Page 1

Web site: http://www.jcmglobal.com

UBA Pro RT/RQ™ Series

Banknote Recycler

Integration Guide

Revision A, October 23, 2019

P/N 960-000209R_Rev. A

Issue #4115-IGE-01-00

© 2019, JAPAN CASH MACHINE CO., LTD.

Page 2

UBA Pro RT/RQ™ Series Banknote Recycler Integration Guide

See Below.

See Below.

See Below.

See Below.

See Below.

Issue #4115-IGE-01-00

REVISION HISTORY

Rev №. Date Reason for Update Comment

A Oct. 23, 2019 Initial Document

International Compliance

• RoHS Directives

• UL & c-UL Marks

• CE Mark

• CB Scheme

• FCC & ISED Regulations

NOTE: All the compliance confirmations above are currently being examined for approval.

Electrical Current Symbol

Direct Current: indicates Direct Current values on product labels.

Copyright © 2019 By JAPAN CASH MACHINE CO., LTD.

This product document (hereinafter referred to as “Manual”) is fully covered by legal Copyrights owned by the JAPAN

CASH MACHINE CO., LTD. (hereinafter referred to as “JCM”) under Japanese laws and other Foreign Countries.

This Manual contains many copyrighted, patented or properly registered equipment items manufactured by JCM, that

are prohibited and illegal to duplicate, replicate, copy in whole, or in part, without the express authorization by JCM with

the following exceptions:

1. When an authorized JCM agency or distributor duplicates the Manual for sales promotion and/or service

maintenance of the product, or technical service personnel education as required; and

2. When an end user duplicates the Manual to maintain operation of the product or operate the product in general.

JCM retains all rights to amend, alter, change or delete any portion of this Manual in whole, or in part, or add items

thereto without notice regarding the product or its related products.

JCM is a registered trademark of JAPAN CASH MACHINE CO., LTD. All other product names mentioned herein may be

registered trademarks or trademarks of their respective companies. Furthermore,

in each case throughout this publication.

™, ® and © are not always mentioned

Page 3

UBA Pro RT/RQ™ Series

i

Banknote Recycler

Table of Contents

Page

1 GENERAL INFORMATION ........................................................................................1

RT and RQ Units.................................................................................................................1

Model Descriptions............................................................................................................2

Type Descriptions..............................................................................................................2

Software Descriptions .......................................................................................................2

Precautions.........................................................................................................................2

User Cautions ......................................................................................................................3

Installation Cautions........................................................................................................................ 3

Mounting, Dismounting & Transportation........................................................................................ 3

Operation Cautions ......................................................................................................................... 3

Preventive Maintenance.......................................................................................................3

Disposal Considerations ......................................................................................................4

Banknote Fitness Requirements..........................................................................................4

Primary Features................................................................................................................4

Transport UnitComponent Names....................................................................................5

2 SPECIFICATIONS ......................................................................................................7

Technical Specifications ......................................................................................................7

Environmental Specifications ......................................................................................................... 8

Electrical Specifications .......................................................................................................8

Structural Specifications.......................................................................................................8

3 INSTALLATION ..........................................................................................................9

Installation Procedure .......................................................................................................9

Grounding ...........................................................................................................................9

Side Installation (For Standard and Stacking Up (SU) Installation types)............................9

Bottom Installation (For Standard Installation Type Only)..................................................10

Bezel Installation ................................................................................................................10

External Harness Installation .............................................................................................10

Cash Box Lock Installation.................................................................................................10

Unlock Procedure...............................................................................................................11

DIP Switch Configurations ..............................................................................................11

Denomination Acceptance Settings (DIP Switches at the front) ........................................11

SW1 and SW2 Configurations ...........................................................................................11

Interface and Recycler Settings (Sub Board 2)..................................................................12

LED Flashing Patterns.....................................................................................................13

4 CONNECTOR PIN ASSIGNMENTS.........................................................................14

USB Interface Connector Pin Assignments (UBA Pro Side)..............................................14

Photo Coupler Interface Connector Pin Assignments (UBA Pro Side) ..............................15

RS232C Interface Connector Pin Assignments (UBA Pro Side)........................................16

cc-Talk Interface Connector Pin Assignments (UBA Pro Side)..........................................17

Power Supply Connector Pin Assignments (RT/RQ Side).................................................18

Interface Connector Pin Assignments (RT/RQ Side).........................................................18

Bezel Connector Pin Assignments (UBA Pro Side) ...........................................................18

5 PREVENTIVE MAINTENANCE ................................................................................19

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 4

ii

UBA Pro RT/RQ™ Series Banknote Recycler

Table of Contents

Page

Refilling Banknotes..........................................................................................................19

Collecting Banknotes ......................................................................................................19

Collecting Banknotes into the Cash Box by the Button......................................................19

Collecting Banknotes into the Cash Box by Command......................................................19

Dispense Settings ..............................................................................................................19

Clearing a Banknote Jam ................................................................................................20

Find where a Banknote Jam occurred ...............................................................................20

Jammed in UBA Pro Unit ...................................................................................................20

Jammed in RT Transport Banknote ...................................................................................20

Jammed in RQ Transport...................................................................................................21

Jammed in Recycler Drum.................................................................................................22

Jammed in Cash Box .........................................................................................................22

Cleaning Procedure .........................................................................................................22

Sensor Cleaning Procedure ...............................................................................................22

Sensor, Roller and Belt Cleaning Locations.......................................................................24

6 STANDARD INTERFACE CIRCUIT SCHEMATICS................................................ 27

Bezel Connector Interface Circuit Schematics...................................................................27

RT/RQ Interface Circuit Schematics (Sub Board 2)...........................................................28

7 OPERATIONAL FLOWCHART ............................................................................... 29

RT/RQ Main Flow Process.................................................................................................29

RT/RQ Accepting Banknotes Flow Process.......................................................................30

RT/RQ Transporting to Recycler Flow Process .................................................................31

RT/RQ Transporting to Cash Box Flow Process................................................................32

RT/RQ Dispensing Flow Process (Normal)........................................................................33

RT/RQ Dispensing Flow Process (Abnormal)....................................................................34

RT/RQ Collecting in Cash Box Flow Process1 ..................................................................34

RT/RQ Collecting in Cash Box Flow Process 2 .................................................................35

8 TROUBLESHOOTING ............................................................................................. 36

Introduction ......................................................................................................................36

Troubleshooting Overview..............................................................................................36

LED Error Codes ..............................................................................................................36

9 UNIT DIMENSIONS.................................................................................................. 39

RT Unit With SH2 Box Outside Dimensions and Installation/Maintenance Space

Requirement.......................................................................................................................39

RT Unit With SH2 Box Outside Dimensions and Installation/Maintenance Space

Requirement.......................................................................................................................40

RQ Unit With SH2 Box Outside Dimensions and Installation/Maintenance Space

Requirement.......................................................................................................................41

RQ Unit With Large Box Outside Dimensions and Installation/Maintenance Space

Requirement.......................................................................................................................42

Bezel Outside Dimensions .................................................................................................43

10 TECHNICAL CONTACT INFORMATION ................................................................ 44

Americas ............................................................................................................................44

JCM American ...............................................................................................................................44

Europe, Middle East, Africa & Russia ................................................................................44

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 5

iii

UBA Pro RT/RQ™ Series Banknote Recycler

Table of Contents

Page

JCM Europe GmbH....................................................................................................................... 44

UK & Ireland.......................................................................................................................44

JCM Europe (UK Office) ............................................................................................................... 44

Asia and Oceania...............................................................................................................44

JCM Gold (HK) Ltd........................................................................................................................ 44

JAPAN CASH MACHINE CO., LTD. (HQ) .................................................................................... 44

11 INDEX .......................................................................................................................45

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 6

iv

THIS PAGE INTENTIONALLY LEFT BLANK

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 7

v

UBA Pro RT/RQ™ Series

Banknote Recycler

List of Figures

Figure 1 RQ and RT Units ........................................................................................1

Figure 2 Precautionary Symbols ..............................................................................2

Figure 3 Unacceptable Banknotes ...........................................................................4

Figure 4 RT/RQ Component Locations ....................................................................5

Figure 5 Grounding ..................................................................................................9

Figure 6 Side Installation (Standard and SU Installation Types) ..............................9

Figure 7 Bottom Installation (Standard Installation Type) ......................................10

Figure 8 Bezel Installation ......................................................................................10

Figure 9 External Harness Installation ...................................................................10

Figure 10 Key Hole Location ....................................................................................10

Figure 11 Key Hole Dimension & Cylinder Length ...................................................11

Figure 12 Key Lock Rotation Requirement ..............................................................11

Figure 13 Key Cap Installation .................................................................................11

Figure 14 SW1 and SW2 Switches ..........................................................................11

Figure 15 Refilling Banknotes ..................................................................................19

Figure 16 Collecting Banknotes 1 ............................................................................19

Figure 17 Collecting Banknotes 2 ............................................................................19

Figure 18 UBA Pro Unit Banknote Jam Clear ..........................................................20

Figure 19 RT Transport Banknote Jam Clear 1 .......................................................20

Figure 20 RT Transport Banknote Jam Clear 2 .......................................................20

Figure 21 RT Transport Banknote Jam Clear 3 .......................................................20

Figure 22 RT Transport Banknote Jam Clear 4 .......................................................20

Figure 23 RT Transport Banknote Jam Clear 5 .......................................................21

Figure 24 RQ Transport Banknote Jam Clear 1 .......................................................21

Figure 25 RQ Transport Banknote Jam Clear 2 .......................................................21

Figure 26 RQ Transport Banknote Jam Clear 3 .......................................................21

Figure 27 RQ Transport Banknote Jam Clear 4 .......................................................21

Figure 28 RQ Transport Banknote Jam Clear 5 .......................................................21

Figure 29 Recycler Drum Banknote Jam Clear 1 .....................................................22

Figure 30 Recycler Drum Banknote Jam Clear 2 .....................................................22

Figure 31 Recycler Drum Banknote Jam Clear 3 .....................................................22

Figure 32 Cash Box Banknote Jam Clear ................................................................22

Figure 33 Sensor and Roller Cleaning .....................................................................23

Figure 34 RT/RQ Sensor, Roller and Belt Cleaning Locations ................................24

Figure 35 Bezel Connector Interface Circuit Schematics .........................................27

Figure 36 RT/RQ Interface Circuit Schematics (Sub Board 2) .................................28

Figure 37 RT/RQ Main Flow Process .......................................................................29

Figure 38 RT/RQ Accepting Banknotes Flow Process .............................................30

Figure 39 RT/RQ Transporting to Recycler Flow Process .......................................31

Figure 40 RT/RQ Transporting to Cash Box Flow Process ......................................32

Figure 41 RT/RQ Normal Dispensing Flow Process ................................................33

Figure 42 RT/RQ Abnormal Dispensing Flow Process ............................................34

Figure 43 RT/RQ Collecting in Cash Box Flow Process 1 .......................................34

Page

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 8

vi

UBA Pro RT/RQ™ Series Banknote Recycler

List of Figures

Page

Figure 44 RT/RQ Collecting in Cash Box Flow Process 2 ....................................... 35

