ARBUS 500

English Version / MI_USA - 0307

EDITION No. 05/2012

Code: 508739

WARNING!

Read Operator's Manual before setting up, operating, or maintaining sprayer.

Failure to follow safety precautions in this manual an in labels on the product

could result in serious injury or death to the operator or bystanders.

Keep manual nearby for futher reference. If manual is demaged or illegible,

contact your Jacto dealer or Jacto at the address below for a replacement.

Operator’s Manual

Jacto Inc.

19217 SW 119th Ave

Tualatin, Oregon 97062

Tel.: (503) 885-8723 Fax: (800) 511-3671

Toll free: (800) 522-8610

E-mail: info@jacto.com

Home page: www.jacto.com

TABLE OF CONTENTS

Introduction

Precautions ................................................................... Chapter 1

Assembly ...................................................................... Chapter 2

Technical Specifications ............................................... Chapter 3

Operations and Adjustments......................................... Chapter 4

Maintenance ................................................................ Chapter 5

Warranty ....................................................................... Chapter 6

ARBUS 500

3

INTRODUCTION

ARBUS 500

JACTO has an ongoing concern for the safe

and effective use of chemicals.

This concern is indispensable, for the use of

chemicals has become a necessary practice

for obtaining a more productive and more

economical harvest.

However, the improper application of

chemicals is harmful to the human being, the

environment and the cultivations themselves.

JACTO's aim is to prepare and guide the farmer

on the proper use of the farm equipment

manufactured by JACTO.

ATTENTION!

The Jacto Arbus 500 equipment has been developed for the exclusive use of

spraying chemicals.

Therefore, read carefully and understand

thor-oughly this manual before operating this

sprayer and keep it always at hand when

handling this sprayer for quick consultation in

case you are not quite sure of some operation

or adjustment.

If you still have questions, contact your Jacto

dealer.

CHAPTER 1 - PRECAUTIONS

The Jacto Arbus 500 sprayer manual refers only to instructions for use and maintenance of parts and components made by Jacto.

Read it carefully and follow the recommendations contained herein. In case of

doubt, please contact JACTO.

> Identification Plate

The machine model, serial number and

lot (manufacturing month and year) are

printed on the machine identification plate.

This information is important to enable

us to keep records on modifications, if

any, made to the material employed and

construction characteristics of the machine.

When ordering replacement parts and

maintenance services, it is essential to

inform the machine model, number and lot

in order to get an expeditious and efficient

response.

JACTO is the registered trademark of MÁQUINAS AGRÍCOLAS JACTO S.A.

MÁQUINAS AGRÍCOLAS JACTO S.A. implements a policy towards the ongoing

enhancement of its products. Therefore, it reserves the right to change its products without prior notice and without incurring in any obligation whatsoever

in connection with such changes.

5

CHAPTER 1 Precautions

Safety manual ....................................................................... 09

ARBUS 500

Safety decals

General safety recommendations

Safety in transportation ........................................................ 17

Safety for unloading the equipment

Cautions during component assembly

Warning when using and filling the tank

Safety when applying chemicals

Safety on maintenance

........................................................................ 11

.......................................... 14

..................................... 18

................................. 20

............................... 21

.......................................... 22

......................................................... 26

CHAPTER 1 - PRECAUTIONS

7

Safety manual

ARBUS 500

Chapter "Precautions" is intended to guide

the operator on the cautions to be taken

during the operation, maintenance and

storage of this equipment.

It is important to remind that this equipment

has been carefully developed to provide

optimum performance with cost savings,

and ease of operation and safety.

CHAPTER 1 - PRECAUTIONS

For that purpose, be always mindful of the

information contained in the instructions

manual. If doubts arise at any time, please

contact us.

The instructions in this manual may be

accompanied by symbols having the

following meanings:

ATTENTION: advises of

potential accident hazard

situations that require permanent

operator's attention.

NOTE: reminders or warnings.

OBSERVATION: advises of or

explains certain instructions/situations.

By disregarding the safety practices you are risking your life and the life of all people

around you.

9

ARBUS 500

> Operator’s and owner’s responsibilities

Safety manual

According to the provisions in Directive

NR31 – Directive on Safety and Health

in Farming Labor, the farm equipment

owner and operator shall contribute to the

safe application of chemicals and other

agro-chemicals, by observing the legal

determinations outlined below.

CHAPTER 1 - PRECAUTIONS

Operator´s responsibilities

• Comply with the determination regarding

safe manners for performing his/her

activities;

• Operate the equipment within the

operating limits and restrictions specified

in this manual;

• Read this manual and make sure that

all information and recommendations

have been understood before putting this

equipment in operation.

Owner responsibilities

• The equipment owner shall keep the

instructions manual at a place where

the operator can have free access to it

whenever necessary.

• Whenever dictated by the kind of

defensive to be sprayed, the employer has

the obligation of providing the operator

with the appropriate PPE – Personal

Protection Equipment, see that the PPE is

properly hygienized, train the employee

and enforce and inspect the use of the PPE.

• The owner shall replace or repair

components of the equipment whenever

such components exhibit defects hindering

the safe operation of the same.

• The owner or whoever in charge shall

take responsibility for qualification of the

equipment operators in order to guarantee

the safe operation thereof.

10

Safety decals

ARBUS 500

Safety and maintenance related decals have

been affixed all over the equipment indicating

any hazardous conditions that could cause

damages or accidents affecting the operator

or the equipment during operation.

ATTENTION: Lubrication point.

P/N: 276220

ATTENTION: Area

where the jack must

be placed to lift the

equipment.

Before operating your equipment, identify

all decals and by reading these pages make

sure that you have understood and are aware

of the meaning of each such symbol.

Keep them in good repair, clean and legible.

Re-plade them immediately in case of

damage by or-dering them through the part

numbers specified below.

CHAPTER 1 - PRECAUTIONS

WARNING: danger of

serious injuries. Do not

perform any action on

the PTO shaft with the

tractor PTO running.

P/N: 379057

P/N: 276238

P/N: 379040

P/N: 379230

ATTENTION: Risk of injuries. Keep away from

the sprayer when it is

running.

WARNING: Read the

instructions manual

before beginning

any action on the

machine.

WARNING: Read the

instructions manual

before beginning any

action on the machine.

P/N: 379248

WARNING: mandatory

use of protection mask.

P/N: 379115

11

ARBUS 500

Safety decals

WARNING: mandatory

use of ear protectors.

CHAPTER 1 - PRECAUTIONS

P/N: 379123

ATTENTION: Risk of

serious injuries. Keep

all protection devices

in its places.

WARNING: mandatory

use of protective clothing.

P/ N: 379131

ATTENTION: Maximum speed allowed

for the machine is 18.5

mph.

P/N: 379065

P/N: 379008

ATTENTION: Risk of

serious injuries. Do not

make any operation

on the PTO shaft if the

PTO is engaged.

Final test of equipment

P/N: 379214

P/N: 379222

P/N: 169128

WARNING: highway

transit of this machine is

prohibited.

