Page 1

Service Manual

Issue: 06/2008

4045-SME-000E

Page 2

TAIKO Service Manual

Preface

Preface

Thank you for purchasing JCM’s TAIKO Bill Acceptor. Please be sure to read the following and any related documents thoroughly to understand the correct operation and features

of this unit.

Note

1. It is forbidden to copy the contents of this manual, in whole or in part, except for the

user’s personal use, without the express permission of Japan Cash Machine Co., Ltd.

2. The information provided in this manual is subject to change without notice.

3. This manual has been written with care and attention to detail; however, should you

find any errors or omissions, please contact Japan Cash machine Co., Ltd. and inform

them of you findings.

4. Please be aware that Japan Cash Machine shall not be held liable by the user for any

damages, losses or third party claims arising from any uses of this product.

5. All Company/Manufacturer names used in this manual are the registered trademarks of

those companies.

Precautions

Machine Design

- We take all possible measures to ensure the quality of this unit. However, performance

degradation or possible short or open circuit faults could occur at the end of a

product’s life. Please ensure safety by sufficiently implementing a fail-safe design.

- Allow sufficient space around the unit to facilitate the collection of banknotes and

cleaning of jams.

Installation

- Do not use the acceptor outside of the operation temperature and humidity ranges

specified in this guide.

- Do not use the acceptor in locations that will obstruct the acceptor’s air holes and

cause the unit to become hot.

- Do not use the acceptor in locations with extreme temperature fluctuations.

- Do not use the acceptor in direct sunlight or incandescent lighting (3000 Lx or greater

at a 15 degrees angle or less).

- Do not use or store the acceptor in locations with high levels of dust.

- The acceptor is for indoor use only; do not use it outside.

- Do not use the acceptor in locations where chemical vapor is present.

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

2

Page 3

TAIKO Service Manual

- When using the acceptor in a location where the air is subject to the car exhaust emissions or cigarette smoke, be sure to clean and maintain the unit at regular intervals.

Wiring

- When installing the TAIKO unit or connecting the wiring harness, make sure that the

power harness from the power terminal.

- When connecting the wiring harness to the TAIKO unit, be sure to confirm the rated

voltage and pin assignments. Failure to do so may result in damage to the unit.

- Be sure to connect the power harness properly. Failure to do so may result in incorrect

input/output due to contact failure.

- Do not pull on the power harness with undue force, as that may cause the harness to

break.

Operation

Preface

- Be sure to turn off the power to the TAIKO unit when opening the upper and lower

covers. Failure to do so may result in your fingers becoming caught in the moving

roller.

- Be careful not to get your finger caught when closing the upper cover.

- Do not modify the TAIKO unit. Doing so may damage the unit.

- Do not expose the TAIKO unit to strong impacts or drop the unit as doing so may

damage the unit.

- Do not wipe the TAIKO unit, either outside or inside, with thinner or organic solvent.

- Do not allow moisture or liquid to enter the TAIKO unit.

- Do not store the acceptor outside of the specified storage temperature and humidity

ranges.

- The following banknotes might be not accepted properly by the TAIKO unit or may

cause a jam or damage to the unit.

a. Banknotes with stain, wear, tears or excessive wrinkles, or that are wet or damp.

b. Dog-eared or creased banknotes

c. Banknotes with incorrect cut dimensions or printing displacement

d. Banknotes with oil smear of oil or foreign objects

Disposal

- Disposal of this unit should be accomplished in accordance with your country’s regulations for similar types of industrial waste.

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

3

Page 4

Preface

TAIKO Service Manual

Product Configurations

TAIKO unit’s are configured as follows.

[Model] PUB-

A. V

alidation Method 7: Optical/Transparency/Reflection

B. Country Code ISO based 3-digit codes

C. Faceplate Type 0: Withdout faceplate

D. Optional Unit

* [Type] *** - * * * * - **

A B C D E F G

11: Optical/Transparency/Reflection/MAG

1: Acceptable Bill Width Max. 82mm/ Min. 67mm

2: Acceptable

3: Acceptable

5: Acceptable Bill Width 66mm

0: Without optional unit

1: With interface pin assignment conversion harness

(ccTalk-compatible)

Bill Width Max.82mm/ Min. 75mm

Bill Width Max.82mm/ Min. 70mm

2: ID-001 Interface Type (Upper tray for 16PIN connector)

3: Individual

E. Board Type 1: Standard

2: Interface pin assignment (ccT

3: Parallel Interface type

F. Operation Code 0: Standard

G

. Interface X4: SERIAL(ID-003)/MDB/PULSE/ccTalk

01 : ID-001 (parallel)

Example: PUB-7 EUR-1020-X4

Indicates the

Type, Type 1 faceplate, Euro software, no optional unit, interface pin assignment

(ccTalk-compatible) type board, standard operation code, and an Serial(ID-003)/

MDB/Pulse/ccTalk interface.

TAIKO model Bill Acceptor with Optical/Transparency Reflection

alk-compatible)

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

4

Page 5

TAIKO Service Manual

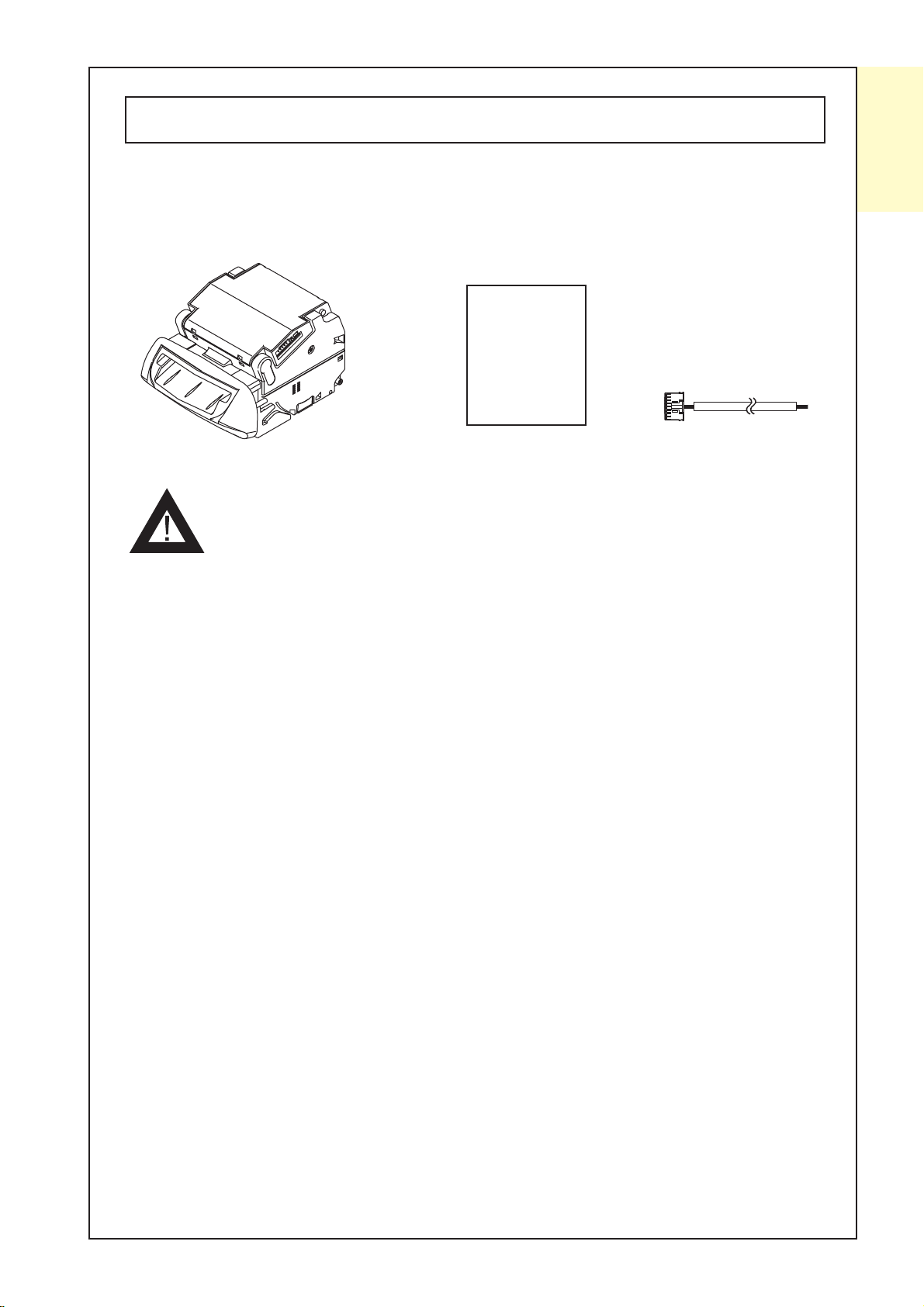

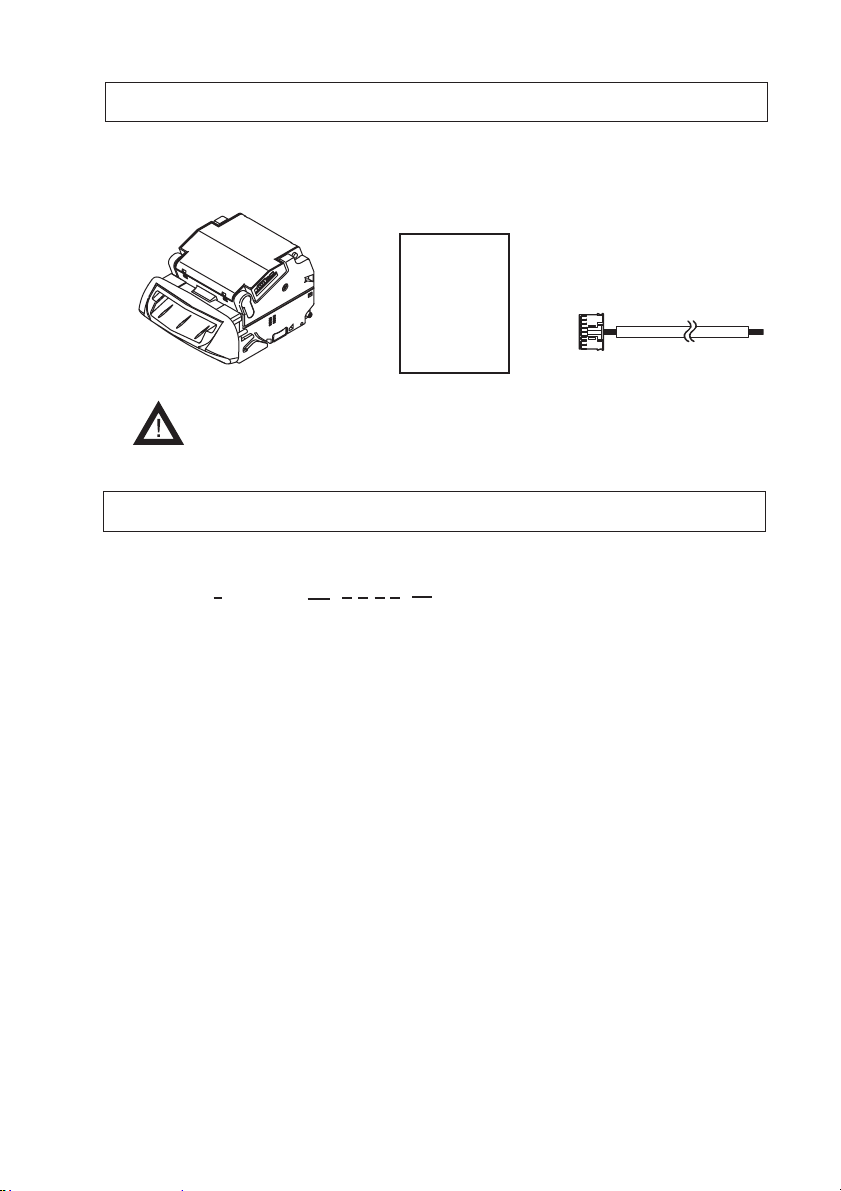

Package Contents

The following items are contained within the TAIKO Package.

Preface

TAIKO unit

- This unit has been carefully packed, with special attention

Installation Guide

ID-001 I/F Harness

(3280-05-100)

* Bandled Item for

TAIKO

Integration

Guide

Parallel Interface

Specification

㪈

taken in regard to quality. However if you happen to find anything damaged of missing, please contact your local distributor immediately.

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

5

Page 6

Preface

TAIKO Service Manual

CE Marking Note

DECLARATION OF CONFORMITY

MANUFACTURER

Name : JAPAN CASH MACHINE CO., LTD.

Address : 3-15, 2-chome, Nishiwaki, Hirano-ku, Osaka, 547-0035 Japan

Phone : +81-6-6703-8405

Fax : +81-6-6704-7843

DETAILS OF PRODUCT : BILL ACCEPTOR

MODEL TYPES : PUB-7, PUB-11

THIS PRODUCT CONFORMS TO THE ESSENTIAL REQURIEMENTS OF :

Electromagnetic Compatibility Directive 89/336/EEC

Amended by 92/31/EEC, 93/68/EEC

Low Voltage Directive 73/23/EEC

Amended by 93/68/EEC

and is supported by the following applicable standards

EN61000-6-1 : 2001

EN61000-4-2 : 1995+A1 : 1998+A2 : 2001

EN61000-4-3 : 2002+A1 : 2002

EN61000-4-8 : 1993+A1 : 2001

EN61000-6-3 : 2001

EN55022 : 1994+A1 : 1995+A2 : 1997(ClassB)

EN60950-1 : 2001+A11 : 2004 First Edition

Authorized signatory on behalf of the responsible person

Name/Signature : Tatsuya Urata/

Date : December 1, 2006

Position : Director and executive officer, general manager manufacturing division

Germany Office

Address : Mundelheimer Weg 60, 40472 Dusseldorf, Germany

Phone : +49-211-530645-0

Fax : +49-211-530645-65

Tatsuya Urata

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

6

Page 7

TAIKO Service Manual

RoHS Compliance

The TAIKO (PUB-7/PUB-11) is a RoHS Compliant products. The following six kind of

hazardous substances restricted by RoHS are NOT contained in the TAIKO unit.

