JCM Industries 412 Installation Manual

P. O. Box 1220, Nash, TX 75569-1220

Phone 800-527-8482 or 903-832-2581

Fax 800-874-9524 or 903-838-6260

www.jcmindustries.com

Typical Specification

JCM 412 Fabricated Tapping Sleeve – Shop Coat Primer, Epoxy Coated Alloy Hardware

Tapping Sleeves shall be the high strength type having a wide body, made of a minimum material

strength of ASTM 285 Grade C, ASTM A-36 Steel or equal, which conforms to and reinforces the pipe.

The sleeve shall have as a minimum 7/8" wide gasket of Nitrile Butadiene Rubber (NBR, Buna-N) per

ASTM D2000 with hydromechancial activated lip, captured in a recessed groove around the outlet; 3/4"

corrosion resistant, high strength low alloy oval neck track head bolt per ASTM A242/ANSI 21.11/AWWA

C-111 and heavy hex nut per A563 epoxy coated and a 3/4" forged steel test outlet. Flanged outlet shall

be AWWA C207 Class D, ANSI 150 lb. drilling, recessed for tapping valve per MSS-SP60, outlets 2” – 12”

rated for 175 PSI* maximum operating pressure. Tapping Sleeve shall be furnished with corrosion

resistant shop coat paint primer.

For outlet sizes 14" and larger, the gasket groove must be consistently positioned about throat of tapping

waterway. Inside diameter of the gasket groove must be set back a minimum of 1" from the waterway to

allow dispersal of forces generated by gasket compression. Gasket grooves machined in a circle and

formed to an elliptical shape will not be an accepted equal.

Nominal pipe sizes 36" and larger shall be of the heavy duty type. Tapping Sleeves shall be JCM 412 or

approved equal.

*Higher test and working pressure ratings available upon request, contact JCM I ndustries.

JCM 400 Series Tapping Sleeves are ANSI/NSF Standard 61 and Standard 61 Annex G Certified.

JCM 400 Series Tapping Sleeves meet MSS-SP124 and ANSI/AWWA Standard C223 Fabricated Steel

and Stainless Steel Tapping Sleeves as applicable.

JCM 412 Tapping Sleeve

Image reflects 6” x 4”

This typical specification, provided by JCM Industries, is a

proposed guideline for use by specifying agencies to ensure

significant design and material features of this product are

included within the agencies’ individual specifications.

Effective 01.30.13

P. O. Box 1220, Nash, TX 75569-1220

Phone 800-527-8482 or 903-832-2581

Fax 800-874-9524 or 903-838-6260

www.jcmindustries.com

Material Specification

JCM 412 Fabricated Tapping Sleeve – Shop Coat Primer, Epoxy Coated Alloy Hardware

Body: ASTM 283 Grade C, ASTM 285 Grade C, ASTM A-36 Steel or equal.

Flange: AWWA C207 Class D, ANSI 150 lb. Drilling, recessed for tapping valve per MSS-SP60.

Optional flanges available upon request.

Gasket: Nitrile Butadiene Rubber (NBR, Buna-N) per ASTM D2000. Molded virgin rubber with a

pressure activated hydromechanical design. Gasket is bonded into a cavity for internal

and external retention. Gasket temperature range -40

Gasket suitable for water, salt solutions, mild acids, bases, and sewage. Optional

gasket materials available.

Bolts: Corrosion resistant, high strength low alloy oval neck track head bolt per ASTM

A242/ANSI 21.11/AWWA C-111 and heavy hex nut per A563 epoxy coated, Powercron

590-534.

Finish: Heavy coat of corrosion resistant shop coat primer.

