Page 1

SUN ODYSSEY 49

OWNER'S MANUAL

CROISIERE

Page 2

Page 3

5.1.2 ISO 10 240

CONTENTS

INTRODUCTION

HISTORY OF UPDATES

Chapter 1............................................................................................................................. Page 5

SPECIFICATIONS AND WARRANTY

Chapter 2 .......................................................................................................................... Page 13

SAFETY

Chapter 3 .......................................................................................................................... Page 25

HULL

Chapter 4 .......................................................................................................................... Page 33

DECK

Chapter 5 .......................................................................................................................... Page 43

RIGGING AND SAILS

Chapter 6 .......................................................................................................................... Page 65

ACCOMMODATIONS

Chapter 7 .......................................................................................................................... Page 75

PLUMBING

Chapter 8 .......................................................................................................................... Page 89

ELECTRIC SYSTEMS

Drawings at the end of the chapter

Chapter 9 .......................................................................................................................... Page 99

DIESEL ENGINE

Chapter 10........................................................................................................................Page 113

LAUNCHING

Chapter 11 ........................................................................................................................Page 117

WINTER STORAGE

PERSONAL NOTES

At the end of the manual

APPENDIX AND OPTIONAL EXTRAS

At the end of the manual

SUN ODYSSEY 49 Anglais

Update 06/2008

Index 7

Code: 981717 Total number of pages: 122

Page 4

5.1.3, 5.2 ISO 10 240

HISTORY OF UPDATES

• Index 0..................................................................................................................................1/12/2002

• Index 1.........................................................................Page 19, 72 ....................................1/12/2003

• Index 2.........................................................................Page 50, 56 ..................................20/09/2005

• Index 3............................................................ Page 6,60,62,66,68 ..................................13/04/2006

• Index 4.............................................................................Page 117 ........................................ 02/2007

• Index 5............................................................................Page 6,23 ........................................ 04/2007

• Index 6................................................................................. Page 6 ........................................05/2007

• Index 7...................................................... Page 53-77-83-85-102 ........................................ 06/2008

Page 5

1/122

5.1.3, 5.2 ISO 10 240

INTRODUCTION

We share a common passion for the sea: we, JEANNEAU as shipbuilders and you who want to live

your passion on the Seven Seas.

We are delighted to welcome you to the great family of JEANNEAU boat owners and we congratulate

you on it.

This manual was meant to help you to enjoy your boat comfortably and safely. It includes the boat

specifications, the equipment provided or installed, the systems and tips on her operation and

maintenance.

Read this manual carefully before you put out to sea so that you can make the most of her and avoid

any damage and any trouble. Get to know your boat before you sail.

We keep improving our boats as we want you to benefit from the technological developments, new

equipment or materials and our own experience. That is the reason why the specifications and

information given are not contractual, they may be modified without prior notice or up dates.

This owner's manual is designed in accordance with the ISO 10 240 standard requirements, it has a

general purpose and it may sometimes list some equipment or accessories or deal with some points or

questions that are not relevant to your own boat. In case of doubt refer to the inventory list you were

given when you bought your boat.

Our network of JEANNEAU authorized dealers will be at your disposal to help you get acquainted with

your boat and will be the most qualified to take care of her maintenance.

If this is your first boat or if you change to a new type of boat which you are not used to, get some

training in boat control and sailing to ensure your safety and comfort. Your dealer, your international

sailing association or your yacht club will be very happy to recommend local sailing schools or

professional instructors.

Even if everything has been provided for and designed for the safety of the boat and the safety of her

users, don't forget that sailing highly depends on the weather conditions, the sea condition, and that

only an experienced and very fit crew, handling a well-maintained boat can sail satisfactorily.

Page 6

2/122

5.1.3, 5.2 ISO 10 240

The sea and wind conditions that correspond to the design categories A, B or C are changeable and are

dependent on the hazards of unusually strong waves or gusty winds. Therefore total safety cannot be

guaranteed, even if your boat meets the requirements of a category.

The sea and the water are not the natural environment of Man and one has to respect their laws and

strength.

Adapt the use of your boat to her condition that wears out with time and use.

Any boat, however solid she may be, may be severely damaged if badly used. This is not compatible

with a secure navigation. Always adapt the speed and direction of your boat to the conditions of the sea.

The 'COLREG', an international regulation in order to prevent collision at sea, published by the

International Maritime Organization, specifies the steering and course regulations, the navigation lights

etc. throughout the world Make sure you know these regulations and you have on board a manual that

explains them.

In numerous countries, a licence, an authorization or a training course is requested. Make sure you have

this legal authorization before you use your boat.

Always use an experienced technician for the maintenance of your boat, the fitting of accessories and

the carrying out of small modifications. The written authorization of the builder or his legal

representative is compulsory for modifications that alter the specifications of the boat, in particular the

vertical layout of the grounds (putting up of a radar, modification of the mast, change of the engine etc.).

Always listen to the weather forecast before you put out to sea.

Make sure the sea and wind conditions will correspond to the category of your boat and you and your

crew are able to handle the boat in these conditions.

For the essential or optional equipment (engine, electronics etc.) refer to their respective manual

delivered with your boat.

Page 7

3/122

5.1.3, 5.2 ISO 10 240

The users of the boat are informed of the following:

- The entire crew must be trained properly.

- The boat shall not be loaded more with than the maximum load recommended by the builder, in

particular the total weight of the food supplies, of the different equipment that are not supplied by

the builder and of the persons on board. The weight of the boat shall be properly distributed.

- The water in the bilge shall be kept at its minimum.

- The stability is reduced when you add weight in the upper parts.

- In case of heavy weather, the hatches, lockers and doors shall be closed in order to minimize the

risk of water coming in.

- The stability may be reduced when you tow a boat or when you lift heavy weights with the davits

or the boom.

- Breakers are serious dangers to stability.

- If your boat is equipped with a liferaft, carefully read the instructions. In the boat there shall be all

the proper safety equipment (harness, flares, liferaft etc.) depending on the type of boat, the

country, the weather

- The crew must be familiar with the use of all the safety equipment and the emergency safety

procedures (MOB, towing etc.).

- Anyone on the deck shall wear a life jacket or a buoyancy aid. Please note that in some countries

it is compulsory to wear an homologated buoyancy aid permanently.

- A part of the data is shown on the builder's plate fixed to the boat. The explanation of these data

is given in the appropriate chapters of this manual.

Keep this manual in a safe place and hand it over to the new owner if you sell your boat.

Page 8

Page 9

5/122

5.1.3, 5.2 ISO 10 240

SPECIFICATIONS AND WARRANTY

YOU R BOAT

TERMS AND CONDITIONS OF WARRANTY

1

Page 10

6/122

5.1.3, 5.2 ISO 10 240

SPECIFICATIONS

L.O.A .................................................................................................................................................... 14,98 m/49’ 2’’

Length of hull....................................................................................................................................... 14,73 m/48’ 4’’

L.W.L..................................................................................................................................................... 12,90 m/42’ 4’’

Max. beam ...............................................................................................................................................4,49 m/14’ 9’’

Waterline beam .......................................................................................................................................3,80 m/12’ 6’’

Ballast weight Deep keel............................................................................................................... 3 750 kg/8 267 lbs

Draft Deep keel ........................................................................................................................................2,15 m/7’ 1’’

Ballast weight Shallow keel .......................................................................................................... 4 100 kg/9 039 lbs

Draft Shallow keel ....................................................................................................................................1,69 m/5’ 6’’

Ballast weight Performance.......................................................................................................... 3 640 kg/8 025 lbs

Draft Performance ...................................................................................................................................2,35 m/7’ 9’’

Light displacement - Deep keel............................................................................................... 12 650 kg/27 893 lbs

Light displacement - Shallow keel........................................................................................... 13 000 kg/28 665 lbs

Light displacement Performance ............................................................................................ 12 500 kg/27 558 lbs

Maximum load displacement - deep keel............................................................................... 17 650 kg/38 911 lbs

Maximum load displacement - shallow keel.......................................................................... 18 000 kg/39 683lbs

Displacement with maximum load Performance ................................................................. 17 500 kg/38 581 lbs

Maximum load recommended by the builder......................................................................... 5 000 kg/11 023 lbs

Including the mass of the persons who are authorized on board (75 kg/16 lbs per adult), the supplies, the

liquids that can be used (fresh water and fuel) in fixed completely full tanks, the additional loads, the optional

equipments, the liferaft and the scope for load.

