Page 1

SmartClass

E1 and E1/Datacom Testers

User’s Guide

Page 2

Page 3

SmartClass

E1 and E1/Datacom Testers

User’s Guide

Page 4

Notice

Every effort was made to ensure that the information in this document was

accurate at the time of printing. However, information is subject to change without notice, and JDSU reserves the right to provide an addendum to this document with information not available at the time that this document was created.

Copyright

Trademarks

© Copyright 2009, JDS Uniphase Corporation. All rights reserved. JDSU,

Enabling Broadband and Optical Innovation, Communications Test and Measurement Solutions, and the JDSU logo are trademarks of JDS Uniphase Corporation (“JDS Uniphase”). All other trademarks are the property of their

respective owners. No part of this guide may be reproduced or transmitted

electronically or otherwise without written permission of the publisher.

JDS Uniphase, JDSU, and SmartClass are trademarks or registered trademarks of JDS Uniphase Corporation in the United States and/or other countries.

Microsoft and Excel are either trademarks or registered trademarks of

Microsoft Corporation in the United States and/or other countries.

PDF is a trademark of Adobe Systems in the United States and/or other countries.

Energizer is either a trademark or registered trademark of Eveready Battery

Company, Inc. in the United States and/or other countries.

Specifications, terms, and conditions are subject to change without notice. All

trademarks and registered trademarks are the property of their respective

companies.

Ordering information

Federal Communications

Commission (FCC) Notice

Industry Canada Requirements

EMC Directive Compliance

This guide is a product of JDSU's Technical Information Development Department, issued as part of the SmartClass E1 and E1/Datacom Testers. The catalog number for a printed guide is ML-21107607. The catalog number for a

CD-ROM containing all user documentation and utilities is CML-21104331.

This product was tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial or residential environment. This product generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to

radio communications.

The authority to operate this product is conditioned by the requirements that no

modifications be made to the equipment unless the changes or modifications

are expressly approved by JDSU.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

This product was tested and conforms to the EMC Directive, 89/336/EEC as

amended by 92/31/EEC and 93/68/EEC for electromagnetic compatibility.

ii SmartClass E1 Tester User’s Guide

Page 5

Low Voltage Directive Compliance

This product was tested and conforms to the Low Voltage Directive, 73/23/

EEC as amended by 93/68/EEC. Conformity with this directive is based upon

compliance with the harmonized safety standard, UL61010-1.

WEEE and Battery Directive

Compliance

JDSU has established processes in compliance with the Waste Electrical and

Electronic Equipment (WEEE) Directive, 2002/96/EC, and the Battery Directive, 2006/66/EC.

This product, and the batteries used to power the product, should not be disposed of as unsorted municipal waste and should be collected separately and

disposed of according to your national regulations. In the European Union, all

equipment and batteries purchased from JDSU after 2005-08-13 can be

returned for disposal at the end of its useful life. JDSU will ensure that all waste

equipment and batteries returned are reused, recycled, or disposed of in an

environmentally friendly manner, and in compliance with all applicable national

and international waste legislation.

It is the responsibility of the equipment owner to return equipment and batteries

to JDSU for appropriate disposal. If the equipment or battery was imported by

a reseller whose name or logo is marked on the equipment or battery, then the

owner should return the equipment or battery directly to the reseller.

Instructions for returning waste equipment and batteries to JDSU can be found

in the Environmental section of JDSU’s web site at www.jdsu.com. If you have

questions concerning disposal of your equipment or batteries, contact JDSU’s

WEEE Program Management team at WEEE.EMEA@jdsu.com.

SmartClass E1 Tester User’s Guide iii

Page 6

iv SmartClass E1 Tester User’s Guide

Page 7

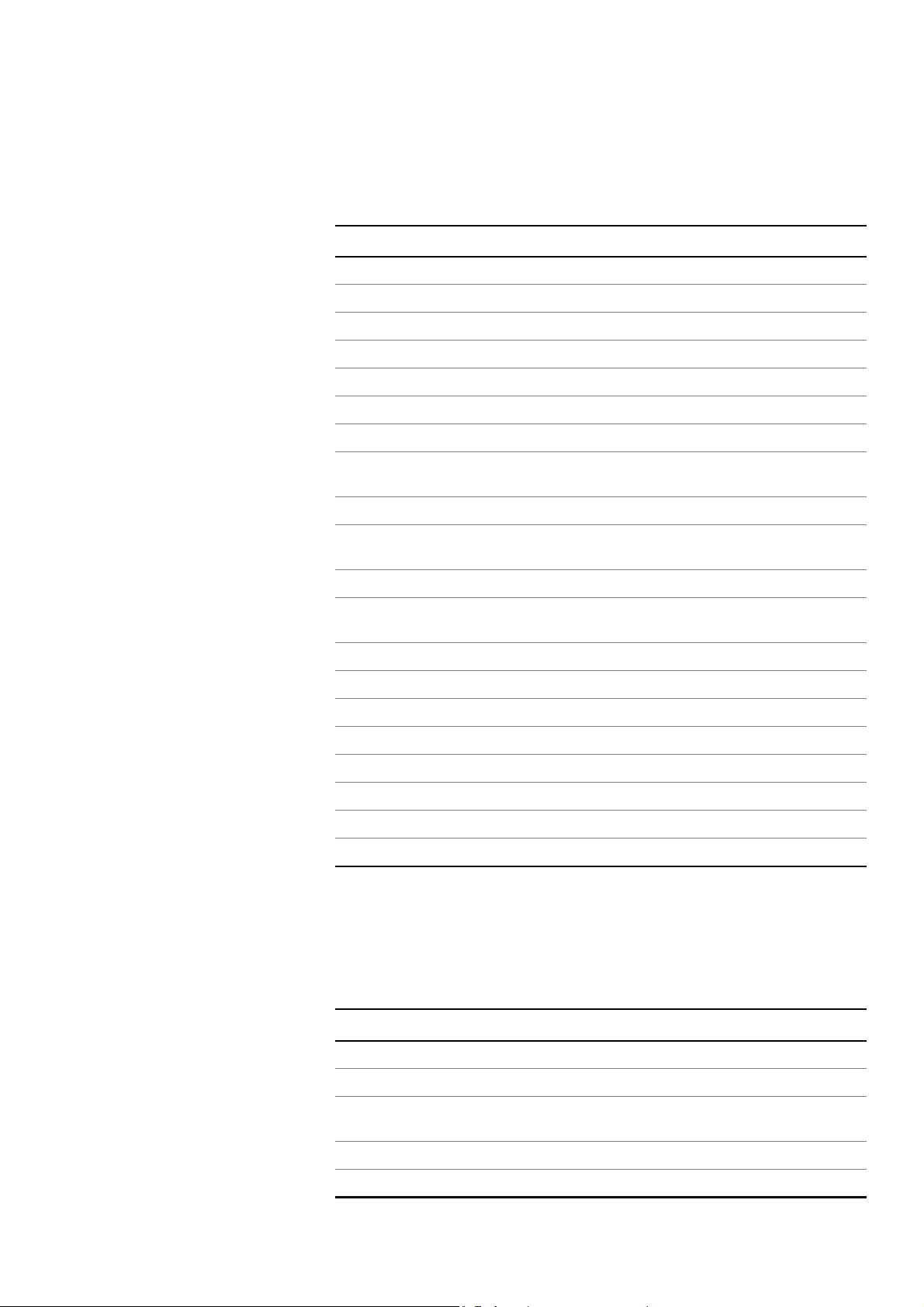

Table of Contents

About this Guide xi

Purpose and scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Safety and compliance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Chapter 1 Getting Started 1

Ship list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features and capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Software options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparation for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Charging the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Exploring the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cancel key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OK key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Arrow keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

*Action key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

#Start key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Backlight key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exploring the side panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Left side panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Right side panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exploring the bottom panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Powering ON your unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Powering OFF your unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SmartClass E1 Tester User’s Guide v

Page 8

Table of Contents

Navigating the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Menu screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Data entry screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Result screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using the keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Selecting a menu option or a configuration setting . . . . . . . . . . . . . . . . 14

Returning to a previous menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Entering numeric values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Typing text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2 Instrument Settings 17

Setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Viewing the software and hardware information . . . . . . . . . . . . . . . . . . 18

Setting the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing the date or time format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the date or time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjusting the contrast and brightness . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Determining the specified battery type . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Managing files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Specifying DB9 port usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Restoring factory defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3 Basic Testing 23

Managing test configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Saving a configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Restoring a configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Viewing a configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Starting or restarting a test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Stopping a test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Timed testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Viewing test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4 E1 Testing 27

About E1 testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Launching an E1 test application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifying test application settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Specifying a test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring test settings automatically . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifying interface settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifying E1 framing settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Specifying E1 signaling (ABCD/Sa) settings . . . . . . . . . . . . . . . . . . . . . 32

Specifying a BERT pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Specifying Error/Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Specifying performance settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specifying VF settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Monitoring a circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Measuring timing slips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Terminate testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Line loopback testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pulse shape analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

vi SmartClass E1 Tester User’s Guide

Page 9

Table of Contents

Measuring Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configuring test settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connecting to the circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Running the test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Testing MFC-R2 Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configuring test settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connecting to the line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Running the test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5 Datacom Testing 51

About data communications testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Launching the datacom application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Specifying test settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Specifying the test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Specifying the interface standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Specifying timing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Specifying the timing mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Specifying transmit and receive timing . . . . . . . . . . . . . . . . . . . . . . 54

Specifying polarity settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Specifying a BERT pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Specifying data parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specifying the data rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Enabling/disabling data loss detection . . . . . . . . . . . . . . . . . . . . . . 58

Specifying the Rx input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Specifying the clock loss threshold. . . . . . . . . . . . . . . . . . . . . . . . . 58

Specifying async settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Specifying flow control settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Specifying G.821 performance settings . . . . . . . . . . . . . . . . . . . . . . . . 60

