User Manual

INTEGRA

Table of contents

Maintenance 3

Important safety instructions for inst allation 3

Important safety instructions for use 3

Equipmetn use 3

Description 4

Technical charac teris tics 4

Installation 5

Fitting the casing 5

Important considerations f or start-up 5

Oper ating 6

*Anti-intrusion f unction 7

Option sw itch 7

Input switch 8

Buttons 8

Times 8

Light indicators 8

Input light indicators 9

Parameter configuration from programmer 9

Programming 9

Programming with ends of runand automatic close 9

Opti onal cards 10

Receiver card 10

Traffic light card 10

This has t hree diff erent functions (with s witc h* to OFF) 10

Traffic control (with switch* to ON) 11

Signal card 11

RADIOBAND/RCS card 11

Magnetic detector c ard 11

Regulatory Data 12

EU Declaration of conformity 12

jcmtechnologies

2

Maintenance

Important safety instructions for installation

Disconnect the power supply whenever you proceed to the installation or repair

of the control panel.

•Before installing the panel, remove all unnecessary ropes or chains and disable any equipment such as locks that is not neces-

sary for theautomatic operation.

•Before installing the panel, check that the doo r is in good mechanical condition, correctly balanced and that it opens and

closes correctly.

•Install the manual unlocking devicea t a height lower than 1.8m.

•Install any permanent control next to the door away from any moving part and at a minimum height of 1.5m.

•An easily accessibledisconnection devicem ust be fitted to thewiring for permanently connected equipment. This device must

ensurethe single-pole cut-off of power. It is wise for this to be an emergencyswitch/isolator.

•Wherethe panel issupplied without an emergency sto p button, this must be incorporated on installation, connected to the

STOP terminal.

•For correct use of thesecurity edge, this must never be activated when thedo or is fully closed. It is wiseto install theends of run

before a ctivating theedge.

•This equipment can only be handled by a specialist f itter, bymaintenance staf f or by a suitably tra ined operator.

•To connect the power supply and motor wiring, 2.5 mm2 section terminals must be used.

•Fuses must only be handled when the appliance is disconnected from the ma ins.

•The instructions for using this equipment must remain in the possession of theuser.

•European door normative EN 124 53 and EN 12445 specify the following minimum protection a nd door safety levels:

- for single-family hom es, prevent thedo or being able to come into contact with any object o r limit thecontact force (e.g. secur-

ity edge) and, in theevent o f automatic closure, a presencedetector (e.g. photocell) must be added.

- for communal a nd public installations, prevent the door being ableto come into contact with any o bject or limit the contact

force (e.g. security edge) and detect presence(e.g. photocell).

Important safety instructions for use

•Do not allow children to play with the door controls.

•Keep the remote controls out of the reach of children.

•Watch thedoor movement and keep people a way until the door is f ully open or closed.

•Precaution when operating the m anual unlocking device, as the door may suddenly fall due to the bad condition of thesprings

or door unbalance. Details on how to use the manual unlocking device must be provided by the ma nufacturer or the device

installer.

•Examine theinstallation frequently, especiallythe cables, springs and supports, to detect signs of wear, damag e or unbalance.

Do not use the door if repair work or adjustments are required, as this may cause dam age.

Equipmetn use

Designed for t he automation of garage doors as per t he general description. Not guaranteed for other uses.

The manufacturer reserves the right to modify equipment specifications without prior notice.

jcmtechnologies

3

Description

Control panel for the control of three-phase motors to 3CV at 400V and single-phase motors to 1.5CV at 230V for industrial

doors. Allows for dead-man open and close operations, automatic dead-man close operations, semi-automatic operations and

automatic operations. Connection t o portable programmer.