Restricted Hazardous Substances

- Plumbum

- Mercury

- Cadmium

- Chromium Hexavalent

- PBB

- PBDE

Preface

Documentation Conventions

The list below describes the documentation convertions used in this manual.

Icon/Mark Descriptions

This icon indecates important information or procedures that must be

followed for correct and risk-free unit operation.

This icon indicates useful or recommended supplemental

information.

1. 2….

See=>

* This indicates useful or important supplemental inforamation

This indicates steps in a procedure. Be sure to perform these steps

in the order given.

This indicates related information to refer.

- All brand names and product names are trademarks or registered trademarks of their respective companies.

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

7

Page 8

Preface

TAIKO Service Manual

Table of Contents

Preface

Preface ............................................................................................................................. 2

Note .................................................................................................................................. 2

Precautions...................................................................................................................... 2

Product Configurations ................................................................................................. 4

Package Contents ........................................................................................................... 5

CE Marking Note ........................................................................................................... 6

RoHS Compliance .......................................................................................................... 6

Documentation Conventions ......................................................................................... 6

Chapter 1 Introduction

1-1. Main Features.......................................................................................................1-2

1-2. Prior to Use ...........................................................................................................1-3

1-3.Component Names ................................................................................................1-4

1-4. System Configuration

..........................................................................................1-5

1-5. Operation Flowchart............................................................................................ 1-6

Chapter 2 Specifications

2-1. Specifications ........................................................................................................2-2

2-1-1. Basic Technical Specifications ......................................................................................... 2-2

2-1-2. Electrical Specifications ................................................................................................... 2-2

2-1-3. Environmental Specifications.......................................................................................... 2-2

2-1-4. Structural Specifications.................................................................................................. 2-3

2-2. Connector..............................................................................................................2-4

2-2-1. Interface Connector

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk specification ................................................... 2-4

2-2-1-1. Interface Connector Pin Assignments

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk specification .......................................... 2-4

2-2-2. Interface Connector

01: ID-001 (parallel) specification ................................................................................... 2-5

2-2-2-1. Interface Connector Pin Assignments

01: ID-001 (parallel) specification ........................................................................... 2-6

2-3. Interface Circuit ................................................................................................... 2-7

2-3-1. ccTalk Interface Circuit ................................................................................................... 2-7

2-3-2. ID-003 (serial)/ MDB Interface4 Circuit........................................................................ 2-8

2-3-3. Pulse Interface Circuit ..................................................................................................... 2-9

2-3-4. ID-001 (parallel) Interface4 Circuit.............................................................................. 2-10

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

8

Page 9

TAIKO Service Manual

2-4. External Dimensions ..........................................................................................2-11

2-4-1. When installing the Type 1/ Type 2/ Type 3 faceplate with TAIKO unit................... 2-11

2-4-2. When installing the Type 5 faceplate with TAIKO unit ............................................. 2-12

2-5. DIP Switch Setting .............................................................................................2-13

2-5-1. Basic Settings

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk specification ................................................. 2-14

2-5-2. Basic Settings

01 : ID-001 (parallel) specification ................................................................................. 2-14

2-6-3. Special Settings ............................................................................................................... 2-14

Chapter 3 Installation / Operation

3-1. Installation/Removal ............................................................................................ 3-2

3-2. Wiring.................................................................................................................... 3-5

3-2-1. Recommended Parts ........................................................................................................ 3-5

3-2-1-1. Reccomended Parts

X4: ID-003 (serial)/ MDB/ Pulse/ ccT

3-2-1-2. Reccomended Parts

01 : ID-001 (parallel) specification .......................................................................... 3-5

3-2-2. Wiring Procedur

e ............................................................................................................. 3-6

3-3. Clearing Bill JAM ................................................................................................3-7

alk specification .......................................... 3-5

Preface

Chapter 4 Download / Adjustment

4-1. Download .............................................................................................................. 4-2

4-1-1. Requirements .................................................................................................................... 4-2

4-1-2. Connecting Procecedure .................................................................................................. 4-3

4-1-3. Download Procedure........................................................................................................ 4-4

4-1-4. Writing Serial No.............................................................................................................. 4-5

4-2. Adjustment............................................................................................................4-6

4-2-1. Requirements .................................................................................................................... 4-6

4-2-2. Adjustment Procedure ..................................................................................................... 4-6

4-3. Palm....................................................................................................................... 4-8

4-3-1. Requirement...................................................................................................................... 4-8

4-3-2. Installing File Converter (PdbConvEN.exe) .................................................................. 4-8

4-3-3. Converting Software Program....................................................................................... 4-9

4-3-4. Download Procedure...................................................................................................... 4-10

4-4. Cloning ................................................................................................................ 4-11

4-4-1. Required Items ............................................................................................................... 4-11

4-4-2. Cloning Procedures ........................................................................................................ 4-11

Chapter 5 Trouble Shooting / Maintenance

5-1. Error Code............................................................................................................5-2

5-1-1. Error Code ........................................................................................................................ 5-2

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

9

Page 10

Preface

TAIKO Service Manual

5-2. Trouble Shooting .................................................................................................. 5-2

5-2-1. General Troubles .............................................................................................................. 5-2

5-2-2. Adjustment Troubles ........................................................................................................ 5-4

5-2-3. Communication Troubles ................................................................................................ 5-5

5-3. Test Mode (Diagnostics) ....................................................................................... 5-6

5-3-1. DIP Switch Setting List .................................................................................................... 5-6

5-3-2. DIP Switch Test Procedure .............................................................................................. 5-6

5-3-3. Transport Motor Forward Rotation Test Procedure .................................................... 5-6

5-3-4. Transport Motor Reverse Rotation Test Procedure...................................................... 5-7

5-3-5. Aging Procedure ............................................................................................................... 5-7

5-3-6. Solenoid Test Procedure................................................................................................... 5-8

5-3-7. Accepting Test Procedure ................................................................................................ 5-8

5-3-8. Entrance Flapper Test Procedure ................................................................................... 5-9

5-3-9. Exit Flapper Test Procedure........................................................................................... 5-9

5-4. Cleaning .............................................................................................................. 5-10

5-5. Maintenance Tool List ....................................................................................... 5-11

5-6. Wiring Diagram .................................................................................................5-12

5-5-1. PUB-7 Wiring Diagram ................................................................................................. 5-12

5-5-2. PUB-11 Wiring Diagram................................................................................................ 5-13

5-7. Product Support .................................................................................................5-14

Chapter 6 Replacement

6-1. Replacement of Faceplate Guide ........................................................................6-2

6-2. Replacement of CPU Board ................................................................................6-3

6-3. Replacement of MAG Board............................................................................... 6-4

6-4. Replacement of Sensor Board .............................................................................6-5

6-5. Replacement of Encoder Board/Motor Unit...................................................... 6-9

6-6. Replacement of Solenoid ...................................................................................6-10

Chapter 7 Exploded View / Parts List

7-1. Entire Unit & Option ........................................................................................... 7-2

7-1-1. Entire Unit & Option Exploded View ............................................................................ 7-2

7-1-2. Entire Unit & Option Parts List ..................................................................................... 7-3

7-2. TAIKO (PUB-7/PUB-11) Unit ............................................................................. 7-4

7-2-1. TAIKO (PUB-7/PUB-11) Unit Exploded View .............................................................. 7-4

7-2-2. TAIKO (PUB-7/PUB-11) Unit Parts List ....................................................................... 7-5

7-3. Bezal Unit.............................................................................................................. 7-7

7-3-1. Bezel Unit Exploded View................................................................................................ 7-7

7-3-2. Bezel Unit Parts List......................................................................................................... 7-8

10

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

Page 11

Bill Acceptor

Integration Guide

Page 12

Table of Contents

1. Precautions .......................................................................................................................... 4

1-1. Machine Design ........................................................................................................... 4

1-2. Installation ................................................................................................................... 4

1-3. Wiring .......................................................................................................................... 4

1-4. Operation ..................................................................................................................... 4

1-5. Disposal ....................................................................................................................... 4

2. Package Contents ................................................................................................................ 5

3. Product Configurations .......................................................................................................5

4. CE Marking ......................................................................................................................... 6

5. RoHS Compliance ............................................................................................................... 7

6. Names of Parts .................................................................................................................... 7

7. Product Specifications ......................................................................................................... 8

7-1. General Specifications ................................................................................................. 8

7-1-1. Basic Specifications .......................................................................................... 8

7-1-2. Electrical Specifications .................................................................................... 8

7-1-3. Environmental Specifications ............................................................................ 8

7-1-4. Installation Specifications ................................................................................. 9

7-2. Connector ..................................................................................................................... 9

7-2-1. Interface Connector

X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification .................................. 9

7-2-1-1.Interface Connector Pin Assignment

X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification ................................ 10

7-2-2. Interface Connector

01:Parallel(ID-001) Specification ............................................................... 11

7-2-2-1. Interface Connector Pin Assignment

01:Parallel(ID-001) Specification ............................................................... 11

7-3. Interface Circuit ......................................................................................................... 12

7-3-1. ccTalk Interface Circuit ................................................................................... 12

7-3-2. Serial(ID-003)/MDB Interface Circuit ............................................................ 13

7-3-3. Pulse Interface Circuit ..................................................................................... 14

7-3-4. Parallel(ID-001) Interface Circuit .................................................................. 15

7-4. External Dimensions .................................................................................................. 16

7-4-1. External Dimensions when installing Type1/Type2/Type3 Faceplate ............. 16

7-4-2. External Dimensions when installing Type5 Faceplate ................................... 17

7-5. DIP Switch Settings ................................................................................................... 18

7-5-1. Basic Settings

X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification ................................ 18

7-5-1-1. Denomination Setting Mode ....................................................................... 19

7-5-1-2. Encryption Code Initializing Setting Mode ................................................ 19

7-5-2. Basic Settings

01:Parallel(ID-001) Specification .............................................................. 20

7-5-3. LED Pattern Setting Mode ......................................................................... 20

2

Page 13

Table of Contents

8. Installation/Removal .........................................................................................................21

9. Wiring ................................................................................................................................ 24

9-1. Recommended Parts .................................................................................................. 24

9-1-1. Recommended Parts X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification ....... 24

9-1-2. Recommended Parts 01:Parallel(ID-001) Specification ..................................... 24

9-2. Wiring Procedure ....................................................................................................... 25

10. Clearing a Banknote Jam ................................................................................................. 26

11. Error Codes...................................................................................................................... 27

12. Cleaning .......................................................................................................................... 27

13. Product Support ............................................................................................................... 28

3

Page 14

1. Precautions

Thank you for purchasing JCM’s TAIKO Bill Acceptor. Please be sure to read the following and

any related documents thoroughly to understand the correct operation and features of this unit.

1-1. Machine Design

- We take all possible measures to ensure the quality of this unit. However, performance degradation or possible short or open circuit faults could occur at the end of a product’s life. Please

ensure safety by sufficiently implementing a fail-safe design.

- Allow sufficient space around the unit to facilitate the collection of banknotes and the clearing of

jams.

1-2. Installation

- Do not use the acceptor outside of the operation temperature and humidity ranges specified in

this guide.

- Do not use the acceptor in location that will obstruct the acceptor’s air holes and cause the unit to

become hot.

- Do not us the acceptor in locations with extreme temperature fluctuations.

- Do not use the acceptor in direct sunlight or incandescent lighting (3000Lx or greater at a 15degree angle or less).

- Do not use or store the acceptor in location with high levels of dust.

- The acceptor is for indoor use only; do not use it outside.

- Do not use the acceptor in locations where chemical vapor is present.

- When using the acceptor in a location where the air is subject to the car exhaust emissions or

cigarette smoke, be sure to clean and maintain the unit at regular intervals.

1-3. Wiring

- When installing the TAIKO unit or connecting the wiring harness, make sure that the power

harness is unplugged from the power terminal to avoid unit damage.

- When connecting the wiring harness to TAIKO unit, be sure to confirm the rated voltage and pin

assignments. Failure to do so may result in damage to the unit.

- Be sure to connect the power harness properly. Failure to do so may result in incorrect input/

output due to contact failure.

- Do not pull on the power harness with undue force, as that may cause the harness to break.

1-4. Operation

- Be sure to turn off the power to the TAIKO unit when opening the upper and lower lid. Failure to

do so may result in your fingers becoming caught in the moving roller.

- Be careful not to get your finger caught when closing the upper lid.

- Do not modify the TAIKO unit. Doing so may damage the unit.

- Do not expose the TAIKO unit to strong impacts or drop the unit as doing so may damage the

unit.

- Do not wipe the TAIKO unit, either outside or inside, with thinner or organic solvent.

- Do not allow moisture or liquid to enter the TAIKO unit.

- Do not store the acceptor outside of the specified storage temperature and humidity ranges.

- The following banknotes might be not accepted properly by TAIKO unit or may cause a jam or

damage to the unit.

a. Banknotes with stains, wear, tears or excessive wrinkles, or that are wet or damp.

b. Dog-eared or creased banknotes

c. Banknotes with incorrect cut dimensions or printing displacement

d. Banknotes with oil smears or foreign objects

1-5. Disposal

- Disposal of this unit should be accomplished in accordance with your country’s regulations for

similar types of industrial waste.

4

Page 15

2. Package Contents

The following items are contained within the TAIKO packaging.

TAIKO unit

* The item is packaged

for Parallel Interface

Specification only.

- This unit has been carefully packed, with special attention taken in re-

gard to quality. However if you happen to find anything damaged or

missing, please contact your local distributor immediately.

Installation Guide

<This guide> (3280-05-100)

Installation

Guide

ID-001 I/F Harness

㪈

3. Product Configurations

TAIKO units are configured as follows.