Service

Rating: 2" to 12" Outlets: 175 PSI. Higher service rating available for specific applications and

sizes.

o

F to 212oF (-40oC - 100oC)

Flange

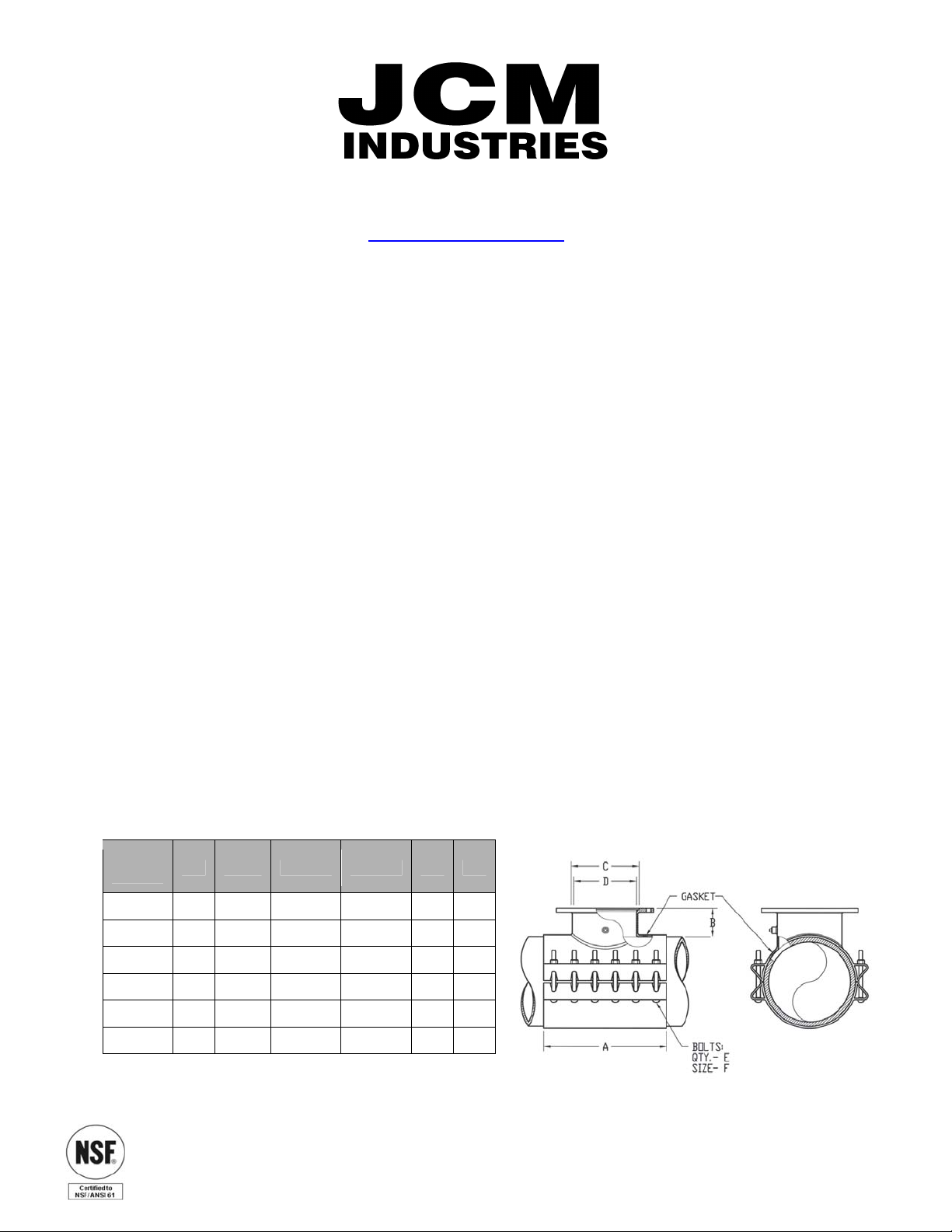

Size*

3 12 5 4-1/32 3-1/2 6 3/4

4 12 5 5-1/32 4-1/2 6 3/4

6 12 5 7-1/32 *6-1/2 6 3/4

8 16 5-1/8 9-1/32 8-1/8 8 3/4

10 20 5-1/2 11-1/16 10-1/4 10 3/4

12 24 5-3/4 13-1/16 12-1/4 12 3/4

*On nominal pipe size 7.45 and smaller dimension D is 6-1/ 8”

A B C D E F

Effective 01.30.13

Loading...

Loading...