Water tank capacity ...........................................................................................................................700 l/185 US gal

Fuel oil tank capacity...........................................................................................................................240 l/63 US gal

Refrigeration unit capacity .................................................................................................................230 l/61 US gal

Recommended engine power (diesel engine)................................................................... 67/100 HP (49/74 kW)

Recommended engine power (Version:Performance)..................................................................110 HP (81 kW)

Battery capacity.................................................................................................2 x 55 Amph +4 x 80 Amph (12 V)

Cabins.........................................................................................................................................................................3/4

Berths ..............................................................................................................................................6/8 (+ 2 in option)

Architect.................................................................................................. Philippe BRIAND, Jeanneau Design

SAILS CLASSICAL /JIB REEFER PERFORMANCE

CE Category 3 cabins 4 cabins

A 10 persons 10 persons

B 12 persons 12 persons

C 14 persons 14 persons

Mainsail Classical ............ 49,20m2/529.58 sq.ft ............. 55,00m2/592 sq.ft

Mainsail Jib reefer.................39m

2

/419.79 sq.ft

Genoa............................ 63,2,00m

2

/628.28 sq.ft .......... 64,80m2/697,5 sq.ft

Spinnaker .................... 141,10m

2

/1 518.79 sq.ft ...141,10m2/1 518.79 sq.ft

I .......................................................... 17 m/55’9"......................... 17 m/55’9"

J .......................................................5,68 m/18’7" ......................5,68 m/18’7"

P ...................................................15,78 m/51’8" .....................15,9 m/52’1"’

E........................................................ 5,6 m/18’4"......................5,70 m/18’8"

The sails are the main propulsion means of the SUN ODYSSEY 49.

Page 11

7/122

5.1.3, 5.2 ISO 10 240

Category A 'In the open sea'

This boat is designed for sailing in winds that may exceed force 8 on the Beaufort scale and in waves of

a significant height of 4 m and more, and the boat is to a large extent self-sufficient. Unusual conditions

such as hurricanes are excluded. You may meet with such conditions when you sail long crossings, for

instance across the oceans, or close to the shore, when you are not protected from the wind or waves

over several hundreds of nautical miles.

The significant height of a wave is the average height of the upper third of the waves, that approximately

corresponds to the height of a wave an experienced observer can assess. Some waves will be twice as

high as this value.

The conformity of the SUN ODYSSEY 49 model to the 97/25/CE directive is attested by Bureau

Veritas.

1

SPECIFICATIONS AND WARRANTY

Page 12

8/122

5.1.3, 5.2 ISO 10 240

YOUR BO AT

Version ..............................................................................

NAME OF THE BOAT ..............................................................................

NAME OF THE OWNER ..............................................................................

ADDRESS ..............................................................................

..............................................................................

..............................................................................

HULL NUMBER ..............................................................................

SERIAL NUMBER ..............................................................................

REGISTRATION NUMBER ..............................................................................

DELIVERY DATE ..............................................................................

DOOR KEY NUMBER ..............................................................................

MAKE OF ENGINE ..............................................................................

ENGINE SERIAL NUMBER ..............................................................................

ENGINE KEY NUMBER ..............................................................................

CHANTIERS JEANNEAU - BP 529 - 85505 LES HERBIERS cedex - FRANCE

Tel. (33) 02 51 64 20 20 - Fax (33) 02 51 67 37 65

Internet : http://www.jeanneau.com(fr).

Your agent

Page 13

9/122

5.7 ISO 10 240

TERMS AND CONDITIONS OF WARRANTY

Article 1

At the time of delivery of the boat the parties sign the Certificate of Delivery supplied by CHANTIERS

JEANNEAU for this purpose and this is equivalent to an agreement of compliance by the

purchaser-user.

The acceptance of delivery of the boat by the purchaser-user without reserve is equivalent to the

acceptance of the apparent condition of the boat in pursuance of the provisions of Section 1642 of the

Civil Code.

The terms of warranty are engaged only upon:

- the return to the After Sales Department in CHANTIERS JEANNEAU of the duly filled in

tear-away section of the Certificate of Delivery and of the Warranty Registration Card,

- the carrying out of the controls and service set forth by CHANTIERS JEANNEAU, being made

clear that the possible expenses of handling, transportation, parking, escorting which have been

incurred in the execution of the above mentioned directives are born exclusively by the

purchaser-user.

Article 2

The warranty is valid for a duration of 12 months from the date of delivery of the boat to the first

purchaser-user and it is strictly limited as the manufacturer chooses, to the replacement or free repair

of any part that has been found defective by the technical specialists of the latter and no compensation

whatsoever shall be paid in this respect.

As for components and accessories which visibly bear the trademark of another supplier, the warranty

shall be limited to the warranty provided by said supplier.

Article 3

With the exception of any prototype boats, RIGIFLEX boats, boats used for business purposes, or

boats specifically designed and/or equipped for racing, which have as a contractual warranty only that

indicated in article 2 above, the structure of the hull, the deck and the hull to deck joint and the hull to

keel joint is warranted against all manufacturing defects identified by the technical specialists of

CHANTIERS JEANNEAU, for a period of 5 years for monohull boats and 3 years for motor boats

and multihull boats.

However, any incident that affects the structure and does not result from a manufacturing defect

covered under the conditions of warranty, that would have resulted or not in the repair of the deck or

hull, shall effectively cancel all terms and conditions of warranty and without prejudice immediately.

The warranty period starts from the date of the first commissioning of the boat and at the latest from

the last day of the model year in which the boat was built, i.e. August 31 of the said year.

This warranty is strictly limited to the free repair of the manufacturing defects either in our yard or by

a repair shop or shipyard we authorized and no compensation whatsoever shall be paid in this respect.

1

SPECIFICATIONS AND WARRANTY

Page 14

10/122

Article 4

The following items are excluded from the terms of warranty as stated in articles 1 and 2 above:

- The transport and carriage expenses for the boat and parts as well as expenses and/or possible

losses resulting from the inability to use the boat and/or accessories, shall be born by the

purchaser,

- The deterioration or damages hereinafter listed as well as their consequences:

• Normal wear and tear,

• Cracks, cracking or fading of the gel coat,

• Damages resulting from:

- changes and modifications or repairs, even partial, performed in workshops different from

those authorized by our company,

- the failure to follow the recommended maintenance procedures stated in the owner's manual

delivered with the boat, or failure to follow the professional procedure,

- improper use, in particular careless use, or rash use, misuse or abnormal use,

- the participation in competitive events,

- acts of negligence as regards to the necessity to take the necessary measures of conservation,

- an accident or catastrophe such as explosion, fire, flood, storm, lightning, transport, riot,

theft, collision,

- unsuitable storage or transport conditions.

Article 5

The bringing into play of the warranty shall extend the period of warranty for a period equal to the one

that is necessary to carry out the repair work under the warranty, on the condition that the

afore-mentioned repair work requires an immobilization of the boat for minimum 7 consecutive days.

Article 6

In order to enjoy the above-specified warranty, the purchaser-user shall present the duly filled in

Certificate of Delivery and Warranty document each time a claim is presented and in a written, precise

and justified document he shall notify his authorized dealer-seller the defect or fault within 15 days from

the day when the defect or fault is discovered otherwise he will not enjoy this warranty.

The authorized dealer-seller shall inform the builder about the purchaser-user's claim within a period of

8 days from its receipt otherwise he shall have to bear the consequences resulting from his delay.

Page 15

11/122

Article 7

The authorized dealers, agents or sellers of CHANTIERS JEANNEAU do not have the authority to

alter the above warranty but, on their own account and in their own responsibility, they may grant

possible additional warranties which can bind the builder under no circumstances.

PRECAUTION BEFORE ANY REPAIR

Contact your seller who will give you the best advice and the suitable parts or materials for the repairs

you can carry out yourself.

It would be better to have important repairs of the hull or engine done by a professional. Your seller

can carry out these repairs or appoint a skilled person to carry them out.

DANGER

Contact your seller to find out what is possible for you to repair and above all what you must not do !

You could endanger your safety and lose your warranty.

1

SPECIFICATIONS AND WARRANTY

Page 16

Page 17

13/122

5.3, 5.5, 5.6 ISO 10 240

SAFETY

SAFETY EQUIPMENT

GAS SYSTEM SAFETY INSTRUCTIONS

FIGHT AGAINST FIRE

BILGE PUMP SYSTEM

EMERGENCY TILLER

2

Page 18

14/122

5.3.3 d) ISO 10 240

POSITION OF THE LIFERAFT

Extra liferaft in cockpit locker to portside.

NOTE: If over 10 persons on board:

2 liferafts compulsory.

Page 19

15/122

SAFETY EQUIPMENT

The liferaft should be placed in a cockpit locker.