Technical characteristics

INTEGRA-ECO

(standard box model)

Panel supply 400V ac3N / 230V ac

Power 3CV / 1.5CV

Optional cards Receiver card, Radioband/RCS, signal, magnetic detector

24Vac output 24V ac/ 0.5A (shared with photocell test output)

Photocellautotest output 24V ac/ 0.5A (shared with security device output)

Auxiliary contact outlet Electro-brake / Electro-lock/ Garage light

230V acoutlet

Operating temperature -20ºC to +85ºC

Sizes 225x195x85 mm 305x225x126 mm

Airtightness IP54 IP56

Equipment category Class II

Limited to (0.05A, 11W) powered at 400V

Limited to (3A, 600W) powered at 230 Vac

INTEGRA

(Industrial boxmodel)

jcmtechnologies

4

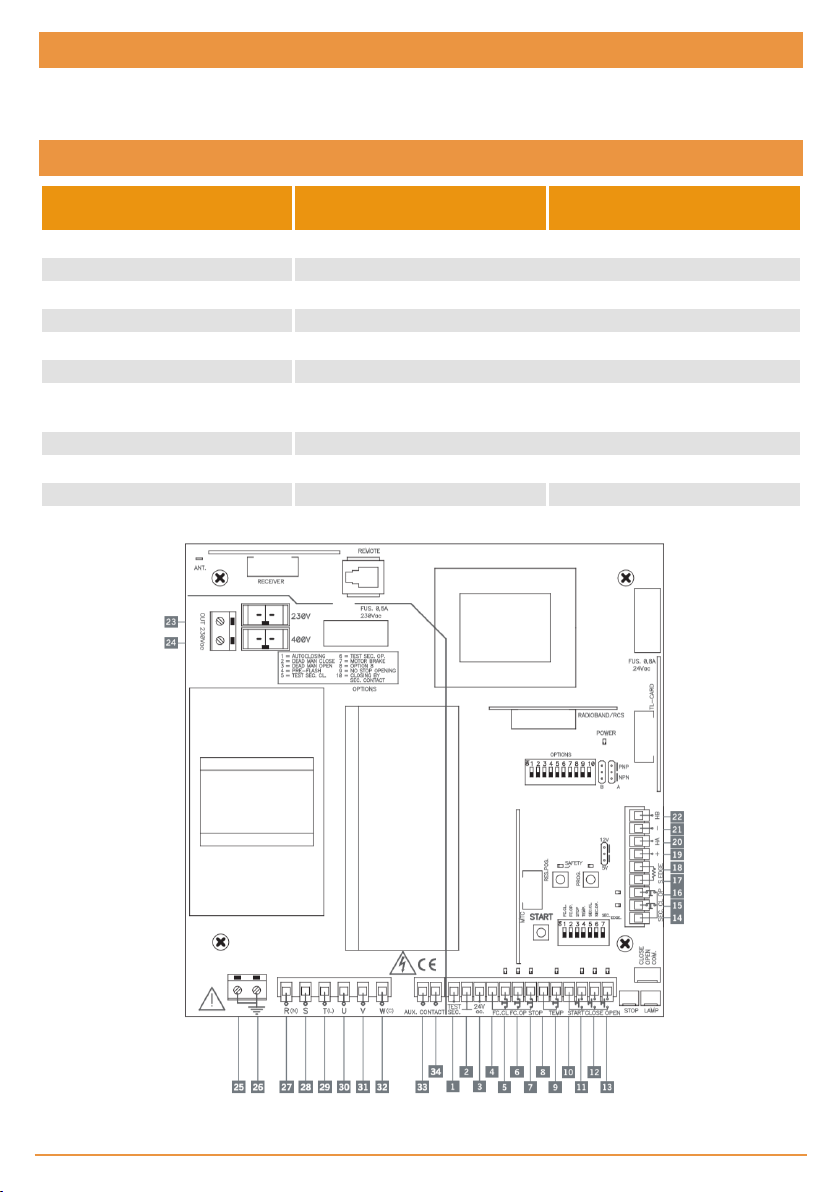

1 Test for security parts 14 Common securities 27 R(N) Power supplyconnection

230V/400V or neutral

2 Common for security part test

and 24Vacoutlet

3 24Vac outlet 16 Security Open contact (NC) 29 T(L) Power supplyconnection

4 Common ends of run and stop 17 Security Close edge (resistive

5 End of run Close ( NC) 18 Security Close edge (resistive

6 End of run Open (NC) 19 Sensor hallpower (+) 12Vd-

7 Stop button (NC) 20 “Sensor hall” HA signalinlet. 33 Auxiliary contact outlet

8 Common temperature contact 21 "Sensor hallpower" (-) 12Vd-

9 Temperature contact (NC) 22 “Sensor hall” HB signalinlet

10 Common buttons 23 230V acoutlet

11 Alternative button (NO) 24 230V acoutlet

12 Close button ( NO) 25 Earthing terminal

13 Start button (NO) 26 Earthing terminal

15 Security Close contact (NC) 28 S Power supply connection

400V

230V/400V

30 U triple phase motor con-

contact 8k2)

contact 8k2)

c/+5Vdcdepending on switch

c/5Vdc depending on switch

nection/ single phase

31 V triple phase motor con-

nection/ single phase

32 W(C) triple phase motor con-

nection/ common single phase

34 Auxiliary contact outlet

Warning: Where working with 230V connection, turn the switch to 230Vac, and

where working with 400V three-phase connection, turn the switch to 400Vac.

Installation

Any handling of the panel for installation must be carried out with the power supply disconnected.

Fitting the casing

•Pa rts: front casing and conta iner box.

•Unscrew thesecuring points. Insert thecables through thelower holes.

Important considerations for start-up