Specifying error settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Performing a self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connecting the E1/Datacom Tester to the circuit. . . . . . . . . . . . . . . . . . 61

Connecting for X.21 testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connecting for RS-232/V.24 and EIA-530 testing. . . . . . . . . . . . . . . . . 62

Connecting for V.35 testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connecting for RS-449/V.36 testing . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

BER Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Monitoring a Datacom interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Frame Relay testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Launching the Frame Relay application . . . . . . . . . . . . . . . . . . . . . . . . 64

Configuring the test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Specifying datacom settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Configuring the frame load settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuring the frame header settings . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring the LMI Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configuring the trace settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Specifying flow control settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Specifying polarity settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Monitoring traffic on Datacom interfaces. . . . . . . . . . . . . . . . . . . . . . . . 71

Transmitting traffic over a Datacom interface . . . . . . . . . . . . . . . . . . . . 72

Chapter 6 VT100 Terminal Emulation 73

About VT100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

VT100 cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Emulating a VT100 terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SmartClass E1 Tester User’s Guide vii

Page 10

Table of Contents

Chapter 7 Test Results 77

E1 Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

E1 Summary results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Statistics results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Signal results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Interface results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Frame Data results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Timeslot results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

BERT results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Performance results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

G.821 results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

G.826 ISM results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

G.826 OOS results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

M.2100 ISM results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

M.2100 OOS results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

VF results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Freezing test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Pulse shape results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Pulse Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Jitter results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Summary results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Jitter results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Graphical and Tabular jitter results . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Jitter Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

MTJ Graph and Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

JTF Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Signal results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Interface results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

BERT results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Event Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

MFC-R2 results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Datacom results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Summary results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Clock results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Control Signal results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Data results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

BERT results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

G.821 performance results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Event Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Frame relay results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Summary results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Clock results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Control Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Data Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

DLCI results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Link results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Ping results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

LMI results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

DLCI list results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Trace results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Event Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Saving results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Viewing saved results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

viii SmartClass E1 Tester User’s Guide

Page 11

Table of Contents

Chapter 8 Maintaining the Batteries 103

Prolonging battery life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Recharging the batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Replacing the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Chapter 9 Troubleshooting 107

Getting Technical Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Resolving problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

General testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

E1 testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Datacom testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix A Signal Lead Names 111

Appendix B Specifications 113

E1 interface connector specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 114

Physical interface specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

E1 circuit testing specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Pulse shape specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Jitter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Manual Jitter Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

MTJ and FMTJ Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Jitter Transfer Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Datacom specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Supported interface standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

About pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

RS-232/V.24 pin assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

X.21 pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

EIA-530 pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

V.35 pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

RS-449/V.36 pin assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Signal Lead Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Environmental specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Warranty information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

SmartClass E1 Tester User’s Guide ix

Page 12

Table of Contents

x SmartClass E1 Tester User’s Guide

Page 13

About this Guide

This chapter describes how to use this guide. Topics discussed in this chapter

include the following:

– “Purpose and scope” on page xii

– “Assumptions” on page xii

– “Safety and compliance information” on page xii

– “Conventions” on page xii

SmartClass E1 Tester User’s Guide xi

Page 14

About this Guide

Purpose and scope

Purpose and scope

Assumptions

The purpose of this guide is to help you successfully use the features and

capabilities of the SmartClass E1Tester.

This guide includes task-based instructions that describe how to configure,

use, and troubleshoot the general functions of the SmartClass E1Tester. Additionally, this guide provides a description of JDSU’s warranty.

This guide is intended for novice, intermediate, and experienced users who

want to use the SmartClass E1Tester effectively and efficiently. We are

assuming that you have basic computer experience and are familiar with basic

telecommunication concepts, terminology, and safety.

Safety and compliance information

Safety and compliance information are contained in a separate guide and are

provided in printed format with the product.

Conventions

This symbols and safety terms used in this guide are described in the following

tables.

Table 1 Symbol conventions

This symbol represents a general hazard.

This symbol represents a risk of electrical shock.

This symbol represents a risk of explosion

This symbol represents a Note indicating related information or

tip.

This symbol, located on the equipment, battery, or packaging

indicates that the equipment or battery must not be disposed of

in a land-fill site or as municipal waste, and should be disposed

of according to your national regulations.

xii SmartClass E1 Tester User’s Guide

Page 15

About this Guide

Conventions

Table 2 Safety definitions

DANGER Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

SmartClass E1 Tester User’s Guide xiii

Page 16

About this Guide

Conventions

xiv SmartClass E1 Tester User’s Guide

Page 17

Chapter1

Getting Started

1

This chapter provides a general description of the SmartClass E1 Tester.

Topics discussed in this chapter include the following:

– “Ship list” on page 2

– “Features and capabilities” on page 2

– “Options” on page 3

– “Preparation for use” on page 5

– “Exploring the front panel” on page 6

– “Exploring the side panels” on page 9

– “Exploring the bottom panel” on page 10

– “Powering ON your unit” on page 10

– “Powering OFF your unit” on page 10

– “Navigating the user interface” on page 11

– “Using the keypad” on page 14

SmartClass E1 Tester User’s Guide 1

Page 18

Chapter 1 Getting Started

Ship list

Ship list

The E1 Tester typically ships in anti-static packing material to stabilize the unit

inside the box. The following items ship standard with the SmartClass E1

Tester:

– SmartClass E1 Tester unit.

– AC Power Adapter with Plug Kit (USA, UK, Australia, Europe) — A power

adapter designed specifically for the SmartClass Tester is included. When

supplying power to the SmartClass Tester using an adapter, you must use

the adapter supplied with your unit. (catalog no. SC1WALLCHARGER)

– Small Carrying Bag (catalog no. 7522/90.03)

– 4 AA Rechargeable NiMH Batteries

(catalog no. BATTAA25AHNIMH4PCK)

– RJ-48 (M) to RJ-48 (M/F) Cable (catalog no. K1599)

– USB Cable (catalog no. CB-50759)

– Documentation CD. The SmartClass E1 Tester User’s Guide and the

Download Manager and Upgrade Instructions are included on the CD.

(catalog no. CML-21104331)

The latest version of the Download Manager utility is available on JDSU’s

Communications Test & Measurement Customer Care site at

http://www.jdsu.com/test_and_measurement/products/descriptions/

SmartClass_E1/index.html.

Safety and compliance information is provided separately, in printed

format.

Features and capabilities

When unpacking the unit, verify that each of the standard items, and any

optional items you ordered, are included in the package.

Features and capabilities of the SmartClass E1 Tester include the following:

– General features

– Color display

– Supported languages: Simplified Chinese, Deutsche, English, French,

Italian, Japanese, Korean, Portuguese, Russian, and Spanish.

– Field replaceable batteries

– Remote control (optional)

– VT-100 terminal emulation (option)

– E1 Testing features

– Dual E1 RJ-48 interfaces (Port 1 Rx/Tx, Port 2 Rx only).

– Analysis for contiguous and non-contiguous timeslots in 64 kbit/s

format.

– Supported framing formats: PCM30C, PCM30, PCM31C, PCM31, and

unframed.

– Insertion of code errors, TSE (bit errors), pattern slips, CRCs, E-bit

errors, FAS, and MFAS errors.

2 SmartClass E1 Tester User’s Guide

Page 19

Chapter 1 Getting Started

– Physical layer defects (alarms), anomalies (errors), and statistics are

collected during the test.

– Auto configure to automatically select the interface, framing, and

pattern.

– Line rate throughput testing

– Line loopback testing

– Round trip delay measurement

– Terminate, Monitor, Bridge, and Loopback testing

– Pulse shape (option)

– MFC-R2 Signaling (option)

– Datacom Testing features

– DTE emulate, DCE emulate and monitor mode

– X.21, V.24 (RS-232), V.35, V.36 (RS-449), EIA-530

–V. delay

–Frame Relay

– G.703 Co-directional, Contra-directional and Centralized interface

testing

Options

Options

Configurations

The SmartClass E1 Tester has factory-configurable options as well as options

available for field upgrade. You can expand your testing capability by

purchasing optional software or accessories.

The SmartClass E1 Tester is factory configurable with or without Datacomm.