LIFERAFT

ADVICE: Don't store anything below the floorboards.

RECOMMENDATION

When sailing, never padlock or lock the liferaft locker.

Before you sail to sea, carefully read the instructions indicated on the liferaft to launch it.

WARNING

- Before you sail, list the compulsory safety equipment.

- Don't exceed the number of persons indicated in the chapter 'Specifications'.

- When you don't take into account the number of persons, the total weight of the persons and

equipment shall never exceed the maximum load recommended by the manufacturer.

- Use the seats provided.

RECOMMENDATION

Close the deck hatches and fore portholes each time before each trip

(including the companionway hatch in heavy weather).

2

SAFETY

Page 20

16/122

5.3.3 d) ISO 10 240

GAS VALVE

NOTE: Same position for the other layouts.

Open valve Closed valve Position of the valves

WARNING

- Don't use a solution containing ammonia.

- Don't use a flame to detect leaks.

- Don't smoke, don't use a naked flame when you change the gas cylinder.

Page 21

17/122

GAS SYSTEM SAFETY INSTRUCTIONS

Type of cylinder: butane, service pressure 10 kg/cm2 or according to current standards of your country).

Close the valves on the system and on the cylinder when the appliances are not used.

Close the valves before you change cylinders and immediately in case of emergency.

Never leave unattended an appliance that is working.

Don't install or store flammable materials above or over the stove (curtains, papers, napkins etc.).

Make sure that the valves of the appliances are closed before you open the cylinder or hose valve.

In case you smell gas or find that the burners have gone out (although appliance models cut off automatically if

the flames go out), turn off the valves of the appliances. Do ventilate the boat in order to get rid of any residual

gas. Find the cause of the problem.

Regularly test the gas system in order to detect any gas leak.

Check all the connections using water and soap or detergent, closing the valves of the appliances and opening

the valve on the cylinder.

If you detect a leak, close the valve of the cylinder and repair before you use it again.

The appliances use the oxygen of the cabin and release combustible gases. Ventilate your boat when using

appliances.

Don't obstruct the air vents and at least leave the door open.

Don't use the oven or stove as back up heaters.

Lock the stove oven when being not used in order to avoid damaging the tubes when sailing.

Never obstruct the fast access to the components of the gas system.

Keep the taps of the empty cylinders turned off and the cylinders disconnected.

Keep the protection, lids, covers and taps in their places.

Store the empty and spare cylinders on the deck or in a locker with a ventilation to the open air.

Don't use the gas cylinder storage place to store other equipment. Only use the proper locker to store the gas

cylinders.

Regularly check and replace the rubber tubings that link the cylinder to one end of the circuit and the stove to

the other one, depending on the norms and regulations in force in your country.

Pay particular attention to keep in good condition the screw thread of the cylinder on which the regulator is.

Check the condition of the regulator every year and change it if necessary. Use regulators identical to the ones

that are fitted.

Have the repairs carried out by someone skilled.

2

SAFETY

Page 22

18/122

5.3.3 i) ISO 10 240, ISO 1869

LOCATION OF THE FIRE EXTINGUISHERS (ISO 9094-2)

Other locations are possible, the extinguishers shall be less than 5 m from all the berths.

An extinguisher shall be compulsorily set less than 2 m away from the extinguisher aperture.

An extinguisher or a fire blanket (ISO 1869) shall be set less than 2 m from any flame appliance.

An extinguisher shall be less than 1 m from the

steering station.

WARNING

The extinguishers are part of the compulsory

equipment.

Extinguisher, per unit, minimum capacity 5 A/34 B.

For the SUN ODYSSEY 49: 20 A/136 B

(4 extinguishers at least).

1. Against saloon settee

2. Against galley cupboard

3. In saloon cupboard

4. In aft cabin

5. In cockpit locker

6. Extinguisher aperture of the engine compartment

Emergency exits in case of fire

A. Deck hatch of the fore cabin

B. Companionway

NOTE: Same position for the other layouts.

Page 23

19/122

FIGHT AGAINST FIRE

The extinguishers must be within easy access and kept away from a possible fire source. The engine

compartment has an aperture that makes it possible to inject the extinguishing product inside without

opening the usual access hatches.

Instructions to follow in case of a fire in the engine compartment bilge:

- Stop the engine.

- Switch off power and stop fuel supply.

- Inject the extinguishing product through the aperture.

- Wait a minute.

- Open the access hatches and repair.

5.3.3 c); 5.3.3 k); 5.5.1 ISO 10 240

1. Fuel oil valve for generating set

2. Fuel oil valve for engine

NOTE: Same position for the other layouts.

2

SAFETY

Page 24

20/122

It is the owner's or the skipper's responsibility:

- To have the extinguishers checked in pursuance of the instructions given.

- To replace the extinguishers by others with an equal or a greater capacity if the extinguishers have

expired or are empty.

- To tell the crew:

• where the extinguishers are and how they work,

• where the release aperture is situated in the engine compartment,

• where the emergency exits are.

- Make sure the extinguishers can be reached easily when people are on board..

WARNING

Keep an extinguisher handy in case the fire should start again.

WARNING

Never:

- Obstruct the ways to the emergency exits.

- Obstruct the safety controls (fuel oil valves, gas valves, power switches).

- Block the extinguishers placed in shelves.

- Leave the boat unattended when a stove or heater is working.

- Use gas lamps in the boat.

- Alter the boat systems (electricity, gas or fuel oil).

- Fill up a tank or change a gas cylinder when an engine is running, a stove or heater is on.

- Smoke while handling fuels or gas.

Page 25

21/122

Keep the bilge clean. Regularly check whether there is fuel oil or gas vapour.

Use only compatible spare parts for the extinguishers. The parts shall have the same specifications or

be technically equivalent as to their resistance to fire.

Always fasten the curtains with their snap fasteners when the gas cooker is working.

Combustible products shall not be stored in the engine compartment. If you store non combustible

products in the engine compartment, they shall be fastened so that they cannot fall on the machine and

block the way. Exits other than the doors and panels of the main access which is equipped with

permanently fitted ladders must be identified with a symbol.

BILGE PUMP SYSTEM

ELECTRIC BILGE PUMP

You can energize the electric bilge pump from the electrical panel.

EMERGENCY BILGE PUMP

The manual bilge pump is in the cockpit.

The control arm of the pump shall be kept accessible whatever the circumstances.

WARNING

The CO2 extinguishers shall be used only to fight electrical fires.

Clear the area immediately after use in order to avoid suffocation.

Air before entering.

2

SAFETY

Page 26

22/122

5.3.3 h) ISO 10 240

EMERGENCY TILLER

Page 27

23/122

EMERGENCY TILLER

The emergency tiller is in an aft locker and shall be easy to get to.

To operate the tiller:

- Use a winch handle and unscrew the tiller cover situated at the back of the cockpit.

- Insert the tiller into the rudder stock and make sure it is fully secure in the square.

RECOMMENDATION

The emergency tiller is designed only to sail at a reduced speed in case of a wheel failure.

2

SAFETY

Page 28

Page 29

25/122

5.3, 5.4, 5.5 ISO 102 40

HULL

CONSTRUCTION

MAINTENANCE OF THE HULL

CARREENING

INSTRUCTIONS TO REPAIR THE GEL COAT

3

Page 30

Page 31

27/122

CONSTRUCTION

Your boat is built in GRP.

Stresses are distributed over the whole bottom surface by means of floors laminated integral with the

hull. The iron ballast is fastened to the hull with bolts and backing plates.

The deck is made of balsa wood sandwich with hard wood inserts where the deck fittings are to be

installed. The deck-to-hull joint is made of polyurethane filler and it is reinforced by the aluminium foot

strap fastening.

MAINTENANCE OF THE HULL

The materials and equipments of your boat have been selected because of their high quality and

performance and ease of maintenance. However you shall carry out a minimum maintenance in order

to protect your boat from outside attacks (salt, sun, electrolysis ...).

Preferably wash your boat on shore.

Use as few cleaning agents as possible.

Don't use aggressive detergent agents or solvents (read next page).

Don't discharge your cleaning product into the water.

PRECAUTION

We strongly advise you against using a pressure washer.

You shall not use hot water or steam.

3

HULL

Page 32

28/122

5.3.3 i) ISO 10 240

CARREENING

Wetted area: 45 m

2

- (These measurements are for 'light boat')

A. Water line

B. Deck line

Page 33

29/122

CARREENING

Refer to chapter 10 for launching instructions.

A (tin-free) anti-fouling painting every year will make it possible to avoid tedious and frequent

careening. An epoxy coat is recommended beforehand. You are reminded that any excessive sanding

before your antifouling paint attacks your gel coat and impairs its reliability.

