JC Penney 3032B User Manual

Dear Penney Customer:

The product you purchased has been

carefully engineered and manufactured

to give you dependable operation.However,

like all mechanical products,

your machine will occasionally require

adjustment and maintenance. This

handbook should be read before

operating or performing any adjustments on your machine. Should you

require technical assistance, please

contact the nearest JCPenney retailstore,

product service center, or

catarog center.

Full One Year Warranty

Within one year of purchase, we will

provide home service to repair this

JCPenney Riding Lawn Mower,

Tractor or Garden Tiller if it is defective

in material or workmanship. Parts and

labor are included. Just contact the

nearest JCPenney Product Service

Center or store for service.

If this Lawn and Garden Equipment is

used for commercial purposes, this

warranty coverage applies for 30 days

from the date of purchase.

It is your responsibility to provide for

routine maintenance as detailed in the

Owner's Manual.

This warranty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

JCPenney Co., Inc., Product Service

Department, Warranty Division, 1301

Avenue of the Americas, New York,

NY 10019.

Customer Responsibilities

.Routine maintenance as detailed in

this owners handbook is the customers responsibility.

.Sharpening blades, servicing air

cleaners, changing oil or spark plugs

and making a~j!Jstments to the car-

buretor are not covered by the

warranty. JCPenney can provide or

make arrangements for these

services.

.Bent or broken crank shafts result-

ing from the striking of foreign

objects are not covered by the

warranty.

".