[Model] PUB-* [Type] *** - * * * * - **

A B C D E F G

A.Validation Method 7: Optical/Transparency/Reflection

11: Optical/Transparency/Reflection/MAG

B. Country Code ISO 3166 based 3-digit codes

C. Faceplate Type 0: Without faceplate

1: Bill Width Min.68mm/Max.82mm

2: Bill Width Min.76mm/Max.82mm

3: Bill Width Min.70mm/Max.82mm

5: Bill Width 66mm

D. Optional Unit 0: Without optional unit

1: With interface pin assignment conversion adapter harness

(ccTalk-compatible)

2:Parallel(ID-001) Interface Type (Upper Tray dedicated 16PIN

connecter)

3:Individual Specification

E. Board Type 1: Standard

2: Interface pin assignment (ccTalk compatible)

3:Parallel Interface Type

F. Operation Code 0: Standard

1:Individual Specification

G. Interface X4: Serial(ID-003)/MDB/Pulse/ccTalk

01:Parallel(ID-001)

5

Page 16

Example: PUB-7 EUR-1020-X4

Indicates the TAIKO model with optical/transparency/reflection validation method,

faceplate type 1, euro software, no optional unit, interface pin assignment (ccTalk

compatible) type board, standard operation code and an Serial(ID-003)/MDB/Pulse/

ccTlak interface.

4. CE Marking

DECLARATION OF CONFORMITY

MANUFACTURER

Name : JAPAN CASH MACHINE CO., LTD.

Address : 3-15, 2-chome, Nishiwaki, Hirano-ku, Osaka, 547-0035 Japan

Phone : +81-6-6703-8405

Fax : +81-6-6704-7843

DETAILS OF PRODUCT : BILL ACCEPTOR

MODEL TYPES : PUB-7, PUB-11

THIS PRODUCT CONFORMS TO THE ESSENTIAL REQURIEMENTS OF :

Electromagnetic Compatibility Directive 89/336/EEC

Amended by 92/31/EEC, 93/68/EEC

Low Voltage Directive 73/23/EEC

Amended by 93/68/EEC

and is supported by the following applicable standards

EN61000-6-1 : 2001

EN61000-4-2 : 1995+A1 : 1998+A2 : 2001

EN61000-4-3 : 2002+A1 : 2002

EN61000-4-8 : 1993+A1 : 2001

EN61000-6-3 : 2001

EN55022 : 1994+A1 : 1995+A2 : 1997(ClassB)

EN60950-1 : 2001+A11 : 2004 First Edition

Authorized signatory on behalf of the responsible person

Name/Signature: Tatsuya Urata/

Date : December 1, 2006

Position : Director and executive officer, general manager manufacturing division

Germany Office

Address : Mundelheimer Weg 60, 40472 Dusseldorf, Germany

Phone : +49-211-530645-0

Fax : +49-211-530645-65

Tatsuya Urata

6

Page 17

5. RoHS Compliance

The TAIKO unit is a RoHS Compliant products. The following six kind of hazardous substances

fulfil the safety limit of the standard restricted by RoHS compliance.

Restricted Hazardous Substances

- Plumbum

- Mercury

- Cadmium

-Hexavalent Chromium

- PBB

- PBDE

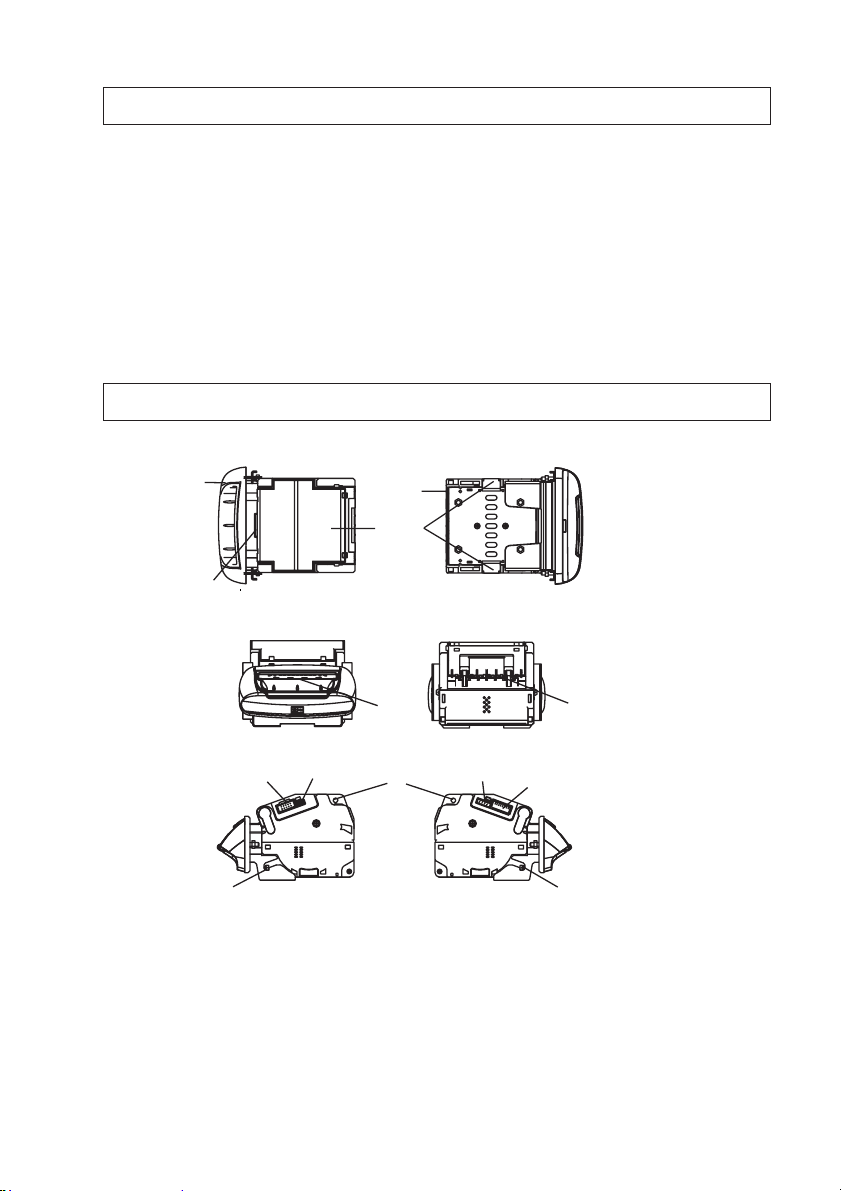

6. Names of Parts

The name of parts for the TAIKO unit are as follows.

A

B

Top

Front

I

H

J

Right

D

C

E

Bottom

F

Rear

K

L

Left

G

M

J

A. Faceplate B. LED lamp

C. Upper lid D. Lower lid

E. Lower lid lock release button F. Bill insertion slot

G. Bill ejection slot H. Interface connector

I. Maintenance connector J. Faceplate installation guide pin

K. Upper lid open/close button L. Optional connector(No Optional Connector for

M. DIP switches Parallel(ID-001) Interface Specification.)

7

Page 18

7. Product Specifications

7-1. General Specifications

7-1-1. Basic Specifications

Acceptable Banknote Size

Insertion Direction *1 4-way

Acceptance Rate *1 95% or higher

Validation Method

Anti-fishing Mechanism Lever and optical sensor combination

Interface

Escrow 1 banknote

LED

*1 May differ depending on the software for your country. For details, refer to the

Software Information Sheet.

*2 Can be selected using the DIP switches. => 7-5-1.Refer to DIP switch settings.

(No DIP switch settings for Parallel(ID-001) Interface Specification.)

7-1-2. Electrical Specifications

Power Supply Voltage 12V ±5% DC

Rated Power Consumption

7-1-3. Environmental Specifications

Operat ion T emperature *1 5oC t o 50oC

Storage Temperat ure -20

Operation Humidity *1 20%RH to 85%RH (No condensation)

Storage Humidity 20%RH to 85%RH (No condensation)

Li gh t Dist urban c e

Installation For indoor use only

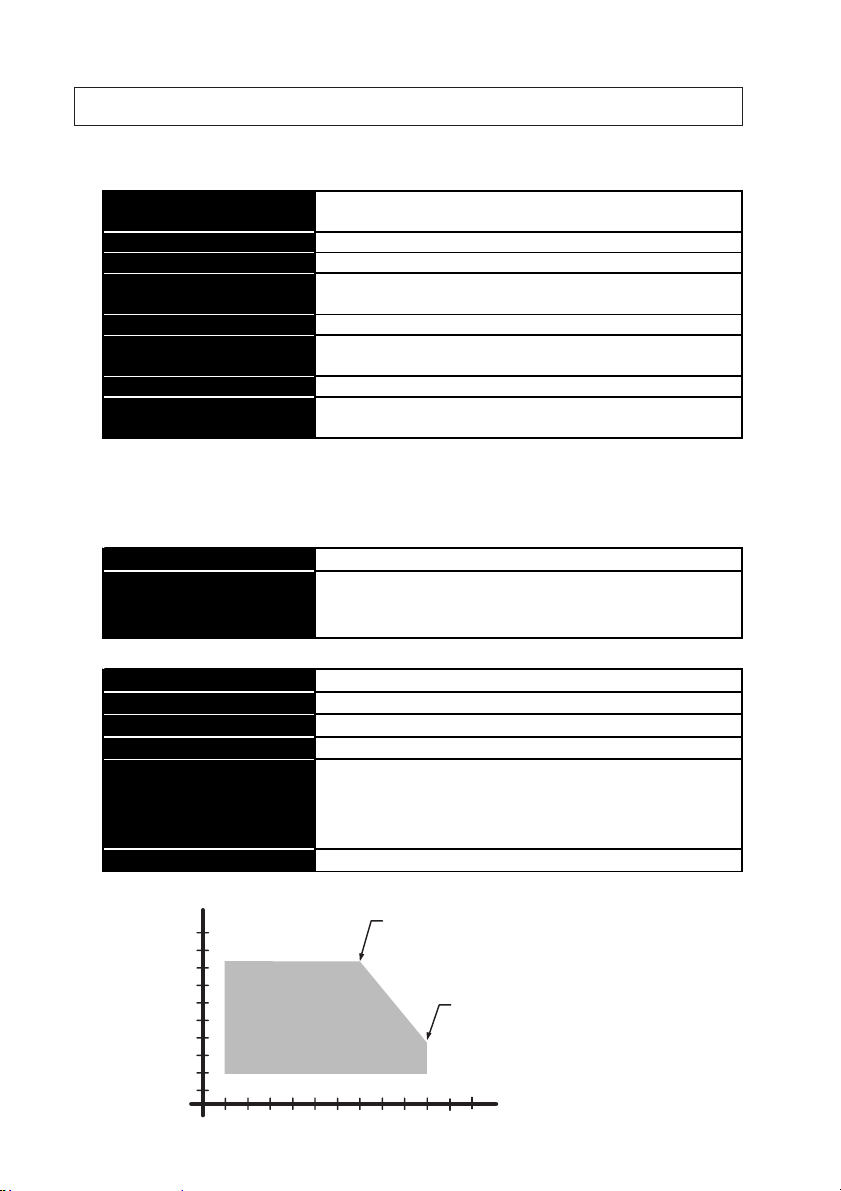

*1 The overall operation temperature and humidity range is as follows.

(RH%)

100

90

80

70

60

50

40

30

20

10

0

Ambient temperature

humidity range

0 5 10 15 20 25 30 35 40 45 50 55 60 (

Length: 120 mm to 160 mm

Width: 62 mm to 82 mm

PUB-7: Optical/T ransparency/Reflection

PUB-11: Opt ical/Transparency/Reflection/MAG

X4:Serial(ID-003)/MDB/Pulse/ccTalk *2

01:Parallel(ID-001)

LED lamp (upper portion of faceplate)

Full-color lightning (gradation/solid)

Standby: Approx. 0.1 A

Operation: Approx. 0.8 A

Max.: Approx. 1.4 A (Max. 300 ms)

o

C t o 60oC

Avoid direct sunlight

Interior lighting must be incandescent lamp

Angle: 15 degrees or more

Illumination: 3000Lx or less

35oC / 85RH%

o

50

C / 40RH%

o

C)

8

Page 19

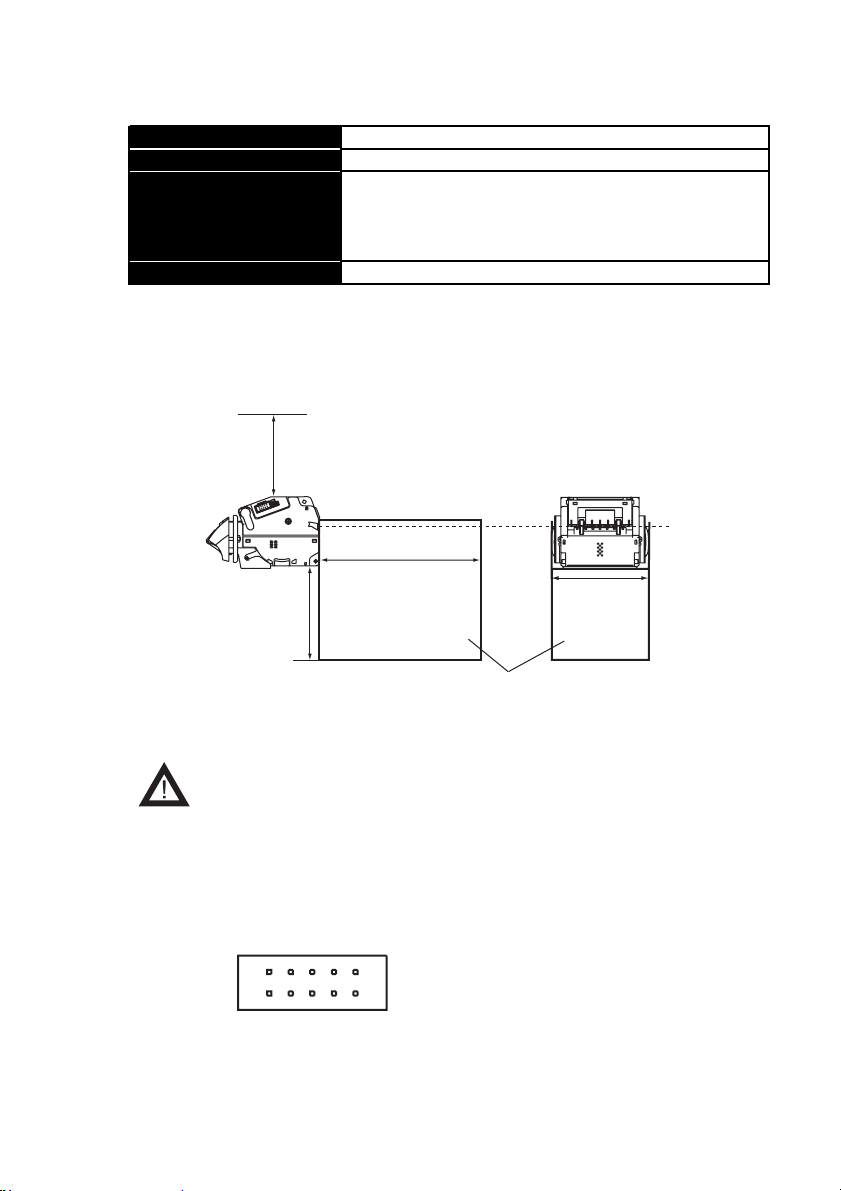

7-1-4. Installation Specifications

t

Mounting *1 Door and Horizontal Mounting (No vibration)

Weight Approx. 0.6 kg

When inst alling Type 1/2/3 faceplate:

External Dimensions

124mm (W) x 88mm (H) x 145.2mm (D)

When inst alling Type 5 faceplate:

124mm (W) x 88mm (H) x 143mm(D)

Cashbox *2 Supplied by t he customer

*1 Allow 100 mm above the unit to open the lid for removal of the unit from the

faceplate

*2 The cashbox must be 100 mm or more in depth from the bottom of the TAIKO

unit, 200 mm or more in depth from the rear of the unit and 100 mm or more in

width. Both sides of the cashbox must be higher than the position of the bill

ejection slot.

