Page 1

Support: http://www.jcmglobal.com/en/contact/default.aspx Web-Site: http://www.jcmglobal.com

Taiko™ Series

Banknote Acceptor

(PUB-7/11)

Operation and Maintenance

Manual

(Revision 4)

P/N 960-100175R_Rev. 4 {EDP #200824}

Issue #4045-SME-01-04

© 2013, Japan CashMachine Co., Limited

Page 2

Taiko™ Series Banknote Acceptor

or

or or

or

E142330, Subscriber 857947001, Vol. 2

Issue #4045-SME-01-04

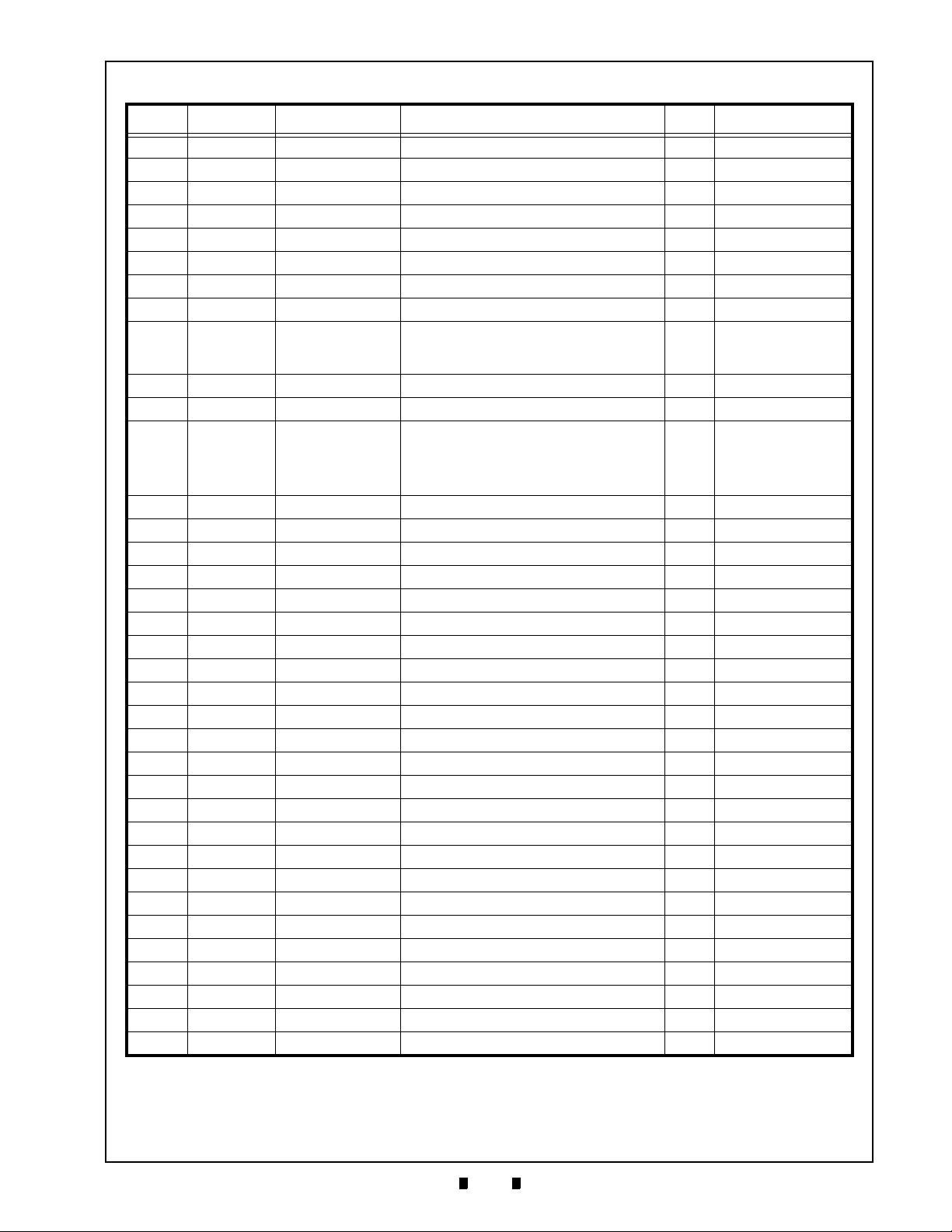

REVISION HISTORY

Rev №. Date Reason for Update Comment

A 7/12/10

12/14/11

28/17/11

3 4/09/12

4 3/25/13

Initial Version

Barcode Coupon Specification Added

Important corrections made to Tables in Section 2.

Added Waffletechnology Cleaning Card availability & Useage

information in Section 2, corrected Part Number Information in

Section 7 and added 2 Tables to Appendix A.

Added EBA Type Bezel in Section 7.

International Compliance

• RoHS Directives

• UL & c-UL Marks

• CE Mark .

This product document (hereinafter referred to as “Manual”) is fully covered by legal Copyrights owned by the Japan

Cash Machine, Co., Ltd., (hereinafter referred to as “JCM”) under Japanese laws and foreign countries. This Manual

contains many copyrighted, patented, or properly registered equipment items manufactured by JCM, that are prohibited

and illegal to duplicate, replicate, or copy in whole, or in part, without the express

authorization by JCM with the following exceptions:

1. When an authorized JCM agency or distributor duplicates the Manual for sales promotion and/or service

maintenance of the product, or technical service personnel education as required; and

2. When an end user duplicates the Manual to maintain operation of the product or operate the product in general.

JCM retains all rights to amend, alter, change or delete any portion of this Manual in whole, or in part, or add items

thereto without notice regarding the product or its related products.

JCM is a registered trademark of Japan CashMachine Co, Limited. All other product names mentioned herein may be

registered trademarks or trademarks of their respective companies. Furthermore,

in each case throughout this publication.

Copyright © 2013 By Japan CashMachine Co, Limited

™, ® and © are not always mentioned

Page 3

i

Taiko™ Series

Banknote Acceptor

Table of Contents

TOC

Page

1 GENERAL INFORMATION.................................................................................. 1-1

Description .................................................................................................................. 1-1

Taiko PUB-7/11 Unit .................................................................................................... 1-1

Model Descriptions .................................................................................................... 1-2

Precautions ................................................................................................................. 1-2

User Cautions ...........................................................................................................................1-2

Installation Cautions ..............................................................................................................1-2

Mounting, Dismounting & Transportation ...............................................................................1-2

Preventive Maintenance ........................................................................................................1-2

Banknote Fitness Requirements ............................................................................................1-3

Primary Features ........................................................................................................ 1-3

Product Label .............................................................................................................. 1-4

Component Names ..................................................................................................... 1-5

Specifications ............................................................................................................. 1-6

Technical Specifications ...........................................................................................................1-6

Environmental Specifications ...................................................................................................1-6

Electrical Specifications ............................................................................................................1-7

Structural Specifications ...........................................................................................................1-7

System Configuration ................................................................................................ 1-7

Unit Dimensions ......................................................................................................... 1-8

Taiko PUB-7 Standard Bezel Unit Outside Dimensions ............................................................1-8

Taiko PUB-7/11 Unit Clearance Dimensions ..........................................................................1-8

Taiko PUB-11 Standard US Bezel Unit Outside Dimensions ....................................................1-9

International Compliance ......................................................................................... 1-10

Technical Contact Information .................................................................................1-11

Americas & Oceania ...............................................................................................................1-11

JCM American ..................................................................................................................... 1-11

Europe, Africa, Russia & Middle East .................................................................................... 1-11

JCM Europe GmbH ............................................................................................................. 1-11

UK & Ireland ...........................................................................................................................1-11

JCM Europe (UK Office) ......................................................................................................1-11

Asia ........................................................................................................................................1-11

JCM Gold (HK) Ltd. .............................................................................................................1-11

Japan Cash Machine Co, Limited (HQ) ............................................................................... 1-11

2 INSTALLATION ................................................................................................... 2-1

Installation and Removal ........................................................................................... 2-1

Installing the PUB-7/11 Taiko Bezel ..........................................................................................2-1

Power Harness Wiring Procedure ............................................................................................ 2-2

Clearing a Banknote Jam ........................................................................................... 2-2

Clearing an Upper Area Banknote Jam ....................................................................................2-2

Clearing a Lower Area Banknote Jam ...................................................................................... 2-3

DIP Switch Configurations ........................................................................................ 2-3

Denomination Setting Mode ..................................................................................................... 2-4

Accept Setting Mode ..............................................................................................................2-4

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 4

ii

Taiko™ Series Banknote Acceptor

Table of Contents

Page

Inhibit Setting Mode .............................................................................................................. 2-4

LED Pattern Setting Mode .......................................................................................................2-4

Defining Pattern 1 ................................................................................................................. 2-4

Defining Pattern 2 ................................................................................................................. 2-4

Encryption Code Initialization Setting Mode ............................................................................ 2-5

Error Codes & Conditions ......................................................................................... 2-5

Interface Connector Pin

Assignments ............................................................................................................... 2-5

Cleaning Procedures ................................................................................................. 2-6

Sensor and Roller Cleaning Procedure ................................................................................... 2-6

Available Cleaning Card ............................................................................................ 2-6

Card Features .......................................................................................................................... 2-6

Directions For Use ................................................................................................................... 2-6

Taiko Sensor and Roller Locations ........................................................................... 2-7

Operational Check ...................................................................................................... 2-7

Standard Interface Circuit Schematics ..................................................................... 2-9

Standard Interface Circuit Schematics (Continued 1) ............................................................ 2-10

Standard Interface Circuit Schematics (Continued 2) .............................................................2-11

Standard Interface Circuit Schematics (Continued 3) ............................................................ 2-12

Standard Interface Circuit Schematics (Continued 4) ............................................................ 2-13

Operational Flowcharts ............................................................................................ 2-15

Operational Flowcharts (Continued) ...................................................................................... 2-16

3 COMMUNICATIONS ............................................................................................ 3-1

Americas & Oceania ................................................................................................................ 3-1

JCM American ....................................................................................................................... 3-1

Europe, Africa, Russia & Middle East ...................................................................................... 3-1

JCM Europe GmbH ............................................................................................................... 3-1

UK & Ireland ............................................................................................................................ 3-1

JCM Europe (UK Office) ........................................................................................................ 3-1

Asia .......................................................................................................................................... 3-1

JCM Gold (HK) Ltd. ............................................................................................................... 3-1

Japan Cash Machine Co, Limited (HQ) ................................................................................... 3-1

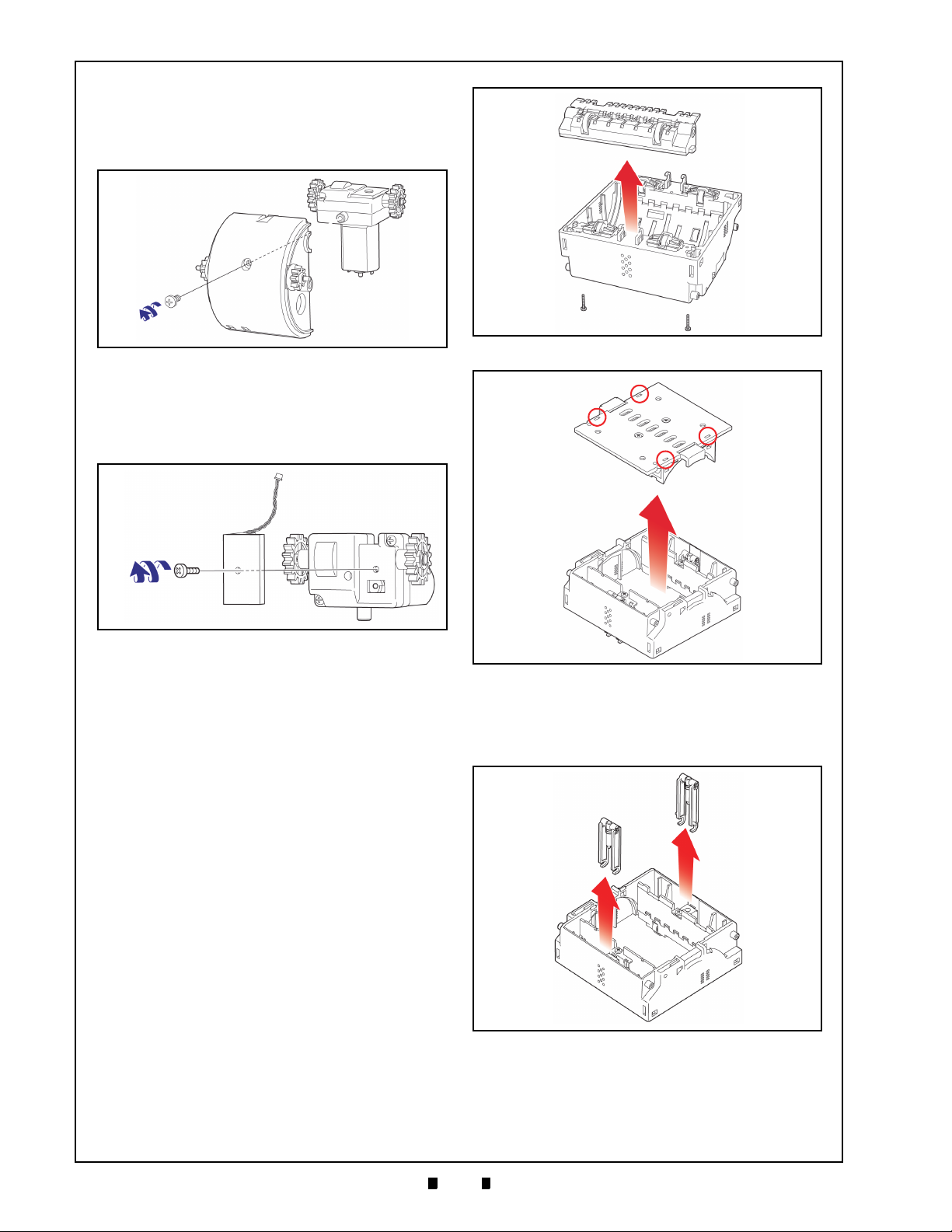

4 DISASSEMBLY/REASSEMBLY ..........................................................................4-1

Tool Requirements ..................................................................................................... 4-1

Primary Unit Disassembly ......................................................................................... 4-1

Bezel Guide Removal .............................................................................................................. 4-1

CPU Circuit Board Removal .................................................................................................... 4-1

MAG Board Removal (PUB-11 Only) ....................................................................................... 4-2

Sensor Circuit Board Removal ................................................................................................ 4-2

Transport Drum Disassembly .................................................................................................. 4-2