@JCPenney Company, Inc. 1980

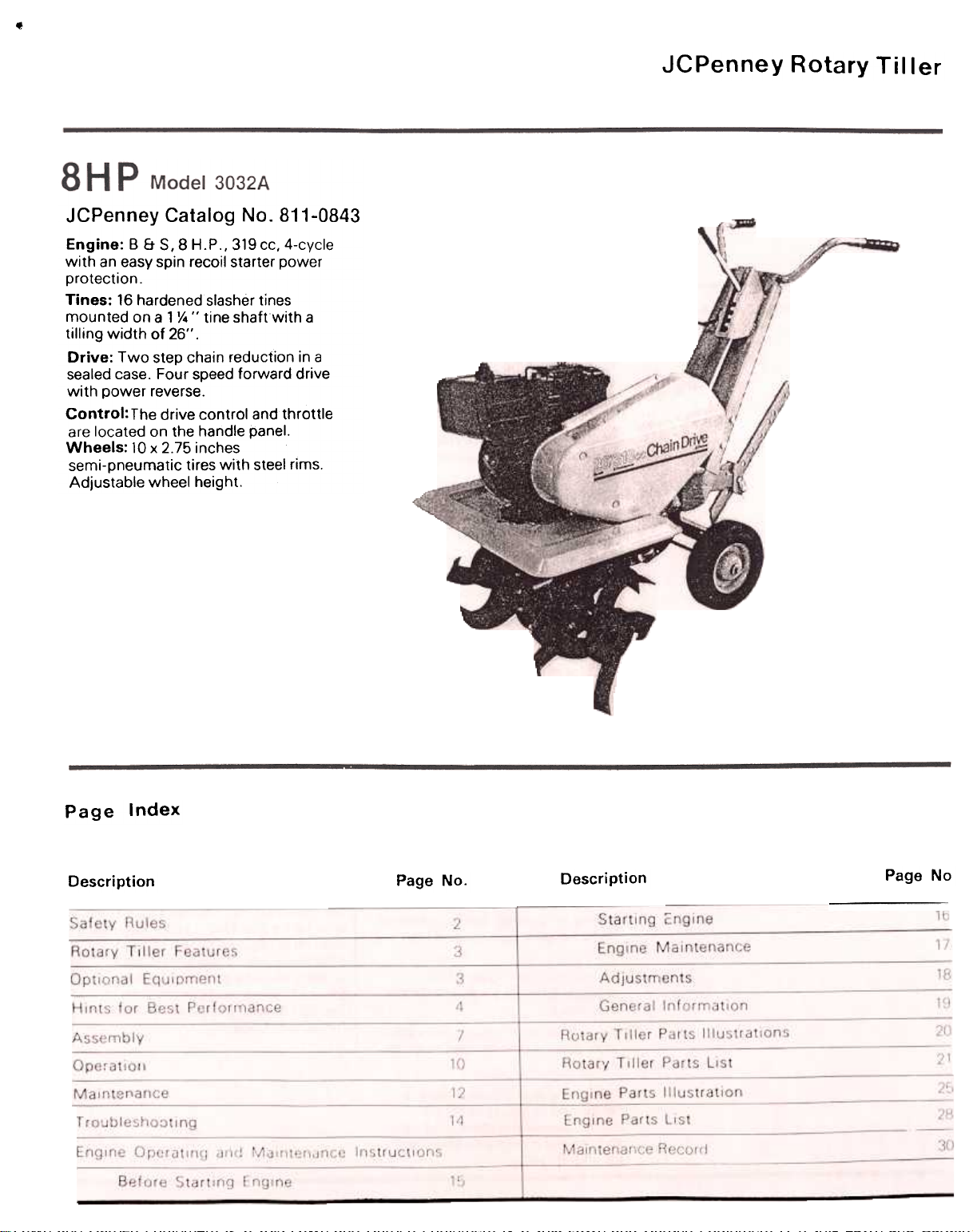

JCPenney Catalog No. 811-0843

Engine: B & S, 8 H.P., 319 cc, 4-cycle

with an easy spin recoH starter power

protection.

Tines: 16 hardened slasher tines

mounted on a 1 y. " tine shaft with a

tilling width of 26".

Drive: Two step chain reduction in a

sealed case. Four speed forward drive

with power reverse.

Control: The drive control and throttle

are located on the handle panel.

Wheels: 10 x 2.75 inches

semi-pneumatic tires with steel rims.

Adjustable wheel height.

JCPenney Rotary Tiller

.

Page Index

Description

Page No.

Description

Page No

Safety Rules

IMPORTANT

SAFE OPERATION PRACTICES FORTILLERS

It is suggested that this manual be read

in its entirety before attempting to

assemble or operate. Keep this manual

in a safe place for future reference and

for ordering replacement parts.

This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see

1 Read the Operating and Service

Owner's Manual carefully. Be

thoroughly familiar with the

controls and the proper use of the

equipment.

2 Never allow children to operate a

power tiller. Only persons well

acquainted with these rules of safe

operation should be allowed to use

your tiller.

3 Keep the area of operation clear of

all persons, particularly small

children and pets.

4 Do not operate equipment when

barefoot or wearing open sandals.

Always wear substantial footwear.

5 Do not wear loose fitting clothing

that could get caught on the tiller.

6 Do not start the engine unless the

shift lever is in the neutral IN)

position.

