Page 1

INSTRUMENT PANEL SYSTEMS

CONTENTS

page page

DESCRIPTION AND OPERATION

CIGAR LIGHTER RELAY ................... 4

INSTRUMENT CLUSTER ................... 2

INSTRUMENT PANEL ..................... 1

INSTRUMENT PANEL CIGAR LIGHTER ....... 3

INSTRUMENT PANEL POWER OUTLET ....... 4

INSTRUMENT PANEL SYSTEM ............. 1

DIAGNOSIS AND TESTING

CIGAR LIGHTER RELAY .................. 12

INSTRUMENT CLUSTER ................... 5

INSTRUMENT PANEL CIGAR LIGHTER ...... 11

INSTRUMENT PANEL POWER OUTLET ...... 12

REMOVAL AND INSTALLATION

CIGAR LIGHTER RELAY .................. 15

CLUSTER BEZEL ........................ 16

GLOVE BOX ........................... 22

GLOVE BOX COMPONENTS ............... 22

GLOVE BOX LATCH STRIKER ............. 24

HEADLAMP SWITCH .................... 17

INSTRUMENT CLUSTER .................. 18

INSTRUMENT CLUSTER COMPONENTS ..... 18

INSTRUMENT PANEL ACCESSORY SWITCH

BEZEL .............................. 15

INSTRUMENT PANEL ASSEMBLY .......... 26

INSTRUMENT PANEL CENTER BEZEL ....... 14

INSTRUMENT PANEL CENTER SUPPORT

BRACKET ............................ 25

INSTRUMENT PANEL END CAP ............ 24

INSTRUMENT PANEL TOP COVER .......... 21

KNEE BLOCKER ........................ 13

STEERING COLUMN OPENING COVER ...... 13

DESCRIPTION AND OPERATION

INSTRUMENT PANEL SYSTEM

DESCRIPTION

The instrument panel serves as the command center of the vehicle, which necessarily makes it a very

complex unit. The instrument panel is designed to

house the controls and monitors for standard and

optional powertrains, climate control systems, audio

systems, lighting systems, safety systems and many

other comfort or convenience items. The instrument

panel is also designed so that all of the various controls can be safely reached and the monitors can be

easily viewed by the vehicle operator when driving,

while still allowing relative ease of access to each of

these items for service. See the owner’s manual in

the vehicle glove box for more information on the features, use and operation of all of the instrument

panel components and systems.

This group is responsible for covering service information for the vehicle instrument panel systems.

However, complete service information coverage for

all of the systems and components housed in the

instrument panel in a single section of the service

manual would not be practical. Therefore, the service

information for any component will be found in the

group designated to cover the vehicle system that the

component belongs to, even though the component is

mounted on or in the instrument panel. If you cannot

locate a listing for the component or system you are

servicing in the table of contents for this group, or if

you are uncertain as to which vehicle system a component belongs to, it is suggested that you refer to

the alphabetical Component and System Index

found at the back of this service manual.

NOTE: This group covers both Left-Hand Drive

(LHD) and Right-Hand Drive (RHD) versions of this

model. Whenever required and feasible, the RHD

versions of affected vehicle components have been

constructed as mirror-image of the LHD versions.

While most of the illustrations used in this group

represent only the LHD version, the diagnostic and

service procedures outlined can generally be

applied to either version. Exceptions to this rule

have been clearly identified as LHD or RHD, if a

special illustration or procedure is required.

INSTRUMENT PANEL

DESCRIPTION

This instrument panel uses a full-width structural

plastic foundation as its primary support. When the

two primary molded plastic components of this structure are vibration welded together they provide superior instrument panel stiffness and integrity to help

XJ INSTRUMENT PANEL SYSTEMS 8E - 1

Page 2

reduce buzzes, squeaks, and rattles even on the

bumpiest roads.

This type of construction also provides improved

energy absorption which, in conjunction with the

dual airbag modules and seat belts, helps to improve

occupant protection. This foundation structure also

serves as the air duct for the heating and air conditioning system panel outlets, which greatly reduces

the number of components used over conventional

instrument panel construction.

Modular instrument panel construction allows all

of the gauges and controls to be serviced from the

front of the panel. In addition, most of the instrument panel electrical components can be accessed

without complete instrument panel removal. If necessary, the instrument panel can be removed from the

vehicle as an assembly.

Removal of the steering column opening cover and

knee blocker provides access to the steering column

mounts, the steering column wiring, the headlamp

switch, the electronic combination flasher, and much

of the instrument panel wiring. Removal of the glove

box provides access to the heating and air conditioning electrical and vacuum harnesses, the blower

motor relay, the radio antenna coaxial cable, the

lower passenger side airbag mounts, and additional

instrument panel wiring.

Removal of the instrument panel center bezel

allows access to the radio, the heating and air conditioning controls, the accessory switches, the cigar

lighter, and the accessory power outlet. Removal of

the instrument cluster bezel allows access to the

instrument cluster. Removal of the cluster assembly

allows access to the cluster illumination and indicator lamp bulbs, and more of the instrument panel

wiring.

Removal of the instrument panel top cover allows

access to the upper passenger side airbag mounts.

Instrument panel removal is required for service of

most internal components of the heating and air conditioning system housing.

INSTRUMENT CLUSTER

DESCRIPTION

Two basic instrument clusters are offered on this

model: low-line, or high-line. Both clusters are electromechanical units that utilize integrated circuitry

and information carried on the Chrysler Collision

Detection (CCD) data bus network for control of all

gauges and many of the indicator lamps. These clusters also incorporate a digital Vacuum Fluorescent

Display (VFD) for the odometer/trip odometer display

functions. Some variations of each cluster exist due

to optional equipment and regulatory requirements.

The low-line cluster includes the following analog

gauges:

• Fuel gauge

• Speedometer.

This cluster also includes provisions for the follow-

ing indicator lamps:

• Airbag indicator lamp

• Anti-lock brake system lamp

• Brake warning lamp

• Coolant temperature warning lamp

• Cruise-on indicator lamp

• Four-wheel drive (Part Time and/or Full Time)

indicator lamps

• Headlamp high beam indicator lamp

• Low oil pressure warning lamp

• Low washer fluid warning lamp

• Malfunction indicator (Check Engine) lamp

• Seat belt reminder lamp

• Sentry Key Immobilizer System (SKIS) indicator

lamp

• Turn signal indicator lamps

• Upshift indicator lamp (manual transmission)

• Voltage warning lamp.

The high-line cluster replaces some of the indicator

lamps found in the low-line cluster with analog

gauges. The high-line cluster includes the following

analog gauges:

• Coolant temperature gauge

• Fuel gauge

• Oil pressure gauge

• Speedometer

• Tachometer

• Voltmeter.

The high-line cluster also adds a check gauges

lamp and a low fuel warning lamp to the remaining

indicator lamps found in the low-line cluster.

Both instrument clusters feature circuitry that has

a self-diagnostic actuator test capability, which will

test each of the CCD bus message-controlled functions of the cluster by lighting the appropriate indicator lamps and positioning the gauge needles at

several predetermined locations on the gauge faces in

a prescribed sequence. For more information on this

function, refer to Instrument Cluster in the Diagnosis and Testing section of this group.