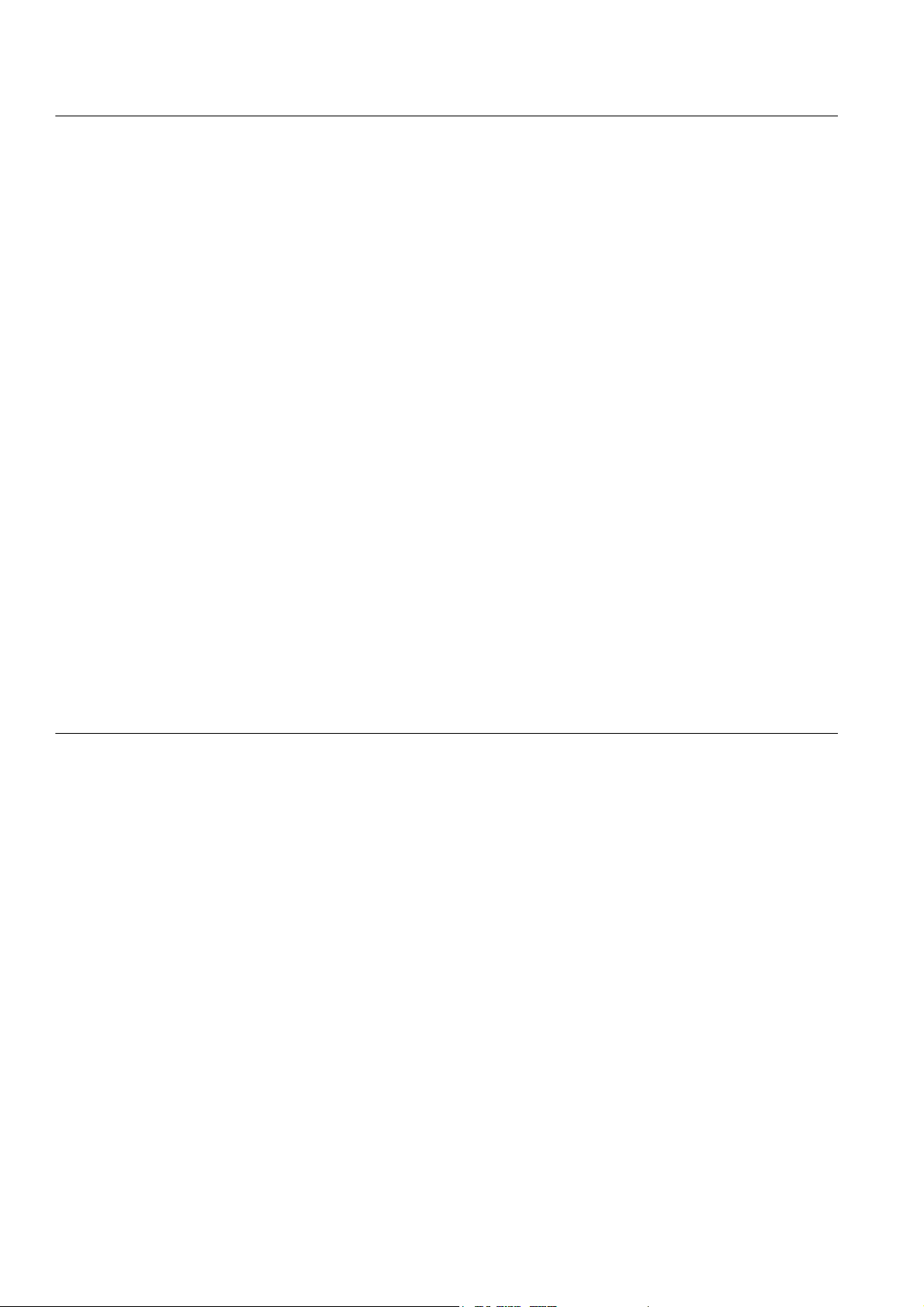

Table 3 describes the available configurations.

Table 3 SmartClass E1 Tester configurations

Catalog Number Option

CSC-E1-P1 SmartClass

CSC-E1-P2 SmartClass E1 Tester with the PS option. Allows you to

test E1 services, including Pulse Shape.

CSC-E1-P3 SmartClass

test E1 services, including Jitter.

CSC-E1-P4 SmartClass

test E1 services, including Pulse Shape and Jitter.

CSC-E1DC-P1 SmartClass E1 Datacomm Tester. Allows you to test E1

and Data communication services.

E1 Tester. Allows you to test E1 services.

E1 Tester with the JIT option. Allows you to

E1 Tester complete package. Allows you to

CSC-E1DC-P2 SmartClass E1 Datacomm Tester with PS and FR

options

Shape, and Data communication services, including Frame

Relay.

CSC-E1DC-P3 SmartClass

VT100 options

Pulse Shape, MFC-R2 signaling, and VT100, as well as

Data communication services, including Frame Relay.

. Allows you to test E1 services, including Pulse

E1 Datacomm Tester with PS, SIG, and

. Allows you to test E1 services including

SmartClass E1 Tester User’s Guide 3

Page 20

Chapter 1 Getting Started

Options

Table 3 SmartClass E1 Tester configurations (Continued)

Catalog Number Option

CSC-E1DC-P4 SmartClass E1 Datacomm Tester with PS and JIT

options

Shape and Jitter, and Data communication services.

CSC-E1DC-P5 SmartClass E1 Datacomm Tester complete package.

Allows you to test E1 services including Pulse Shape, Jitter,

MFC-R2 signaling, and VT100, as well as Data communication services, including Frame Relay.

. Allows you to test E1 services, including Pulse

Software options

Table 5 lists the software options offered for the E1 Tester.

Table 4 SmartClass E1 Tester software options

Catalog Number Option

CSC-E1-PS SmartClass Pulse Shape SW Option. Allows measuring of

displaying a graphical representation of the E1

and

pulse

. (Applicable to CSC-E1 and CSC-E1DC)

CSC-E1-FR SmartClass Frame Relay option. Allows you to test frame

relay services over Datacomm interfaces. (Applicable to

CSC-E1DC only)

CSC-E1-SIG SmartClass Signaling option. Allows you to test MFC-R2 sig-

naling. (Applicable to CSC-E1DC only)

CSC-E1-VT100 SmartClass VT100 option. Allows emulation of a VT100 ter-

minal. (Applicable to CSC-E1DC only)

CSC-E1-JIT SmartClass Jitter option. Allows measurement of jitter.

(Applicable to CSC-E1DC only)

CSC-E1-RC SmartClass Remote Control Option. Allows remote

access and control of the instrument using specific

commands. A command guide is available with this

option. (Applicable to CSC-E1 and CSC-E1DC)

Optional accessories

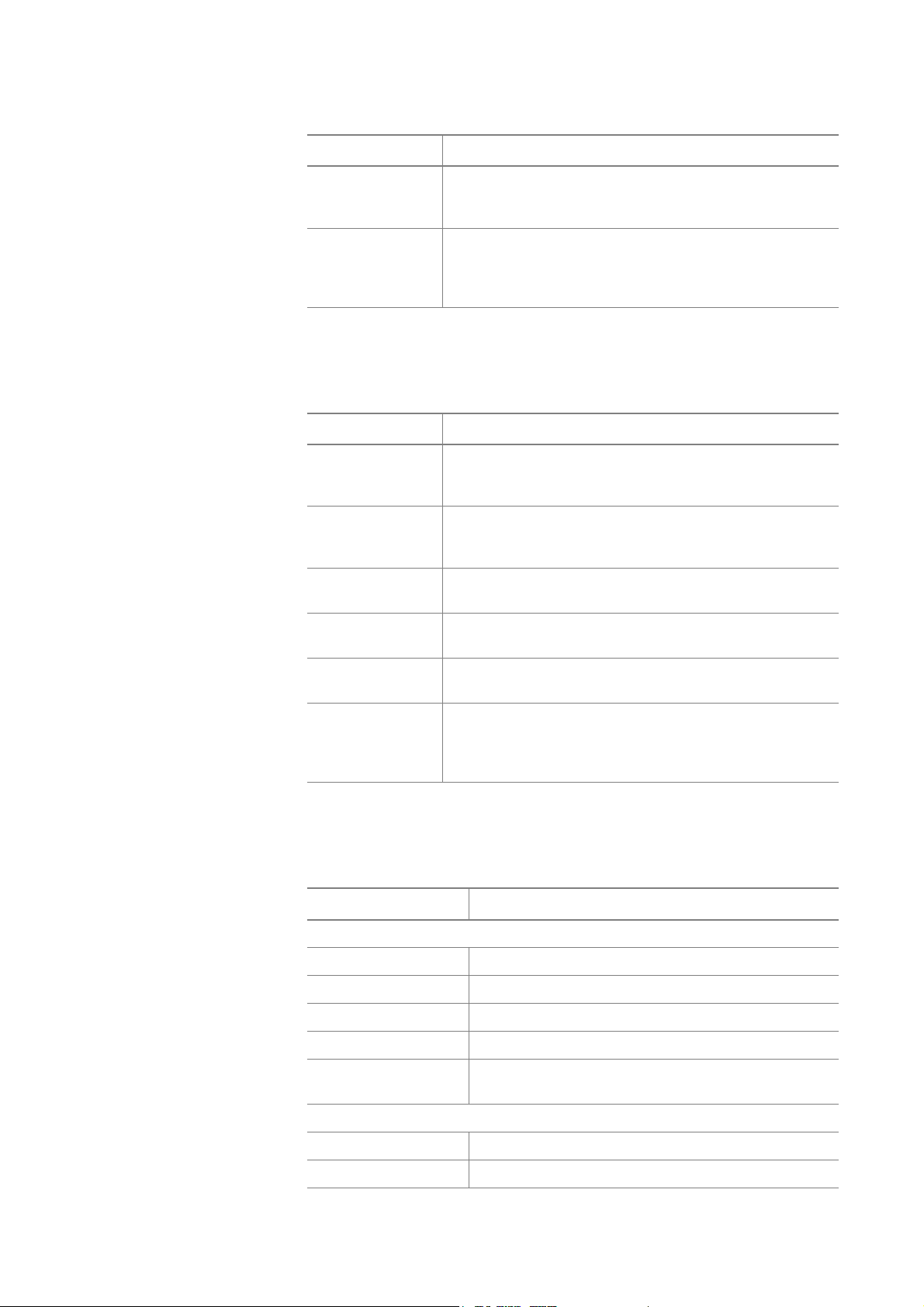

Table 5 lists the optional accessories offered for the E1 Tester.

Table 5 SmartClass E1 Tester optional accessories

Catalog Number Accessory

General

CC-120101 Large Carrying Bag

AC-009801 Large Strand Hook

SCACARCHARGER SmartClass 12V car adapter

ML-21107607 Printed

ML-21121114 Printed SmartClass E1 Tester Remote Control Ref-

erence Guide (English)

E1 testing

K1597 Balanced RJ-48 to balanced CF Y-cable

CB-44995 RJ-48 (balanced) to dual BNC (unbalanced) cable

4 SmartClass E1 Tester User’s Guide

SmartClass E1 Tester User’s Guide (English)

Page 21

Chapter 1 Getting Started

Preparation for use

Table 5 SmartClass E1 Tester optional accessories (Continued)

Catalog Number Accessory

CB-0045402 External 2M Reference Clock cable

Datacom testing

CB-44391 X.21 10 MHz DTE/DCE Emulate

CB-44346 X.21 Monitor

CB-44385 V.24 DTE/DCE Emulate

CB-44348 V.24 Monitor

CB-44389 V.35 DTE/DCE Emulate

CB-44341 V.35 Monitor

CB-44388 V.36 DTE/DCE Emulate

CB-44347 V.36 Monitor

CB-21128081 68-pin MDR to DB-15 cable (DTE emulation, for inter-

face to network)

Preparation for use

General preparation

CB-21118474 68-pin MDR to Bananas (for Co-directional, Contra-

directional and Centralized testing)

To order accessories for your E1 Tester, contact JDSU Customer Care, your

JDSU TAC representative, or your local JDSU sales office. You can also

contact JDSU through the company web site, www.jdsu.com.