Figure 45 RT Unit With SH2 Box Outside Dimension and Installation/

Maintenance Space Requirement ........................................................... 39

Figure 46 RT Unit With Large Box Outside Dimension and Installation/

Maintenance Space Requirement ........................................................... 40

Figure 47 RQ Unit With SH2 Box Outside Dimension and Installation/

Maintenance Space Requirement ........................................................... 41

Figure 48 RQ Unit With Large Box Outside Dimension and Installation/

Maintenance Space Requirement ........................................................... 42

Figure 49 Bezel Outside Dimensions ...................................................................... 43

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 9

vii

UBA Pro RT/RQ™ Series

Banknote Recycler

List of Tables

Table 1 RT/RQ Product Model Number Specifications............................................2

Table 2 RT/RQ Type Number Specifications...........................................................2

Table 3 RT/RQ Software Number Specifications.....................................................2

Table 4 RT/RQ Component Names.........................................................................6

Table 5 RT/RQ Technical Specifications .................................................................7

Table 6 RT/RQ Environmental Specifications..........................................................8

Table 7 RT/RQ Electrical Specifications ..................................................................8

Table 8 RT/RQ Structural Specifications .................................................................8

Table 9 Denomination Acceptance Settings ..........................................................11

Table 10 Sub Board 2 Interface Settings .................................................................12

Table 11 Recycler and Transport LEDs Flashing Patterns ......................................13

Table 12 Status LED Flashing Patterns ...................................................................13

Table 13 USB Interface Connector Pin Assignments (UBA Pro Side).....................14

Table 14 Photo Coupler Interface Connector Pin Assignments (UBA Pro Side) .....15

Table 15 RS232C Connector Pin Assignments (UBA Pro Side)..............................16

Table 16 cc-Talk Interface Connector Pin Assignments (UBA Pro Side).................17

Table 17 Power Supply Connector Pin Assignments (RT/RQ Side)........................18

Table 18 Interface Connector Pin Assignments (RT/RQ Side) ................................18

Table 19 Bezel Connector Pin Assignments (UBA Pro Side) ..................................18

Table 20 RT/RQ Sensor Cleaning Methods.............................................................25

Table 21 LED Error Codes.......................................................................................36

Page

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 10

viii

THIS PAGE INTENTIONALLY LEFT BLANK

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 11

UBA Pro RT/RQ™ Series

1

1 GENERAL INFORMATION

NOTE: Refer to the UBA Pro Series

Universal Banknote Acceptor Integration

Guide for the UBA Pro product‘s details.

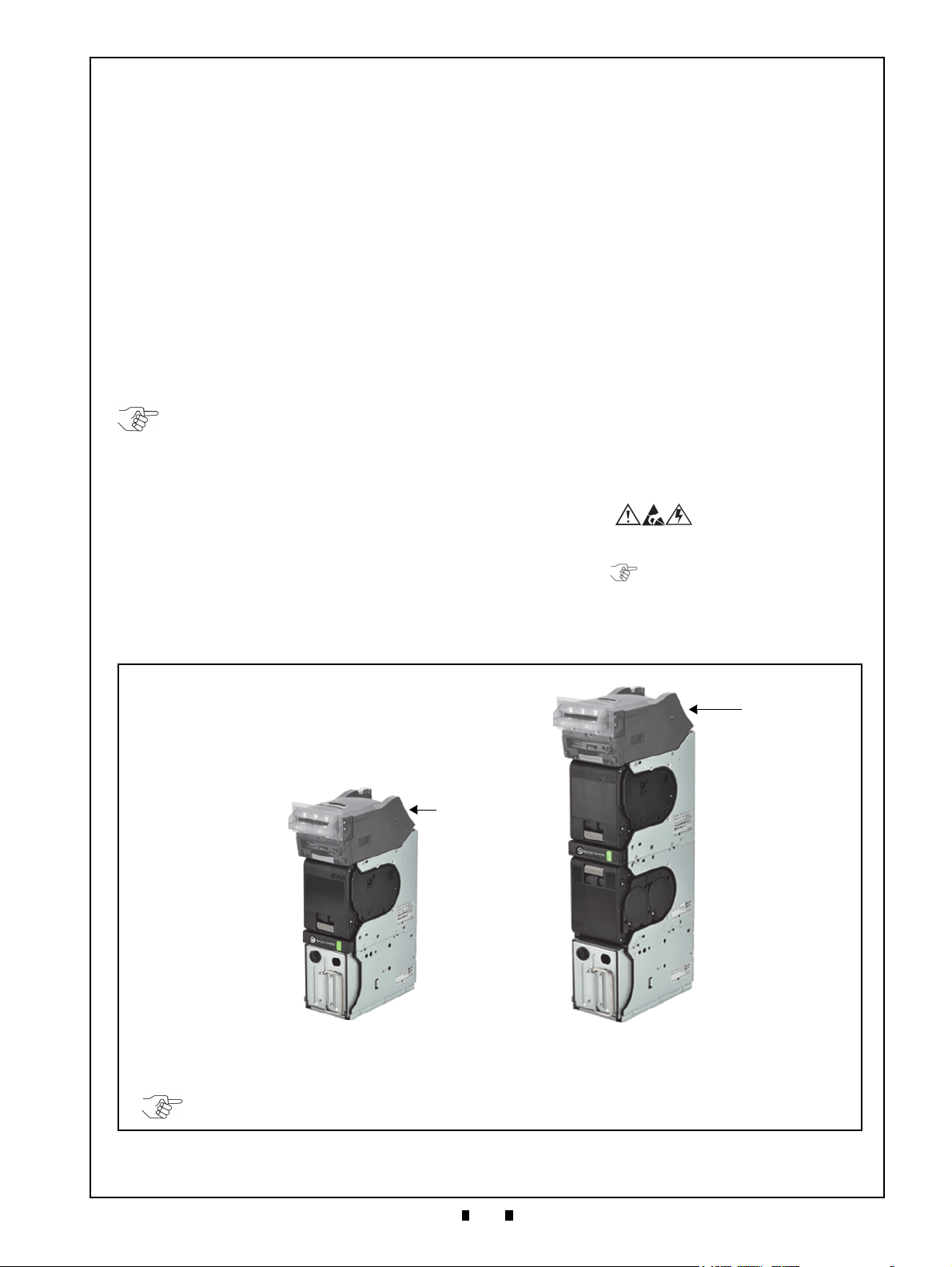

RT and RQ Units

Figure 1 RQ and RT Units

Figure 1 RQ and RT Units

RT Unit

RQ Unit

UBA Pro

(1 Recycler, Twin Drums)

(2 Recyclers, Quad Drums)

NOTE: The Stacking Up (SU) installation is also available by using a specified SU Bezel.

UBA Pro

Banknote Recycler

Integration Guide

Revision A

This section provides a general overview of the

UBA Pro RT/RQ™ Series Banknote Recycler (RT/

RQ) pictured in Figure 1.

The RT/RQ Unit is a Banknote Recycler compatible with the UBA Pro Series Universal Banknote

Acceptor.

This section is designed to help you navigate

through this guide with ease, and provides the following information:

• RT and RQ Units

• Model Descriptions

• Type Descriptions

• Software Descriptions

• Precautions

• Primary Features

• Component Names

• Specifications

• Unit Dimensions

• Technical Contact Information

In order to make operation of this device easier and

make navigation within this manual simpler, the

following illustrations were used within the text:

• Safety Instructions need to be observed in order to

protect the operators and the equipment; these are

identified with Bold text and the following

pictographs:

• Special Notes affect the use of the RT/RQ Unit;

these are identified with italic text and the following

pictograph:

• Steps require the operator to perform specific

actions; these are identified with sequential

numbers (1, 2, 3, etc.).

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 12

2

Section 1 UBA Pro RT/RQ™ Series Banknote Recycler General Information

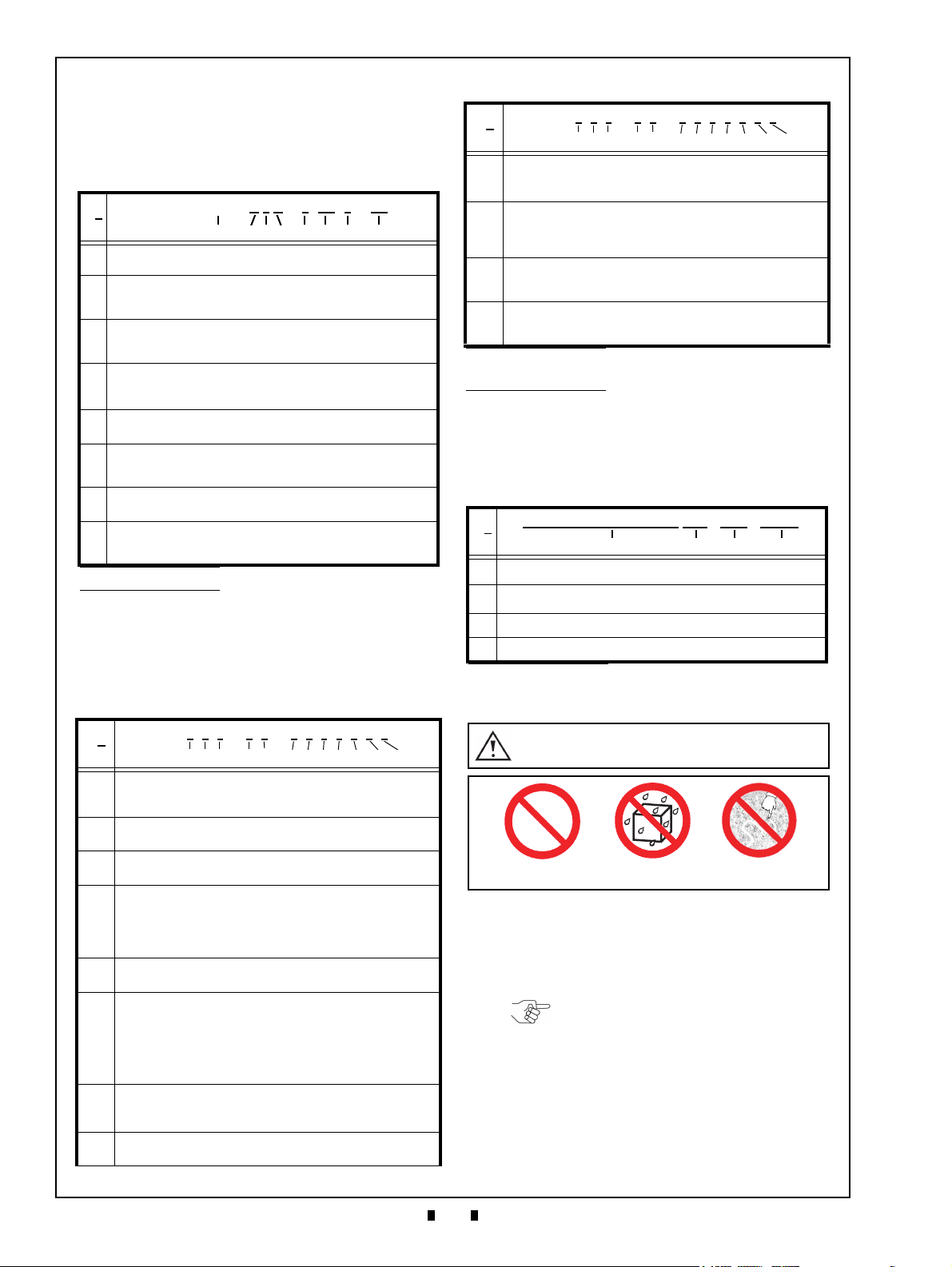

Model: UBA - 5 * 0 - (*) * * (*) - * *

(1)

(2)(3)(4) (6) (7) (8)(5)

Typ e: * * * - * * - * * * * * * *

(1)(2)(3)

(4)

(6)(7)(8)(9)(10)(11)(12)

(5)

Typ e: * * * - * * - * * * * * * *

(1)(2)(3)

(4)

(6)(7)(8)(9)(10)(11)(12)

(5)

(A)

(D)

UBA-5**-(*)**(*)-RC-T/Q * * * - 0 * * - V * .**

(B) (C)

Caution: User cautions should be

included in any user guides or manuals.

