Page 1

COD. 1248054-GB / 1.1

1

Frequency

MOTION: 868,35MHz

RADIOBAND1G: 868,90MHz

Coding

High security rolling code

Memory

RBMOT30: 30 codes / RBMOT500: 500 codes

RADIOBAND1G: Ex. 6 RADIOBAND/TBX (3 on relay 1, 3 on relay 2)

Supply

12/24V ac/dc

Power supply range

9-24 / 21-35V dc

8-16 / 15-28V ac

Number of relays

MOTION: 2 relays (R1 and R2)

RADIOBAND1G: 2 relays (B1 and B2)

Relay contacts

1A

Standby/Op. consumption

RBMOT30: 18mA / 115mA / RBMOT500: 22mA/244mA

Self-test input

2 0/12/24V AC/DC inputs with selectable polarity

Radiated power

< 25mW

Op. temperature

-20ºC to +70ºC

Watertightness

IP54 (with glands IP65)

Size

63x55x15mm

Box dimensions

140x220x55mm

Range (guaranteed)

MOTION: 100m

RADIOBAND1G: 10m

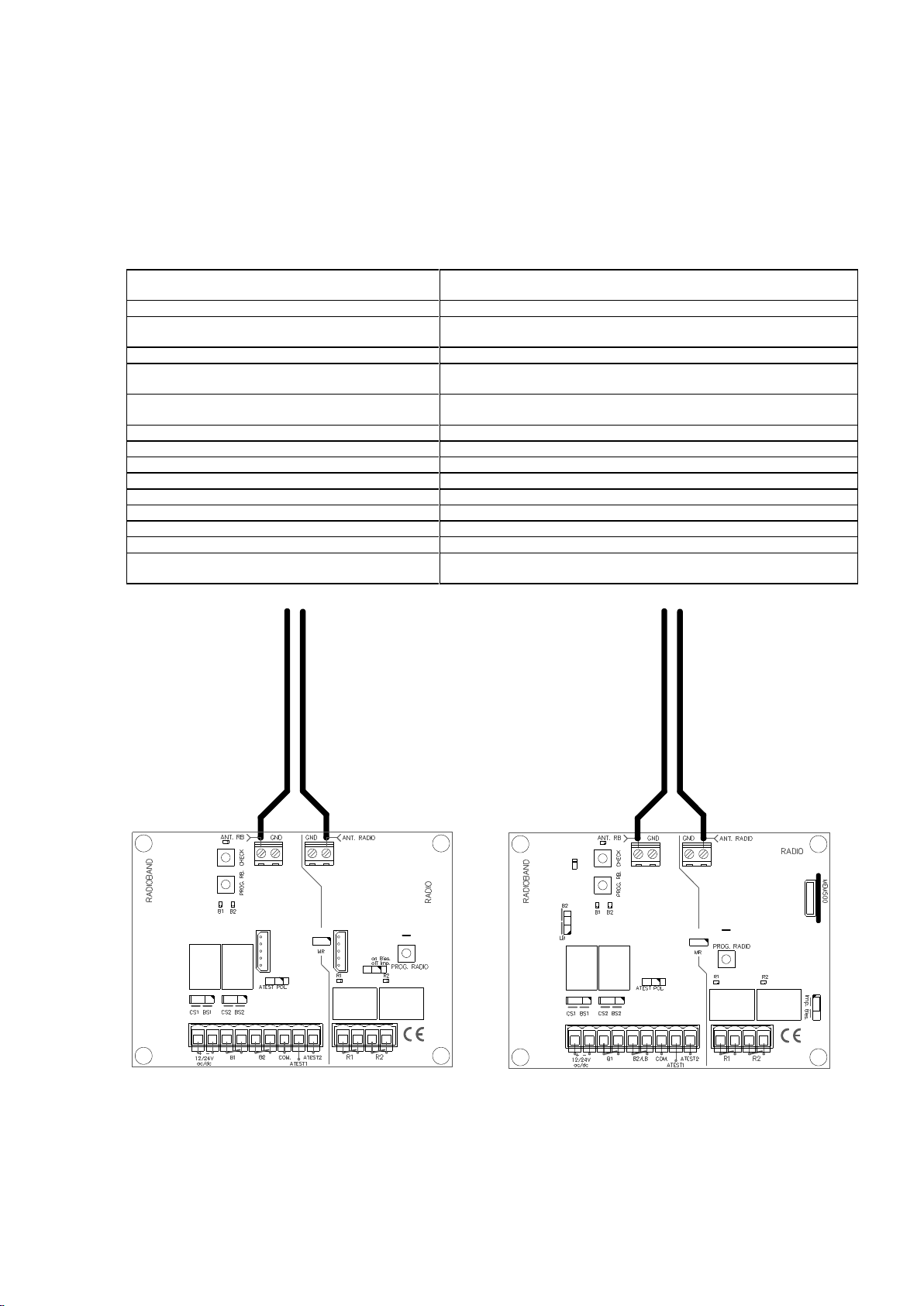

RBMOT30 / RBMOT500

GENERAL DESCRIPTION

This equipment consists of 30 or 500 codes MOTION receiver and receiver to RADIOBAND 1G

system.

