JCM Industries 111 Installation Manual

Installation Instructions

Model 111 Full Repair Clamps

Read instructions before starting installation*

Review of “Tricks of the Trade” on the reverse will assist wit h installation.

For purposes other than water, contact JCM Industries for application and product assistance .

1. Clean and scrape pipe. Remove any scale, pipe wrap, debris or dirt that may interfere with the complete

sealing of the gasket. Inspect pipe for integrity, size, outside diameter and surface irregularities. Confirm the

proper size and range of repair clamp. Inspect fitting to ensure all par ts are included.

For fittings furnished with stainless steel hardware, see reverse for fastener management.

2. Lubricate the pipe and the fitting gasket with soapy water. Do not use oil base pipe lubr ic ant. Loo sen n uts of

bolts and back nuts to the end of the bolt (complete remo val of bolt s is not necessary). Release square necked

bolts from lug ears and open the clamp.

3. Wrap gasket around pipe and center over damaged area. Install stainless steel clamp shell over the gasket,

ensure gasket stainless steel armor plate is centered at the open gap between shell lugs. Placement stainless

“tips” aid in feeling positioning in adverse conditions . Engage bolt(s) in slotted receiver lugs and finger tighten

to hold in place. Begin bolt tightening.

4. Tighten bolt(s) evenly to the following torque values, ensure torque values with calibrated field torque wrench:

Nominal sizes 1/2” - 1-1/4” with 3/8” Bolts 25 Foot Pounds

Nominal sizes 1-1/2” - 2” with 7/16” Bolts 35 Foot Pounds

5. Complete installation of fitting, return after approximately 15 minutes and confirm minimum bolt torque levels

have been maintained.

For Use on Natural Gas Distribution Applications

Rating: CIP 2” thru 8” 100 PSI Gas

CIP 10” and 12” 60 PSI Gas

Steel 1-1/4” thru 8” 100 PSI Gas

Steel 10” and 12” 60 PSI Gas

INT111-0115

*Ensure fitting is suitable for application (confirm size, materials, pressure ratings, line content, meets local governing & association standards, etc.).