This section explains how to start using your E1 Tester.

When you unpack the E1 Tester, do the following:

– Inspect the tester for damage.

– If undamaged, save the box and packing materials in case you need to

ship the tester in the future.

Before using the E1 Tester for the first time, do the following:

– If you are using alkaline batteries, verify that your unit is OFF, and then

install fresh batteries in the tester.

– If you are using rechargeable batteries, verify that your unit is OFF, and

then install the batteries in the tester. Before testing, make sure the

batteries have been fully charged (see “Recharging the batteries” on

page 104).

– Turn the unit ON (see “Powering ON your unit” on page 10).

– When prompted, specify the type of battery you installed.

– Verify that your unit is operating properly by navigating through a few

menus.

SmartClass E1 Tester User’s Guide 5

Page 22

Chapter 1 Getting Started

Exploring the front panel

– If the Batt LED is red, replace the batteries (see “Replacing the batteries”

on page 105). If you suspect that the batteries are fine, and the batteries

are fully charged, it’s possible the charger has detected a fault condition.

See “Resolving problems” on page 108 for details.

Charging the batteries

Exploring the front panel

The SmartClass Tester uses an AC adapter or four (4) AA batteries (alkaline

or rechargeable NiMH batteries). The first time you use the SmartClass Tester,

or after prolonged storage, use the AC adapter to power the unit and charge

NiMH batteries only. For details on charging and maintaining batteries, see

Chapter 8 “Maintaining the Batteries”.

The controls and LEDs on the SmartClass front panel, shown in Figure 1, are

used to operate the unit, set up tests, and view data.

Status LEDs

LCD

Arrow keys

OK key

Cancel key

Keypad

(includes *Action and #Start keys)

Backlight key

Power key

Figure 1 SmartClass front panel

The label near the top will say “SmartClass E1/Data”, if you have the

E1/Datacomm configuration.

The following paragraphs describe each of the controls and LEDs on the front

panel.

6 SmartClass E1 Tester User’s Guide

Page 23

Chapter 1 Getting Started

Exploring the front panel

Status LEDs

These indicators report the status of the unit. The function of the LEDs change

depending on the application. Table 6 describes each of the Status LEDs.

Table 6 Status LEDs

Status LED Description

Sync For E1 testing:

Green

– Solid—A signal is present and synchronization is established

on all active receivers.

– Flashing—Auto-framing is running on at least one active

receiver.

Red

– At least one of the active receivers does not have frame syn-

chronization.

Off

– No signal has been detected on any receiver.

For Datacom testing:

Green

– Solid—A receive clock is present.

Red

– Solid—A receive clock was present at some point in the past,

but was lost.

Off

– No receive clock has been detected on any receiver.

Data/LpBK Green

– Solid—Synchronization is established with BERT pattern for all

active receivers.

– Flashing—Auto-pattern is running on at least one active

receiver.

Red

– At least one of the active receivers does not have pattern syn-

chronization.

Amber

– For E1 testing: The E1 Tester has been placed in a line loop-

back mode.

Off

– The E1 Tester is not in a line loopback mode, which means the

selected traffic pattern is live on all active receivers, or no pat-

tern synchronization has been detected on the receiver.

Err/Alm Red

– Flashing —The LED flashes for one second when an error or

alarm occurs. Or, for E1 testing, flashes when the unit is

searching for framing or a pattern during Auto Config.

Amber

– At least one error or alarm has occurred since that last reset.

Off

– All Summary results are OK. No error or alarm has been

received.

SmartClass E1 Tester User’s Guide 7

Page 24

Chapter 1 Getting Started

Exploring the front panel

Table 6 Status LEDs

Status LED Description

Batt Green

– Solid—An external source is powering the unit.

Red

– Low battery, or the charger has detected a fault condition.

Amber

– The battery is charging.

Off

– A battery is powering the unit.

LCD

Cancel key

OK key

Arrow keys

Keypad

*Action key

The LCD is a 320 x 240 pixel color display with contrast control and backlight.

Use the Cancel key to exit a data entry screen without changing your settings,

or to return to the previous menu.

Use OK to accept a changed setting or to proceed to the next menu.

Use the arrow keys to navigate through menu selections. For E1 testing, when

viewing the test results, use the left or right arrow key to switch between Rx1

and Rx2 result screens. For Datacom testing, in monitor mode use the left or

right arrow to switch between DCE and DTE.

Use the keypad to enter numbers, make menu selections, enter alphabetic

characters, and so on. Throughout the menus, the numbers associated with

each function provide a quick way to perform tests with simple number

sequences.

Use the *Action key to insert errors or alarms during testing.

#Start key

Backlight key

Power key

8 SmartClass E1 Tester User’s Guide

Use the #Start key to restart your test and transmit traffic immediately after you

configure your test. After starting the test, the unit automatically displays test

results associated with your application.

Use the backlight key to adjust the brightness level on your LCD. The SmartClass E1 provides four brightness levels on the LCD. Pressing the backlight

key once increases the brightness by one level. The brightness level returns to

the original level when you press the backlight key the fourth time.

Use the power key to turn power ON (see “Powering ON your unit” on

page 10), put the unit into sleep mode, or turn power OFF (see “Powering OFF

your unit” on page 10).

Page 25

Exploring the side panels

Chapter 1 Getting Started

Exploring the side panels

The connectors located on the side panels are used to connect the E1 Tester

to the circuit for testing.

Left side panel

Right side panel

Figure 2 shows the left side panel.

RS232 Connector

RJ-48 Connectors

Figure 2 SmartClass E1 Tester left side panel

Use the RJ-48 jacks (labeled RX1/TX1 and RX2/Ext Clk) to connect to E1

circuits. See Table 5 on page 4 for cables that are available for the SmartClass

E1 Tester.

The RS232 connector is only used on the SmartClass E1/Datacomm configuration. It is used to connect to network elements when using the optional

VT-100 emulation feature.

The right side panel has a universal connector, shown in Figure 3, that is used

to connect to Datacom circuits

universal connector

Figure 3 SmartClass E1 Tester right side panel

The universal connector supports several interface standards. Use the

connector and adaptor cables (see Table 5 on page 4) to connect to the appropriate test interface. For pin assignments for the supported interface standards, see Appendix A on page 111.

SmartClass E1 Tester User’s Guide 9

Page 26

Chapter 1 Getting Started

Exploring the bottom panel

Exploring the bottom panel

The SmartClass AC adapter and USB device ports are located on the bottom

panel. The USB device port is used to establish connections that allow you to

run reports from a remote device (typically a PC or laptop) or update the software using the Download Manager utility.

Powering ON your unit

Powering OFF your unit

USB device portAC adapter port

Figure 4 SmartClass bottom panel

The following procedure describes how to power ON the E1 Tester.

To power ON your unit

– Press and hold the Power key for a few seconds.

The SmartClass E1 splash screen appears for a few seconds, and then the

Main Menu appears.

The following procedure describes how to power OFF the E1 Tester.

To power OFF your unit

1 Press and hold the Power key for a few seconds.

The Power Control menu appears.

2 Do one of the following:

– If you want to be able to restart the unit quickly, select Enter Sleep

Mode. The test stops, and then the user interface disappears. If the

backlight is ON, the unit automatically turns it OFF. When you are

ready to resume testing, press the Power key for a few seconds to

redisplay the user interface.

NOTE: If your unit is in sleep mode for more than two hours, it will automatically turn itself OFF.

10 SmartClass E1 Tester User’s Guide

Page 27

Navigating the user interface

Chapter 1 Getting Started

Navigating the user interface

– To conserve power and completely power OFF your unit, select Shut

Down. A message briefly appears informing you that the unit is shut-

ting down.

Power is OFF.

The user interface of the SmartClass is designed to be intuitive and easy to

use. Using the LCD and keypad, you can set up the unit, configure test parameters, and view test results. This section describes the user interface, and

explains how to navigate through the menus and screens.