100 mm or more

Depth from rear of unit

200 mm or more

Width

Depth from bottom of unit

100 mm or more

100 mm or more

Position of

bill ejection slo

Side

Cashbox

Rear

7-2. Connector

- If a relay board is attached to the TAIKO unit, do not attempt to re-

move it.

7-2-1. Interface Connector

X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification

The following diagram is the interface connector as viewed from the acceptor side or from a

relay board.

9

Box Type Plug

XG4C-1034 (Omron)

10

1

2

9

Page 20

7-2-1-1. Interface Connector Pin Assignment

X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification

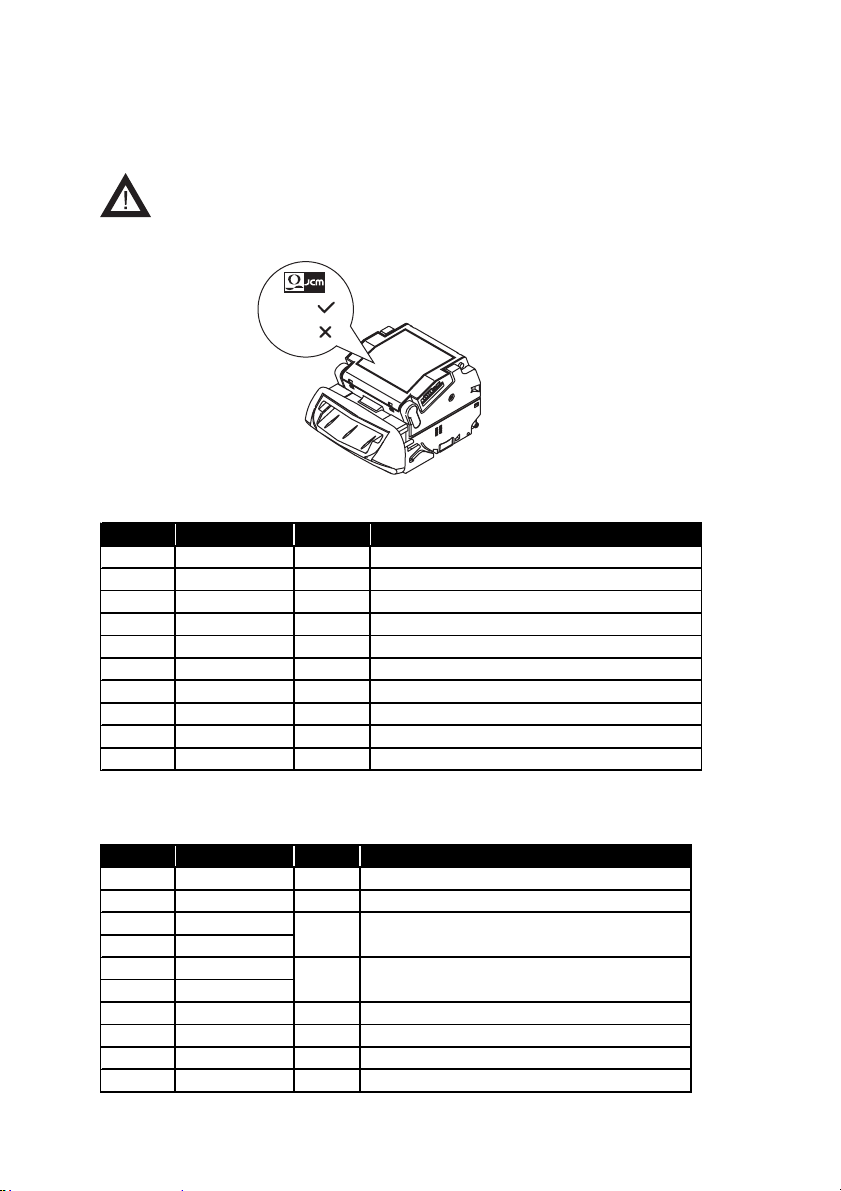

- The following pin assignment is for TAIKO units with a blue JCM logo

label. If the logo is black, the pin assignment may differ. For details,

contact JCM.

Blue

Black

ccTalk Communication

Pin No. Signal Name I/O *1 Function

1 ccTalk+ IN/OUT ccTalk Send/Receive Line

2 NC - Not Connected

3 NC - Not Connected

4 NC - Not Connected

5 NC - Not Connected

6 NC - Not Connected

7 VCC - 12V DC Power Supply

8 VSS - Power Supply GND

9 NC - Not Connected

10 NC - Not Connected

*1 Conditions for the I/O (Input/Output) column are from the acceptor side.

Serial(ID-003)/MDB Communication

Pin No. Signal Name I/O *1 Function

1 NC - Not Connected

2 NC - Not Connected

3 RXD4RXD+

5 T XD6TXD+

7 VCC - 12V DC Power Supply

8 VSS - P o wer Sup p ly GN D

9 NC - Not Connected

10 NC - Not Connected

*1 Conditions for the I/O (Input/Output) column are from the acceptor side.

Data Receive Line

IN

(Active when current is applied)

Data Send Line

OUT

(Active when current is applied)

10

Page 21

Pulse Communication

Pin No. Signal Name I/O *1 Function

1 NC - Not Connected

2 NC - Not Connected

3

4

5 VEND(-)

6VEND(+)

ENABLE/

DISABLE (-)

ENABLE/

DISABLE (+)

Enable/Disable Signal Input Line

IN

(Enable when the current is applied.

Disable when the current is NOT

Pulse Signal Outp ut Line

OUT

(Active when the current is applied.)

applied.)

7 VCC - 12V DC Power Supply

8 VSS - Power Supply GND

9 NC - Not Connected

10 NC - Not Connected

*1 Conditions for the I/O (Input/Output) column are from the acceptor side.

7-2-2. Interface Connector

01:Parallel(ID-001) Specification

The following diagram is the interface connector as viewed from the acceptor side or from a

relay board.

16PIN Connector

S16B-PADSS-1 (JST)

7-2-2-1.Interface Connector Pin Assignment

01:Parallel(ID-001) Specification

Pin No. Signal Name I/O *1 Function

1VCC-12V DC Power Supply

2VCC-12V DC Power Supply

3 VSS - Power Supply GND

4 NC - Not Connected

5 ACK ACK Receiv e Line

6 REJ REJ Receive L in e

IN

7 INH INH Receive Line

8 VALID VALID Send Line

9 VEND1 VEND1 Send Line

10 VEND2 VEND2 Send Line

OUT

11 VEND3 VEND3 Send Line

12 NC - Not Connected

13 NC - Not Connected

1 4 BU SY BU SY Se n d L i n e

15 ABN ABN Send Line

OUT

16 STKF STKF Send Line

*1 Conditions for the I/O (Input/Output) column are from the acceptor side.

11

Page 22

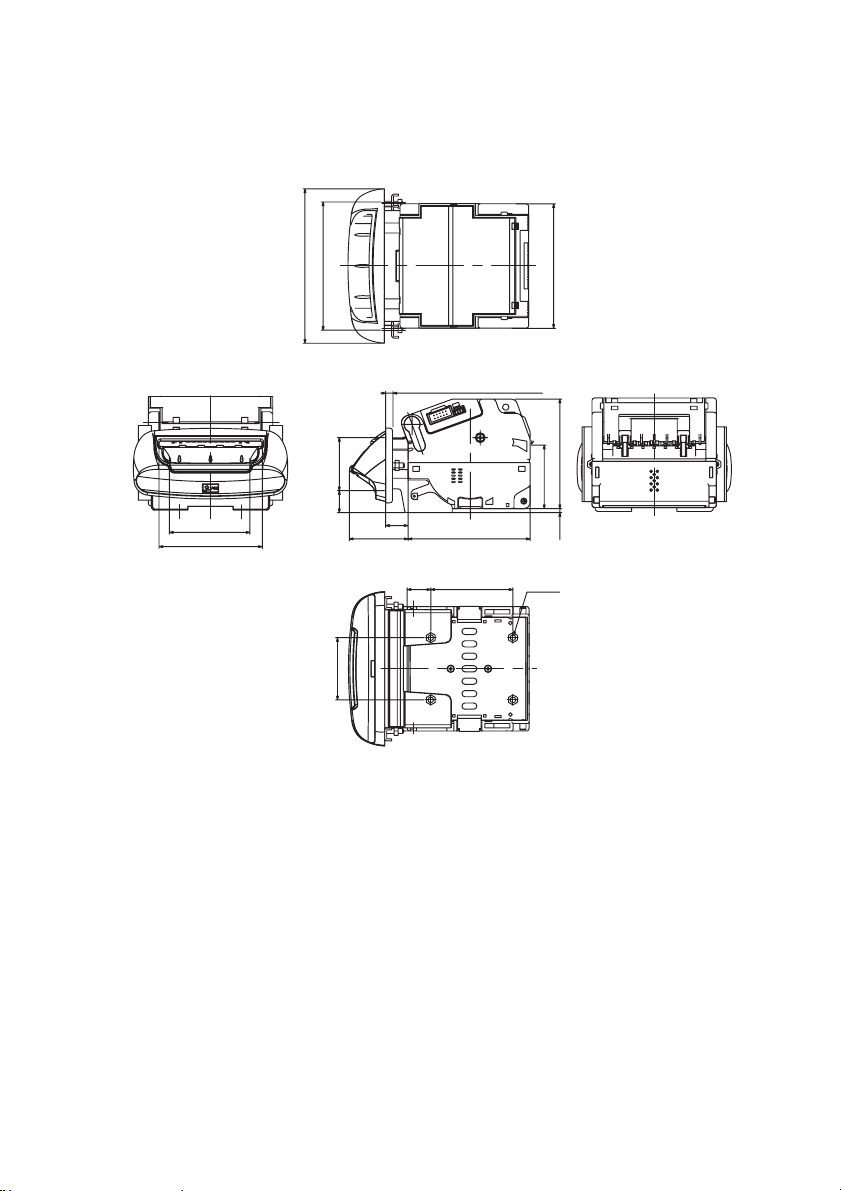

7-4. External Dimensions

7-4-1. External Dimensions when installing Type1/Type2/Type3 Faceplate

Unit:mm

A*

83

(Max. Bill Width 82)

Front Rear

* The length of A differs depending

on the faceplate type.

Type1: 68(Min. Bill Width 67)

Type2: 76(Min. Bill Width 75)

Type3: 71(Min. Bill Width 70)

124

103 (Door Installation Position)

2 to 6mm (Panel Thickness)

42.7 (Door Installation Position)

17.6

18

50

Top

Right Side

19 66

Bottom

100

88

(Bill Ejection Position)

51

9847.2

3.2

4-M4

16

Page 23

7-4-2. External Dimensions when installing Type5 Faceplate

Unit:mm

125

103

(Door Installation Position)

Top

‚2㨪6mm(Panel Thickness)

38.3

(Door Installation Position)

25.4

67

(Acceptable Bill Width 66)

Front Rear

45 98

30

20

Right Side

11.4

39.6

Bottom

100

51(Bill Ejection Position)

88

3

17

Page 24

7-5. DIP Switch Settings

The communication method and various functions of the TAIKO unit can be set with the DIP

switches on the left side of the unit.

ON

87654321

Left Side

7-5-1. Basic Settings X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification

SW#

1 Test Mode * 1 Normal Mode

2 Double-Scan Mode *2 Normal Mode

3

4 Fiv e (5) drum cycle (fish ing p reventi on) *3 No rmal operat io n

5

6

7

8

678

OFF OFF OFF

ON OFF OFF

OFF O N OFF ccTalk (No t Encry pted)

ON ON O FF ccTalk (En crypted )

--ON Pulse *4

ON OFF

Refer to the Software Specification s

SW#

*1 For details about the TEST mode, refer to the TAIKO Service Manual.

*2 The acceptance rate will be improved but operation time will be increased if a

banknote is rejected.

*3 Fishing prevention will be improved but operation time will be increased.

*4 For details on the Pulse I/F, refer to the Software Information Sheet.

Setting Item

Reserved

I/F Setting

ID-00 3

MDB

18

Page 25

7-5-1-1. Denomination Setting Mode(Denomination Setting Mode is available for only

Serial(ID-003)/MDB/Pulse/ccTalk Specification Interface Specification. When using

Parallel(ID-001) Interface Specification, DIP switches should be used in order to configure

the accept/inhibit setting.(Ref. 7-5-2))

Perform the accept/Inhibit Setting of the banknote denomination based on the software for your

country. The default settings are to accept all denomination.

Accept Setting

ON

87654321

To perform the accept setting, set DIP switch Nos.1 and 6 to ON and then turn on the power to the

TAIKO unit. After the LED flashes white, set DIP switch No.1 to OFF to enter the setting mode.

Insert the denomination of banknote that you want accepted into the insertion slot. The setting is

registered if the LED remains lit light blue and the banknote is returned. Insert the next denomina-

tion of banknote that you want to be accepted.