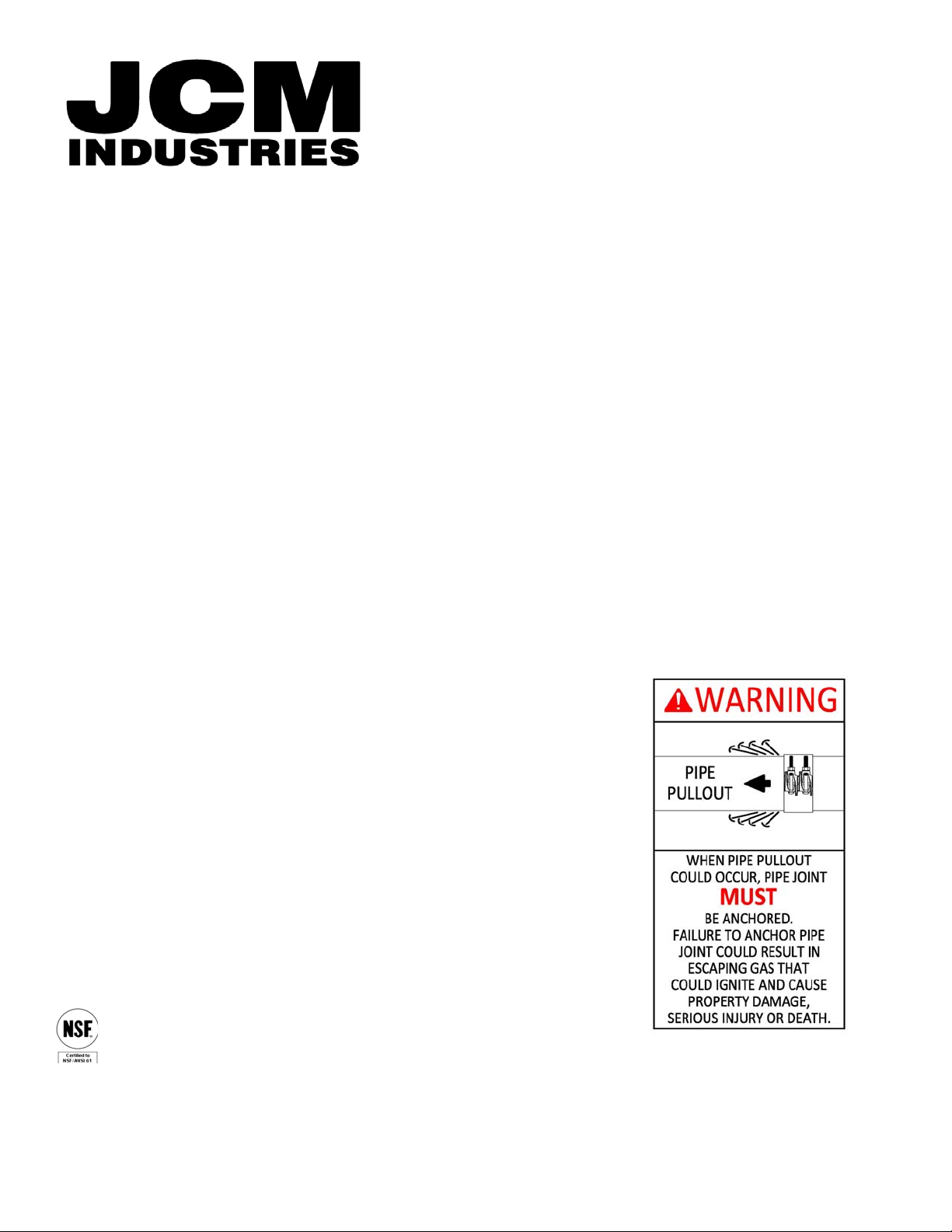

Pipeline operation forces, including pressure fluctuations, thermal expansion/contraction, movement/shifting, etc. will influence the success of the

application. Proper anchorage, restraint, harnessing, thrust blocks or other devices must be provided to prevent pipe movement (lateral, angular, axial) or

pipe pullout from the bolt-on fitting. Inspection of the pipe integrity is the responsibility of t he end user. JCM recommends the use of calibrated torque

wrench. Failure to follow installation instructions will result in voided product warranty.

For application review or questions contact JCM Industries at 1-800-527-8482, 903-832-2581

Tricks of the Trade for Installation

Model 111 Full Repair Clamps

Years of field experience, special applications and product testing have revealed many subtleties regarding application and

installation of repair clamps. For maximum performance under adverse conditions take advantage of the JCM “Tricks of the

Trade.”

• Always clean and lubricate pipe with water or soapy water. This helps overcome friction when adjusting the clamp. Do not use oil base

pipe lubricant; the oil does not disperse, leaves residue and prevents the gasket from sealing/adhering to the pipe wall. Use water

solvent lubricant. Use of a mirror will assist inspection of backside of pipe or pipe in cramped, limited space.

• Place a reference mark on the pipe back from the damaged area to help in centering clamp over break.

Clamps provide maximum performance when centered over damage area.

• For installation on pipe under pressure: lubricate the clamp gasket with soap/water mixture, assemble clamp

on the pipe beside the damaged area, lightly engage bolts and slid the clamp over the damaged area,

proceed with installation steps.

• Damage involving large holes or massive pitted areas - use stainless steel plate over large holes (under

repair clamp) to provide the gasket a surface to seal against.

• Lubricating clamp bolts will ease clamp installation and assure proper torquing of bolts.

JCM Quality Fitting Equipped With 18-8 Stainless Steel Bolts and Nuts

When not properly handled it is the nature of stainless steel fasteners to gall and freeze (seize up). This is due to the inherent properties

of the stainless material. Galling and freezing is often triggered by the presence of metal chips, burrs and grains of sand on the threads of

the bolts and nuts. Extra care has been taken by JCM prior to assembly and packing of this fitting to assure a trouble-free installation.

1. The nuts and bolts are made from material of different hardness so that they have different strengths.

2. Nuts are coated with a special antiseize coating. Additional lubricant may be needed. A Molybdenum-Base lubricant is

recommended.

3. Each nut is assembled by hand to be sure that it went on the bolt freely.

4. The bolts and nuts are handled carefully to avoid damage to the threads.

5. The bolts and nuts are made to exacting specifications to assure that the correct material is used and that the thread form is correct.

Stainless hardware is especially susceptible to galling. JCM supplies specially coated nuts to eliminate the galling caused by

overtorquing, but the bolt threads must be kept clean, free from nicks and not pitched or thrown into the tool bucket during the

installation process. Use of the JCM 901 Master Wrench or JCM 905 Torque Wrench with Deep Socket is highly recommended.

Use of pneumatic wrench for installation could cause hardware to seize and is not recommended.

Loading...

Loading...