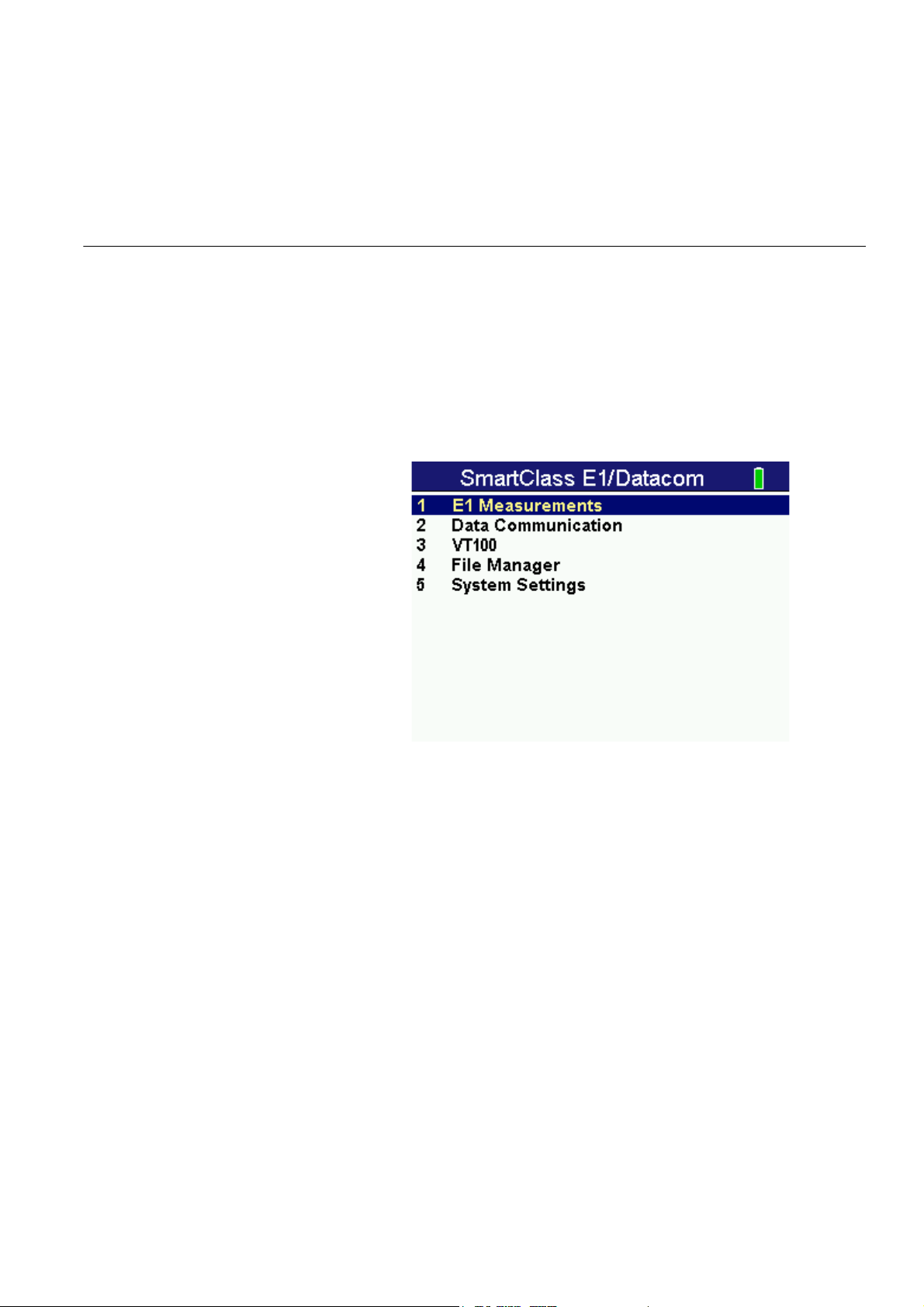

When you power up the SmartClass E1 Tester, the Main Menu of the user

interface appears. Figure 5 illustrates the Main menu for the SmartClass E1/

Datacom tester.

Figure 5 SmartClass E1/Datacom Tester Main Menu

There are 3 types of screens on the user interface:

– Menus

– Data entry screens

– Results screens

SmartClass E1 Tester User’s Guide 11

Page 28

Chapter 1 Getting Started

Navigating the user interface

Menu screens

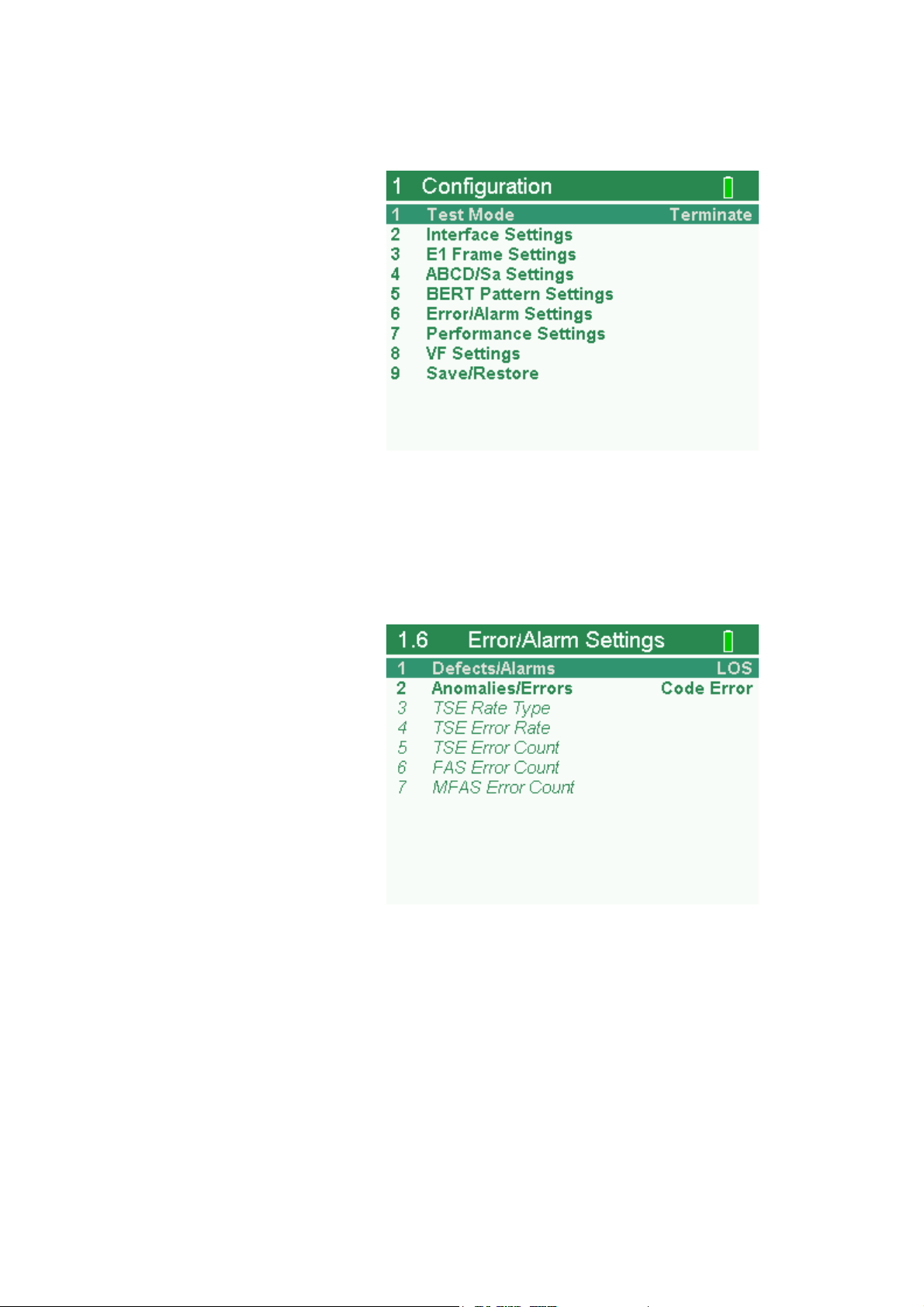

Figure 6 illustrates the Configuration menu screen for the SmartClass E1

tester.

Figure 6 SmartClass E1 Tester Configuration menu screen

Menu screens provide a series of selections that take you to another menu

screen, a data entry screen, or a results screen.

Figure 7 illustrates the Error/Alarm settings menu screen listing each of the

available error or alarm settings.

Figure 7 SmartClass E1 Tester Error/Alarm Settings menu screen

12 SmartClass E1 Tester User’s Guide

Page 29

Chapter 1 Getting Started

Navigating the user interface

Data entry screens

Result screens

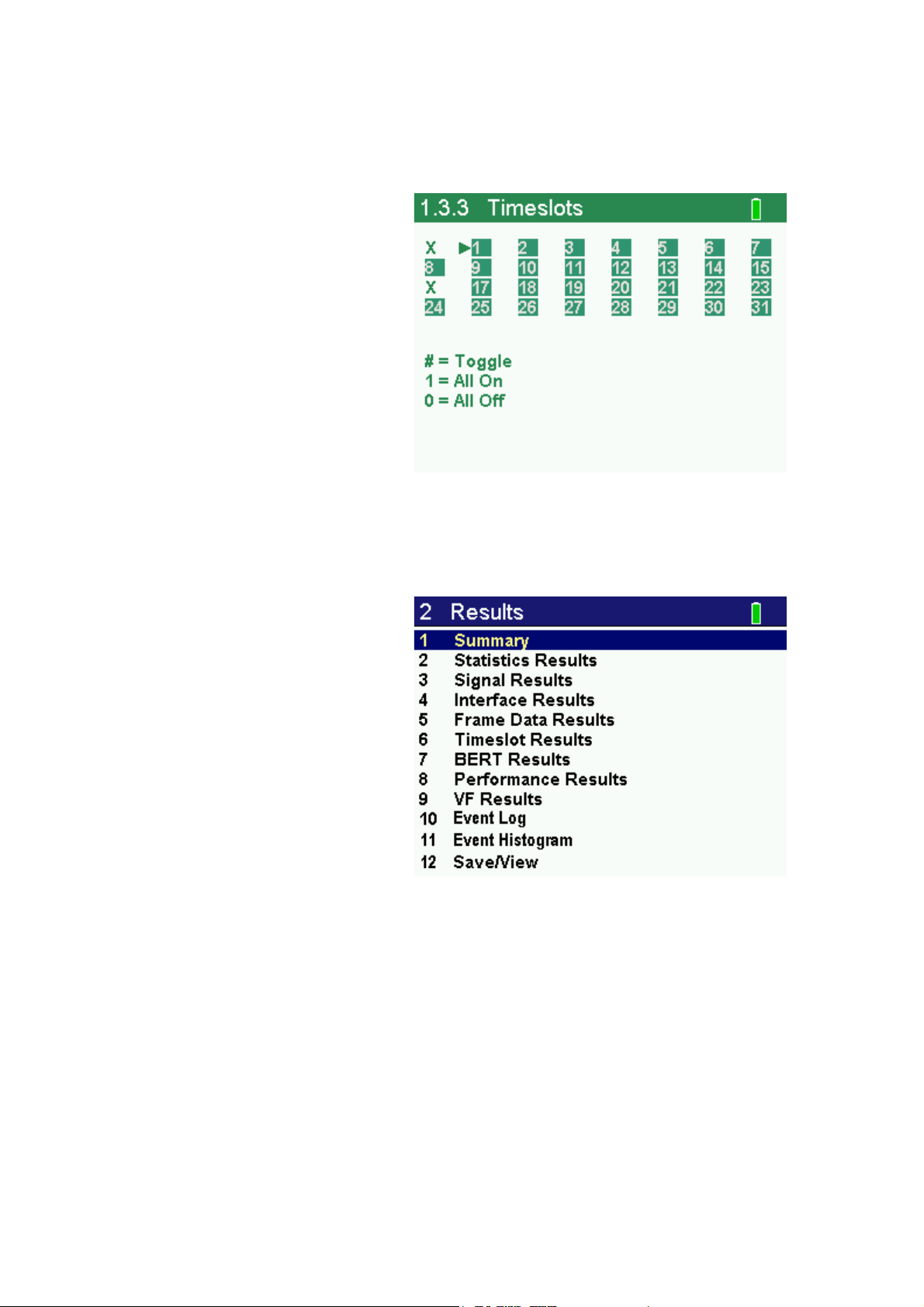

Data entry screens provide a list of selectable options, or allow you to enter

data or specify settings using the keypad. Figure 8 illustrates the Timeslots

screen, used to specify the timeslots you want to use to transmit traffic in.