Warning: Never actuate the packaging

washer valve unless

the bottle is properly placed over the

spraying nozzle.

12

P/ N: 013169

Safety decals

ARBUS 500

ATTENTION: Do not

get into the main tank

of the sprayer.

CHAPTER 1 - PRECAUTIONS

P/N: 380014

P/N: 379073

WARNING: Hand

washing water reservoir.

WARNING: Caution

when opening the main

reservoir cap.

ATTENTION: Nut torque table.

P/N: 379164

ATTENTION: Tire pressure table.

P/ N: 379172

Machine identification plate

P/N: 983932

P/N: 391631

DANGER: Keep

away from PTO

shaft when the

machine is running.

P/N: 039396

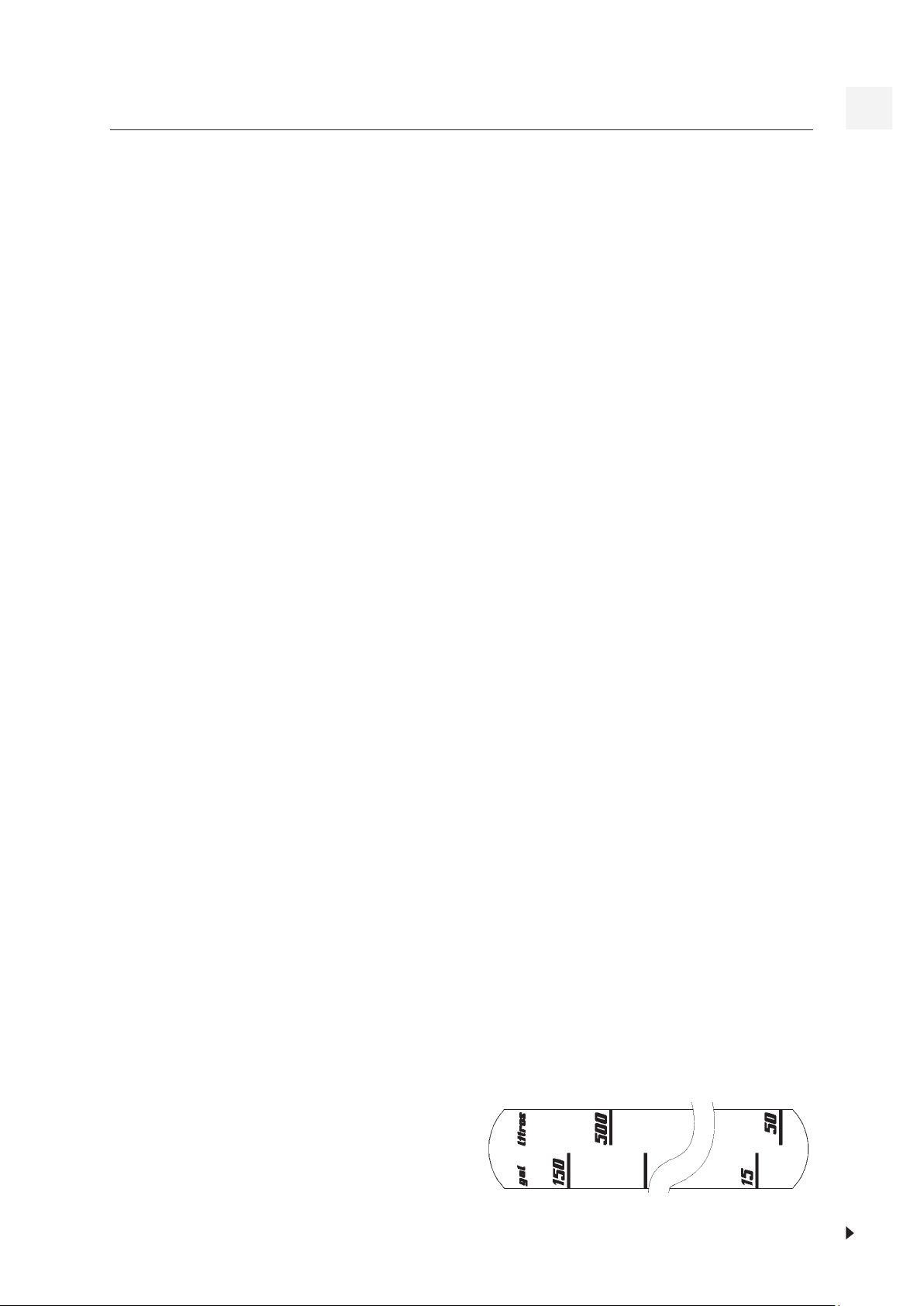

Level indicator of the main tank.

P/N: 090233

13

ARBUS 500

• Only skilled and qualified operator

and knowledgeable of the information

contained in the manuals accompanying

the product should operate the Jacto Arbus

500 sprayer;

• Before starting any operation, it is very

important to learn about all information

CHAPTER 1 - PRECAUTIONS

contain in this manual. In case of doubt,

refer to Jacto's technical assistance.

• Do not ingest alcoholic beverages,

tranquilizers or stimulating substances both

before and during work.

• During manipulation of the setup,

always use approved, recommended and

appropriate PPEs such as: long-sleeve

overalls, waterproof coat or apron, waterproof

gloves, waterproof broad brim hat, boots

and special protection masks provided with

filters suitable for each kind of product. In

case of doubts, read the chemical label or

contact the manufacturer of the same.

General safety recommendations

• When checking the machine components

that are in direct contact with the farm

chemicals, use approved PPEs and

according to the recommendation stated

on the product label.

• If the tractor is of the cab type and

provided with air cleaning system, clean

your footwear and remove contaminated

clothing. Keep the same outside the cab

within a properly sealed container.

• If recommended by the tractor

manufacturer, use ear protector.

• Use approved, recommended and suitable

breathing mask if the label on the chemical

requires such personal protection equipment.

• Redouble the precautions. Keep away

from places where obstacles exist such as

trees, stones, holes, erosion ditches, electric

network, etc.

14

General safety recommendations

ARBUS 500

• Use under adverse and not recommended

conditions can compromise the integrity of

the equipment and components, entailing

loss of warranty and disclaimer by the

manufacturer for any accident and the

resulting consequences.

• Avoid parking the equipment on slopes. If

necessary, place chocks under the wheels

when parking the equipment on upward or

downward slopes.

• Keep the ladder, platform and handrail

always clean; oils and greases can cause

accidents.

• Do not use the equipment if some critical

component needs to be repaired. Provide

for the repair before.

CHAPTER 1 - PRECAUTIONS

• This equipment can cause accidents if

used improperly or irresponsibly.

• Do not step on the machine while it is

moving.

15

ARBUS 500

General safety recommendations

∙Inordertopreventaccidentsusethe

correct speed suited to each type of

terrain or crop.

∙This equipment was designed and

manufactured to support operations

in the crop fields or internal roads of

the property within the speed limits

CHAPTER 1 - PRECAUTIONS

as recommended by Jacto (limit of up

to 18.5 mph for transportation on the

property internal roadways and up to

7.5 mph whilst spraying). The use of the

equipment over the abovementioned

speedlimitsisnotapprovedbyJacto.