Figure 2 Precautionary Symbols

Type1 Type2 Type3

Figure 2 Precautionary Symbols

NOTE: Refer to “Banknote Fitness

Requirements” on page 4.

Model Descriptions

Table 1 lists the RT/RQ Product Model Number Descriptions.

Table 1 RT/RQ Product Model Number

Specifications

o

N

(1)

Model Name (UBA Pro Series)

Validation Sensor

(2)

5 = World Wide Type 1 (Standard)

6 = Reserved

Barcode Sensor Board (Optional)

(3)

0 = Upper only (Standard)

1 = Upper and Lower

Acceptor Head Unit Type

(4)

0 = Centering Type (Banknote Short Side: 62mm - 85mm)

1 = Reserved

Input Section Unit (Optional)

(5)

None = Standard

Stacking Type

(6)

SH2 = Horizontal Down (82mm, SH2 Box)

SS = Vertical Down (85mm, Large Box)

Cash Box Access

(7)

None = Front Access (Standard)

Recycler Type

(8)

RT = 1 Recycler (Twin Drums)

RQ = 2 Recyclers (Quad Drums)

*. Refer to the UBA Pro Series Universal Banknote Acceptor Integration Guide for

the UBA Pro Unit’s details.

†. The acceptable Banknote width depends on the Cash Box. Refer to “Technical

Specifications” on page 7 for each Cash Box’s acceptable Banknote size.

*

†

Type Descriptions

Table 2 lists the RT/RQ Type Number Descriptions.

Table 2 RT/RQ Type Number Specifications

Tab le 2 RT/RQ Type Number Specifications

o

N

Interface Setting (Factory Default)

(9)

P = Photo-Coupler Isolation

R = RS232C

External Harness

0 = Reserved

(10)

1 = Standard Harness (with power cord)

2 = USB I/F Harness (with power cord)

Cash Box Faster/Lock (Optional)

(11)

0 = None

1 = Thumb Twist Lock Fastener for the Cash Box

Battery (For Recycler Detection)

(12)

0 = No Battery

1 = Battery Equipped

*. Small pieces of paper or receipts might accidentally be inserted into the UBA Pro

Unit. The Bezel Spacer makes the distance to the Sensor longer and the Sensor

may not detect such foreign objects. Also, small pieces of paper or receipts are difficult to detect and remove.

†. Refer to “SW1 and SW2 Configurations” on page 11 for details.

†

Software Descriptions

Table 3 lists the RT/RQ Software Number

Descriptions.

Table 3 RT/RQ Software Number Specifications

o

N

(A) Software Model Name

(B)

Country Code (Denomination)

(C) Interface Protocol Name

(D) Software Version

*. The Country Code is indicated by three (3) Alphabetical Characters following the

JIS Standard.

*

Precautions

o

N

Cash Box Capacity

(1)

4 = 400 notes, SH2 Box (New Banknote)

8 = 800 notes, Large Box, (New Banknote)

Cash Box Type

(2)

0 = Standard

Cash Box Handle

(3)

0 = Standard

Sub Board Type

0 = Reserved

1 = Reserved

(4)

2 = Sub Board 2 (RS232/Photo-Coupler Isolation/TTL/ccTalk/1 USB)

3 = Reserved

4 = Reserved

Acceptor Head Unit Cover

(5)

0 = Black (Standard)

Bezel

0 = No Bezel

1 = Black/2 Green LEDs (Bezel 85) (Standard Installation)

2 = Reserved

(6)

8 = Reserved

9 = Reserved

A = Reserved

B = Black/2 Blue LEDs (SU Installation)

Bezel Spacer

(7)

0 = No Bezel Spacer

1 = With Bezel Spacer

Optional Circuit Board

(8)

0 = Reserved

*

The Figure 2 symbols are defined as follows:

1. (Type 1) Do not insert a damaged or exhibited

unfit condition Banknote; it may cause a jam

inside the unit.

2.

(Type 2) Do not expose the unit to water. The unit

contains several precision electronic devices that

can be damaged if water or any liquid is sprayed

or spilled into the unit.

3.

(Type 3) Do not install the unit in a dusty

environment. Dust may damage the unit or

degrade its performance.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 13

3

General Information UBA Pro RT/RQ™ Series Banknote Recycler Section 1

Caution: DO NOT use any alcohol,

solvents, abrasive cleaning agents,

or citrus-based cleaners that can

damage the plastic surface of the

device when cleaning it.

WARNING: This Unit is designed

for use with a Limited Power

Source! Design the Host Cabinet

space to meet all local related

safety standards.

Caution: Make Interface Harness

connections to the Host Machine

shorter than 9.84 Feet (3 Meters) in

length. Cut off all unused portions

of the Interface Harness wiring to

avoid static electrical effects or

short circuit possibilities that

could cause damage to the Unit.

User Cautions

Careful measures are taken in the design of this

product to ensure its quality; however, the following cautions should be read and understood by all

users in order to confirm safe operation.

Installation Cautions

The Installation Cautions are defined as follows:

1. Do not allow the Unit to endure or operate at a

high temperature, in high humidity and/or in a

dusty environment.

2. Do not install the Unit into an area where excessive vibration or shock are present.

3. The Unit is not designed for outside installation.

Be sure that the Host Machine contains enough

protection to avoid wet or dusty conditions when

installing in either an indoor or open-air space.

4. Avoid exposing the Unit to direct Sunlight and/or

Incandescent Lamp illumination having a

Gradient Angle of 15 Degree or more, and an

illumination index of 3000 Lux or less.

5. Ensure that the Host Machine is designed for

daily operational access for maintenance and/or

clearing a Banknote jam (refer to “Unit Dimensions” on page 39).

6. When installing the equipment, connect the

Frame Housing to the Frame Ground of the Host

Machine.

7. If an unused Interface Harness exists, cut the

Harness off short to avoid attracting static electricity or a short circuit possibility that may cause

damage to the Unit.

8. Because this equipment is a component product,

close the Host Machine’s door before using it.

9. Do not operate the RT/RQ Unit without the Cash

Box and/or the Recycler or while the Cash Box

and/or the Recycler’s door is open.

10. This Unit is designed to use a Limited Power

Source. Be sure that the Host Machine’s cabinet

material design meets local safety standards.

11. Do not use the Unit where it may be exposed to

airborne evaporated or sporadic chemicals and/or

oil.

12. Ensure that the Host Machine is designed considering the risk of electronic components that can

cause induced noise. The noise generated by the

components on the Host Machine may affect and

degrade the Validation performance.

Mounting, Dismounting & Transportation

Methods for Mounting, Dismounting, and Transporting the Unit are as follows:

1. Be sure to remove the Power from the RT/RQ

Unit before attaching or unplugging Connector

Plugs to avoid the risk of damage to the Unit.

2. Be sure to carry the Unit by both hands when

transporting it. Holding the Unit by one hand

may cause personal injury if the Unit accidentally

becomes disassembled and falls away from the

Frame housing.

3. Be careful not to use excessive outside pressure

on the Recycler, or subject it to excessive vibration during transportation.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

4. Check that the UBA Pro Unit does not drop off

the Unit Frame while pulling the Recycler forward from the Frame.

Operation Cautions

The Operation Cautions are defined as follows:

1. When closing the UBA Pro Unit, ensure it firmly

clicks into place.

2. When installing the Recycler, ensure it firmly

clicks into place.

3. Do not remove the Recycler and/or the Cash Box

during operation.

4. Do not throw or pound hard on the Recycler.

5. Be sure to follow the specified measures when

removing or re-seating any removal unit of the

RT/RQ Unit. Improper handling may cause personal injury and/or damage to the equipment.

6. The Recycler is not protected by a key. Caution is

advised for cash handling.

Preventive Maintenance

The Preventive Maintenance requirements are

defined as follows:

1. Be sure to remove the Power from the RT/RQ

Unit before beginning a maintenance procedure,

except for the Recycler and the Cash Box. The

equipment produces improper operating signals

while in maintenance mode that may cause personal injury.

2. If the Transport Path and/or Sensors are dirty due

to dust, foreign objects or other such debris

adhering to it, the Banknote acceptance rate will

degrade. Clean the Unit once a month to keep its

performance optimal.

3. Use a soft, lint-free cloth, cotton swab or a compressed air spray to clean dust and debris from

the Banknote path and the inside areas of the

Recycler.

4. Do not redesign or disassemble the Recycler.

Unauthorized use by inadequately-trained

personnel, or use outside the original manufacturer’s intent for operation voids the warranty.