Figure 8 SmartClass E1 Tester Data Entry screen

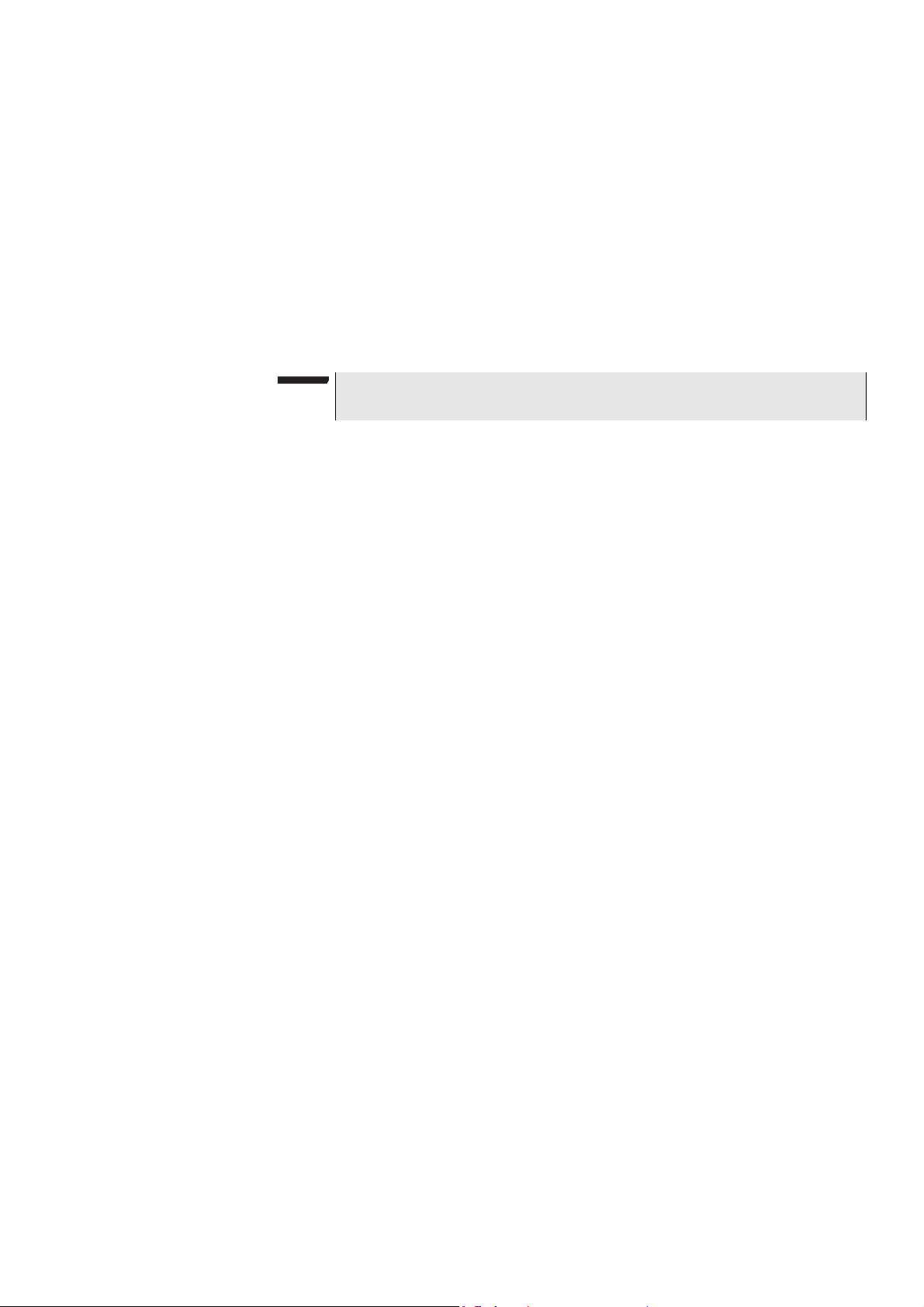

Figure 9 illustrates a Result screen.

Figure 9 SmartClass E1 Tester Result screen

These screens display test results. The results are split into categories. Press

the arrow keys to navigate through the result categories (screens).

SmartClass E1 Tester User’s Guide 13

Page 30

Chapter 1 Getting Started

Using the keypad

Using the keypad

Use the keypad to enter alpha-numeric values, or to navigate to different

screens by specifying the menu number corresponding to the screen. When

entering alpha-numeric values for a test setting:

– The left arrow positions the cursor one position to the left.

– The down arrow operates as a Backspace key, and typically clears the

character one position to the left of the cursor. If the cursor is on the first

character of a text entry field, the down arrow deletes the first character.

– If you are entering text, the up arrow serves as a Caps Lock key.

Selecting a menu option or a

configuration setting

Returning to a previous menu

Entering numeric values

There are three ways to select a menu option or configuration setting.

– Use the arrow keys to scroll to the desired option then press the OK key.

– Press the number associated with the menu option.

– Change on/off or enable/disable values using the left and right arrow keys

on your keypad. For example, if the current value is ON, pressing the left

arrow a single time changes the value to OFF. Pressing it a second time

changes it back to ON.

Use the Cancel key to return to the previous menu.

To enter numeric values

1 Use the arrow keys to scroll to and highlight the setting you want to

specify.

2 Press OK.

3 Use the keypad to type the numeric value.

4 If you want to move to the next field, use the right arrow key.

5 If you want to enter a minus sign (-), and the setting accepts negative

values, press the # key.

6 If you want to enter a decimal point, and the setting accepts floating

decimal values, press the asterisk (*) key.

Typing text

14 SmartClass E1 Tester User’s Guide

To type text

1 Use the arrow keys to scroll to and highlight the setting you want to

specify.

2 Press OK.

Page 31

Chapter 1 Getting Started

Using the keypad

3 Use the keypad to type the text.

– Repeatedly pressing a key scrolls through the selections for that key.

For example, repeatedly pressing the 2 key will scroll through A, B, C

and 2.

– To toggle between upper and lower case, press the up arrow.

– To delete the previous character, press the down arrow.

– Use the left and right arrow to navigate through typed text.

– To enter a space between characters, press the 0 (zero) key once.

– To scroll through and select a special character such as:

. @ / , ‘ - ? ! _ 1

press the 1 (one) key.

NOTE

You can not enter a space when specifying a filename.

SmartClass E1 Tester User’s Guide 15

Page 32

Chapter 1 Getting Started

Using the keypad

16 SmartClass E1 Tester User’s Guide

Page 33

Chapter2

Instrument Settings

2

This chapter describes how to configure the basic settings of the instrument.

Topics discussed in this chapter include the following:

– “Setting the language” on page 18

– “Viewing the software and hardware information” on page 18

– “Setting the date and time” on page 19

– “Adjusting the contrast and brightness” on page 20

– “Determining the specified battery type” on page 20

– “Managing files” on page 20

– “Setting options” on page 21

– “Restoring factory defaults” on page 21

SmartClass E1 Tester User’s Guide 17

Page 34

Chapter 2 Instrument Settings

Setting the language

Setting the language

The following instructions explain how to specify the language for your

SmartClass E1Tester.

To specify the language for the SmartClass E1 tester

1 Power ON your tester by pressing and holding the key for a few

seconds.

The SmartClass E1 splash screen appears briefly, and then the

SmartClass E1 main menu appears.

2 Select System Settings. A menu appears listing each of the system

settings.

3 Select Language. A menu appears listing the available languages.

4 Select the language. After a brief moment, the main menu appears, and

options appear in the language you selected.

The language for the E1 Tester is specified.

NOTE:

If you select the wrong language by mistake, you can return to the language

selection menu by selecting the last item on the Main Menu, and then the

last menu on the System Settings menu.

Viewing the software and hardware information

The Version Info screen displays the current version of the software loaded on

your unit, whether your hardware is jitter capable, and the factory-assigned

SCE ID number.

To view the software and hardware information

1 Select System Settings from the Main Menu.

2 Select Version Info.

The software version and SCE ID Number appear. The screen may also

display “Jitter-capable hardware”.

NOTE:

The jitter option requires both newer hardware and an option code. Thus,

having hardware that is jitter capable does not guarantee that the option is

enabled. To verify whether your unit includes the jitter option, view the E1

Measurement menu. If it includes a selection for E1 Jitter, the option is

enabled.

18 SmartClass E1 Tester User’s Guide

Page 35

Setting the date and time

Chapter 2 Instrument Settings

Setting the date and time

The E1 Tester has an internal clock that you can set to provide accurate time

stamps for test results. By default, the clock uses a 12-hour format and

presents dates in a MM/DD/YYYY format. You can optionally configure your

unit to use a 24-hour time format or a DD/MM/YYYY date format. For example,

you can configure the E1 Tester to display midnight, January 15th in the

following manner:

Time format Time displayed Date format Date displayed

Changing the date or time

format

Setting the date or time

12-hour 12:00:00 AM

24-hour 00:00:00 DD/MM/YYYY 15/01/2007

The following procedure describes how to change the date or time format on

your unit.

To change the date or time format

1 Select System Settings from the Main Menu.

2 Select Set Time/Date Format.

3 Do one of the following:

– To change the format used to display the time, select Time Format,

and then select the new format.