∙Jacto does not recommend or

approvethe towingofthe sprayer by

vehicles, except tractors under the

abovementionedconditions.

∙Usage under adverse and not

recommended conditions may

compromise the integrity of the

equipmentanditscomponents,resulting

inthelossofwarrantyandexempting

the manufacturer from any accident and

its consequences.

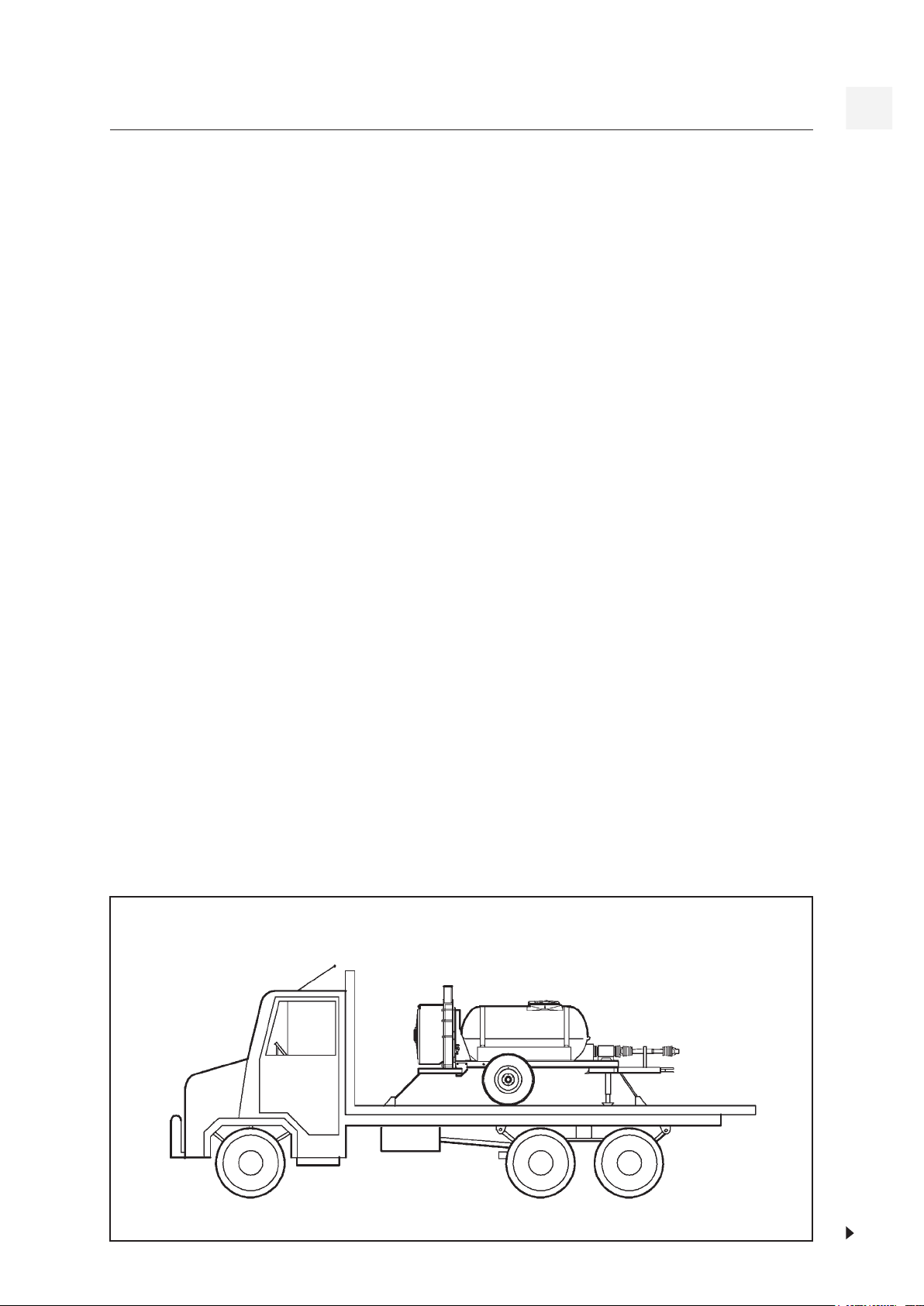

Formovementandtransportationthe

∙

useoftrucksorrampsisrecommended,

taking care for it to be fully fastened

to prevent accidents due to poor

positioning.

Under no hypothesis operate the

∙

equipmentwithoutitsprotectioncovers

or the protection cover on the drive

shaft.

16

General safety recommendations

> Transportation safety

ARBUS 500

• Before starting transportation, it is very

important that the path over which the

equipment will pass be carefully studies

and that the agencies regulating such method of transportation be consulted regarding the precautions and current legislation.

• All highways, roads, local roads, ways

and streets whose utilization characteristics are influenced by natural factors (climate, growth of tree without man's actions,

etc.) and construction (material employed,

height of bridges, nearness of electric networks, roadway width, etc.). Such characteristics shall be carefully evaluated prior to

transportation of the equipment.

• If in doubt, do not transport the equipment. Hire a company specialized in that

kind of service.

• Wash the equipment on the outside after its use. Even if it appears to be clean,

the ropes employed for fastening the equipment shall not be used again for binding

foodstuff; they may be contaminated and,

accordingly, contaminate such foodstuff.

• Make use of the PPEs when tying the

equipment. If necessary, make a combined

use of the mandatory PPEs for tying the

equipment and the mandatory PPEs for application of the chemicals. That combination will reduce the risks of contamination

during fastening of the equipment.

• Equipment fastening to the cart or truck

shall be performed by the tying points (see

figure below). Any tying carried out at random, while appearing to be safe and secure, is extremely dangerous and can cause

serious accidents. If in doubt, contact Jacto.

CHAPTER 1 - PRECAUTIONS

• Make sure that the chemical circuit has

been washed and that the chemical reservoir has been entirely drained after such

washing. Spill of setup leftovers, although

minimal, can endanger the life of people,

animals and cause serious damages to the

environment.

17

ARBUS 500

Safety for unloading the equipment

• Unloading shall take place at spots specifically created for unloading such type of

equipment. Do not improvise for unloading the equipment.

• Wear the PPEs during removal of the ropes fastening the equipment to the cart. If

the equipment is not new, make use of a

CHAPTER 1 - PRECAUTIONS

combination of the mandatory PPEs for unloading the equipment (e.g., safety boots,

gloves, hardhats, etc.) and mandatory PPEs

for chemical spraying (e.g., masks, gloves,

etc.) in order to reduce the risk of contamination and accidents.

• For unloading the equipment, use a tractor having the capability to carry out such

task. Selection of the tractor shall take into

account its drag capacity and spraying mechanism weight.

• Do not untie the mobile parts of the

equipment, for instance: PTO shaft, before

unloading the equipment down from the

truck or cart and position it on a safe place.