Page 14

4

Section 1 UBA Pro RT/RQ™ Series Banknote Recycler General Information

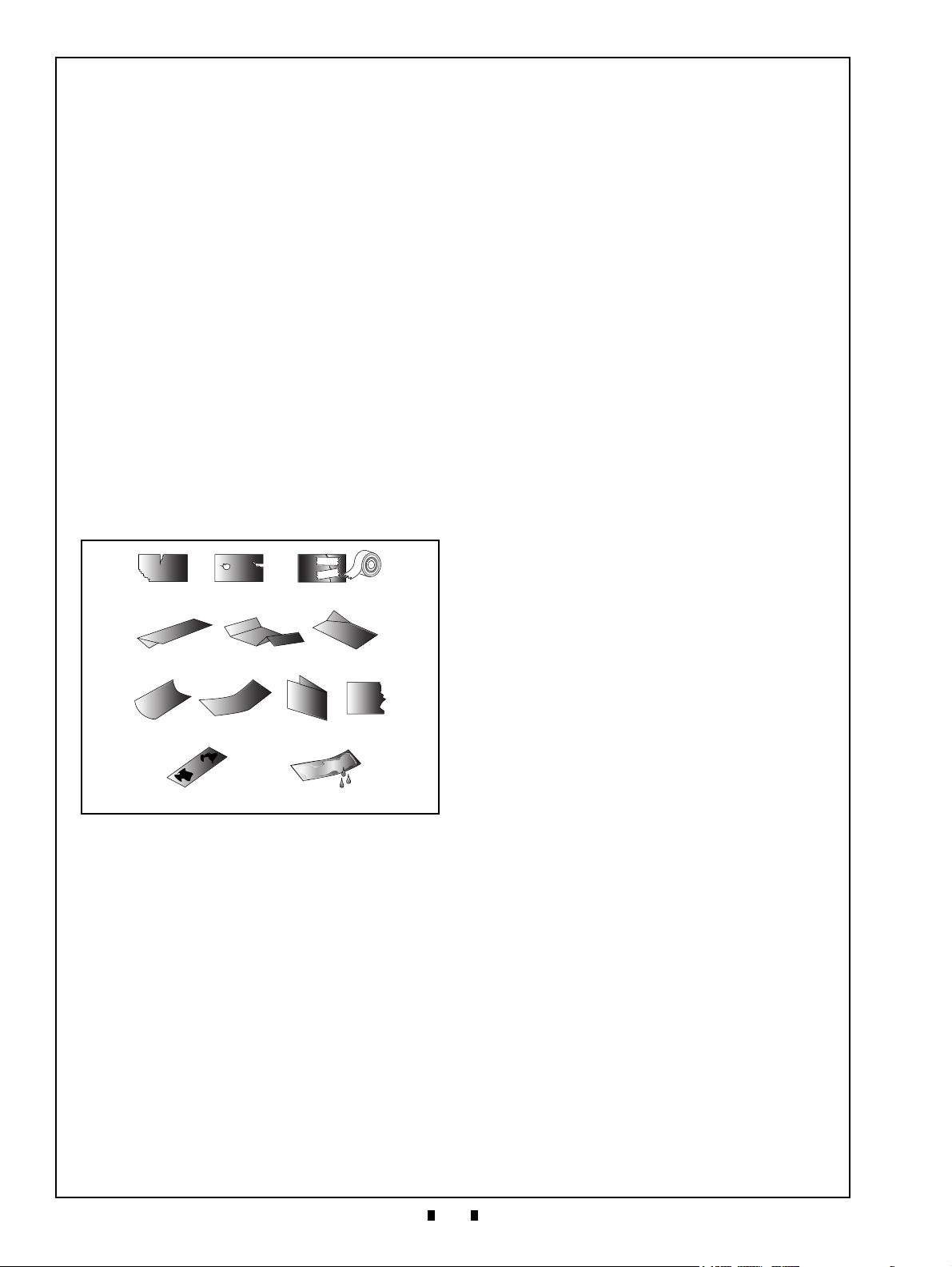

Figure 3 Unacceptable Banknotes

Figure 3 Unacceptable Banknotes

Damaged or Taped Banknotes

Wrinkled or Folded Banknotes

Curled, Folded or Partial Banknotes

Dirty Banknotes

Wet or Oiled Banknotes

Disposal Considerations

The battery disposal requirements are defined as

follows:

1. Do not allow positive (+) and negative (-) battery

terminals to touch each other.

2. Use caution so that batteries stored or transported

together do not short circuit.

3. Follow federal, state and local regulations for

battery disposal.

Banknote Fitness Requirements

The following Banknote types may not validate

correctly, or can cause a Banknote jam and/or damage to the Unit’s Transport path. Banknotes exhibiting the conditions listed below and illustrated in

Figure 3 should be avoided:

• Torn

• Worn

• Taped

• Excessive folds or wrinkles

• Dirty

• Wet

• Adhering foreign objects and/or oil

• Excessive miscuts, misaligns and/or misprints

• The Automatic Centering Mechanism allows the

Unit to read Banknotes ranging from 62 to 85mm in

width, and it will automatically center Banknotes

inserted obliquely to help improve the acceptance

rate (the acceptable Banknote width depends on the

Cash Box).

• Easily access to all the note paths for maintenance

efficiency.

• Able to stack up to 800 Banknotes in the plastic

Cash Box (only Large Box).

• The JCM patented Anti-Pullback Mechanism

provides powerful protection against Banknote

stringing operations.

Primary Features

The RT/RQ Unit contains the following primary

features:

• The RT Unit is equipped with one high capacity

compact Recycler, containing two drums for

recycling two denominations of Banknotes.

• The RQ Unit is equipped with two high capacity

compact Recyclers, each containing two drums for

recycling four denominations of Banknotes.

• Each Recycler’s Drum can store up to 30

Banknotes.

• The Recycler is lockable and removal, and contains

a memory device to assure safe and secure cash

handling.

• Processing speed is approximately double or

greater than the previous UBA-RC Series Units.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 15

General Information UBA Pro RT/RQ™ Series Banknote Recycler Section 1

5

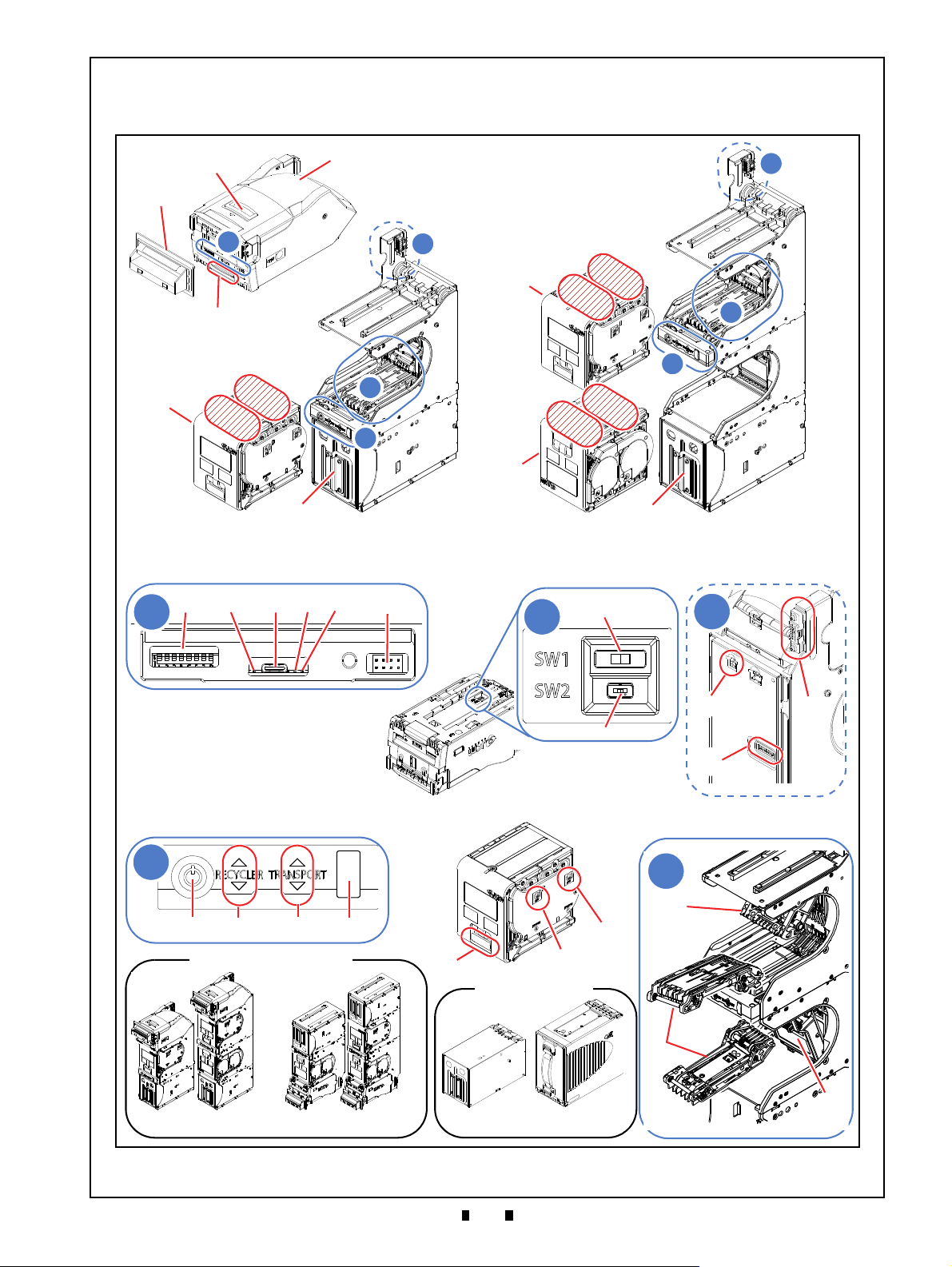

Figure 4 RT/RQ Component Locations

Figure 4 RT/RQ Component Locations

Standard

Stacking Up (SU)

SH2 Box

Large Box

RQ Unit

RT Unit

Recycler Direction

for RT Transport

Recycler Direction

H

1

H

1

I I

D

r

u

m

1

D

r

u

m

2

L

M

}

}

L

}

H

2

D

r

u

m

2

D

r

u

m

1

D

r

u

m

1

D

r

u

m

2

3

4

1

K

2

G

G

K

K

for RQ Transport (flipped)