– To change the format used to display the date, select Date Format,

and then select the new format.

The format is changed.

The following procedure describes how to set the date or time.

MM/DD/YYYY 01/15/2007

To set the date or time

1 Select System Settings from the Main Menu.

2 Select Set Time/Date.

3 Do one of the following:

– To set the time, select Set Time, and then enter the time.

– To set the date, select Set Date, and then enter the date.

The date or time is set.

SmartClass E1 Tester User’s Guide 19

Page 36

Chapter 2 Instrument Settings

Adjusting the contrast and brightness

Adjusting the contrast and brightness

The following procedure describes how to adjust the contrast and brightness.

To adjust the contrast and brightness

1 Select System Settings from the Main Menu.

2 Select Contrast/Brightness.

3 Change the contrast level using the left or right arrow key.

4 Change the brightness using the up or down arrow key.

5 Press the Cancel key to return to the previous Menu.

The contrast and brightness are set. You can also press and hold the Backlight

key, and then press the right and left arrows to adjust contrast of the display.

Determining the specified battery type

Managing files

The following procedure describes how to determine the type of battery you

specified when you installed batteries in your unit (see “Replacing the

batteries” on page 105).

To determine the specified battery type

1 Select System Settings from the Main Menu.

2 Select Battery Selection.

A screen briefly appears indicating the type of battery you specified, and then

the System Settings menu appears.

The following procedure describes how to view or delete test configuration or

test result files.

To view or delete files

1 Select File Manager from the Main Menu.

The File Manager menu appears.

2 Select Config Files or Result Files.

A list of files appears.

3 Use the down arrow to scroll to the desired file, and then do one of the

following:

– If you want to view the file, press the OK key.

– If you want to delete the file, press the left arrow key.

A menu appears asking you to verify whether or not you want to delete

the file.

To delete the file, select Yes.

The file is deleted.

20 SmartClass E1 Tester User’s Guide

Page 37

Specifying DB9 port usage

The E1 Tester has one DB9 RS232 serial port but both the VT100 and remote

control options use this port. This menu specifies which option will use the port.

This menu only appears if your unit has both options.

To specify the DB9 port usage

1 Select System Settings from the Main Menu.

2 Select RS232 DB9 port usage.

3 Choose which option will use the DB9 port.

The port usage is specified.

Setting options

The Set Options item on the System Settings menu allows you to add optional

functionality to your SmartClass E1 Tester. If the options were ordered at the

same time the unit was ordered, they will be installed at the factory. If you order

a field upgrade, you will receive a package with an option code to enter here,

along with additional instructions.

Chapter 2 Instrument Settings

Specifying DB9 port usage

The default is VT100.

Restoring factory defaults

The following procedure describes how to restore the E1 Tester to use factory

default test application and system settings.

To restore factory default settings

1 Select System Settings from the Main Menu.

2 Select Restore Defaults.

3 Select Yes to restore the settings, or No to keep the current settings.

Factory defaults are restored.

SmartClass E1 Tester User’s Guide 21

Page 38

Chapter 2 Instrument Settings

Restoring factory defaults

22 SmartClass E1 Tester User’s Guide

Page 39

Chapter3

Basic Testing

3

This chapter provides instructions for basic tests or procedures that are

common among testing applications. Topics discussed in this chapter include

the following:

– “Managing test configurations” on page 24

– “Starting or restarting a test” on page 25

– “Stopping a test” on page 25

– “Timed testing” on page 25

SmartClass E1 Tester User’s Guide 23

Page 40

Chapter 3 Basic Testing

Managing test configurations

Managing test configurations

After specifying test settings, you can save the configuration, and then restore

it at a later time when you want to run a test using the same settings. You can

also view a stored test configuration to verify it matches the desired settings

before using it. If you no longer need the configuration, you can delete it.

Saving a configuration

Restoring a configuration

To save a test configuration

1 If you haven’t already done so, launch your test application (see

“Launching an E1 test application” on page 28), and configure the test

(see “Specifying test application settings” on page 29).

2 On the Configuration menu, select Save/Restore-View.

A menu appears.

3 Select Save Config.

A screen appears prompting you for a filename for the configuration file.

4 Enter a filename, and then press OK.

The configuration file is saved.

To restore a saved test configuration

1 On the Configuration menu, select Save/Restore-View.

A menu appears.

2 Select Restore/View.

A menu appears listing all saved configurations.

3 Use the up and down arrows to highlight the configuration you want to

restore, and then the right arrow.

Viewing a configuration

The configuration is restored.

To view a saved test configuration

1 On the Configuration menu, select Save/Restore-View.

A menu appears.

2 Select Restore/View.

A menu appears listing all saved configurations.

3 Use the up and down arrows to highlight the configuration you want to

restore, and then press OK.

The configuration is displayed on the screen.

24 SmartClass E1 Tester User’s Guide

Page 41

Starting or restarting a test

Chapter 3 Basic Testing

Starting or restarting a test

After you configure your test, you are ready to start or restart the test.

To start or restart the test

1 If you haven’t already done so, launch your test application (see

“Launching an E1 test application” on page 28 or “Launching the datacom

application” on page 52), and configure the test (see “Specifying test application settings” on page 29 or page 53).

2 Press the # Start key.

The unit clears your test results, the test restarts, and the unit transmits the

traffic you configured.

The test starts or restarts.

NOTE

You can also start or restart a test by pressing the Cancel key until you get

to the BERT menu, and then select Action, and then selecting the corresponding option on the Action menu.

Stopping a test

Timed testing

You can stop a test any time.

To stop a test

1 Press Cancel until you get to the main test menu, and then select Action.

A menu of actions applicable to you test appears.

2 Select Stop Test.

A message appears indicating the tester is stopping the test.

The test stops.

If you wish to run a test for a specific amount of time, you can do a timed test.

To do a timed test

1 If you haven’t already done so, launch your test application (see

“Launching an E1 test application” on page 28 or “Launching the datacom

application” on page 52), and configure the test (see “Specifying test application settings” on page 29 or page 53).

2 On the Configuration menu, select Timed Test.

3 Select Enabled, and then select either On or Off.

4 Select Duration, and then enter the number of seconds to run the test.

The test runs for the specified duration.

SmartClass E1 Tester User’s Guide 25

Page 42

Chapter 3 Basic Testing

Viewing test results

Viewing test results

After the E1 tester is connected to the circuit and test is started, the unit immediately accumulates and displays results in the Summary and Signal result

categories. After you start a test and transmit traffic, additional test results

populate the remaining categories.

To view test results

1 If you haven’t already done so, launch a test application (see “Launching

an E1 test application” on page 28 or “Launching the datacom application”

on page 52).

2 Start the test.

3 On the Main menu for the test, select Results.

A menu of result categories applicable to you test appears.

4 Select a result category.

5 If necessary, use the up / down arrow keys or the OK key to select Rx1 or

Rx2 results.

Remote Control

Test results appear for the category you selected. After the test is complete

and all results have accumulated, the status bar at the bottom of the results

display blinks and indicates that the results are complete.

You can clear existing result values and then accumulate new values using the

Restart action.

The test results for the category appear. For descriptions of test results, see

Chapter 7 “Test Results”.

With the remote control option, you can connect to a E1 Tester in order to

control it remotely using command lines via the serial interface. A command

guide is available with the option.

26 SmartClass E1 Tester User’s Guide

Page 43

Chapter4

E1 Testing

4

This chapter provides task-based instructions for turning up and troubleshooting E1 service using the SmartClass E1 Tester. Topics discussed in this

chapter include the following:

– “About E1 testing” on page 28

– “Launching an E1 test application” on page 28

– “Specifying test application settings” on page 29

– “Monitoring a circuit” on page 38

– “Measuring timing slips” on page 39

– “Terminate testing” on page 40

– “Line loopback testing” on page 41

– “Pulse shape analysis” on page 42

– “Measuring Jitter” on page 43

– “Testing MFC-R2 Signaling” on page 46

SmartClass E1 Tester User’s Guide 27

Page 44

Chapter 4 E1 Testing

About E1 testing

About E1 testing

The SmartClass E1 tester is intended to be used to commission and maintain

E1 circuits. Typically this involves out-of-service testing to ensure that the

physical layer is clean and there are no problems with network equipment or

improper provisioning.

You can use the SmartClass E1 in the following ways:

– To terminate a circuit, and then loop back to another SmartClass unit or

piece of network equipment to perform BER testing.

– To perform BER analysis end-to-end between two SmartClass units (typi-

cally requires two technicians) with analysis performed in both directions.

This allows you to easily isolate faults on the circuit.

– To passively monitor one or two E1 circuits (in-service testing) by exam-

ining transmission layer metrics such as CRC and frame errors or timing

slips.

– To perform BER testing on individual timeslots within an E1 circuit.

– To perform line loopback testing to monitor the circuit.

– To measure an E1 pulse and display a graph of the pulse shape

Launching an E1 test application

The following procedure describes how to launch an E1 test.

To launch an E1 test

1 Power ON your tester by pressing and holding the key for a few

seconds.

The SmartClass E1 splash screen appears for a few seconds, and then

the SmartClass E1 main menu appears.

2 Select E1 Measurements. The E1 Measurements menu appears.

3 Select an application; for example, E1 BERT.

A message briefly appears stating that the unit is launching the test application.

A test menu appears for the application, listing the following options:

– Configuration. Select this option to configure your test.

– Results. Select this option to observe test results associated with your

test.

– Error/Alarm. Select this option to insert errors or alarms as you test.

This is only available in the E1 BERT application.

– Action. Select this option to perform key actions required for your test,

such as starting or restarting a test, starting traffic or looping up a unit.

You can also press the Action button at any time to view a menu of

actions applicable to your test.

The E1 test application is launched.

28 SmartClass E1 Tester User’s Guide

Page 45

Specifying test application settings

Before transmitting traffic over a link, you can specify interfaces and settings

that filter received traffic for analysis.