The instrument cluster circuitry also integrates a

chime tone generator and a timer circuit. These

items replace the chime or buzzer module, and the

separate timer circuit for the rear window defogger

system. Refer to Chime Warning System in the

Description and Operation section of Group 8U Chime/Buzzer Warning Systems for more information

on the chime functions of the instrument cluster.

Refer to Rear Window Defogger System in the

Description and Operation section of Group 8N -

8E - 2 INSTRUMENT PANEL SYSTEMS XJ

DESCRIPTION AND OPERATION (Continued)

Page 3

Electrically Heated Systems for more information on

the timer function of the instrument cluster.

The instrument clusters for this model are serviced

only as complete units. If a cluster gauge or the cluster circuit board are faulty, the entire cluster must be

replaced. The cluster lens, the cluster hood and

mask, the rear cluster housing cover, the odometer

reset knob boot and the incandescent lamp bulbs and

holders are available for service replacement.

OPERATION

GAUGE

With the ignition switch in the On or Start positions, voltage is supplied to all gauges through the

instrument cluster electronic circuit board. With the

ignition switch in the Off position, voltage is not supplied to the gauges. The gauges do not accurately

indicate any vehicle condition unless the ignition

switch is in the On or Start positions.

All of the instrument cluster gauges, except the

odometer, are air core magnetic units. Two fixed electromagnetic coils are located within the gauge. These

coils are wrapped at right angles to each other

around a movable permanent magnet. The movable

magnet is suspended within the coils on one end of a

shaft. The gauge needle is attached to the other end

of the shaft.

One of the coils has a fixed current flowing

through it to maintain a constant magnetic field

strength. Current flow through the second coil

changes, which causes changes in its magnetic field

strength. The current flowing through the second coil

is changed by the instrument cluster electronic circuitry in response to messages received on the

Chrysler Collision Detection (CCD) data bus network.

The gauge needle moves as the movable permanent

magnet aligns itself to the changing magnetic fields

created around it by the electromagnets. The instrument cluster circuitry is programmed to move all of

the gauge needles back to the low end of their respective scales after the ignition switch is turned to the

Off position.

INDICATOR LAMP

Indicator lamps are located in the instrument cluster and are served by the cluster circuit board and

connectors. Many of the indicator lamps in the

instrument cluster are controlled by the instrument

cluster circuitry in response to messages received

over the Chrysler Collision Detection (CCD) data bus

network.

The anti-lock brake system lamp, brake warning

lamp, four-wheel drive indicator lamps, headlamp

high beam indicator lamp, low washer fluid warning

lamp and turn signal indicator lamps are hard wired.

The seat belt reminder lamp is controlled by the

instrument cluster programming. The instrument

cluster circuitry uses CCD data bus messages from

the Powertrain Control Module (PCM), Airbag Control Module (ACM), and the Sentry Key Immobilizer

Module (SKIM) to control all of the remaining indicator lamps.

Each of the indicator lamps in the instrument cluster uses incandescent bulbs and holders, which are

available for service replacement.

CLUSTER ILLUMINATION LAMP

The cluster illumination lamps are hard wired in

the instrument cluster. When the park or head lamps

are turned on, the cluster illumination lamps light.

Illumination brightness is adjusted by rotating the

headlamp switch knob (clockwise to dim, counterclockwise to brighten). The instrument cluster illumination lamps receive battery feed from the panel

dimmer rheostat in the headlamp switch through a

fuse in the fuseblock module.

The instrument cluster electronic circuitry also

monitors the cluster illumination lamp dimming level

whenever the park or head lamps are turned on. The

instrument cluster electronic circuitry responds by

adjusting the dimming level of the odometer Vacuum

Fluorescent Display (VFD), and sending dimming

level messages over the Chrysler Collision Detection

(CCD) data bus network. When the park lamps or

headlamps are turned off, the VFD is illuminated at

full brightness for improved daylight visibility.

Each of the cluster illumination lamps is located on

the instrument cluster circuit board. Each cluster

illumination lamp has a replaceable bulb and bulb

holder.

INSTRUMENT PANEL CIGAR LIGHTER

DESCRIPTION

A cigar lighter is standard equipment on this

model. The cigar lighter is installed in the instrument panel accessory switch bezel, which is located

near the bottom of the instrument panel center bezel

area, below the heater and air conditioner controls.

The cigar lighter base is secured by a snap fit within

the accessory switch bezel.

The cigar lighter receptacle is serviced only as a

part of the accessory switch bezel unit. If the cigar

lighter base is faulty or damaged, the accessory

switch bezel unit must be replaced. The cigar lighter

knob and heating element unit is available for service. This component cannot be repaired and, if

faulty or damaged, it must be replaced.

XJ INSTRUMENT PANEL SYSTEMS 8E - 3

DESCRIPTION AND OPERATION (Continued)

Page 4

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or receptacle shell. The receptacle shell

is connected to ground, and an insulated contact in

the bottom of the shell is connected to battery current. The cigar lighter receives battery voltage from a

fuse in the junction block through the cigar lighter

relay only when the ignition switch is in the Accessory or On positions. Refer to Cigar Lighter Relay

in the Description and Operation section of this

group for more information on this component.

The cigar lighter knob and heating element are

encased within a spring-loaded housing, which also

features a sliding protective heat shield. When the

knob and heating element are inserted in the receptacle shell, the heating element resistor coil is

grounded through its housing to the receptacle shell.

If the cigar lighter knob is pushed inward, the heat

shield slides up toward the knob exposing the heating element, and the heating element extends from

the housing toward the insulated contact in the bottom of the receptacle shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the receptacle shell. These clips engage and hold

the heating element against the insulated contact

long enough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element causing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heating element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the receptacle shell, the protective

heat shield slides downward on the housing so that

the heating element is recessed and shielded around

its circumference for safety.

CIGAR LIGHTER RELAY

DESCRIPTION

The cigar lighter relay is an electromechanical

device that switches fused battery current to the

cigar lighter when the ignition switch is turned to

the Accessory or On positions. The cigar lighter relay

is located in the junction block, on the right cowl side

panel below the instrument panel in the passenger

compartment.

The cigar lighter relay is a International Standards

Organization (ISO) relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions.

The cigar lighter relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one movable) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the electromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is connected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

INSTRUMENT PANEL POWER OUTLET

DESCRIPTION

An accessory power outlet is standard equipment

on this model. The power outlet is installed in the

instrument panel accessory switch bezel, which is

located near the bottom of the instrument panel center bezel area, below the heater and air conditioner

controls. The power outlet base is secured by a snap

fit within the accessory switch bezel. A plastic protective cap snaps into the power outlet base when the

power outlet is not being used, and hangs from the

power outlet base mount by an integral bail strap

while the power outlet is in use.

The power outlet receptacle unit and the accessory

power outlet protective cap are serviced only as a

part of the accessory switch bezel unit. If the power

outlet base is faulty or damaged, the entire accessory

switch bezel unit must be replaced.

OPERATION

The power outlet base or receptacle shell is connected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the junction block at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the receptacle shell that are used to secure the cigar lighter

heating element to the insulated contact.

8E - 4 INSTRUMENT PANEL SYSTEMS XJ

DESCRIPTION AND OPERATION (Continued)

Page 5

DIAGNOSIS AND TESTING

INSTRUMENT CLUSTER

If all of the gauges and/or indicator lamps are inoperative, perform the Preliminary Diagnosis. If an

individual gauge or Chrysler Collision Detection

(CCD) data bus message-controlled indicator lamp is

inoperative, go directly to the Actuator Test. If an

individual hard wired indicator lamp is inoperative,

refer to Instrument Cluster - Hard Wired Lamp

Diagnosis in the Diagnosis and Testing section of

this group for the procedures to diagnosis that lamp.