• After placing the equipment on a safe

place and far away from electric mainlines,

reset the jack to its rest position and uncouple the equipment from the tractor.

18

Safety for unloading the equipment

ATTENTION!

By disregarding the safety practices you are risking your own life and the life of

all people around you.

This manual contains important safety warnings. Read it carefully and be on

the alert to any possibility of personal accident. Keep all decals affixed to the

machine and replace the same if necessary.

ARBUS 500

• The improper handling by untrained people can give rise to serious or fatal accidents.

• Do not perform adaptations or improvisations; they compromise your equipment

and put your safety at risk.

• Do not allow children, aged people or

animals to stand close to the equipment

during use, maintenance or even with the

equipment stored.

• Keep hands, feet, loose clothing and long

hair away from moving parts.

• Before performing any kind of service,

adjustment or maintenance to your equipment, switch off the power take-off and

the tractor engine.

• If the equipment was used, even if it has

been washed and looks quite clean, wear

all PPEs recommended for handling the

chemical.

• Do not touch PTO shafts, belts, fans or

any other moving parts of the equipment

with the PTO coupled of the tractor diesel

engine running.

• When uncoupling the machine, hold it

on firm and level ground; if the equipment

is provided with parking brake, actuate the

same!

• Do not operate the pump without liquid.

• Do not allow the power take-off to ope-

rate in excess of 540 rpm.

• Keep the machine in perfect upkeep at

all times.

• Safety-related decals were applied across

the equipment to orient on the risk of damage or accident that may occur to the

operator or equipment.

• Request a JACTO representative during

the technical delivery of the equipment

for a proper assembly instructions, maintenance, warranty instructions to be carefuly

explained.

CHAPTER 1 - PRECAUTIONS

• Use of PTO shafts not provided with protection covering is strictly forbidden.

19

ARBUS 500

> Warning for adjusting and connecting PTO shaft to the tractor

Cautions during component assembly

• Refer to the tractor user manual before

performing this operation.

• Turn off the tractor diesel engine, apply

the parking brake and remove the starting

key from the contact keyhole before coupling the PTO shaft to the tractor PTO.

CHAPTER 1 - PRECAUTIONS

• Try to couple the PTO shaft to the tractor

PTO. If necessary to adjust the PTO shaft

length, use the PPEs specific to this operation such as: goggles, gloves, boots, etc.

• When coupling the PTO shaft to the tractor, make sure that the safety pin is securely

locked.

• Directions on how to properly adjust

the PTO shaft length will be described in

chapter 2 “ASSEMBLY” of this manual.

• After length adjustment, clean and lubricate the PTO shaft components. Wear safety gloves for this operation too.

• Never use a PTO shaft not fitted with

shroud.

• The PTO shaft will be adjusted to

its specific use on the Jacto PH 400

equipment. Use of the PTO shaft on any

other equipment is not recommended.

• Do not perform adaptations for

reutilization of the PTO shaft.

• Fasten the PTO shaft covering safety chain

to the tractor; that chain will prevent the

PTO shaft covering from turning together

with the PTO shaft.

• Before actuating the tractor PTO, fill the

main reservoir.

20

Warning when using and filling the tank

> Fresh water tank for hand wash

ARBUS 500

• The fresh water tank on this sprayer is for

washing hands only. Only use clean water

when filling this tank. The use of soap or

solutions are prohibited.

• Do not in any circumstances use the

water for drinking.

>13gallonswaterreservoir

∙ The filling instructions for this

reservoir are described in the chapter

“OPERATIONS AND ADJUSTMENTS”

in this manual. The cautions to be taken

when filling this reservoir are:

∙

Ensure that the vent, located on the clean

water reservoir’s cover is unobstructed before filling the tank with clean water. If this

vent is blocked then filling may be carried

out with the reservoir’s cover open.

• It’s extremely important to keep this tank

always full.

The water from this reservoir must be

∙

exclusively used for washing out the 132

gallons reservoir and in washing out the

containers that is mounted on the agricultural chemical doser.

∙

Do not use the water from this reservoir

for hand washing. Only the last phase of

the triple washing out of the containers

must be done with water from this reservoir.

CHAPTER 1 - PRECAUTIONS

>132-gallonsreservoir

There are two methods for supplying the

132-gallons water reservoir. The instructions for this operation are described in

chapter 4 “OPERATIONS AND ADJUSTMENTS” of this manual. Following are the

precautions to be taken when supplying

this reservoir:

• During the 132-gallons reservoir supply

operation, it is extremely important that all

those engaged in the operation be using

the specified PPEs. It is very important to

read the label of the chemical being used

in the application. You will find on that label several information on the product and

precautions to be adopted, etc.

∙

Avoid perform the spraying with this reservoir empty.

• The setup residue remaining inside the

supply hose shall be collected with a bucket and returned to the reservoir which

the mixture was prepared in. Do not let

this residue to drop on the ground.

• Do not contaminate water springs. Supply of the sprayer shall be carried out at

places designed for that purpose.

• Avoid capturing water from sources such

as rivers, lakes, dams, creeks, etc.

• By following these recommendations,

you will be preserving the environment.

• Before beginning to supply the 132-gallons

reservoir, make sure that the reservoir drain

valve is shut.

21

ARBUS 500

Safety when applying chemicals

1 • READ the sprayer instructions manual.

For an efficient spraying operation, it is

necessary to know the sprayer employed in

detail. Only thus will we prevent wasting

chemical or improper use of the equipment,

and the desired result will be achieved.

2 • Proper SETTING of the sprayer is a sim-

ple operation. Only with the sprayer pro-

CHAPTER 1 - PRECAUTIONS

perly set will the best results be achieved.

3 • USE approved, recommended and sui-

table protection equipment (PPEs). During

handling, setup of the mixture or spraying,

use all protection equipment recommended by the chemical manufacturer.

After the spraying operation, take a shower

and change clothing. The used clothing

shall be immediately washed and segregated from the regular use clothing to eliminate the chemical residue. In case of contact with chemicals, wash the affected part

with running water for at least 15 minutes.

Remember: most contamination cases

occur at the time of setup of the mixture,

where the chemical is still concentrated,

and gets in contact with the hands.

If the manufacturer of the product to be

used recommends using a breather mask

during application, use it!

4 • KEEP the sprayer in perfect condition:

Make sure that no leaks exist. If detected,

eliminate the same! Leaks not only represent

chemical waste but also uneven application

and contamination of the environment.

5 • USE the appropriate nozzle: There is

an appropriate nozzle for each chemical

to be applied. Climate conditions will also

influence nozzle selection. The mixture

volume varies from one chemical to

another one. The chemical manufacturer

should be consulted for the optimum

nozzle option.

