Page 1

ZPPKG0574

REV 0 REV 0

P5000i Digital Analysis Microscope

Automated ber end face inspection and analysis system

USER MANUAL

Page 2

USER MANUAL2

NOTICE Every eort was made to ensure that the information in this document was accurate at the time

of printing. However, information is subject to change without notice, and JDSU reserves the

right to provide an addendum to this document with information not available at the time that

this document was created.

COPYRIGHT © Copyright 2011 JDSU, LLC. All rights reserved. JDSU, Enabling Broadband and Optical

Innovation, and its logo are trademarks of JDSU, LLC. All other trademarks and registered

trademarks are the property of their respective owners. No part of this guide may be reproduced

or transmitted electronically or otherwise without written permission of the publisher.

TRADEMARKS JDSU is a trademark of JDSU in the United States and other countries.

RibbonDrive is a trademark of JDSU.

Hirose is a trademark of Hirose Electric Group.

MTP is a registered trademark of US Conec, Ltd.

Pentium is a registered trademark of Intel Corporation.

Windows is a registered trademark of Microsoft Corporation.

Vista is a registered trademark of Microsoft Corporation.

Excel is a registered trademark of Microsoft Corporation.

Specications, terms, and conditions are subject to change without notice. All trademarks and

registered trademarks are the property of their respective companies.

PATENTS RibbonDrive Tips: US Patent No. 6,751,017 / 6,879,439

CleanBlast: US Patent No. 7,232.262

TESTED EQUIPMENT All pre-qualication tests were performed internally at JDSU, while all nal tests were performed

externally at an independent, accredited laboratory. This external testing guarantees the

unerring objectivity and authoritative compliance of all test results. JDSU's Commerce and

Government Entities (CAGE) code under the North Atlantic Treaty Organization (NATO) is

0L8C3.

FCC INFORMATION Electronic test equipment is exempt from Part 15 compliance (FCC) in the United States.

EUROPEAN UNION Electronic test equipment is subject to the EMC Directive in the European Union. The EN61326

standard prescribes both emission and immunity requirements for laboratory, measurement,

and control equipment. This unit has been tested and found to comply with the limits for a

Class A digital device.

INDEPENDENT

LABORATORY TESTING

This unit has undergone extensive testing according to the European Union Directive and

Standards.

Page 3

P5000i Digital Analysis Microscope 3

Chapter 2

FIBERCHEKPRO™ SOFTWARE / DRIVER INSTALLATION ......................................6–11

Software Install ........................................................................................................................ 6

JDSU (ueye_boot) Driver Install ........................................................................................ 8

JDSU (usbser) Driver Install ................................................................................................. 9

Hardware Install ....................................................................................................................10

TABLE OF CONTENTS

Chapter 4

DEVICE PLATFORMS ........................................................................................................... 20–21

Overview .................................................................................................................................20

Compatible Platforms .........................................................................................................21

Proles ......................................................................................................................................20

Optical Settings ..................................................................................................................... 21

Operating the P5000i on JDSU Test Platforms ...........................................................21

Live View Controls ................................................................................................................ 21

Test View Controls ................................................................................................................21

Device Setup Controls ........................................................................................................21

Chapter 3

FIBERCHEKPRO™ SOFTWARE ........................................................................................ 12–19

Overview .................................................................................................................................12

Controls (LIVE VIEW) ............................................................................................................ 14

Controls (TEST VIEW) ...........................................................................................................15

Using FiberChekPRO with P5000i Digital Analysis Microscope ..........................16

Optical Settings ..................................................................................................................... 18

Proles ......................................................................................................................................19

Chapter 1

P5000i DIGITAL ANALYSIS MICROSCOPE ..................................................................... 4–5

Overview ................................................................................................................................... 4

Controls ...................................................................................................................................... 5

Specications ........................................................................................................................... 5

Page 4

USER MANUAL4

P5000i Digital Analysis Microscope

1

Overview The P5000i Digital Analysis Microscope is a portable handheld microscope used

to inspect and certify both the bulkhead (female) and patch cord (male) sides of

ber connectors as well as other optical devices, such as transceivers. The probe

is specially designed to t and operate comfortably and easily in-hand, allowing

the user to inspect hard-to-reach connectors that are installed on the back side

of patch panels or inside hardware devices. The P5000i automatically inspects and

analyzes the ber end faces, detects scratches and defects, and provides instant

Pass/Fail results. This eliminates subjectivity and time-consuming guesswork from

the inspection process.

