Page 1

Jeep Wrangler

Diagnosis & Repair Manual

Water Leaks

Rev. A

Page 2

General Notes

1. This manual applies to all Jeep models: 2/4 door & Hard/Soft Top

2. Before testing the vehicle, perform a review of the top system. Make sure all the latches

are engaged, none of the top seals are puckered or distorted, the door seals are

installed correctly, the tops are not out of alignment, etc.

3. Each leak area can have multiple root causes, as noted in the diagnosis tree. It is

important to water test each repair before starting the next.

4. If a leak cannot be reproduced, it is due to the period of time the vehicle is under wet

conditions. Some leaks may take hours before leaking.

5. If a leak cannot be reproduced, apply all the repairs to the applicable areas as noted in

the diagnosis road map.

6. When the door is open, there is water run off from the roof that can soak the carpet. Be

sure to explain to the customer that this cannot be fixed. This is an unfortunate

condition with this type of vehicle, similar to convertibles.

7. It is important to understand where the leak ENDS up when diagnosing the vehicle.

Where the leak ends up, does not always explain where the leak originates. Refer to the

diagnosis tree when determining which repairs to perform.

8. This repair procedure does NOT cover every possible water leak on the Jeep Wrangler.

The issues identified in this document are the major leaks that show up in the field.

9. Generally, a car wash is the preferred method to diagnose a vehicle.

10. If a hose is required, place on the top of the vehicle facing forward making sure water is

getting to all areas. Do NOT directly spray in the area of question. This can create a

“false” leak that cannot be fixed.

11. This manual is not intended to be a service manual. The content identifies the major

areas of water leaks, the critical characteristics of each area and how to repair them.

READ FIRST READ FIRST

i

Page 3

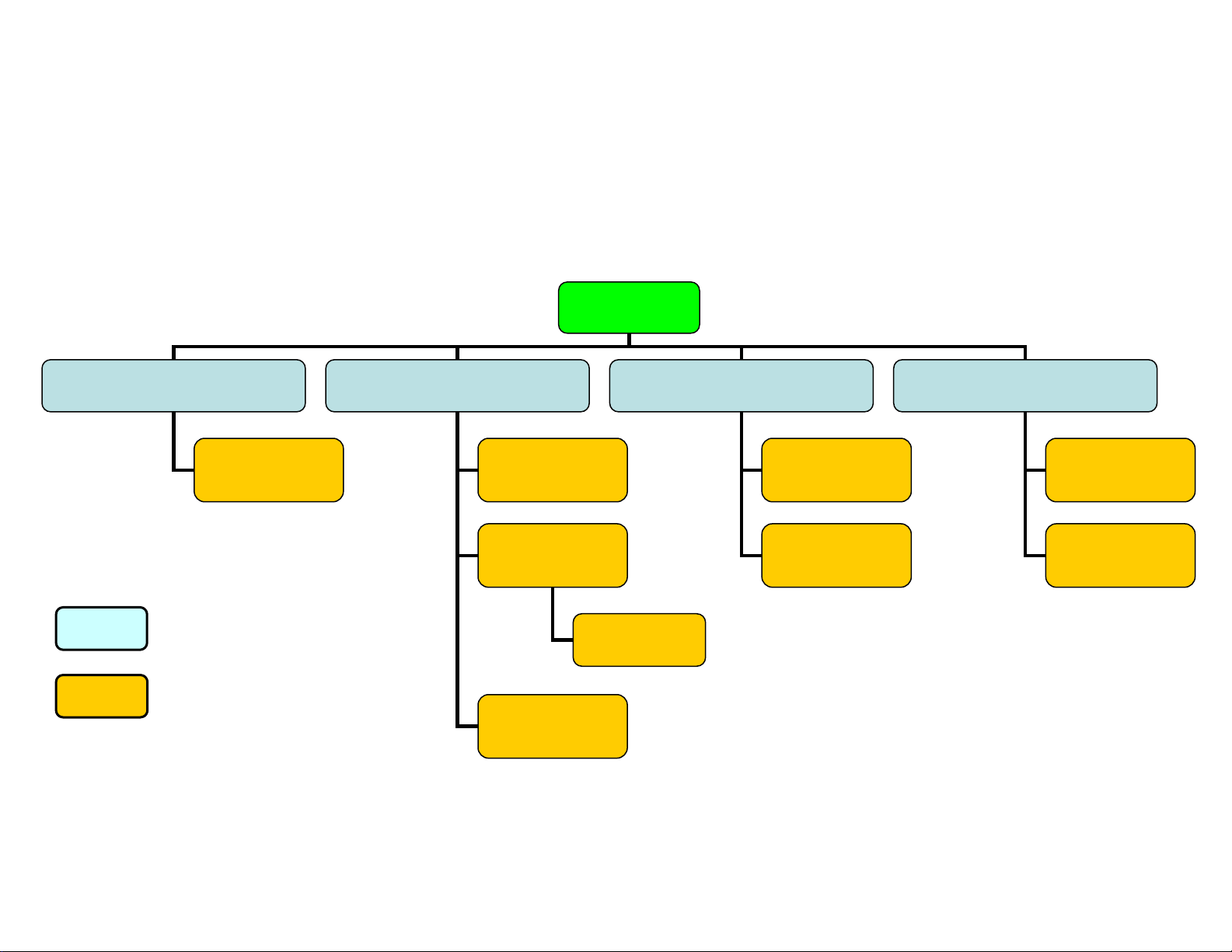

Diagnosis Road Map

p

r

(Pag

JK Hard/Soft Top

Water is on center of Instrument

Panel / Shifter

Freedom Top

(Pages 6-11)

Area of leaks

Repair Procedures

Water is on door trim panel or

Instrument Panel at A-pillar

Windshield Header

Seal

(Pages 1-2)

Door Fit

(Page 3)

A-Pillar

Mucket/Foam

(Pages 4-5)

Water at Rear Hard Top Panel /

B-

illa

Door Primary

Seal

Hard Top Seal

(Pages 12-14)

B-Pillar

Mucket/Foam

-

Water is on front carpet

Rear Wheel Flare

Holes

es 17-18)

Cowl Side Panel

(Pages 19-20)

ii

Page 4

Table of Contents

I. Diagnosis Road Map i

II. General Notes ii

III. Water leak on Door Trim or Instrument Panel

a) Repair procedure for Windshield Header Seal 1-2

b) Repair procedure for Door Fits 3

c) Repair procedure for A-pillar mucket/foam 4-5

IV. Water leak on Instrument Panel/Console Center

a) Repair procedure for Freedom Panel Seal 6-11

b) Repair procedure for Freedom Panel latches 11

V. Water leak at B-plr

a) Repair procedure for Hard Top Seal 12-14

b) Repair procedure for B-pillar Mucket 15-16

VI. Water leak on front carpet

a) Repair procedure for rear wheel flare hole 17-18

b) Repair procedure for cowl side leaks 19-20

VII. Appendix

a) Foam Kit 21

b) Replacement part numbers 22

iii

Page 5

Windshield Header Seal Repair Procedure

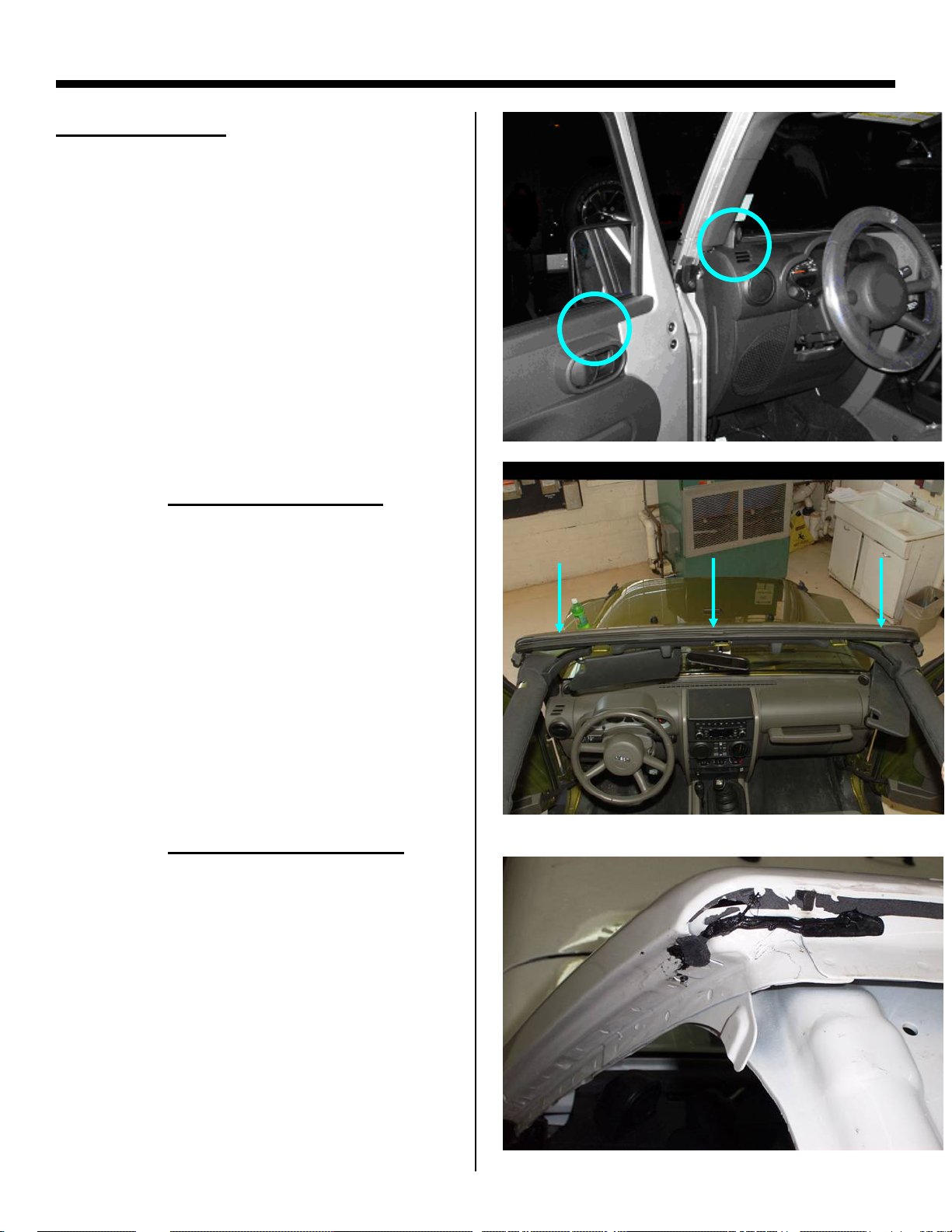

AREA OF LEAK:

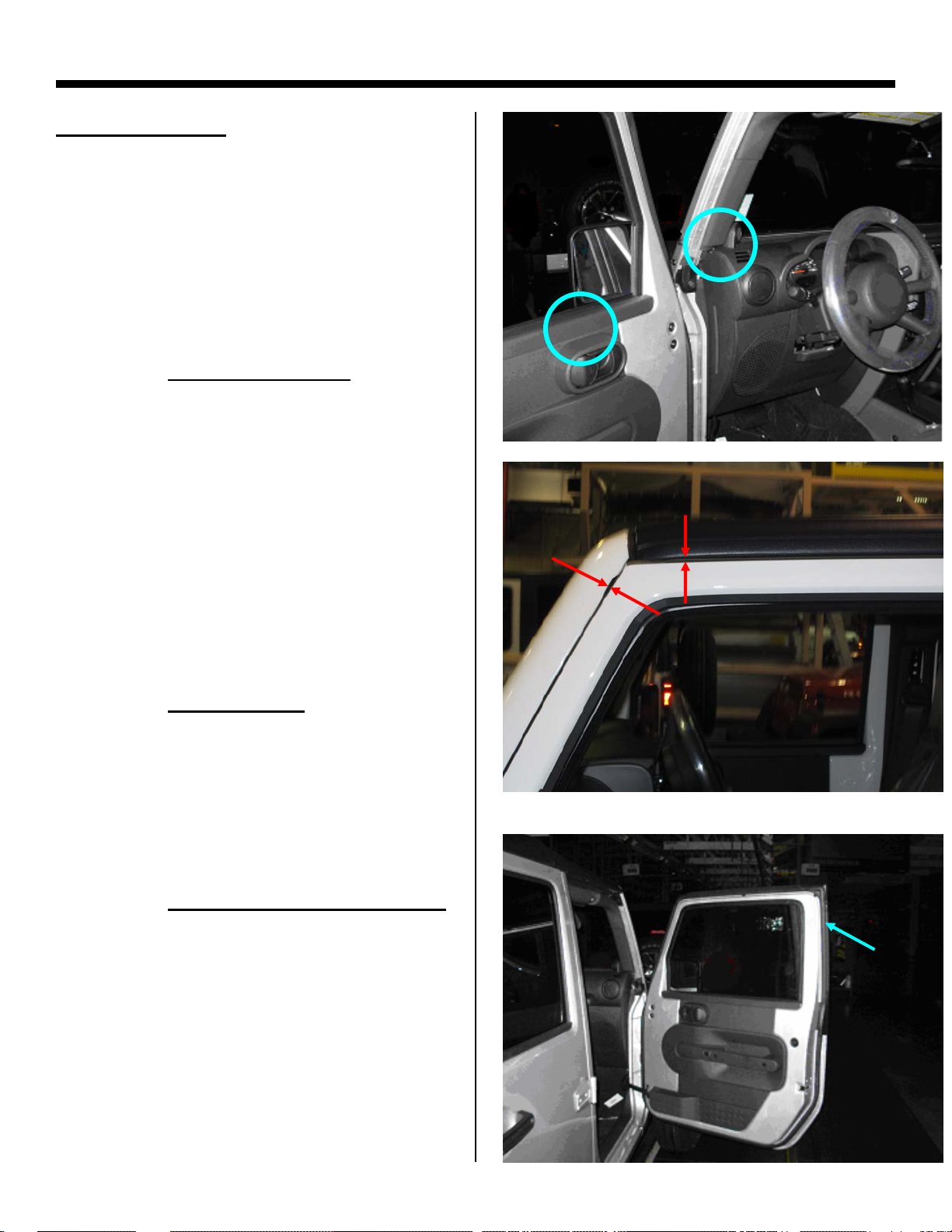

• This repair procedure is applicable

when water is evident on the:

o Door trim panel

or

o Instrument panel (a-pillar)

STEP 1: Remove Header Seal

• Figure 1

STEP 2: Remove/Clean Surface

• Remove all butyl and tape residue

• A rubber wheel bit can be used

• Clean surface with 3M adhesive

cleaner

• Alcohol wipe entire surface and allow

to dry

Labor Op. Code: 235135

Figure 1

Figure 2

1

Page 6

Windshield Header Seal Repair Procedure

STEP 3: Install Butyl

• NOTE: This operation is only

applicable for vehicles built before

6/1/2008. Vehicles built after this

date, should already have sealer

present in this area.

• Install 4mm butyl (68027813AA) as

shown (Figure 4)

• Make sure to fill in all holes, wrinkles

and step offs to allow for a smooth

surface to bond the tape/butyl from

the new seal

• NOTE: Excessive amount of butyl

can cause transition voids/leaks.

Make sure to smooth out butyl.