22

Do not enter with or keep inside the

tractor cab the personal protection equipment (PPEs) used during handling or

setup of the mixture in order not to contaminate the place. When inside the tractor cab during operation of the machine

and/or spraying operation, use only an

ear protector. If noticing that contamination has occurred (if feeling chemical

smell) caused by carelessness in working

with the door open or letting contaminated materials coming in (e.g.: PPEs), use

immediately an approved and suitable

breathing mask and contact Jacto's Technical Assistance;

Safety when applying chemicals

ARBUS 500

6 • DO NOT clear nozzles, vales or tubing

with your mouth: Use protection gloves

for this operation. Any spraying equipment

contains chemical residue.

Never let sprayer parts contact your mouth;

this is the fastest means of contamination.

If need arises to clear the nozzles, one

may also employ a nylon bristle brush

(toothbrush).

7 • DO NOT contaminate water sources:

The spraying mechanism refill shall be

performed at places designed for that

purpose or by means of appropriate

refilling vehicles (trucks, carts, etc.).

Avoid capturing water from sources

such as rivers, lakes, dams, creeks, etc.

with the aid of the sprayer return system.

PRESERVE THE ENVIRONMENT!

CHAPTER 1 - PRECAUTIONS

8 • DO NOT eat, drink or smoke: when

handling the mixture or during application

of the chemical, keep foodstuff far away

from the treated areas.

9 • KEEP children away from the

sprayed areas. Remove children, domestic

animals and unprotected people from the

treated areas. Do not allow children or

other persons not necessary for the services

to remain in the chemical handling and

application areas.

10 • APPLY the recommended dosages:

The dosages recommended by the

manufacturers shall be followed. Any

change to the dosage or calculation error

may bring about serious consequences to

the cultivation or the environment. Do not

use chemicals in cultivations which the

same have not been recommended for.

23

ARBUS 500

11 • DO NOT spray with strong winds

blowing over the area: Excess wind can

cause many problems. It will prevent the

chemical from reaching its target, causing

a poor distribution of chemical over the

cultivation; it can also carry the sprayed

mixture to water springs, wild animals and

the entire environment. Do not spray if

CHAPTER 1 - PRECAUTIONS

the wind velocity is higher than 6 mph .

Do not spray in the absence of winds. Such

a situation can cause a thermal reversal.

A good application can be obtained with

winds blowing at 2 to 4 mph velocity,

temperature from between 44 and 86°F

and relative air humidity over 55%. Do not

spray against the direction of the wind or

during the day warmest hours.

Safety when applying chemicals

12 • WASH the packaging before disposing

the same. When preparing the mixture,

wash the used packaging for about 30

seconds.

13 • TO NOT reuse empty packaging;

Even after several washing operations,

chemical packaging still retain residue. Do

not burn empty packaging material. After

washing, render the same unusable (pierce

the packaging bottom) and store it at a

safe place until the same are picked up ad

recycled.

14 • NEVER fill the sprayer to the top. By

doing so, you will prevent the mixture from

overflowing and possible contamination of

the operator and the environment. When

supplying the reservoir, do it up to the

maximum limit indicated in its graduated

scale.

24

Safety when applying chemicals

ARBUS 500

15 • When CARRYING chemicals: Never

carry them close to foodstuff or animal

feed. Never buy packaging exhibiting leaks.

Never buy or use chemicals past their shelf

life. Never carry chemicals inside the cab. If

an accident occurs causing chemical spill,

take steps towards preventing the chemical

from running into lakes or rivers. Notify the

authorities and the chemical manufacturer.

16 • STORING THE CHEMICAL: Build a

brickwork storehouse for chemicals.

• Line the floor with waterproof material.

Do not rest the product piles on the floor

or against walls. Use a footboard. Keep at

the place a drum with sand to absorb leaks,

if any. Install faucet and shower outside the

storehouse for the chemical appliers.

CHAPTER 1 - PRECAUTIONS

17 • SYMPTOMS of intoxication:

unconsciousness, anxiety, convulsions,

weakness, headache, indisposition,

dizziness, blurred vision, qualms of nausea,

vomits, belly ache, diarrhea, urine with

different color and consistency; eye, nose

and throat irritation, cough and tears.

18 • FIRST aid: if the victim vomits, let him/

her stay sitting. Never serve any alcoholic

beverage or milk to intoxicated (poisoned)

persons. Keep the victim calm and in a

comfortable position. Find the chemical

label. Call a doctor.

25

ARBUS 500

Safety on maintenance

• Awareness of and compliance with the

recommendations contained in this manual will reduce the maintenance costs and

extend the service life of the equipment.

• The maintenance services shall be carried

out by qualified and skilled professionals.

Even if the equipment has been washed,

it will be necessary to wear the following

CHAPTER 1 - PRECAUTIONS

PPEs: long-sleeve overalls, waterproof coat

or apron, waterproof gloves, goggles and

boots and special protection masks provided with appropriate filters.

• Use original parts, for they warrant a perfect operation of the equipment.

• Maintenance services shall be performed

with the equipment coupled to the tractor,

with the tractor wheels chocked and the

diesel engine and tractor PTO shut down.

• Do not make improvisations nor use inappropriate tools during maintenance to the

equipment.

• Lubricating oil filters and oils shall be

checked from time to time and changed

whenever necessary or recommended.

• Every maintenance service on hydraulic

tubing or hoses shall be performed after

de-pressurization of the circuit. Redouble

your warning during this kind of maintenance.

• The identification of spots exhibiting possible leaks shall be made with paper, never with the hands.

• With the equipment coupled to the tractor and the PTO, be careful and keep away

from the moving parts of the equipment;

these must be provided with their respective protections. In case of doubt, call the

authorized technical assistance.

• In case that no possibility exists of providing maintenance service to the equipment with the diesel engine shut down and

outside sheds, keep the shed doors and

windows wide open to allow continuous

circulation of air. Internal combustion engines running within closed environments

cause toxic gases and can asphyxiate the

operator within a few minutes.

• Performance of cleaning, lubrication and

maintenance services with the machine

running is forbidden, unless such running

condition is indispensable for the performance of such operations, in which case

special protection and signaling steps shall

be taken against occupational accidents.

• Welding services on bars, chassis or other

metal parts of the equipment may only be

performed after removal of the tractor battery cables and after draining and washing

of the chemical reservoir.

• Keep the machine decals in perfect repair at all times. They contain important

notices and recommendations.

• The removable protectors shall only be

removed for cleaning, lubrication and repair or adjustment operations. Once the

service is completed, they shall be put

back.

• The component lubrication work shall

be carried by a skilled, qualified and authorized individual. Such procedure involves a number of risks such as slipping,

contamination, etc. During the procedure,

use of gloves, goggles, boots provided with

antiskid sole is recommended. If the equipment has been used, use also approved

and appropriate breather mask.

• Do not enter in the 132–gallons reservoir.

If necessary, call the specialized technical

assistance.