Encoder Board and Drive Motor Removal ............................................................................... 4-3

Entrance and Exit Solenoid Removal ...................................................................................... 4-4

5 WIRING DIAGRAMS ............................................................................................ 5-1

PUB-7 System Wiring Diagrams ............................................................................... 5-1

PUB-7 System Wiring Diagrams (Continued) .......................................................................... 5-2

PUB-11 System Wiring Diagrams .............................................................................. 5-3

PUB-11 System Wiring Diagrams (Continued) ........................................................................ 5-4

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 5

iii

Taiko™ Series Banknote Acceptor

Table of Contents

Page

6 CALIBRATION AND TESTING............................................................................ 6-1

Workbench Tool Requirements ................................................................................. 6-1

Software Download Preparation ...............................................................................................6-2

Software Downloading Procedure ............................................................................ 6-2

PC Program Installation ...........................................................................................................6-2

Palm Pilot Program Installation ................................................................................................6-2

Writing a New Serial Number .................................................................................... 6-3

Upgrading/Replacing Software .................................................................................................6-3

Programming Requirements ..................................................................................................6-3

Re-Programming Connection Procedure .................................................................................6-5

Serial Number Writer Application Use ......................................................................................6-5

Cloning Units .............................................................................................................. 6-5

Required Items .........................................................................................................................6-5

Cloning Procedures ...............................................................................................................6-5

Calibration Procedures .............................................................................................. 6-7

Calibration Description .............................................................................................................6-7

Calibration Tool Requirements .................................................................................................6-7

When to Calibrate .....................................................................................................................6-7

Initial Settings ...........................................................................................................................6-7

Performance Test Diagnostics .................................................................................. 6-7

DIP Switch Tests ....................................................................................................................6-8

No.1 Transport Motor Forward Rotation Test ...................................................................................... 6-8

No.2 Transport Motor Reverse Rotation Test...................................................................................... 6-8

No.3 Aging Test Procedure ................................................................................................................. 6-8

No.4 Solenoid Test Procedure............................................................................................................. 6-9

No.5 Acceptance Test Procedure........................................................................................................ 6-9

No.6 Entrance Flapper Test Procedure ............................................................................................... 6-9

No.7 Exit Flapper Test Procedure ....................................................................................................... 6-9

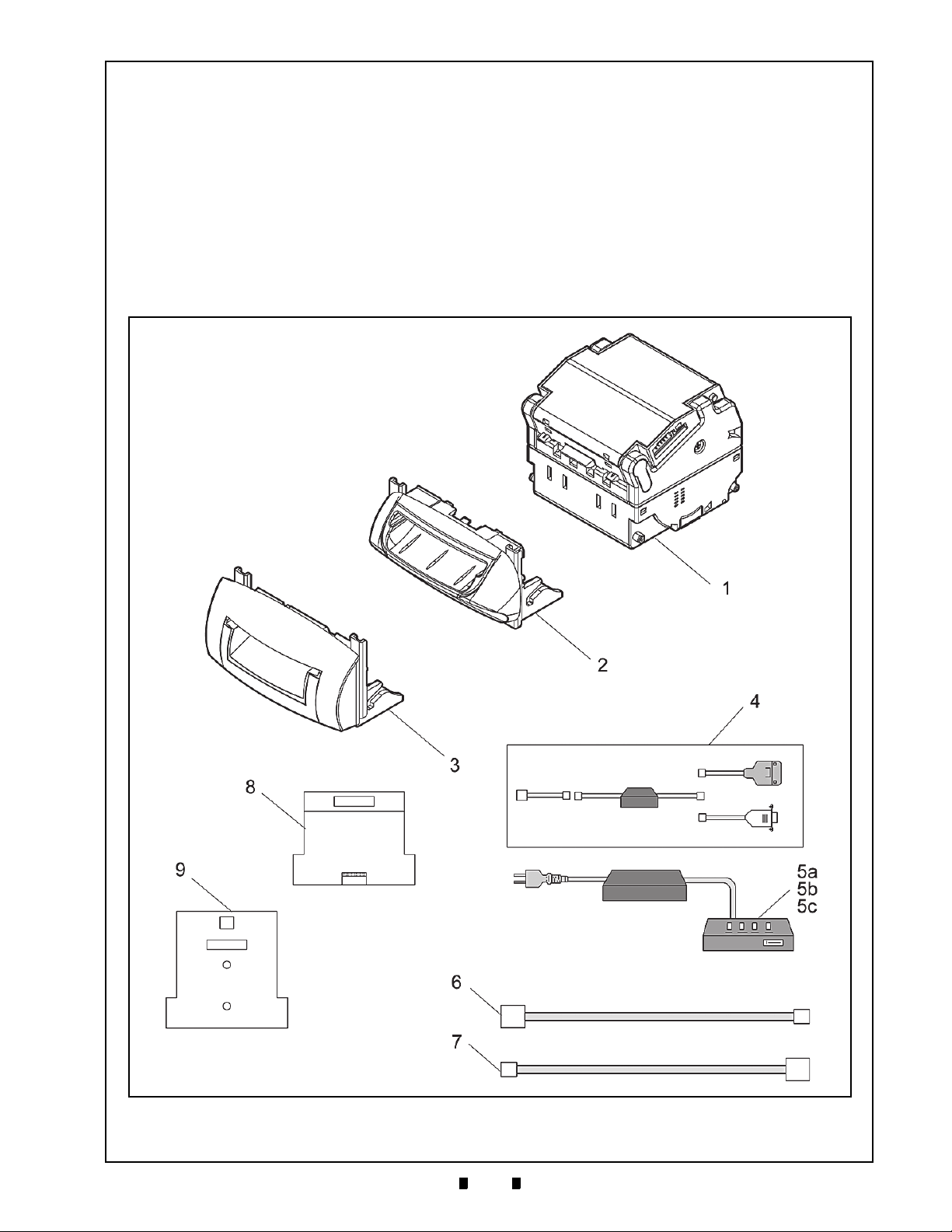

7 EXPLODED VIEWS AND PARTS LISTS ............................................................ 7-1

Entire Taiko Unit Exploded View ............................................................................... 7-1

Primary Taiko PUB-7/11 Unit Parts List ....................................................................................7-2

Complete Taiko Unit Exploded View ........................................................................................ 7-3

Complete Taiko PUB-7/11 Units Parts List ...............................................................................7-4

Taiko Bezel Unit Exploded View ................................................................................ 7-8

Taiko PUB-7/11 Bezel Units Parts List ......................................................................................7-9

Taiko EBA Type Bezel Unit Exploded View ............................................................ 7-10

Taiko EBA Type Bezel Units Parts List ...................................................................................7-11

8 INDEX................................................................................................................... 8-1

A TROUBLESHOOTING .........................................................................................A-1

Introduction .................................................................................................................A-1

Troubleshooting Overview ........................................................................................A-1

Fault Table Listings ....................................................................................................A-1

Error Codes and Conditions ......................................................................................A-4

B GLOSSARY..........................................................................................................B-1

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 6

THIS PAGE INTENTIONALLY LEFT BLANK

Taiko™ Series Banknote Acceptor

iv

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 7

v

Taiko™ Series

Banknote Acceptor

List of Figures

LOF

Figure 1-1 Taiko PUB-7/11 Unit .............................................................................. 1-1

Figure 1-2 Precautionary Symbols .......................................................................... 1-2

Figure 1-3 Unacceptable Banknotes ....................................................................... 1-3

Figure 1-4 Installation Simplicity.............................................................................. 1-3

Figure 1-5 Scan Frequency Capability .................................................................... 1-3

Figure 1-6 Taiko Anti-Pullback Feature ................................................................... 1-4

Figure 1-7 Palm Pilot Programmable ...................................................................... 1-4

Figure 1-8 LED Pattern Selectable.......................................................................... 1-4

Figure 1-9 PUB-11 Top Panel Instruction Label...................................................... 1-4

Figure 1-10 PUB-7 Top Panel Instruction Label........................................................ 1-4

Figure 1-11 Taiko PUB-7/11 Component Names...................................................... 1-5

Figure 1-12 Taiko PUB-7/11 System Configuration .................................................. 1-7

Figure 1-13 Taiko PUB-7 Complete Unit Outside Dimensions.................................. 1-8

Figure 1-14 Taiko PUB-7/11 Banknote Acceptor’s Clearance Dimensions .............. 1-8

Figure 1-15 Taiko PUB-11 (US Dollar) Complete Unit Outside Dimensions............. 1-9

Figure 2-1 Taiko Bezel Cut-Out Dimensions........................................................... 2-1

Figure 2-2 Opening Taiko’s Upper Lid .................................................................... 2-1

Figure 2-3 Removing the Taiko Bezel ..................................................................... 2-1

Figure 2-4 Installing the Taiko Bezel ....................................................................... 2-1

Figure 2-5 Mounting the Taiko Bezel ...................................................................... 2-2

Figure 2-6 Installing the Taiko Bezel ....................................................................... 2-2

Figure 2-7 Closing the Taiko Upper Lid................................................................... 2-2

Figure 2-8 Attaching a Taiko Power Connector ...................................................... 2-2

Figure 2-9 Upper Area Banknote Jam Removal ..................................................... 2-3

Figure 2-10 Lower Area Banknote Jam Removal ..................................................... 2-3

Figure 2-11 Left Side DIP Switch Block Location...................................................... 2-3

Figure 2-12 “Accept’ Mode DIP Switch Settings ....................................................... 2-4

Figure 2-13 ‘Inhibit’ Mode DIP Switch Settings ......................................................... 2-4

Figure 2-14 Define Pattern 1 DIP Switch Settings .................................................... 2-4

Figure 2-15 Define Pattern 2 DIP Switch Settings .................................................... 2-4

Figure 2-16 Encryption Mode DIP Switch Settings ................................................... 2-5

Figure 2-17 ID-003/MDB/Pulse Interface Connector................................................. 2-5

Figure 2-18 ID-001 Interface Connector.................................................................... 2-5

Figure 2-19 Sensor Cleaning .................................................................................... 2-6

Figure 2-20 JCM Waffletechnology Cleaning Card................................................... 2-6

Figure 2-21 Taiko Sensor Cleaning Locations .......................................................... 2-7

Figure 2-22 Serial ID-003/MDB Communications Interface Schematic Diagram...... 2-9

Figure 2-23 ccTalk Communications Interface Schematic Diagram ....................... 2-10

Figure 2-24 Pulse Communications Interface Schematic Diagram......................... 2-11

Figure 2-25 Parallel ID-001 Communications Interface Schematic Diagram .......... 2-12

Page

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 8

vi

Taiko™ Series Banknote Acceptor

List of Figures

Page

Figure 2-26 Parallel ID-062 Communications Interface Schematic Diagram .......... 2-13

Figure 2-27 Taiko Operational Flowchart (Part 1) ................................................... 2-15

Figure 2-28 Taiko Operational Flowchart (Part 2) ................................................... 2-16

Figure 2-29 Taiko Operational Flowchart (Part 3) ................................................... 2-16

Figure 4-1 Taiko Bezel Guide Removal....................................................................4-1

Figure 4-2 Taiko CPU Board Cover Removal............................................................ 4-1

Figure 4-3 Taiko CPU Circuit Board Removal...........................................................4-1

Figure 4-4 Taiko MAG Circuit Board Disconnect.......................................................4-2

Figure 4-5 Taiko MAG Circuit Board Disconnect.......................................................4-2

Figure 4-6 Taiko Side Mounting Screw Removals..................................................... 4-2

Figure 4-7 Upper Lid and Side Covers Removal ....................................................... 4-2

Figure 4-8 Taiko Transport Drum Removal ...............................................................4-3

Figure 4-9 Right & Left Transport Drum End Cover Removal ...................................4-3

Figure 4-10 Dual Feed Roller Assembly Removal..................................................... 4-3

Figure 4-11 Transport Drum Separation....................................................................4-3

Figure 4-12 Upper Guide Prism Removal.................................................................. 4-3

Figure 4-13 Upper Guide Sensor Board Removal.....................................................4-3

Figure 4-14 Motor Drive Assembly Removal .............................................................4-4

Figure 4-15 Encoder Circuit Board Removal ............................................................. 4-4

Figure 4-16 Lower Guide Assembly Removal ...........................................................4-4

Figure 4-17 Lower Guide Assembly Cover Removal................................................. 4-4

Figure 4-18 Lower Guide Lever Removals ................................................................ 4-4

Figure 4-19 Entrance & Exit Solenoid Removal ........................................................4-5

Figure 5-1 PUB-7 12 Volt DC System Wiring Diagram............................................ 5-1

Figure 5-2 PUB-7 24 Volt DC System Wiring Diagram............................................ 5-2

Figure 5-3 PUB-11 12 Volt DC System Wiring Diagram (with Mag) ........................ 5-3

Figure 5-4 PUB-11 24 Volt DC System Wiring Diagram (with Mag) ........................ 5-4

Figure 6-1 Required PUB-7/11 PC Download Workbench Tool ..............................6-1

Figure 6-2 Required PUB-7/11 Palm Pilot Download Workbench Tool................... 6-1

Figure 6-3 Typical Tungsten Series Palm Pilot Handheld with JCM Software

Icons....................................................................................................... 6-2

Figure 6-4 Taiko DIP Switch & Port Location .......................................................... 6-2

Figure 6-5 Taiko PC Download Program Screen ....................................................6-2

Figure 6-6 Taiko Palm Conversion Screen.............................................................. 6-3

Figure 6-7 Taiko Palm Program Download Screen .................................................6-3

Figure 6-8 Taiko Re-Programming Software Tool Connection Configuration ......... 6-4

Figure 6-9 JCM Serial Number Writer Screen ......................................................... 6-5

Figure 6-10 Taiko Clone Software Tool Connection Configuration ...........................6-6

Figure 6-11 Removing Taiko from Bezel Mount ........................................................ 6-7

Figure 6-12 Adjustment DIP Switch Setting...............................................................6-7

Figure 6-13 Reference Paper Insertion .....................................................................6-7

Figure 6-14 Adjustment Complete Paper Ejection.....................................................6-7

Figure 7-1 Entire Taiko Unit Exploded View ............................................................ 7-1

Figure 7-2 Complete Taiko PUB-7/11 Unit Exploded View .....................................7-3

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 9

vii

Taiko™ Series Banknote Acceptor

List of Figures

Page

Figure 7-3 Taiko PUB-7/11 Bezel Unit Exploded View ..............................................7-8

Figure 7-4 Taiko PUB-7/11 Bezel Unit Exploded View ............................................7-10