STEP 4: Install Seal

• Locate and install new seal, Pt #:

55397454AE

• Remove release tape and pressurize

seal firmly in contact with header

sheet metal to smooth out adhesive

tape and butyl, starting at the ends

and working toward the center. A

small roller or firm finger pressure

should be used to insure the tape is

adhered completely from side to side,

THIS STEP IS CRITICAL

Where to

place butyl

Figure 3

Butyl

Figure 4

Line seal

up here

Labor Op. Code: 235135

Critical area to pressurize

Figure 5

2

Page 7

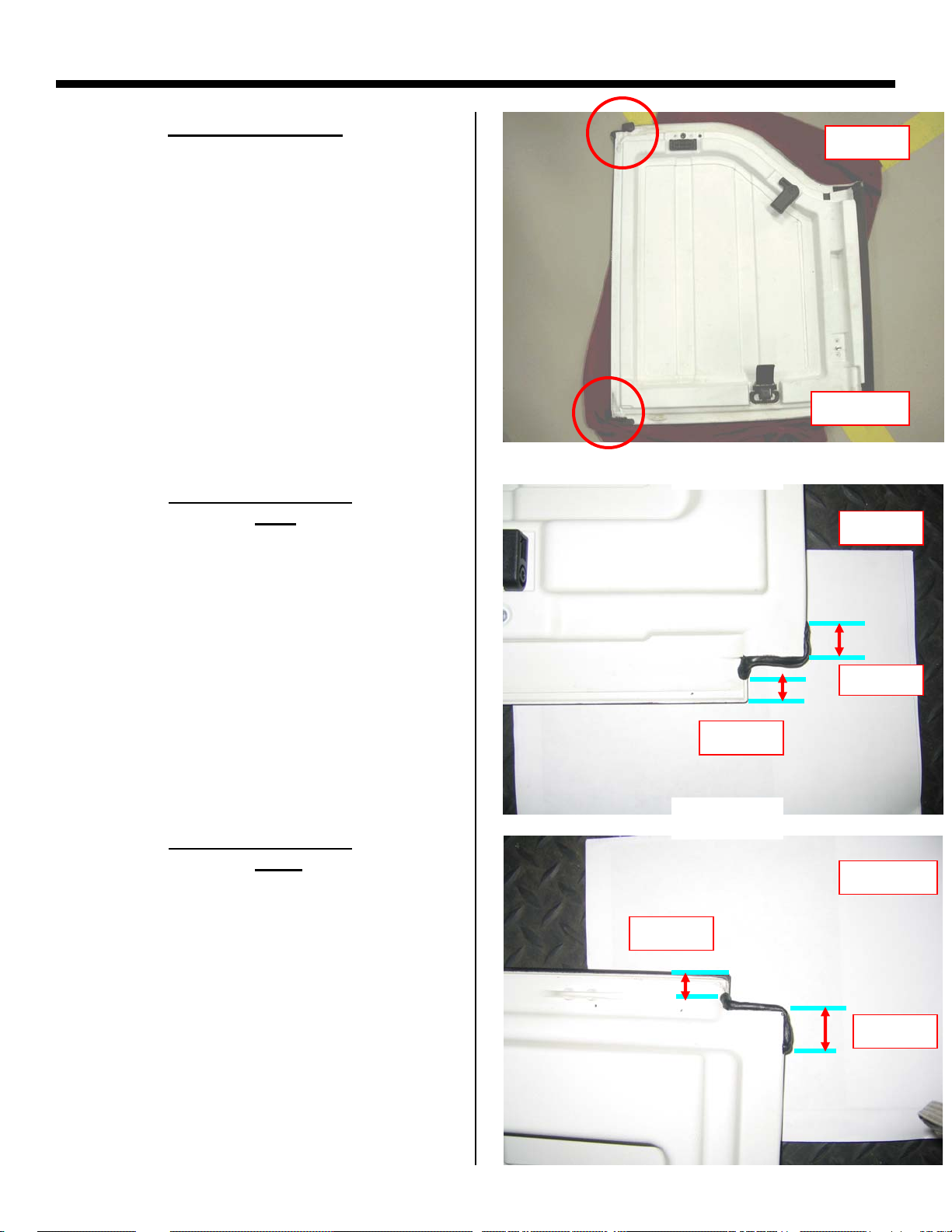

Door Fit Repair Procedure

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o Door trim panel

or

o Instrument panel (a-pillar)

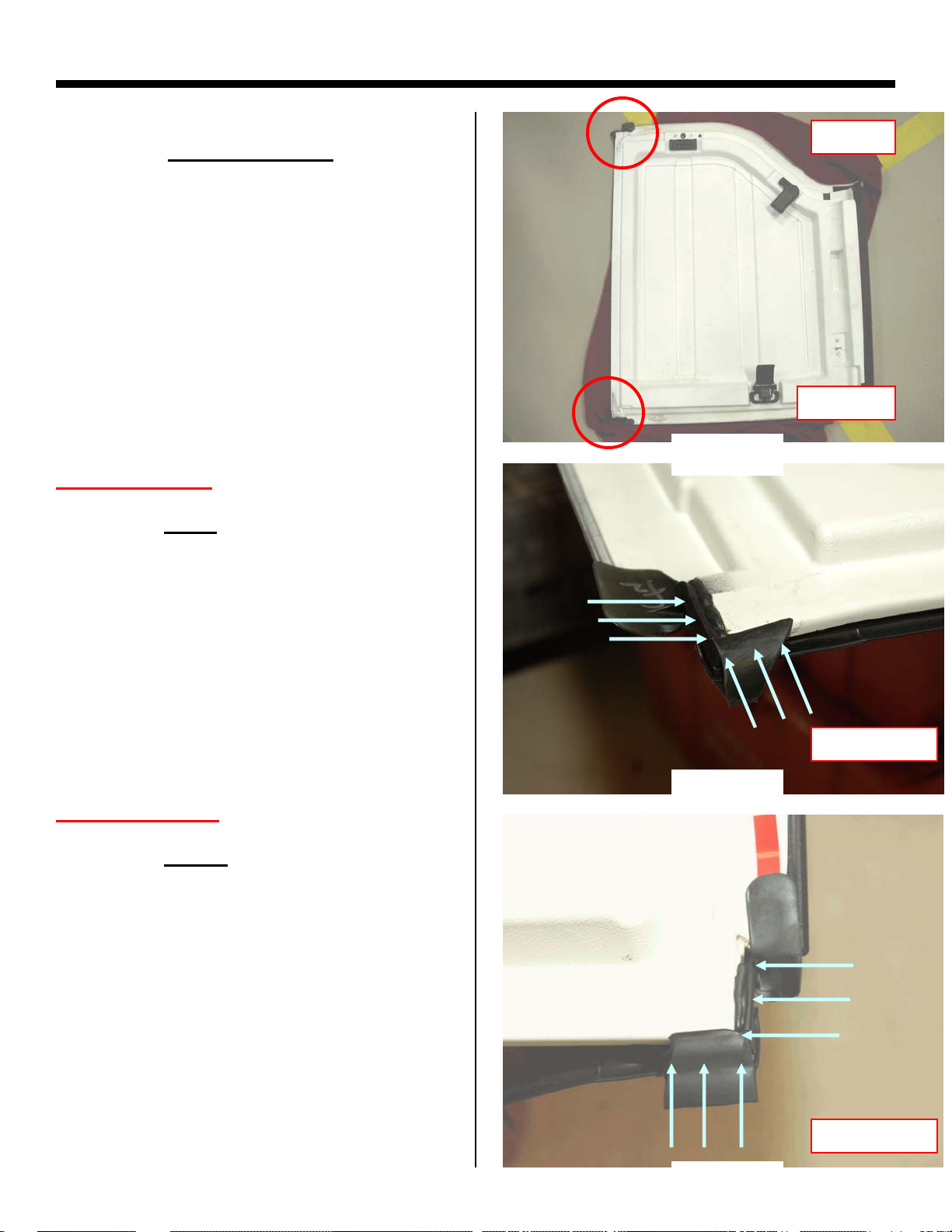

STEP 1: Door Gap Checks

• Measure door gaps

• The specifications are as follows:

• The gap spec. is 5.0 +/- 2.0 mm

• The flush spec. is 0.0 +/- 2.0 mm

• If the door fit is not to spec, proceed

to Step 2

STEP 2: Adjust Doors

• Adjust the door gap and flushness as

described in DealerConnect>

TechCONNECT under: Service info>

23 – Body> Body Structure> Gap and

Flush> Specifications Service Manual

STEP 3: Replace Door Primary Seal

• If the doors are adjusted, the door

seal must be replaced

• Part #: 55395274/5AN

Figure 6

Labor Op. Code: 230010

Figure 7

3

Page 8

A-Pillar Foam/Mucket Repair Procedure

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o Door Trim Panel

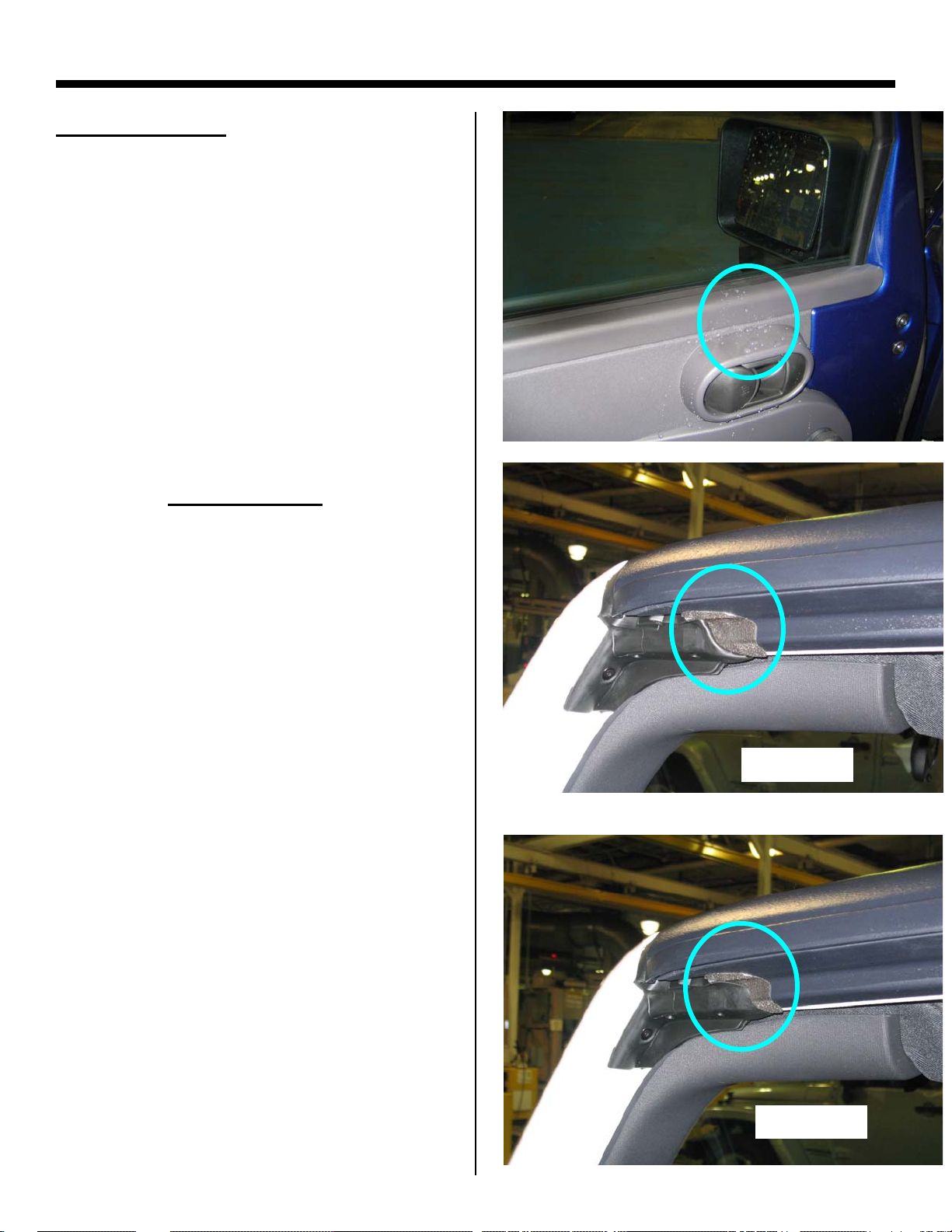

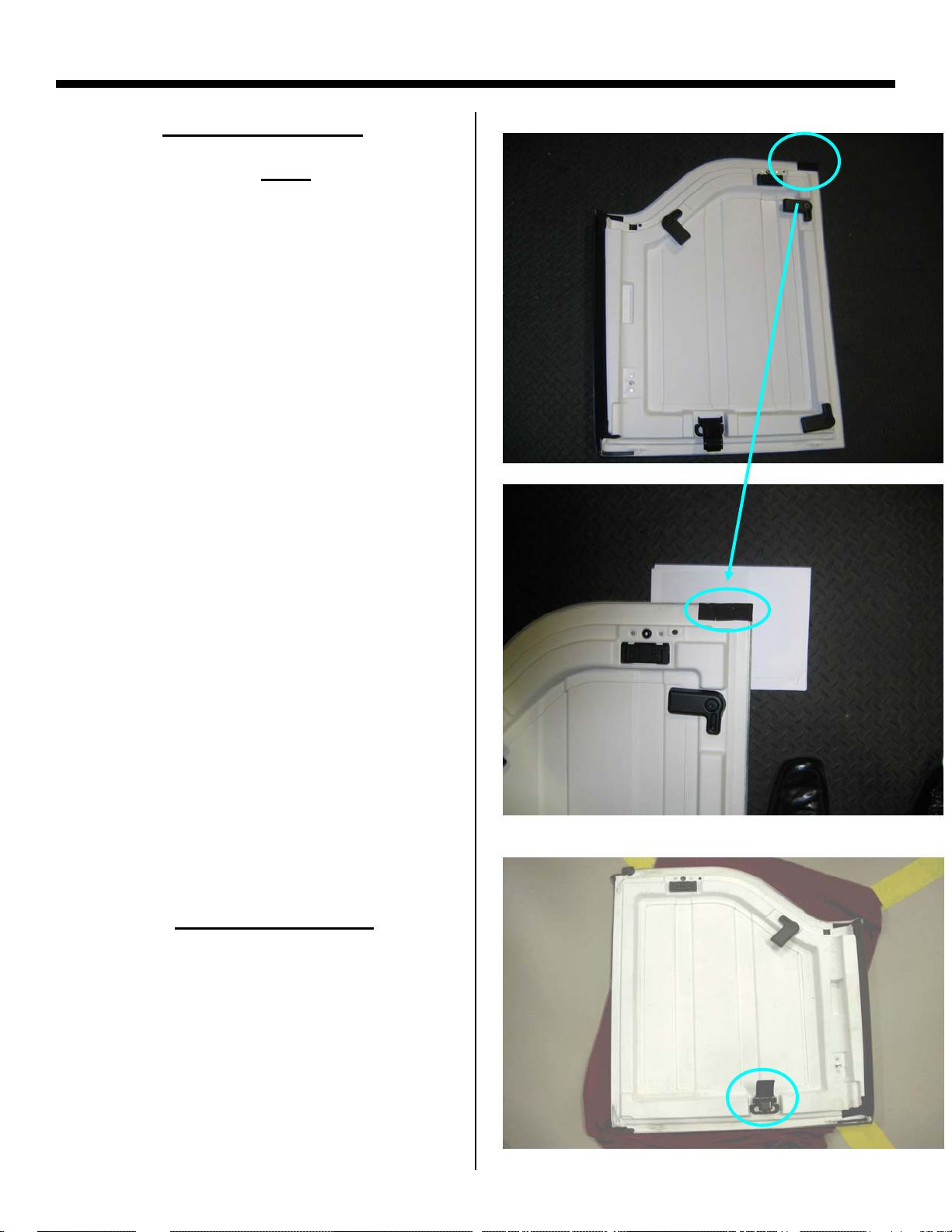

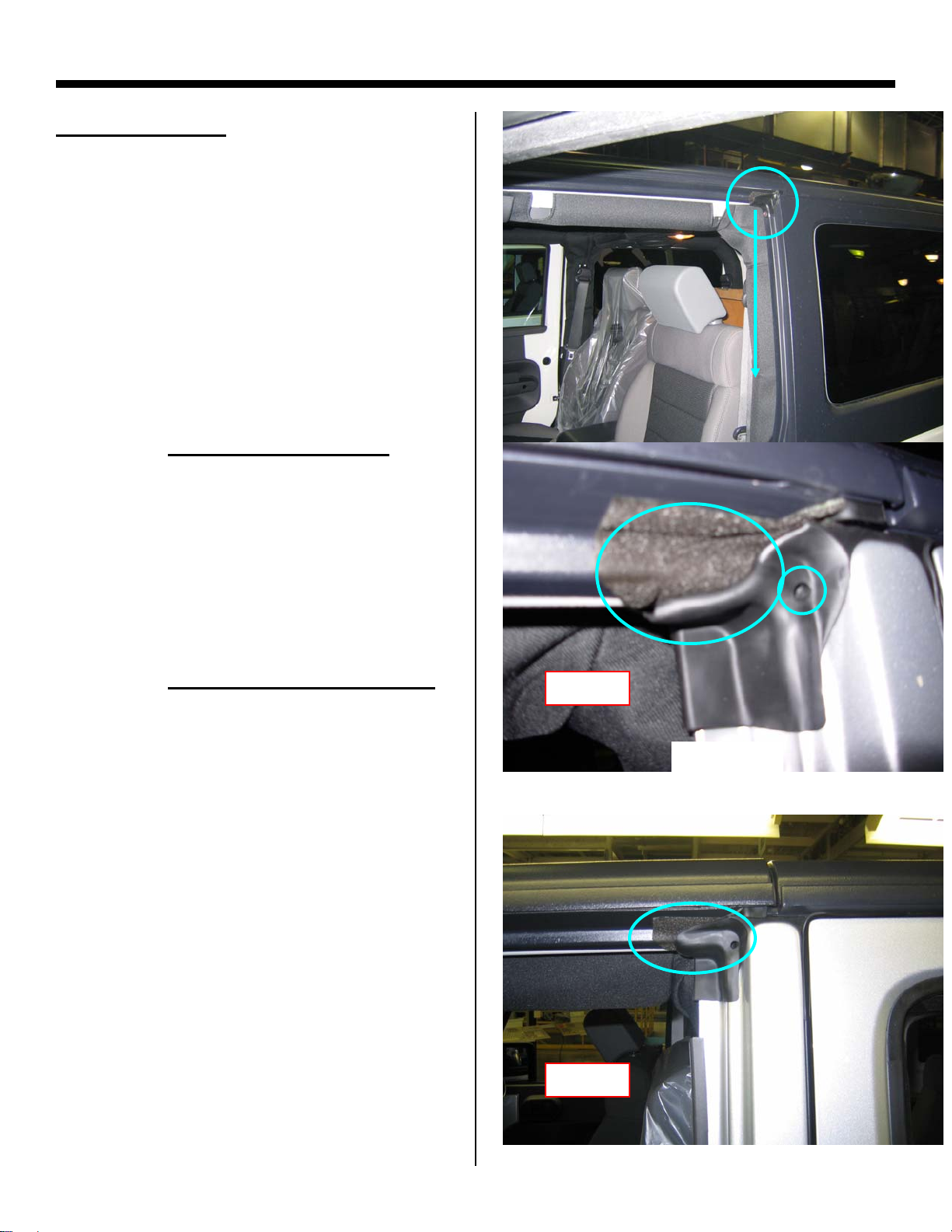

STEP 1: Header Mucket

• NOTE: This issue/repair applies to

both hard and soft top vehicles

• Inspect the header seal mucket for

the seal rolled under the freedom

panel or side rail. (Figure 8)

• If the seal is folded under, remove the

freedom panel or side rail and reinstall making sure not to distort the

mucket (Figure 9)

Labor Op. Code:

BAD

Figure 8

Figure 9

GOOD

4

Page 9

A-Pillar Foam/Mucket Repair Procedure

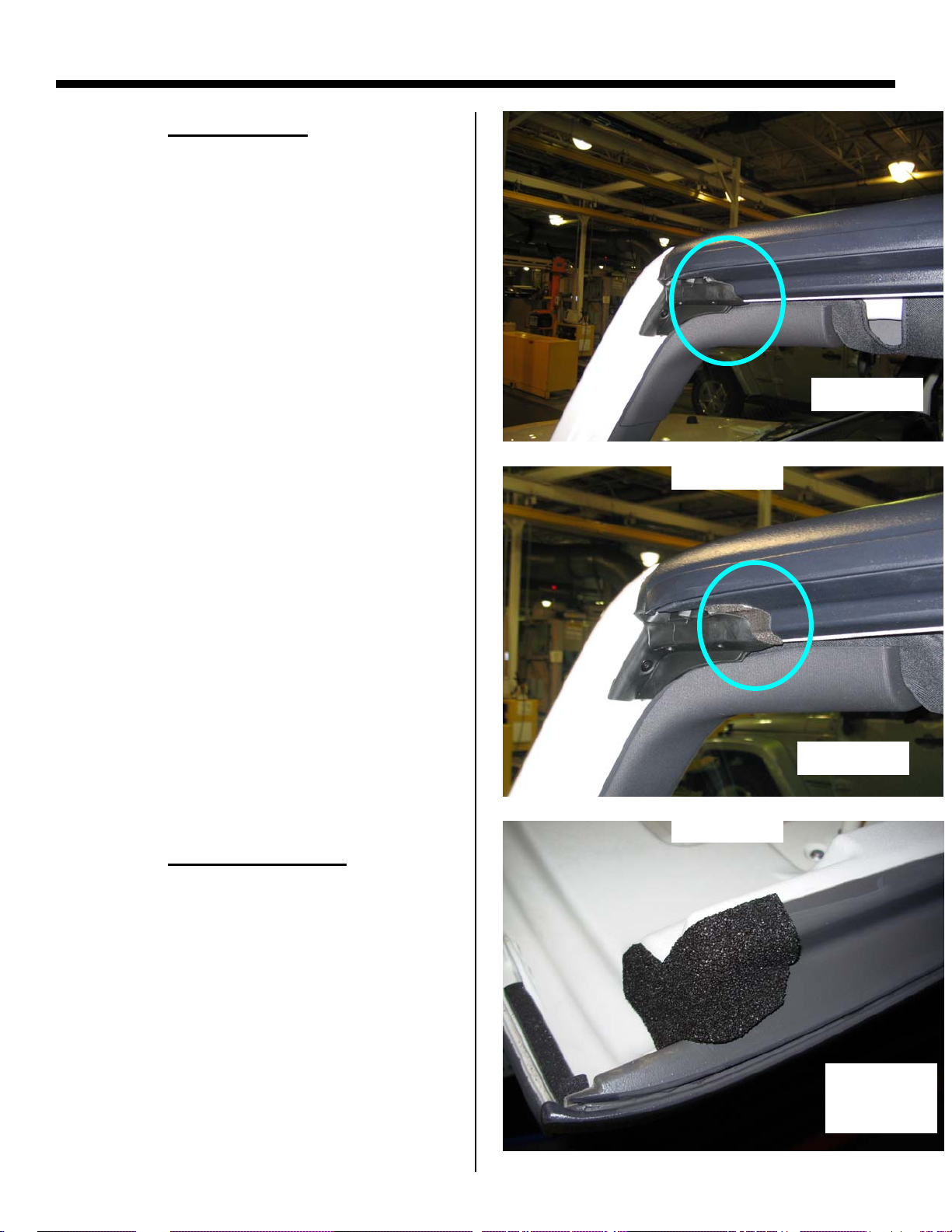

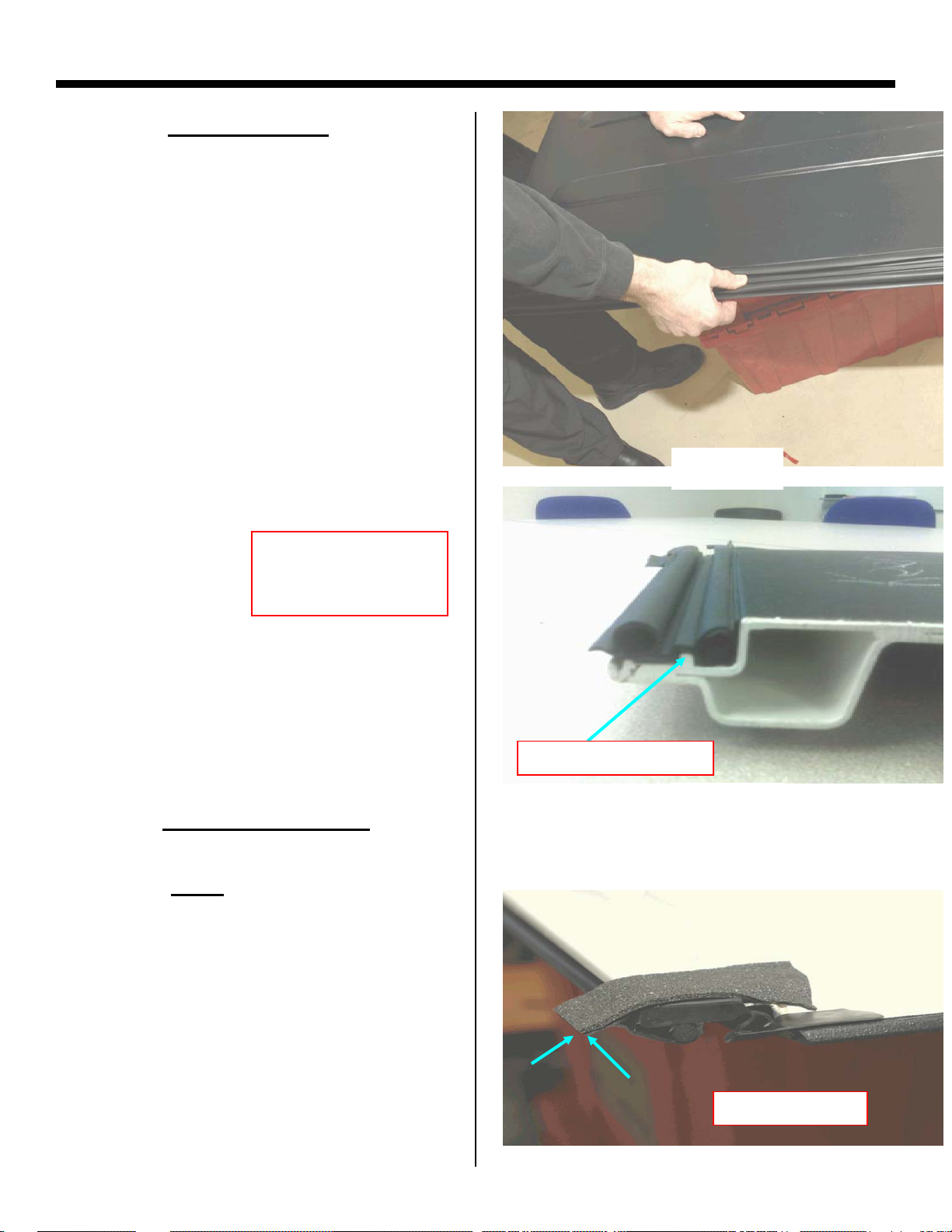

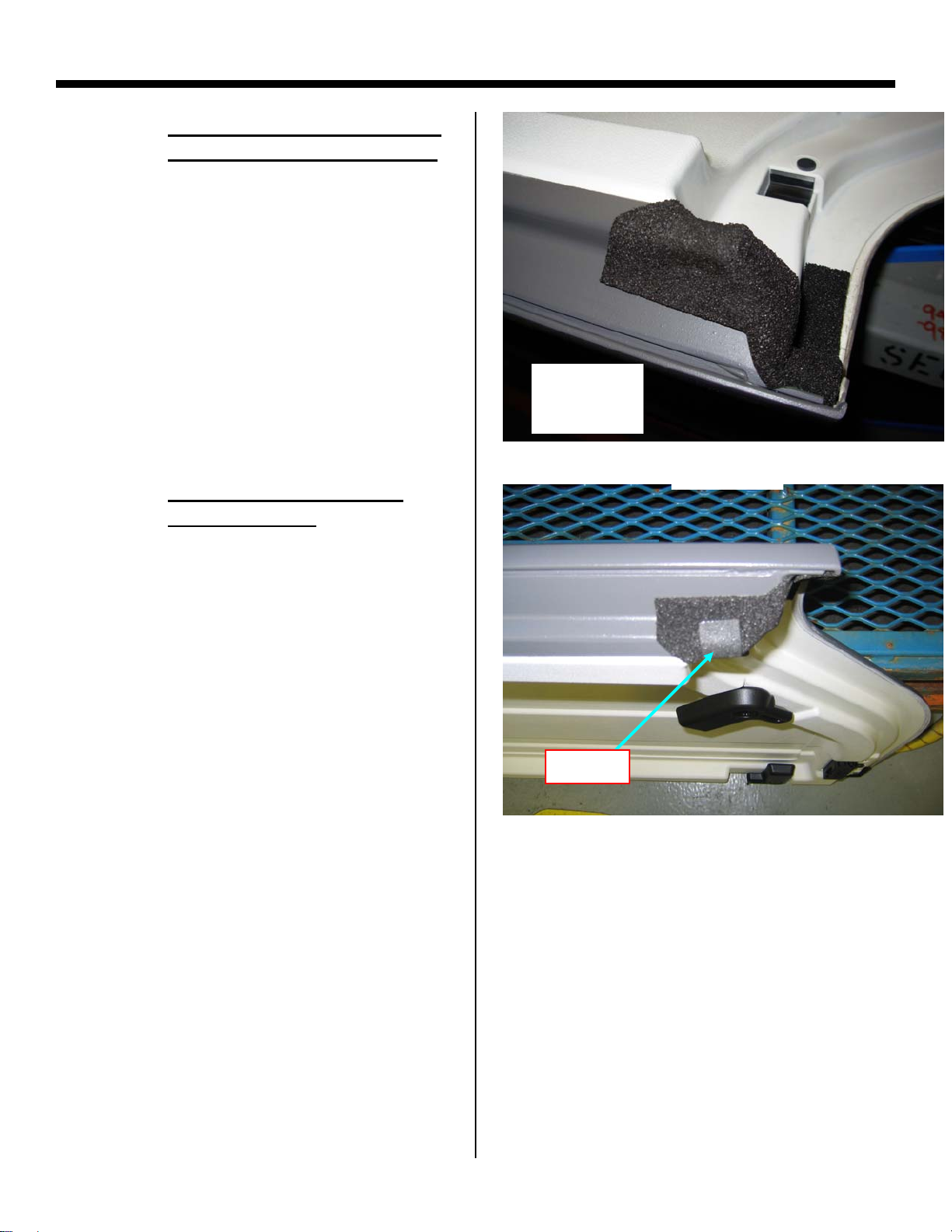

STEP 2: A-Pillar Foam

• NOTE: This issue/repair applies to

both hard and soft top vehicles

• Inspect the freedom panel or side rail

for damaged/missing foam

(Figure 10)

• If the foam is damaged or missing,

replace the foam using the foam kit

(68026937AB)

STEP 2: Foam Installation

• Install the foam to the freedom panel

as shown in Figure 12

• The foam installation is similar for

the soft top rail

BAD

Figure 10

GOOD

Figure 11

Labor Op. Code:

RH Panel

Shown

Figure 12

5

Page 10

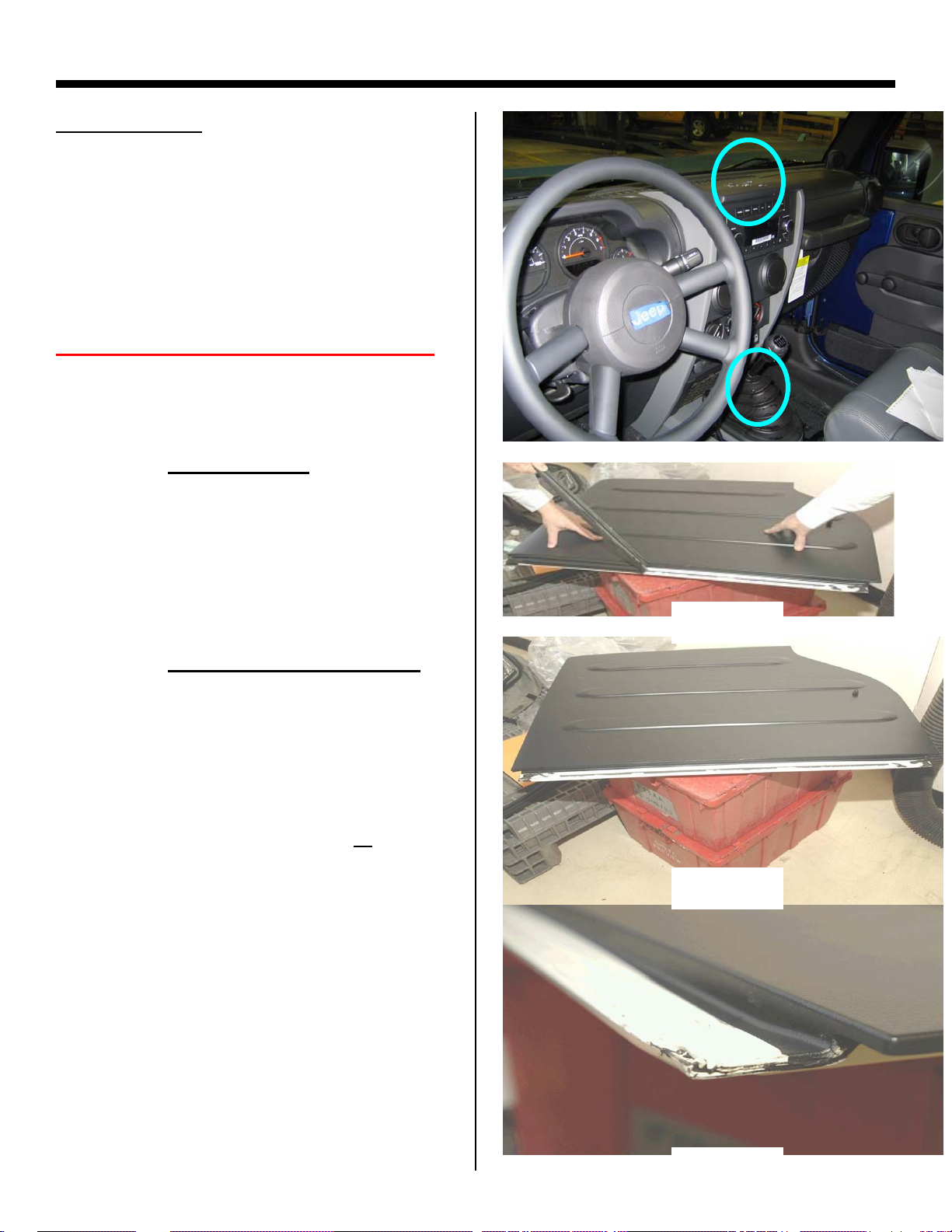

B-Pillar Mucket/Foam Seal Repair

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o Instrument panel (Center)

or

o Console / Shifter

RIGHT HAND FREEDOM PANEL

STEP 1: Seal Removal

• Remove seal on Right panel

STEP 2: Tape and Butyl Removal

• Remove tape and butyl residue from

panel

• A rubber wheel bit can be used

• Clean Seal Surface with: 3M General

Purpose Adhesive Cleaner or

Products Acrysol, (if available) and

allow to dry completely

• Wipe seal surface with alcohol and

allow to dry completely.

Labor Op. Code:

Kent

Figure 13

Figure 14

Figure 15

6

Page 11

B-Pillar Mucket/Foam Seal Repair

R

R

STEP 3: Butyl Installation

• Place right hand freedom panel

upside down on a covered surface to

prevent scratching

• Apply 4 mm diameter Butyl, Pt #

68027813AA, to Rear Notch (Figure

17)

• Note: Follow groove between panels

and push butyl firmly in place

• Apply 4 mm diameter Butyl

68027813AA, to Front Notch

(Figure 18)

• Note: Follow groove between panels

and push butyl firmly in place

, Pt #

REA

FRONT

15mm

Figure 16

REA

20mm

15mm

Figure 17

FRONT

20mm

Labor Op. Code:

Figure 18

7

Page 12

B-Pillar Mucket/Foam Seal Repair

R

STEP 4: Seal Installation

• Keep freedom panel upside down for

the initial installation of the seal

• Remove tape liner from seal

NOTE: Secure the end molds first, then

finish with the middle of the seal

Rear Seal Mold

• Align REAR edge of NEW seal, Pt #

55397095AG to Right Freedom Panel

Notch.

• Compress butyl by installing seal in

direction of arrows (Figure 20)

• Note: No gap between installed seal

and outer edge of freedom panels.

(Figure 20)

Front Seal Mold

• Align FRONT edge of NEW seal, Pt #

55397095AG to Right Freedom Panel

Notch

• Compress butyl by installing seal in

direction of arrows (Figure 21)

• Note: No gap between installed seal

and outer edge of freedom panels.

(Figure 21)

REA

FRONT

Figure 19

Rear Mold

Figure 20

Labor Op. Code:

Figure 21

Front Mold

8

Page 13

B-Pillar Mucket/Foam Seal Repair

STEP 5: Pressurize Seal

• Flip panel back over to complete the

seal installation

• Locate seal cross car against the

middle rib in the freedom panel and

pressurize starting at the ends and

working toward the center

• A small roller or firm finger pressure

should be used to insure the seal

tape is adhered from front to rear,

THIS STEP IS CRITICAL

STEP 6: Install foam at Front

• Install GREY 30 X 75 mm Foam from

kit (68026937AB) along trim lines of

flame tip (Figure 24)

• NOTE: Make sure foam covers butyl

completely

This photo is for

reference only. Panel

was cut to show rib.

Locator rib in panel

Figure 22

Figure 23

Labor Op. Code:

Front of panel

Figure 24

9

Page 14

B-Pillar Mucket/Foam Seal Repair

STEP 7: Install foam at Rear

• Install BLACK 30 X 75 mm Foam from

kit (68026937AB) along trim lines of

flame tip (Figure 25)

• NOTE: Make sure foam covers butyl

completely

Figure 25

LEFT HAND FREEDOM PANEL

STEP 8: Install butyl at Rear

• Place Left hand freedom panel

upside down on a covered surface to

prevent scratching

• Add 4mm diameter butyl,

(68027813AA) to rear inboard corner

groove (Figure 27)

• Note: Push butyl firmly into groove

between panels until flush

REAR

Figure 26

70 mm

25 mm

Figure 27

Labor Op. Code:

10

Page 15

B-Pillar Mucket/Foam Seal Repair

STEP 9: Install foam at Rear

• Add 30 X 75 mm Black Foam from Kit

(68026937AB) to cover butyl

(Figure 28)

• NOTE: Make sure foam covers butyl

completely

STEP 10: Install front latches

• NOTE: This applies to both Right and

Left panels

• If the vehicle MDH is prior to 12/07/07,

replace the front latches with part

number 68004562AB (Figure 29)

Labor Op. Code:

Figure 28

Figure 29

11

Page 16

B-Pillar Mucket/Foam Seal Repair

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o B-pillar roll bar

o B-pillar trim

o Freedom panel screw holes

NOTE: Water that enters anywhere along

the hard top seal can travel over to the Bpillar and leak from the hard top

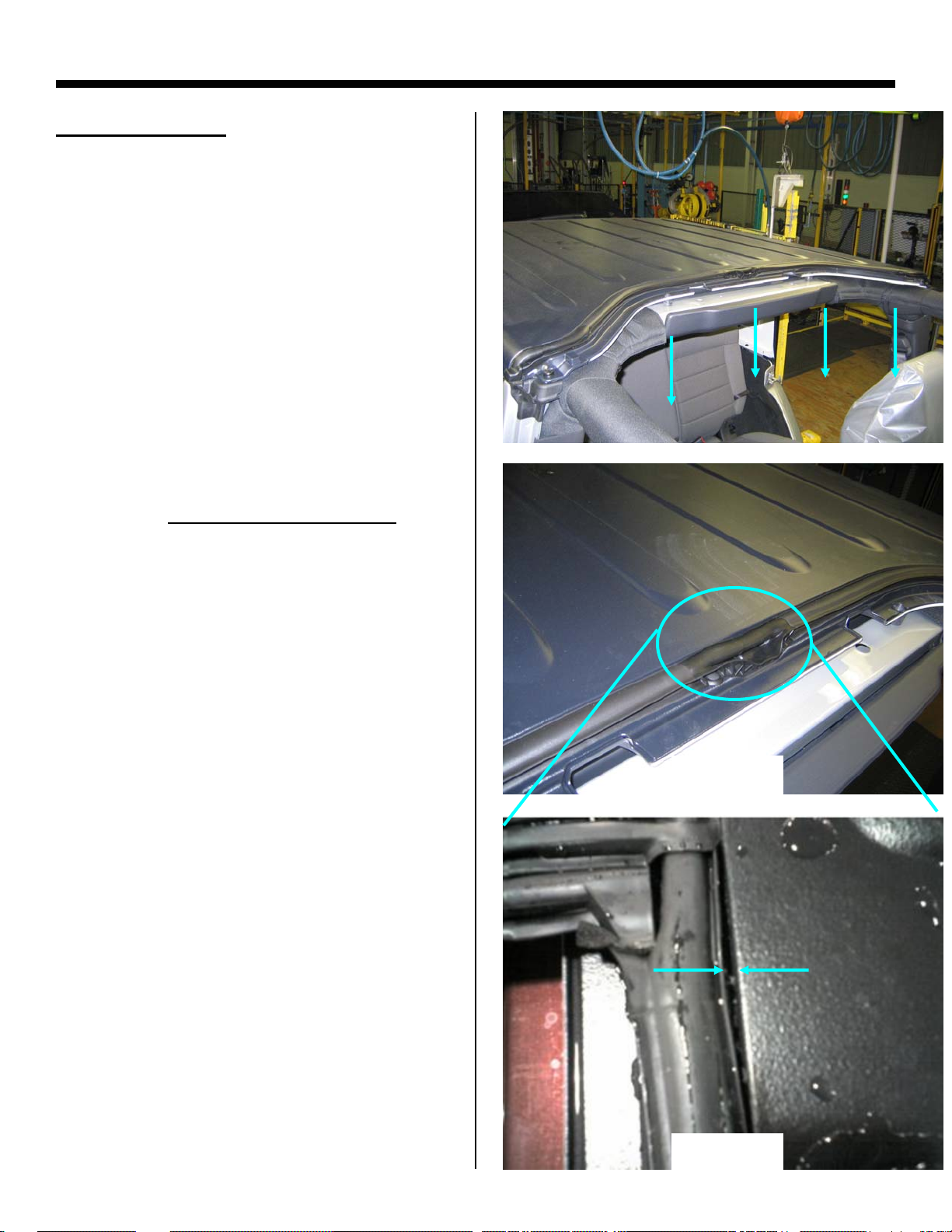

STEP 1: Inspect Hard Top Seal

• Inspect for any gaps between the

seal and hard top (Figure 30,31)

Figure 30

Labor Op. Code:

Figure 31

12

Page 17

B-Pillar Mucket/Foam Seal Repair

STEP 1: Inspect Hard Top Seal

(cont.)

Inspect the end molds for poor

•

installation (Figure 32)

BAD GAP

•

Inspect underneath the seal for any

skips with the tape/butyl along the

entire seal (Figure 34 & 35).

Figure 34

GOOD GAP

Figure 32

Figure 33

TAPE SKIP

Figure 35

Labor Op. Code:

13

Page 18

B-Pillar Mucket/Foam Seal Repair

STEP 2: Replace Hard Top Seal

If there are multiple skips or the leak

cannot be stopped, replace seal.

Remove all tape/butyl and clean with

alcohol prior to installation

A rubber wheel bit can be used to

remove the tape

Pre-apply butyl (68027813AA) on

hard top prior to installing the seal

(Figure 36)

It is critical that then end molds are

installed correctly and sufficient

pressure is applied to wet out the

butyl/tape (Figure 36)

Labor Op. Code:

Apply butyl

as shown

Pressurize

Figure 36

2mm

underflush

Figure 37

14

Page 19

B-Pillar Mucket/Foam Seal Repair

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o B-plr trim or seat

NOTE: This repair applies to 4 door hard

top or soft top models

STEP 1: Inspect mucket detail

Inspect the mucket for a rolled under

condition (Figure 38)

Inspect the mucket for a missing

drain hole

STEP 2: Replace the mucket detail

If either of these conditions exist,

replace the mucket detail

(Part #:55395708/9AE)

Reinstall the panel or side rail making

sure not to distort the mucket

BAD

Figure 38

Labor Op. Code:

GOOD

Figure 39

15

Page 20

B-Pillar Mucket/Foam Seal Repair

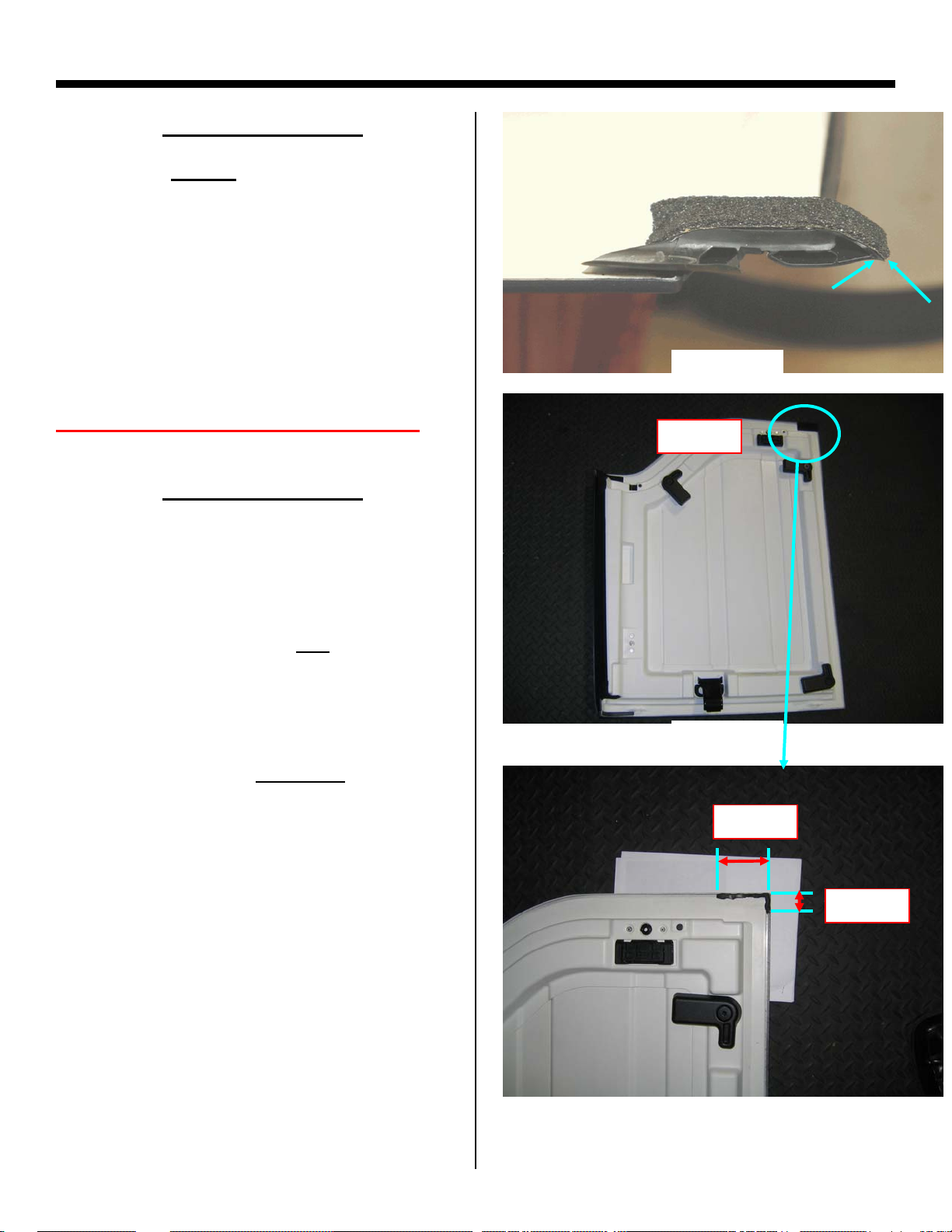

STEP 3: Inspect Freedom Panel for

damaged or missing foam

• If the foam is damaged or missing,

replace the foam using the foam kit

(68026937AB)