The P5000i can deliver these results to a PC/Laptop and JDSU test platforms, such

as the MTS/T-BERD 2000/4000/6000 and HST-3000.

CHAPTER 1 P5000i Digital Analysis Microscope

Page 5

P5000i Digital Analysis Microscope 5

P5000i Digital Analysis Microscope CHAPTER 1

Dimensions 140 x 46 x 44 mm (5.5 x 1.8 x 1.7 in)

Weight 110 g (3.9 oz)

LOW-Mag field-of-view

(FOV)

Horizontal: 740 μm

Vertical: 550 μm

HIGH-Mag FOV Horizontal: 370 μm

Vertical: 275 μm

Live image 640 x 480; 8 fps

Connector USB 2.0

Cord length 183 cm ( 6-ft)

Focus control Adjustable, in-probe

Camera sensor 2560 x 1920, 1/2.5-in (1.02 cm) CMOS

Resolution < 1 μm

Light source Blue LED, 100,000+ hour life

Lighting technique Coaxial

Power source USB port

Certification CE

Warranty 1 year

Specications

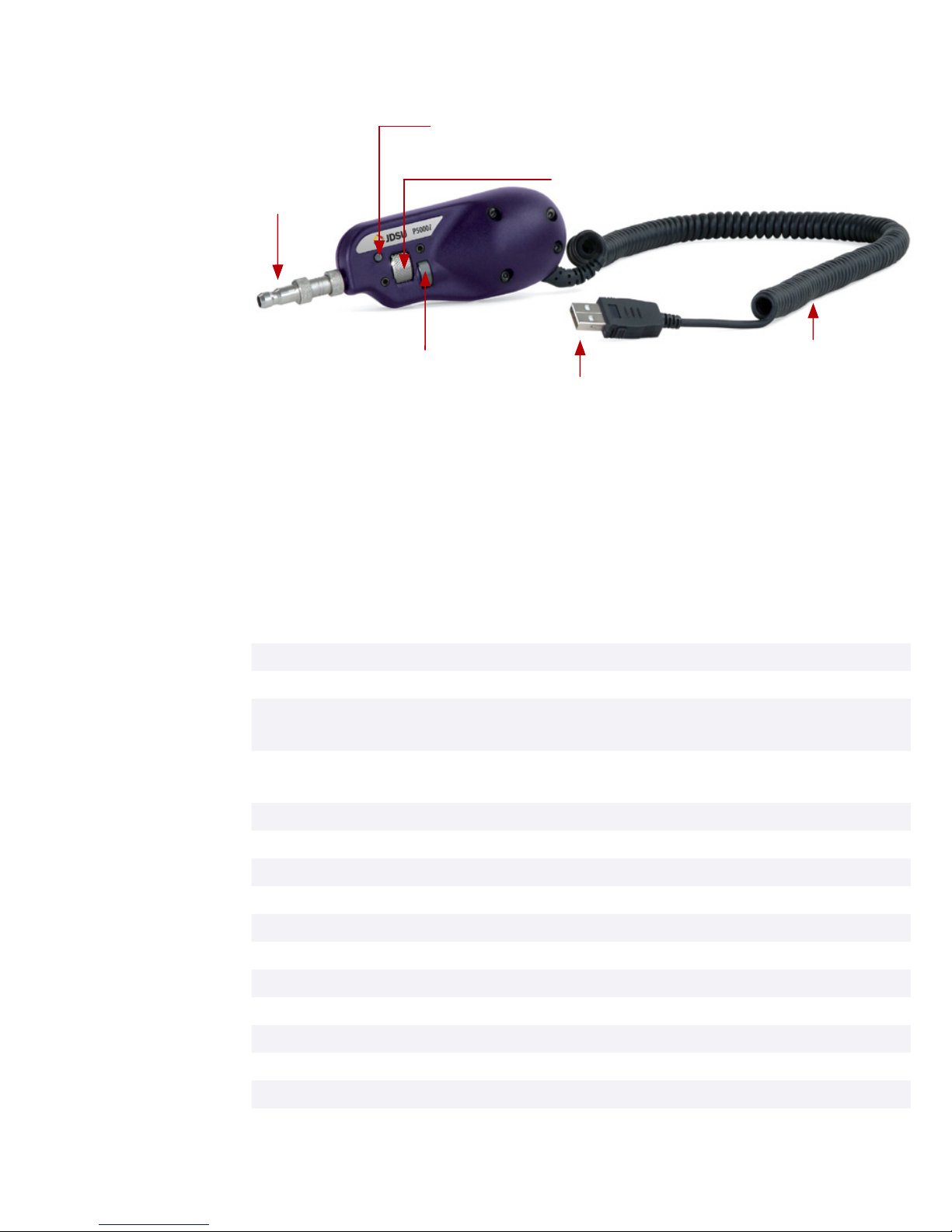

Controls

Instantly captures and analyzes the ber image.QuickCapture Button

Allows the user to switch between LOW and HIGH magnications of the ber end

face image.