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 10

viii

THIS PAGE INTENTIONALLY LEFT BLANK

Taiko™ Series Banknote Acceptor

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 11

ix

Taiko™ Series

Banknote Acceptor

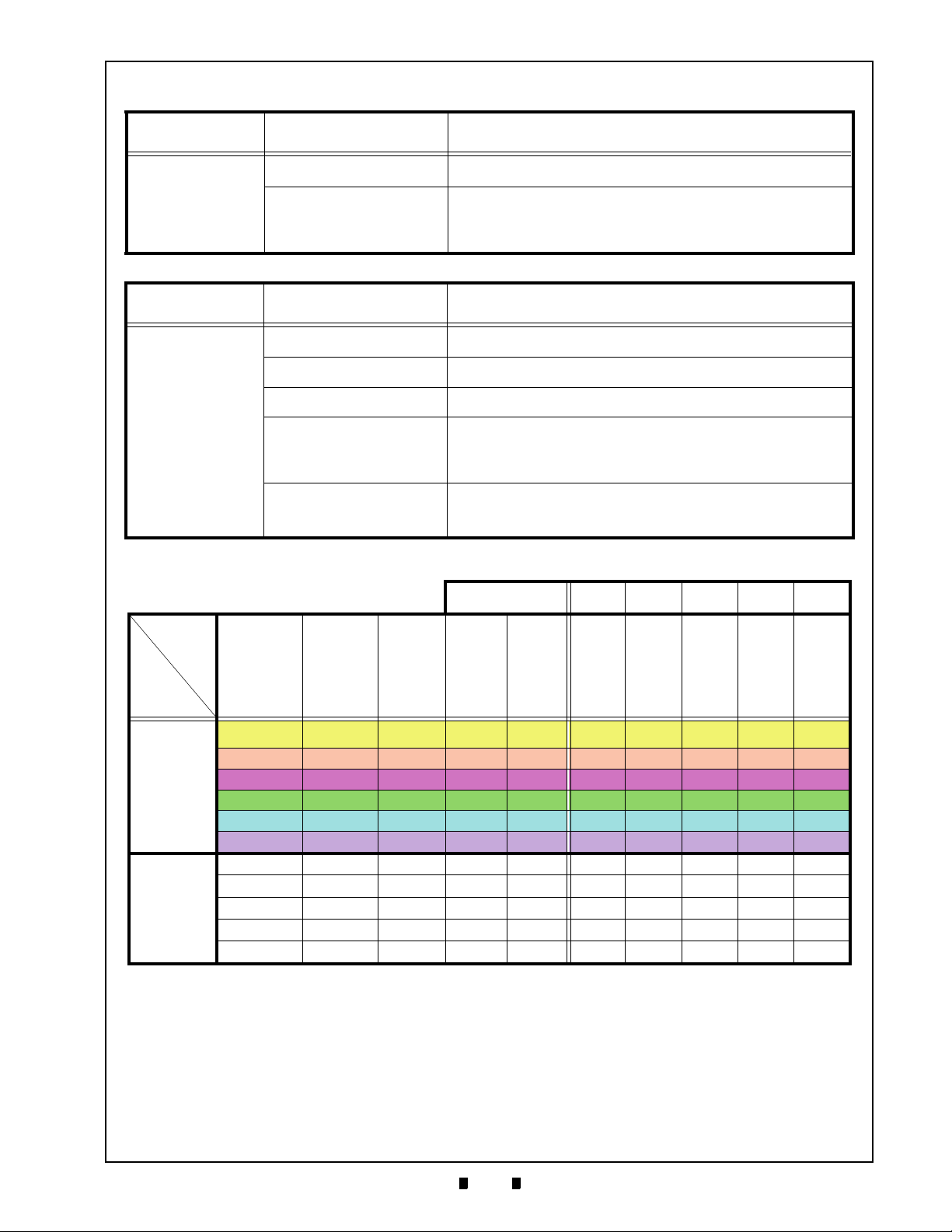

List of Tables

Page

LOT

Table 1-1 Taiko PUB-7/11 Model Number Specifications........................................ 1-2

Table 1-2 Taiko PUB-7/11 Technical Specification.................................................. 1-6

Table 1-3 Taiko PUB-7/11 Environmental Specification .......................................... 1-6

Table 1-4 Taiko PUB-7/11 Electrical Specification................................................... 1-7

Table 1-5 Taiko PUB-7/11 Structural Specification.................................................. 1-7

Table 2-1 Power Connector Specifications .............................................................. 2-2

Table 2-2 Typical DIP Switch Settings ..................................................................... 2-3

Table 2-3 Programming DIP Switch Settings........................................................... 2-4

Table 2-4 Red LED Error Code Flash Definitions .................................................... 2-5

Table 2-5 Serial ID-003/MDB Interface Pin Assignments ........................................ 2-5

Table 2-6 ccTalk Interface Pin Assignments............................................................ 2-5

Table 2-7 Pulse Interface Pin Assignments ............................................................. 2-5

Table 2-8 Parallel ID-001 Interface Pin Assignments............................................... 2-6

Table 2-9 Taiko Sensor Type Cleaning Methods..................................................... 2-7

Table 6-1 Test Bench Interface Protocols................................................................ 6-4

Table 6-2 Taiko TEST DIP Switch Settings.............................................................. 6-8

Table 6-3 Aging Test Error Codes............................................................................ 6-8

Table 6-4 Solenoid Error Codes............................................................................... 6-9

Table 6-5 LED Flash Error Codes............................................................................ 6-9

Table 7-1 Primary Taiko PUB-7/11 Unit Parts List................................................... 7-2

Table 7-2 Complete Taiko PUB-7/11 Units Parts List .............................................. 7-4

Table 7-3 Taiko PUB-7/11 Bezel Units Parts List..................................................... 7-9

Table 7-4 Taiko EBA Type Bezel Units Parts List.................................................. 7-11

Table A-1 General Fault Conditions ......................................................................... A-1

Table A-2 Adjustment Fault Conditions .................................................................... A-3

Table A-3 Communication Fault Conditions .............................................................A-3

Table A-4 Taiko Usage Specifications (Part 1)......................................................... A-3

Table A-5 Taiko Usage Specifications (Part 2)......................................................... A-4

Table A-6 Red LED Error Code Flash Definitions .................................................... A-4

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 12

x

Taiko™ Series Banknote Acceptor

THIS PAGE INTENTIONALLY LEFT BLANK

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 13

1-1

Taiko™ Series

1 GENERAL INFORMATION

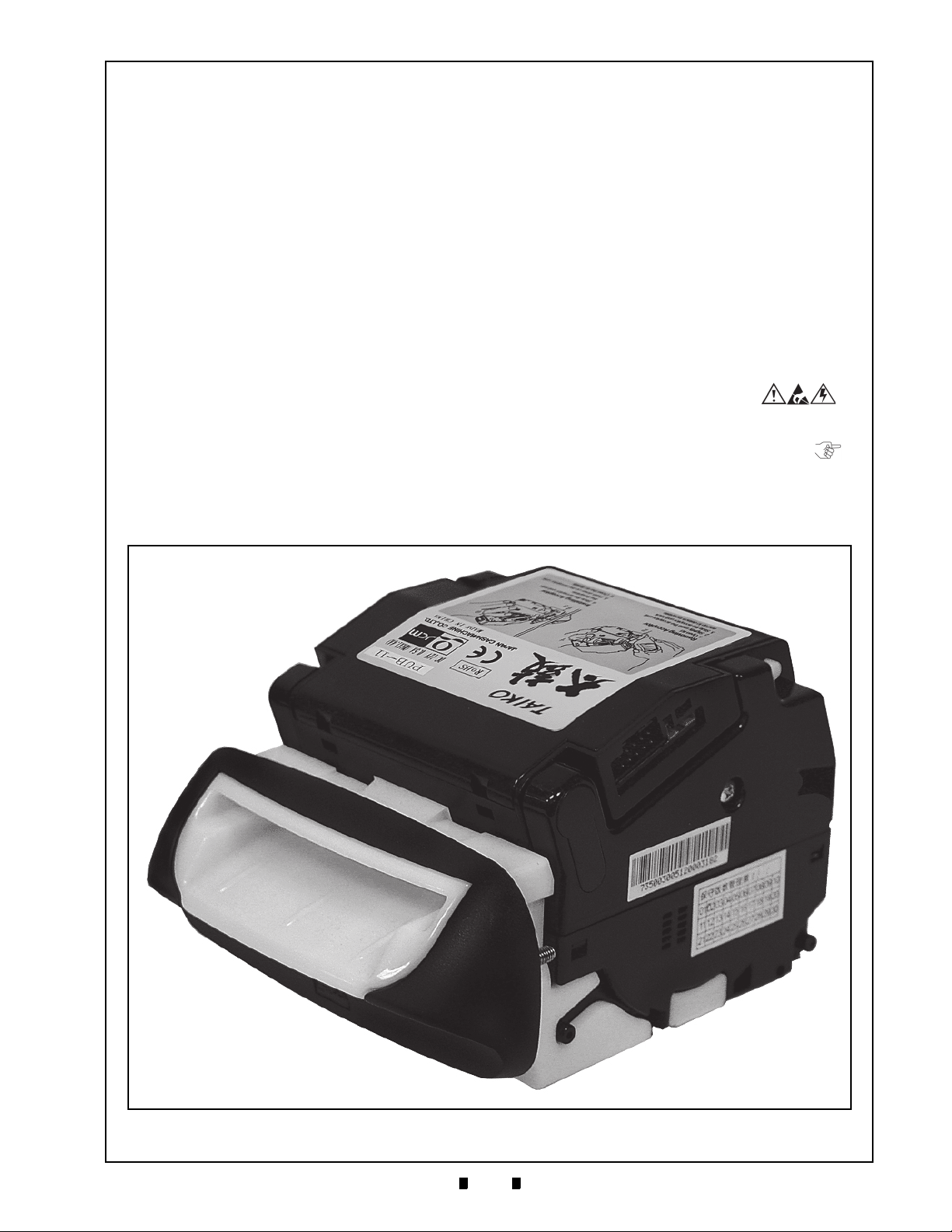

Taiko PUB-7/11 Unit

Figure 1-1 Taiko PUB-7/11 Unit

Banknote Acceptor

Section 1

Description

This section provides a general overview of the

Taiko™ Banknote Acceptor Series (PUB-7/11)

pictured in

designed to help you navigate through this guide

with ease and provides the following information:

• Taiko™ PUB-7/11 Unit

• Component Names

• Model Description

• Type Description

• Software Description

• Precautions

• Primary Features

• Specifications

• System Configuration

Figure 1-1. This first section is

• Unit Dimensions

• International Compliance

• Technical Contact Information.

In order to make operation of this device easier and

make navigation within this manual simpler, the

following illustrations were used within the text:

• Safety Instructions, which need to be

observed in order to protect the operators and

equipment, have been written in bold text and

have been given the pictographs:

• Special Notes, which effect the use of the

Banknote Acceptor, have been written in italic

text and have been given the pictograph:

• Steps, requiring the operator to perform

specific actions are given sequential numbers

(1., 2., 3., etc).

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 14

1-2

Section 1 Taiko™ Series Banknote Acceptor General Information

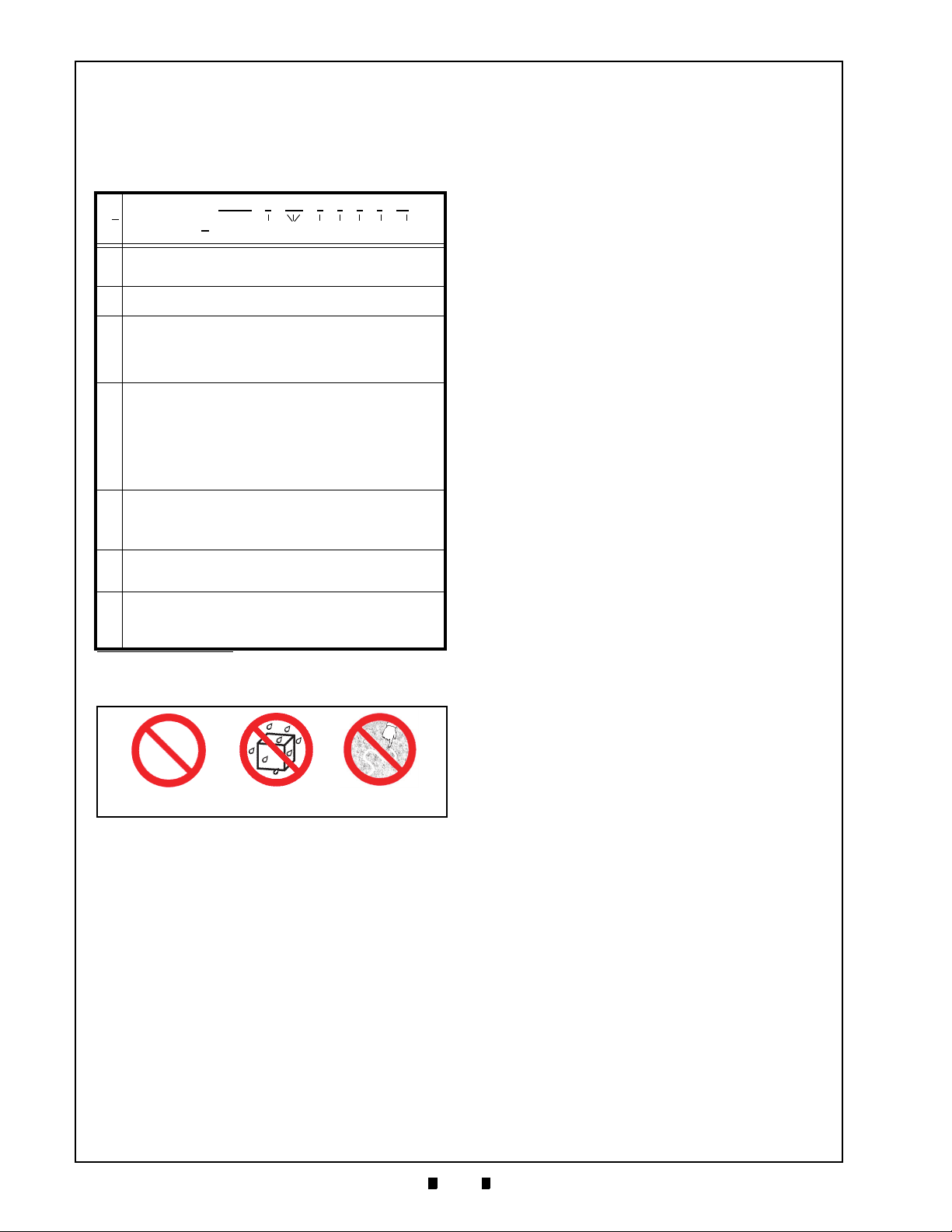

Type 1 Type 2 Type 3

Figure 1-2 Precautionary Symbols

Model Descriptions

Table 1-1 lists the Product Model Number

Descriptions.