26

CHAPTER 2 Assembly

Choosing the tractor ............................................................. 03

Hitching the sprayer to the tractor ....................................... 04

ARBUS 500

CHAPTER 2 - ASSEMBLY

1

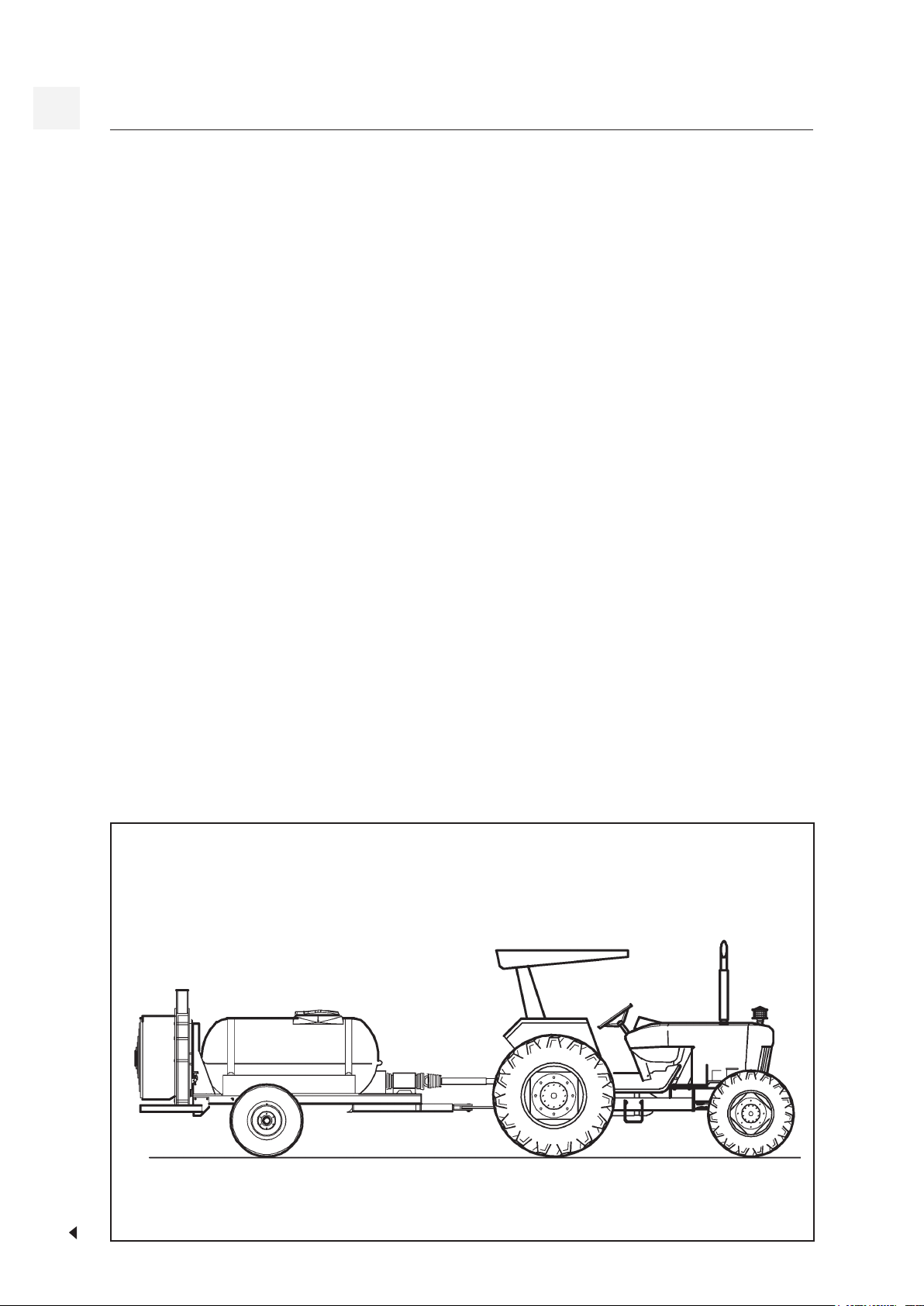

Choosing the tractor

ARBUS 500

The different working standards encountered by agricultural equipment leads us to

comply with the following criteria when

choosing a tractor for products of Jacto Arbus 500 and Arbus 500 Grape sprayers.

• Check the weight of the machine (lb) on

the identification plate of the product.

• Check the capacity (in gallons) of the backup reservoir.

> Choosing the tractor considering the power consumption

• The tractor should have power (HP) at least 90% higher than the power required to run

the sprayer.

Ex.: Power required by the sprayer = 8.1 HP

Example:

Empty machine weight = 768.80 lb

Reservoir capacity = 151.90 + 13.20 + 3.96

= 169.07 gallons

Total cower consumption = 8.1 HP

CHAPTER 2 - ASSEMBLY

Tractor recomended: Minimum tractor nominal power = 15.4 HP

> Choosing the tractor according to the lift capacity of the hydraulic system

• Choose tractors whose gross mass is, at least, equal to the sum of the empty weight of the

machine plus the weight equivalent to the capacity of the reservoir.

Example: Empty machine weight = 762.80 lb

Reservoir capacity = 169.07 gallons (approximately 1,410.96 lb)

Gross Machine Mass = 2,173.76 lb

Recommendedtractor:grossmassequalorgreaterthan2,173.76lb.

ATTENTION!

The tractor recomended in this case should have minimum power of 15.4 HP.

The recommended tractor should, in this case, at least have 2,173.76 lb gross

mass.

The above values are used as an orientation. The correct values must be obtained using real data of your equipment.