STEP 4: Add additional foam to

freedom panel

Add a piece of foam to the freedom

panel as shown in Figure 41. This

foam can be created by cutting the 30

x 75mm GREY foam in half from the

foam kit (68026937AB)

Figure 41

NOTE: This foam is in addition to the foam

that is already on the panel

RH Panel

Shown

Figure 40

FOAM

Figure 41

Labor Op. Code:

16

Page 21

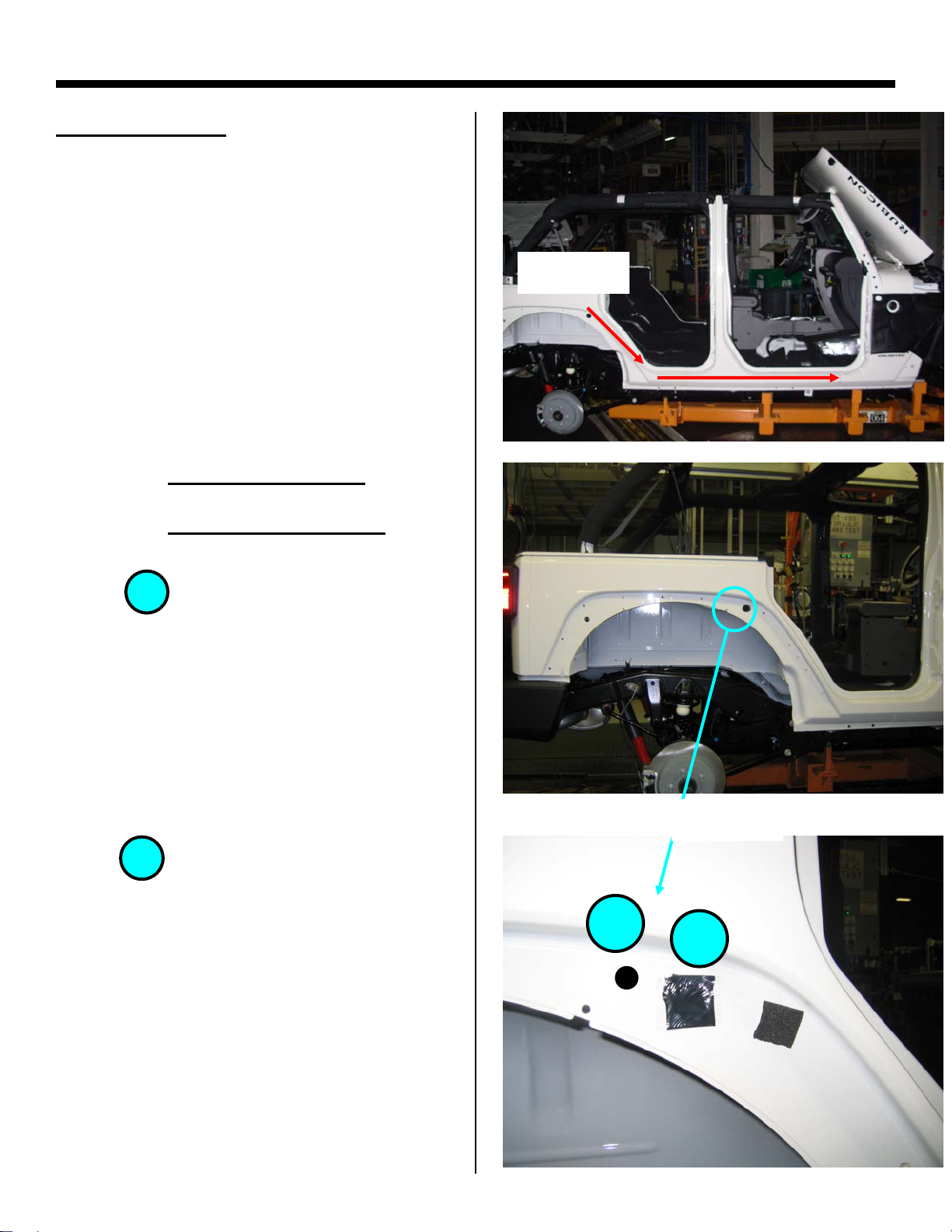

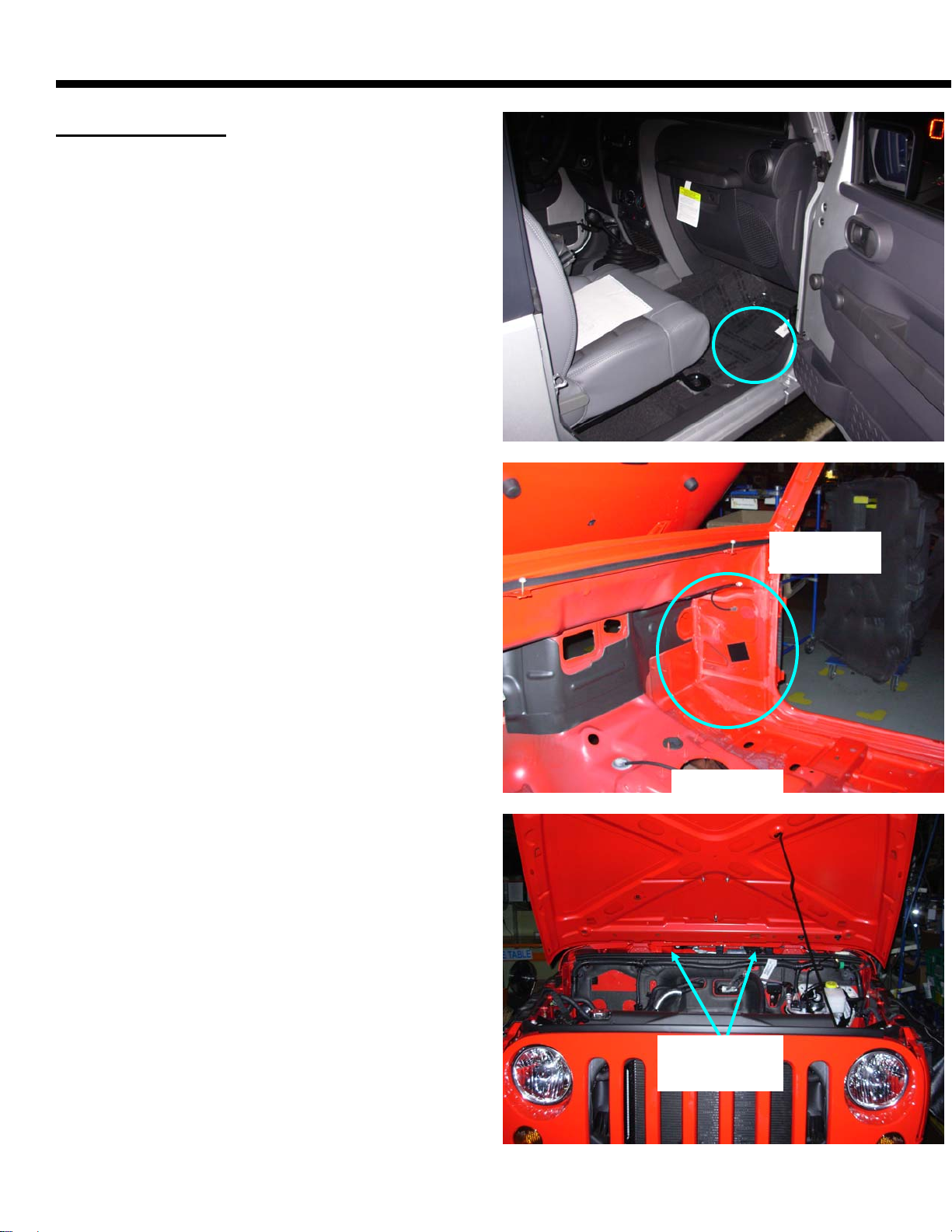

Rear Wheel Flare Hole Repair

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o Front floor (wet carpet)

o Under seat

NOTE: This leak can be diagnosed by

applying a hose to the upper rear flare and

inspecting for water traveling along the

floor to the front

STEP 1: Remove Rear Flare

STEP 2: Replace/Install Patch

Hole :

1

NOTE: Vehicles built prior to 5/28/08 will

require this repair

• Inspect the body for missing or mis-

aligned tape over the hole as seen in

Figure 43

Add/Replace a tape patch over the

hole

Hole:

NOTE: Vehicles built prior to 5/01/09 will

require this repair

• Inspect the body for missing or mis-

Add/Replace a tape patch over the

Labor Op. Code:

2

aligned tape over the hole as seen in

Figure 43

hole

Leak Path

Figure 42

1

2

Figure 43

17

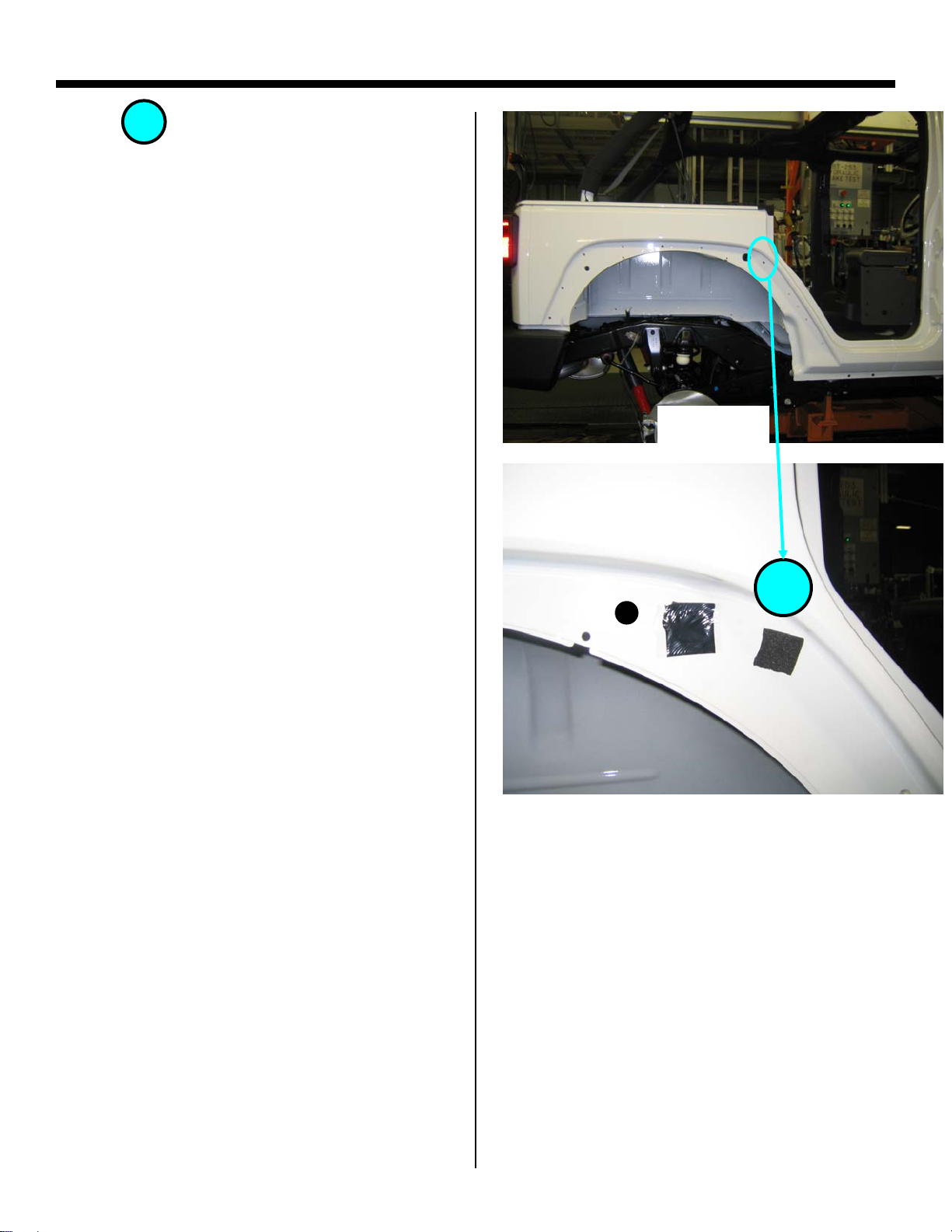

Page 22

Rear Wheel Flare Hole Repair

Hole:

NOTE: Vehicles built prior to 7/22/08 will

require this repair

• Cut the BLACK 30 x 75 foam from the

Make sure the foam does not extend

Re-install flare

3

foam kit (68026937AB) in half and

apply over this hole (Figure 45)

past the flare trim line (appearance

issue)

Figure 44

3

Figure 45

Labor Op. Code:

18

Page 23

Cowl Side Panel Repair

AREA OF LEAK:

• This repair procedure is applicable

when water is evident on the:

o Front floor (wet carpet)

NOTE: These leaks can be diagnosed by

applying a hose in the cowl panel (Figure

47).