Table 1-1 Taiko PUB-7/11 Model Number

Specifications

Model: PUB - * - *** - * - * - * - * - **

o

N

No (1) (2) (3) (4) (5) (6) (7)

Validation Method

(1)

7 = Optical/Transmissive/Reflection

11 = Optical/Transmissive/Reflection/Magnetic (MAG)

Country Code

(2)

Type - ISO 3116 based 3-digit codes

Bezel

0 = No Bezel

1 = Banknote Width Minimum = 67mm/Maximum = 82mm (Euro)

(3)

2 = Banknote Width Minimum = 75mm/Maximum = 82mm (British)

3 = Banknote Width Minimum = 70mm/Maximum = 82mm (China/Taiwan)

5 = Banknote Width Minimum = 66mm (US Dollar)

Optional Unit

0 = Without Optional Unit

1 = With Optional Interface Pin Assignment Conversion Adaptor

Harness Unit (ccTalk Compatible)

2 = Parallel (ID-001) Interface Type (Upper Tray dedicated 16-Pin

(4)

Connector)

3 = Individual Specification

4 = 24V DC Specification

5 = Barcode Coupon Specification

CPU Board Type

0 = Standard

(5)

2 = Interface Pin Assignment (ccTalk Compatible)

3 = Parallel Interface

4 = 24V DC/12V DC

Optional Code

(6)

0 = Standard

1 = Individual Specification

Interface

X4 = ID-003 (Serial)/MDB/Pulse/ccTalk

(7)

01 = ID-001 (Parallel)

03 = ID-003 (Serial) (For Barcode Specification)

62 = ID-062

*. 24V DC is only available when using the Optional 24V DC Version.

*

Precautions

The Figure 1-2 symbols are defined as follows:

1. (Type 1) Do not insert a torn, folded, or wet

Banknote, as this action may cause a Banknote

jam inside the unit.

2. (Type 2) Do not expose the unit to water. The unit

contains several precision electronic devices

which can be damaged if water or any liquid is

sprayed or spilled into the unit.

3. (Type 3) Do not install the unit into a dusty

environment. Dust may affect and degrade the

sensor’s performance.

U

SER CAUTIONS

Careful measures are taken in this product to

ensure its quality; however, the following cautions

should be read and understood by all users in order

to confirm safe operation.

Installation Cautions

The Installation Cautions are defined as follows:

1. Do not allow the Unit to endure or operate at a

high temperature, in high humidity and/or in a

dusty environment.

2. Do not use the Acceptor where temperature variations widely fluctuate.

3. Do not install the Unit into an area where excessive vibration, shock or chemical vapors are present.

4. This equipment is intended for indoor use only.

Be sure that the Host Machine contains enough

protection to avoid wet or dusty conditions when

installing.

5. Avoid exposing the Unit to direct Sunlight and/or

incandescent Lamp illumination having a Gradi

ent Angle of 15 Degree or more, and an illumination index of 3,000 Lux or less.

6. Insure that the Host Machine is designed for

daily operational access such as maintenance

and/or cleaning a Banknote Jam.

7. Be sure to use in the specified power range and

pin assignment. If not, the Unit may be damaged.

8. Be sure to connect the power harness connectors

firmly, otherwise an incorrect input/output con

-

tact failure may occur.

9. Do not pull on the power harness to disconnect

its connector or damage may occur.

10. Do not obstruct the Acceptor’s air holes in order

to provide sufficient cooling to the Unit.

Mounting, Dismounting & Transportation

Methods for Mounting, Dismounting & Transporting the Unit are as follows:

1. Be sure to turn the Power OFF before mounting

or removing the Unit from its permanent loca

tion. Plugging or unplugging Connector Plugs

from their receptacles while the Power is ON

may cause damage to the Unit.

2. When reassembling a disassembled Unit Section,

ensure that each part is properly placed in its

correct location.

3. Be sure to carry the Unit by both hands when

transporting it. Holding the Unit by one hand

may cause personal injury if the Unit accidently

becomes disassembled and falls apart.

4. Be careful not to use excessive outside pressure

on the Unit, or subject it to excessive vibration

during transportation.

5. Do not throw or pound hard on the Unit.

Preventive Maintenance

The Preventive Maintenance requirements are

defined as follows:

1. Be sure the Power to the Unit is OFF before

beginning a Maintenance Procedure. The equip

ment produces improper operating signals while

in maintenance mode that may cause personal

injury.

2. Be sure to remove power to the Unit when opening the upper or lower lid. The active Roller may

cause personal injury.

-

-

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 15

1-3

General Information Taiko™ Series Banknote Acceptor Section 1

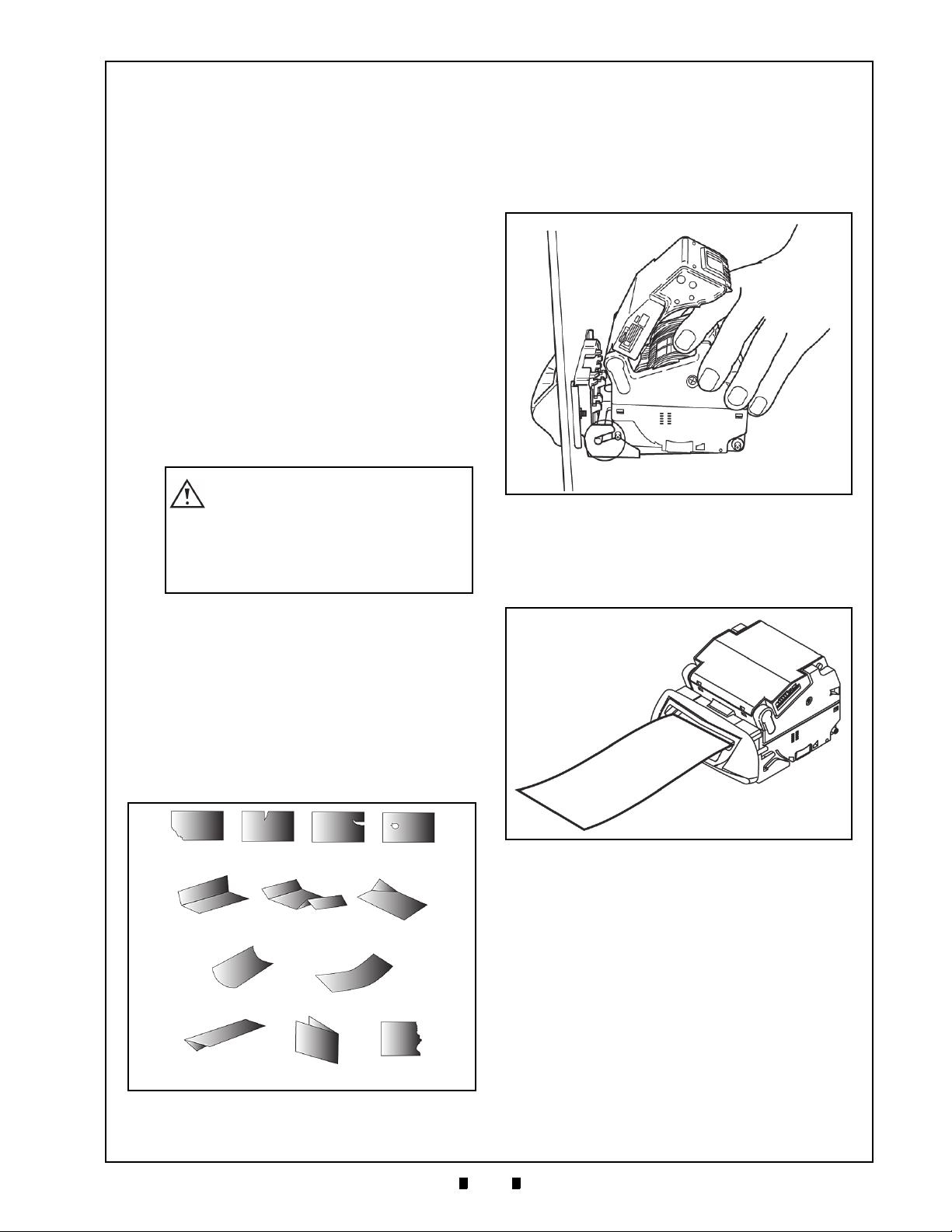

Caution: Do not use any Alcohol,

thinner or citrus based products

for cleaning any surfaces. The

Lenses can become clouded by

chemical effect that may cause

acceptance errors.

Damaged Banknotes

Wrinkled Banknotes

Curled Banknotes

Folded or Partial Banknotes

Figure 1-3 Unacceptable Banknotes

Figure 1-4 Installation Simplicity

Figure 1-5 Scan Frequency Capability

3. Be careful that foreign objects or dust may

intrude the Unit when opening the Guide Area.

4. When closing the Unit, ensure all service door

locks click into place.

5. If the Validator section is dirty due to dust, foreign objects or other such debris adhering to it,

the Banknote acceptance rate will degrade.

Clean the Unit once a month to keep its performance stable.

6. Use a soft, lint-free cloth, Cotton swab or Compressed Air spray to clean dust and debris from

the Banknote transportation path.

7. Perform cleaning and maintenance regularly

when using the equipment in a place where

excessive Automobile exhaust emission or Ciga

rette Smoke may exist.

8. Be sure that the Guide or individual Unit Sections are properly placed in their correct location

following a maintenance procedure.

9. Do not redesign or disassemble the Unit. Unauthorized use by inadequately trained personnel,

or use outside the original manufacture’s intent

for operation voids the warranty.

Banknote Fitness Requirements

1. The following Banknote types may not validate

correctly, or can cause a Banknote jam and/or

damage to the Unit’s Transport path. Banknotes

exhibiting the conditions listed below and illus

trated in Figure 1-3 should be avoided:

• Having perforated or torn areas

• Having excessive folds

• Wet or damp

• Having excessive wrinkles

• Shabby/warn condition

• Adhering foreign objects and/or oil.

Primary Features

The Taiko™ PUB-7/11 Series of Banknote Acceptors contains the following primary features:

• Installation and removal of a TAIKO Unit is

-

-

very easy because of its clip-on style. Anyone

can install a TAIKO Unit quickly.

• Data scanning frequency can be selected by

setting DIP Switches. Scanning once or twice

is selectable. The acceptance rate can be

improved by setting it to scan twice.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

• This JCM patented Anti-Pullback Mechanism

provides powerful protection against Banknote

stringing (fishing). The drum rotates every

time a Banknote passes through the Unit, and

tangles any foreign object attached to the

Banknote such as string and/or tape around

itself.

• One of five rotations is DIP Switch selectable.

The greatest fishing protection is obtained by

selecting the five rotation setting.

Page 16

1-4

Section 1 Taiko™ Series Banknote Acceptor General Information

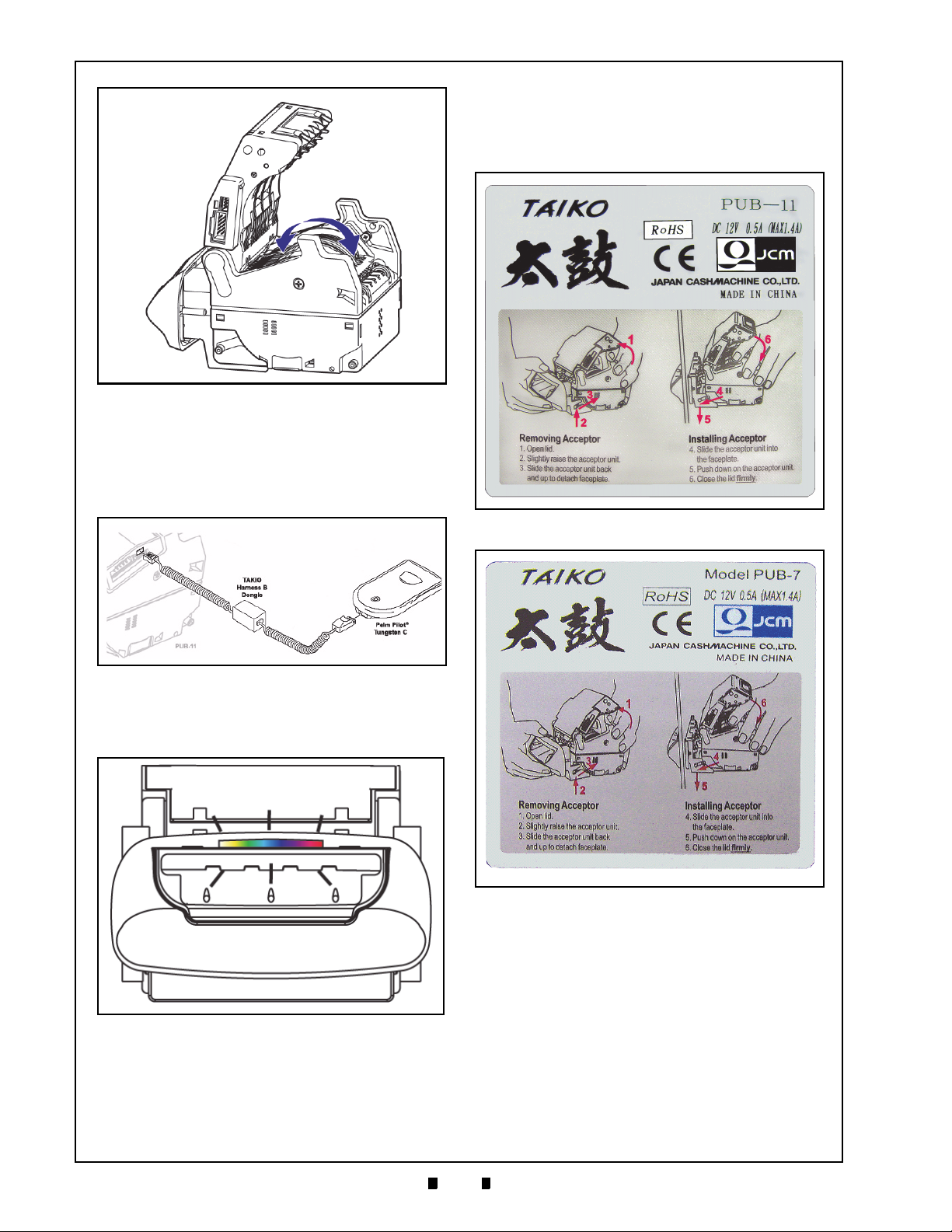

Figure 1-6 Taiko Anti-Pullback Feature

Figure 1-7 Palm Pilot Programmable

Figure 1-8 LED Pattern Selectable

Figure 1-9 PUB-11 Top Panel Instruction Label

Figure 1-10 PUB-7 Top Panel Instruction Label

Product Label

Figure 1-9 and Figure 1-10 illustrates the simple

installation instructions contained on the Taiko™

top panel label.