ADVICE: Gently sand.

Your boat may regain her shine as new if polished. If a lasting and isolated problem arises, contact your

dealer.

The builder tested and approved a certain number of biodegradable cleaning and restoring products that

protect both material and environment.

3

HULL

Page 34

30/122

INSTRUCTIONS TO REPAIR THE GEL COAT

MIXING RATIO

Our products contain an accelerator, you just have to add the catalyst (a colourless liquid). The usual

ratio is 2 %.

The gel setting time (working time) is about 1/2 h, curing takes about 10 h.

APPLICATION

- To fill up a blister hole or a scratch, sand and clean the area with acetone.

- Prepare the necessary amount of gel coat, preferably on a glass plate.

- Apply the product with a spatula or a point and the layer shall be thick enough to make possible a

further sanding.

- In order to blend minor touching up on smooth surfaces, stick sellotape (or even better, a mylar

tape) on the freshly applied gel coat.

- Remove sellotape after curing.

- To get a highly shiny finish, sand with extra fine abrasive and water then polish.

WARNING

Please respect the following conditions to repair successfully:

-Dry weather.

- Temperature between 15° C and 25° C.

DANGER

The catalyst is a dangerous product:

- Keep it out of the reach of children.

- Avoid contact with skin and mucous membranes.

- In case of contact wash with soapy water and rinse thoroughly.

Page 35

31/122

STORAGE

To keep them properly, store the gel coat components in a cool dry and dark place.

Keep the components 6 months maximum.

Polyester products are flammable ; take the usual precautions.

CLEANING YOUR TOOLS

Clean all your tools with acetone.

3

HULL

Page 36

Page 37

33/122

5.3, 5.4, 5.5 ISO 10 240

DECK

NAVIGATION

MOORING

TOW ING

ANCHORING

MAINTENANCE OF THE DECK

STEERING GEAR

4

Page 38

34/122

5.3.1 ISO 10 240

DECK LAYOUT

A. Mooring cleats

R. Towing

L. Lifeline (fastened on the mooring

cleats or on the optional

chainplates)

E. Swimming ladder

Page 39

35/122

NAVIGATION

MOORING

A sufficient number of mooring lines suitably sized and suitable for the environment shall be on board

for mooring your boat.

- Always manoeuvre your boat using the engine.

- Make allowance for the current and wind when you handle your boat.

- Protect your boat to the highest degree with suitably sized fenders.

- Always keep the mooring ropes unfouled and stored away.

- Handle your boat at a reduced speed.

AFTER MOORING

- Protect the mooring lines against chafing with plastic sleeves.

- Make allowance for the variations in tides if need be.

TOW ING

TOWI NG B OA T

- Tow another boat at a reduced speed and as smoothly as you can.

- Pay particular attention when you throw or catch the towing rope (it may foul on the propeller).

NOTE: The stability may be reduced when you tow a boat.

TOWE D BO AT

- Keep steering your boat and see to it that you stay in the wake of the towing boat.

DANGER

Wear your life jacket.

In heavy weather, wear your safety harness and fasten yourself to the boat.

When sailing, close and lock the door or doors giving access to the transom extension

DANGER

Don't try to stop the boat with your foot, your hand or a boat hook.

4

DECK

Page 40

36/122

ANCHORING

As a rule, set the anchor in at least 3 times the depth of water.

ANCHORING

- Have your boat pointed into the wind and without speed.

- Pay out the chain while moving back slowly.

- Secure the cablet on the mooring cleat.

PRECAUTION

Before anchoring check the depth of water, the power of the current and the nature of the sea bed.

PRECAUTION

Keep the engine running during the anchoring operations to avoid discharging the batteries.

Page 41

37/122

HEAVING UP THE ANCHOR

- Lock the cable lifter snubber.

- Ensure the chain is properly set on the cable lifter.

- Slowly go near the anchor, using your engine (Don't use your windlass to winch the boat).

- Heave the anchor completely.

- Visually check the last meters till the anchor gets into contact with the davit.

- If you just change berth, check the position of the anchor on the stem fitting.

- When sailing, store the anchor in the chain locker.

- With an electric windlass, switch the power off as soon as the chain is fast.

STERN ANCHORING

Stern anchoring shall be performed with the engine declutched.

- Secure the required length of cablet on the mooring cleat.

- Pay out the anchor line slowly.

- Take care you don't damage the propeller or rudder.

MAINTENANCE

WARNING

Windlass operations are dangerous:

- Always keep the anchor line unfouled and free.

- Always proceed with care, using gloves and always wearing shoes.

RECOMMENDATION

After each trip rinse the windlass and mooring line with fresh water.

Refer to the manufacturer's instructions for windlass maintenance at the beginning or end of the

season.

4

DECK

Page 42

Page 43

39/122

MAINTENANCE OF THE DECK

Preferably wash your boat on shore.

Use as few cleaning agents as possible.

Don't use solvents or aggressive detergent agents (Refer to chapter 3 "Hull").

Don't discharge cleaning products into the sea.

Regularly brush the deck with a degreasing shampoo and fresh water.

ADVICE: Use only products similar to the ones that are included in the maintenance case you

have been delivered with your boat.

DECK FITTING

- Rinse thoroughly all your equipments with fresh water.

- Periodically lubricate turnbuckles, winches, tracks and travellers with water-rpellent grease.

- Thoroughly and frequently wash off the pulleys and sheaves with clear water.

- Clean and polish with "Rénovateur chrome et inox Jeanneau" (supplied in the maintenance case)

the stainless steel parts that may have small rusty spots or minor oxidation pits.

OUTSIDE TEAK WOOD/TEAK DECK

Regularly clean the woodworks with fresh water using a sponge (if need be add some gentle soap).

PLEXIGLAS

- Rinse plexiglas with fresh water.

- Brighten up with a soft rag soaked with liquid paraffin.

- Use polish paste to remove scratches.

PRECAUTION

Don't use solvent, alcohol, acetone on plexiglas.

4

DECK

Page 44

40/122

5.3.1 i) ISO 10 240

STEERING GEAR

Access to the steering cables through the aft cockpit locker

1. Steering wheel

2. Wheel column

3. 6 mm diameter steering cable

4. Cable adjustment

5. Emergency tiller

Page 45

41/122

STEERING GEAR

- Regularly check its tension.

- Don't tighten the steering cables excessively.

- Lubricate all the elements.

Maintain the nylon, ertalon or teflon bushes only with WD40.

4

DECK

Page 46

Page 47

43/122

5.3, 5.4, 5.5 ISO 10 240

RIGGING AND SAILS

STANDING RIGGING

RUNNING RIGGING

WINCHES

SAIL SETTING

SAILS

5

Page 48

44/122

5.3.2 ISO 10 240

STANDING RIGGING

Version: Classical

Version: Performance

Dy: Dyform

Designation

Num-

ber

Type Diam. (mm) Length (m)

1 Forestay 1 1*19 12 17,730

2 D1 2 1*19 12 6,090

3 V1 2 1*19 14 6,030

4 D2 2 1*19 8 5,840

5 V2/D3 2 1*19 12 10,860

6 Backstay 2 1*19 8 19,550

Designation

Num-

ber

Type Diam. (mm) Length (m)

1 Forestay 1 Dy 1*19 12 18,400

2 D1 2 Dy 1*19 12 6,090

3 V1 2 Dy 1*19 14 6,030

4 D2 2 Dy 1*19 8 5,840

5 V2/D3 2 Dy 1*19 12 10,860

6 Backstay 1 Dy 1*19 10 14,100

7 Briddle 2 1*19 8 6,050

Page 49

45/122

STANDING RIGGING

Your JEANNEAU dealer was responsible for stepping the mast of your boat.

To mast or unstep the mast yourself, proceed as follows:

BEFORE MAST INSTALLATION

- Protect the mast against possible chafing by the crane hook and cable.

- Tie down the shrouds and all the riggings to the base of the mast with a lashing long enough to

guide the mast heel when stepping the mast.

- Protect the spreader end fittings and the roller furler drum.

- Put a rope of about 1,50 m with an eye and thimble at both ends and covered with rags round the

mast. Place the rope under the second tier of spreaders. Link together both thimbles (that are ahead

of the mast) with a shackle large enough to receive the crane hook. Raise the whole till it is taut

under the spreader bases.

DURING MAST INSTALLATION

- Take the necessary steps to avoid damaging the mast head equipments.

- Use the backstay and lashing at the base of the mast to control the handling.

- Make sure the base of the mast integrally bears on its base plate.