Inhibit Setting

ON

87654321

To perform the inhibit setting, set DIP switch Nos.1, 6 and 7 to ON and then turn on the power to

the TAIKO unit. After the LED flashes white, set DIP Switch No.1 to OFF to enter the setting

mode. Insert the denomination of banknote that you want inhibited into the insertion slot. The

setting is registered if the LED remains lit orange and the banknote is returned. Insert the next

denomination of banknote that you want inhibited.

- The accept/inhibit setting for banknote denominations can be

confirmed with the LED lamp.

After the initial operation is performed, the LED will flash a number

of times equal to the total number of banknote denominations. Blue

indicates an accept setting and yellow means a inhibit setting.

Example: If 5, 10 and 20 Euro notes are set to be accepted and 50

and 100 euro notes to be inhibited, the LED will flash the

corresponding 5 times as follows: blue, blue, blue, yellow

and yellow.

7-5-1-2. Encryption Code Initializing Setting Mode(This Mode is for only ccTalk

Specification.)

When using ccTalk Communication (Encryption) Mode and the encryption code is unknown,

perform the Encryption Code Initializing Setting to initialize the Encryption Code to the last 6

digits of the TAIKO serial number.

ON

87654321

Set DIP switch Nos. 1 to 6 to ON (Set DIP switch Nos. 7 and 8 to OFF) and then supply the power

to the TAIKO unit. Set DIP switch No. 1 to OFF to initialize the encryption code.

19

Page 26

7-5-2. Basic Settings 01:Parallel(ID-001) Specification

SW#

1 Test Mode * 1 Normal Mode

2

3 Double-Scan Mode *2 Normal Mode

4 Five (5) drum cycle (fishing prevention) *3 Normal operation

5 Inh ib it Settin g * 4 Accep t Set ti ng *4

6 Inh ib it Settin g * 4 Accep t Set ti ng *4

7 Inh ib it Settin g * 4 Accep t Set ti ng *4

8 Inh ib it Settin g * 4 Accep t Set ti ng *4

ON OFF

Escrow Mode No Escrow Mode

Setting Item

*1 For details about the TEST mode, refer to the TAIKO Service Manual.

*2 The acceptance rate will be improved but operation time will be increased if a

banknote is rejected.

*3 Fishing prevention will be improved but operation time will be increased.

*4 For details of the accept/inhibit setting, refer to the Software Information Sheet.

7-5-3. LED Pattern Setting Mode

The LED pattern can be changed according to your preference. Select between pattern 1 and

pattern 2. The default setting is pattern 1.

Define Pattern 1

ON

87654321

Set DIP switch Nos.1, 2 and 7 to ON and then turn the power to the TAIKO unit. Set DIP switch

No.1 to OFF to set the LED pattern to pattern 1.

Define Pattern 2

ON

87654321

Set DIP switch Nos.1, 3 and 7 to ON and then turn on the power to the TAIKO unit. Set DIP

switch No.1 to OFF to set the LED pattern to pattern 2.

20

Page 27

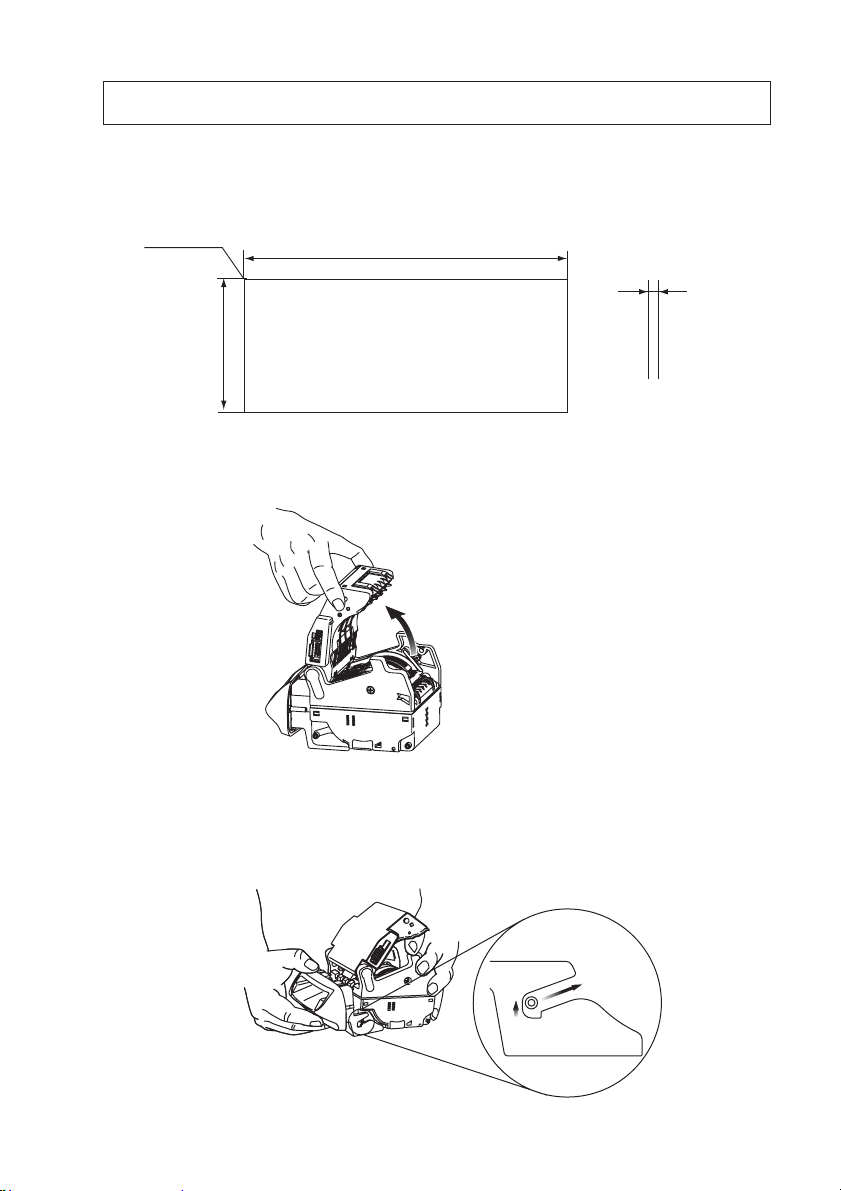

8. Installation/Removal

Perform the following procedure when installing the TAIKO unit.

1. Use the panel cutting dimensions given below and create the correct size of opening required for

installing the TAIKO unit to the door.

4-R3 (Max)

43 mm

2. Hold in the upper lid open/close buttons on both sides of the TAIKO unit and open the upper lid

in the direction of the arrow.

105 mm

Panel Thickness

2 mm to 6 mm

3. Grasp the TAIKO unit with your hand under the upper lid.

4. Press down slightly on the faceplate and raise up on the TAIKO unit. Slide the TAIKO unit up

and back to detach it from the faceplate.

21

Page 28

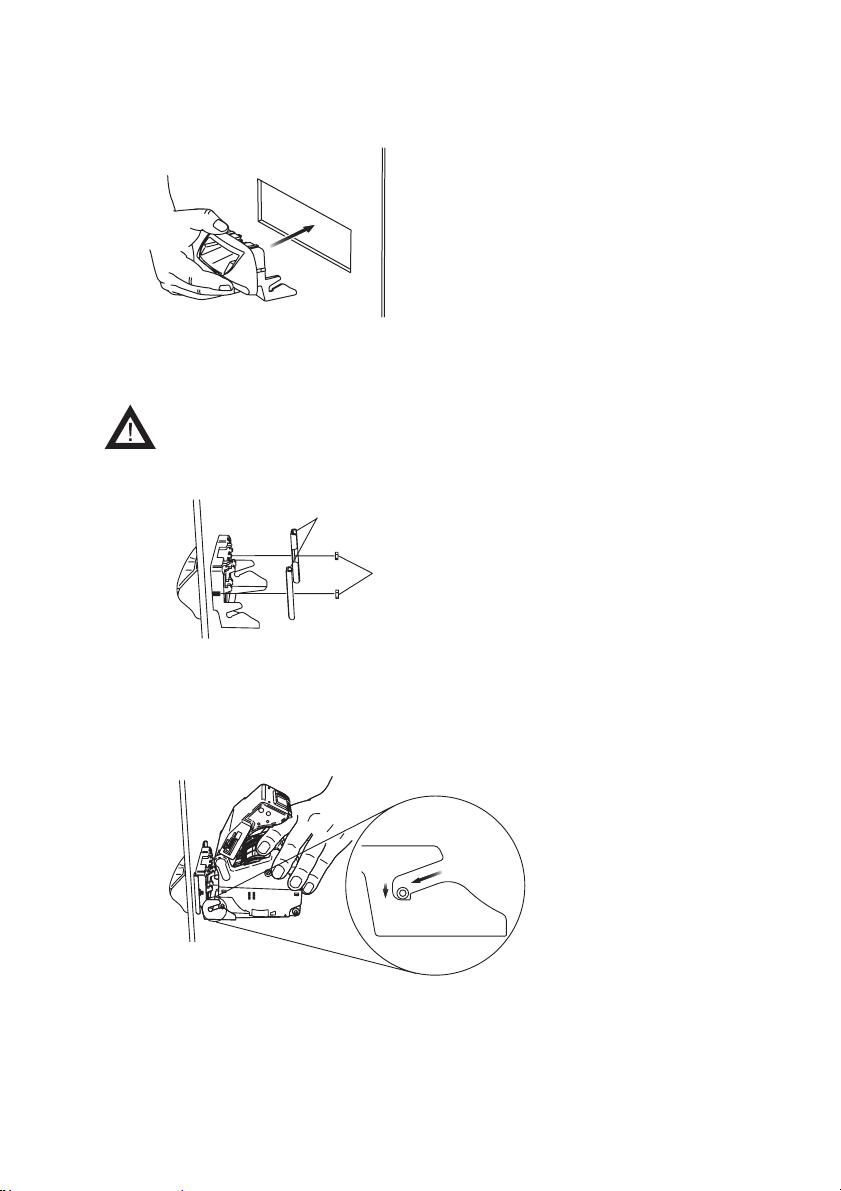

5. Remove the faceplate brackets (2) and the hexagonal nuts (2) from the faceplate, then insert the

faceplate into the cutout from the front side of the door.

6. Fix the faceplate onto the door using the faceplate brackets (2) and the hexagonal nuts (2).

- Tightening the nuts with too much force can damage the faceplate.

The required torque is 0.7 Nm.

Faceplate brackets

Hexagonal nuts

7. Hold in the upper lid open/close buttons once again, open the upper lid, and grasp the TAIKO

unit with your hand under the upper lid.

8. Insert the faceplate installation guide pin into the faceplate guide, and slide the TAIKO unit all

the way into the guide and then push down, as indicated by the arrows.

22

Page 29

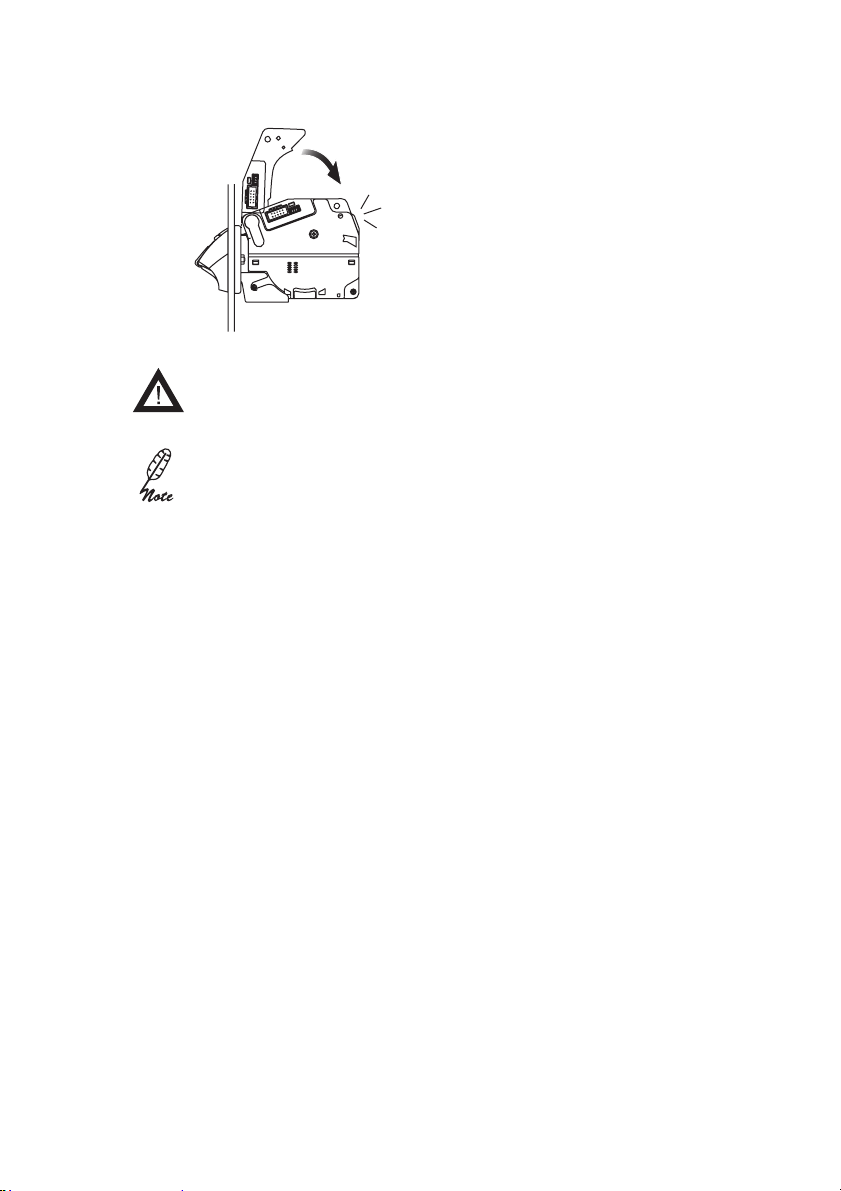

k

9. Close the upper lid firmly until it clicks into place.

Clic

- Be careful not to get your finger caught when closing the upper lid.

- Confirm that the TAIKO unit and faceplate are installed securely to the

door.

- To remove the TAIKO unit, perform the procedure shown above in re-

verse order.