Magnication Control

Allows the user to adjust focus manually of the live ber end face image on the

display.

Focus Control

FOCUS CONTROL

MAGNIFICATION CONTROL

6 FT COIL CABLE

QUICKCAPTURE™ BUTTON instantly captures and analyzes fiber image

INSPECTION TIP

USB 2.0 CONNECTOR

Page 6

USER MANUAL6

FiberChekPRO Software / Driver Installation

Software Installation

(for use with a

PC/laptop)

2

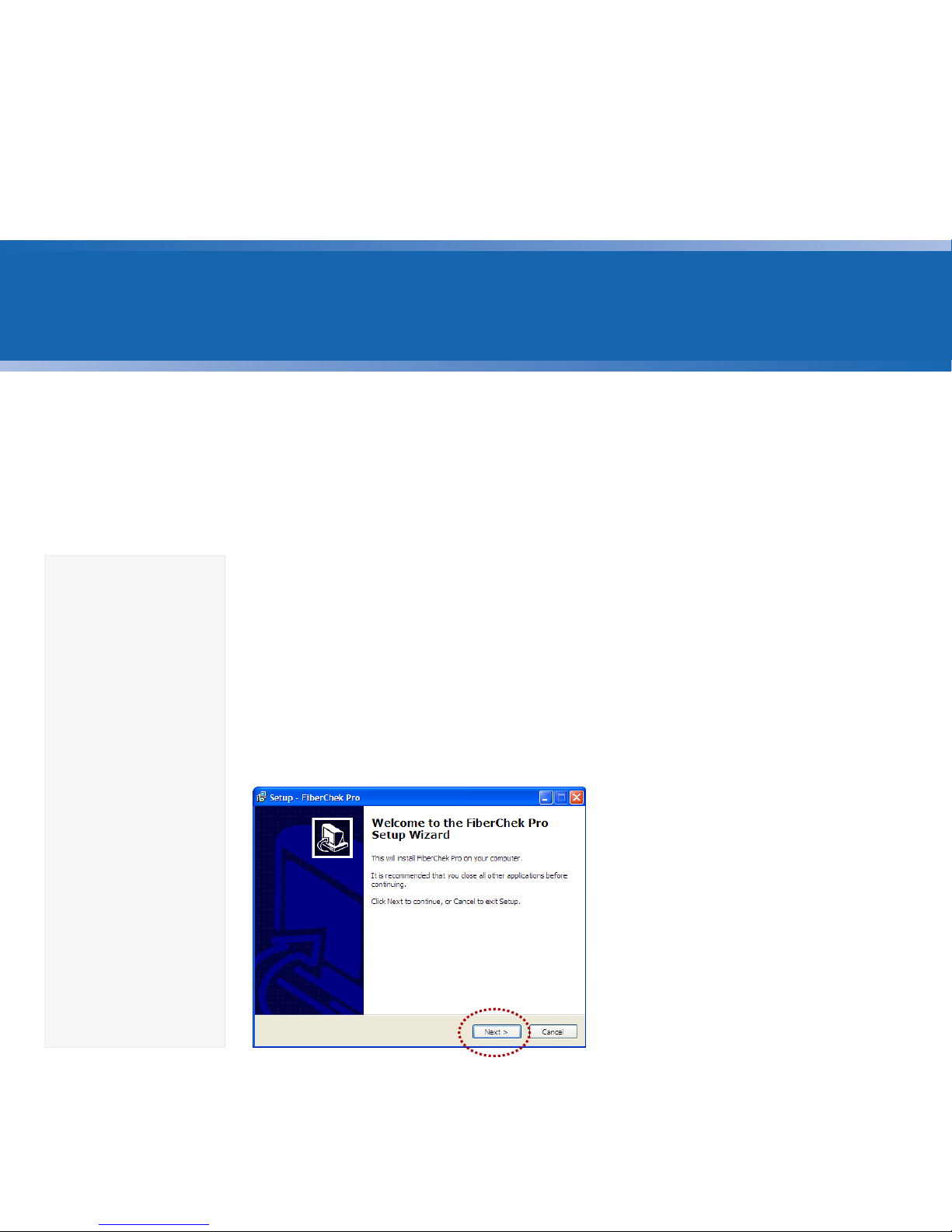

IMPORTANT! Install the software before attaching the microscope to PC.