DANGER

Before you lift the mast, make sure you have room that is clear enough

(Risk of electrocution when in contact or near electric cables).

5

RIGGING AND SAILS

Page 50

Page 51

47/122

AFTER MAST INSTALLATION

- Check the spreaders for tightening and position (always above the horizontal position).

- Lubricate all the bottle screws.

- Stretch tightly the rigging (Refer to chapter 5, "Cable adjustment").

- Reconnect the electric cables (Refer to chapter 8, "Electricity").

- Check the tightening of the fastening pins on the bottle screws. Protect the fastening pins with

adhesive tape.

- Put the boom back. Refit all ropes.

- Adjust the mast after a few trips.

5

RIGGING AND SAILS

Page 52

48/122

5.3.2 ISO 10 240

CLASSICAL MAST / MAST PERFORMANCE

1. Masthead lights

2. Backstay attachment

3. Spinnaker halyard sheave

4. Shroud attachment

5. Eye for spinnaker halyard block

6. Forestay attachment

7. Genoa halyard sheave

8. Flying baby stay fitting (optional extra)

9. Spi pole lift halyard sheave (genoa 2)

10. Lazy jack eye

11. Spreader attachment + Shroud attachment

12. Wire for radar

13. Engine navigation light/Deck searchlight

14. Spi pole traveller sheave

15. Genoa halyard exit

16. Spi halyard exit

17. Boom topping lift exit

18. Spi pole topping lift exit

19. Main halyard exit

20. Automatic reef eyes

21. Gooseneck

22. Spi pole rail

23. Step

24. Spi pole traveller adjustment cleat

25. Spi pole traveller control

26. Vang fittings

27. Mast step

28. Main topping lift cleat

29. Main sheet eye

Page 53

49/122

UNSTEPPING THE MAST

- Mark the rope locations with stickers.

- Proceed in reverse order compared with the mast installation.

CABLE ADJUSTMENT

A professional carried out the pre-adjustment and the cable tightening.

After a few sea trips, adjust the mast definitively to get a perfect widthwise rectitude of the mast.

To keep the mast straight lengthwise when sailing get a balanced adjustment when in port:

- Slightly pre-bend the mast lengthwise, the middle of the mast bending forwards and the head

backwards.

- The pole shall be about half the section of the profile.

BALANCE ADJUSTMENTS IN PORT

- Before you fasten the backstay, tighten the upper shrouds (because the boat is rigged with swept

back spreaders).

- Tighten hard the whole rigging (when sailing with 15 to 20 knots, the leeward rigging is slightly

slack and it is normal).

- When you get a perfect widthwise and lengthwise rectitude when in port, symetrically slacken the

aft lower shrouds (on portside and starboard) by 2 bottle screw turns.

- To end the lengthwise adjustment, tighten hard the backstay bottle screw till you get a fair stability

of the forestay when sailing with a wind at 15 to 20 knots.

Keep all the bottle screws adjusted and use the pins. Keep the adjustment throughout your sailing

season.

ADVICE: When you are not sailing, slacken the backstay.

5

RIGGING AND SAILS

Page 54

50/122

IN-MAST ROLLER FURLER

1 . Masthead light

2 . Backstay attachment

3 . Spinnaker halyard sheave

4 . Main furler swivel

5 . Shroud attachment

6 . Spinnaker halyard eye

7 . Forestay attachment

8 . Genoa halyard sheave

9 . Flying baby stay fitting (Optional extra)

10 . Sheave of spi pole topping lift (Genoa 2)

11 . Spreader attachment + Shroud attachment

12 . Mouse line for radar

13 . Engine navigation light / Deck searchlight

14 . Spi pole traveller sheave

15 . Spi halyard exit

16 . Genoa halyard exit

17 . Spi pole topping lift exit - Genoa 2 (Optional extra)

18 . Boom topping lift exit

19 . Main halyard exit

20 . Spi pole rail

21 . Main topping lift cleat

22 . Spi pole traveller adjustment cleat

23 . Spi pole eye

24 . Mast step

25 . Vang fittings

26 . Furling mechanism

27 . Gooseneck

28 . Main furling line eye

29 . Main sheet eye

30 . Boom rail

31 . Boom traveller

32 . Boom fitting

Page 55

51/122

MAINTENANCE

Before each trip, carefully inspect the mast from top to bottom.

Periodically check the rigging tightening and the lock nut or pin locking (you should check it for the

first time after a few days sailing in all types of weather).

Secure and lubricate the bottle screws with tallow, graphite grease or other.

Never lubricate the bottle screws with silicone.

Check the bottle screw tightening.

Inspect the bottle screws for possible wear (due to the chainplate friction if the rigging is slack).

Change any shroud or stay with severed wires or kinks.

Regularly check the chainplates and inside tie rods for condition.

ADVICE: Your JEANNEAU dealer can carry out all the maintenance operations.

DANGER

To hoist a crew member up to the top of the mast, make a bowline with the halyard directly on the

bosun's chair ring

(never use the halyard snap shackle or shackle).

Do not hoist a crew member when sailing in heavy weather.

5

RIGGING AND SAILS

Page 56

52/122

MAST FOOT

A. Genoa halyard

B. Main halyard

C. Main sheet

D. Kicker tackle - Mainsail

E. Foot tuning line - Mainsail

F. Furling line

G. Reef 1 (automatic) (Available)

H. Reef 2 (automatic) (Available)

I. Reef 3 (Classical) (Jib reefer)

L. Spinnaker halyard

M. Spinnaker boom topping lift

N. Spinnaker boom downhaul

P. Fore stay sail halyard

L

M

H

E

D

C

I

G

B

A

G

IF

A

B

C

M

D

E

H

L

N

TD

BD

P

OPTION

OPTION

OPTION

Page 57

53/122

RUNNING RIGGING

MAINTENANCE

Change any distorted or dented sheave. Inspect the pins of the sheaves at the top of the mast once a

year.

Regularly check the jam cleat jaws for condition.

Inspect the halyards for wear and condition.

Regularly clean the blocks (waste grease, corrosion spot).

Slightly lubricate the block pins.

Avoid untimely gybes in order to reduce the premature wear on the sheets and attachment points.

5

RIGGING AND SAILS

Page 58

54/122

RUNNING RIGGING FOR THE STARBOARD MAINSAIL

Version: Classical

Version: Performance

Rope designation

Num

ber

Type Colour

Diam.

(mm)

Length (m)

1 Traveller adjustment 2 FO Black 8 8

2 Kicking strap 1 FO Black 10 17

3 Foot tuning line 1 TS White/red 12 14

4 Reef 2 (automatic) 1 TS White/green 12 30

5 Lazy-jacks 2 FO Grey 6

Rope designation

Num

ber

Type Colour

Diam.

(mm)

Length (m)

1 Traveller adjustment 2 FO Black 8 8

2 Kicking strap 1 FO Black 10 17

3 Foot tuning line 1 Dy White/red 12 14

4 Reef 2 (automatic) 1 TS White/green 12 30

5 Lazy-jacks 2 FO Grey 6

TS: Simple braid FO: Halyard braid

Dy: Dyneema

Page 59

55/122

WINCHES

Avoid rope jamming during winch handling. Do not leave loose ropes on the winches but fasten them

on cleats.

Adjust the winches on receipt of your boat (rinse them regularly during the season). The winches should

rotate freely, they need overhaul as soon as it slightly seizes.

MAINTENANCE

RECOMMENDATION

Carry out the complete maintenance of the winches regularly

(before and during the sailing season).

- Remove the drums and clean them.

- Lubricate the drums with a film of white grease or Teflon to reduce the friction and fight against

corrosion (this type of grease is clean, non toxic and biodegradable).

WARNING

Refer to the manufacturer's instructions to remove the winches and put them back.

Improper refitting may result in accidents (e.g. kick of the crank handle).

5

RIGGING AND SAILS

Page 60

56/122

RUNNING RIGGING FOR THE PORT MAINSAIL

Version: Classical

Version: Performance

Rope designation

Num

ber

Type Colour

Diam.

(mm)

Length (m)

1 Traveller adjustment 2 FO Black 8 8

2 Boom topping lift 1 TS Grey 10 44

3 Reef 1 (automatic) 1 TS White/yellow 12 22

4

Reef 3 (optional

extra)

1 FO White/blue 12 27 + 1

5 Main sheet Red

6 Main halyard 1 FO Black 14 41

Rope designation

Num

ber

Type Colour

Diam.