23

Page 30

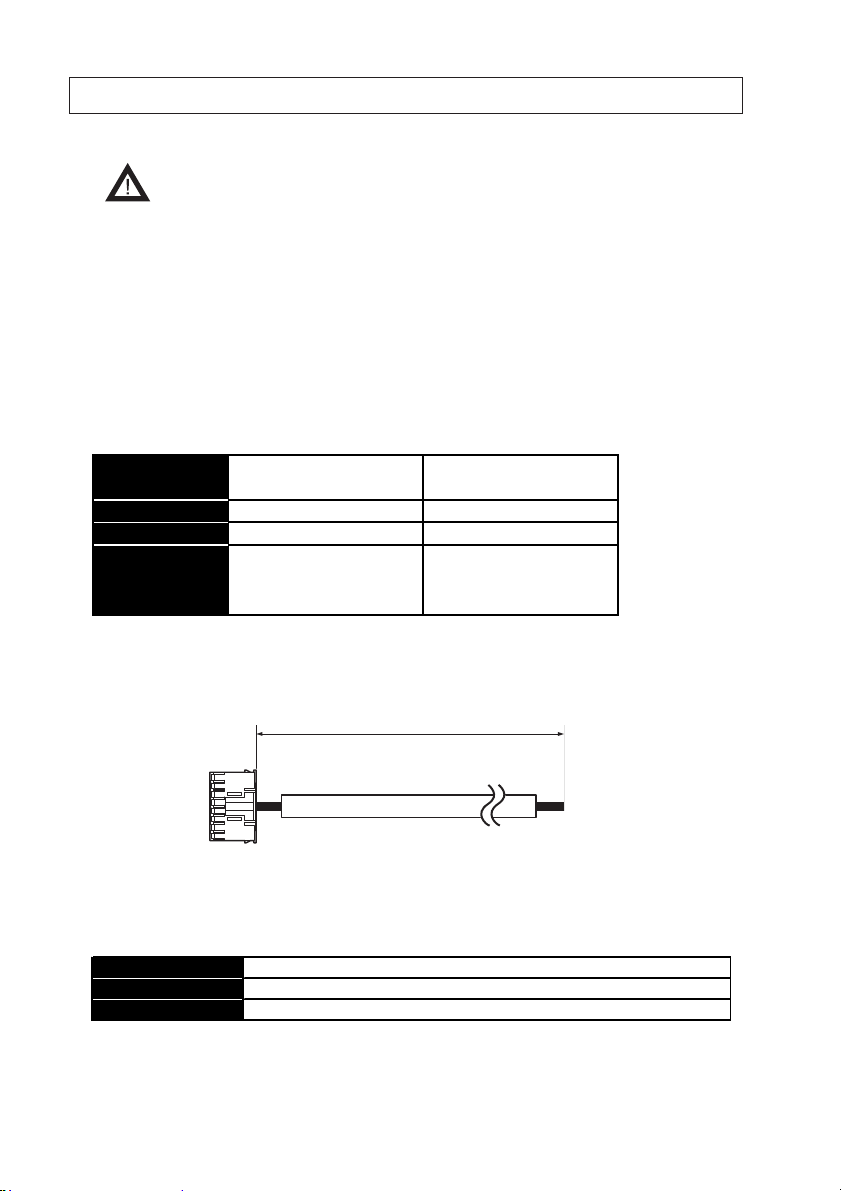

9. Wiring

Connect the power harness to the TAIKO unit.

- When installing the TAIKO unit or connecting the wiring the harness,

make sure that the power harness is unplugged from the power termi-

nal.

- The TAIKO unit is designed to use only 12V DC (

other power level can damage the unit.

- Do not pull on the power harness with undue force, as that may cause

the power socket to become disconnected.

9-1. Recommended Parts

9-1-1. Recommended Parts X4:Serial(ID-003)/MDB/Pulse/ccTalk Specification

We recommend the following parts for wiring.

+5%) input. Any

So c k e t

Rock Lever Socket

XG5M-1032-N (Omron)

Socket for flat cable

XG4M-1030-T (Omron)

Semi Cover XG5X-0501 (Omron) -

Rock Lever II XG4Z-0002 (Omron) -

1.27 mm pitch Flat Cable

Applicable Wires UL1061 AWG24

AWG28

UL2651/UL20012

9-1-2. Recommended Parts 01:Parallel(ID-001) Specification

For Parallel(ID-001) Interface Specification, "ID-001 I/F Harness (3280-05-100)"as on the

picture below.

㪣㪔㪈㪇㪇㪇㫄㫄

㪟㪦㪬㪪㪠㪥㪞

㪧㪘㪛㪧㪄㪈㪍㪭㪄㪈㪄㪪

㪓㪡㪪㪫㪕

㪫㪜㪩㪤㪠㪥㪘㪣

㪪㪧㪟㪄㪇㪇㪉㪫㪄㪧㪇㪅㪌㪣

㪈

ޟ+&+(*CTPGUU㧔㧕ޠ

About Pin assignments, please refer 7-2-2-1. Interface Connector assignment ID-001(Parallel).

We recommend the following parts if the packaged Harness(3280-05-100) will not be used.

Housing PADP -16V-1-S (JST)

Terminal SPH-002T-P0.5L (JST)

Applicable Wires UL1007 AWG26

24

Page 31

9-2. Wiring Procedure

Perform the following procedure when connecting the power harness.

1. Confirm that there is no power being supplied to the power harness.

2. Connect the power harness to the TAIKO unit’s interface connector.

3. Turn on the power and confirm that the TAIKO unit operates properly.

25

Page 32

10. Clearing a Banknote Jam

When a banknote becomes jammed inside the TAIKO unit, follow the instructions below to

remove the jammed banknote.

- Be sure to turn off the power to the TAIKO unit when opening the upper

and lower lids. Failure to do so may result in your fingers becoming

caught in the moving roller.

Open the upper lid

1. Confirm that the power to the Taiko unit is turned off.

2. Hold in the upper lid open/close buttons and open the upper cover, then pull out the jammed

banknote.

- Be careful not to get your finger caught when closing the upper cover.

Open the lower lid

1. Confirm that the power to the TAIKO unit is turned off.

2. Remove the faceplate from the TAIKO unit.

3. Hold in the lower cover lock release buttons and remove the lower lid, then pull out the jammed

banknote.

See => “6. Installation/Removal”

26

Page 33

11. Error Codes

The number of times the LED lamp flashes red indicates the type of error that has occurred in the

TAIKO unit. The LED lamp is located in the middle of the faceplate.

See=> “4. Names of Parts”

# of times

LED flashing

Description

Red 2 ROM error

Red 3 Banknote remains inside ejection slot

Red 4 Banknote remains inside transport path

Red 5 EEPROM read/write error

Red 6 Motor error

Red 8 Entrance solenoid sensor error

Red 9 Exit solenoid sensor error

Red 12 Fra ud det e c t ed

12. Cleaning

If paper or other type of dust or a foreign object adheres to the validation-related parts, the

acceptance rate may drop. Thus, it is recommended that validation-related parts be cleaned once a

month. Wipe any dirt off the sensors with lint-free cloth or cotton bud. Completely remove all

paper or the other type of dust, as well as any foreign objects, from the rollers.

- Do

NOT wipe the TAIKO unit with organic solvents such a thinner or

benzine.

Snesors/Rollers Location

Optical/Transparency Sensors

Pinch Rollers

Feed Rollers

MAG Sensor (PUB-11 Only)

With the upper lid open

With the lower lid open

27

Page 34

13. Product Support

If you happen to experience any problems or errors with your TAIKO unit, or have any inquiries

regarding your unit, consult with your nearest JCM contact as shown below. Please be sure to

make a note of the problem points and symptoms, or the content of you inquiry, prior to making

contact.

Japan

Japan Cash Machine Co., Ltd. (Headquarters)

No. 3-15, Nishiwaki 2-Chome, Hirano-ku, Osaka 547-0035

Japan

Phone: +81-66-703-8406 Fax: +81-66-704-7843

URL:

www.jcm-hq.co.jp

America, Oceania

JCM American Corporation

925 Pilot Road

Las Vegas, NV 89119

U.S.A.

Phone: +1-702-651-0000 Fax: +1-702-644-5512

e-mail: customerservice@jcm-american.com URL: www.jcmamerican.com

Europe, Russia, Middle East, Africa

Japan Cash Machine Germany GmbH

Mündelheimer Weg 60

D-40472 Düsseldorf

Germany

Phone: +49-211-530645-0 Fax: +49-211-530645-65

e-mail: support@jcm-germany.com URL: www.jcm-germany.com

UK, Ireland

JCM United Kingdom Ltd.

Unit B, Third Avenue, Denbigh West Business Park

Bletchley, Milton Keynes, Buckinghamshire MK1 1EJ,

UK

Phone: +44-870-770-2863 Fax: +44-190-837-7834

e-mail: info@jcm-uk.com URL: www.jcm-uk.com

Asia (Other than Japan)

JCM Gold (HK) Ltd.

Unit 1-7, 3F, Favor Industrial Centre

2-6 Kin Hong Street, Kwai Chung, N.T.

Hong Kong

Phone: +852-2429-7187 Fax: +852-2929-7003

e-mail: cs@jcmgold.com.hk URL: www.jcmgold.com.hk

Notice

Be aware that JCM shall not be held liable by the user for any damage, losses, or third party claims

arising from the use of this products.

28

Page 35

Note

29

Page 36

Note31Note

30

Page 37

Page 38

Copyright 2007 Japan Cash Machine Co.Ltd. All rights reserved. 08.05 4045-IGE-001A

c

Page 39

TAIKO Service Manual

Chapter

2

Specifications

2-1. Specifications

2-2. Connector

2-3. Interface Circuit

2-4. External Dimensions

2-5. DIP Switch Settings

Issue: 10/2007

4045-SME-002J

Page 40

TAIKO Service Manual

2-1. Specifications

2-1-1. Basic Technical Specifications

2

CHAPTER

2-1-2. Electrical Specifications

Acceptable Bankenote

Length: 120 mm to 160 mm

Width: 62 mm to 82 mm

Insertion Direction *1 4-way

Accepting Rate *1 95% or higher

Validation Method

PUB-7: Optical/Transparency/Reflection

PUB-11: Optical/Transparency/Reflection/MAG

Anti-Fishing Mechanism Lever and optical sensor combination

Interface

X4: ccTalk/Serial(ID-003)/MDB/Pulse *2

01 : Prallel (ID-001)

Escrow 1 banknote

LED

LED lamp (upper potion of faceplate)

Full-color lightning (gradation/solid)

*1 May differ depending on the software for your country. For details, refer to the

Software Information Sheet.

*2 Cn be selected using the DIP switches. See =>2-5-1 Dip Switch Settings

(01:ID-001 Parallel Interface Specification doesn’t have DIP Switch Setting.)

Power Supply Voltage 12V DC ±5 %

Standby: Approx. 0.1 A

Rated Power Consumption

Operation: Approx. 0.8 A

Max: Approx. 1.4 A (Max. 300 ms)

2-1-3. Environmental Specifications

Operation Temperature *1

Storage Temperature

Operation Humidity *1 20%RH to 85%RH (No condensation)

Storage Humidity 20%RH to 85%RH (No condensation)

Light Disturbande

Installation For indoor use only

*1 The overall operation temperature and humidity range is as follows.

(RH%)

100

90

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40 45 50 55 60 (oC)

Ambient temperature

humidity range

5oC to 50oC

-20oC to 60oC

Avoid direct sunlight

Interior lighting must be incandescent lamp

Angle: 15 dgrees or more

Illumination: 3000 Lx or less

35oC / 85RH%

50oC / 40RH%

2-2

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 41

2-1-4. Installation Specifications

Installation *1 Door holizontal mounting (No vibration)

Weight Approx. 0.6 kg

With Type 1/2/3 faceplate:

External Dimentions

Cahsbox *2 Supplied by the customer

*1 Allow 100 mm above the unit to open the lid for removal of the unit from the

faceplate.

*2 The cashbox must be 100 mm or more in depth from the bottom of the TAIKO

unit, 200 mm or more in depth from the rear of the unit and 100 mm or more in

width. Both sides of the cashbox must be higher than the position of the bill ejection slot.

124mm (W) x 88mm (H) x 145.2mm (D)

With Type 5 faceplate:

124mm (W) x 88mm (H) x 143mm(D)

TAIKO Service Manual

CHAPTER

2

100 mm or more

Depth from bottom of unit

100 mm or more

Depth from rear of unit

200 mm or more

Side

Position of

bill ejection slot

Width

100 mm or more

Cashbox

Rear

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-3

Page 42

TAIKO Service Manual

2-2. Connector

- When a relay board has connected to the TAIKO unit, it was

2-2-1. Interface Connector

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk Specification

2

CHAPTER

2-2-1-1. Interface Connector Pin Assignments

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk Specification

fixed inside so do not r

The following diagram is the interface connector as viewed

from the acceptor side or from a relay board.

Box Type Plug XG4C-1034 (Omron)

- The following pin assignment

emove from the TAIKO unit.

is for TAIKO units with a

blue JCM logo label. If the

logois black, the pin assignment may differ. For details,

contact JCM.

Blue

Black

ccTalk Communication

Pin No. Signal Name I/O *1 Function

1 ccTalk+ IN/OUT ccTalk Send/Receive Line

2 NC Not Connected

3 NC Not Connected

4 NC Not Connected

5 NC Not Connected

6 NC Not Connected

7 Vcc 12V DC Power Supply

8 Vss Power Supply GND

9 NC Not Connected

10 NC Not Connected

2-4

*1 Conditions for the I/O (Input/Output) column are from the Bill Acceptor side.

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 43

ID-003 (serial)/ MDB Communication

1

15

Pin No. Signal Name I/O *1 Function

1 NC - Not Connected

2 NC - Not Connected

3 RXD4 RXD+

5 TXD6 TXD+

7 Vcc - 12V DC Power Supply

8 Vss - Power Supply GND

9 NC - Not Connected

10 NC - Not Connected

*1 Conditions for the I/O (Input/Output) column are from the Bill Acceptor side.