For complete circuit diagrams, refer to Instrument

Cluster in the Contents of Group 8W - Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

PRELIMINARY DIAGNOSIS

(1) If the indicator lamps operate, but none of the

gauges operate, go to Step 2. If all of the gauges and

the data bus message-controlled indicator lamps are

inoperative, go to Step 5.

(2) Check the fused B(+) fuse in the Power Distribution Center (PDC). If OK, go to Step 3. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(3) Check for battery voltage at the fused B(+) fuse

in the PDC. If OK, go to Step 4. If not OK, repair the

open fused B(+) circuit to the battery as required.

(4) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Connect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument cluster

wire harness connector A. If OK, refer to Instru-

ment Cluster - Actuator Test in the Diagnosis and

Testing section of this group. If not OK, repair the

open fused B(+) circuit to the fuse in the PDC as

required.

(5) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 6.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(6) Turn the ignition switch to the On position and

check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 7. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(7) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Install the instrument cluster. Connect the battery

negative cable. Turn the ignition switch to the On

position. Set the park brake. The red brake warning

lamp should light. If OK, go to Step 8. If not OK, go

to Step 9.

(8) Turn the ignition switch to the Off position.

Turn on the park lamps and adjust the panel lamps

dimmer rheostat in the headlamp switch to the full

bright position. The cluster illumination lamps

should light. If OK, refer to Instrument Cluster -

Actuator Test in the Diagnosis and Testing section

of this group. If not OK, go to Step 10.

(9) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument cluster. Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused ignition switch output (run/start) circuit cavity of the

instrument cluster wire harness connector A. If OK,

refer to Instrument Cluster - Actuator Test in the

Diagnosis and Testing section of this group. If not

OK, repair the open fused ignition switch output

(run/start) circuit to the fuse in the junction block as

required.

(10) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Check for continuity between the ground circuit cavity of the

instrument cluster wire harness connector A and a

good ground. There should be continuity. If OK, refer

to Instrument Cluster - Actuator Test in the

Diagnosis and Testing section of this group. If not

OK, repair the open ground circuit to ground as

required.