Check that the Open button opens and the Close butt on closes. Wherethis is not the c ase, invert motor cables U and V.

Any optional cards must be connected to t he panel with t he power s upply disconnected.

jcmtechnologies

5

Operating

Open

(OPEN)

Close

(CLOSE)

Start

(START)

Temper ature

(TEMP)

Stop

(STOP)

Ends of run

(FC.CL / F C.OP)

Security contact

(SEC.CL / SEC.OP)

Security edge

(SEC.EDGE)

24 Vac output

Auto-test output

(TEST. SEC)

Auxiliary Contact

(Aux. Contact)

Contact normallyopen to open. If pressed during the closing operation it stops and

opens (untilthe end of the limit switch). Acts as “Dead-Man” if kept pressed down with

Option 3 of the options switch triggered.

Contact normallyopen to close. If it is pressed while the door is opening, it stops. Acts as

“Dead-Man” if kept pressed down with Option 2of the options switch triggered.

Contact normallyopen to open and close. The first press opens, the second press

stops (until the limit switch) and the third closes. If pressed during the closing operation

it stops and inverts (untilthe end of the limit switch). The Start contact onlyacts as an

open button when using a traffic light card with traffic control enabled.

Contact normallyclosed for connection to a temperature sensor for the motor . When it

indicates that the motor has exceeded the security limit, the operation willstop until it

has cooled. Where not used, turn option 4 (TEMP) on the input switch to ON.

Contact normallyclosed. Thisdetains the operation on standby for a new order. Where

not used, turn option 3 (STOP) on the input switch to ON.

Contacts normallyclosed to mechanically indicate the open and closed end of run.

Where not used, turn option 1 (FC.CL) and 2(FC.OP) on the input switch to ON.

Contact normallyclosed, photocell or magnetic detector type. Thisacts by causing stoppage and partial inversion during opening and stoppage and total inversion dur ing closure. Where not used, turn option 5 (SEC.CL) and 6 (SEC.OP) on the input switch to

ON. The security close contact also acts as a close button when the vehicle has passed

if Option 10 on the options switch is enabled.

Resistive contact for resistive security edge. Thisacts on closing, causing stoppage and

inversion. Where not used, turn option 7 (SEC.EDGE) on the input switch to ON.