A

B

C

D

E

J

J

Recycler

N

P

O

Installation Type

Cash Box

UBA Pro Bottom View

5

6

4

3

1

2

E

1

2

F

1

2

G

3

J

1

2

2

Transport UnitComponent Names

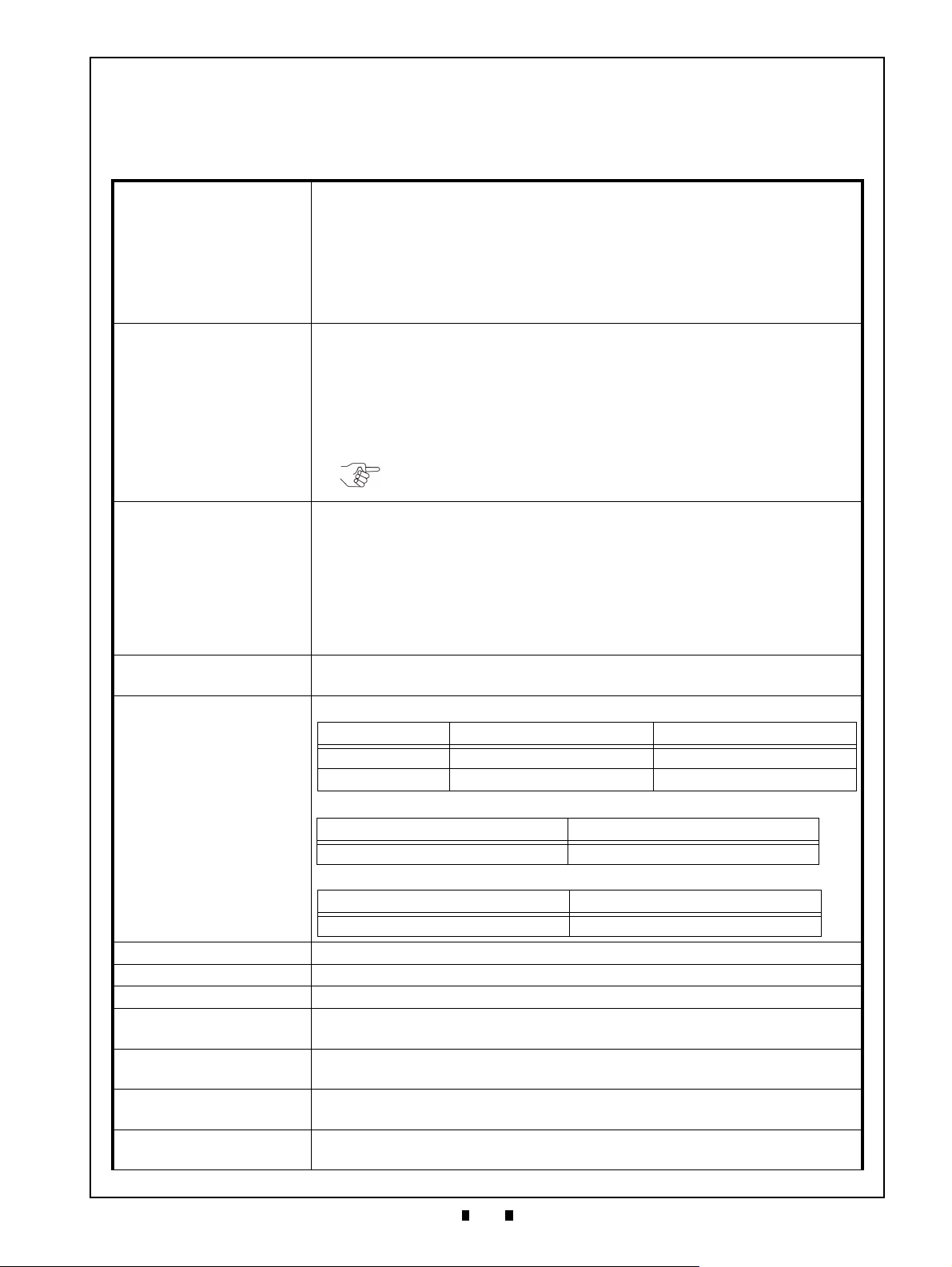

Figure 4 illustrates the RT/RQ component names and locations.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 16

Section 1 UBA Pro RT/RQ™ Series Banknote Recycler General Information

6

Table 4 RT/RQ Component Names

Sym. Description Sym. Description

A Acceptor Head Unit (UBA Pro)

B Upper Guide Access Lever

H

Recycler (RT Transport)

1

H

Recycler (RQ Transport)

2

C Bezel I Cash Box

D Acceptor Head Unit Release Lever

1 Transport Unit

J

1 DIP Switches (Front) 2 Front Transport Unit

2 UBA Pro Status LED (Orange)

1 Recycler Lock

3 USB Type-C Connector (Maintenance) 2 Recycler LED

E

4 UBA Pro Status LED (Green) 3 Transport LED

5 UBA Pro Status LED (Red) 4

K

Status LED/Collect Button

*

6 Bezel Connector L RT Transport

1 SW1 (Bottom) M RQ Transport

F

2 SW2 (Bottom) N Recycler Release Lever

1 Interface Connector O Drum 1 Shaft

G

2 Power Connector P Drum 2 Shaft

3 DIP Switches (Rear) -

*. With the Collect Button (Status LED), the Banknotes are sent from the Recycler into the Cash Box. Refer to “Collecting Banknotes into the Cash Box by the Button” on

page 19.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 17

Specifications UBA Pro RT/RQ™ Series Banknote Recycler Section 2

7

NOTE: In case of Large Box, a Banknote wider than 82mm (3.22in.)

up to 85mm (3.44in.) is directly transported to the Cash Box.

Destination RT RQ

Collect to Recycler Approx. 2 seconds (to Drum 1) Approx. 2 seconds (to Drum 3)

Collect to Cash Box Approx. 2.9 seconds Approx. 3.2 seconds

RT RQ

Approx. 2 seconds (from Drum 1) Approx. 2 seconds (from Drum 1)

RT RQ

Approx. 2.4 seconds (from Drum 1) Approx. 2.7 seconds (from Drum 1)

2 SPECIFICATIONS

This section provides specifications of the UBA Pro RT/RQ™ Series Banknote Recycler (RT/RQ).

Technical Specifications

Acceptance Rate:

Banknote Types Accepted:

Table 5 RT/RQ Technical Specifications

98% or greater

The following Banknote Types are excluded:

*

• Banknotes with excess or unclear graphics

• Double (dual) Banknotes

• Worn, dirty, wet, stained, torn or excessively-wrinkled Banknotes

• Banknotes having folded corners or edges

• Banknotes having the wrong cut dimensions or a printing displacement

RT/RQ Unit with SH2 Box

• Length: 120-170mm (4.72-6.69in.)

• Width: 62-82mm (2.44-3.22in.)

RT/RQ Unit with Large Box

• Length: 120-165mm (4.72-6.49in.)

• Width (for Recycler): 62-82mm (2.44-3.22in.)

• Width (for Cash Box): 62-85mm (2.44-3.44in.)

Standard Specification

• Interleaved Barcode Read: 2 of 5

• Narrow Bar Width: 0.5mm-0.6mm (0.019-0.023 in.)

Barcode Coupon†:

• Wide Bar to Narrow Bar ratio = 3:1

• Characters: 18 Characters

• Print Position: Middle (Divides a Coupon equally to the left, right, top and bottom

of the Coupon’s center line)

• Print Width: Wider than 10mm (0.39 in.)

Insertion Direction:

‡

Processing Speed

Escrow: 1 Note

Validation Method: Optical

Anti-Pullback Mechanism: Pull-Back (PB) Unit (Anti-pullback System - JCM Patented)

Diagnostic Indicators:

Cash Box

Cash Box Capacity

Recycler:

††

:

:

‡‡

:

Banknote:

Barcode Coupon: Four-way with Upper and Lower Barcode Sensor option

From Banknote insertion to stacking operation completion

From Recycler to completion of dispensing operation

From Recycler to completion of collecting operation (into Cash box):

Acceptor Head Unit (UBA Pro): Status LEDs (Red/Green)

RT/TQ Unit: Full-color LEDs (White/Yellow/Red/Green/Magenta/Cyan/Blue)

SH2 Box (Metal): Secure Type

Large Box (Plastic): Secure Type

SH2 Box (Metal): 400 Notes

Large Box (Plastic): 800 Notes (New Banknotes Only)

2 Denomination Integral Recycler

Drum Type (2 Drums are equipped in a Recylcer Unit)

Refer to the specific Country’s “Software Information Sheet”

**

:

(New Banknotes Only)

**

:

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 18

Section 2 UBA Pro RT/RQ™ Series Banknote Recycler Specifications

8

100

90

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40 45 50 55 60

Hydrothermal Condition Table

Humidity [%RH]

Allowable

and Humidity Range

35ºC/85RH%

50ºC/40RH%

Operating Temperature

15ºC/15RH%

5ºC/40RH%

Temperature [°C]

Table 5 RT/RQ Technical Specifications (Continued)

Recycler Capacity

***

:

RT Unit: Max. 60 Notes (Max. 30 Notes x 2 Drums)

RQ Unit: Max. 120 Notes (Max. 30 Notes x 4 Drums)

USB (USB Specification Rev. 2.0 Compliance) (Full Speed/12Mbps)

Interfaces:

Photo-Coupler Isolation

RS232C

cc-Talk

*. The Banknotes accepted on the second attempt are included. The Acceptance Rate Test was conducted on more than 100 Banknotes. Refer to the “Software Information

Sheet” for each Country’s Acceptance Rate parameters.

†. Refer to the specific Country’s Barcode Ticket Specification for more details.

‡. Excludes the time lag associated with Host Communication (Power Supply: +24V DC, Temperature: 25º C ±5º C).

**. The average per note when 10 notes are inserted.

††.A key and lock are not included (A tang is provided). Refer to “Cash Box Lock Installation” on page 10 for the installation. (2 Key Hole Caps are fitted in place to cover existing

holes when shipped).

‡‡.The number of Polymer Banknotes stacked depends on the Banknote’s condition and denomination.

***.150mm New Banknote Only

Environmental Specifications

Table 6 RT/RQ Environmental Specifications

Operating Temperature: 5ºC to +50ºC (41ºF to 122ºF) *Depends on hydrothermal conditions

Storage Temperature: -20ºC to +60ºC (-4ºF to 140ºF) *Depends on hydrothermal conditions

Relative Operating Humidity: 15% to 85% RH (non-condensing)

Relative Storage Humidity: 30% to 85% RH (non-condensing)

Visible Light Sensitivity: Avoid contact with direct Sunlight

Installation: Indoors Only

Electrical Specifications

*

Supply Voltage†:

Current Consumption:

*. Measured on a new and factory default RQ Unit.

†. Use a Limited Power Source.

Table 7 RT/RQ Electrical Specifications

24V DC (±5%) (6A or higher Recommended)

Standby: 0.4A

Operation: 2.0A

Peak: 3.8A

Structural Specifications

Table 8 RT/RQ Structural Specifications

Weight Empty:

Mounting:

Outside Dimensions: Refer to “Unit Dimensions” on page 39 of this Service Manual Section.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

RT (with SH2 Box): 8kg (17.63lbs)

RQ (with SH2 Box): 11.4kg (25.13lbs)

Horizontal, 0 degrees, ±0 degrees angle

(Stacking Up (SU) installation is available. Refer to “Installation Procedure” on page 9.)

Page 19

9

Installation UBA Pro RT/RQ™ Series Banknote Recycler Section 3

3 INSTALLATION

NOTE: Do Not exert external pressure

on the UBA Pro Unit. Strong pressure

on the Unit may cause the Unit‘s

performance to degrade.

NOTE: Ensure that there is sufficient

space to open, clean and maintain a UBA

Pro Unit. (Refer to “Unit Dimensions” on

page 39).

Caution: Be sure to use specified Screw

Holes when installing the Unit.

Caution: To keep the Unit’ performance

optimal, ensure that the mounting

location is horizontally at 0 degrees on a

flat surface and strong enough to

ensure the Unit weight.

Caution: Be sure to connect the Frame

Housing to the Frame Ground of the

Host Machine.

NOTE: Prepare the following Grounding

Wire, Screw and Washer for grounding:

• Grounding Cable with Conductor Diameter

1.6mm or lager

• M4 W Washer (Large) Pan Head, Iron/

Chromium (III), 12mm or shorter

• Toothed Washer

• Tightening Torque: 120N·cm

NOTE: Refer to “Unit Dimensions” on

page 39) for each Frame Ground

location.

Figure 5 Grounding

Figure 5 Grounding

Edge Side

Round

Side

a

b

c

d

NOTE: Prepare the following Screw:

• M4 Screw (the length of each M4 Screw

should not extend more than 6mm long

from the inside of the Frame)

• Tightening Torque: 120N·cm

Figure 6 Side Installation (Standard and SU

Figure 6 Side Installation (Standard and SU

Installation Types)

a

1

a

2

a

3

a

4

a

5

a

6

a

7

a

8

a

1

a

2

a

3

a

4

a

5

a

6

a

7

a

8

SH2 Box Frame Large Box Frame

This section provides installation and operating

instructions for the UBA Pro RT/RQ™ Series

Banknote Recycler (RT/RQ). The information

within contains the following features:

• Installation Procedure

• Cable Interconnection

• DIP Switch Configuration

• LED Flashing Patterns

Installation Procedure

Holes are provided in each Frame Unit to accommodate mounting the RT/RQ Unit

tion. Select and perform the following steps

required to install the RT/RQ Unit.

during installa-

Grounding

1. Install the Toothed Washer (Figure 5 a), the

Grounding Wire (Figure 5 b) and then the Screw

(Figure 5 c) into the Frame Ground (Figure 5 d)

in order.