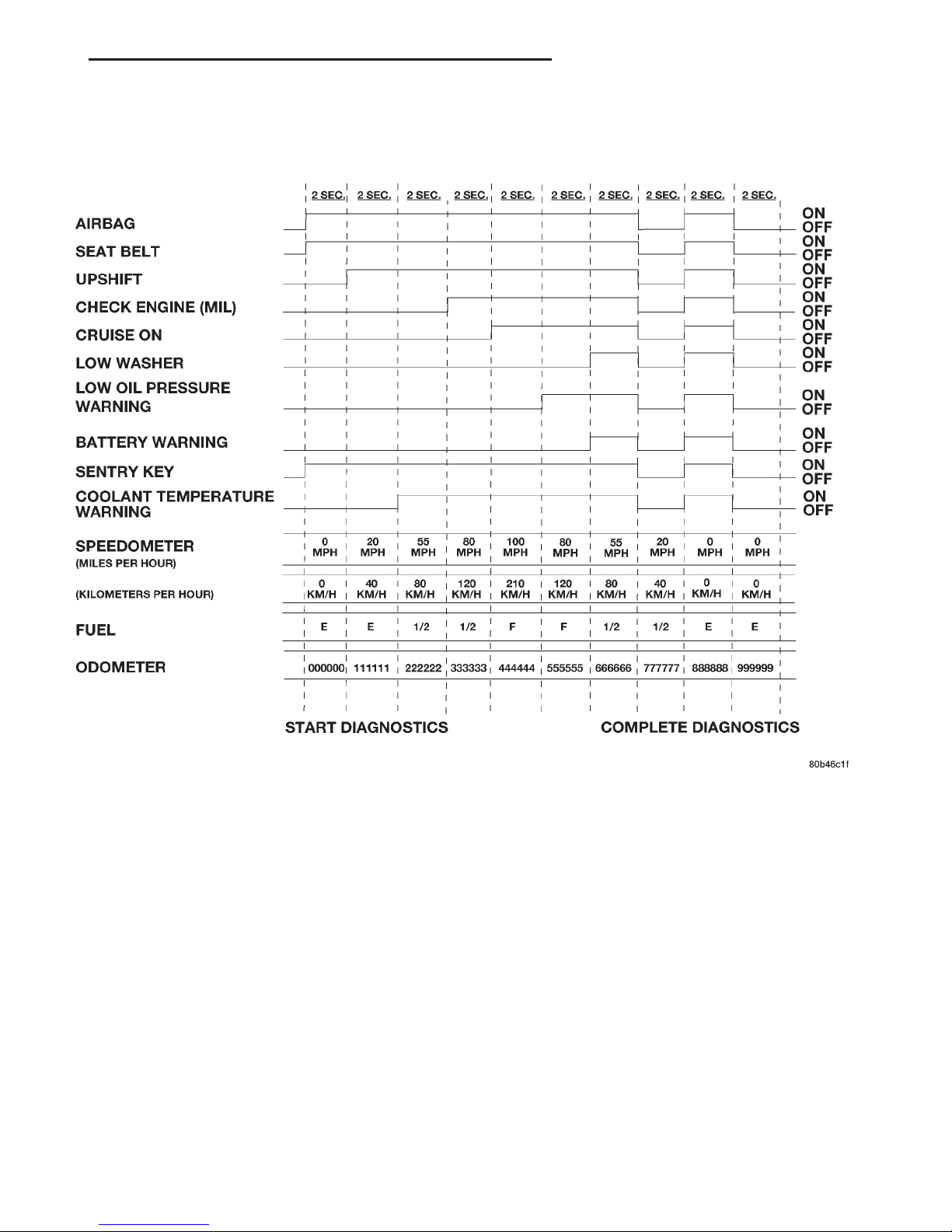

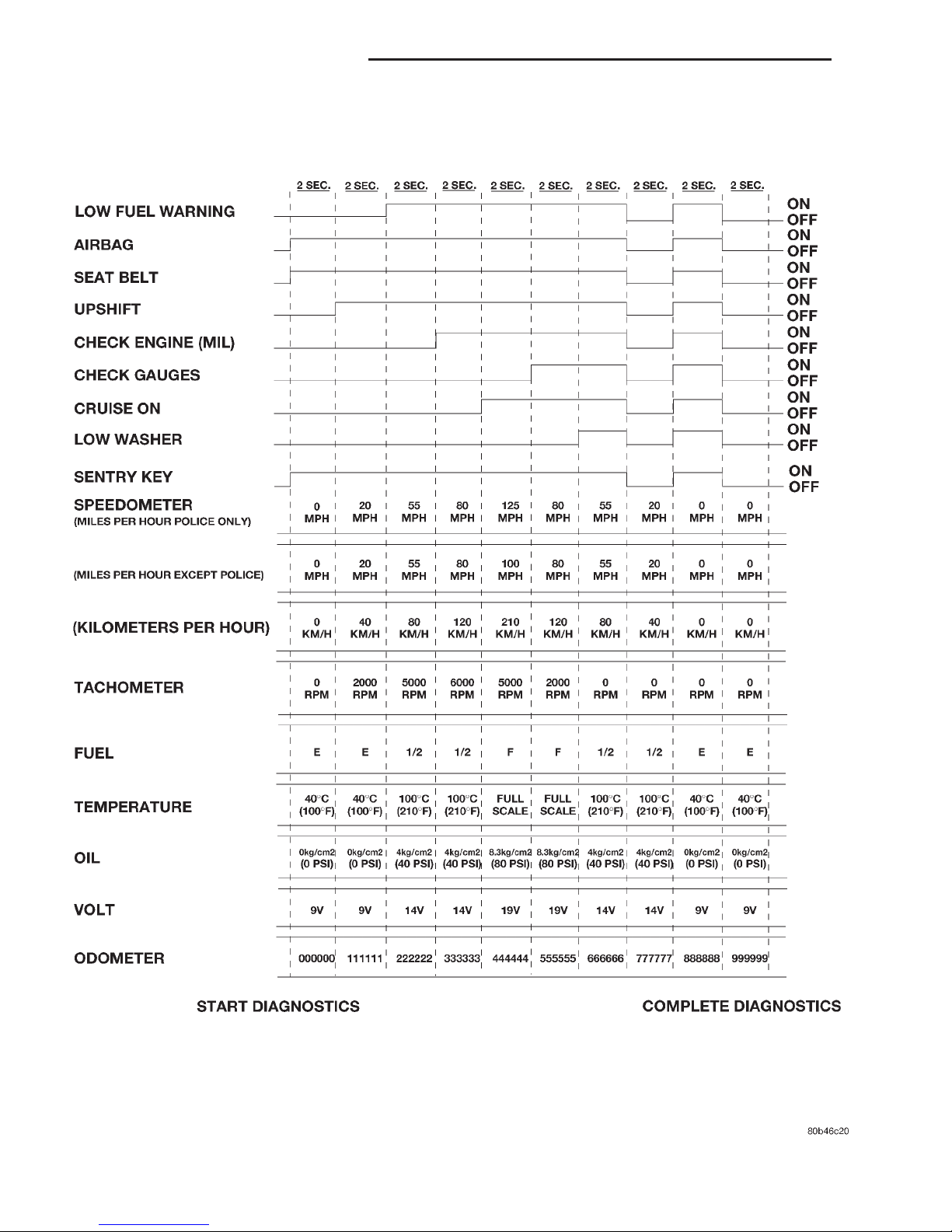

ACTUATOR TEST

The instrument cluster actuator test will put the

instrument cluster into its self-diagnostic mode. In

this mode the instrument cluster can perform a selfdiagnostic test that will confirm that the instrument

cluster circuitry, the gauges, and the CCD data bus

message controlled indicator lamps are capable of

operating as designed. During the actuator test the

instrument cluster circuitry will position each of the

gauge needles at various specified calibration points,

and turn all of the CCD data bus message-controlled

lamps on and off at specified time intervals (Fig. 1)

or (Fig. 2).

Successful completion of the actuator test will confirm that the instrument cluster is operational. However, there may still be a problem with the CCD data

bus, the Powertrain Control Module (PCM), the Airbag Control Module (ACM), the Sentry Key Immobi-

XJ INSTRUMENT PANEL SYSTEMS 8E - 5

Page 6

lizer Module (SKIM) or the inputs to one of these

electronic control modules. Use a DRB scan tool and

the proper Diagnostic Procedures manual for testing

of these components.

If an individual gauge does not respond properly,

or does not respond at all during the actuator test,

the instrument cluster should be removed. However,

check that the gauge mounting screws on the instrument cluster electronic circuit board for proper tightness before considering instrument cluster

replacement. If the gauge mounting screws check

OK, replace the faulty cluster.

If an individual indicator lamp does not illuminate

during the actuator test, the instrument cluster

should be removed. However, check that the incandescent lamp bulb is not faulty and that the bulb

holder is properly installed on the instrument cluster

electronic circuit board before considering instrument

cluster replacement. If the bulb and bulb holder

check OK, replace the faulty instrument cluster.

(1) Begin the test with the ignition switch in the

Off position.

(2) Depress the trip odometer reset button.

(3) While holding the trip odometer reset button

depressed, turn the ignition switch to the On position, but do not start the engine.

(4) Release the trip odometer reset button.

(5) Compare the operation of the suspect gauge(s)

and/or indicator lamp(s) with the Instrument Cluster

Actuator Test chart (Fig. 1) or (Fig. 2).

(6) The instrument cluster will automatically exit

the self-diagnostic mode and return to normal operation at the completion of the test, if the ignition

switch is turned to the Off position during the test,

or if a vehicle speed message indicating that the

vehicle is moving is received from the PCM on the

CCD data bus during the test.

(7) Go back to Step 1 to repeat the test, if

required.

HARD WIRED LAMP DIAGNOSIS

Each of the lamps found in this section depends

upon a hard wired circuit input to the instrument

cluster for proper operation. The following procedures

will help to diagnose conditions that may cause an

inoperative hard wired lamp circuit condition.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

ANTI-LOCK BRAKE SYSTEM LAMP

The diagnosis found here addresses an inoperative

Anti-lock Brake System (ABS) lamp condition. If the

ABS lamp stays on with the ignition switch in the

On position, or comes on and stays on while driving,

refer to Antilock Brakes in the Diagnosis and Testing section of Group 5 - Brakes for diagnosis. If no

ABS problem is found, the following procedure will

help locate a short or open in the ABS lamp circuit.

For complete circuit descriptions, refer to Instru-

ment Cluster in the Contents of Group 8W - Wiring

Diagrams.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument cluster. Connect the battery

negative cable. Turn the ignition switch to the On

position and within five seconds check for continuity

between the ABS warning indicator driver circuit

cavity of the instrument cluster wire harness connector A and a good ground. There should be continuity

for five seconds after ignition On, and then an open

circuit. If OK, replace the faulty bulb. If not OK, go

to Step 4.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the Controller Anti-lock Brake (CAB) wire

harness connector. Check for continuity between the

ABS warning indicator driver circuit cavity of the

instrument cluster wire harness connector A and a

good ground. There should be no continuity. If OK, go

to Step 5. If not OK, repair the shorted ABS warning

indicator driver circuit as required.

(5) Check for continuity between the ABS warning

indicator driver circuit cavities of the instrument

cluster wire harness connector A and the CAB wire

harness connector. There should be continuity. If OK,

refer to Antilock Brakes in the Diagnosis and Testing section of Group 5 - Brakes for diagnosis of the

CAB. If not OK, repair the open ABS warning indicator driver circuit as required.