To power any equipment at a voltage of 24 Vacwith a maximum consumption of 0,5A

(shared with photocell test output).

24 Vac output for auto-test of security parts with a maximum consumption of 0,5A

(shared with 24Vacoutput).

Normallyopen contact that has three different functions depending on the position of

Option switches 7 and 8.

Auxiliary Contact Function Option switch 7 Option switch 8

Electro-brake: Enableselectro-brake to unblock

motor during operations.

ON OFF

Anti-intrusion function * ON ON

Electro-lock: Enables electro-lock 3 secondsbefore

the start of the opening operation.

Garage light: Enables gar age light during the door

operating time plus 2 minutes.

jcmtechnologies

6

OFF OFF

OFF ON

*Anti-intrusion function

Activates the auxiliary contact on the f ollowing cases:

•If during the opening o r closing movements, or with thedoor opened, it detects the passage of more than one vehicleby the

close safety contact (SEC.C L). If this occurs durning the opening movement, the door willf inish opening. If this occurs during

the closing, the doo r will invest up until being completely open. Thedo or remains opened, without m aking auto-colosing even if

it is activated.

•If the control panel has not given theo rder to open and closing end o f course (FC.CL) is deactivated. For example, if someone

tries to open thedo or by f orce.

Deactivation of the alarm (auxiliary contact)

•The a larm willbe disabled in any case using the buttons START, OPEN or C LOSE, o r by a transmitter programmed. The STOP

button stops the alarm when the door is wide open.

Operation

counter

An operation counter and operation limit number is fitted. On reaching the limit number

of operations, the panel switches to dead man operations and the POWER light flashes

(only INTEGRA model)

Option switch

Option

No. Lower position – OFF (default option) Upper position –ON

1 Does not close automatically Automatic closure

2 Operating normallyclose “Dead man” close*

3 Operating normallyopen “Dead man” open*

4 Operating without Pre-signal Pre-signal before handling

5 Operating without C. security close test C. security close test

6 Operating with C. securityopen test C. security open test

7 See table Auxiliary Contact Function

8 See table Auxiliary Contact Function

9 Allows for radio reverse on opening Does not allow for radio reverse on opening

10 The security close contact works are normal

* The “dead man” close and open moves the door while the button is pressed down.

The security close contact also acts asthe close

button when the vehicle has passed

jcmtechnologies

7

Input switch

Nº Opción Lower position - OFF Upper position – ON (default option)

1 (FC.CL) End of run close connected End of run close not connected

2 (FC.OP) End of run open connected End of run open not connected

3 (STOP) Stop button connected Stop button not connected

4 (TEMP) Temperature contact connected Temper ature contact non connected

5 (SEC.CL) Security Close contact connected SecurityClose contact not connected

6 (SEC.OP) Security Open contact connected Security Open contact not connected

7 (SEC.EDGE) Security Close edge connected Security Close edge not connected

Buttons

START Start/stop button

PROG Programming button

RES POS Position reset button. *

* This button performs the position reset when the panel operates using sensor hall. To do so, the

door must be totally closed and the button kept pressed down until the programming led flashes.

Times

Controlling Minimum Maximum

Motor operating 1s 180s

Wait for automatic close 1s 180s

Light indicators

POWER Indicates power

PROG Indicates programming

Number of flashes Error Code

1 flash

2 flashes

STOP/SAFETY

LAMP ( in INT EGRA

model)

Blinks indicating security activated

3 flashes

4 flashes Security edge error 4

5 flashes

6 flashes Sensor Hallerror 6

Security edge autotest

error

Security close contact

autotest

Security close contact

autotest

RADIOBAND/RCS card

autotest error

jcmtechnologies

8

1

2

3

5

Input light indicators

Function Indicates Default status

OPEN Open function Normallyoff

CLOSE Close function Normallyoff

START Open/close function Nor mally off

TEMP Temperature sensor Normallyon

STOP Stop button Normally on

FC.OP End of run Open Normally on

FC.CL End of run Close Normallyon

SEC.OP Security Open contact Nor mally on

SEC.CL Security Close contact Normallyon

Parameter configuration from programmer

There are different parameters that c an be c onfigured by portable programmer. Below is a description of the most basic. Refer

to the programmer instruction manualfor further information.