Leak area

Figure 46

Apply hose

in cowl area

Labor Op. Code: 235001

Figure 47

19

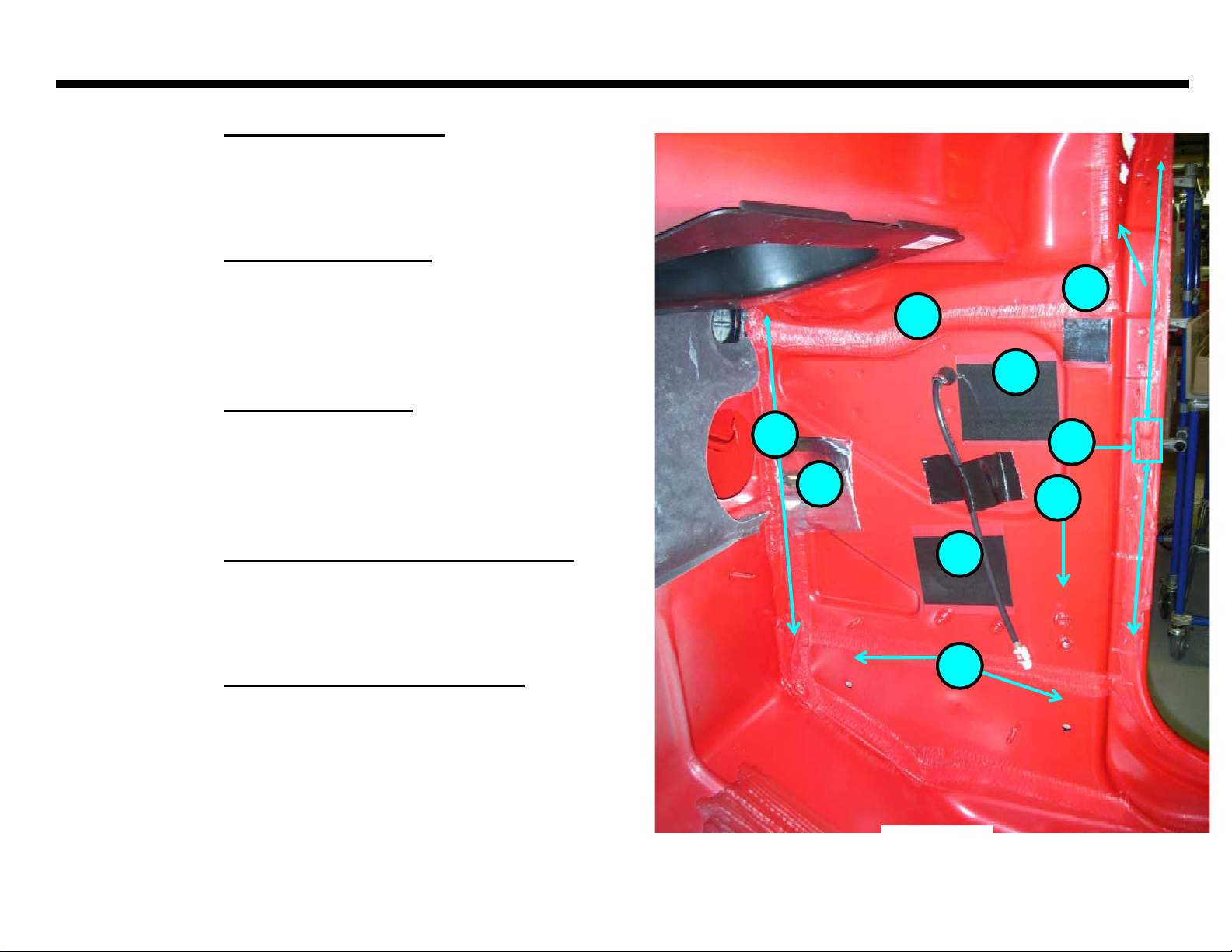

Page 24

Cowl Side Panel Repair

Condition 1: Mastic patches/Plugs

Repair 1: Replace patch/plug

Condition 2: Check strap bracket

Repair 2: Remove bracket and apply a butyl

to holes

Condition 3: Seam sealer skips

Repair 3: Apply clear sealer

(part #: 04467708) to skip

Condition 4: Scuff trim foam damaged/missing

Repair 4: Replace trim clips

Condition 5: Antenna grommet not seated

Repair 5: Re-install grommet

Labor Op. Code: 235001

_-

1

5

1

3

1

Figure 48

1

4

3

2

20

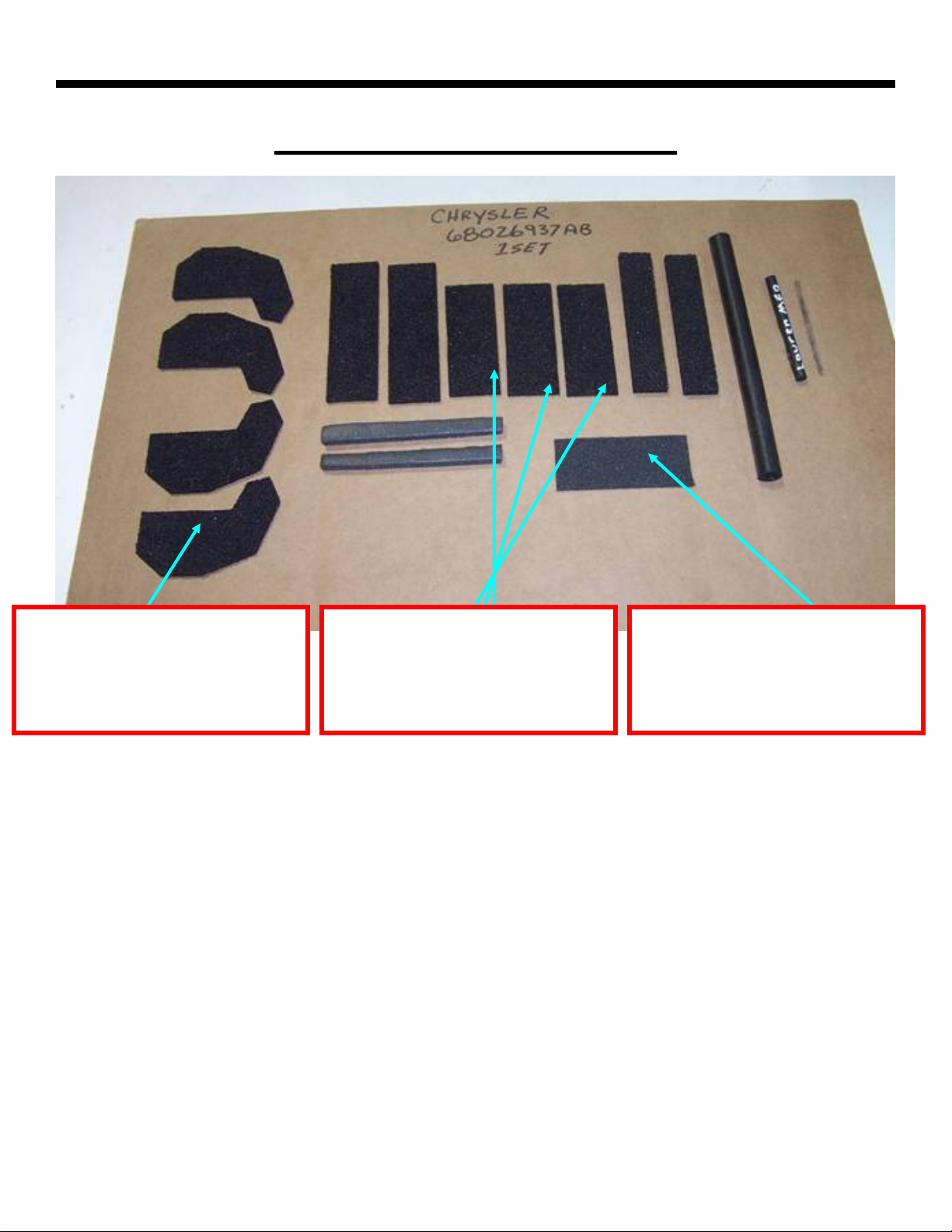

Page 25

Appendix

Foam Kit: 68026937AB

A/B-Pillar Foam

Used on Pages (5,16,)

30 mm x 75mm BLACK Foam

Used on Pages (10,11)

30 mm x 75mm GREY Foam

Used on Pages (9,16)

Labor Op. Code:

21

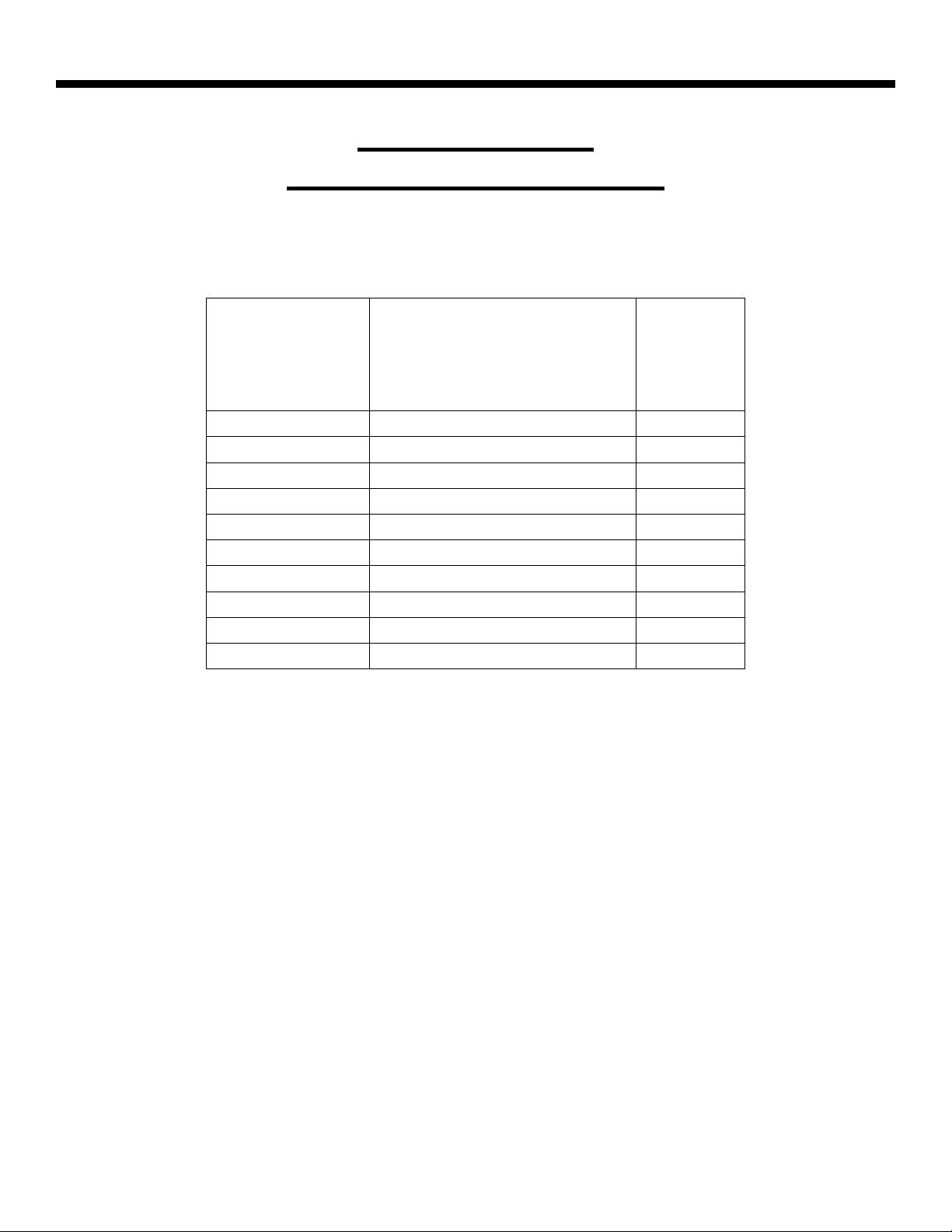

Page 26

Appendix

Jeep Wrangler

Replacement Parts List

Part # Part Name Page(s)

68027813AA Butyl 2,7,10,14

04467708 Clear Sealer 20

68026937AB Foam Kit 5,9-11,16

55397454AE Windshield Header Seal 2

55395274/5AN Front Door Primary Seal 3

55395708/9AE B-Pillar Mucket 15

55397095AG Freedom Panel Seal 8

55397046AF Hard Top Seal 4DR 14

55397058AF Hard Top Seal 2DR 14

68004562AB Freedom Panel Latch 11

Labor Op. Code:

22

Page 27

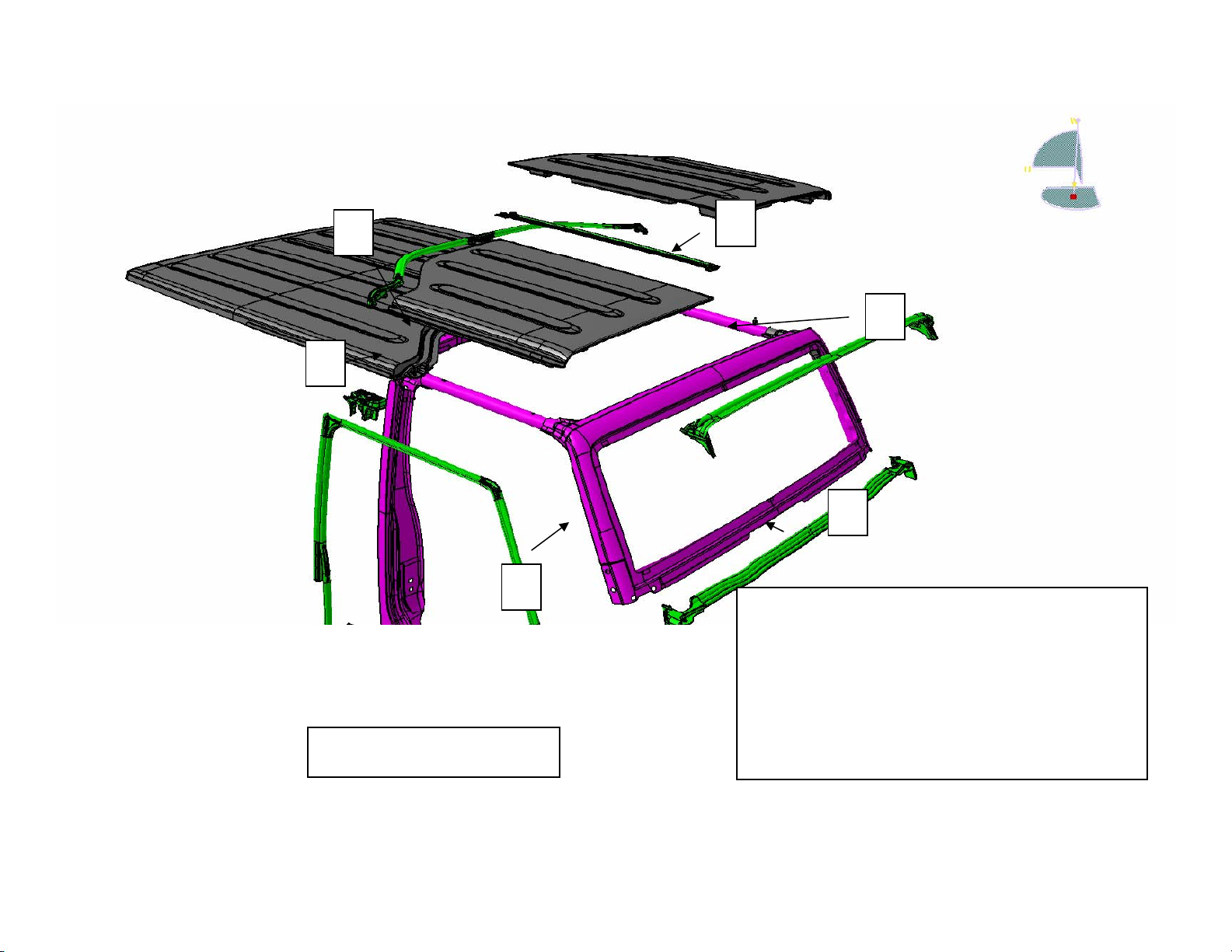

JK Freedom Top

-Center Front-

Water Leak Repair

Reference TSB # 23-020-08 As Required for additional Repair Information

10/14/2008 1

Page 28

4

5

6

1

2

3

1.Windshield header seal

2.Windshield to cowl seal

3.Front door weatherseal

4.B pillar mucket

5.Hard top seal

Outside View

10/14/2008 2

6.Center freedom panel seal

Page 29

9

7

12

9

8

10

11

13

7. Left Freedom Panel

8. Panel to Panel Latches

9. Panel to Hard Top Latches

10. Hard Top

11. Right Freedom Panel

12. Latch & Base Assembly 68004562AB

Inside View

10/14/2008 3

13 Sport Bar Thumb Screws

Page 30

*Please note:

This package addresses water leaks that come from

inside the vehicle when the door is closed.