BRAKE WARNING LAMP

The diagnosis found here addresses an inoperative

brake warning lamp condition. If the brake warning

lamp stays on with the ignition switch in the On

position and the park brake released, or comes on

8E - 6 INSTRUMENT PANEL SYSTEMS XJ

DIAGNOSIS AND TESTING (Continued)

Page 7

Fig. 1 Low-Line Instrument Cluster Actuator Test

XJ INSTRUMENT PANEL SYSTEMS 8E - 7

DIAGNOSIS AND TESTING (Continued)

Page 8

Fig. 2 High-Line Instrument Cluster Actuator Test

8E - 8 INSTRUMENT PANEL SYSTEMS XJ

DIAGNOSIS AND TESTING (Continued)

Page 9

while driving, refer Base Brake System for vehicles

not equipped with the four wheel anti-lock brake system, or refer to Antilock Brakes for vehicles

equipped with the four wheel anti-lock brake system

in the Diagnosis and Testing section of Group 5 Brakes for further diagnosis. If no brake system

problem is found, the following procedure will help

locate a short or open circuit, or a faulty switch. For

complete circuit diagrams, refer to Instrument

Cluster in the Contents of Group 8W - Wiring Diagrams.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the wire harness connector at the park

brake switch. With the park brake released, check for

continuity between the park brake switch terminal

and a good ground. There should be no continuity. If

OK, go to Step 4. If not OK, adjust or replace the

faulty park brake switch.

(4) Disconnect the wire harness connector at the

brake warning switch. Check for continuity between

the two terminals of the brake warning switch. There

should be continuity. If OK, go to Step 5. If not OK,

replace the faulty brake warning switch.

(5) Check for continuity between each of the two

brake warning switch terminals and a good ground.

In each case, there should be no continuity. If OK, go

to Step 6. If not OK, replace the faulty brake warning switch.

(6) With both the park brake switch and the brake

warning switch wire harness connectors still disconnected, check for continuity between the red brake

warning indicator driver circuit cavity of the park

brake switch wire harness connector and a good

ground. There should be no continuity. If OK, go to

Step 7. If not OK, repair the shorted red brake warning indicator driver circuit as required.

(7) With the ignition switch held in the Start position, check for continuity between the red brake

warning indicator driver circuit cavity of the park

brake switch wire harness connector and a good

ground. There should be continuity. If OK, go to Step

8. If not OK, repair the open red brake warning indicator driver circuit to the ignition switch as required.

(8) Turn the ignition switch to the Off position.

Remove the instrument cluster. Check for continuity

between the red brake warning indicator driver circuit cavity of the instrument cluster wire harness

connector A and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted red brake warning indicator driver circuit as

required.

(9) Check for continuity between the red brake

warning indicator driver circuit cavities of the instrument cluster wire harness connector A and the brake

warning switch wire harness connector. There should

be continuity. If OK, replace the faulty bulb. If not

OK, repair the open red brake warning indicator

driver circuit as required.

FOUR-WHEEL DRIVE INDICATOR LAMP - FULL TIME

The diagnosis found here addresses an inoperative

four-wheel drive indicator lamp condition. If the

problem being diagnosed is related to lamp accuracy,

be certain to confirm that the problem is with the

lamp or switch and not with a damaged or inoperative transfer case or transfer case linkage. Refer to

NV242 Diagnosis in the Diagnosis and Testing section of Group 21 - Transmission for more information. If no transfer case problem is found, the

following procedure will help locate a short or open

in the indicator lamp circuit. For complete circuit

diagrams, refer to Instrument Cluster in the Contents of Group 8W - Wiring Diagrams.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the transfer case switch wire harness connector. Check for continuity between the ground circuit cavity of the transfer case switch wire harness

connector and a good ground. There should be continuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Connect the battery negative cable. Turn the

ignition switch to the On position. Install a jumper

wire between the full time four wheel drive indicator

lamp driver circuit cavity of the transfer case switch

wire harness connector and a good ground. The full

time four-wheel drive indicator lamp should light. If

OK, replace the faulty transfer case switch. If not

OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

XJ INSTRUMENT PANEL SYSTEMS 8E - 9

DIAGNOSIS AND TESTING (Continued)

Page 10

Remove the instrument cluster. With the transfer

case switch wire harness connector still disconnected,

check for continuity between the full time four wheel

drive indicator lamp driver circuit cavity of the

instrument cluster wire harness connector B and a

good ground. There should be no continuity. If OK, go

to Step 6. If not OK, repair the shorted full time four

wheel drive indicator lamp driver circuit as required.

(6) Check for continuity between the full time four

wheel drive indicator lamp driver circuit cavities of

the instrument cluster wire harness connector B and

the transfer case switch wire harness connector.

There should be continuity. If OK, replace the faulty

bulb. If not OK, repair the open full time four wheel

drive indicator lamp driver circuit as required.

FOUR-WHEEL DRIVE INDICATOR LAMP - PART TIME

The diagnosis found here addresses an inoperative

four-wheel drive indicator lamp condition. If the

problem being diagnosed is related to lamp accuracy,

be certain to confirm that the problem is with the

lamp or switch and not with a damaged or inoperative transfer case or transfer case linkage. Refer to

NV231 Diagnosis or NV242 Diagnosis in the Diagnosis and Testing section of Group 21 - Transmission

for more information. If no transfer case problem is

found, the following procedure will help locate a

short or open in the indicator lamp circuit. For complete circuit diagrams, refer to Instrument Cluster

in the Contents of Group 8W - Wiring Diagrams.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the transfer case switch wire harness connector. Check for continuity between the ground circuit cavity of the transfer case switch wire harness

connector and a good ground. There should be continuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Connect the battery negative cable. Turn the

ignition switch to the On position. Install a jumper

wire between the part time four wheel drive indicator

lamp driver circuit cavity of the transfer case switch

wire harness connector and a good ground. The part

time four-wheel drive indicator lamp should light. If

OK, replace the faulty transfer case switch. If not

OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument cluster. With the transfer

case switch wire harness connector still disconnected,

check for continuity between the part time four

wheel drive indicator lamp driver circuit cavity of the

instrument cluster wire harness connector B and a

good ground. There should be no continuity. If OK, go

to Step 6. If not OK, repair the shorted part time

four wheel drive indicator lamp driver circuit as

required.

(6) Check for continuity between the part time

four wheel drive indicator lamp driver circuit cavities

of the instrument cluster wire harness connector B

and the transfer case switch wire harness connector.

There should be continuity. If OK, replace the faulty

bulb. If not OK, repair the open part time four wheel

drive indicator lamp driver circuit as required.

HEADLAMP HIGH BEAM INDICATOR LAMP

The diagnosis found here addresses an inoperative

headlamp high beam indicator lamp condition. If the

problem being diagnosed is related to inoperative

headlamp high beams, refer to Headlamp Diagno-

sis in the Diagnosis and Testing section of Group 8L

- Lamps for diagnosis of the headlamp system. If no

headlamp system problems are found, the following

procedure will help locate an open in the high beam

indicator lamp circuit. For complete circuit diagrams,

refer to Instrument Cluster in the Contents of

Group 8W - Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster.

(2) Connect the battery negative cable. Turn the

headlamps on and select the high beams with the

multi-function switch stalk. Check for battery voltage

at the high beam indicator driver circuit cavity of the

instrument cluster wire harness connector A. If OK,

replace the faulty bulb. If not OK, repair the open

high beam indicator driver circuit to the headlamp

dimmer (multi-function) switch as required.

LOW WASHER FLUID WARNING LAMP

The diagnosis found here addresses an inoperative

low washer fluid warning lamp condition. If the problem being diagnosed is related to lamp accuracy, be

certain to confirm that the problem is with the lamp

or washer fluid level sensor and not with a damaged

or empty washer fluid reservoir. Inspect the reservoir

for proper fluid level and signs of damage or distortion that could affect sensor performance before you

proceed with lamp diagnosis. Refer to Washer Sys-

tem in the Diagnosis and Testing section of Group

8K - Wiper and Washer Systems for more information. For complete circuit diagrams, refer to Instru-

8E - 10 INSTRUMENT PANEL SYSTEMS XJ

DIAGNOSIS AND TESTING (Continued)

Page 11

ment Cluster in the Contents of Group 8W - Wiring

Diagrams.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Turn the ignition switch to the Off position.