7 Do not stand in front of the tiller

while starting the engine.

S Do not place feet and hands on or

near the tines when starting the

engine or while the engine is

running.

9 Do not leave the tiller unattended

with the engine running.

10 Do not walk in front of the tiller

while the engine is running.

11 Do not fill gasoline tank while

engine is running. Spilling gasoline

on hot engine may cause a fire or

explosion.

12 Do not run the engine while

indoors. Exhaust gases are deadly

poisonous.

13 Be careful not to touch the muffler

after the engine has been running,

it is hot.

operating section of this manual for

proper fuel and amount.

Your tiller is a precision piece of powerequipment,

not a play thing. Therefore,exercise

extreme caution at all times.

15 Use caution when tilling near

buildings and fences, rotating tines

can cause damage or injury.

16 Before attempting to remove rocks,

bricks and other objects from tines,

stop the engine and be sure the

tines have stopped completely.

Disconnect the spark plug wire and

ground to prevent accidental

starting.

17 Check the tine and engine

mounting bolts at frequent intervals

for proper tightness.

18 Keep all nuts, bolts and screws

tight to be sure the equipment is in

safe working condition;

19 Never store the equipment with

gasoline in the tank inside of a

building where fumes may reach an

open flame or spark. Allow the

engine to cool before storing in

any enclosure.

14 Before any maintenance work is

performed or adjustments are

made. remove the spark plug wire

and ground it on the engine block

for added safety.