(mm)

Length (m)

1 Traveller adjustment 2 FO Black 8 8

2 Boom topping lift 1 FO Grey 10 38

3 Reef 1 (automatic) 1 Dy White/yellow 12 25

4

Reef 3 (optional

extra)

1Dy White/blue 12 26

5 Main sheet 1 Dy Red 12 25

6Main halyard 1

Vec/

Dy

Black/red 12 44

TS: Simple braid Vec: Vectran

Dy: Dyneema FO: Halyard braid

Page 61

57/122

AUTOMATIC REEFING SYSTEM

When you reef down automatically, the mainsail halyard shall not be too loose, otherwise the reefing

blocks take up improper positions.

ADVICE: After you reefed down for the first time, mark the halyard at the level of the jammer

(with highlighter pen or sewn whipping) in order to shake out the halyard precisely during the

next handlings.

PRECAUTION

Once the reef pendants are hauled taut, the reef pendants shall never be less than twenty or so

centimeters.

5

RIGGING AND SAILS

Page 62

Page 63

59/122

SAIL SETTING

LAZY-BAG

- Spread out the lazy-bag on the deck.

- Slide the battens in and close the batten pockets.

- Hank on the lazy-bag until you have the front part about level with the gooseneck.

- Fasten the lazy-bag to the tack with the strap provided.

- Stretch the lazy-bag from the back before you fasten the lazy-jacks.

- Put the mainsail into the lazy-bag.

- Tighten up the starboard side.

ADVICE: Install the lazy-bag before the mainsail.

MAINSAIL

With the mainsail being on the deck:

- Screw the pins of the mast sliders for battens into their boxes.

- Slide in the battens through the leech.

- Screw the box cap until you get the required tension (the tightening screw shall not project beyond

the sail).

- Do not forget the small locking screw.

Put the mainsail into the lazy-bag.

- Set the boom ring in velcro about level with the clew.

- Fit the mainsail onto its slides, begin with the headboard and finish with the tack.

ADVICE: Weather permitting, hoist the mainsail gradually.

5

RIGGING AND SAILS

Page 64

60/122

RUNNING RIGGING FOR THE GENOA

Version: Classical

Version: Performance

Rope designation

Nu

mber

Type Colour

Diam.

(mm)

Length (m)

1 Genoa furler 1 FO White/blue 10 24

2 Traveller adjustment 2 FO Blue 8 12

3 Genoa sheet 2 FO Blue 14 7

4

Staysail sheet (optional

extra)

2FO 14

5 Genoa halyard 1 FO Blue 14 40

6 Staysail halyard = spinnaker boom topping lift

Rope designation

Nu

mber

Type Colour

Diam.

(mm)

Length (m)

1 Genoa furler 1 FO White/blue 10 24

2 Traveller adjustment 2 FO Blue 8 12

3 Genoa sheet 2 Dy Blue 12 22

4

Staysail sheet (optional

extra)

2FO 14

5 Genoa halyard 1 Dy Blue/Black 12 42

6 Staysail halyard = spinnaker boom topping lift

Dy: Dyneema FO: Halyard braid

Page 65

61/122

SAIL SETTING

FURLING GENOA

Before getting under way take advantage of a windless period of time and hoist the genoa.

Hand pre-roll the drum to set the furling line on it.

Pay attention to the drum winding direction: The sacrificial strip of the genoa shall be wrapped outside.

- Secure the head and halyard to the swivel. Secure the tack to the drum and sheets.

- Insert the bolt rope into the hole and hoist it and take care that you do not tear it.

- Have the halyard taut enough but hoist less taut than a sail on a normal stay. Hoist it until the

horizontal creases disappear (Adjust the tension of the luff after a few sea trips).

- Before you furl the genoa, remove the ring that is used to guide the bolt rope. Keep this ring in a

safe place and put it back before any handling (lowering etc.).

- Pull on the line from the cockpit to furl the genoa.

Never force it in case it seizes when you furl or unfurl the head sails. Make sure a halyard is not jammed

in the furler.

ADVICE: When you are not sailing, slacken the genoa halyard.

MAINTENANCE

- Regularly rinse the drum and swivel.

- Lubricate the bearings if recommended by the manufacturer.

- Unrig the sails if your boat is not to be used for long.

STAYSAIL

Install the flying baby stay then proceed as follows:

- Spread the staysail on the deck.

- Fasten the tack pig tail.

- Fasten the luff snap hooks and you will begin by the lower part.

- Fasten the sheets then hoist.

5

RIGGING AND SAILS

Page 66

62/122

RUNNING RIGGING FOR THE SPINNAKER

Rope designation

Num

ber

Type Colour

Diam.

(mm)

Length (m)

1 Spinnaker sheet 2 Dy Red 12 27

2 Spinnaker guy 2 Dy Green 12 27

3

Spinnaker boom

downhaul

1 FO Black/red 10 23

4

Spinnaker boom topping lift

1FO Grey 10 40

5 Spinnaker halyard 1 Dy Red 12 45

6

Spinnaker boom traveller adjusting line

1FO Grey 8 5

Dy: Dyneema FO: Halyard braid

Page 67

63/122

SAILS

How long a sail lasts mainly depends on its regular maintenance.

Piece of advice: At the end of the sailing season, and if possible before winter, leave your sails

to a specialist to have efficient maintenance and repairs.

When sailing, trim the sails properly in accordance with the stresses in order to reduce the harmful

strains on the fabric.

Avoid tears and wear: Use protective items against chafing on the the accessories with rough surfaces

(protective items for spreaders, stanchions etc.).

Between two sea trips, slacken the halyard (for the sails on furler) and the mainsail foot tuning line.

Have a sail maker's kit and a user's manual so that you may carry out the emergency repairs waiting for

the sailmaker's assistance.

CLEANING AND MAINTENANCE

Rinse the sails with fresh water from time to time and dry quickly in order to avoid mildew.

Avoid drying the sails to windward when on the mast (when the sails lift, the seams are worn, the sails

may be torn by the rigging).

To remove grease stains: Use trichlorethylene then immediately rinse with water.

SAIL STORAGE/FOLDING

Avoid storing a wet sail to prevent mildew from appearing.

Accordion fold the sail parallel to the foot, then roll it up to the bag dimensions.

PROTECTION

UV rays are harmful to polyester and nylon. If the sails remain on the mast, even for 24 h, protect them

with a cover or a protection fabric placed on the leech and foot of the furled sails.

Our agents' network offers you accessories that have been selected by the yard and are consistent with

your needs.

5

RIGGING AND SAILS

Page 68

Page 69

65/122

5.3, 5.4, 5.5 ISO 10 240

ACCOMMODATIONS

MAINTENANCE

FABRICS

6

Page 70

66/122

5.3.1 ISO 10 240

3 CABINS

2WASH ROOMS

4 CABINS

3 WASH ROOMS

4 CABINS

4WASH ROOMS

Page 71

67/122

MAINTENANCE

INSIDE

- Take advantage of the fine weather to take the settee and berth cushions out.

- Put the cushions vertically if you leave the boat for long.

- Use blinds to protect the inside of the boat against UV rays.

- Carefully remove all crumbs.

- Make sure the bilges are clean and dry.

INSIDE VARNISH

- Rinse the inside varnish with fresh water mixed with spot remover and shampoo.

- Polish the inside varnish with shammy leather.

RECOMMENDATION

Preferably wash your boat on shore.

Use as few cleaning agents as possible.

Don't discharge your cleaning product into the water.

6

ACCOMMODATIONS

Page 72

Page 73

69/122

FABRICS

ADVICE: Mark up each cover and foam when dismantling.

STAIN REMOVAL

- Remove as much stain as you can with a knife blade (from the edge towards the centre).

- Dab with a clean rag.

- Remove the stain with solvent on a clean rag. Never pour the solvent directly over the stain.

- Rub with a clean and dry rag.

- Brush the fabric against the grain.

- Use the vacuum cleaner when the fabric is dry.

PVC OR COATED FABRICS

- Use a sponge and water and soap (household soap type).

- Dab away resistant stains with a rag soaked with white spirit, do not rub them.

PRECAUTION

For the PVC fabrics, don't use any solvent or solvent based product

(pure alcohol, acetone, trichloroethylene).