Disconnect the wire harness connector from the

washer fluid level sensor. Install a jumper wire

between the two cavities of the washer fluid level

sensor wire harness connector. Turn the ignition

switch to the On position. The low washer fluid

warning lamp should light. Remove the jumper wire

and the lamp should go off. If OK, replace the faulty

washer fluid level sensor. If not OK, go to Step 4.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cavity of the washer fluid level sensor wire harness connector and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open ground circuit to ground as required.

(5) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. The washer

fluid level sensor wire harness connector is still disconnected. Check for continuity between the low

washer fluid level sense circuit cavity of the instrument cluster wire harness connector B and a good

ground. There should be no continuity. If OK, go to

Step 6. If not OK, repair the shorted low washer

fluid level sense circuit as required.

(6) Check for continuity between the low washer

fluid level sense circuit cavities of the instrument

cluster wire harness connector B and the washer

fluid level sensor wire harness connector. There

should be continuity. If OK, replace the faulty bulb.

If not OK, repair the open low washer fluid level

sense circuit as required.

TURN SIGNAL INDICATOR LAMP

The diagnosis found here addresses an inoperative

turn signal indicator lamp condition. For any other

turn signal problem, refer to Turn Signal and Haz-

ard Warning Systems in the Diagnosis and Testing

section of Group 8J - Turn Signal and Hazard Warning Systems for further diagnosis. If no turn signal or

hazard warning system problem is found, the following procedure will help locate a short or open in the

indicator lamp circuit. For complete circuit diagrams,

refer to Instrument Cluster in the Contents of

Group 8W - Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster.

(2) Connect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument cluster wire

harness connector (connector A - left, or connector B right). There should be a switching (on and off) battery voltage signal. If OK, replace the faulty (right or

left) indicator lamp bulb. If not OK, repair the open

(right or left) turn signal circuit to the turn signal/

hazard warning (multi-function) switch as required.

INSTRUMENT PANEL CIGAR LIGHTER

For complete circuit diagrams, refer to Horn/Cigar Lighter in the Contents of Group 8W - Wiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the cigar lighter knob and element

from the cigar lighter receptacle shell. Check for continuity between the inside circumference of the cigar

lighter receptacle shell and a good ground. there

should be continuity. If OK, go to Step 2. If not OK,

go to Step 3.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the insulated contact

located at the back of the cigar lighter receptacle

shell. If OK, replace the faulty cigar lighter knob and

element. If not OK, go to Step 3.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument panel accessory switch bezel.

Check for continuity between the ground circuit cavity of the cigar lighter wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 4. If not OK, repair the open ground circuit to

ground as required.

(4) Connect the battery negative cable. Turn the

ignition switch to the Accessory or On positions.

Check for battery voltage at the cigar lighter relay

output circuit cavity of the cigar lighter wire harness

connector. If OK, replace the faulty cigar lighter

receptacle (instrument panel accessory switch bezel

unit). If not OK, refer to Cigar Lighter Relay in

the Diagnosis and Testing section of this group for

further diagnosis.

XJ INSTRUMENT PANEL SYSTEMS 8E - 11

DIAGNOSIS AND TESTING (Continued)

Page 12

CIGAR LIGHTER RELAY

The cigar lighter relay (Fig. 3) is located in the

junction block, on the right cowl side inner panel

below the instrument panel in the passenger compartment. For complete circuit diagrams, refer to

Horn/Cigar Lighter in the Contents of Group 8W Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the cigar lighter relay from the junction block. Refer to Cigar Lighter Relay in the

Removal and Installation section of this group for the

procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (electromagnet) should be 75 6 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the junction block is connected to battery voltage and

should be hot at all times. Check for battery voltage

at the fused B(+) circuit cavity of the accessory relay

wire harness connector. If OK, go to Step 2. If not

OK, repair the fused B(+) circuit to the fuse in the

junction block as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is connected to the common feed terminal (30) in the energized position. This terminal supplies battery voltage

to the cigar lighter when the relay is energized by

the ignition switch. There should be continuity

between the junction block cavity for relay terminal

87 and the cigar lighter relay output circuit cavity of

the cigar lighter wire harness connector at all times.

If OK, go to Step 4. If not OK, repair the open cigar

lighter relay output circuit to the cigar lighter wire

harness connector as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It receives battery

feed to energize the cigar lighter relay when the ignition switch is in the Accessory or On positions. Turn

the ignition switch to the On position. Check for battery voltage at the fused ignition switch output (acc/

run) circuit cavity for relay terminal 86 in the

junction block. If OK, go to Step 5. If not OK, repair

the open fused ignition switch output (acc/run) circuit

to the ignition switch as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. The junction block

cavity for this terminal should have continuity to

ground at all times. If not OK, repair the open

ground circuit to ground as required.

INSTRUMENT PANEL POWER OUTLET

For complete circuit diagrams, refer to Horn/Cigar Lighter in the Contents of Group 8W - Wiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted circuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Distribution Center (PDC) as required.

Fig. 3 Cigar Lighter Relay

8E - 12 INSTRUMENT PANEL SYSTEMS XJ

DIAGNOSIS AND TESTING (Continued)

Page 13

(3) Remove the plastic protective cap from the

power outlet receptacle. Check for continuity between

the inside circumference of the power outlet receptacle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.

(4) Check for battery voltage at the insulated contact located at the back of the power outlet receptacle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the instrument panel accessory switch

bezel. Check for continuity between the ground circuit cavity of the power outlet wire harness connector

and a good ground. There should be continuity. If

OK, go to Step 6. If not OK, repair the open ground

circuit to ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle (instrument panel

accessory switch bezel unit). If not OK, repair the

open fused B(+) circuit to the junction block fuse as

required.

REMOVAL AND INSTALLATION

STEERING COLUMN OPENING COVER

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is so equipped, move the tilt

steering column to the fully raised position.

(3) Remove the three screws that secure the lower

edge of the steering column opening cover to the

lower instrument panel reinforcement (Fig. 4).

(4) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the upper edge of the

steering column opening cover just below the cluster

bezel on each side of the steering column away from

the instrument panel far enough to disengage the

two snap clip retainers from the receptacles in the

instrument panel.

(5) Remove the steering column opening cover

from the instrument panel.

INSTALLATION

(1) Position the steering column opening cover to

the instrument panel.

(2) Align the snap clip retainers on the steering

column opening cover with the receptacles in the

instrument panel.

(3) Press firmly on the steering column opening

cover over the snap clip locations until each of the

snap clips is fully engaged in its receptacle.

(4) Install and tighten the three screws that secure

the lower edge of the steering column opening cover

to the lower instrument panel reinforcement. Tighten

the screws to 2.2 N·m (20 in. lbs.).

(5) Reconnect the battery negative cable.

KNEE BLOCKER

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INSTALLATION

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. Refer to Steering Col-

umn Opening Cover in the Removal and Installation section of this group for the procedures.

(3) Remove the two screws that secure the knee

blocker to the instrument panel (Fig. 5).