2. Tighten the Screw to secure the Wire and Washer.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Side Installation (For Standard and Stacking Up (SU) Installation types)

When a side mounting configuration is preferred, per-

form the following procedure:

1. Secure the left and right side of the RT/RQ Frame

into its intended location using 8 (eight) M4

Screws from each side of the Frame (Figure 6 a

through a

).

8

1

Page 20

10

Section 3 UBA Pro RT/RQ™ Series Banknote Recycler Installation

Caution: This installation is allowed only

when the RT/RQ unit is used as Standard

installation.

NOTE: Prepare the following Screw:

• From Inside: M4 Screw

• From Outside: φ4 Stud (the maximum length

of each Stud should not extend more than

10mm long from the inside of the Bottom

Frame

• Tightening Torque: 120N·cm

Figure 7 Bottom Installation (Standard Installa-

Figure 7 Bottom Installation (Standard Installation

Type)

a

1

a

2

a

3

a

4

b

1

b

2

b

3

b

4

NOTE: Prepare the following Screw:

• M3x16 Screw (provided)

• Tightening Torque: 60N·cm

Figure 8 Bezel Installation

Figure 8 Bezel Installation

b

1

a

b

2

NOTE: Prepare the following Screw:

• M3x12 Screw (provided)

• Tightening Torque: 80N·cm

Figure 9 External Harness Installation

Figure 9 External Harness Installation

d

1

d

2

a

b

c

Figure 10 Key Hole Location

Figure 10 Key Hole Location

Key Holes

Bottom Installation (For Standard Installation Type Only)

When a bottom mounting configuration is preferred,

perform the following procedure:

1. From Inside:

Secure the inside of the RT/RQ Bottom Frame

into its intended location using four (4) M4

Screws (Figure 7 a

From Outside:

Secure the outside of the RT/RQ Bottom Frame

into its intended location using the four (4)

threaded φ4 Studs (Figure 7 b

through a4).

1

1

through b4).

External Harness Installation

1. Pug in the Power Cable (Figure 9 a) and the

Interface Harness (Figure 9 b) into each Connector.

2. Secure the Connector (Figure 9 c) using two (2)

specified Screws (Figure 9 d

& d2).

1

Bezel Installation

1. Secure the Bezel (Figure 8 a) using two (2) specified Screws (Figure 8 b

& b2).

1

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Cash Box Lock Installation

One or two security locks can be installed onto a

Cash Box. When installing a security lock, the following attachment accessories may be required:

• Two Key Spacers

• Plate Lock Keys

• Key Cap Attachment.

Page 21

11

Installation UBA Pro RT/RQ™ Series Banknote Recycler Section 3

Figure 11 Key Hole Dimension & Cylinder

Length

Figure 11 Key Hole Dimension & Cylinder Length

Ø

1

9

.

1

16.1 mm

1

-1

/

8

i

n

.

5

/

8

i

n

.

2

0

.5

m

m

NOTE: When two locks are installed, they

must rotate in the same direction as

illustrated in Figure 12.

Figure 12 Key Lock Rotation Requirement

Figure 12 Key Lock Rotation Requirement

Unlock

Unlock

5/8” or 1-1/8” hole

20.5mm hole

NOTE: When using only one lock, the

remaining blank hole does not provide

access to Cash Box contents. However,

some regulatory authorities may require

installation of a Key Cap.

Figure 13 Key Cap Installation

Figure 13 Key Cap Installation

Use Key Cap

NOTE: There are many lock designs, and

Key Spacer washers may be required for

some lock types. Locks vary greatly in price,

security, keying policies, et cetera. The

customer is responsible for selecting a Lock

with performance that fits the intended

purpose. JCM does not test or endorse

any

specific brand of Lock for its security

characteristics.

NOTE: Front DIP Switch settings may vary

based on Software. Refer to each Country’s

“Software Information Sheet” for making the

proper switch settings.

ON

OFF

NOTE: Refer to the UBA Pro RC Series

Banknote Recycler Integration Guide for

the Recycler options.

Figure 14 SW1 and SW2 Switches

Figure 14 SW1 and SW2 Switches

SW1

SW2

Bottom View

Choose a Lock that fits a standard 5/8”, 1-1/8” or

20.5mm hole dimension format (Figure 11). In

addition, when two locks are to be installed, both

locks must be identical.

Unlock Procedure

Make sure lock(s) are installed and rotates in the

correct direction(s).

DIP Switch Configurations

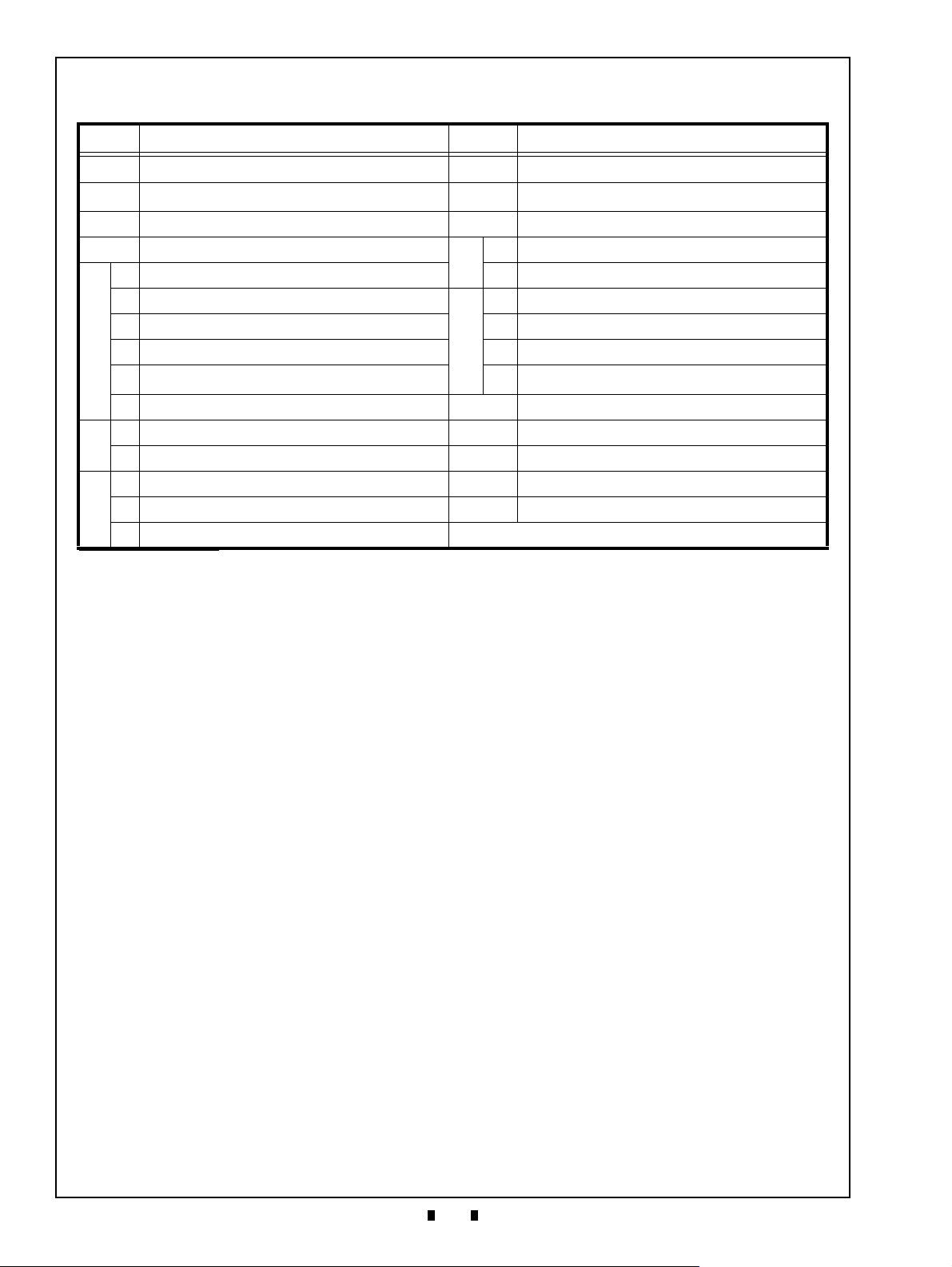

Denomination Acceptance Settings (DIP Switches at the front)

Table 9 lists the default Front DIP Switches configurations for the acceptable denominations.

Table 9 Denomination Acceptance Settings

Switch No. Switch ON/OFF Description

1

2

3

4

5

6

7

8

*. Not Applicable (N/A). Never Switched to ON.

ON VEND 1 INHIBIT

OFF VEND 1 ACCEPT

ON

OFF VEND 2 ACCEPT

ON

OFF VEND 3 ACCEPT

ON

OFF VEND 4 ACCEPT

ON

OFF VEND 5 ACCEPT

ON

OFF VEND 6 ACCEPT

ON

OFF VEND 7 ACCEPT

*

OFF

VEND 2 INHIBIT

VEND 3 INHIBIT

VEND 4 INHIBIT

VEND 5 INHIBIT

VEND 6 INHIBIT

VEND 7 INHIBIT

OFF (Fixed)

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

SW1 and SW2 Configurations

The UBA Pro CPU Circuit Board contains two (2)

DIP Switches that are located adjacent to one

another. The interface and the Recycler option can

be configured by these Switches (Figure 14).

Page 22

12

Section 3 UBA Pro RT/RQ™ Series Banknote Recycler Installation

NOTE: For the USB interface, no need to

configure the SW1 switch.

SW 1

SW 2

Front

Back

Interface and Recycler Settings (Sub Board 2)

The SW1 switch equipped on the Sub Board 2 is to

set an interface RS232C, Photo-Coupler Isolation,

or ccTalk (Table 10).

Table 10 Sub Board 2 Interface Settings

Settings Description

Photo-Coupler Isolation

SW1

-

RS232C

cc-Talk

USB

To use a UBA Pro Unit

with a Recycler Unit(s)

SW2

To use a UBA Pro Unit

without a Recycler(s)

*. Refer to the UBA Pro Series Operation and Maintenance Manual for using the

UBA Pro unit with a Recycler(s).

*

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 23

Installation UBA Pro RT/RQ™ Series Banknote Recycler Section 3

13

NOTE: Refer to “LED Error Codes” on page 36 for a detailed explanation of each error code.

OFF

OFF

OFF

OFF

ON

ONONON

Status LED

OFF

Cyan Flashes

White ON

Blue Flashes

Green ON

Yellow Flashes

White Flashes

Red Flashes

Green Flashes

Green ↔ Red

Flashes

Magenta Flashes

LED Flashing Patterns

The LED Color Pattern indications listed in Table 11 and Table 12 occur during various RT/RQ Unit operating and error conditions.