This package does not address

water that drips into the Vehicle

when the door is open.

This is a normal condition!

10/14/2008 4

Page 31

These parts with

Light Blue shaded

boxes are Optional /

Replace as required

2 Pair.

Foam Kit Contents

68026937AB

20 mm x 95 mm x 5 mm-

30 mm x 95 mm x 3 mmthick. 2 pieces.

thick. 2 pieces.

7mm OD x 71mm. 2 pieces

2 Pair

13mm OD x 8mm ID x 160mm. 1 piece.

9 mm x 100 mm x 6.35 mmthick. 2 pieces.

10/14/2008 5

30 mm x 75mm x 3 mmthick. 3 pieces. Black

Foam

30 mm x 75mm x 2 mmthick 1 piece. Gray Foam

These 4 pieces of foam are required

for the freedom panel repair.

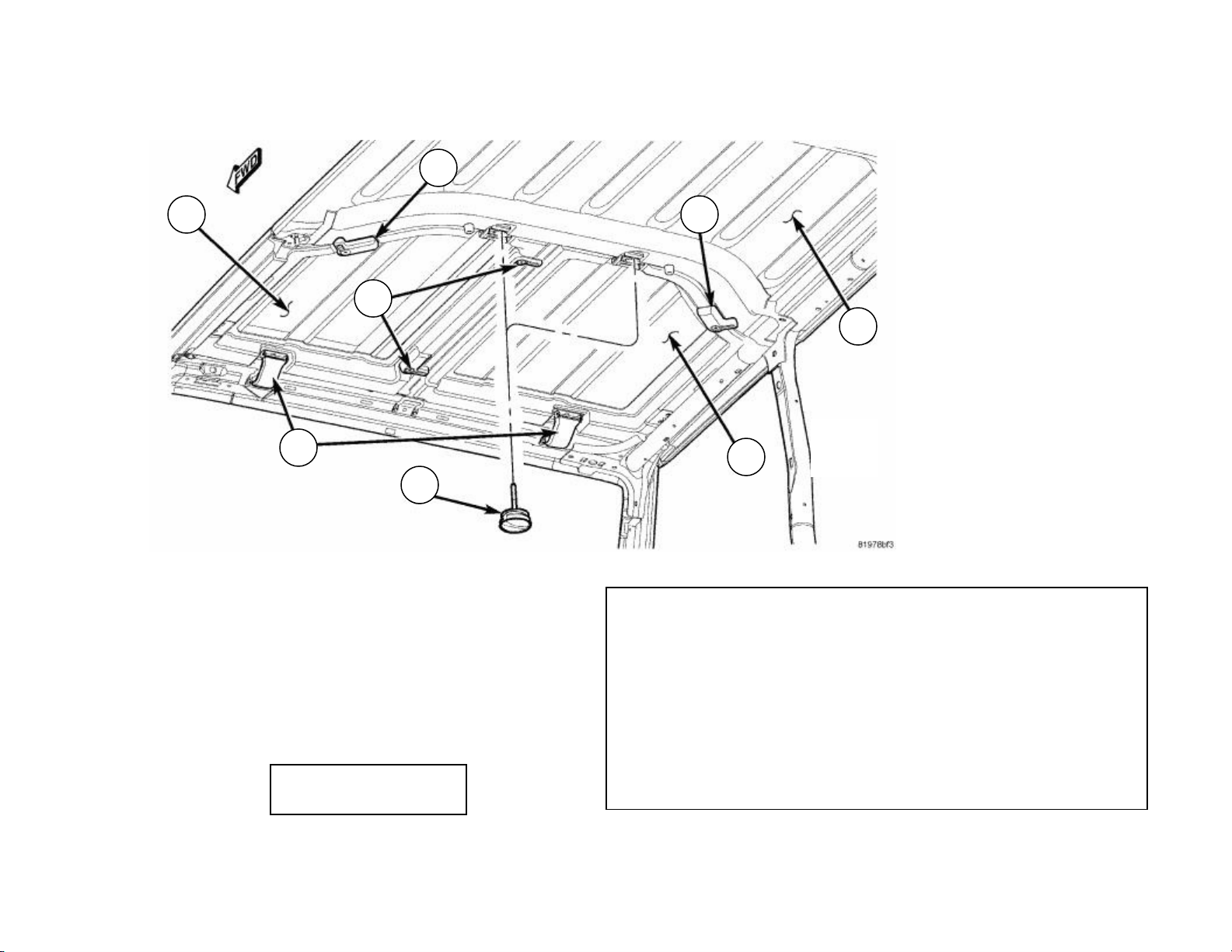

Page 32

Additional Hard Top Foam Locations Included in

the foam kit. Replace as required.

3

1

4

4

3

1

2

3

4

2

2

1

10/14/2008 6

Page 33

Right Freedom Panel

Weather Strip Removal & Freedom panel Cleaning

10/14/2008 7

Page 34

Remove Right Freedom Panel Center Seal

10/14/2008 8

Page 35

Remove old Butyl & Tape from Right Freedom Panel

10/14/2008 9

Page 36

Note: Old Butyl Removed from Right Freedom Panel

Seal Surface

(White Strip)

Clean Seal Surface with: 3M General Purpose Adhesive Cleaner or Kent

Products Acrysol, (if available) and allow to dry completely. Rough up Seal

Surface with Medium Scotch Bright pad. Wipe Seal Surface with Alcohol and

allow to dry completely.

10/14/2008 10

Page 37

Note: Old Butyl Removed from Right Freedom Panel, Front &

Rear Notches

10/14/2008 11

Page 38

Place Right Freedom Panel

Upside down on a covered

work surface to prevent paint

Scratching.

Freedom Panel Notch Butyl installation

10/14/2008 12

Page 39

Page 15 Rear notch

Page 14 Front notch

10/14/2008 13

Page 40

Apply New 4 mm diameter Butyl, Pt # 68027813AA to Right

Freedom Panel, Front Notch. Note: Follow Groove between

panels and Push Butyl firmly in place.

Front Inboard

Butyl inside Grooves

20 mm

15 mm

10/14/2008 14

Page 41

Apply New 4 mm diameter Butyl, Pt # 68027813AA to Right

Freedom Panel, Rear Notch. Note: Follow Groove between

panels and Push Butyl firmly in place.

Front

Inboard

Butyl inside Grooves

15 mm

10/14/2008 15

20 mm

Page 42

Page 17 Rear Weather

Strip

Page 18 Front Weather

Strip

Freedom Panel Weather Strip installation

10/14/2008 16

Page 43

Align Rear edge of NEW Weather Strip, Pt # 55397095AG to

Right Freedom Panel Notch. Note: No gap between installed

Weather Strip and outer edge of freedom panels.

Compress butyl by installing

Weather Strip in direction of Arrows

Smooth out Butyl after

W/Strip installation

10/14/2008 17

Page 44

Align Front edge of NEW Weather Strip, Pt # 55397095AG to

Right Freedom Panel Notch. Note: No gap between installed

Weather Strip and outer edge of freedom panels.

Smooth out Butyl after

Weather Strip installation

Note: Remove Release tape and Press Weather Strip Firmly in

contact with Freedom Panel, Front AND Rear .

10/14/2008 18

Page 45

Note Both Ends of new W/Strip Located and installed to

Freedom Panel Center section still shown unattached

10/14/2008 19

Page 46

If Vehicle MDH is Before 12/17/07 Replace this Latch

on Right & Left Freedom Tops with 68004562AB.

Right Freedom Top Shown

Freedom Panel Latch and Base Assembly

Right and Left

10/14/2008 20

Page 47

Flip Right Freedom Panel

over to complete Weather

Strip installation.

10/14/2008 21

Page 48

Remove Release Tape, Locate W/Strip cross car against Rib in

the freedom panel and Pressurize to Freedom Panel starting at

the ends and working toward the center.

Cross Car Direction

Rib

10/14/2008 22

Page 49

A Small Roller or firm finger pressure should be used to

insure the Weather Strip tape is adhered from front to rear,

THIS STEP IS CRITICAL

10/14/2008 23

Page 50

Top View

Front, page 25 Rear, page 26

Flame Tips

Note: Make sure vertical rubber lip does not roll or get tucked under freedom

panel. Correct condition shown is Required at the Front AND

10/14/2008 24

Rear.

Page 51

Apply 3M 4298 adhesive promoter on the under side of the

flame tip and allow to dry. Align Gray 30 X 75 mm Foam

from kit along trim lines of Flame Tip.

Align Foam along these edges of Flame Tip

Front Flame Tip under side

10/14/2008 25

Page 52

Apply 3M 4298 adhesive promoter on the under side of the

flame tip and allow to dry. Align Black 30 X 75mm Foam

from kit along trim lines of Flame Tip.

Align Foam along these edges

of Flame Tip

Rear Flame Tip under side

10/14/2008 26

Page 53

Trim away excess Black Foam.

Rear Flame Tip - Top View

10/14/2008 27

Page 54

Left Freedom Panel

Place Left Freedom Panel Upside down on a covered work

surface to prevent paint Scratching

Clean Seal Surface with: 3M General Purpose Adhesive

Cleaner or Kent Products Acrysol, (if available) and allow to

dry completely. Rough up Seal Surface with Medium Scotch

Bright pad. Wipe Seal Surface with Alcohol and allow to dry

completely

Rear Inboard Corner Butyl & Foam installation

10/14/2008 28

Page 55

Add 4mm diameter Butyl, Pt # 68027813AA to Rear Inboard

Corner groove, Left Freedom Panel

Note: Push Butyl Firmly into groove

between panels until Flush

Outboard

100mm

100mm

Front

Front

10/14/2008 29

70mm

70mm

Page 56

Add 30 X 75 mm Black Foam from Kit to cover butyl

Front

10/14/2008 30

Page 57

Add 30 X 75 mm Black Foam from Kit to cover butyl.

Note Make sure Foam covers Butyl.

Outboard

10/14/2008 31

Page 58

Note: REMINDER Refer to Page 20 If Vehicle MDH is

Before 12/17/07

Freedom Top with 68004562AB.

. Replace Latch on Right & Left

Left Freedom Panel complete.

10/14/2008 32

Page 59

JK “A” Pillar- Header

Weather Strip

Water Leak Repair

Reference TSB # 23-025-08 As Required for additional Repair Information

10/14/2008 1

Page 60

*Please note:

This package addresses water leaks that come from

inside the vehicle when the door is closed.

This package does not address water

that drips into the Vehicle when the

door is open.

This is a normal condition!

10/14/2008 2

Page 61

5

4

6

1

2

1.Windshield header seal

3

2.Windshield to cowl seal

3.Front door weatherseal

4.B pillar mucket

Outside View

5.Hard top seal

6.Center freedom panel seal

10/14/2008 3

Page 62

Check door fit

• The door gap spec. is 5 +/-1.5 mm

Door Must be Flush to slightly under flush to A- Pillar

Adjust door Gap AND Flushness as described in

Body Section 23 of the Service Manual

10/14/2008 4

Page 63

Header Weather Strip

Remove Header Weather Strip from Body sheet metal and

clean up / remove all traces of old Tape and Butyl from

painted sheet metal surfaces before reinstallation of

butyl bead and new weather strip.

Clean Seal Surface with: 3M General Purpose Adhesive

Cleaner or Kent Products Acrysol, (if available) and allow to

dry completely.

Weather Strip Removal & Butyl Clean Up

10/14/2008 5

Page 64

Weather Strip Removal & Butyl Clean Up

All tape residue & butyl must be

removed across the entire

windshield frame!

Clean up / remove all traces of old Tape and Butyl from painted sheet

metal surfaces.

Alcohol wipe the clean sheet metal

and new weather strip.

10/14/2008 6

before installation of butyl bead

Page 65

Header Weather Strip

Butyl Placement and New Weather Strip Installation.

Right Side Shown on Pages 8, 9, & 10.

Left Side Not Shown but symmetrical / identical to Right

10/14/2008 7

Page 66

Fill in Gaps between Sheet Metal, Wrinkles, Holes

and Notches in this area with butyl until smooth.

3 mm x 3 mm butyl pad as

located ABOVE TAPE and

on mold line see page 11

Note: Vehicles built after 6/1/2008

MDH have this area filled in with

seam sealer from assembly plant.

Note:

60 mm

60 mm

Butyl bead MUST be

completely covered

by the header seal

mucket in this area.

Be careful DO NOT

allow squeeze out,

outside of installed

mucket!

20 mm

Inboard

10/14/2008 8

Right Side A-pillar

Page 67

Note: Green dots Show the area

where the header weather Strip

Adhesive Tape is to be located

4 mm diameter bead 68027813AA

Replacement Butyl Position. See

page 9 for Butyl Dimensions

Locate each end of the

Inboard

header weather strip

using this flange on

each side.

Right Side A-pillar

10/14/2008 9

Page 68

Locate and install NEW Weather Strip, Pt # Strip 55397454AB.

Remove Release tape and Pressurize Weather Strip Firmly in

contact with Header Sheet Metal to smooth out adhesive tape

and butyl, starting at the ends and working toward the center.

A small Roller or firm finger pressure should be used to insure

the Weather Strip tape is adhered completely from side to

side, THIS STEP IS CRITICAL

Gently pull weather strip rearward at mold line shown on page

9 and insert a 3 mm x 3 mm square piece of butyl .

10/14/2008 10

Page 69

Mold Line

3 mm x 3 mm butyl pad Shown

behind Weather Strip ABOVE

TWO SIDED TAPE and centered

over mold line

Inboard

Right Side A-pillar

10/14/2008 11

Header Seal Installed

Page 70

JK -B Pillar-

Water Leak Repair

9/4/2008 1

Page 71

*Please note:

This package addresses water leaks that come from

inside the vehicle when the door is closed.

This package does not address water

that drips into the Vehicle when the

door is open.

This is a normal condition!

9/4/2008 2

Page 72

5

4

6

1

2

1.Windshield header seal

3

2.Windshield to cowl seal

3.Front door weatherseal

4.B pillar mucket

Outside View

5.Hard top seal

6.Center freedom panel seal

9/4/2008 3

Page 73

Note Seal Shown with sealer skips allows water

behind seal. This requires the need for additional

Butyl to be placed to fill in these voids

Hard Top Seal at Center

W/Strip Repair -Try this step Prior to Replacement

9/4/2008 4

Page 74

Hard Top Seal at Center

Hard Top Seal at Center

Inspect the entire seal length side to side

Note Seal Shown gapping to roof

allows water behind seal. This

requires the seal to be replaced

to ensure it is firmly attached to the hard

top.

If tape is not firmly attached

replace the seal.

9/4/2008 5

Page 75

Hard Top Weather Strip

Remove Hard Top Weather Strip from Hard Top and clean

up / remove all traces of old Tape and Butyl from painted

surfaces before reinstallation of new weather strip.

Clean Seal Surface with: 3M General Purpose Adhesive

Cleaner or Kent Products Acrysol, (if available) and allow to

dry completely.

Weather Strip Removal & Butyl Clean Up

9/4/2008 6

Page 76

Hard Top Weather Strip

Alcohol wipe the clean painted surfaces, And Allow Alcohol

to dry completely before insallation of new weather strip.