3

ARBUS 500

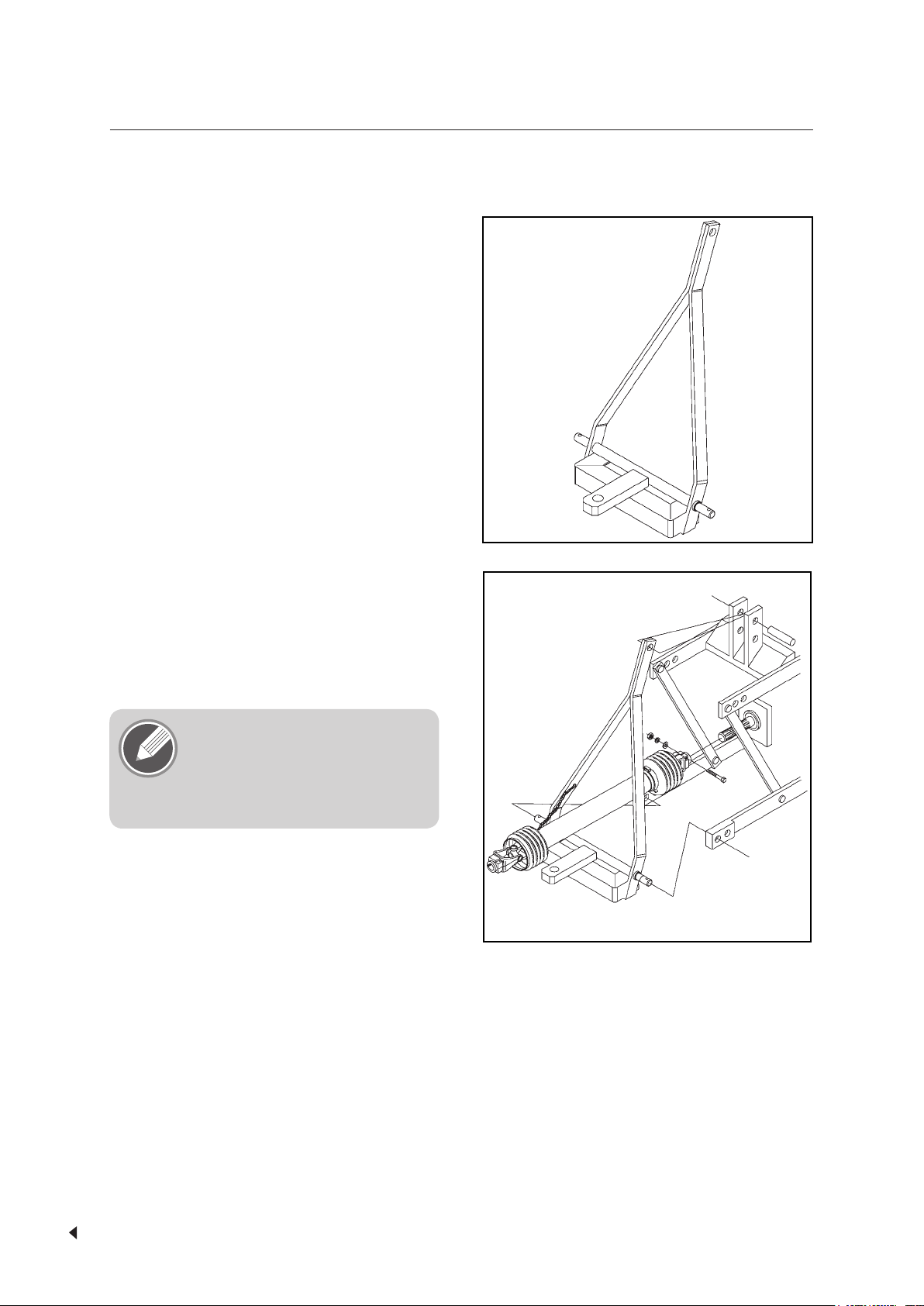

> Agrale 4100 and 4120 tractors

Hitching the sprayer to the tractor

• If the tractor does not have an adequate

drawbar, it is necessary to install the hitch

as shown below. And it is also necessary

hitch for Agrale 4100

and 4120 tractors

to connect the speed-reducing box to the

PTO, so that the pump does not work at a

CHAPTER 2 - ASSEMBLY

rotation over than 540 rpm.

• Install the hitch on the 3-point system

of the tractor, so that the PTO works on

its center.

PTO and the 3-point

system of the Agrale 4100

and 4120 tractors

NOTE :

The pump rotation must not

exceed 540 rpm.

4

Hitching the sprayer to the tractor

> Adjusting the PTO shaft male and female tubes

• Position the tractor until its rear tire gets

close to the sprayer’s tongue.

• Connect the PTO shaft.

ARBUS 500

BOMBA

+/-

1.96in

+/-

1.96in

TPD

75º

• Adjust the male and female tubes lengths

(recommended overlap: 1.96 in).

ATTENTION!

When maneuvering, disengage

the PTO and keep the tire from

touching the sprayer’s tongue,

otherwise this will damage the

sprayer’s transmission.

NOTE:

CHAPTER 2 - ASSEMBLY

Before cutting the PTO shaft

tubes, check for all the possibilities of adjustment on both

tractor’s drawbar and sprayer’s

tongue. Make sure the hitch pin

is mounted with cotter pin.

5

ARBUS 500

Hitching the sprayer to the tractor

• Hitch the sprayer to the tractor (figures A and B).

OBSERVATION:

If the sprayer is assembled with

CHAPTER 2 - ASSEMBLY

tracking axle, there must be

a space between the sprayer

head and the PTO shaft to

allow the sprayer to work normally (fig. - C). Then, lock the

hydraulic lift lever (fig. - D).

TRACKING AXLE

A

ATTENTION!

The improper hitch of the

sprayer with tracking axle to the

tractor, can cause damages to

the equipment.

FIXED AXLE

B

C

6

HEIGHT ADJUSTMENT

D

Hitching the sprayer to the tractor

> Adjusting the drawbar

ARBUS 500

Maximum

(static)

load

in lift

Hole

1

Distance between

the PTO and the

hitch point

14 in 1,003.10 lb

2 10 in 1,300.72 lb

A

2

• Fit the drawbar pin in the proper hole

(1 or 2) to vary the distance between the

PTO and the hitch point (figure A).

CHAPTER 2 - ASSEMBLY

NOTE:

For heavy load, the hole no. 2 is

recommended (figure A).

1

ATTENTION!

The figures shown in above table were obtained on a 63 HP

tractor.

For explanation in detail, please consult the operator’s manual of your tractor..

> Adjusting the sprayer height and the tractor’s drawbar

• Adjusting the sprayer height.

B

• Set the tractor's drawbar so as to allow

the sprayer to work on level after being

hitched (see figure B).

• Invert the drawbar to vary the height of

the hitch point (see figure C).

C

7

ARBUS 500

>ConventionalPTOshaft

• Adjust the drawbar length in relation to

the PTO as shown in the figure below.

IDEAL CONNECTION

Hitching the sprayer to the tractor

A

short

B

long

CHAPTER 2 - ASSEMBLY

• Distance A = B or as close as possible.

Ex.: If A = 15.74 in, then B should be somewhere between 13.77 and 17.71 in.

NOTE:

In order to know what is the

load in kilogram put on the drawbars of tractors trailing Arbus line sprayers, just add the

sprayer weight to the tank capacity and multiply the total by

0.12.

drawbar

hitch

NOTE:

hitch

The bigger hole on the hitch

must always be on the lower

position.

bigger hole

8

CHAPTER 3 Technical Specifications

Presentation – Arbus 500 ....................................................... 03

Technical specifications ........................................................ 04

ARBUS 500

CHAPTER 3 - TECHNICAL SPECIFICATIONS

1

Equipment presentation

ARBUS 500

13

12

11

10

3

1

2

4

9

8

5

7

6

CHAPTER 3 - TECHNICAL SPECIFICATIONS

1 - Hitch

2 - Jack

3 - Pump

4 - Fan lock

5 - Level indicator

6 - Belts tension

7 - Nozzle branch

8 - Tank

9 - Lever of the package washer

10 - Tank for washing the circuit

11 - Gauge

12 - Chemical control

13 - PTO Shaft

3

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model ..........................................ARBUS 500 / ARBUS 500 WITH HITCH 4100

Weight

Empty machine weight ........................................................................................ 727 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Height .................................................................................................................... 46 in

Axle .................................................................................................................. adjustable

Track width

Minimum ............................................................................................................... 35 in

Máximum ..........................................................................................................47. 50 i n

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

4

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 16

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................... 175/70 R13 GPS2

Pressure ........................................................................................................... 32/33 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 1,580

3

Air volume without deflector (ft

/h) 494,405.3

Air volume with deflector (ft3/h) 494,405.3

Air speed without deflector (mph) 44.74

Air speed with deflector (mph) 35.41

POWER CONSUMPTION

(

Maximumworkingrotationat540rpm)

Component HP

Fan 2,6

Pump at 28 Kgf/cm

2

3,6

Total 6,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 727 LB.