6

ACCOMMODATIONS

Page 74

70/122

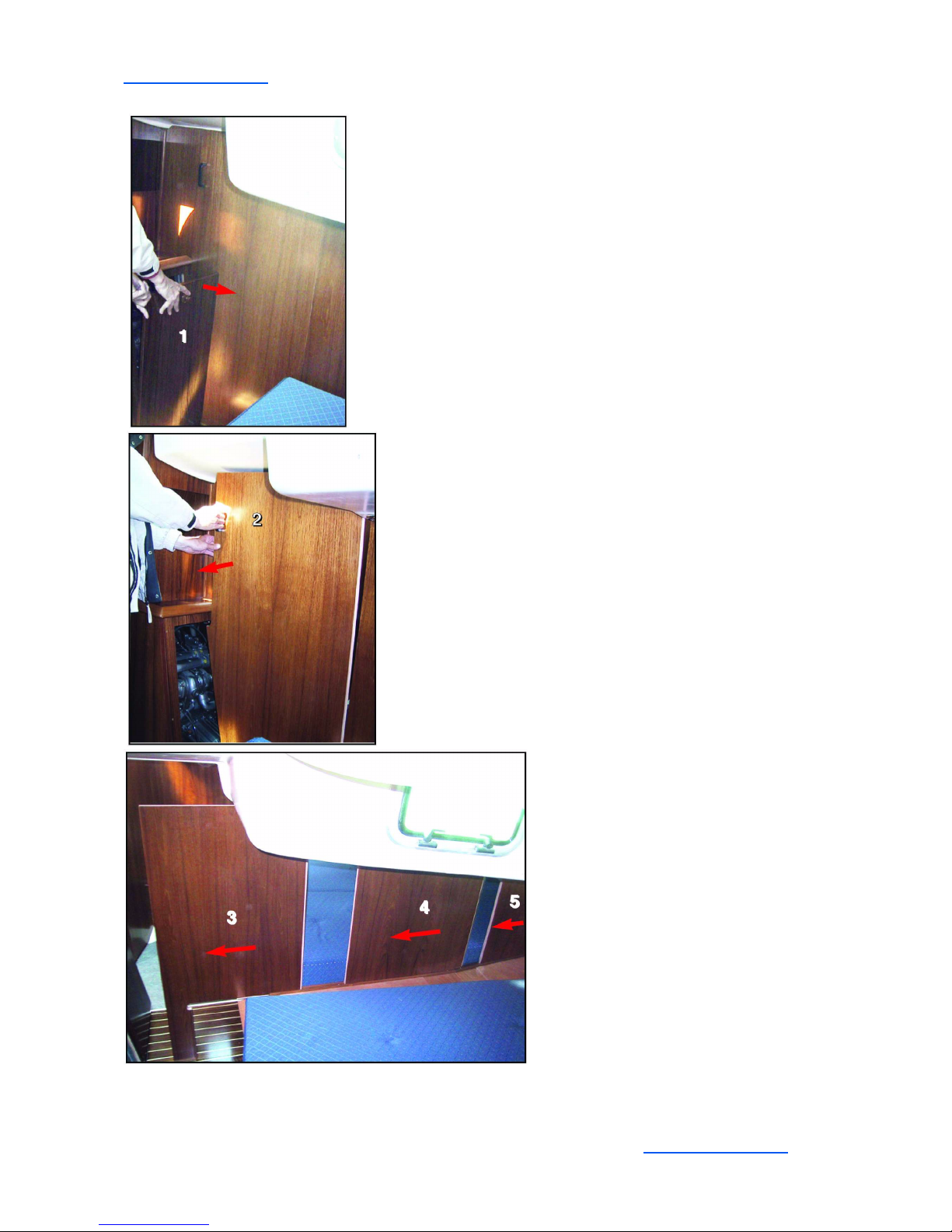

CONVERSION OF THE AFT CABIN

1. Remove the port engine hatch.

2. Take off the central bulkhead

pulling on the handle.

3. Take off the first section of the

bulkhead.

4. , 5. Take off the other sections

sliding them.

NOTE: All the bulkhead and face sections are stored below the aft berth.

Page 75

71/122

FABRICS

100% POLYESTER/DRALON JACQUARD

If you cannot remove the fabric:

- Clean with the vacuum cleaner.

- Clean with synthetic foam (please refer to the product instructions).

If you can remove the fabric:

- Hand wash with an ordinary washing powder at 30° C.

In both cases, dry cleaning is possible. Remove the stains as soon as possible with a damp rag.

COTTON JACQUARD

-Dry clean.

- Do not iron.

- Do not use hypochlorite.

- Remove the stains with fractionated petrol.

ALCANTARA

- Wash in warm water with a neutral pH soap.

- Dry it naturally.

- Dry clean with perchloroethylene.

LEATHER

- Use a leather cream for ordinary care.

- Do not use detergent.

- Do not use silicone based products.

- Clean with a sponge and soapy water.

- Remove ball point pen marks with methylated spirit.

- Remove the grease stains with an absorbent powder (e.g. talcum powder).

6

ACCOMMODATIONS

Page 76

72/122

CONVERSION OF THE FORE CABIN

1. Unbolt and take off the upper part of the central bulkhead.

2. Lift the lower part of the central bulkhead.

3., 4., 5., 6. Take off the other sections by sliding them out.

STORAGE OF THE REMOVABLE BULKHEADS

7. Unscrew the vertical panel of the locker under the berth.

8. Store the bulkhead sections.

Page 77

73/122

MAINTENANCE

RECOMMENDATION

The builder tested and approved a certain number of biodegradable cleaning and restoring products

that protect both material and environment.

The related technical data is available at your JEANNEAU dealer.

6

ACCOMMODATIONS

Page 78

Page 79

75/122

5.3, 5.5, 5.6 ISO 10 240

PLUMBING

WATER TANK FILLING

FRESH WATER SYSTEM

GAS SYSTEM

DRAINAGE SYSTEM

SEWAGE

7

Page 80

76/122

5.3.3 a); 5.3.3 g); 5.3.3 k) ISO 10 240

FRESH WATER AND GAS

Hot water hoses

Cold water hoses

Gas pipe

1. Vent

2. Filler and filling pipe

3. Tank

4. Shower

5. Mixer tap

6. Gas system shut-off valve

7. Gas cylinder and regulator

8. Water heater

9. Foot pump

10. 3 way valve for sea water/fresh water

11. Hoses for engine coolant

12. Valves for tank selection

13. Flowmeter

14. Fresh water filter

15. Pressurized water unit

16. Expansion chamber

17. Deck shower

18. Filter (refer to "Draining")

19. Bilge pump (refer to "Draining")

A. For 3 and 4 washroom versions

B. For 2 shower room version

NOTE: Same position for the other layouts.

Page 81

77/122

WATER TANK FILLING

In order to prevent any handling mistakes, never fill the water and fuel tanks at the same time.

During filling, avoid handling contaminants near the fillers.

Open and close the filler caps with the suitable key.

Check the filler cap seals for condition during filling.

The tanks are fitted with overflow outlets and vents.

Never insert the water filling hose deep down into the system in order to prevent any over-pressure in

the systems.

MAINTENANCE

NOTE: It may happen that the capacity of the fresh water tank or tanks indicated on the page

"Specifications" cannot be completely used depending on the trim and load of the boat.

WARNING

Tanks nominal load capacity cannot be fully used based due to trim and boat loading. A 20% reserve

should be kept..

RECOMMENDATION

- Pay attention to the quality of the water for the filling up. Check if it is drinking water.

- It is possible to sterilize the tanks with a Clonazione tablet (sold at the Chemist's).

- If the boat is not used for long, purify the tanks and pipes with acetic acid (or white vinegar).

- Inspection ports are provided on tanks and make possible the cleaning of the inside.

- Do not use chlorine-based products (they may spoil the quality of the tank stainless steel).

- For winter storage instructions and precautions, refer to Chapter 11.

7

PLUMBING

Page 82

78/122

5.3.3 a); 5.3.3 g) ISO 10 240

GALLEY DRAINING

1. Thru-hull fitting with valve, draining of the sink

2. Thru-hull fitting with valve, water inlet of the sea water pump

3. Thru-hull fitting with valve, draining of the draining board

4. Sea water foot pump

THRU-HULL FITTING

Thru-hull fitting closed Thru-hull fitting open

Page 83

79/122

FRESH WATER SYSTEM

GAS SYSTEM

Refer to chapter 2, "Safety".

Refer to "Fresh water and gas" diagram.

When changing the cylinder, refit the cap in place on the regulator threaded section (to avoid corrosion).

PRECAUTION

- Never operate the water system equipment when the valve is closed or the tank is empty (the

electrical equipment may be damaged).

- Check the water filter for condition (refer to manufacturer's instructions).

- Close the taps of empty tanks.

RECOMMENDATION

Shut off the gas safety valve and the regulator tap when the stove is not in use.

7

PLUMBING

Page 84

80/122

5.3.3 a); 5.3.3 d); 5.3.3 g); 5.3.3 k) ISO 10 240

DRAINAGE SYSTEM

NOTE: Same position for the other layouts.