1. Insert FiberChekPRO™ CD

• Insert FiberChekPRO CD and wait for the automatic Welcome to the

FiberChekPRO Setup Wizard menu to launch OR locate the setup file

on the software CD and open.

2. Install FiberChekPRO Software

Minimum

System

Requirements

• PC/laptop with

Pentium® III

1.0 GHz CPU or

higher

• Windows® 2000

(SP4), XP® or

Vista® Operating

System

• 50 MB of hard

drive space

for application

software

• One open USB

2.0 port

• 128 MB RAM

• At the Welcome to the

FiberChekPRO Setup Wizard

menu click Next > to continue.

CHAPTER 2 P5000i Digital Analysis Microscope

Page 7

P5000i Digital Analysis Microscope 7

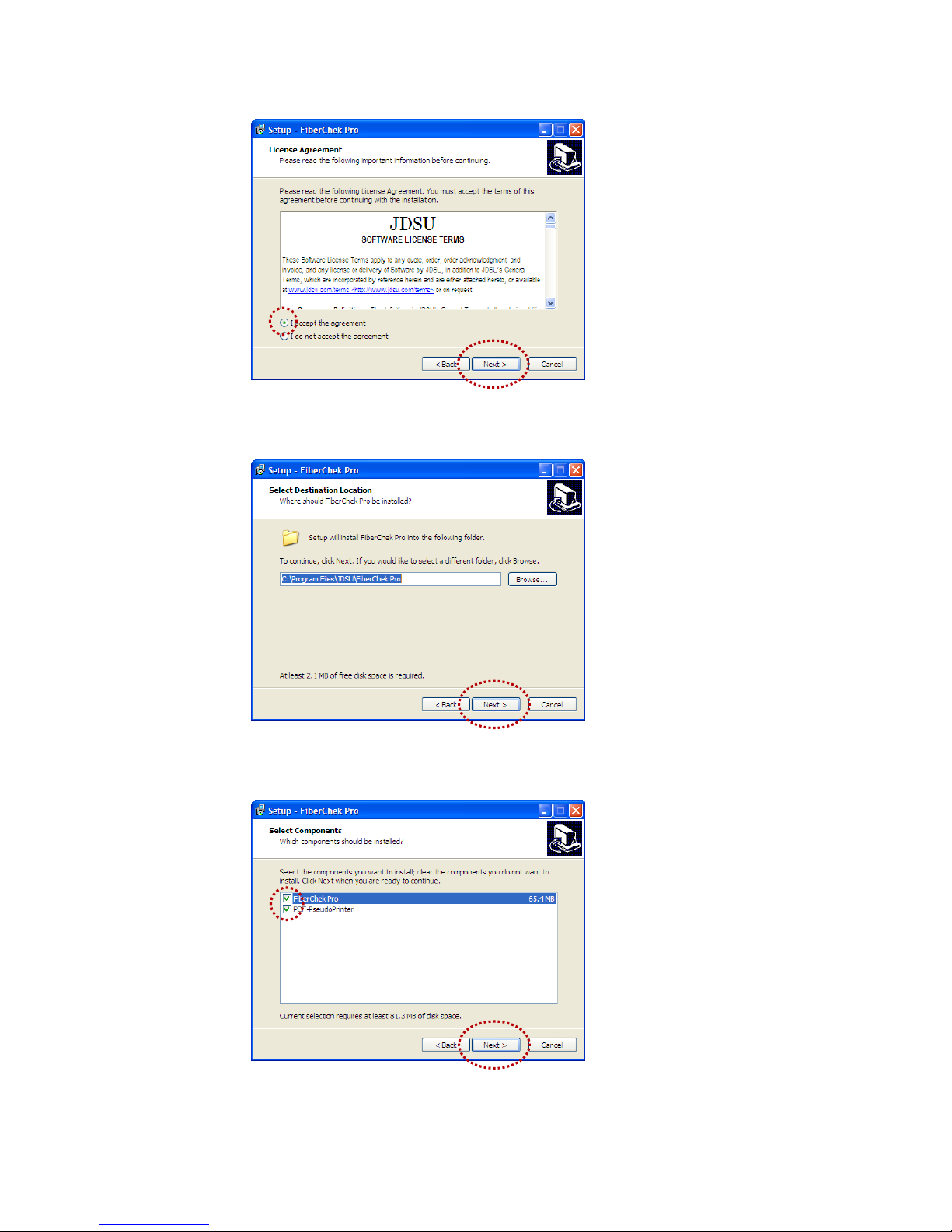

• At the License Agreement menu

select I accept the agreement

button, then click Next > to

continue.