2

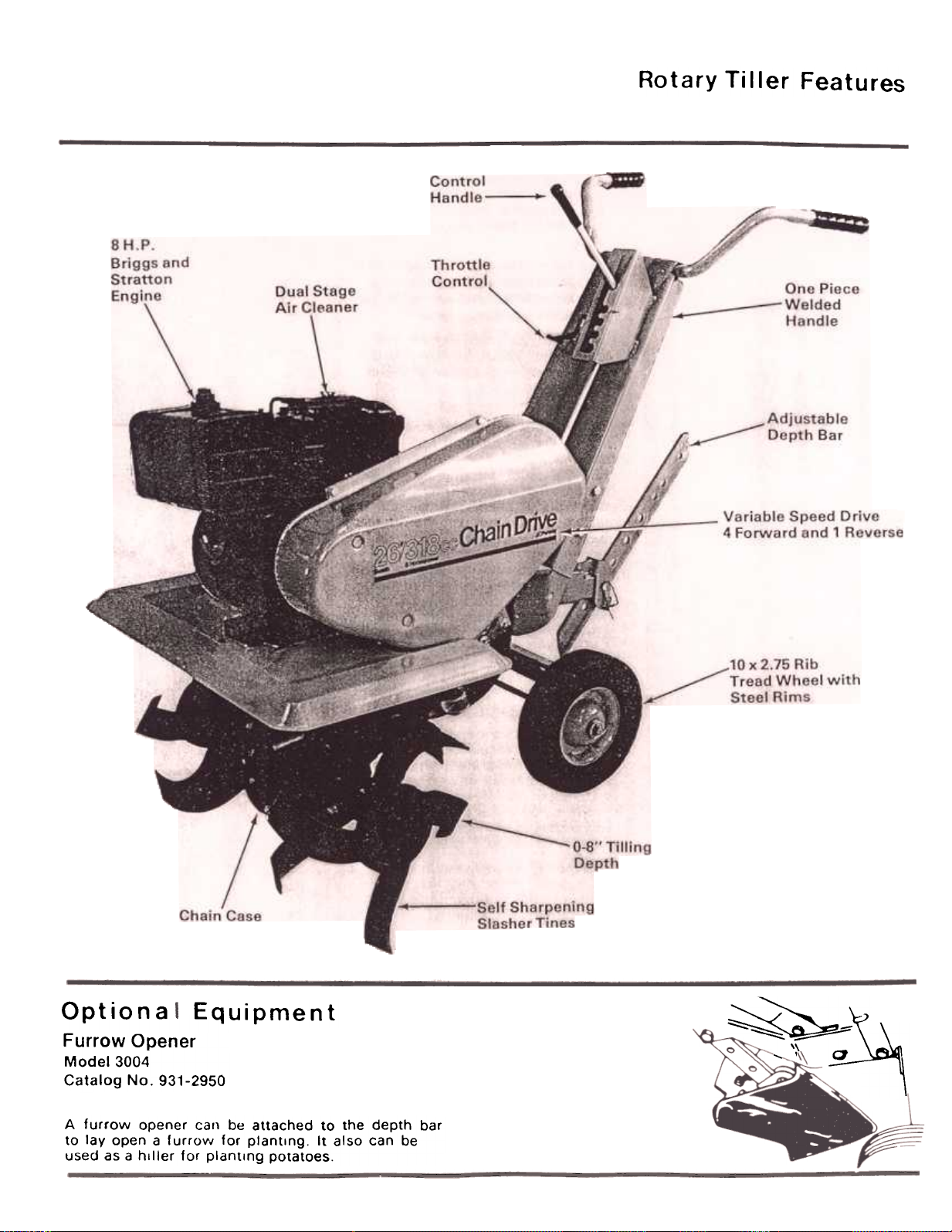

Rotary Tiller Features

Optiona Equipment

Furrow Opener

Model 3004

Catalog No. 931-2950

A furrow opener can be attached to the depth bar

to lay open a furrOV'J for planting. It also can be

used as a hiller for planting potatoes.

;;;;;~~~

~

Hintsfor Best Performance

Your power drive train is comprised of

a variable speed pulley with four

forward speeds, reverse, and a two

step, double chain, reduction to thetines.

The 1 Y4 inch tine shaft is supported by

two self-lubricating bronze bearings.

The 16 hardened tines will handle the

toughest of gardening tasks.

T en inch by 2.75 inch rib tread tires

support the back of the tiller. The rear

wheel height is adjustable for greater

versatility.