• The Taiko™ Unit can connect to a Palm Pilot®

(Tungsten C) hand held unit for ease of

programming. The required software program

can be downloaded from the Palm easily in the

field.

• The LED pattern can be changed by DIP

Switch settings depending on the user’s desire

to use Pattern 1 or Pattern 2.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 17

1-5

General Information Taiko™ Series Banknote Acceptor Section 1

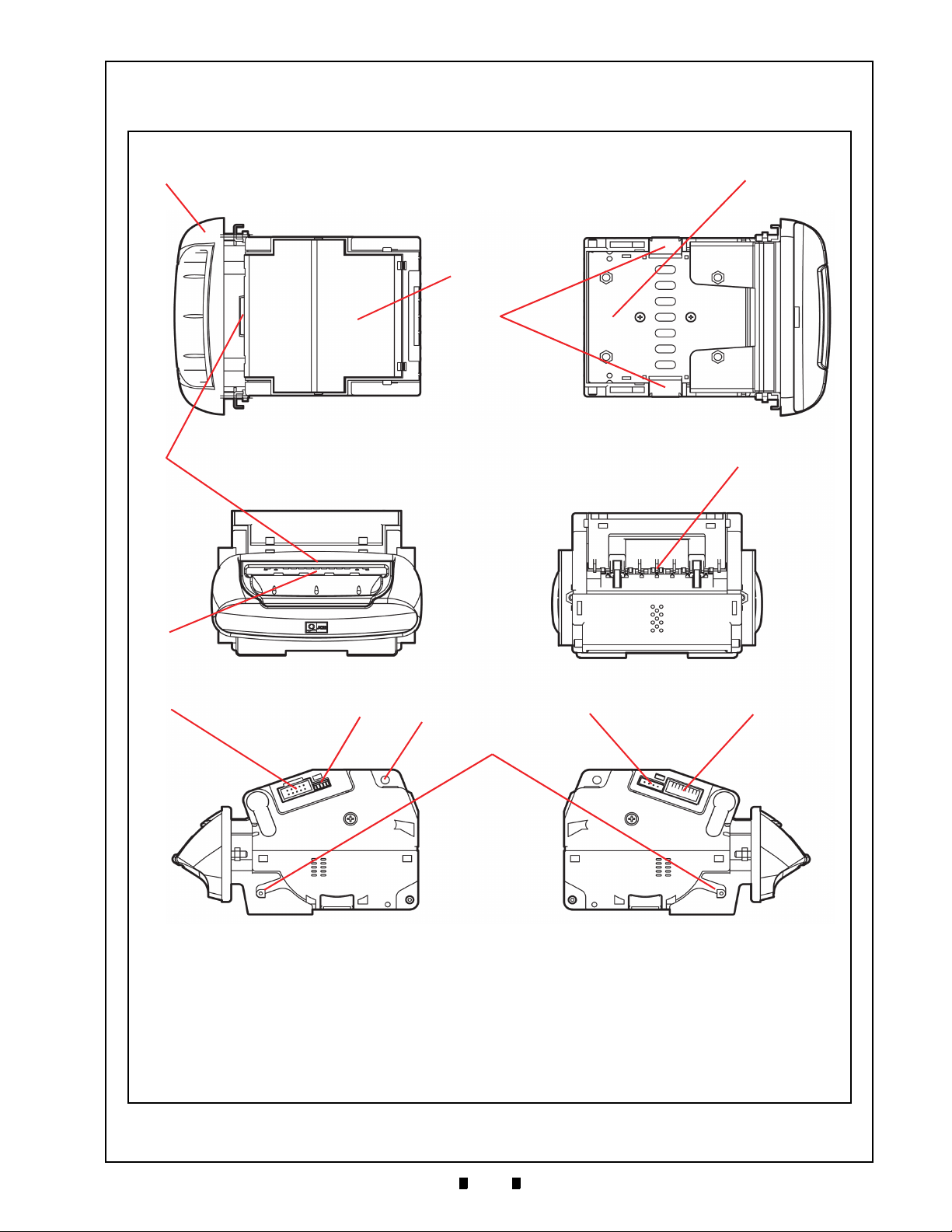

Figure 1-11 Taiko PUB-7/11 Component Names

a) Bezel

b) Upper Guide Lid

c) Lower Guide Lid

d) Lower Guide Locking Button

e) LED Display Lens

f) Banknote Insertion Slot

g) Banknote Exit Slot

h) Interface Connector

i) Maintenance Connector

j) Upper Lid Open/Close Button

k) Optional Interface Connector

l) DIP Switch Block

m)Bezel Installation Guide Pin

e

k

f

g

l

c

j

a

b

hi

d

m

Front Rear

Top Bottom

Right Left

Component Names

Figure 1-11 illustrates the Taiko™ PUB-7/11 Component Names and Locations.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 18

1-6

Section 1 Taiko™ Series Banknote Acceptor General Information

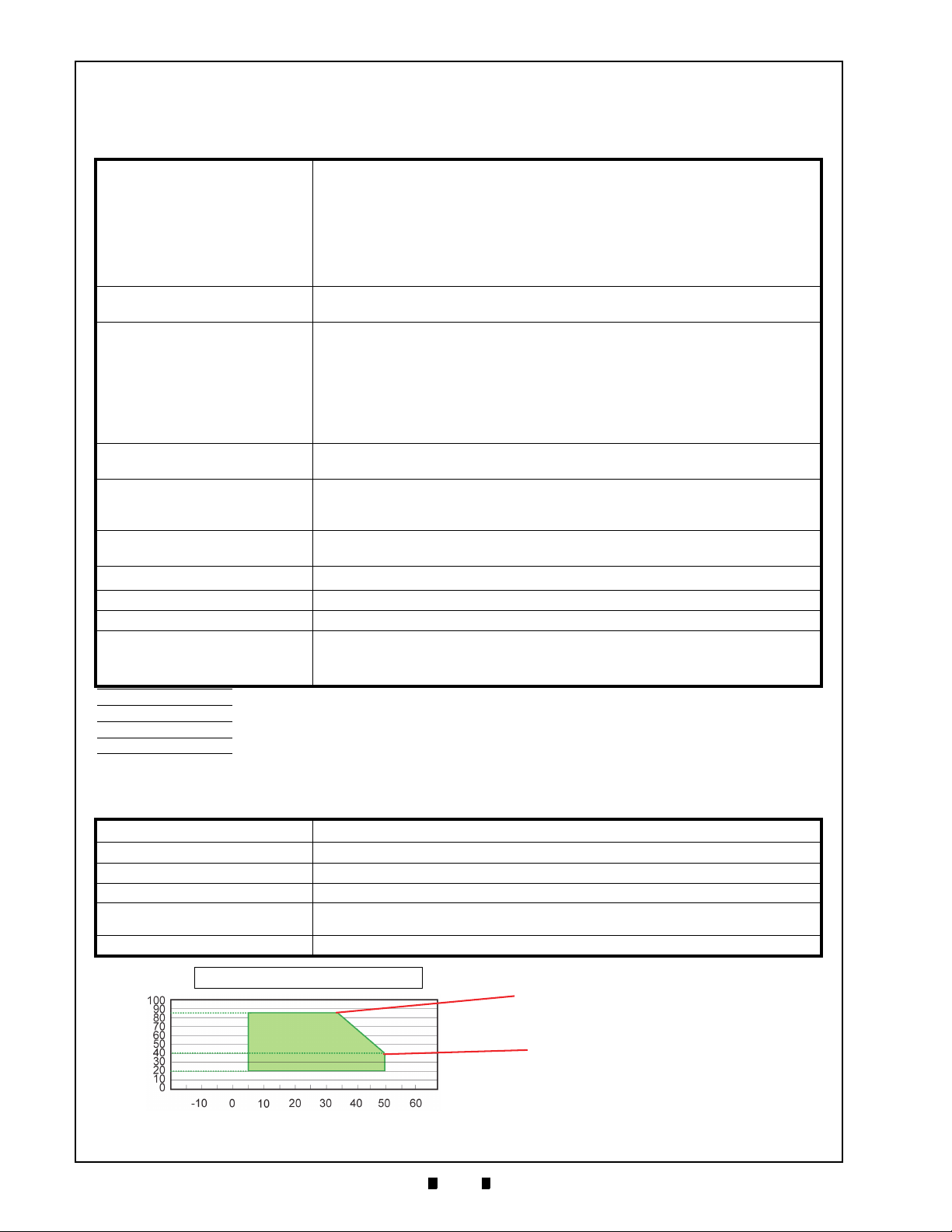

Specifications

T

ECHNICAL SPECIFICATIONS

Hydrothermal Condition Table

Humidity [%RH]

Temperature [ºC]

Allowable

and Humidity Range

Operating

Temperature

35ºC/85%

50ºC/40%

Table 1-2 Taiko PUB-7/11 Technical Specification

†

Acceptance Rate*:

Banknote Types Accepted:

95% or greater

Note: The following banknote types are excluded:

a) Banknotes with excess or poor magnetism or unclear graphics

b) Double (dual) Notes

c) Worn, dirty, wet, stained, torn or excessively wrinkled Banknotes

d) Banknotes having folded corners or edges

e) Banknotes having the wrong cut dimensions or printing displacement

f) Returned Banknotes because of incorrect or failed insertion.

Long side: 120~160mm (4.72~6.3 in.)

Short side: 62~82mm (2.44~3.23 in.)

Standard Specification

a) Read code interleaved: 2 of 5

b) Narrow Bar: 0.5mm-0.6mm (0.019-0.023 in.)

Barcode Coupon‡:

Insertion Direction:

c) Wide Bar to Narrow Bar ratio = 3:1

d) Characters: 18 Characters

e) Print Position: Middle (Divide a Coupon equally on the left, right, top and

bottom of the Coupon’s center)

f) Print Width: Wider than 10mm (0.39 in.)

Banknote: Four-way

Barcord Coupon: Two way (Barcode Surface Up)

Approximately 2 seconds (from Banknote insertion to denomination signal

Processing Speed**:

output)

Approximately 3 seconds (from Banknote insertion to credit signal output)

Validation Method:

Diagnostic Indicators††:

PUB 7 = Optical (4 wavelength), Transmissive and Reflection

PUB 11 = Optical (4 wavelength), Magnetic, Transmissive and Reflection

Front Panel Bezel LED, Full color illuminating (Gradation & Solid)

Escrow: 1 note

Anti-stringing Mechanism: Pull-Back (PB) Unit (Anti-pullback system - JCM Patented)

**

Interface:

X4: ID-003 (Serial)/MDB/Pulse/ccTalk

01: Parallel (ID-001)

03: Serial (ID-003)

*. When security measures against counterfeiting are implemented, the software may not fulfill the specified acceptance rate level.

†. Refer to the Software Information Sheet related to the specific Country's software.

‡. Refer to the Barcode Coupon Specification.

**.Excluded Host communication time lag. (Power Supply: +12V DC, Temperature: 25ºC ±5ºC)

††.DIP Switch selectable.

E

NVIRONMENTAL SPECIFICATIONS

Table 1-3 Taiko PUB-7/11 Environmental Specification

Operating Temperature: +5ºC to +50ºC (41ºF to 122ºF)

Storage Temperature: -20ºC to +60ºC (-4ºF to 140ºF)

Relative Operating Humidity: +20% to 85% RH (non-condensed)

Relative Storage Humidity: +20% to 85% RH (non-condensed)

Visible Light Sensitivity:

Installation: Indoors Only

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Avoid contact with direct sunlight (Interior lighting must be incandescent with a

Radiant Angle of 15 Degree or more having an Illumination index of 3000 Lux or less)

Page 19

1-7

General Information Taiko™ Series Banknote Acceptor Section 1

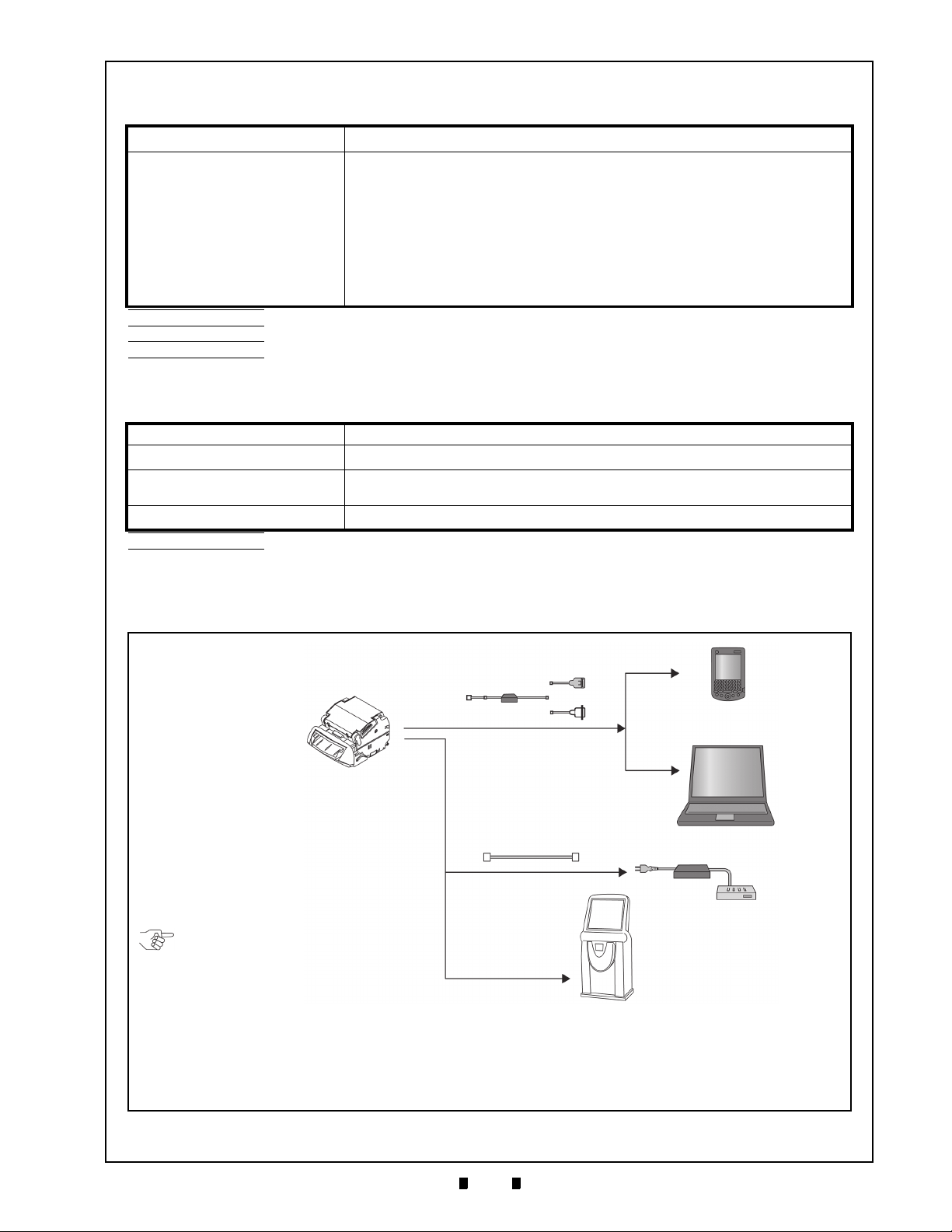

Figure 1-12 Taiko PUB-7/11 System Configuration

a

b

c

d

g

f

e

Maintenance Connector

Interface

Connector

Communications

NOTE: The Communications Harness

needs to be prepared by the Customer.