• At the Select Destination Location

menu, accept the default location

(strongly recommended) for the

application files OR click Browse to

select a user-defined location then

click Next > to continue.

FiberChekPRO Software / Driver Installation CHAPTER 2

• At the Select Components menu,

check all the components you

want to install, and make sure the

box next to PDF-PseudoPrinter

is checked and click Next > to

continue.

Page 8

USER MANUAL8

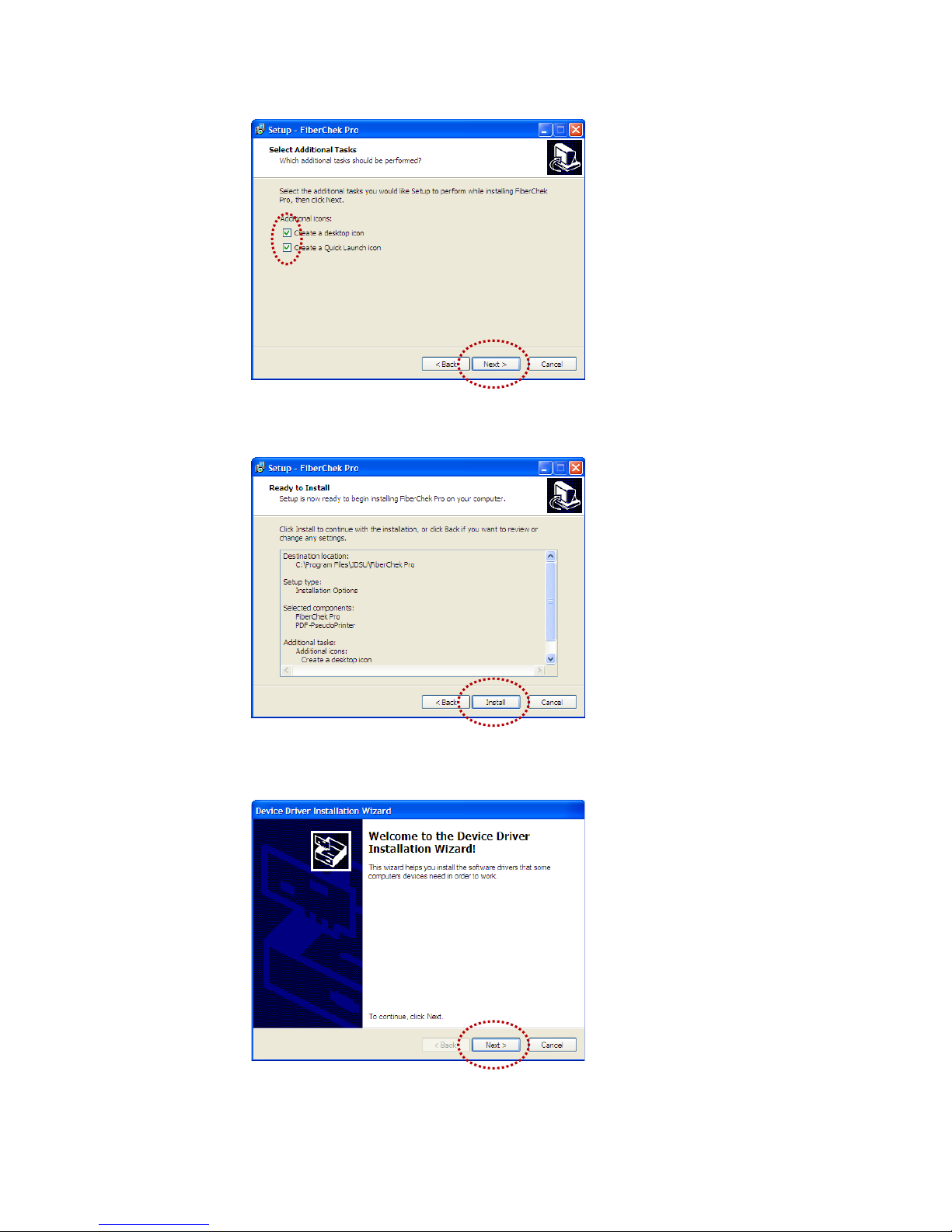

• At the Ready to Install menu,

confirm settings then click Install

to continue.