Fig. 4 Steering Column Opening Cover Remove/

Install

XJ INSTRUMENT PANEL SYSTEMS 8E - 13

DIAGNOSIS AND TESTING (Continued)

Page 14

(4) Pull the upper edge of the knee blocker away

from the instrument panel far enough to disengage

the two lower mounting tabs from the mounting slots

in the lower instrument panel reinforcement.

(5) Remove the knee blocker from the instrument

panel.

INSTALLATION

(1) Position the knee blocker to the instrument

panel.

(2) Install and tighten the four screws that secure

the knee blocker to the instrument panel. Tighten

the screws to 2.2 N·m (20 in. lbs.). Be certain that

the mounting screws are located in the screw hole on

each side of the steering column that is closest to the

driver side front door of the vehicle (Fig. 6).

(3) Install the steering column opening cover onto

the instrument panel. Refer to Steering Column

Opening Cover in the Removal and Installation section of this group for the procedures.

(4) Reconnect the battery negative cable.

INSTRUMENT PANEL CENTER BEZEL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the instrument panel center bezel away from the instrument panel far enough

to disengage the six snap clip retainers that secure it

from the receptacles in the instrument panel (Fig. 7).

(3) Remove the center bezel from the instrument

panel.

INSTALLATION

(1) Position the center bezel to the instrument

panel.

(2) Align the snap clips on the center bezel with

the receptacles in the instrument panel.

(3) Press firmly on the center bezel over each of

the snap clip locations until each of the six snap clips

is fully engaged in its receptacle on the instrument

panel.

(4) Reconnect the battery negative cable.

Fig. 5 Knee Blocker Remove/Install

Fig. 6 Knee Blocker Mounting Screw Location

Fig. 7 Instrument Panel Center Bezel Remove/Install

8E - 14 INSTRUMENT PANEL SYSTEMS XJ

REMOVAL AND INSTALLATION (Continued)

Page 15

INSTRUMENT PANEL ACCESSORY SWITCH

BEZEL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel. Refer to Instrument Panel Center Bezel in

the Removal and Installation section of this group for

the procedures.

(3) Remove the three screws that secure the accessory switch bezel to the instrument panel (Fig. 8).

(4) Pull the accessory switch bezel away from the

instrument panel far enough to access the instrument panel wire harness connectors.

(5) Disconnect the instrument panel wire harness

connectors from the connector receptacles, the accessory switches, the cigar lighter and the accessory

power outlet on the back of the accessory switch

bezel.

(6) Remove the accessory switch bezel from the

instrument panel.

INSTALLATION

(1) Position the accessory switch bezel to the

instrument panel.

(2) Reconnect the instrument panel wire harness

connectors to the connector receptacles, the accessory

switches, the cigar lighter and the accessory power

outlet on the back of the accessory switch bezel.

(3) Position the accessory switch bezel onto the

instrument panel.

(4) Install and tighten the three screws that secure

the accessory switch bezel to the instrument panel.

Tighten the screws to 2.2 N·m (20 in. lbs.).

(5) Install the center bezel onto the instrument

panel. Refer to Instrument Panel Center Bezel in

the Removal and Installation section of this group for

the procedures.

(6) Reconnect the battery negative cable.

CIGAR LIGHTER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1)

Disconnect and isolate the battery negative cable.

(2) Remove the fuse access panel by unsnapping it

from the right cowl side trim panel.

(3) Remove the stamped nut that secures the right

cowl side trim to the junction block stud (Fig. 9).

(4) Remove the screw located above the fuse access

opening that secures the right cowl side trim to the

right cowl side inner panel.

(5) Remove the screw that secures the right door

sill trim and the right cowl side trim to the right

door opening sill.

(6) Remove the right cowl side trim panel from the

vehicle.

(7) Refer to Junction Block in the Contents of

Group 8W - Wiring Diagrams for cigar lighter relay

identification and location.

(8) Remove the cigar lighter relay from the receptacle in the junction block.

INSTALLATION

(1) Refer to Junction Block in the Contents of

Group 8W - Wiring Diagrams for the proper cigar

lighter relay location.

(2) Position the cigar lighter relay to the receptacle

in the junction block.

(3) Align the terminals of the cigar lighter relay

with the cavities in the junction block receptacle.

(4) Push on the cigar lighter relay case firmly and

evenly until all of the relay terminals are fully seated

within the cavities of the junction block receptacle.

Fig. 8 Instrument Panel Accessory Switch Bezel

Remove/Install

XJ INSTRUMENT PANEL SYSTEMS 8E - 15

REMOVAL AND INSTALLATION (Continued)

Page 16

(5) Position the right cowl side trim to the right

door sill trim.

(6) Install and tighten the screw that secures the

right cowl side trim to the right door sill trim.

Tighten the screw to 2.2 N·m (20 in. lbs.).

(7) Position the right cowl side trim to the right

cowl side inner panel.

(8) Install and tighten the screw that secures the

right cowl side trim to the right cowl side inner

panel. Tighten the screw to 2.2 N·m (20 in. lbs.).

(9) Install the stamped nut that secures the right

cowl side trim to the junction block stud.

(10) Install the fuse access panel by snapping it

onto the right cowl side trim panel.

(11) Reconnect the battery negative cable.

CLUSTER BEZEL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the knee blocker from the instrument

panel. Refer to Knee Blocker in the Removal and

Installation section of this group for the procedures.

(3) Remove the center bezel from the instrument

panel. Refer to Instrument Panel Center Bezel in

the Removal and Installation section of this group for

the procedures.

(4) Remove the four screws exposed by the center

bezel removal that secure the cluster bezel to the

instrument panel.

(5) Remove the headlamp switch knob and shaft

from the headlamp switch. Refer to Headlamp

Switch in the Removal and Installation section of

this group for the procedures.

(6) Disengage the two ends of the steering column

sight shield from each other at the connector located

below the lower steering column shroud (Fig. 10).

(7) If the vehicle is so equipped, set the tilt steering column in its lowest position.

(8) Using a trim stick or another suitable wide

flat-bladed tool, gently pry around the perimeter of

the cluster bezel to disengage the five snap clips from

their receptacles in the instrument panel.

(9) Remove the cluster bezel from the instrument

panel.

INSTALLATION

(1) Position the cluster bezel to the instrument

panel.

(2) Align the snap clips on the cluster bezel with

the receptacles in the instrument panel.

Fig. 9 Right Cowl Side Trim Remove/Install

Fig. 10 Cluster Bezel Remove/Install

8E - 16 INSTRUMENT PANEL SYSTEMS XJ

REMOVAL AND INSTALLATION (Continued)

Page 17

(3) Press firmly on the cluster bezel over each of

the snap clip locations until each of the snap clips is

fully engaged in its receptacle.

(4) Engage the two ends of the steering column

sight shield with each other at the connector located

below the lower steering column shroud.

(5) Install the headlamp switch knob and shaft

onto the headlamp switch. Refer to Headlamp

Switch in the Removal and Installation section of

this group for the procedures.

(6) Install and tighten the four screws that secure

the cluster bezel to the instrument panel beneath the

instrument panel center bezel. Tighten the screws to

2.2 N·m (20 in. lbs.).

(7) Install the center bezel onto the instrument

panel. Refer to Instrument Panel Center Bezel in

the Removal and Installation section of this group for

the procedures.