IN

OUT

Data Send Line

(Active when the current is applied)

Data Receive Line

(Active when the current is applied)

TAIKO Service Manual

CHAPTER

2

Pulse Communication

Pin No. Signal Name I/O *1 Function

1 NC - Not Connected

2 NC - Not Connected

3Enable/Disable (-)

4Enable/Disable (+)

5Vend(-)

6Vend(+)

7 Vcc - 12V DC Power Supply

8 Vss - Power Supply GND

9 NC - Not Connected

10 NC - Not Connected

*1 Conditions for the I/O (Input/Output) column are from the Bill Acceptor side.

Out

Enable/Disable Signal Input Line

In

(Enable when the current is applied.

Disable when the current is NOT

PULSE Signal Output Line

(Active when the current is applied.)

2-2-2. Interface Connector

01: ID-001 (parallel) Specification

The following diagram is the interface connector as viewed

from the acceptor side or from a relay board.

applied.)

2

16

16PIN Connector S16B-PADSS-1(JST)

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-5

Page 44

TAIKO Service Manual

2-2-2-1. Interface Connector Pin Assignments

01: ID-001 (parallel) Specification

Pin No.

2

CHAPTER

Si gn a l

Name

1 VCC - 12V DC Power Supply

2 VCC - 12V DC Power Supply

3 VSS - Power Supply GND

4 NC - Not Connected

5 ACK ACK signal receive line

6 REJ REJ signal receive line

7 INH INH signal receive line

8 VALID VALID signal send line

9 VEND1 VEND1 signal send line

10 VEND2 VEND2 signal send line

11 VEND3 VEND3 signal send line

12 NC - Not Connected

13 NC - Not Connected

14 BUSY BUSY signal send line

15 ABN ABN signal send line

16 STKF STKF signal send line

I/O *1 Function

IN

OUT

OUT

*1 Conditions for the I/O (Input/Output) column are from the Bill Acceptor side.

2-6

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 45

PW12V

GND

D5V

D5V

D5V

PW12V

22K

22K

D18

R14

R12

1SS400

R1

10K

D17

RB520S-30

34

IC1B

354

D20

14A

SN74LV

TR 1B

ISS400

TAIKO Service Manual

CHAPTER

2

UMH9 N

GND

12V±5%

GND/ccTalk

CN1

ACCEPTOR CPU BOARD

7

8

12V±5%

GND/ccTalk

7

8

DC12V

CONTROL BOARD(Example)

GND

Power

DC5V DC12V

DC5V

DC5V

1SS400

22K

10K

2SC2712Y

RB520S-30

22K

ccTalk

1

ccTalk

1

1SS400

10K

IC1D

98

NC9

9

HC14

47K

GND

10 Reserve

10

Reserve

2

2

Reserve

3

3

Reserve

4

4

Reserve

5

5

Reserve

6

6

ccTalk (Example)

2-3. Interface Circuit

2-3-1. ccTalk Interface Circuit

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-7

Page 46

TAIKO Service Manual

2

CHAPTER

GND

12V±5%

7

8

GND

12V±5%

7

8

GND

PW12V

CN1

ACCEPTOR CPU BOARD

Reserve

1

Reserve

1

D5V

PWGND

R10

C2

100pF

4

PC2

1

1K 1/4W

RXD +

4

TXD +4

8

IC1D

SN74LV14A

9

3

PS2811(K)

2

R24

D21

RXD -

3

TXD -

3

DGND

470Ω

1SS400

D5V

5

R15

22K

IC1C

6

SN74LV14A

PW12V

R9

1K 1/4W

354

2

1

UMH9 N

TR 2B

PC 1

PS2811(K)

3

4

C1

Reserve

2

Reserve

2

PWGND

100pF

TXD +

6

RXD +

6

TXD -

5

RXD -

5

D19

1SS400

MDB/ID003

MDB/ID003

PW12V

NC9

Reserve9

Reserve

10

Reserve

10

DC12V

CONTROL BOARD(Example)

GND

Power

52uS

MAX 9600bps

MDB/ID003 (Example)

2-3-2. ID-003 (Serial)/MDB Interface Circuit

DC5V

104uS

RL=470Ω

(1KΩVQΩ)

12

IC1A

34

IC1B

GND

10mA

(5mA to 15mA)

HC14

* At leaset 5mA is necessary.

HC14

DC12V

TYP=10mA

* At leaset 5mA is necessary.

2SK1580

GND

HC14

IC1C

56

2-8

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 47

TAIKO Service Manual

GND

12V±5%

7

8

GND

12V±5%

7

8

PWGND

PW12V

CN1

ACCEPTOR CPU BOARD

Reserve

1

Reserve

1

NC9

Reserve

9

PW12V

Reserve

10

Reserve

10

Reserve

2

Reserve

2

PW12V

C1

PWGND

1

PC 1

100pF

4

D5V

R9

2

3

TXD +

6

RXD +

6

R15

22K

1K 1/4W

354

5

IC1C

6

SN74LV14A

UMH9 N

TR 2B

PS2811(K)

D19

1SS400

TXD -5

RXD -

5

PWGND

PULSE

PULSE

D5V

R10

SN74LV14A

C2

100pF

4

PC2

1

1K 1/4W

RXD +

4

TXD +4

8

9

3

2

IC1D

R24

PS2811(K)

D21

RXD -

3

TXD -

3

DGND

470Ω

1SS400

CHAPTER

2

DC12V

CONTROL BOARD(Example)

GND

2-3-3. Pulse Interface Circuit

Setting of DIP Switch

- Pulse Width

- Pulse Speed

PULSE (Example)

DC5V

RL=470Ω

(1KΩVQΩ)

12

IC1A

34

IC1B

GND

10mA

(5mA to 15mA)

HC14

* At leaset 5mA is necessary.

HC14

DC12V

TYP=10mA

FET=ON

(FET=ON ENABLE)

2SK1580

HC14

IC1C

56

(FET=OFF DISABLE)

GND

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-9

Page 48

TAIKO Service Manual

2

CHAPTER

4

-

4

-

V3.3D

V5D

-

-

V21CD

DNG

4

-

$%+

)%8.05

35

4

-

-

4

4

4

4

-

V5D

4

-

#%+

#8.05

12

#%+

4

(R

-

%

(R

%

34

4

-

DNGD

17

$%+

4

(R

-

%

DNGD

(R

%

5

&<

4

3

1

2

2

0*/7

#46

61

0'</7

DNGD

DNGD

5

0*/7

$46

34

2

0*/7

#46

5

0*/7

$46

34

2

0*/7

#46

DNGDDNGDDNGDDNGD

16

16

5

0*/7

$46

34

2

0*/7

#46

5

0*/7

$46

34

2

0*/7

#46

DNGDDNGDDNGDDNGD

16

16

rޓ8

ACCEPTOR CPU BOARD

0%

rޓ8

V21CD

CONTROL BOARD(Example)

rޓ8

&0)

rޓ8

&0)

'84'5'4

-%#

,'4

*0+

,'4

712B613

*0+

CCV

C

-%#

DNG

(#&6

㪭㪏㪅㪇㫏㪸㪤䋺㪣㪦㪭

811

㫉㪼㫍㫀㫉㪛㩷㪝㪆㪠

A

M

M

㪭㪇㪊䌾㪌䋺㪚㪚㪭

㫉㪼㫍㫀㫉㪛䇭㪝㪆㪠

FA28326DT

&+.#8

&0'8

&+.#8

&0'8

㪘㫄㪇㪊䌾㪘㫄㪈䋺㪠

A

B

811

712

61 3C514

&0'8

&0'8

&0'8

&0'8

D

'84'5'4

'84'5'4

CCV

㪘㫄㪇㪊䌾㪘㫄㪈䋺㪠

㪭㪇㪊䌾㪌䋺㪚㪚㪭

M

㫉㪼㫍㫀㫉㪛䇭㪝㪆㪠

EFA28326DT

;57$

;57$

315

(-65

0$#

0$#

(-65

G

F

316

21 7

2-10

CCV

2-3-4. ID-001(Parallel) Interface Circuit

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 49

TAIKO Service Manual

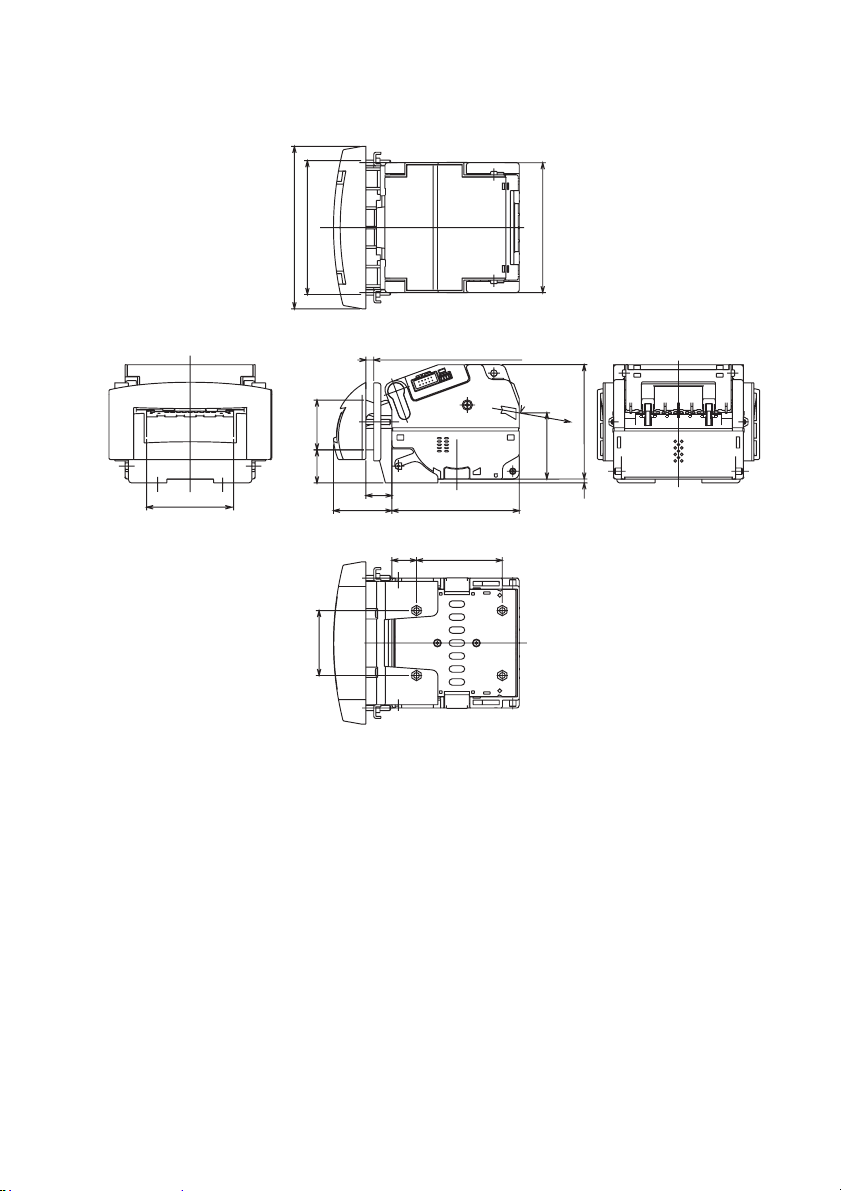

2-4. External Dimensions

2-4-1. When installing the Type1/Type2/Type3 faceplate with TAIKO unit

Unit:mm

124

A*

83

(Max. Banknote Width 82)

Front Rear

* The length of A differs depending on the faceplate type.

Type1: 68(Min. Banknote Width 67)

Type2: 76(Min. Banknote Width 75)

Type3: 71(Min. Banknote Width 70)

103 (Door Installation Position)

Top

2 to 6mm (Panel Thickness)

42.7 (Door Installation Position)

17.6

50

18

Right Side

19 66

100

CHAPTER

2

88

(Bill Ejection Position)

51

9847.2

3.2

4-M4

Bottom

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-11

Page 50

TAIKO Service Manual

2-4-2. When installing the Type5 faceplate with TAIKO unit

Unit:mm

2

CHAPTER

125

103

(Door Installation Position)

Top

‚2㨪6mm(Panel Thickness)

38.3

(Door Installation Position)

25.4

67

(Acceptable Bill Width 66)

Front Rear

30

20

45 98

Right Side

11.4

39.6

100

88

51(Bill Ejection Position)

3

Bottom

2-12

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 51

TAIKO Service Manual

p

d

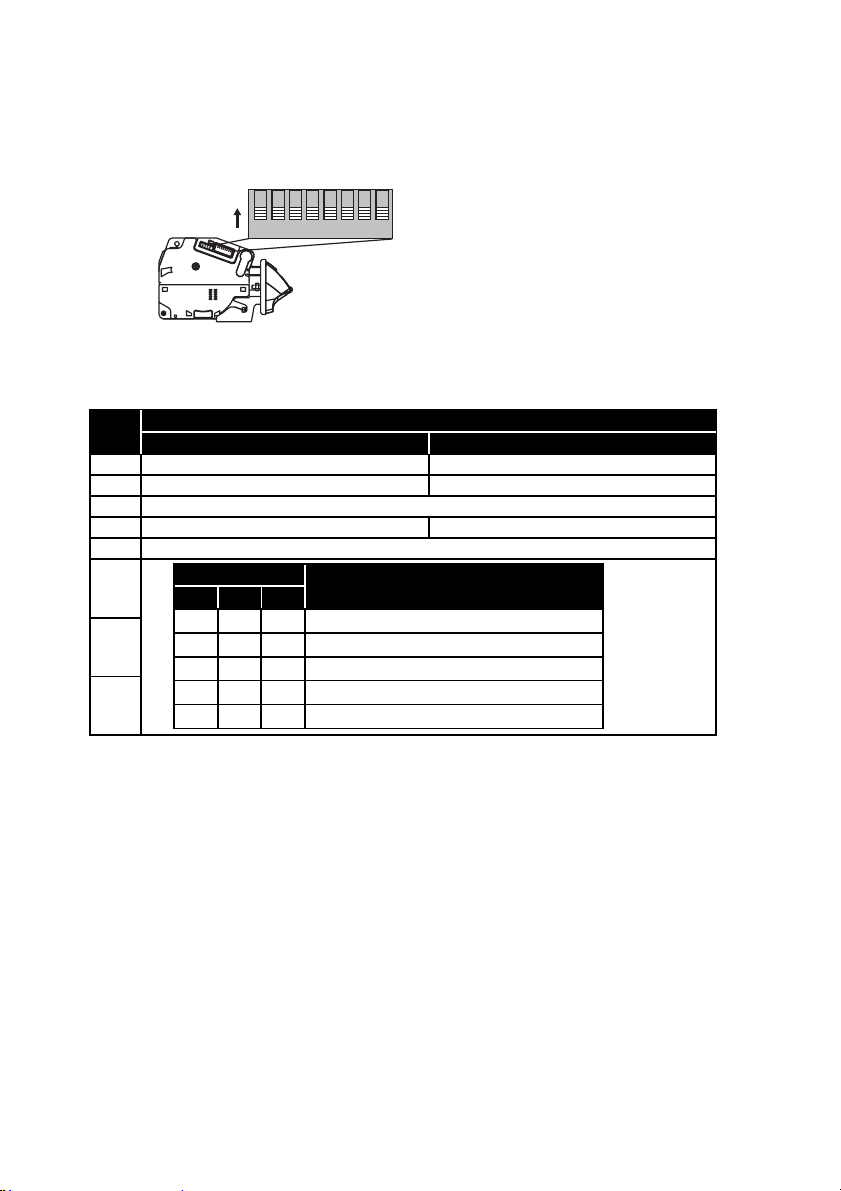

2-5. DIP Switch Settings

The communication method and various functions of the TAIKO unit can be set with the

DIP switches on the left side of the unit.