FOR THE 3 AND 4 WASHROOM VERSIONS 2 WASHROOM VERSION

Thru-hull fitting with valve

Electric pump

Water intake hose

Draining hose

Draining hose

Filter

1. Sump

2. Boiler draining

3. Ice box draining

4. Compartment drain

5. Manual bilge pump in cockpit

Page 85

81/122

DRAINAGE SYSTEM

Waste water from the sink, washbasins and heads is drained off by thru-hull fittings with ball valves (the

valve is closed when the valve handle is perpendicular to the hose, the valve is open when the valve

handle is in line with the hose).

All the floors have holes (limber holes) for the water flow.

A watertight bilge tray under the engine receives the possible oil leaks.

A main sump above the ballast collects the water coming from the boarded floor.

The main sump is partially drained by an electric or a manual pump. Regularly dry the sump with a

sponge.

MAINTENANCE

RECOMMENDATION

- Regularly check the valves and thru-hull fittings for proper operation and watertightness.

- Turn off the valves when the water system is not in use.

- Visually check the water pump flow.

- Check the clamps and flexible hose connections for tightness.

- Pay attention to the seals for condition.

- Regularly make sure that the strum box and bilge are perfectly clean.

- Immediately switch off the electric system in case a pump is running while all the water supplies

are turned off.

- In case of a leak check the system.

WARNING

The bilge pump system is not designed to provide buoyancy to the boat in case of damage.

The bilge pump system is designed to drive out the water being either sea spray or leaks but

absolutely not the water coming through a hole in the hull, this hole being the result of a damage.

7

PLUMBING

Page 86

82/122

5.3.3 a); 5.3.3 k) ISO 10 240

FORE WASHROOM

1. Thru-hull fitting with valve for heads

draining

2. Thru-hull fitting with valve for

shower tray draining

3. Thru-hull fitting with valve for

washbasin draining

4. Thru-hull fitting with valve for heads

water intake

5. Holding pump for shower tray

6. Pump filter

AFT WASHROOM

Page 87

83/122

SEWAGE

USE OF THE MARINE HEADS

Before you use the heads, check that the water intake valve and draining valve are open.

To empty the bowl:

- Set the control lever of the pump slantwise (FLUSH).

- Operate the pump.

To dry the bowl:

- Set the lever back vertical (DRY).

- Operate the pump.

In order to avoid clogging the heads, use absorbent paper exclusively.

Schedule a regular rinsing through of the heads with fresh water.

Close the valves after each use (in particular when the boat is unattended).

USE OF THE WASHBASINS AND SHOWERS

- Close the valves and turn off the taps after use.

- Operate the pump switch to drive the water out of the shower.

RECOMMENDATION

When you are in a marina, use the club-house sanitary facilities (if there are).

Since it is prohibited to discharge the waste waters in some marinas or countries, you shall use a waste

holding tank (WHT).

7

PLUMBING

Page 88

84/122

SIMPLE TANK

Fig. 1

TANK EQUIPPED WITH A 3 WAY VALVE

Fig. 2

1. Heads water intake hose with a thru-hull fitting and a valve

2. Tank draining hose with a thru-hull fitting and a valve

3. Heads filler

4. Tank vent hole

5. Waste holding tank (WHT) (about 45 l)

6. 3 way valve

7. Heads draining hose with thru-hull fitting and valve

Page 89

85/122

USE OF MARINE HEADS EQUIPPED WITH A WASTE HOLDING TANK (WHT) OPTIONAL EXTRA

There are two different types of WHT: The simple tanks (Fig. 1) and the tanks equipped with 3 way

valves (Fig. 2).

Open the water intake valve (ref. 1) (valve handle parallel to the pipe).

In the case of a direct discharge into the sea:

- Fig. 1: Open the draining valve (ref. 2).

- Fig. 2: Close the access to the tank with the 3 way valve (ref. 6). Open the draining valve (ref. 7).

In case you store the waste waters in the tank:

- Fig. 1: Make sure the draining valve is closed (ref. 2) (valve handle perpendicular to the pipe).

- Fig. 2: Make sure the draining valves are closed (ref. 2, 7) (valve handle perpendicular to the pipe).

Open the access to the tank with the 3 way valve (ref. 6).

To drain the bowl, set the control lever of the pump slantwise (FLUSH) then operate the pump.

To dry the bowl, set the lever vertical (DRY) then operate the pump.

In order to avoid clogging the heads:

- Use absorbent paper exclusively.

- Schedule a regular rinsing through of the system with fresh water.

WARNING

Tanks nominal load capacity cannot be fully used based due to trim and boat loading. A 20% reserve

should be kept..

WARNING

Ask for information about the laws in force in your country or your marina about discharging your

waste waters into the sea.

PRECAUTION

Close the valves after each use and above all when the boat is unattended.

7

PLUMBING

Page 90

Page 91

87/122

To empty the tank:

- In an authorized area, open the draining valve (ref. 2).

- In a marina equipped with a system to suck the waste waters, put the sucking hose into the tank

through the deck filler (ref. 3). Start the pump of the sucking system. The filler caps are opened

and closed with an appropriate key. When the tank is empty, check the cap seal for condition then

close the filler.

PRECAUTION

Regularly check how full the tank is. High pressure due to too high a level may cause leaks or more

unpleasant troubles.

7

PLUMBING

Page 92

Page 93

89/122

5.3, 5.4, 5.5, 5.6 ISO 10 240

ELECTRIC SYSTEMS

BATTERY SWITCH

BATTERIES

OPERATION

230 V SYSTEM

SHORE POWER

MAST HARNESS CONNECTION

ELECTRONICS

DRAWINGS AND DIAGRAMS (AT THE END OF THE CHAPTER)

8

Page 94

90/122

5.3.3 b); 5.5.1 ISO 10 240

BATTERY SWITCH

NOTE: Same position for the other layouts.

1. Optional extra

2. Battery switch + Engine

3. Battery switch -

4. Battery switch + House

5. Windlass circuit breaker

Page 95

91/122

BATTERY SWITCH

The electricity onboard is 12 V DC.

The electrical system consists of service batteries. The batteries supply power to all the functions on

board. The engine has its own battery. The house and engine systems can be used simultaneously or

separately depending on the needs.

Switch on by turning the battery switches (12 V).

BATTERIES

The a.c. generator connected to the engine is used to charge the battery.

Keep the batteries charged enough (essential to ensure them a correct service life).

The discharge of the batteries must not exceed 70 % of the rating.

Use the battery charger when in a marina in order to start sailing with properly charged batteries

(optional extra).

Always check the battery and charge system condition before you put out to sea.

PRECAUTION

Switch off all the battery switches when the boat is unattended.

PRECAUTION

Never run the engine when the circuit to charge the batteries is disconected (it may destroy the a.c.

generator).

8

ELECTRIC SYSTEMS

Page 96

Page 97

93/122

MAINTENANCE

RECOMMENDATION

- Keep the batteries clean and dry in order to avoid premature wear.

- Periodically check the electrolyte level. Add some distilled water if need be.

- Have the acidity level of the battery checked if unused for long.

- Tighten and maintain the terminal connectors by gresing them regularly.

- Disconnect the batteries and remove them if winter stored or unused for long.

WARNING

- Handle the batteries with care (Please refer to the manufacturer's instructions).

- In case of electrolyte splashing, thoroughly rinse the part of the body that has been in conctact

with it.

- Obtain medical advice.

8

ELECTRIC SYSTEMS

Page 98

Page 99

95/122

OPERATION

The electrical switchboard does not require any routine maintenance

In case an electric appliance is not energized, check:

- The main power supply (batteries, battery switches).

- The switches and circuit breakers on the line.

- the relevant electrical unit.

You can use the automatic reset switch to read the fuel gauge (to avoid electrolytic problems).

PRECAUTION

Never leave the boat unattended when the electric fitting is on (except the safety equipments directly

connected to the battery and protected by a circuit breaker).

Disconnect the 230 V before you open the electric panel or cupboard.

WARNING

Never work on a live electric fitting.

PRECAUTION

- Never modify an electric fitting and relevant diagrams yourself.

- Call in a technician skilled in marine electricity to carry out any electric modification.

- Never change the breaking capacity (amperage) of the overcurrent safety devices.

- Never install or replace the electric appliances (or any electric equipement) by components

exceeding the capacity (amperage) of the circuit (Watt for bulbs).

8

ELECTRIC SYSTEMS

Page 100

96/122

5.3.3 b) 5.5.1 ISO 10 240

SHORE POWER

Loading...

Loading...