•Operation by Time: I ndicates / selects if the panel is programmed to operate by time.

•Operation by Pulses: Indicates / selects if the panel is program med to o perate by pulses.

•Oper. counter limit: I ndicates / selects the limit number of operations for the panel.

•Operation counter: Indicates thenumber of operations made to date.

•Oper.Count.Limit Active: Indicates / selects if there is a limited number of operations or not.

•Autoclosing time: Indicates / selects theseconds of automatic standby time.

•Equip.: Shows an equipment identifier.

Programming

•During programming, the control panel does not take all possible securities into account.

•Before starting any type of time programming, it is wiseto have the corresponding options correctly selected and ensurethe

cards to be used a re inserted.

•WhereRADIOBAND/RCS cards are used, thepanel must be pro grammed with the card inserted.

•Operations can be programmed indifferently using the “Test” / “Start” button or through a transmitter recorded on a pluggable

radio card for control pa nels.

•Wherea sensor hall is used, its pulse type is memorised in thepanel during programming.

Programming with ends of run and automatic close

Close the door with the limit switches (where applicable) duly connected.

Press the TIMER PROG butt on t o enter programming. The red PROG led w ith light up. T he first time TEST is pressed, the

door opens to the end of run openand the automatic standby timer begins. The second time TEST is pressed, the automatic

standby timer stops and t he door closes to t he end of run c lose.

Press the TIMER PROG butt on again to exit programming (the red PROG led will s witch off).

jcmtechnologies

9

Optional cards

Receiver card

This acts on the panel with t ransmitters, proximity keys or s mart cards in the same way as the start button.

If working with a receiver c ard f or dead-man (only available in 868MHz) and options 2 and 3 of the options switch are ON, chan-

nel 1 opens andchannel 2 closes.

In any other case, channel2 is not operative.