(8) Install the knee blocker onto the instrument

panel. Refer to Knee Blocker in the Removal and

Installation section of this group for the procedures.

Be certain that the two ends of the steering column

sight shield connector are engaged with each other

before installing the knee blocker.

(9) Reconnect the battery negative cable.

HEADLAMP SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: IF THE HEADLAMP SWITCH WAS ON,

WAIT FIVE MINUTES TO ALLOW THE CERAMIC

DIMMER RESISTOR TO COOL. IF THE CERAMIC

DIMMER RESISTOR IS NOT ALLOWED TO COOL, IT

CAN BURN YOUR FINGERS.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the knee blocker from the instrument

panel. Refer to Knee Blocker in the Removal and

Installation section of this group for the procedures.

(3) Pull the headlamp switch control knob out to

the On position stop.

(4) Reach up under the instrument panel through

the outboard side of the steering column opening to

access and depress the headlamp switch control knob

and shaft release button on the inboard side of the

switch body.

(5) While holding the release button depressed,

pull the headlamp switch control knob and shaft out

of the headlamp switch.

(6) Remove the spanner nut that secures the headlamp switch to the instrument panel (Fig. 11).

(7) Pull the headlamp switch into the steering column opening area of the instrument panel far

enough to access the instrument panel wire harness

connectors.

(8) Disconnect the two instrument panel wire harness connectors from the headlamp switch.

(9) Remove the headlamp switch from the instrument panel.

INSTALLATION

(1) Position the headlamp switch to the instrument panel steering column opening.

(2) Reconnect the two instrument panel wire harness connectors to the headlamp switch.

(3) Position the headlamp switch behind its

mounting hole on the instrument panel.

(4) Install and tighten the spanner nut that

secures the headlamp switch to the instrument

panel. Tighten the nut to 2.7 N·m (24 in. lbs.).

(5) Insert the shaft of the headlamp switch control

knob and shaft unit through the opening in the spanner nut and into the headlamp switch.

(6) Push the headlamp switch control knob and

shaft unit all the way into the headlamp switch body.

(7) Install the knee blocker onto the instrument

panel. Refer to Knee Blocker in the Removal and

Installation section of this group for the procedures.

(8) Reconnect the battery negative cable.

Fig. 11 Headlamp Switch Remove/Install

XJ INSTRUMENT PANEL SYSTEMS 8E - 17

REMOVAL AND INSTALLATION (Continued)

Page 18

INSTRUMENT CLUSTER

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. Refer to Cluster Bezel in the Removal and

Installation section of this group for the procedures.

(3) Remove the four screws that secure the instrument cluster to the instrument panel (Fig. 12).

(4) Pull the instrument cluster rearward far

enough to disengage the two self-docking instrument

panel wire harness connectors from the connector

receptacles on the back of the cluster housing. Do

not pull on the instrument cluster by the lens

or mask sections, or the cluster components

may become separated.

(5) Remove the instrument cluster from the instrument panel.

INSTALLATION

(1) Position the instrument cluster to the instrument panel.

(2) Align the instrument cluster with the cluster

opening in the instrument panel and push the cluster

firmly and evenly into place. The instrument panel

has two self-docking wire harness connectors that

will be automatically aligned with, and connected to

the cluster connector receptacles when the cluster is

installed in the instrument panel.

(3) Install and tighten the four screws that secure

the instrument cluster to the instrument panel.

Tighten the screws to 2.2 N·m (20 in. lbs.).

(4) Install the cluster bezel onto the instrument

panel. Refer to Cluster Bezel in the Removal and

Installation section of this group for the procedures.

(5) Reconnect the battery negative cable.

INSTRUMENT CLUSTER COMPONENTS

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include: the incandescent

instrument cluster indicator lamp and illumination

lamp bulbs (including the integral bulb holders), the

odometer reset knob boot, the cluster lens, the cluster hood and mask unit, the instrument cluster housing rear cover, and the instrument cluster housing

(including the odometer reset knob, the gauge mask,

the gauges and the instrument cluster electronic circuit board). Following are the service procedures for

the instrument cluster components.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRECAUTIONS COULD RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

CLUSTER BULB

This procedure applies to each of the incandescent

cluster illumination lamp or indicator lamp bulb and

bulb holder units. However, the illumination lamps

and the indicator lamps use different bulb and bulb

holder unit sizes. They must never be interchanged.

Be certain that any bulb and bulb holder unit

removed from the cluster electronic circuit board is

reinstalled in the correct position. Always use the

correct bulb size and type for replacement. An incorrect bulb size or type may overheat and cause damage to the instrument cluster, the electronic circuit

board and/or the gauges.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

Fig. 12 Instrument Cluster Remove/Install

8E - 18 INSTRUMENT PANEL SYSTEMS XJ

REMOVAL AND INSTALLATION (Continued)

Page 19

(3) Turn the bulb holder counterclockwise about

sixty degrees on the cluster electronic circuit board.

(4) Pull the bulb and bulb holder unit straight

back to remove it from the bulb mounting hole in the

cluster electronic circuit board (Fig. 13).

CLUSTER LENS

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

(3) Work around the perimeter of the cluster housing to disengage each of the latches that secure the

cluster lens to the cluster housing (Fig. 14).

(4) Gently pull the cluster lens away from the clus-

ter housing.

ODOMETER RESET KNOB BOOT

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

(3) Remove the cluster lens from the cluster housing. Refer to Instrument Cluster Components -

Cluster Lens in the Removal and Installation section of this group for the procedures.

(4) Remove the odometer reset knob boot by pulling it out of the cluster lens.

CLUSTER HOOD AND MASK

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

(3) Remove the cluster lens from the cluster housing. Refer to Instrument Cluster Components -

Cluster Lens in the Removal and Installation section of this group for the procedures.

Fig. 13 Cluster Bulb Locations

Fig. 14 Instrument Cluster Components

XJ INSTRUMENT PANEL SYSTEMS 8E - 19

REMOVAL AND INSTALLATION (Continued)

Page 20

(4) Work around the perimeter of the cluster housing to disengage each of the latches that secure the

cluster hood and mask unit to the cluster housing

(Fig. 14).

(5) Gently pull the cluster hood and mask unit

away from the cluster housing.

CLUSTER HOUSING REAR COVER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

(3) Work around the perimeter of the cluster housing to disengage each of the latches that secure the

rear cover to the cluster housing (Fig. 14).

(4) Gently pull the rear cover away from the back

of the cluster housing.

CLUSTER HOUSING

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instrument panel. Refer to Instrument Cluster in the

Removal and Installation section of this group for the

procedures.

(3) Remove all of the cluster illumination lamp

and indicator lamp bulb and bulb holder units from

the electronic circuit board. Refer to Instrument

Cluster Components - Cluster Bulbs in the

Removal and Installation section of this group for the

procedures.

(4) Remove the cluster hood and mask unit from

the cluster housing. Refer to Instrument Cluster

Components - Cluster Hood and Mask in the

Removal and Installation section of this group for the

procedures.

(5) Remove the rear cover from the cluster housing. Refer to Instrument Cluster Components -

Cluster Housing Rear Cover in the Removal and

Installation section of this group for the procedures.

INSTALLATION

CLUSTER BULB

This procedure applies to each of the incandescent

cluster illumination lamp or indicator lamp bulb and

bulb holder units. However, the illumination lamps

and the indicator lamps use different bulb and bulb