The forward and penetrating acti-;n

of the tiller is obtained from the

rotating action of the tines in the

soi I. The depth bar acts as a brake

for the tiller and controls the depth

and forward speed. By lowering the

setting of the depth bar. the forward

speed of the tiller is reduced and

the working depth of the tines is

increased. Raising the setting of the

depth bar increases the forward

speed and reduces the working

depth. When soil condition.s are

severe and several passes must be

made over a certain area the depth

bar setting should be lowered each

time a pass is made.

Further control of tilling depth and

travel speed can be obtained by

variation of pressure on the handle.

A downward pressure on the handles will increase the working depth

and reduce the forward speed. An

upward pressure on the handles will

reduce the working depth and increase the forward speed.

The type of soil and working conditior-.s will determine the actual

setting of the depth bar and the

handle pressure required.

When tilling ground that has not been

tilled before, do not try to till to maximum depth in one pass. Set the depth

bar for half the depth you desire, then

reset the depth bar to full depth and go

over the tilled area the second time.

Till only when the soil is relatively dry

and crumbles easily. If the soil is too

wet when you till it will leave large

clods of soil rather than a good seed

bed.

4

Hintsfor Best Performance

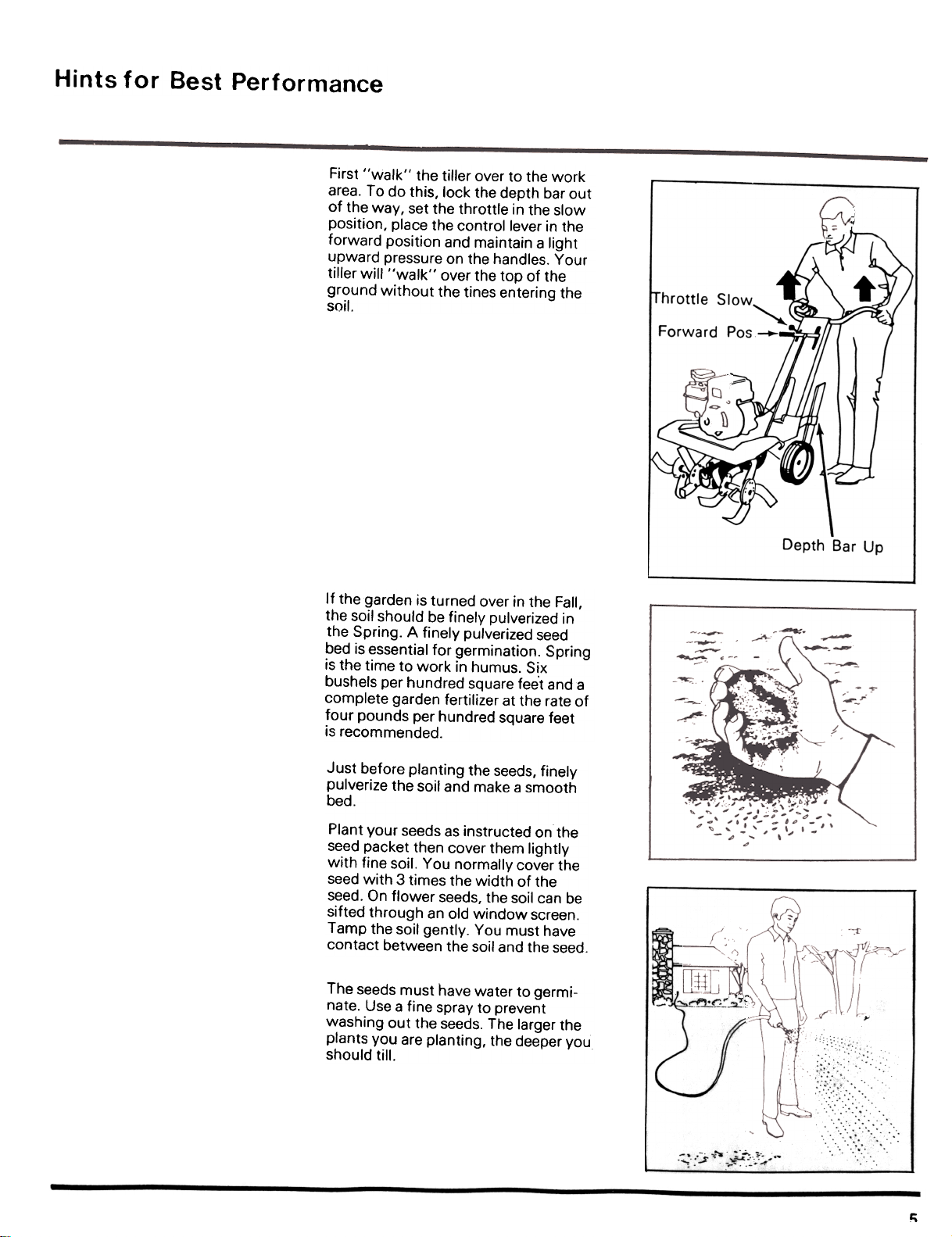

First "walk" the tiller over to the work

area. To do this, lock the depth bar out

of the way, set the throttle in the slow

position, place the control lever in the

forward position and maintain a light

upward pressure on the handles. Your

tiller will "walk" over the top of theground

without the tines entering thesoil.

.

If the garden is turned over in the Fall,

the soil should be finely pulverized in

the Spring. A finely pulverized seed

bed is essential for germination. Spring

is the time to work in humus. Six

bushels per hundred square fee't and a

complete garden fertilizer at the rate of

four pounds per hundred square feet

is recommended.

Just before planting the seeds, finely

pulverize the soil and make a smoothbed.

Forward Pos

SIOW",,~

~

Bar Up

~

Depth

~

Plant your seeds as instructed on the

seed packet then cover them lightly

with fine soil. You normally cover the

seed with 3 times the width of the

seed. On flower seeds, the soil can be

sifted through an old window screen.

Tamp the soil gently. You must have

contact between the soil and the seed.

The seeds must have water to germinate. Use a fine spray to prevent

washing out the seeds. The larger the

plants you are planting, the deeper you

should till.

.-:;:: .OJ~" ~;:j":;~'.

, "