Harness

a) Taiko™ PUB-7/11 Unit

b) Palm Pilot Tungsten C

c) PC (Windows 98SE/2000/XP)

d) JCM Power Supply Unit (EDP# 116125, JAC Part# 501-000187RA)

e) Taiko™ Harness B (EDP# 116488, JAC Part# 400-100573RA)

f) Taiko™ Harness A (EDP# 121797, JAC Part# 400-100551RA)

g) Host Machine (Gaming, Vending, etc.)

E

LECTRICAL SPECIFICATIONS

Table 1-4 Taiko PUB-7/11 Electrical Specification

Supply Voltage*:

12V DC ±5%/24V DC ±10%

†

Standard Specification

Standby = 0.1A [12V DC]/0.1A [24V DC]

Operation = 0.5A [12V DC]/0.5A [24V DC]

Maximum = Approximately 1.4A (Maximum of 300ms) [12V DC]/

Current Consumption‡:

Approximately 1.0A (Maximum of 300ms) [24V DC]

Barcode Specification

Standby = 0.1A [12V DC]

Operation = 0.6A [12V DC]

Maximum = Approximately 1.6A (Maximum of 300ms) [12V DC]

*. 12V DC = 7-Pin, 24V DC = 9-Pin.

†. 24V DC is available only when the optional 24V DC Specification is used.

‡. Use the CLASS2 Limited Power Source.

**.Motor Initializing or Motor Lock Up current consumption.

S

TRUCTURAL SPECIFICATIONS

**

Table 1-5 Taiko PUB-7/11 Structural Specification

Weight: Approximately 0.6kg (1.3 lbs)

Mounting*:

Outside Dimensions:

Cash Box:

*. Allow 3.93 inches (100mm) above the Unit for opening the Lid and Bezel removal.

†. Cash Box must be 3.93 inches (100mm) or more in depth from the bottom of the TAIKO Unit, 7.87 inches (200mm) or more in depth from the Unit rear

and 3.93 inches (100mm) or more in width.

Horizontal (on door - non vibrating)

See “Taiko PUB-7 Standard Bezel Unit Outside Dimensions” on page 1-8

of this Manual.

User prepared

†

System Configuration

Figure 1-12 illustrates a typical Taiko™ PUB-7/11 system configuration.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 20

1-8

Section 1 Taiko™ Series Banknote Acceptor General Information

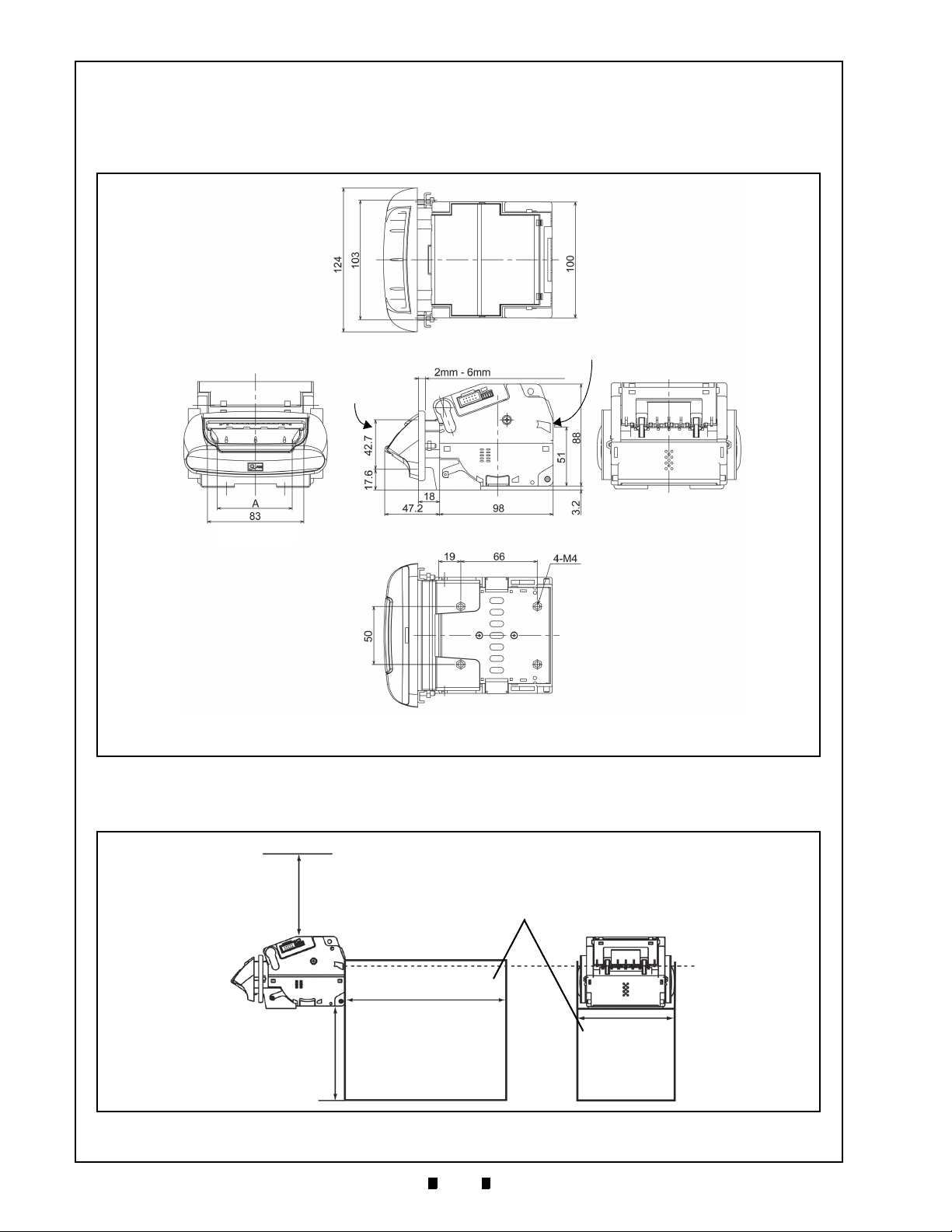

NOTE: All Dimension are in Millimeters

Door Installation

Position

(Panel Thickness)

51 (Banknote

Ejection Position)

A = 68 (Type 1: Minimum Width @ 67mm)

76 (Type 2: Minimum Width @ 75mm)

71 (Type 3: Minimum Width @ 70mm)

(Maximum Banknote Width 82)

Right Side

Rear Side

Front Side

Top Side

Bottom Side

Figure 1-13 Taiko PUB-7 Complete Unit Outside Dimensions

Overhead Space

3.93 inches

(100mm) or more

Depth Behind Unit

7.87 inches

(200mm) or more

Width

3.93 inches

(100mm)

or more

Depth Below Unit

3.93 inches

(100mm) or more

Banknote Ejection

Slot Position

Cash Box

Figure 1-14 Taiko PUB-7/11 Banknote Acceptor’s Clearance Dimensions

Unit Dimensions

T

AIKO

PUB-7 S

Figure 1-13 illustrates the Taiko™ PUB-7 Type 1, Type 2 or Type 3 Standard Bezel Unit outside dimensions.

TANDARD BEZEL UNIT OUTSIDE DIMENSIONS

Taiko PUB-7/11 Unit Clearance Dimensions

Figure 1-14 illustrates the Taiko™ PUB-7/11 Unit’s open Acceptor clearance dimensions.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 21

1-9

General Information Taiko™ Series Banknote Acceptor Section 1

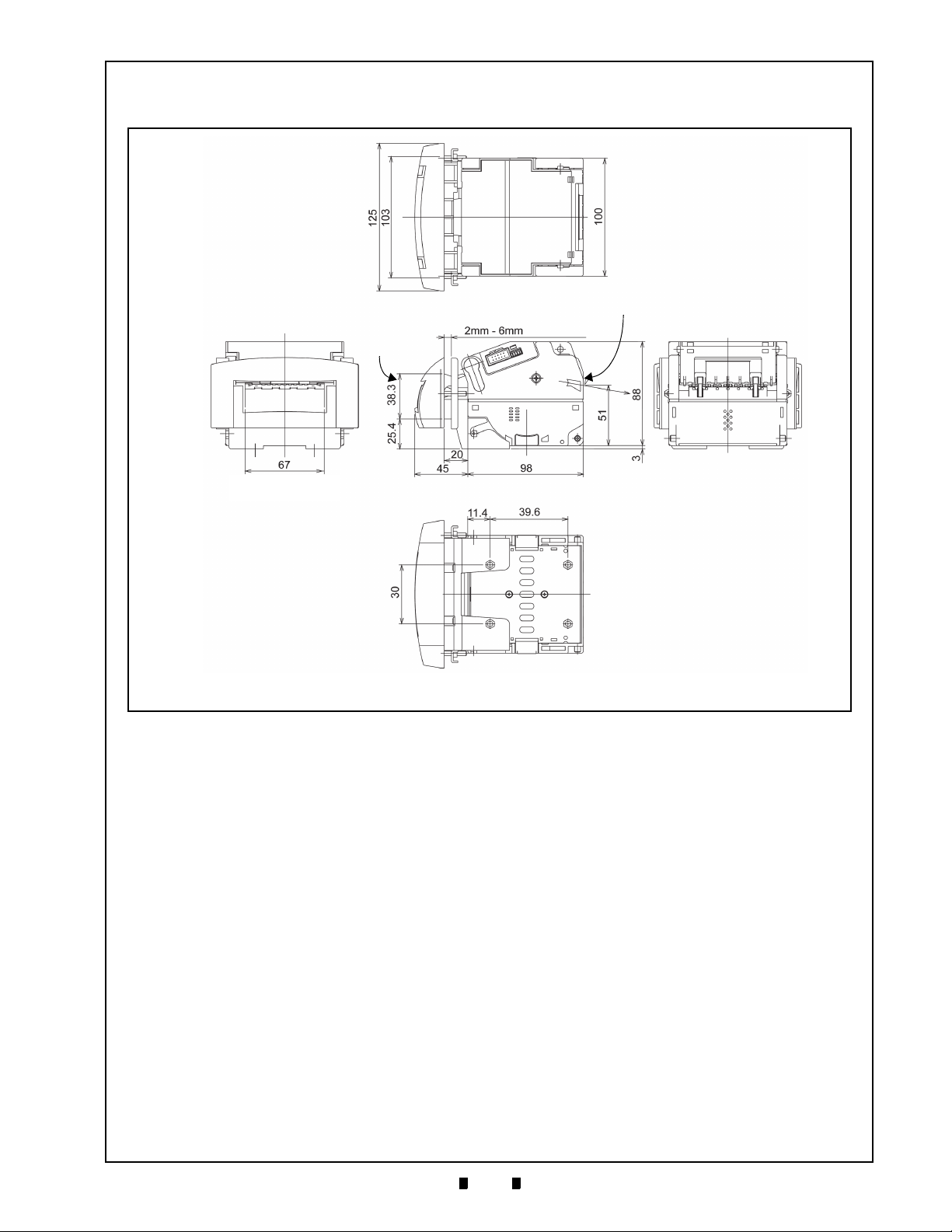

NOTE: All Dimension are in Millimeters

Door Installation

Position

(Panel Thickness)

51 (Banknote

Ejection Position)

A = 68 (Type 1: Minimum Width @ 67mm)

76 (Type 2: Minimum Width @ 75mm)

71 (Type 3: Minimum Width @ 70mm)

(Maximum Banknote Width 66)

Right Side

Rear Side

Front Side

Top Side

Bottom Side

Figure 1-15 Taiko PUB-11 (US Dollar) Complete Unit Outside Dimensions

T

AIKO

PUB-11 S

TANDARD

US B

EZEL UNIT OUTSIDE DIMENSIONS

Figure 1-15 illustrates the Taiko™ PUB-11 Type 5 Standard US Bezel Unit outside dimensions.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 22

1-10

Section 1 Taiko™ Series Banknote Acceptor General Information

or

or or

or

E142330, Subscriber 857947001, Vol. 2

International Compliance

• RoHS Directives

• UL & c-UL Marks

• CE Mark .

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 23

1-11

General Information Taiko™ Series Banknote Acceptor Section 1

To obtain further Technical Information regarding the Taiko™ PUB-7/11 Device, please contact the closest office to your location listed below:

Technical Contact Information

A

SIA

& O

A

MERICAS

JCM American

Phone: +1-702-651-0000

Fax: +1-702-644-5512

925 Pilot Road, Las Vegas, NV 89119

E-mail: support@jcmglobal.com

E

UROPE

, A

FRICA

, R

USSIA

& M

JCM Europe GmbH

Phone: +49-211-530-645-60

Fax: +49-211-530-645-65

Muendelheimer Weg 60

D-40472 Duesseldorf Germany

E-mail: support@jcmglobal.eu

UK & I

RELAND

JCM Europe (UK Office)

Phone: +44 (0) 190-837-7331

Fax: +44 (0) 190-837-7834

JCM Gold (HK) Ltd.