ON

87654321

Left Side

CHAPTER

2

2-5-1. Basic Settings

X4: ID-003 (serial)/ MDB/ Pulse/ ccTalk Specification

SW#

ON OFF

1 Test Mode *1 Normal Mode

2 Double-Scan Mode *2 Normal Scan Mode

3

4 Five (5) drum cycles (fishing prevention) *3 Normal Operation

5

6

7

8

6 7 8 I/F Setting

OFF OFF OFF ID-003 (SERIAL)

ON OFF OFF MDB

OFF ON OFF ccTalk (Non Encrypted)

ON ON OFF ccTalk (Encrypted)

--ON PULSE *4

*1 For details about the Test Mode, refer to 5-3. Test Mode.

*2 The acceptance rate will be improved but operation time will be increased if a

banknote is rejected.

*3 Fishing prevention will be improved but operation time will be increased.

*4 For Details about Pulse I/F, refer to the Software Information Sheet.

Refer to the Software S

Setting Item

Reserve

ec ifica tio ns

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-13

Page 52

TAIKO Service Manual

2-5-2. Basic Settings

01: ID-001 (parallel) Specification

SW#

1 TestMode*1 NormalMode

2 EscrowMode NoEscrowMode

3 Double‑ScanMode*2 NormalScanMode

4 Five(5)drumcycles(fishingprevention)*3 NormalOperation

5 DenominationSetting"INHIBIT"*4 DenominationSetting"ACCEPT"*4

6 DenominationSetting"INHIBIT"*4 DenominationSetting"ACCEPT"*4

7 DenominationSetting"INHIBIT"*4 DenominationSetting"ACCEPT"*4

8 DenominationSetting"INHIBIT"*4 DenominationSetting"ACCEPT"*4

2

CHAPTER

2-5-3. Special Settings

SettingItem

ON OFF

*1 For details about the Test Mode, refer to 5-3. Test Mode.

*2 The acceptance rate will be improved but operation time will be increased if a

banknote is rejected.

*3 Fishing prevention will be improved but operation time will be increased.

*5 For Details about demomination Stting “INHIBIT”/”ACCEPT”, refer to the Soft-

ware Information Sheet.

Setting Items

Denomination

Setting Mode

LED Pattern

Setting Mode

Encryption Code Initializing

Setting Mode

Download Mode *1

Adjustment Mode *1

Accept Setting

Inhibit Setting

Define Pattern 1

Define Pattern 2

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

ON

OFF OFF OFF OFF

ON

OFF OFF OFF OFF

ON ON

ON

OFF

ON ON ON ON ON ON

ON

OFF OFF OFF OFF OFF

ON ON

OFF OFF OFF OFF

ON

OFF OFF OFF

OFF OFF OFF OFF OFF

ON

OFF OFF

ON ON

ON

ON

OFF OFF

ON ON

OFF

OFF

OFF

ON

2-14

*1 For details about Software Download and Adjustment, refer to Chapter 4 Down-

load/Adjustment.

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 53

TAIKO Service Manual

Denomination Setting Mode (This mode is for only ID-003 (serial)/ MDB/ Pulse/

ccTalk Specification. Denomination Settings “INHIBIT”/”ACCEPT” are set by DIP

Switches (See=>2-5-2) for ID-001 Parallel Interface Specification.)

Perform the accept/inhibit setting for the banknote denomination based on the software for your

country. The default settings are to accept all denominations.

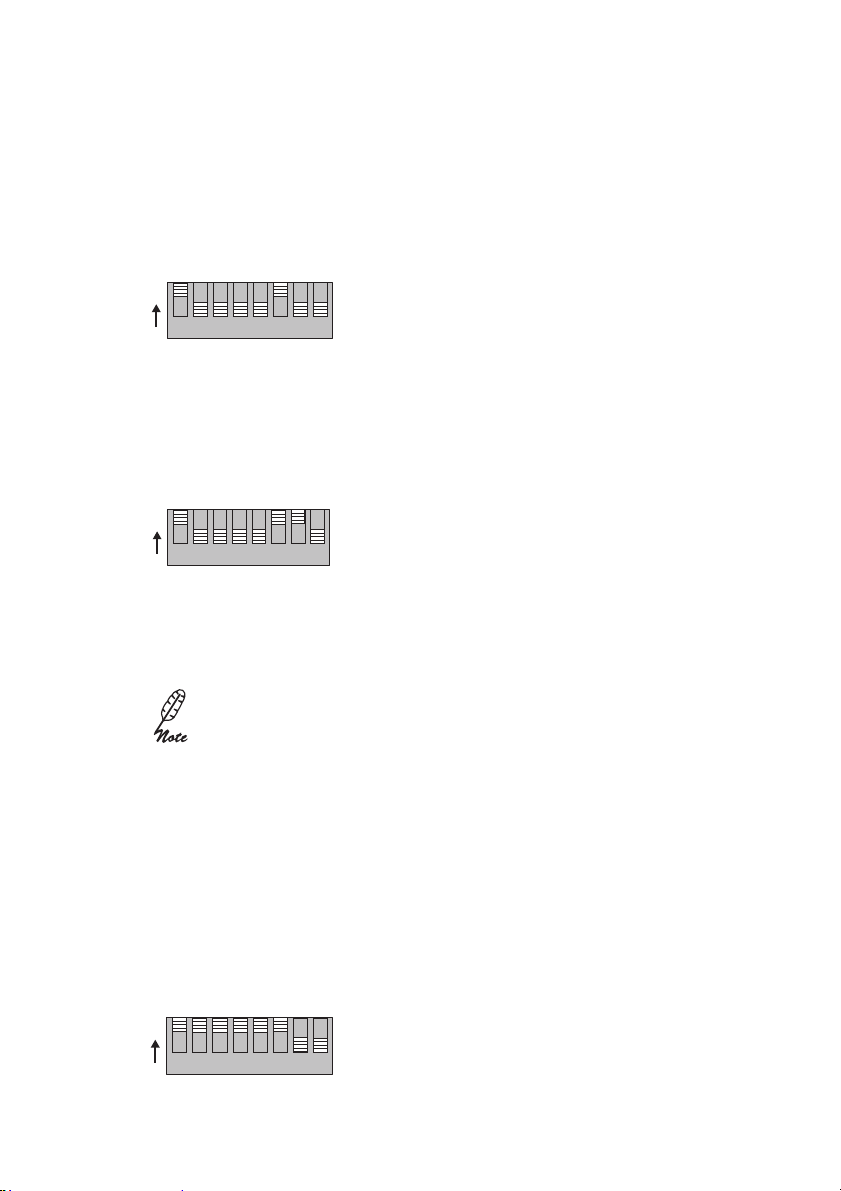

Accept Setting

ON

87654321

To perform the accept setting, set DIP switch Nos.1 and 6 to ON and then turn on the power to

the TAIKO unit. After the LED flashes white, set DIP switch No.1 to OFF to enter the setting

mode. Insert the denomination of banknote that you want accepted into the insertion slot. The

setting is registered if the LED remains lit light blue and the banknote is returned. Insert the next

denomination of banknote that you want accepted.

Inhibit Setting

ON

87654321

To perform the inhibit setting, set DIP switch Nos.1, 6 and 7 to ON and then turn on the power

to the TAIKO unit. After the LED flashes white, set DIP switch No.1 to OFF to enter the setting

CHAPTER

2

mode. Insert the denomination of banknote that you want inhibit into the insertion slot. The setting

is registered if the LED remains lit orange and the banknote is returned. Insert the next denomination of banknote that you want inhibited.

- The accept/reject setting for banknote denominations can be confirmed with

the LED lamp. After the initial operation is performed, the LED will flash a

number of times equal to the total number of banknote denominations. Blue

indicates an accept setting and red means a reject setting.

Example: If 5, 10 and 20 euro notes are set be accepted and 50 and 100 euro notes to

be rejected, the LED will flash the corresponding 5 times aws follows: blue,

blue, blue, blue, red and red.

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.

2-15

Page 54

TAIKO Service Manual

LED Illumination Pattern Setting

1.•Make a note of the current DipSw setting.

2.•Power off.

3.• [Pattern 1] Power up the acceptor with DipSw1,2,7 = ON. Other switches = OFF.

[Pattern 2] Power up the acceptor with DipSw1,3,7 = ON. Other switches = OFF.

[Pattern 3] Power up the acceptor with DipSw1,7 = ON. Other switches = OFF.

[Pattern 4] Power up the acceptor with DipSw1,2,3,7 = ON. Other switches = OFF.

[Pattern 5] Power up the acceptor with DipSw1,4,7 = ON. Other switches = OFF.

[Pattern 6] Power up the acceptor with DipSw1,2,3,4,7 = ON. Other switches = OFF.

4.•Power up.

5.•Set DipSw1 = OFF, then LED illumination pattern is selected.

6.•If Setting is completed, Power OFF.

7.•Restore the original DipSw setting.

8.•Power up.

9.•Acceptor returns to standby mode and the setup is completed.

-•#1: Change color one into another color with SOFT Crossing

-•#2: Change color one into another color with HARD Crossing

-•#3: Lit in solid blue.

-•#4: Lit in solid green.

-•#5: Blink slowly in blue.

-•#6: Blink slowly in green.

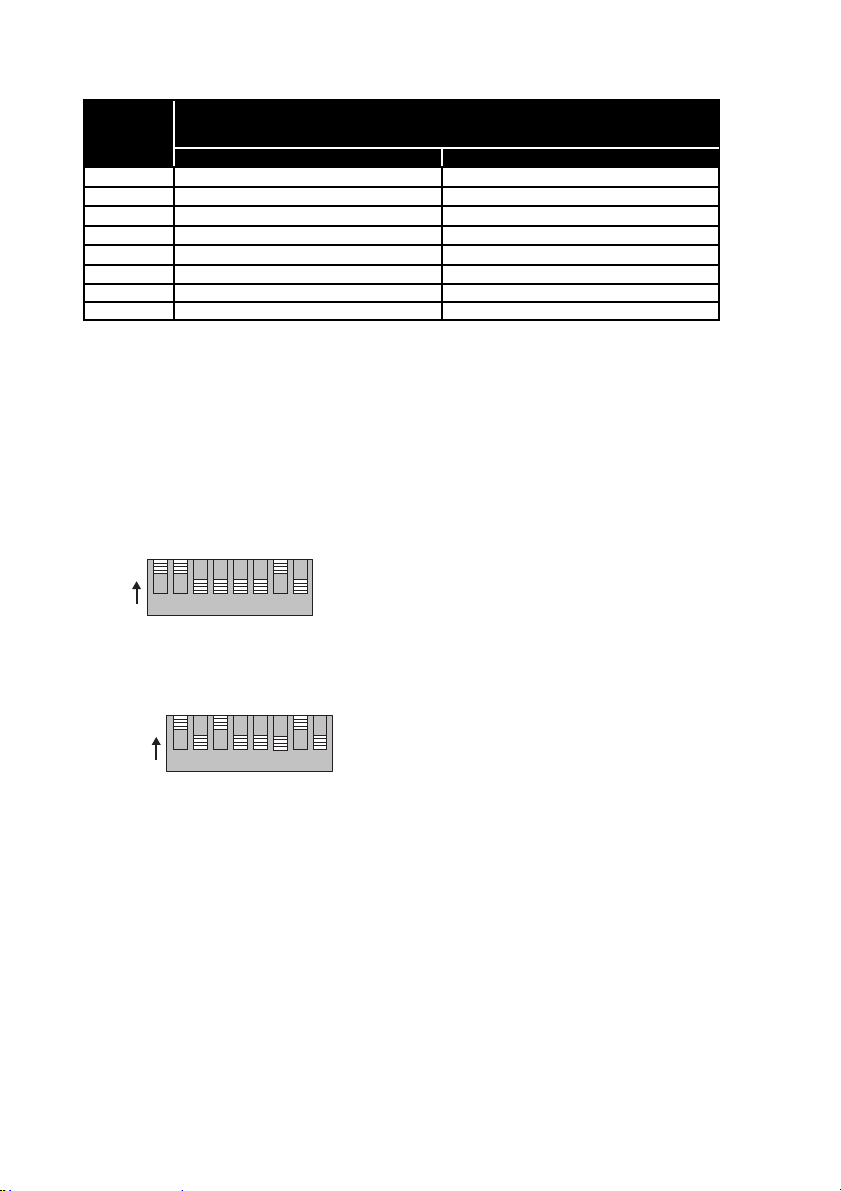

LED Pattern Setting Mode

The LED pattern can be changed according to your perference. Select between pattern 1 and

pattern 2. The default setting is pattern 1.

Define Pattern 1

t Define Pattern 2

2

Here on top you see two examples for DIP Switch settings.

CHAPTER

ON

87654321

ON

87654321

.

.

2-16

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

Page 55

TAIKO Service Manual