Locate & install NEW Weather Strip, Pt # 55397058AI (2 DR)

or 55397046AF (4 DR). Place seal tight against roof / without

gaps as shown on page 5. Remove Release tape & Pressurize

Weather Strip Firmly in contact with Roof to smooth out

adhesive tape, Make sure adhesive tape is FIRMLY

PRESSURIZED against the roof panel while maintaining a zero

gap condition from side to side. A small Roller or firm finger

pressure should be used to insure the Weather Strip tape is

adhered completely side to side, THIS STEP IS CRITICAL

9/4/2008 7

Page 77

B- Pillar Weather Strip

Remove B - Pillar Mucket Weather Strip from body and

clean up / remove all traces of old Tape and Butyl from

painted surfaces before reinstallation of butyl bead and

new weather strip. Clean Seal Surface with: 3M General

Purpose Adhesive Cleaner or Kent Products Acrysol, (if

available) and allow to dry completely.

PAGE / S 9 & 11 Show the RIGHT SIDE B–PILLAR &

PAGE 12 SHOWS THE LEFT SIDE, THESE REWORKS

MUST BE DONE ON BOTH SIDES OF THE TRUCK

Mucket Removal, Clean Up, Butyl & Mucket

install and Mucket drain hole and Dam rework

9/4/2008 8

Page 78

Add a 4 mm diameter bead of Butyl 68027813AA

Add a 4 mm diameter bead of Butyl 68027813AA

as shown to fill in sheet metal gaps.

as shown to fill in sheet metal gaps.

Top of Right B – Pillar With Mucket Seal removed

Top of Right B – Pillar With Mucket Seal removed

9/4/2008 9

Page 79

B- Pillar Weather Strip

Vehicles built After July 1, 2008 will have the drain hole

& foam already installed.

The steps on the next page show how to add the drain

hole & foam dam.

If B-Pillar weather strip needs to be replaced order the

following part numbers:

55395708AC – RT Side

55395709AC – LT Side

9/4/2008 10

Page 80

Note Single hole paper punch used to add Drain Hole

Hole Shown

located at the

rearward /

lowest position

possible

9/4/2008 11

Front

Right B – Pillar ALL VIEWS

Page 81

Foam Tape must be adhered to the front portion

of the drain cup as shown to act as a dam

Left B – Pillar TOP VIEW

9/4/2008 12

Page 82

JK –Half Doors-

Water Leak Repair

9/4/2008 1

Page 83

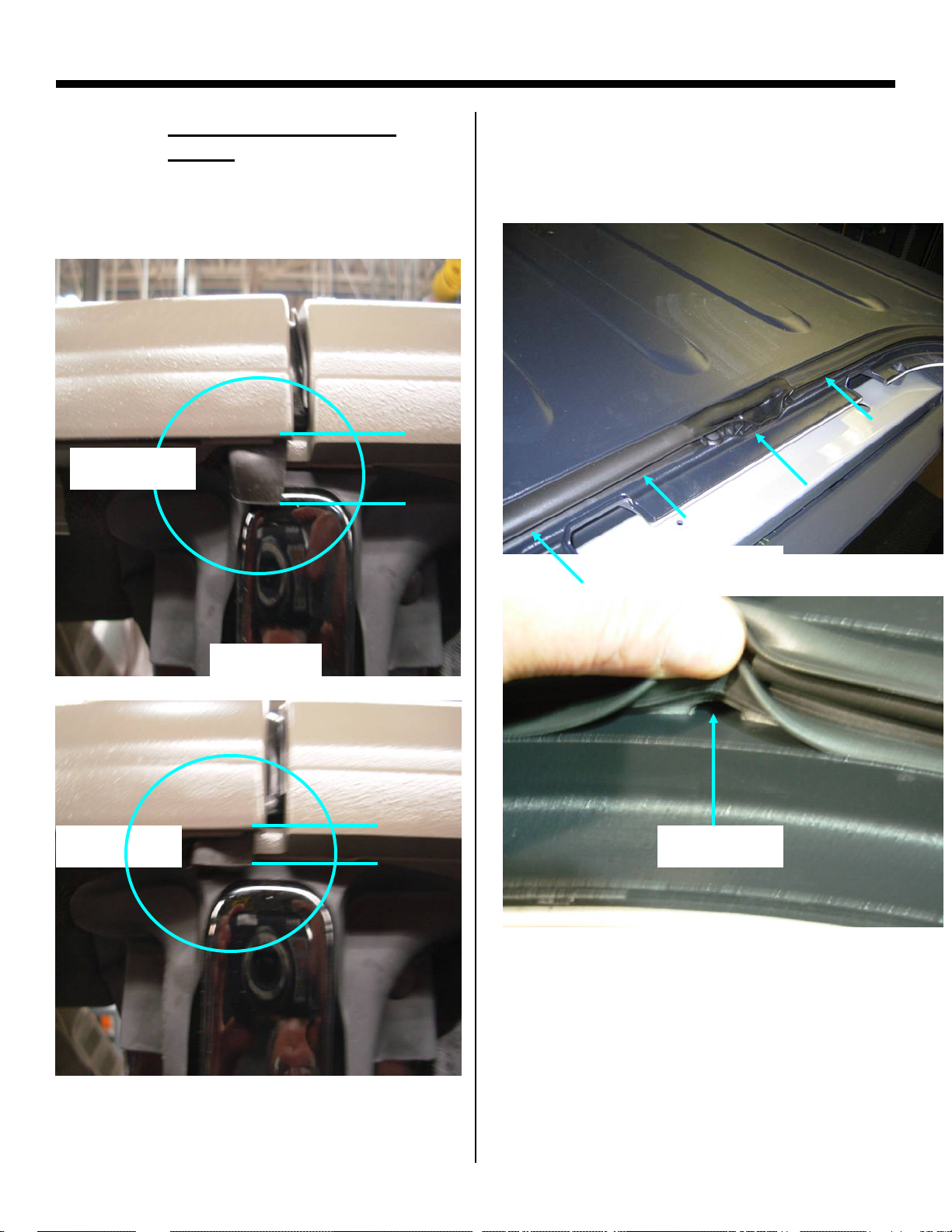

Measuring of Door Posts For Proper Preload

1. Lay Door on Flat Clean Surface.

2. Measure Posts.

3. Use Heat Gun to Heat up Posts as shown

on page 3.

4. Slide Pipe over Posts and Bend to Correct

Dimension as shown on

page 3.

Set this dimension as shown to the upper edge

of each peg to the dimensions shown on page 3

9/4/2008 2

Page 84

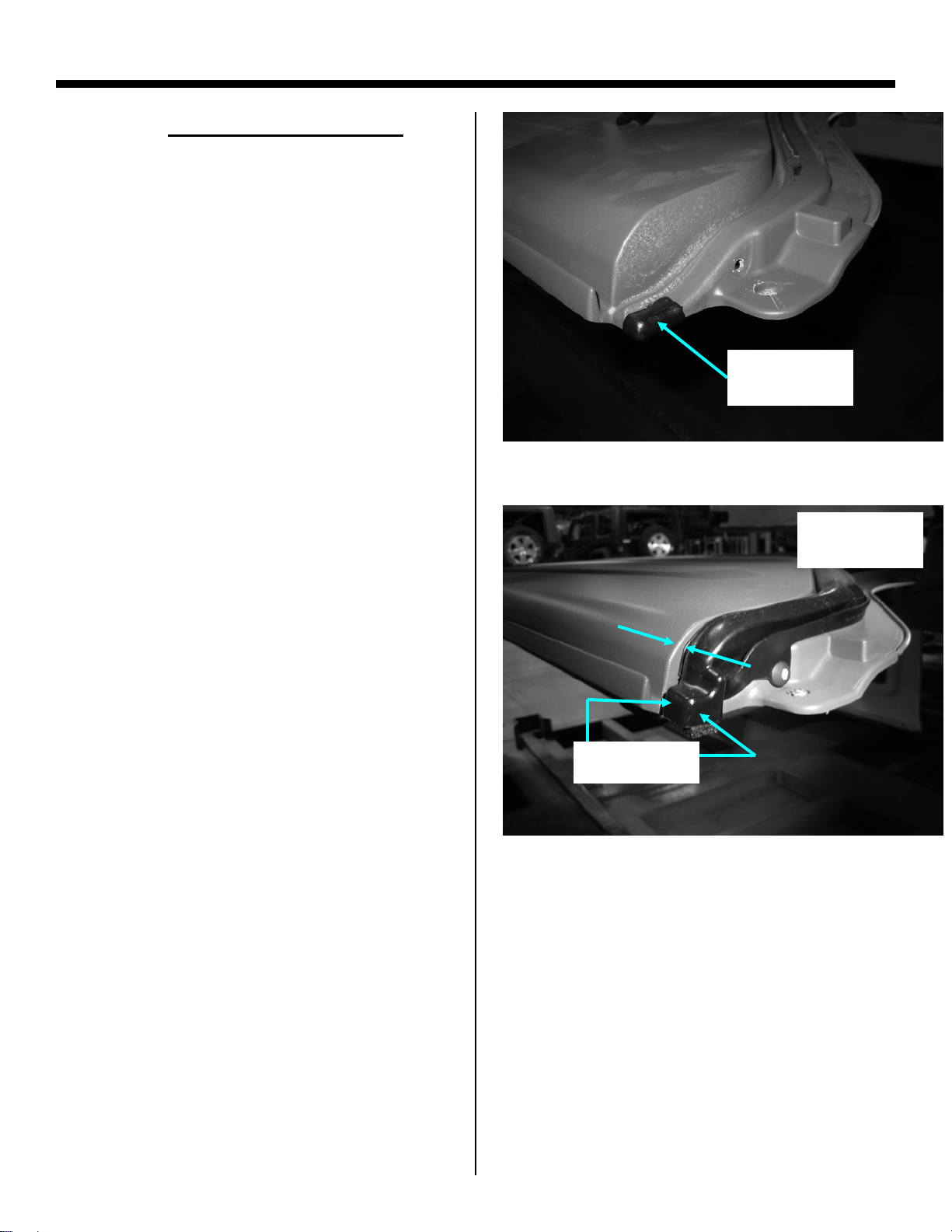

Heat Post: Caution too much heat will melt

Door, Maintain 12 inches for 2 Min. Max

Once heated Slide Pipe Over Post and Bend Post to

Correct Dimension

Front Door Post Dimensions (R & L)

Front Post 46.0mm

Rear Post 37.0mm

Rear Door Post Dimensions (R & L)

Front Post 30.0mm

Rear Post 40.0mm

9/4/2008 3

Note: Dimensions are from flat surface to the top of post.

Page 85

Add 4 mm diameter bead 68027813AA Butyl

Between Door Seal and door as shown on Page 5.

Front Door Upper “A” Pillar Corner

9/4/2008 4

Page 86

Add 4mm Diameter Butyl bead 6 inches

forward, and 6 inches rearward as shown

in RED

s

e

h

c

n

I

6

s

e

ch

n

I

6

Door “A” Pillar Corner

Close up view of area circled on page 4

Front of Door

9/4/2008 5

Page 87

Make Sure Seals Are Installed Correctly

Seal is not seated in channel

Correct

9/4/2008 6

Page 88

MUCKET

68003655AB KIT DOOR RAIL SEAL

4DR JK

B-PILLAR FOAM

B-PILLAR MUCKET FOAM

A-PILLAR FOAM

A-PILLAR FRONT

FOAM

C-PILLAR FOAM

9/4/2008 7

Page 89

MUCKET

68003645AB KIT DOOR RAIL SEAL

2DR JK

A-PILLAR FOAM

A-PILLAR FRONT

FOAM

B-PILLAR FOAM

9/4/2008 8

Page 90

JK – Soft Top Water

Leak Repair Tips

10/14/2008 1

Page 91

Header Seal Cup Folded under

10/14/2008 2

Correct

Page 92

Proper Quarter Window Installation

Incorrect – Retainer Not Rolled into Door Rail

Correct

10/14/2008 3

Page 93

Half Door, Side Curtain, or Rear Window Zipper Leaks

Can Be repaired by using Beeswax or Snow Seal as a

sealant.

10/14/2008 4

Water Seeping Through Zipper

Tape or Zipper Teeth

Page 94

MUCKET

68003655AB KIT DOOR RAIL SEAL

4DR JK

B-PILLAR FOAM

B-PILLAR MUCKET FOAM

A-PILLAR FOAM

A-PILLAR FRONT

FOAM

C-PILLAR FOAM

10/14/2008 5

Page 95

MUCKET

68003645AB KIT DOOR RAIL SEAL

2DR JK

A-PILLAR FOAM

A-PILLAR FRONT

FOAM

B-PILLAR FOAM

10/14/2008 6

Page 96

JK Water Leak Foam Repair Kit – Supplemental Information

P/N 68026937AA

23-041-07 Soft Top – Water Leak at Upper A-Pillar, Door Seal to Door Rail Interface

23-001-07 Modular Hard Top Freedom Panel Water Leaks

Foam Kit includes the following foam pieces:

Foam to be installed

on right Freedom

Panel as per Fig. 6.

Both pieces to be

installed on Freedom

Panels as per Fig. 4,

one on the left panel

and one on the right

Both pieces to be

installed on Freedom

Panels as per Fig. 5,

one on the left panel

and one on the right

Foam to be installed

on Freedom Panels as

per Fig. 7, one on the

left panel and one on

the right

Foam to be installed

on Windshield Header

Seal as per Fig. 3

All four pieces (two

right and two left) to

be installed on

Freedom Panels as per

Fig. 4, one left and

one right to be

installed on door rails

as per Fig. 1 & 2

Foam to be installed

on right Freedom

Panel as per Fig. 8.

Page 1 of 5

Page 97

Figure 1 – Rough Position of Foam on Right

Door Rail. Reference location 1 on both left

and right sides of vehicle.

(1) – Door frame rail foam

(2) – New black foam (Red highlighted

foam). One piece left handed and one piece

right handed. Loose fit to door frame rail.

(3) – Plastic door frame rail - Leading

end/edge removed from vehicle to affect

repair.

Reference – Foam Locations on Vehicle (Soft Tops)

1

Figure 2 – Black Foam Fully Seated

– Ensure that header seal is not

Note

pinched under foam when re-installing

the door rail.

Page 2 of 5

Page 98

C

Left Side

View

Right Side

View

A1

B2

Reference – Foam Locations on Vehicle (Hard Tops)

B1

Top View

A1

B1

A2

Front of Vehicle

A2

B2

D

Rear of Vehicle

Page 3 of 5

Page 99

(3)

(2)

Figure 3 – Windshield Header Seal Molded

Detail (Upper A-Pillar shown without tops)

Reference Locations A1 & A2

(1)

1 - Dark Gray Foam at End of Header Seal - Left Side of

Windshield Frame shown.

2 - Windshield Header Seal

3 - Windshield Frame - Upper A-Pillar - Left Side

(3)

(1)

(1)

(2)

(1)

(2)

Figure 4 – Rear of left Freedom Panel shown. Figure 5 – Front of left Freedom Panel Figure 6 – Rear of right Freedom Panel shown.

Reference locations B1 & B2. shown. Reference locations A1 & A2. Reference location D.

(1) – Blue highlighted foam (1) - Orange highlighted foam (1) – Dark green highlighted foam

(2) – 2-way freedom panel locator (2) - Red highlighted foam

(3) - Red highlighted foam

Page 4 of 5

Page 100

N

(1)

(1)

ew Seal

Figure 7 – Front of left Freedom Panel showing Figure 8 – Front of right freedom panel showing

one additional foam, required only on vehicles one additional foam, required on vehicles built

built prior to 3/01/07. Reference locations A1 prior to 3/27/07, unless a new seal was installed

& A2. as shown by photos on side. Reference location C.

(1) – Turquoise highlighted foam (1) – Purple highlighted foam

Old Seal

Page 5 of 5

Loading...

Loading...