CHAPTER 2 P5000i Digital Analysis Microscope

JDSU Inc (ueye_boot)

Driver Installation

• At the Welcome to the Device

Driver Installation Wizard menu,

click Next > to continue.

• At the Select Additional Tasks

menu, select/check options for

FiberChekPRO icon/shortcut

placement then click Next > to

continue.

Page 9

P5000i Digital Analysis Microscope 9

JDSU (usbser)

Driver Installation

• At the Completing the Device

Driver Installation Wizard menu,

click Finish to complete JDSU Inc

(ueye_boot) driver installation.

FiberChekPRO Software / Driver Installation CHAPTER 2

• At the Welcome to the Found New

Hardware Wizard menu, click

Next > to continue.

• At the Completing the Device

Driver Installation Wizard menu,

click Finish to complete

JDS Uniphase (usbser) Ports

driver installation.

Page 10

USER MANUAL10

3. Hardware Installation

• Plug the probe microscope into

the computer.

• Wait for the automatic Found

New Hardware Wizard menu to

launch.

Hardware

Installation

CHAPTER 2 P5000i Digital Analysis Microscope

• At the Information menu, click

Next > to continue.

• At the Completing the

FiberChekPRO Setup Wizard, click

Finish to complete software and

driver installation.

Page 11

P5000i Digital Analysis Microscope 11

This page intentionally left blank.

FiberChekPRO Software / Driver Installation CHAPTER 2

Page 12

USER MANUAL12

FiberChekPRO Software

3

Overview The P5000i Digital Analysis Microscope uses FiberChekPRO (automated

analysis software) to operate on a PC/Laptop, and instantly captures, analyzes and

grades ber endface images to obtain a PASS/FAIL result and generate certication

reports.

FiberChekPRO is a software application used to determine the acceptability

of optical ber end faces through automated inspection and analysis. Used in

conjunction with JDSU’s P5000i Digital Analysis Microscope, FiberChekPRO will

identify and characterize defects and contamination then provide a PASS or

FAIL result according to a pre-congured failure criteria setting. In addition, the

program allows users to archive data, generate reports and obtain an Optical Power

Measurement (OPM) with both the MP-series and FI-series test tools from JDSU.

CHAPTER 3 P5000i Digital Analysis Microscope

Page 13

P5000i Digital Analysis Microscope 13

FiberChekPRO™

FiberChekPRO Performs the Following Automated Procedures

1. Acquires the ber image.

2. Analyzes the image.

3. Finds defects and their location to ber core.

4. Measures and evaluates the defects within each specied Zone.

5. Determines whether defects within the Zones are acceptable according to the

pre-congured failure criteria for each Zone.

6. Displays the results as PASS or FAIL.

7. Saves or prints all relative results in designated directory or printer, respectively.

FiberChekPRO Software CHAPTER 3

Page 14

USER MANUAL14

Allows the user to select the specic microscope they want to have active for

displaying on the screen. If multiple microscopes are connected, each one will

appear in a drop down list.

Controls (LIVE VIEW)

MICROSCOPE

CHAPTER 3 P5000i Digital Analysis Microscope

TIP Allows the user to select the best optical settings for the type of inspection tip that

is attached to their probe. Users can select from several pre-congured optical

settings or create their own. For more information, see the OPTICAL SETTINGS section

on page 18.

PROFILE Allows the user to select from various PROFILES, which contain the analysis

parameters by which PASS/FAIL criteria are determined. Users can select from

several pre-congured PROFILES or create their own. For more information, see the

PROFILES section on page 19.

IMAGE CONTROLS Provide specic controls for ne tuning the image. In LIVE view, users can select

between viewing at LOW or HIGH magnication.

FOCUS QUALITY

METER

A visual gauge that aids the users in nding the optimal focus point. Optimal focus

level is reached when the blue bar is closest to the red line.

TEST Initiates the automated PASS/FAIL test process.

SAVE Allows the user to capture and save the image as it appears on the screen.