-

Hints for Best Performance

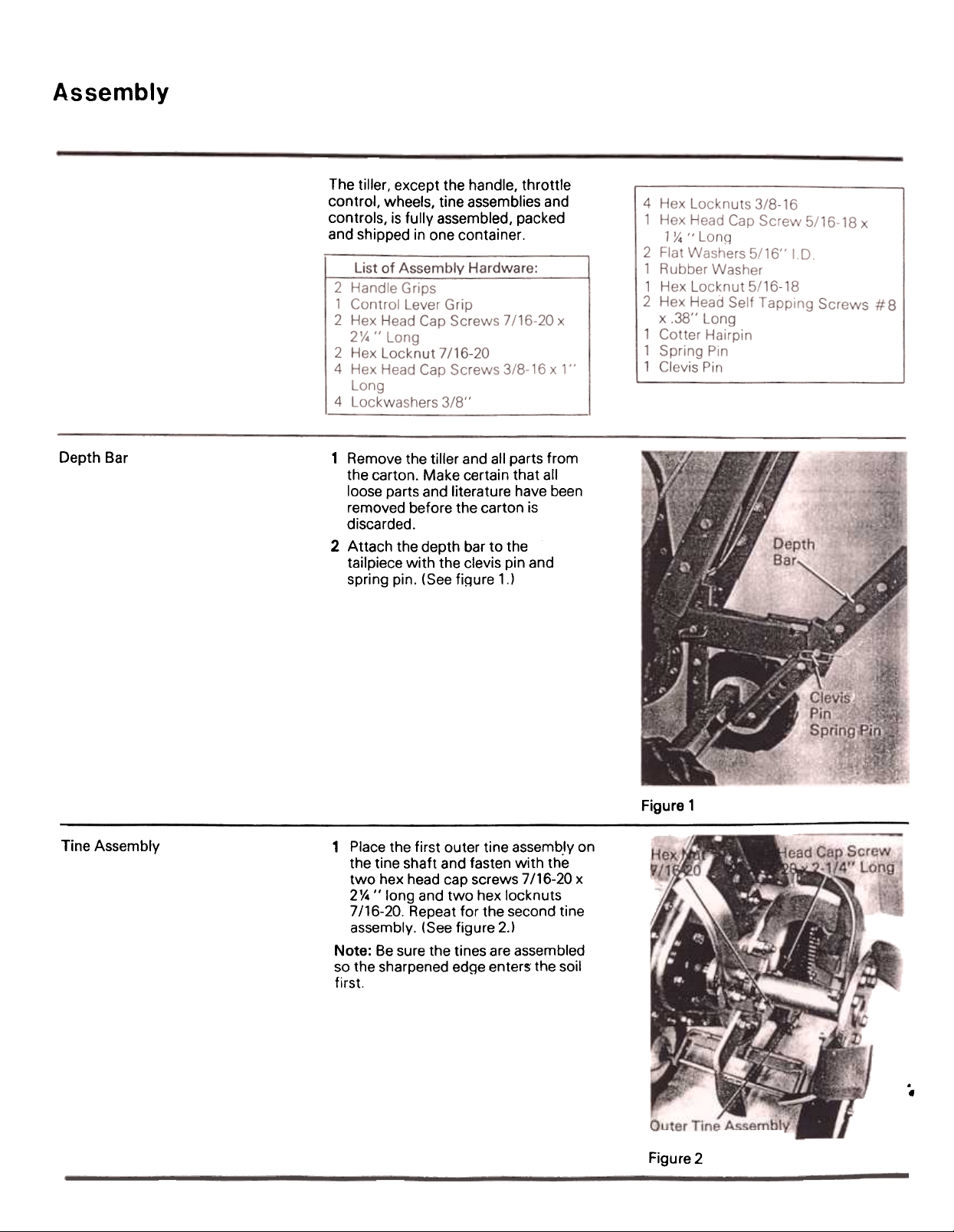

Plants such as grass, with shallow

roots, need only two to four inches

tilled soil whereas plants with a deep

root system should have a deeply tilledbed.

Till the soil as soon as it is

workable in the Spring. You can till to a

maximum depth of six to eight inches.

