Exterior View

Use 100% clear

silicone sealant

(color matched

Wood

trim

Clad cover

strip

polyurethane sealant

may be used on

metal clad), to seal

the exterior joints.

Joints

to be

sealed

Seal any metalto-metal cladding

joints if applicable.

Do not seal the 1/8"

weep gap on the sill

Weep

gap

Sill

ends. When sealing

between the existing

sill and the sill

adapter on a wood product, leave 1" weep gaps on both ends.

AFTER INSTALLATION

Finish any exposed wood surfaces. Metal-clad aluminum does not

require additional nishing.

Please visit jeld-wen.com for warranty, nishing instructions and care

and maintenance information.

Thank you for choosing

©2014 JELD-WEN, inc.; This publication and its contents are owned by JELD-WEN, inc. and are protected under the U.S. Copyright Act and other intellectual property laws. All trademarks, service marks,

logos and the like (whether registered or unregistered) are owned or controlled by JELD-WEN, inc. or others. Unauthorized use or duplication of JELD-WEN intellectual property is prohibited.

JELD-WEN reserves the right to change product specications without notice. Please check our website, jeld-wen.com, for current information.

(05/14)

6

Loading...

Loading...