Chapter 4 E1 Testing

Specifying test application settings

Specifying a test mode

The SmartClass E1 can operate in the following test modes:

– Terminate Mode: This mode separates the Transmit and Receive side of

an E1 path. The received E1 signal is terminated and a completely independent signal is transmitted.

Use this mode to test out of service lines using the RX1/TX1 port. You can

generate and send test patterns on TX1 and receive patterns on RX1.

RX2/Ext Clk is not used in this mode.

– Monitor Mode (PMP Monitor): This mode measures signal parameters

and monitors traffic at an E1 access point (the PMP – Protected Monitor

Point). The PMP typically has a resistive loss of -26dB. The tester applies

gain to the input signal to compensate for the reduced PMP amplitude.

Both of the receivers are monitored simultaneously. However, the E1

tester does not transmit any traffic in this mode. This permits simultaneous

non-intrusive monitoring of the E1 line.

– Bridge Mode (HI-Z Monitor): This mode allows you to bridge onto a

terminated E1 line with a high impedance (Hi-Z). This permits simultaneous non-intrusive monitoring on the E1 line. The transmitter on the E1

line is not used in this mode.

– Line Loopback: This mode loops the entire E1 circuit. This configuration

will loop the incoming data back out the transmitter yet still allow the

receiver to monitor the incoming signal.

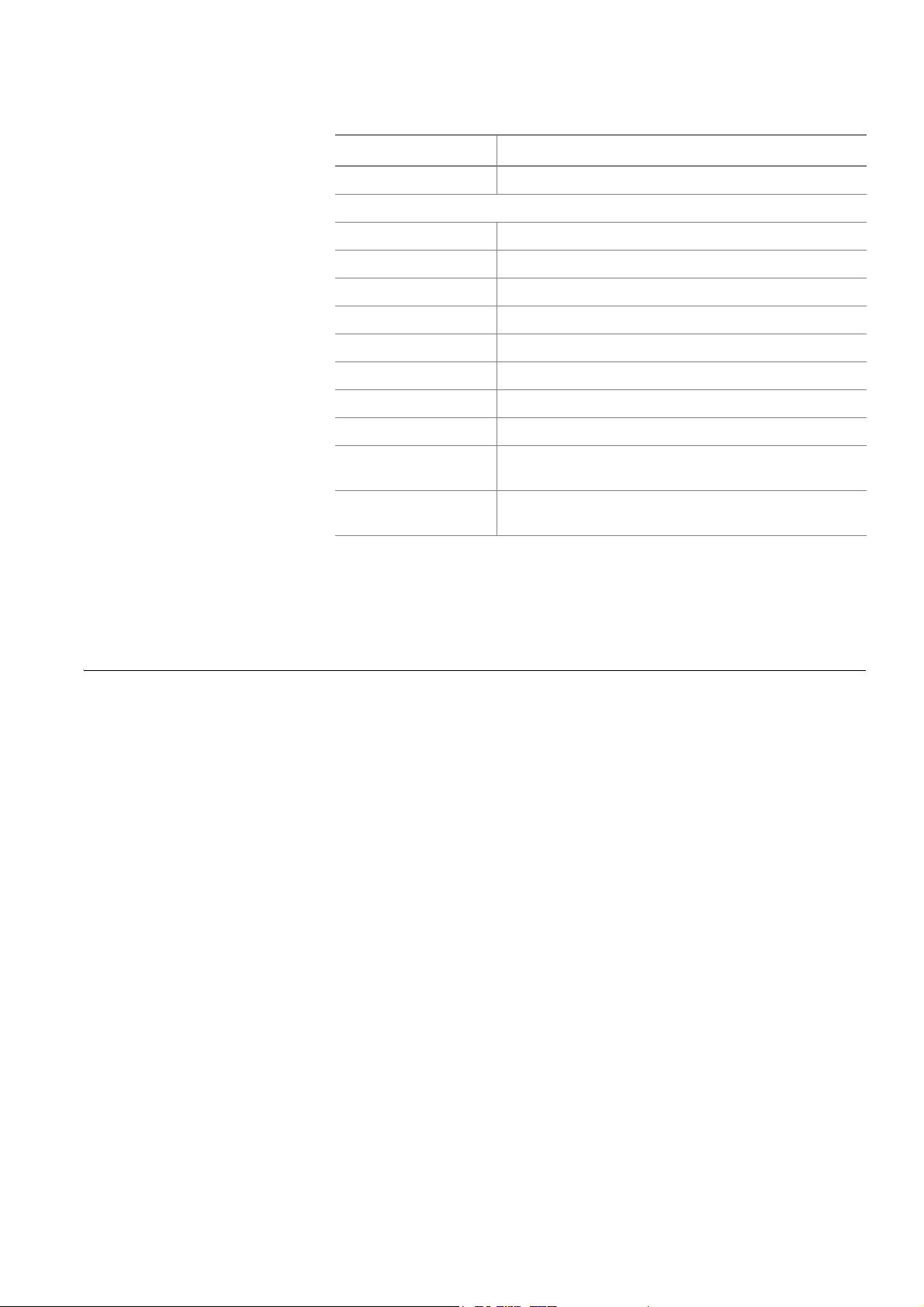

Table 7 lists the transmitter/receiver used in the test modes supported by the

SmartClass E1 tester:

Table 7 SmartClass E1 Tester Test Modes

Test Mode Rx1 Tx1 Rx2 Rx1 VF

Terminate X X X

Monitor X X X

Bridge X X X

Line Loopback X X X

To specify a test mode

1 If you haven’t already done so, launch an E1 application (see “Launching

an E1 test application” on page 28).

2 On the Configuration menu, select Test Mode, and then use the up or

down arrow to specify one of the following:

– Terminate

–Monitor

– Bridge

– Line Loopback

SmartClass E1 Tester User’s Guide 29

Page 46

Chapter 4 E1 Testing

Specifying test application settings

3 If you need to specify other settings for the test, press Cancel to return to

the Configuration menu.

The test mode is specified.

Configuring test settings

automatically

You can use the Auto Configure feature to configure the interface, framing, and

pattern settings automatically.

To configure the interface, framing, and pattern settings automatically

1 If you haven’t already done so, launch your test application (see

“Launching an E1 test application” on page 28).

2 Connect the E1Tester to the circuit.

3 On the test menu, select Action.

The Action menu appears.

4 On the Action menu, select Auto Configure.

The SmartClass E1 will attempt to automatically configure the interface,

framing, and pattern. If this attempt fails, the E1 tester will set the framing

to Unframed and the pattern to Live. You can also configure the framing

and pattern settings manually. See “Specifying E1 framing settings” on

page 31 and “Specifying a BERT pattern” on page 33.

The interface, framing, and pattern settings are automatically configured.

Proceed to configure the following settings for the test:

– VF settings, see “Specifying VF settings” on page 37.

– E1 signaling settings, see “Specifying E1 signaling (ABCD/Sa) settings” on

page 32.

– Defect and anomaly settings, see “Specifying Error/Alarm settings” on

page 35.

– Performance settings, see “Specifying performance settings” on page 36.

Specifying interface settings

Before you transmit E1 traffic, you can specify the characteristics of the interface you want to transmit the traffic on, such as the line coding for the signal

you want to transmit, the transmit clock, and the slip reference for the receiver.

To specify interface settings

1 If you haven’t already done so, launch an E1 BERT application (see

“Launching an E1 test application” on page 28).

2 On the Configuration menu, select Interface Settings, and then specify

values for the following settings:

Setting Parameter

Line Coding Select one of the following line coding

options:

– HDB3: High Density Bipolar 3

– AMI: Alternate mark inversion

30 SmartClass E1 Tester User’s Guide

Page 47

Chapter 4 E1 Testing

Specifying test application settings

Setting Parameter

Tx Clock Select one of the following:

– Internal

– Rx1

– Rx2

– Ext. BNC

NOTE: If timing is lost, the SmartClass reverts

to internal timing.

Tx Clk Offset (ppm) Enter a value, from -100 through 100 ppm, to

indicate the offset frequency generated by the

2048 kbit/s internal clock.

To specify negative numbers, press the # key.

To delete a single character, press the down

arrow key.

Slip Reference Select one of the following slip reference

options:

– Rx2

– Ext. BNC

Specifying E1 framing

settings

3 If you need to specify other settings for the test, press Cancel to return to

the Configuration menu.

The interface settings are configured.

Before transmitting E1 traffic, you can specify the framing format and payload

of the traffic you want to transmit.

To specify E1 framing settings

1 If you haven’t already done so, launch an E1 application (see “Launching

an E1 test application” on page 28).

2 On the Configuration menu, select E1 Frame Settings, and then specify

values for the settings listed below:

Setting Parameter

Framing Select the framing format for the signal:

– PCM31C

– PCM31

– PCM30C

– PCM30

– Unframed

Payload Select the payload:

– Bulk: full E1 circuit

– nx64k: individual timeslot(s) from an E1

circuit

SmartClass E1 Tester User’s Guide 31

Page 48

Chapter 4 E1 Testing

Specifying test application settings

Setting Parameter

Timeslots

nx64k payload only)

(

Idle Byte

nx64k payload only)

(

Do one of the following:

– To turn all the available channels on,

press 1.

– To turn all the available channels off,

press 0.

– To turn on only the selected channels, use

the arrow keys to point at the channels

you want to turn on, and then press the #

key to select the channel. You can select

multiple channels.

When you have finished selecting timeslots,

press OK. At least one timeslot must be

selected.

Specify the idle byte pattern you want to insert

into the selected timeslots.

For example, (MSB) 10101010 (LSB), the

MSB is sent first.

3 If you need to specify other settings for the test, press Cancel to return to

the Configuration menu.

The framing settings are configured.

Specifying E1 signaling

(ABCD/Sa) settings

Before transmitting E1 traffic, you can specify settings for E1 signaling.

To specify E1 signaling settings

1 If you haven’t already done so, launch an E1 test application (see

“Launching an E1 test application” on page 28).

2 On the Configuration menu, select ABCD/Sa Settings, and then specify