IDDLE EAST

Japan Cash Machine Co, Limited (HQ)

CEANIA

Phone: +852-2429-7187

Fax: +852-2929-7003

Unit 1-7, 3/F., Favor Industrial Centre

2-6 Kin Hong Street, Kwai Chung,

N.T. Hong Kong

E-mail: asiapactechsupport@jcmglobal.com

Phone: +81-6-6703-8400

Fax: +81-6-6707-0348

2-3-15, Nishiwaki, Hirano-ku, Osaka 547-0035

JAPAN

E-mail: Shohin@jcm-hq.co.jp

All of these Websites are available via:

http://www.jcmglobal.com

Unit B, Third Avenue

Denbigh West Business Park

Bletchley, Milton Keynes,

Buckinghamshire MK1 1DH, UK

E-mail: support@jcmglobal.eu

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 24

1-12

Section 1 Taiko™ Series Banknote Acceptor General Information

THIS PAGE INTENTIONALLY LEFT BLANK

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 25

2-1

Taiko™ Series

2 INSTALLATION

WARNING: Turn the equipment power OFF before removing or replacing any

Taiko™ components!

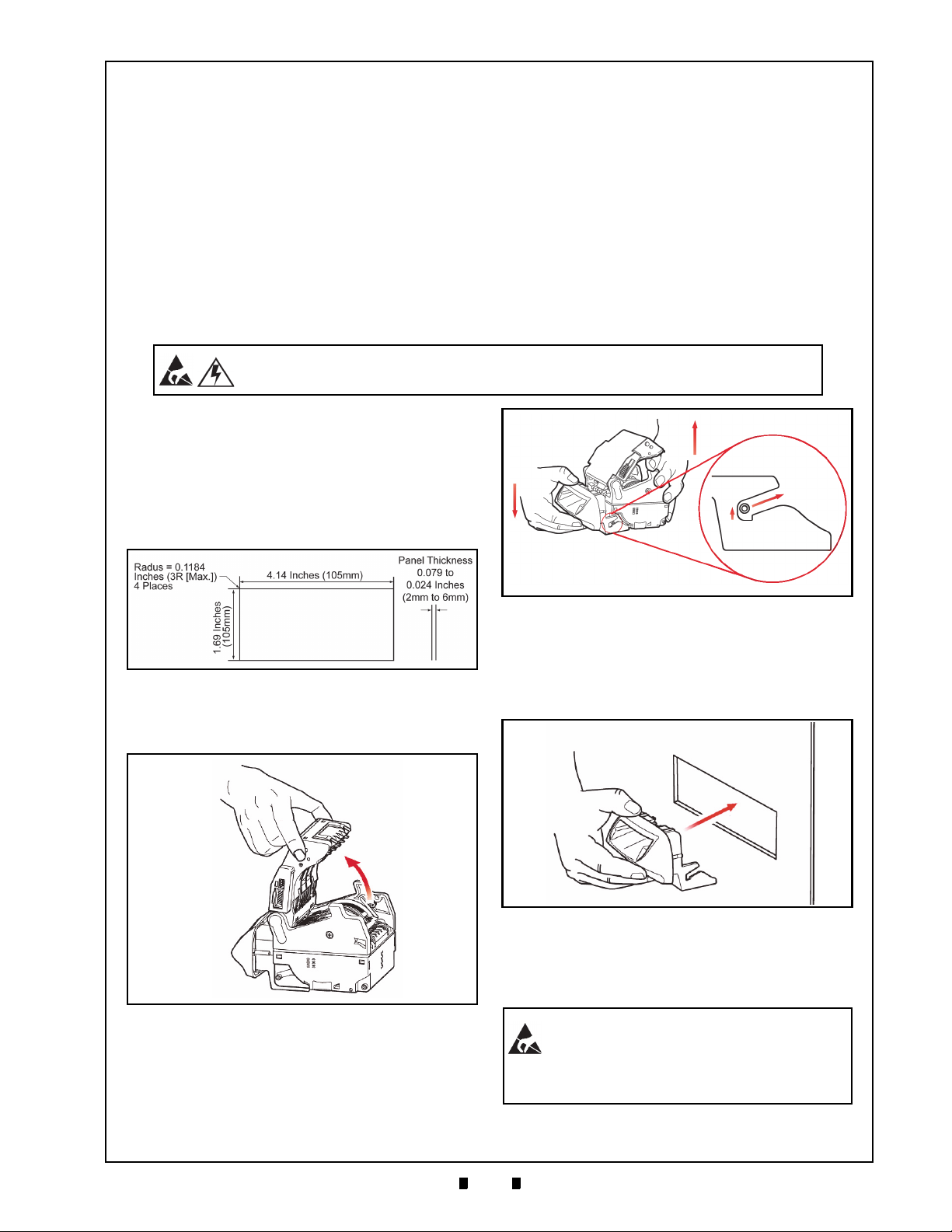

Figure 2-1 Taiko Bezel Cut-Out Dimensions

Figure 2-2 Opening Taiko’s Upper Lid

Figure 2-3 Removing the Taiko Bezel

Figure 2-4 Installing the Taiko Bezel

WARNING: Tightening the Nuts with too

much force can damage the Bezel. The

necessary torque is 0.513 foot-lbs

(0.7Nm).

Banknote Acceptor

Section 2

This section provides installation/operation

instructions for the Taiko™ Banknote Acceptor

Series (PUB-7/11). This section contains the

following information:

• Installation and Removal

• DIP Switch Configurations

Installation and Removal

Installing the PUB-7/11 Taiko Bezel

To install or remove a Taiko™ PUB-7/11 Unit

Bezel in a door or wall perform the following steps:

1. Create the correct sized opening required to

install the Taiko™ Bezel, using the Panel Cut-Out

Dimensions shown in

2. Open the Upper Lid in the arrow direction shown

in Figure 2-2 by pressing in on the Upper Lid

Open/Close Buttons.

Figure 2-1.

• Connector Pin Assignments

• Preventive Maintenance

• Clearing Banknote Jam

• Cleaning

• Interface Schematic

• Operational Flowchart..

6. Remove the two (2) Bezel Brackets and the two

(2) Hexagonal Nuts from the Bezel.

7. Insert the Bezel into the previously cut-out

area in the Door Front Panel as shown in

Figure 2-4.

3. Hold the Taiko™ Unit by placing your hand

under the Upper Lid (

4. Slightly press down on the Bezel and raise the

5. Slide the body back and up to detach it from the

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

rear Taiko™ Unit body (

Bezel section (

See Figure 2-3 ).

See Figure 2-3 ).

See Figure 2-3 ).

8. Set the Bezel in the door hole and attach the two

(2) Bezel Brackets to the back side of the Bezel

using the two (2) Hexagonal Nuts previously

removed (

See Figure 2-5).

Page 26

2-2

Section 2 Taiko™ Series Banknote Acceptor Installation

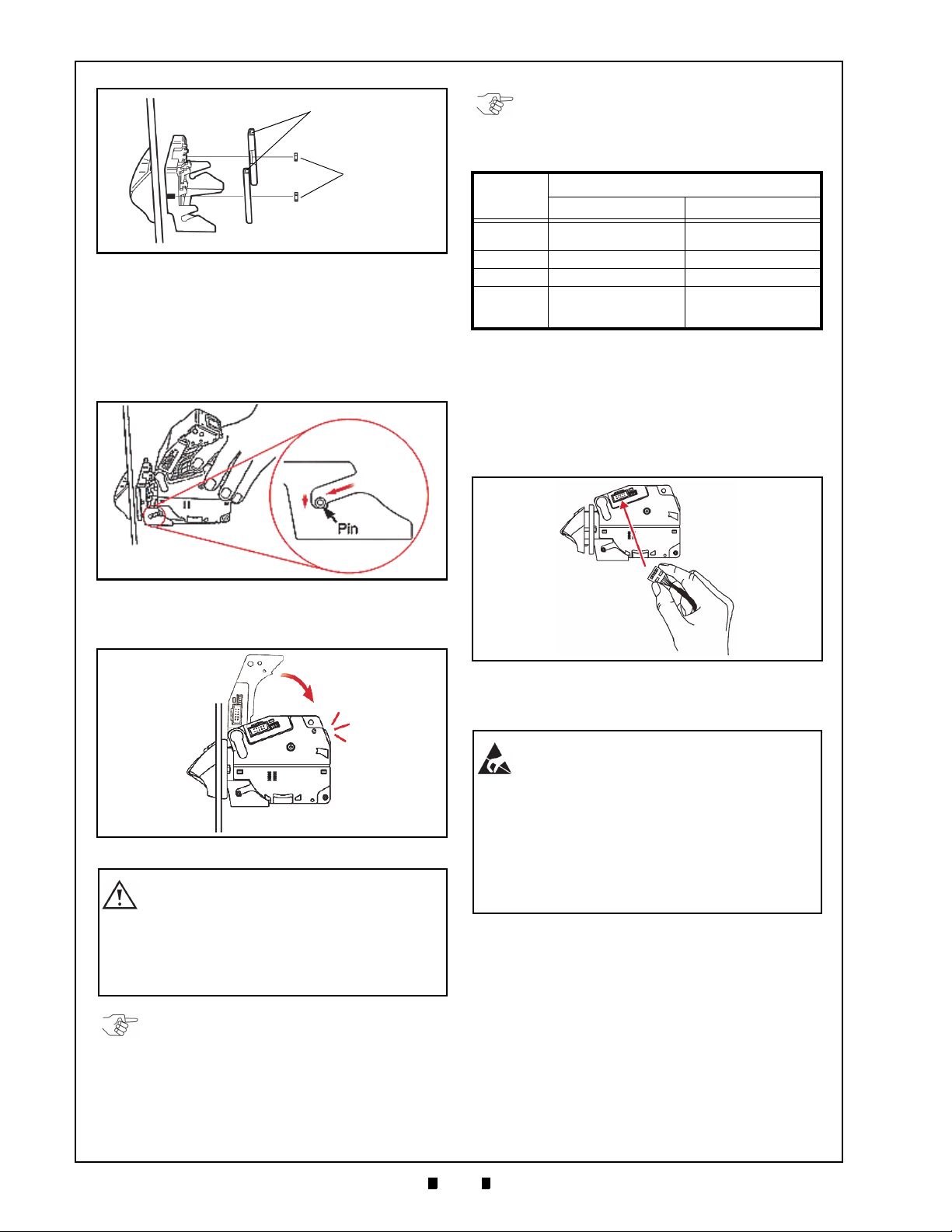

Figure 2-5 Mounting the Taiko Bezel

Bezel Brackets

Hexagonal

Nuts

Figure 2-6 Installing the Taiko Bezel

Figure 2-7 Closing the Taiko Upper Lid

Click

Caution: Ensure that the Taiko Unit body

and Bezel are firmly installed and stably

fixed to the door before closing the

Upper Lid; When closing the Upper Lid,

be careful not to get your finger caught

under the lid when pressing it closed.

NOTE: When removing a Taiko Unit, perform the

reverse procedure as previously described.

NOTE: DIP Switch settings may vary based on

Software changes related to the specific Country

using the Taiko Unit.

Figure 2-8 Attaching a Taiko Power Connector

WARNING: When installing a Taiko Unit,

or connecting its Harness Plug, be sure

power to the harness is disconnected.

The Taiko Unit is only designed to use a

12 Volt DC input. Any other power level

can damage the Taiko Unit!

If the power Harness itself is strongly

pulled on, it may tear loose from its

Connector’s Pins.

Table 2-1 Power Connector Specifications

Connector

XG4M-1030-T

(Omron)

1.27mm Pitch Flat

Ribbon Cable, AWG28

UL2651 or UL20012

9. Open the Upper Lid by pressing-in and holding

down the Upper Lid Open/Close Buttons while

lifting the Lid up (

See Figure 2-6 ).

10. Insert the Bezel Installation Guide Pin into the

Bezel Guide (See Figure 2-6 ).

11. Slide the Guide all the way in and push down on

the Taiko™ Unit body (

See Figure 2-6 ).

Part

Plug

Semi-Cover XG5X-0501 (Omron) N/A

Lock Lever 2 XG4Z-0002 (Omron) N/A

Applicable

Wire Size

Lock Lever Socket Ribbon Cable Socket

XG5M-1032-N

(Omron)

UL1061 WAG24

Once the Power Interface Connector Plug has been

fastened to the Power/Signal Cable being used,

perform the following steps:

1. Confirm the power is NOT supplied to the new

Power Harness.

2. Insert the new Power Harness Socket into the

right side Panel Interface Connector of the

Taiko™ Unit Body (

See Figure 2-8).

12. Close the Upper Lid firmly until a locking Click

is heard (

Power Harness Wiring Procedure

Before beginning to build a Power Interface

Connector, ensure one of the two plug types listed

in

Table 2 -1 are available.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

See Figure 2-7).

3. Supply power and confirm that the Taiko™ Unit

operates properly.

Clearing a Banknote Jam

Clearing an Upper Area Banknote Jam

When an upper area Banknote jam occurs, the

Front Panel Red LED Display will begin blinking

three (3) time with a pause between blink sets.

Perform the following steps to clear a Banknote

jam within the Taiko™ Unit’s Acceptor area:

1. Remove Power from the Taiko™ Unit.

Page 27

2-3

Installation Taiko™ Series Banknote Acceptor Section 2

Figure 2-9 Upper Area Banknote Jam Removal

Caution: When closing the Upper Lid,

be careful not to get your finger caught

under the Lid when closing it!

Figure 2-10 Lower Area Banknote Jam Removal

NOTE: Re-install the Taiko Unit onto the Bezel

by reversing the steps related to, and beginning

from Figure 2-6 on page 2-2 of this Section.

Figure 2-11 Left Side DIP Switch Block Location

Left Side

ON

DIP Switch Block

ON

6 7 8 IF Setting

OFF OFF OFF ID-003 Serial

ON OFF OFF MDB

OFF ON OFF ccTalk (Non-Encrypted)

ON ON OFF

ccTalk (Encrypted)

*

*. If the encryption code is unclear, refer to the “Encryption Code Initia lization

Setting Mode” on page 2-5 of this Section to initialize the Encryption Code.

--ON

Pulse

†

†. For detailed i nformation concerning Communication Settings, refer to the

individual Country’s Software Information Sheet.

2. Press-in on the Upper Lid Open/Close Buttons

and open the Upper Lid in the direction indicated

in

Figure 2-9 .

3. Remove the jammed Banknote as illustrated in

Figure 2-9 .

Clearing a Lower Area Banknote Jam

When a lower area Banknote jam occurs, the Front

Panel Red LED Display will begin blinking four (4)

times with a pause between blink sets.