5

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model ......................ARBUS 500 GRAPE / ARBUS 500 GRAPE WITH HITCH 4100

Weight

Empty machine weight ........................................................................................ 763 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Width (with deflector) .............................................................................................73 in

Height .................................................................................................................... 46 in

Axle .................................................................................................................. adjustable

Track width

Minimum ............................................................................................................... 35 in

Máximum ..........................................................................................................47. 50 i n

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

6

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 14

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................... 175/70 R13 GPS2

Pressure ........................................................................................................... 32/33 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 1,580

3

Air volume without deflector (ft

/h) 494,405.3

Air volume with deflector (ft3/h) 494,405.3

Air speed without deflector (mph) 44.74

Air speed with deflector (mph) 35.41

POWER CONSUMPTION

(Maximumworkingrotationat540rpm)

Component HP

Fan 2,6

Pump at 28 Kgf/cm

2

3,6

Total 6,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 727 LB.

7

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model ..............................................................................................ARBUS 500

Weight

Empty machine weight ........................................................................................ 727 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Height .................................................................................................................... 46 in

Axle .................................................................................................................. adjustable

Track width

Minimum ............................................................................................................... 35 in

Máximum ..........................................................................................................47. 50 i n

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

8

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 16

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................... 175/70 R13 GPS2

Pressure ........................................................................................................... 32/33 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 2,035

3

Air volume (ft

/h) 733,838.8

Air speed (mph) 50.95

POWER CONSUMPTION

(Maximumworkingrotationat540rpm)

Component HP

Fan

Pump at 28 Kgf/cm

2

4,6

3,6

Total 8,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 727 LB.

9

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model .................................................................................. ARBUS 500 GRAPE

Weight

Empty machine weight ........................................................................................ 763 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Width (with deflector) .............................................................................................73 in

Height .................................................................................................................... 46 in

Axle .................................................................................................................. adjustable

Track width

Minimum ............................................................................................................... 35 in

Máximum ..........................................................................................................47. 50 i n

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

10

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 14

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................... 175/70 R13 GPS2

Pressure ........................................................................................................... 32/33 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 2,035

3

Air volume with deflector (ft

Air speed with deflector (mph)

/h) 692,167.5

44.84

POWER CONSUMPTION

(Maximumworkingrotationat540rpm)

Component HP

Fan

Pump at 28 Kgf/cm

2

4,6

3,6

Total 8,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 727 LB.

11

ARBUS 500

Technical Specifications

Model .............................................ARBUS 500 / ARBUS 500 WITH HITCH 4100

Weight

Empty machine weight ........................................................................................ 763 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Height .................................................................................................................... 46 in

Axle ......................................................................................................................tracking

Track width ................................................................................................ 40 in

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

12

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 16

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................................... 7.35 -14

Pressure ............................................................................................................... 24/26 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 1,580

3

Air volume without deflector (ft

/h) 494,405.8

Air volume with deflector (ft3/h) 194,405,8

Air speed without deflector (mph) 44.74

Air speed with deflector (mph) 35.41

POWER CONSUMPTION

(Maximumworkingrotationat540rpm)

Component HP

Fan 2,6

Pump at 28 Kgf/cm

2

3,6

Total 6,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 763 LB.

13

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model ......................ARBUS 500 GRAPE / ARBUS 500 GRAPE WITH HITCH 4100

Weight

Empty machine weight ........................................................................................ 763 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Width (with deflector) .............................................................................................73 in

Height .................................................................................................................... 46 in

Axle ......................................................................................................................tracking

Track width ................................................................................................ 40 in

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

14

Gauge

Model ...................................................................................................... Glycerin-filled

Control

Model ..................................................................................................................... VAR

Technical Specifications

ARBUS 500

Filter

Model .............................................................................................................. FVS-100

Mesh .......................................................................................................................... 60

Nozzles

Models .............................................................................................................JA-2/JA-4

Material ..............................................................................................................ceramic

Working pressure ...................................................................................... 60 to 300 PSI

Flow rate ..................................................................... JA-4=0.50 gpm / JA-2= 0,26 gpm

Nozzle quantity .......................................................................................................... 14

Nozzle holder ......................................................................................................... bijet

Tires

Type .................................................................................................................... 7.35 -14

Pressure

............................................................................................................... 24/26 PSI

Recommendedworkingvelocity ................................................................ 1.5 to 4 mph

CHAPTER 3 - TECHNICAL SPECIFICATIONS

Filler unit (optional)

Model .................................................................................................................. EJ-250

FAN FUNCTIONAL FEATURES

Specifications ARBUS 500

Fan diameter (in) 21.65

Rotation (rpm) 1,580

3

Air volume without deflector (ft

/h) 494,405.8

Air volume with deflector (ft3/h) 194,405,8

Air speed without deflector (mph) 44.74

Air speed with deflector (mph) 35.41

POWER CONSUMPTION

(

Maximumworkingrotationat540rpm)

Component HP

Fan 2,6

Pump at 28 Kgf/cm

2

3,6

Total 6,2

ATTENTION!

THE TRACTOR MUST BE CHOSEN CONSIDERING THE NOMINAL POWER

INDICATED IN THE TABLE ABOVE, AS WELL AS ITS WEIGHTWHICH MUST

NOT BE LESS THAN 763 LB.

15

CHAPTER 3 - TECHNICAL SPECIFICATIONS

ARBUS 500

Technical Specifications

Model ..............................................................................................ARBUS 500

Weight

Empty machine weight ........................................................................................ 763 lb

Dimensions

Total lenght .......................................................................................................... 110 in

Width (without deflector) ........................................................................................ 43 in

Width (with deflector) .............................................................................................72 in

Height .................................................................................................................... 46 in

Axle ......................................................................................................................tracking

Track width ................................................................................................ 40 in

Ground clearance.................................................................................................. 9.36 in

Main tank

Material ....................................................................................................... Poliethylene

Capacity ........................................................................................................152 gallons

Clean water tank

Material ....................................................................................................... Poliethylene

Capacity ...........................................................................................................4 gallons

Tank for washing the chemical circuit

Material ....................................................................................................... Poliethylene

Capacity ......................................................................................................... 13 gallons

Levelgauge ................................................................ Level indicator with graduated scale

Agitation ............................................................................................................Hydraulic

Pump

Model ............................................................................................................... JP-50 V

Working rotation ...............................................................................................540 rpm

Flow rate ....................................................................................................... 13.20 gpm

Power needed ................................................................................3,6 HP at 28 Kgf/cm

Piston quantity .............................................................................................................3

2

16

Gauge

Model ...................................................................................................... Glycerin-filled

Control