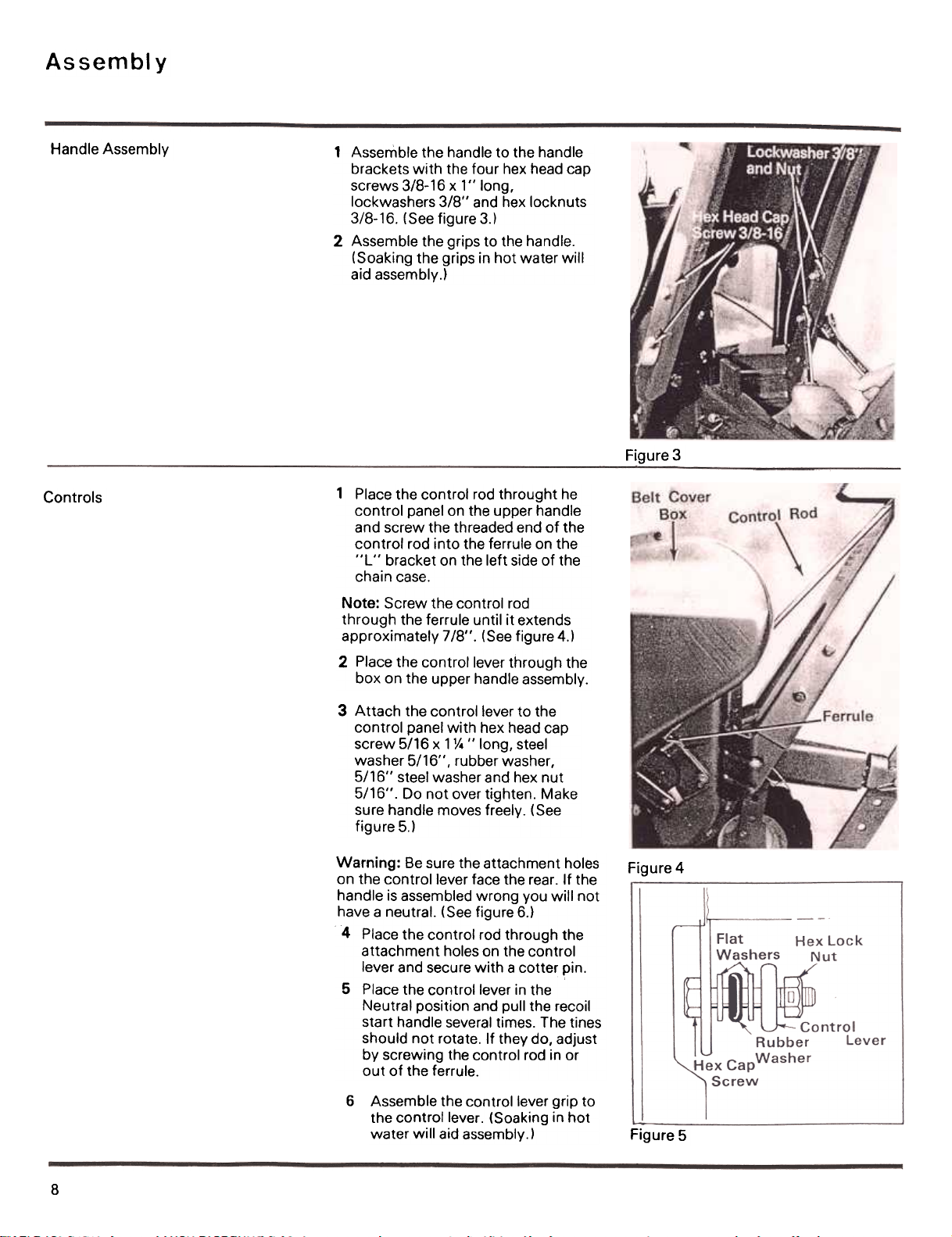

When preparing a yard for a lawn, the

soil should be leveled so it is well

drained and free from high spots. If

you do not level out the irregularities in

the soil first, you will not be able to do

this once the lawn is established.

E~tra care in leveling your yard before

you sow your seed will be well worth it.

Just before planting the seeds the

particles of soil should be no larger

than a quarter inch. Water the soil to

settle the dirt. This will also show you

low spots that should be filled in beforesowing.

Use a fine spray to prevent

disturbing the soil. Frequent watering

is a must.

6

Assembly

The tiller. except the handle, throttle

control, wheels, tine assemblies and

controls, is fully assembled, packed

and shipped in one container.

Depth Bar

Tine Assembly

1 Remove the tiller and all parts from

the carton. Make certain that all

loose parts and literature have been

removed before the carton is

discarded.

2 Attach the depth bar to the

tailpiece with the clevis pin and

spring pin. (See fi~ure 1.)

Figure 1

Place the first outer tine assemb.ly on

the tine shaft and fasten with the

two hex head cap screws 7/16-20 x

2%" long and two hex locknuts

7 /16-20. Repeat for the second tine

assembly. (See figure 2.1

Note: Be sure the tines are assembled

so the sharpened edge enters the soil

first.

.

Figure 2

1

.

Assembly

Handle Assembly

Controls

Assemble the handle to the handle

brackets with the four hex head cap

screws 3/8-16 x 1" long,

lockwashers 3/8" and hex locknuts

3/8-16. (See figure 3.)2

Assemble the grips to the handle.

(Soaking the grips in hot water will

aid assembly.)

Figure 3

Place the control rod throught he

control panel on the upper handle

and screw the threaded end of the

control rod into the ferrule on the

"L" bracket on the left side of the

chain case.

Note: Screw the control rod

through the ferrule until it extends

approximately 7/8". (See figure 4.1

2 Place the control lever through the

box on the upper handle assembly.

Attach the control lever to the

control panel with hex head cap

screw 5/16 x 1 Y4" long, steel

washer 5/16", rubber washer,

5/16" steel washer and hex nut

5/16". Do not over tighten. Make

sure handle moves freely. (See

figure 5.)

Warning: Be sure the attachment holes

on the control lever face the rear. If the

handle is assembled wrong you will not

have a neutral. (See figure 6.)

4 Place the control rod through the

attachment holes on the control

lever and secure with a cotter pin.

5 Place the control lever in the

Neutral position and pull the recoil

start handle several times. The tines

should not rotate. If they do, adjust

by screwing the control rod in or

out of the ferrule.

6

Assemble the control lever grip to

the control lever. (Soaking in hot

water will aid assembly.)