Perform the following steps to clear a Banknote

jam within the Taiko™ Unit’s Transport area:

1. Remove Power from the Taiko™ Unit.

2. Remove the Taiko™ Unit body from the mounted

Bezel Section (review removal instruction shown

in

Figure 2-3 on page 2-1 of this Section).

3. Remove the Lower Lid by pressing-in on the

Lower Lid Lock Release Button (See Figure 2-10

).

4. Remove the jammed Banknote as illustrated in

See Figure 2-10 .

DIP Switch Configurations

The communication method and various Taiko™

Unit functions can be selected by using the Unit’s

Left side set of DIP Switches (

Table 2 -2 lists the various typical DIP Switch settings available for programing the Taiko™ Unit.

Table 2-2 Typical DIP Switch Settings

Switch

No.

1

2

3 Reserved Reserved

4

5

6

Double Scan Mode

Five (5) Drum Rotation

(Anti-Fishing Prevention)

Switch Position Setting

ON OFF

Test Mode 1

‡

Cycles

Refer to the specific Country’s Software

See Figure 2-11).

*

†

Normal Scan Mode

Normal Operation

Specifications

Normal Mode

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

7

8

*. For details concerning the Test Mode, refer to “Performance Test

Diagnostics” on page 6-7 in Section 6.

†. The acceptance rate will be improved, but operation time will be

increased if a Banknote (note) is rejected.

‡. Anti-Fishing prevention will be improved, but operation time will

increase.

Table 2 -3 lists the various special DIP Switch

settings available for programing the Taiko™ Unit.

Page 28

2-4

Section 2 Taiko™ Series Banknote Acceptor Installation

ON

Figure 2-12 “Accept’ Mode DIP Switch Settings

ON

Figure 2-13 ‘Inhibit’ Mode DIP Switch Settings

ON

NOTE: The Accept/Reject setting for a Banknote

denomination can be confirmed by observing the

Front Panel LED Color. After an initial operation

is performed, the LED will flash a number of

times equal to the total number of Banknote

denominations processed. Blue indicates an

‘Accept’ setting and Red indicates a ‘Reject’

setting.

Figure 2-14 Define Pattern 1 DIP Switch Settings

ON

Figure 2-15 Define Pattern 2 DIP Switch Settings

ON

Table 2-3 Programming DIP Switch Settings

Setting Function SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

LED

Pattern 1

Pattern 2

Mode

Accept

Setting

Inhibit

Setting

Define

Define

ON OFF OFF OFF OFF ON OFF OFF

ON OFF OFF OFF OFF ON ON OFF

ON ON OFF OFF OFF OFF ON OFF

ON OFF ON OFF OFF OFF ON OFF

ON ON ON ON ON ON OFF OFF

*

ON OFF OFF OFF OFF OFF ON ON

*

ON ON OFF OFF OFF OFF OFF ON

“Software Downloading Procedure” on page 6-2 in

Denom.

Val ue

Setting

Mode

Pattern

Setting

Mode

Encryption Code

Initialization Setting

Download Mode

Adjustment Mode

*. For details concerning Taiko™ Software Download and Adjustment

Modes, refer to

Section 6 of this Service Manual.

Denomination Setting Mode

Perform the Accept/Inhibit setting function for the

Banknote Denomination required based on the

Software requirements of the Specific Country in

which it is being used. The default settings are to

accept all Denominations of the Specific Country.

A

CCEPT SETTING MODE

To establish an “Accept” setting function, perform

the following steps:

2. Set DIP Switch No.1, No. 6 and No.7 to ON

(

See Figure 2-13).

3. Re-apply Power to the Taiko™ Unit.

4. After the Front Panel LED display flashes White,

set DIP Switch No.1 to the OFF position to enter

the Setting Mode.

5. Insert the Banknote Denomination to be inhibited

into the Insertion Slot. The setting is registered if

the Front Panel LED display remains lit an

Orange Color, and the inserted Banknote is

returned.

6. Insert next Banknote Denomination to be inhibited until all required values have been processed.

The Banknote ‘Accept’ or ‘Inhibit’ programing

operations are now complete.

LED Pattern Setting Mode

The LED Color Pattern Type can be changed

according to user preference. Select between Pat

tern 1 or Pattern 2. The default setting is Pattern 1.

D

EFINING PATTERN

1

To define a “Pattern 1” (a flashing Color Sequence)

operating function, perform the following steps:

1. Remove Power from the Taiko™ Unit.

2. Set DIP Switch No.1, No.2 and No.7 to ON

(

See Figure 2-14).

-

1. Remove power from the Taiko™ Unit.

2. Set DIP Switch No.1 and No.5 to ON (See Figure

2-12 above).

3. Re-apply Power to the Taiko™ Unit.

4. After the Front Panel LED display flashes White,

set DIP Switch No.1 to the

OFF position to enter

the Setting Mode.

5. Insert the Banknote Denomination to be accepted

into the Insertion Slot. The setting registered is

correct if the Front Panel LED Display remains lit

a light Blue Color, and the inserted Banknote is

returned.

6. Insert the next Banknote Denomination to be

accepted until all required values have been

processed, set and accepted.

I

NHIBIT SETTING MODE

To establish an “Inhibit” setting function, perform

the following steps:

1. Remove Power from the Taiko™ Unit.

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

3. Re-apply Power to the Taiko™ Unit.

4. Set DIP Switch No.1 to OFF to cause the LED

Display Pattern to emulate “Pattern 1” when

operating.

D

EFINING PATTERN

2

To define a “Pattern 2” (a fading Color Sequence)

operating function, perform the following steps:

1. Remove Power from the Taiko™ Unit.

2. Set DIP Switch No.1, No.3 and No.7 to ON

(

See Figure 2-15).

3. Re-apply power to the Taiko™ Unit.

4. Set DIP Switch No.1 to OFF to cause the LED

Display Pattern to emulate “Pattern 2” when

operating.

Page 29

2-5

Installation Taiko™ Series Banknote Acceptor Section 2

Figure 2-16 Encryption Mode DIP Switch Settings

ON

Figure 2-17 ID-003/MDB/Pulse Interface

Connector

Internal 10-Pin S10B-PADSS-1 (JST)

Figure 2-18 ID-001 Interface Connector

Internal 16-Pin S16B-PADSS-1 (JST)

Encryption Code Initialization Setting Mode

When using the ccTalk Communication Mode (e.g.,

The Encryption Mode) and the Encryption Code is

unknown, set the Encryption Code Initialization

Setting to start the Encryption Code in order to

identify the last 6 Digits of the specific Taiko™

Serial Number located on the back side of a

Taiko™ Unit.

To set the “Encryption Mode” operating function,

perform the following steps:

1. Remove Power from the Taiko™ Unit.

2. Set DIP Switch No.1 through No.6 to ON, and

Switches No.7 and No.8 to

OFF (See Figure 2-

16).

3. Re-apply Power to the Taiko™ Unit.

4. Set DIP Switch No.1 to OFF to initialize the

Encryption Code setting.

The Taiko™ installation DIP Switch settings are

now complete.

Error Codes & Conditions

Table 2 -4 lists the Red Error Code flash sequence

definitions displayed by the Taiko™ Front Panel

LED indicator.

Table 2-4 Red LED Error Code Flash Definitions

Red

Flashes

2

ROM Error

3 Banknote Jam inside Ejection Slot

4 Banknote remains inside on the Transport Path

5 EEPROM Read/Write Error

6 Motor Error

8 Entrance Solenoid Error

9 Exit Solenoid Error

12 Sensor Operation with Abnormal Timing

Interface Connector Pin

Error Indicated

Assignments

Table 2 -5, Table 2-6, Table 2-7 and Table 2-8 list

the various Connector Pin Labels for adapting these

available Communication Standards to the Unit.

Table 2-5 Serial ID-003/MDB Interface Pin

Assignments

Pin No.

*. I/O (Input/Output) is the function viewed from the Banknote Acceptor

Side.

†. 24V DC is available only when the optional 24V DC Specification is

used.

Signal

Name

1 NC - No Connection

2 NC - No Connection

3 RXD-

4 RXD+

5 TXD-

6 TXD+

7 Vcc - +12V DC Power (7-Pin)

8 Vss - Power Ground

9 Vcc -

10 NC - No Connection

*

I/O

Data Receive Line

IN

(Active when current is present)

Data Send Line

OUT

(Active when current is present)

+24V DC Power (9-Pin)

Function

†

Table 2-6 ccTalk Interface Pin Assignments

Pin No.

*. I/O (Input/Output) is the function viewed from the Banknote Acceptor

Side.

†. 24V DC is available only when the optional 24V DC Specification is

used.

Signal

Name

1 ccTalk IN/OUT ccTalk Send/Receive Line

2 ccTalk - ccTalk GND Line

3 NC - No Connection

4 NC - No Connection

5 NC - No Connection

6 NC - No Connection

7 Vcc - +12V DC Power (7-Pin)

8 Vss - Power Ground

9 Vcc -

10 NC - No Connection

*

I/O

+24V DC Power (9-Pin)

Function

†

Table 2-7 Pulse Interface Pin Assignments

Pin No.

*. I/O (Input/Output) is the function viewed from the Banknote Acceptor

Side.

†. 24V DC is available only when the optional 24V DC Specification is

used.

Signal

Name

1

2 NC - No Connection

3

4

5 Vend (-)

6 Vend (+)

7 Vcc - +12V DC Power (7-Pin)

8 Vss - Power Ground

9 Vcc -

10 NC - No Connection

NC

Enable/

Disable (-)

Enable/

Disable (+)

*

I/O

-

No Connection

Enable/Disable Signal Input Line

IN

(Enabled when current is present)

(Disabled when current is present)

No Connection

Pulse Signal Output Line

OUT

(Active when current is present)

+24V DC Power (9-Pin)

Function

†

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 30

2-6

Section 2 Taiko™ Series Banknote Acceptor Installation

Caution: Do not use Alcohol, thinner or

citrus based products for cleaning any

surfaces. The Lenses can become

clouded by chemical effect that may

cause acceptance errors.

Figure 2-19 Sensor Cleaning

Lens

Roller

Lint-free Cloth Cotton Swab Air

Before

Cleaning

After

Cleaning

Belt

Figure 2-20 JCM Waffletechnology Cleaning Card

New Cleaning Card

Cleaning Card Pouch

Table 2-8 Parallel ID-001 Interface Pin

Assignments

Pin No.

*. I/O (Input/Output) is the function viewed from the Banknote Acceptor

Side.

Signal

Name

1 Vcc - +12V DC Power

2 Vss - +12V DC Power Ground

3 Vss - Power Supply Ground

4 NC - No Connection

5 ACK

6 REJ REJect Signal Receive Line

7 INH INHibit Signal Receive Line

8 VAL ID

9 VEND1 VEND1 Valid Send Signal Line

10 VEND2 VEND2 Valid Send Signal Line

11 VEND3 VEND3 Valid Send Signal Line

12 NC - No Connection

13 NC - No Connection

14 BUSY

15 ABN ABortNote Signal Line

16 STKF STacKerFull Signal Line

*

I/O

ACKnowledge Signal Receive Line

IN

Vend VALID Send Signal Line

OUT

BUSY Signal Send Line

OUT

Function

Cleaning Procedures

To clean the Taiko™ Unit, gently rub the Sensors

and Rollers clean using a dry, soft, lint-free cloth

ONLY.

Do not use any Alcohol, solvents, Citrus based

products or scouring agents that may cause damage

to the Validation Section Sensors and/or Rollers.

Sensor and Roller Cleaning Procedure

To clean the Taiko™ Unit, proceed as follows:

1. Turn the Taiko™ Unit and Host Machine’s Power

Supply’s OFF.

2. Open the Taiko™ Upper Guide Lid.

3. Clean the appropriate path and Lens of each

Sensor (See Figure 2-21 areas “a” through “k”

and the corresponding descriptions listed in Table

2-9 to locate each Sensor that require cleaning).

Available Cleaning Card

A JCM Waffletechnology Bill Validator Cleaning

Card is now available (JCM Part No. 501-000252R,

Manufacturer’s Part No. KWJCM-B5B15M). The

Cleaning Card is designed to be used as a supple

mental part of a Preventive Maintenance program

to help in reducing dirt and Paper dust build-up

within a Unit. This will optimize performance

between regular Preventive Maintenance intervals.

This is the only cleaning card authorized for use on

the Taiko (PUB-7/11) Validator (

See Figure 2-20).

Card Features

• A unique Waffletechnology design that hugs all

surfaces to insure complete surface cleaning

• Specially designed scrubber patterns insure

that belts and O-ring Rollers are cleaned and

lubricated to prevent them from drying out.

Directions For Use

1. Remove Cleaning Card from pouch and insert it

into the Banknote Validator.

2. The Cleaning Card will be accepted and then

automatically returned.

3. Dispose of used Card in an environmentally safe

manner.

For more information and a list of Authorized

Waffletechnology Distributers visit:

http://www.jcmwaffletechnology.com.

-

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 31

2-7

Installation Taiko™ Series Banknote Acceptor Section 2

Taiko Sensor and Roller Locations

Figure 2-21 illustrated the various Taiko Sensor cleaning locations, and Table 2-9 respectively lists the

Taiko Sensor Type Cleaning Methods.

Figure 2-21 Taiko Sensor Cleaning Locations

Dummy Head

b

c

d

g

d

e

b

f

e

j

h

a

a

i

Magnetic

Head Roller

k

g

Table 2-9 Taiko Sensor Type Cleaning Methods

Sym. Sensor Type Cleaning Method

a

b Validation Sensor

c Entrance Flapper Sensor

d Entrance Sensor

e Side Sensor Prism

f Upper Transport Sensor

g Entrance Sensor Prism

h Bend Lever Sensor

i Upper Transport Sensor Prism

j Lower Transport Sensor

k Lower Transport Sensor Prism

*. Wipe and clean all of the Rollers and Green Belts shown in Figure 2-21 using a soft lint-free Cloth.

Side Sensor

Operational Check

Once the Taiko™ Unit is installed, perform the

following steps to ensure the Taiko™ Unit is in its

normal Operational Mode:

Wipe clean using a lint free cloth or blow clean using

Compressed Air.

1. Remove Power and perform Test No.5 “Acceptance Test Procedure” on page 6-9 of Section 6 in

this Service Manual.

2. Return the DIP Switches to their pre-Test Operational Mode positions, and re-apply Power to the

Taiko™ Unit.

*

P/N 960-100175R_Rev. 4 {EDP #200824} © 2013, Japan CashMachine Co., Limited

Page 32

2-8

Section 2 Taiko™ Series Banknote Acceptor Installation

THIS PAGE INTENTIONALLY LEFT BLANK