Table 11 Recycler and Transport LEDs Flashing Patterns

Recycler LED Cause and Solution Transport LED Cause and Solution

Operating Operating

Operating Operating

Error occurred in a Drum of the RT

Transport side.

Error occurred in a Drum of the RQ

Transport side.

Error occurred in the RT Transport side.

Error occurred in the RQ Transport side.

Table 12 Status LED Flashing Patterns

Status LED Cause and Solution Status LED Cause and Solution

Stand-by (Test Mode)/Operating

or

Error occurred in the UBA Pro Unit.

(Refer to the UBA Pro Series Universal

Banknote Acceptor Integration Guide

for the UBA Pro Unit’s details.)

Turning power on

Stand-by (Normal Mode)

Error occurred while a Banknote

was being dispensed.

Return the cash in the RT/RQ Unit.

Error occurred after a Banknote

was determined to dispense.

Return the cash to the customer.

Error occurred while a Banknote

was being accepted.

Return the cash to the customer.

Error occurred while turning power on.

Error occurred when the Unit was in

stand-by.

Error occurred when Banknotes were

being collected.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Error occurred after a Banknote

was determined to accept.

Return the cash in the RT/RQ Unit.

Downloading softer from Acceptor

Head Unit to Recycler.

Page 24

Section 4 UBA Pro RT/RQ™ Series Banknote Recycler Connector Pin Assignments

14

4 CONNECTOR PIN ASSIGNMENTS

This section provides the pin assignments of the UBA Pro RT/RQ™ Series Banknote Recycler (RT/RQ).

The information within contains the following features:

• USB Interface Connector Pin Assignments (UBA Pro Side)

• Photo Coupler Interface Connector Pin Assignments (UBA Pro Side)

• RS232C Interface Connector Pin Assignments (UBA Pro Side)

• cc-Talk Interface Connector Pin Assignments (UBA Pro Side)

• Power Supply Connector Pin Assignments (RT/RQ Side)

• Interface Connector Pin Assignments (RT/RQ Side)

• Bezel Connector Pin Assignments (UBA Pro Side)

USB Interface Connector Pin Assignments (UBA Pro Side)

Table 13 USB Interface Connector Pin Assignments (UBA Pro Side)

Socket (UBA Pro Unit Side): DRA-20PC-FO (JAE)

Contact (UBA Pro Unit Side): D02-22-26P-10000 (JAE)

Socket (Frame Side): DRA-20SC-FO (JAE)

Contact (Frame Side): D02-22-26S-10000 (JAE)

Contact (Frame Side) Pin No.3, No.13: D02-22-22S-10000 (JAE)

Recommended Wires: Slit Wire UL1061 AWG #26

Pin No. Signal Name

1 - - Reserved (For the UBA Pro Side)

2 - - Reserved (For the UBA Pro Side)

3 M.RES IN Acceptor Reset Signal Line

4 NC - No Connection

5 - - Reserved (For the UBA Pro Side)

6 NC - No Connection

7 NC - No Connection

8 Vbus IN USB Communication Vbus Signal Line (+5V DC)

9 -DATA IN/OUT USB Communication Input/Output Signal Line

10 +DATA IN/OUT USB Communication Input/Output Signal Line

11 - - Reserved (For the UBA Pro Side)

12 GND (USB) - USB Communication Ground (0V DC)

13 NC - No Connection

14 LED POWER - LED Drive Line (Anode)

15 - - Reserved (For the UBA Pro Side)

16 NC - No Connection

17 - - Reserved (For the UBA Pro Side)

18 LED - - LED Drive Line (Cathode)

19 NC - No Connection

20 - - Reserved (For the UBA Pro Side)

*. I/O (input/output) is the terminal as viewed from the RT/RQ Unit’s side.

I/O

*

Function

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 25

Connector Pin Assignments UBA Pro RT/RQ™ Series Banknote Recycler Section 4

15

NOTE: The Interface setup is required. Refer to “Interface and Recycler Settings (Sub Board 2)” on

page 12 for the settings.

Photo Coupler Interface Connector Pin Assignments (UBA Pro Side)

Table 14 Photo Coupler Interface Connector Pin Assignments (UBA Pro Side)

Socket (UBA Pro Unit Side): DRA-20PC-FO (JAE)

Contact (UBA Pro Unit Side): D02-22-26P-10000 (JAE)

Socket (Frame Side): DRA-20SC-FO (JAE)

Contact (Frame Side): D02-22-26S-10000 (JAE)

Contact (Frame Side) Pin No.3, No.13: D02-22-22S-10000 (JAE)

Recommended Wires: Slit Wire UL1061 AWG #26

Pin No. Signal Name

I/O

*

Function

1 - - Reserved (For the UBA Pro Side)

2 - - Reserved (For the UBA Pro Side)

3 M.RES IN Acceptor Hard Reset Signal Line

4 TXD OUT Output Signal Line from Acceptor to Host

5 - - Reserved (For the UBA Pro Side)

6 RXD IN Input Signal Line from Host to Acceptor

7 GND (I/F) - Interface Power Supply (Photo Coupler 0V DC)

8 NC - No Connection

9 NC - No Connection

10 NC - No Connection

11 - - Reserved (For the UBA Pro Side)

12 NC - No Connection

13 NC - No Connection

14 LED POWER - LED Indicator Power Supply Line (Anode)

15 - - Reserved (For the UBA Pro Side)

16 NC - No Connection

17 - - Reserved (For the UBA Pro Side)

18 LED - LED Indicator Control Line (Cathode)

19 NC - No Connection

20 - - Reserved (For the UBA Pro Side)

*. I/O (input/output) is the terminal as viewed from the RT/RQ Unit’s side.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 26

Section 4 UBA Pro RT/RQ™ Series Banknote Recycler Connector Pin Assignments

16

NOTE: The Interface setup is required. Refer to “Interface and Recycler Settings (Sub Board 2)” on

page 12 for the settings.

RS232C Interface Connector Pin Assignments (UBA Pro Side)

Table 15 RS232C Connector Pin Assignments (UBA Pro Side)

Socket (UBA Pro Unit Side): DRA-20PC-FO (JAE)

Contact (UBA Pro Unit Side): D02-22-26P-10000 (JAE)

Socket (Frame Side): DRA-20SC-FO (JAE)

Contact (Frame Side): D02-22-26S-10000 (JAE)

Contact (Frame Side) Pin No.3, No.13: D02-22-22S-10000 (JAE)

Recommended Wires: Slit Wire UL1061 AWG #26

Pin No. Signal Name

I/O

*

Function

1 - - Reserved (For the UBA Pro Side)

2 - - Reserved (For the UBA Pro Side)

3 M.RES IN Acceptor Hard Reset Signal Line

4 TXD OUT Output Signal Line from Acceptor to Host

5 - - Reserved (For the UBA Pro Side)

6 RXD IN Input Signal Line from Host to Acceptor

7 NC - No Connection

8 NC - No Connection

9 NC - No Connection

10 NC - No Connection

11 - - Reserved (For the UBA Pro Side)

12 NC - No Connection

13 GND (I/F) - Interface Power Supply (RS232C 0V DC)

14 LED POWER - LED Indicator Power Supply Line (Anode)

15 - - Reserved (For the UBA Pro Side)

16 NC - No Connection

17 - - Reserved (For the UBA Pro Side)

18 LED - LED Indicator Control Line (Cathode)

19 NC - No Connection

20 - - Reserved (For the UBA Pro Side)

*. I/O (input/output) is the terminal as viewed from the RT/RQ Unit’s side.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 27

Connector Pin Assignments UBA Pro RT/RQ™ Series Banknote Recycler Section 4

17

NOTE: The Interface setup is required. Refer to “Interface and Recycler Settings (Sub Board 2)” on

page 12 for the settings.

cc-Talk Interface Connector Pin Assignments (UBA Pro Side)

Table 16 cc-Talk Interface Connector Pin Assignments (UBA Pro Side)

Socket (UBA Pro Unit Side): DRA-20PC-FO (JAE)

Contact (UBA Pro Unit Side): D02-22-26P-10000 (JAE)

Socket (Frame Side): DRA-20SC-FO (JAE)

Contact (Frame Side): D02-22-26S-10000 (JAE)

Contact (Frame Side) Pin No.3, No.13: D02-22-22S-10000 (JAE)

Recommended Wires: Slit Wire UL1061 AWG #26

Pin No. Signal Name

I/O

*

Function

1 - - Reserved (For the UBA Pro Side)

2 - - Reserved (For the UBA Pro Side)

3 M.RES IN Acceptor Hard Reset Signal Line

4 NC - No Connection

5 - - Reserved (For the UBA Pro Side)

6 NC - No Connection

7 NC - No Connection

8 NC - No Connection

9 NC - No Connection

10 NC - No Connection

11 - - Reserved (For the UBA Pro Side)

12 NC - No Connection

13 GND (I/F) - Interface Power Supply (cc-Talk 0V DC)

14 LED POWER - LED Indicator Power Supply Line (Anode)

15 - - Reserved (For the UBA Pro Side)

16 TXD OUT Output Signal Line from Acceptor to Host

17 - - Reserved (For the UBA Pro Side)

18 LED - LED Indicator Control Line (Cathode)

19 NC - No Connection

20 - - Reserved (For the UBA Pro Side)

*. I/O (input/output) is the terminal as viewed from the RT/RQ Unit’s side.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 28

Section 4 UBA Pro RT/RQ™ Series Banknote Recycler Connector Pin Assignments

18

413

2

143257

86

9

10

Power Supply Connector Pin Assignments (RT/RQ Side)

Table 17 Power Supply Connector Pin Assignments (RT/RQ Side)

Header Type: 43045-0424 (MOLEX)

Contact Type: 43030-0001 (MOLEX)

Housing: 43025-0400 (MOLEX)

Recommended Wires: Slit Wire UL1007 AWG #20-24

Pin No. Signal Name I/O Function

1 VHOST24V - +24V DC Power Supply

2 NC - No Connection

3 PGND - 0V DC Power Supply

4 NC - No Connection

Interface Connector Pin Assignments (RT/RQ Side)

Table 18 Interface Connector Pin Assignments (RT/RQ Side)

Header Type: B10B-PADSS-1 (JST)

Contact Type: SPH-002T-P0.5L (JST)

Housing: PADP-10V-1-S (JST)

Recommended Wires: Slit Wire UL1061 AWG #22-28

Pin No. Signal Name I/O Function

1 - - Reserved (The pin is used on the UBA Pro Side)

2 - - Reserved (The pin is used on the UBA Pro Side)

3 - - Reserved (The pin is used on the UBA Pro Side)

4 - - Reserved (The pin is used on the UBA Pro Side)

5 - - Reserved (The pin is used on the UBA Pro Side)

6 - - Reserved (The pin is used on the UBA Pro Side)

7 - - Reserved (The pin is used on the UBA Pro Side)

8 - - Reserved (The pin is used on the UBA Pro Side

9 - - Reserved (The pin is used on the UBA Pro Side)

10 NC - No Connection

Bezel Connector Pin Assignments (UBA Pro Side)

Table 19 Bezel Connector Pin Assignments (UBA Pro Side)

Header Type: RF-H08(07)2SD-1110 (JST)

Contact Type: RF-SC2210 (JST)

Housing: RF-08 (JST)

Recommended Wires: Slit Wire UL1007 AWG #24-26

Pin No. Signal Name

1 NC - No Connection

2 NC - No Connection

3 NC - No Connection

4 NC - No Connection

5 +13V (Power) - +13V DC Power (from UBA Pro)

6 GND (Power) - 0V DC Power (from UBA Pro)

7 LED Power - LED Drive Line (Anode)

8 LED- - LED Drive Line (Cathode)

*. I/O (input/output) is the terminal as viewed from the RT/RQ Unit’s side.