Figure 4

5

1

1

3

Figure

8

Assembly

Controls

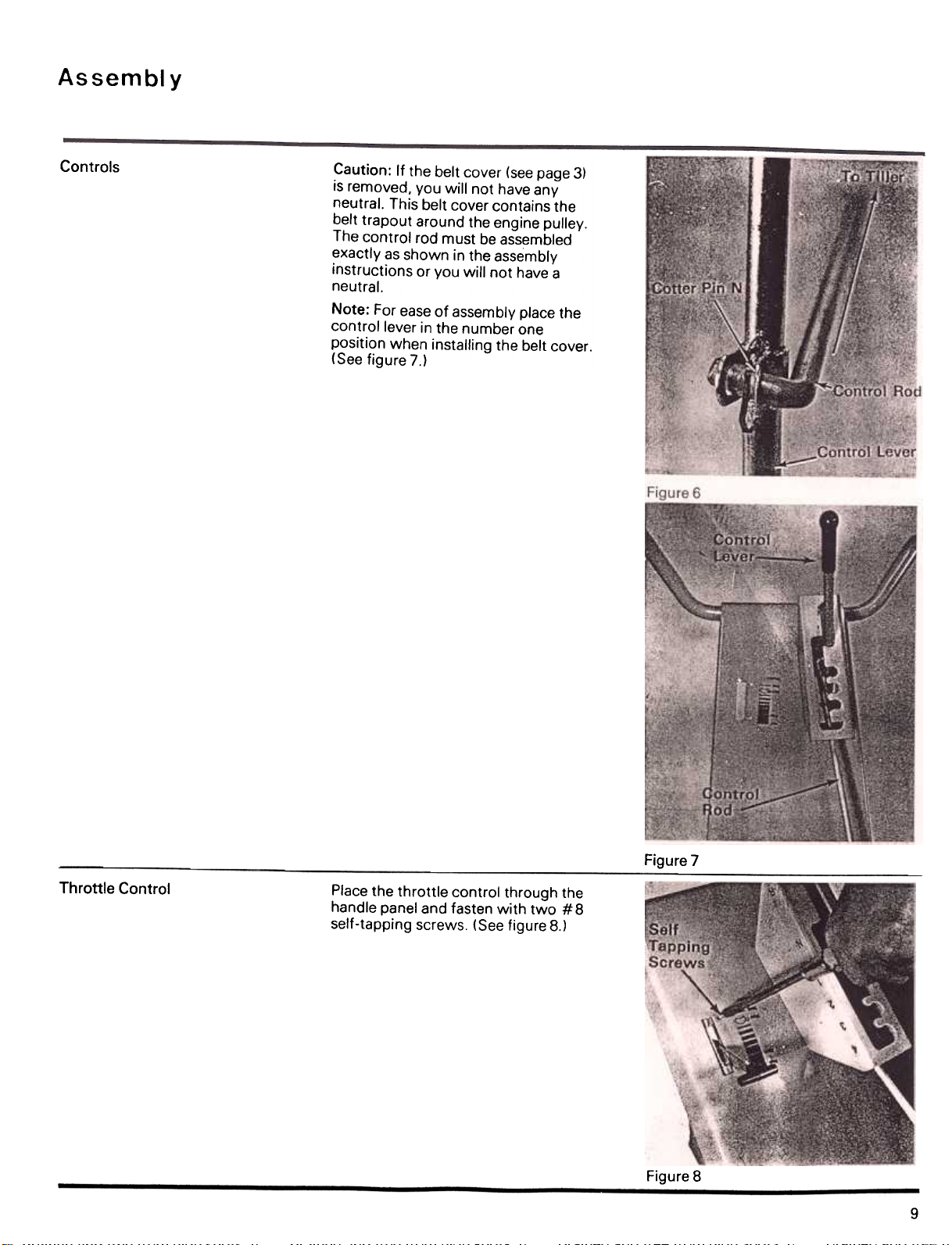

Caution: If the belt cover (see page 3)

is removed, you will not have any

neutral. This belt cover contains the

belt trapout around the engine pulley.

The control rod must be assembled

exactly as shown in the assembly

instructions or you will not have a

neutral.

Note: For ease of assembly place the

control lever in the number one

position when installing the belt cover.

(See figure 7.)

Throttle Control

Figure 7

Place the throttle control through the

handle panel and fasten with two # 8

self-tapping screws. (See figure 8.)

Figure 8

9

Loading...

Loading...