MICROSCOPE

TEST

SAVE

TIP PROFILE IMAGE CONTROLS

Page 15

P5000i Digital Analysis Microscope 15

Provides specic controls for ne tuning the image. In TEST view, users can:

• SelectbetweenviewingatLOWorHIGHmagnication

• TurntheoverlaydetailsONorOFF

• TurntheScratchViewfeatureONorOFF

Controls (TEST VIEW)

IMAGE CONTROLS

LIVE Allows the user to return back to a live image.

SAVE REPORT Generates a summary report of the tested ber on the screen.

DETAILS Allows the user to view more specic information on the analysis results for the

tested ber on the screen.

MICROSCOPE

LIVE

SAVE REPORT

DETAILS

IMAGE CONTROLS

FiberChekPRO Software CHAPTER 3

Page 16

USER MANUAL16

• Select the appropriate inspection

tip that corresponds to the

connector type and side being

inspected and attach to probe.

INSPECTION TIP BARREL ASSEMBLY

• In the TIP section, select the pre-

configured Optical Setting from

the dropdown list (see page 18

for descriptions).

1. Open/Launch FiberChekPRO

2. Install Inspection Tip

• Locate FiberChekPRO application

and open.

Using FiberChekPRO

with P5000i Digital

Analysis Microscope

CHAPTER 3 P5000i Digital Analysis Microscope

FiberChekPRO

Desktop Icon

3. Select Prole Setting

• From the pre-configured PROFILE

settings dropdown list, select

the appropriate connector being

inspected.

Page 17

P5000i Digital Analysis Microscope 17

5. Focus the Fiber End Face Image On Screen

• Adjust the focus of the fiber end

face image on the computer

screen by turning the Focus

Control on the microscope.

6. Test

• Press the QuickCapture button

on the probe OR click the TEST

button from the FiberChekPRO

toolbar to run analysis.

FiberChekPRO Software CHAPTER 3

4. Inspect Fiber

• Insert the probe into the bulkhead

(for probe) or insert the path cord

ferrule into the probe tip.

Page 18

USER MANUAL18

Optical Settings

• StandardTips(withBAP1)

Select when using standard tips with FBPP-BAP1 barrel assembly. Tips that use this

setting include FBPT-SC, FBPT-LC, FBPT-ST, FBPT-FC, FBPT-SC-APC & FBPT-FC-APC.

• StandardTips(withBAP2)

Select when using standard tips with the FBPP-BAP2 barrel assembly for longer

reach inspection. Note: The FBPP-BAP2 accepts the same tips as the FBPP-BAP1.

• Mil/AeroTips&Guides(withBAP3)

Select when using guides designated for inspecting Military & Aerospace

connectors with the narrow barrel assembly (FBPP-BAP3).

• LongReach(-L)Tips

Select when using long reach inspection tips. Note: Long Reach inspection tips are

noted with the sux “-L” on the part number (ex: FBPT-SC-L, FBPT-LC-L, etc.).

• RibbonTips

Select when using tips designated for inspecting ribbon connectors. Note: Ribbon

connectors contain an array of multiple bers in a single connector (ex: FBPT-MTP).

• E2000Tips

Select when using long reach E2000 inspection tips (ex: FBPT-E2000).

• SC-A6Tip(60DegreeAngle)

Select when using SC inspection tips with a 60 degree angle. Note: Angled

inspection tips are typically noted with the sux “-A6” on the part number (ex: FBPTSC-A6, FBPT-SCA-A6).

NOTE: Users can also create new Optical Settings for specialty tips or applications. See the

FiberChekPRO user manual for details.

Optical Settings congure the P5000i for optimal performance with a given

tip. Users can select the best optical settings for the type of inspection tip that

is attached to their probe. The P5000i comes pre-congured with the following

optical settings:

CHAPTER 3 P5000i Digital Analysis Microscope

Page 19

P5000i Digital Analysis Microscope 19

Proles Contains the analysis parameters by which PASS/FAIL criteria are determined. Users

can activate which proles they want to appear in the PROFILE drop down list on

the main menu by selecting Setup > Analysis Proles.

Proles listed in the ACTIVE section will appear in the drop down menu. Users can

select from several pre-congured PROFILES or create their own.

NOTE: Double-click on an active prole to nd out more information about it.