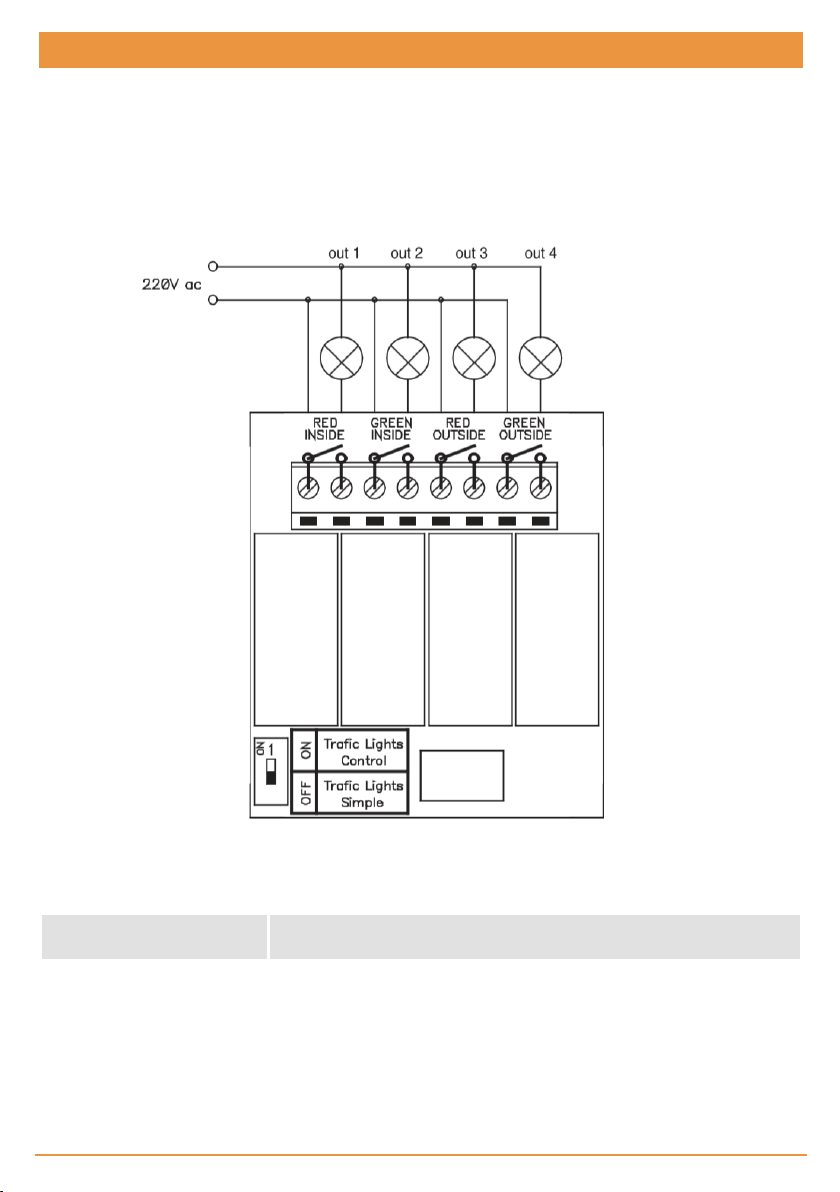

Traffic light card

This has three different functions (with switch* to OFF)

Output 1 Signal.

Output 2

Output 3 and 4

Light contact – acts for the entire time that the door is operating, plus 10

seconds

Traffic lights. Outlet 3 activates the red trafficlight that works during door

movement. Outlet 4 activates the green trafficlight that isonly lit when the

door isfullyopen

jcmtechnologies

10

Traffic control (with switch* to ON)

When this optionis activated, the traffic light interprets the Alternative contact as an outdoor open button and the Open c on-

tact as the indoor open button.

While the door remains closed, nosignals are given. When t he open order is received, the indoor and outdoor redlight contact

gives a warning f lash for 3 seconds before carryingout the operation.

As the door is opening, t he two red lights will switch on (indoor and outdoor).

Once t he door is open, t he correspondinglights will come on, depending on the act ivation point:

Pushbutton Activation Red signal Green signal

OPEN Interior open button Exterior lamp Inter ior lamp

START Exterior open button Interior lamp Exterior lamp

Before beginningthe close manoeuvre, the interior or exterior green light contact (depending on the case) w ill give an inter-

mittent pre-warningof 3 seconds. While the dooris closing, the two red lamps will light (interior/exterior).

* Warning: this switch must be enabled and disabled using when the power

supply to the panel is disconnected.

Signal card

Through the contact of a relay intermittently activated, this gives a warning3 s econds before the opening and c losing move-

ments are started and while t hey are underway.

RADIOBAND/RCS card

Optional radio-communications c ard f or security edges.

Magnetic detector card

This allows for the same f unction as an outside magnetic detector althoughwithout the need for an external power supply. It

can beused as an open button and/or security contact. It also includes the frequency changer s election and delay application

for presence deactivation.

jcmtechnologies

11

Regulatory Data

EU Declaration of conformity

The manufacturer JCM TECHNOLOGIES, S.A. declares that t he product INTEGRA cumple con los requisitos esenciales de

la Directiva RED 2014/53/UE y de la Directiva RoHS 2011/65/UE.

See website www.jcm-t ech.com/declarations/

JCM TECHNOLOGIES, SA

C/COSTA D'EN PARATGE, 6B

08500VIC (BARCELONA)

SPAIN

UM_3201266_Integra_EN_Rev01

jcmtechnologies

12

Loading...

Loading...