I/O

*

Function

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 29

19

Preventive Maintenance UBA Pro RT/RQ™ Series Banknote Recycler Section 5

5 PREVENTIVE MAINTENANCE

NOTE: Do Not manually refill the

Banknotes directly into the Recyclers.

Figure 15 Refilling Banknotes

Figure 15 Refilling Banknotes

NOTE: Enable the Collect Button function

by sending a Command from the Host

Machine (disabled by default).

NOTE: The Banknotes in each Drum

will be transported note-by-note into

the Cash Box.

Figure 16 Collecting Banknotes 1

Figure 16 Collecting Banknotes 1

a

Figure 17 Collecting Banknotes 2

Figure 17 Collecting Banknotes 2

a

b

c

NOTE: The Banknotes in each Drum

will be transported note-by-note into

the Cash Box.

NOTE: Before setting the Recycler’s

denomination values, check the Banknote

sizes against the Recycler’s size limitation

settings (refer to “Technical Specifications”

on page 7). This operation should be

performed once appropriate Operator

training has been completed.

This section provides the preventive maintenance

for the UBA Pro RT/RQ™ Series Banknote Recycler (RT/RQ). It includes the following information:

• Refilling Banknotes

• Collecting Banknotes

• Clearing a Banknote Jam

• Cleaning Procedures

Refilling Banknotes

Banknotes can be refilled into the Recycler by

using the UBA Pro Unit.

To refill Banknotes into the Recycler, perform the

following procedure:

1. Insert Banknotes note-by-note in a single fashion

into the Insertion Slot or Bezel (Figure 15).

2. Remove the Cash Box (Figure 17 a).

3. Use the appropriate User-supplied Key(s) to

unlock the Cash Box (Figure 17 b).

4. Open the Cash Box Door and remove the collected Banknotes (Figure 17 c).

Collecting Banknotes

To collect Banknotes from the Recycler, perform

one (1) of the following two (2) procedures.

Collecting Banknotes into the Cash Box by the Button

1. Press the Collect Button on the RT/RQ Unit (Figure 16 a).

Collecting Banknotes into the Cash Box by Command

1. Send a Command to the RT/RQ Unit from the

Host Machine in order to collect Banknotes.

2. Remove the Cash Box (Figure 17 a).

3. Use the appropriate User-supplied Key(s) to

unlock the Cash Box (Figure 17 b).

4. Open the Cash Box Door and remove the collected Banknotes (Figure 17 c).

Dispense Settings

Dispensing Banknotes from each Drum of the

Recycler to the Insertion Slot or the Bezel is possible. Banknote denomination dispensing is predetermined by settings made for each Drum.

To change the dispensable Banknote denomination

values, replace the Recycler with another Unit containing the different denomination settings.

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Page 30

20

Section 5 UBA Pro RT/RQ™ Series Banknote Recycler Preventive Maintenance

NOTE: Do Not re-insert a removed

Banknote caused by Banknote Jam or

error.

NOTE: Refer to the UBA Pro Series

Universal Banknote Acceptor

Integration Guide for the UBA Pro

Unit’s details.

Figure 18 UBA Pro Unit Banknote Jam Clear

Figure 18 UBA Pro Unit Banknote Jam Clear

a

b

Figure 19 RT Transport Banknote Jam Clear 1

Figure 19 RT Transport Banknote Jam Clear 1

a

Figure 20 RT Transport Banknote Jam Clear 2

Figure 20 RT Transport Banknote Jam Clear 2

b

c

a

Figure 21 RT Transport Banknote Jam Clear 3

Figure 21 RT Transport Banknote Jam Clear 3

a

b

c

Figure 22 RT Transport Banknote Jam Clear 4

Figure 22 RT Transport Banknote Jam Clear 4

a

b

Clearing a Banknote Jam

Find where a Banknote Jam occurred

Check each LED to determine where and/or in

which Unit a Banknote is jammed (refer to “LED

Error Codes” on page 36).

Jammed in UBA Pro Unit

To remove jammed Banknotes from the UBA Pro

Unit, proceed as follows to clear it.

1. Lift up on the Upper Guide Access Lever to open

the UBA Pro’s Cover (Figure 18 a).

2. Remove any jammed Banknote found there. (Figure 18 b).

3. Remove any jammed Banknote found there (Figure 20 c).

4. If the Banknote jam location is not visible, press

down on the Front Transport Unit’s Release

Lever (Figure 21 a) to pull up the Front Transport

Unit (Figure 21 b).

5. Remove any jammed Banknote found there (Figure 21 c).

Jammed in RT Transport Banknote

To remove jammed Banknotes from the RT Transport, proceed as follows to clear it.

1. Unlock the Recycler Release Lock (Figure 19 a).

6. If the Banknote jam location is not visible, pull

and release the Transport Unit’s Release Lever

(Figure 22 a) to lift the Transport Unit (Figure 22

b).

2. Press down on the Release Lever (Figure 20 a) of

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

the Recycler installed in the RT Transport to

remove the Recycler (Figure 20 b) out of the RT

Transport.

7. Remove the Transport Unit out of the RT Transport (Figure 23 a).

Page 31

21

Preventive Maintenance UBA Pro RT/RQ™ Series Banknote Recycler Section 5

Figure 23 RT Transport Banknote Jam Clear 5

Figure 23 RT Transport Banknote Jam Clear 5

a

b

Figure 24 RQ Transport Banknote Jam Clear 1

Figure 24 RQ Transport Banknote Jam Clear 1

a

Figure 25 RQ Transport Banknote Jam Clear 2

Figure 25 RQ Transport Banknote Jam Clear 2

b

c

a

Figure 26 RQ Transport Banknote Jam Clear 3

Figure 26 RQ Transport Banknote Jam Clear 3

b

c

a

Figure 27 RQ Transport Banknote Jam Clear 4

Figure 27 RQ Transport Banknote Jam Clear 4

b

a

Figure 28 RQ Transport Banknote Jam Clear 5

Figure 28 RQ Transport Banknote Jam Clear 5

a

b

8. Remove any jammed Banknote found there (Figure 23 b).

Jammed in RQ Transport

To remove jammed Banknotes from the RQ Transport, proceed as follows to clear it.

1. Unlock the Recycler Release Lock (Figure 24 a).

5. Remove any jammed Banknote found there (Figure 26 c).

6. If the Banknote jam location is not visible, press

down on the Transport Unit’s Lever (Figure 27 a)

to pull down the Transport Unit (Figure 27 b).

2. Press up on the Release Lever (Figure 25 a) of

the Recycler installed in the RQ Transport to

remove the Recycler (Figure 25 b) out of the RQ

Transport.

3. Remove any jammed Banknote found there (Figure 25 c).

4. If the Banknote jam location is not visible, press

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

up on the Front Transport Unit’s Lever (Figure 26

a) to pull down the Front Transport Unit (Figure

26 b).

7. Remove the Transport Unit (Figure 28 a).

8. Remove any jammed Banknote found there (Figure 28 b).

Page 32

22

Section 5 UBA Pro RT/RQ™ Series Banknote Recycler Preventive Maintenance

NOTE: Be sure to send a command and

update the number of Banknotes in the

Recycler(s) after removing a jammed

Banknote in order to maintain the

Banknote count match.

Figure 29 Recycler Drum Banknote Jam Clear 1

Figure 29 Recycler Drum Banknote

Jam Clear 1

a

Figure 30 Recycler Drum Banknote Jam Clear 2

Figure 30 Recycler Drum Banknote

Jam Clear 2

a

RT Transport

RQ Transport

b

b

b

NOTE: Do Not manually rotate any Drum

when there is no Banknote to avoid the

risk of damage to the Recycler.

NOTE: Do Not put a tool directly inside

of the Recycler to remove a jammed

Banknote. A winded film may be pulled

out resulting in damage to the Recycler.

Figure 31 Recycler Drum Banknote Jam Clear 3

Figure 31 Recycler Drum Banknote

Jam Clear 3

b

6mm Hex

a

Nut Driver

Figure 32 Cash Box Banknote Jam Clear

Figure 32 Cash Box Banknote Jam Clear

a

b

NOTE: Performing specified routine

cleaning at least once a month is required to

maintain optimal performance.

NOTE: Refer to the UBA Pro Series

Universal Banknote Acceptor

Integration Guide for the UBA Pro

Unit’s details.

Jammed in Recycler Drum

To remove jammed Banknotes from the Recycler

Drum, proceed as follows to clear it.

1. Unlock the Recycler Release Lock (Figure 29 a).

Jammed in Cash Box

To remove jammed Banknotes from the Cash Box,

proceed as follows to clear it.

1. Pull the Cash Box (Figure 32 a) out of the Frame.

2. Remove any jammed Banknote found there (Figure 32 b).

2. Release the Release Lever (Figure 30 a) of the

desired Recycler to remove the desired Recycler

(Figure 30 b) out of the Frame.

3. Flip the Recycler.

4. Use a 6mm Hex Nut Driver to rotate the desired

Drum Shaft (Figure 31 a) in the dispense direction indicated by the arrow.

5. Remove the jammed Banknote (Figure 31 b).

P/N 960-000209R_Rev. A © 2019, JAPAN CASH MACHINE CO., LTD.

Cleaning Procedure

To clean the RT/RQ Unit Banknote path, gently rub

the Sensors and Rollers using a dry, soft, lint-free,

Micro-fiber Cloth ONLY.

Sensor Cleaning Procedure

Perform the following steps to clean the UBA Pro

and RT/RQ Unit’s Sensors:

1. Remove electrical power from the RT/RQ Unit.

2. Open the UBA Pro Unit’s Cover.

3. Clean the Sensor Lens and Rollers in the

Banknote Path.

4. Pull the Recycler out of the RT/RQ Frame.

5. Clean the Sensor Lenses, Roller and Belts located

in the RT/RQ Frame, Recycler and/or Cash Box.

Page 33

Preventive Maintenance UBA Pro RT/RQ™ Series Banknote Recycler Section 5

23

Caution: DO NOT use alcohol, solvents,

abrasive cleaning agents, or citrusbased cleaners that can damage the

plastic surface of the device when

cleaning it. The lenses can become

clouded by chemical evaporation

residue that may cause acceptance

errors.

Caution: Be sure to use non-flammable

compressed air only.

Caution: DO NOT let liquids or fluids