FiberChekPRO Software CHAPTER 3

Page 20

USER MANUAL20

Device Platforms

4

Overview

Proles

The P5000i Digital Analysis Microscope also operates on several other JDSU

handheld test platforms to instantly capture, analyze and grade ber endface

images to obtain a PASS/FAIL result and generate certication reports. P5000i will

operate on these platforms in a similar way to FiberChekPRO. The user will always

specify what prole to test against and what tip is attached (found in setup or options

menu). For more information on using the P5000i with other device platforms, see

the user manuals for the specic tool or platform.

CHAPTER 4 P5000i Digital Analysis Microscope

Compatible

Platforms

Other platforms that P5000i connects to include but are not limited to:

• MTS/T-BERD2000

• MTS/T-BERD4000

• MTS/T-BERD6000

• T-BERD5800

• HST-3000

• MAP-200

JDSU platforms capable of using the P5000i will come pre-loaded with proles

matching the requirements in IEC-61300-3-35. Users can create new proles using

FiberChekPRO and export them to the JDSU test platform as follows:

1. Create the new prole in FiberChekPRO and close the application.

2. Use Windows Explorer and Browse to the FiberChekPRO install folder (the

default location is C: Program Files/JDSU/FiberChekPro).

Page 21

P5000i Digital Analysis Microscope 21

Device Platforms CHAPTER 4

3. Select the folder named "Proles - Shortcut" (this opens up a folder with all of

your proles in FiberChekPRO).

4. Copy the Proles you want to add onto the test platform and save to a

portable USB memory stick.

5. Connect the USB memory stick to the test platform and save the prole le(s)

to the location specied in the platform manual.

Optical Settings congure the P5000i for optimal performance with a given

tip. Users can select the best optical settings for the type of inspection tip that

is attached to their probe. The P5000i comes pre-congured with a selection of

default optical settings (see page 18). Additional settings can be added to the

P5000i using FiberChekPRO. See the FiberChekPRO user manual for further details

on this process.

Optical Settings

Operating the

P5000i on JDSU

Test Platforms

While each JDSU test platform will have its own user interface, all platforms will

have common controls for inspection and analysis.

Live View Controls Focus Quality: A visual gauge that aids the users in nding the optimal focus

point. Optimal focus level is reached when the blue bar is closest to the red line.

Test: Initiates the automated PASS/FAIL test process.

Magnication Selection: Select between viewing at LOW or HIGH magnication.

Test View Controls Live: Allows the user to return back to a live image.

Overlays: Toggles an overlay of the zones and analysis details ON or OFF.

Magnication Selection: Select between viewing at LOW or HIGH magnication

inspected image.

Save Report: Generates a summary report of the tested ber on the screen.

Device Setup

Controls

Tip: Allows the user to select the best optical settings for the type of inspection

tip that is attached to their probe. Users can select from several pre-congured

optical settings or create their own. For more information, see the OPTICAL SETTINGS

section on page 18.

Prole: Allows the user to select from various PROFILES, which contain the

analysis parameters by which PASS/FAIL criteria are determined. Users can select

from several pre-congured PROFILES or create their own. For more information

about PROFILES, see the PROFILES section on page 19.

Page 22

USER MANUAL22

Customer Support

JDSU Communication Test and Measurement Headquarters

One Milestone Center Court

Germantown, MD 20876-7100

Toll Free: 1 866 228-3762

Tel: + 1 301 353-1550

Fax: + 1 301 353-1536

Web: www.jdsu.com/inspect

Technical Assistance for JDSU Fiber Inspection, Cleaning and Test

Tel: 1 800 304-3202

Hours: M–F 7:00 AM to 5:30 PM (Pacic Standard Time)

E-mail: FIT.Service@jdsu.com

Customer Care for JDSU Fiber Inspection, Cleaning and Test

Tel: 1 800 304-3202

E-mail: Ger.NewOrders@jdsu.com

P5000i Digital Analysis Microscope

Page 23

P5000i Digital Analysis Microscope 23

This page left intentionally blank.

Page 24

NORTH AMERICA

TEL: 1 866 228 3762

FAX: 1 301 353 9216

LATIN AMERICA

TEL: +1 954 688 5660

FAX: +1 954 345 4668

ASIA PACIFIC

TEL: +852 2892 0990

FAX: +852 2892 0770

EMEA

TEL: +49 7121 86 2222

FAX: +49 7181 86 1222

www.jdsu.com/inspect

Test and Measurement Regional Sales

ZPPKG0574

REV 0

Product specications and descriptions in this document subject to change without notice. © 2011 JDS Uniphase Corporation. June 2011

Loading...

Loading...