TECHNICAL CHARACTERISTICS

Page 2

COD. 1248054-GB / 1.1

2

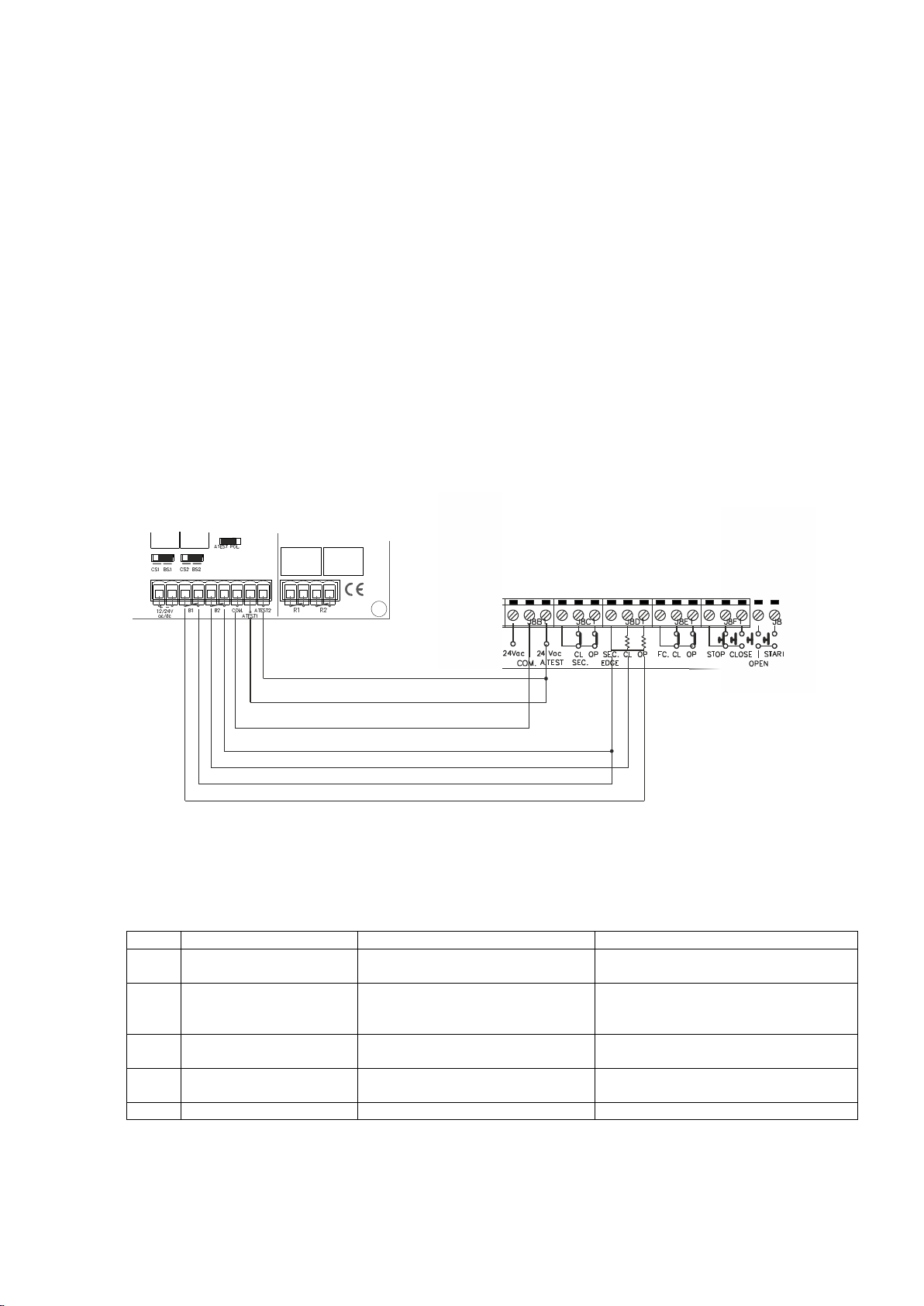

TWO SAFETY EDGES CONNECTION WITH

NEGATIVE POLARIZATION AUTOTEST

CONTROL PANEL

RBMOTION

Led

ON

OFF

Flashing

R1

Relay R1 Activation

R1 desactivated, state by default

Every 5 seconds, correct supply of the

equipment

R2/LB

Relay R2 Activation/

Indicates if the transmitter

has low battery

R2 desactivated, state by default/

Indicates if the transmitter„s battery is

working properly

Every 5 seconds, correct supply of the

equipment

B1

Relay B1 Activation or

band not connected

B1 desactivated, correct safety edge

state

B2

Relay B2 Activation or

band not connected

B2 desactivated, correct safety edge

state

CHECK

Coverage (See CHECK funcftion)

RBMOT30 / RBMOT500

INSTALLATION AND CONNECTIONS

Attach the rear part of the housing to the wall using the plugs and screws supplied. Pass the cables

through the bottom of the receiver. Connect the power cables to the terminals marked in the mother

board, as indicated. Install the receiver, close to the door and avoid metal surfaces between the

receiver and the transmitter RADIOBAND. Pass the cables through the bottom of the receiver.

Program transmitters and transmitters RADIOBAND as programming section. Fix the front of the

receiver to the back with the screws supplied for the purpose.

1- Power supply 12/24V AC/DC: (+)

2- Power supply 12/24V AC/DC: (-)

3,4- R1: Connection to the safety band input of the control panel (resistive contact 8.2k) with

jumper in position BS1. Or to the control panel safety contact input (NC) with jumper in position CS1.

5,6- R2: Connection to a second safety band input of the control panel (resistive contact 8.2k) with

jumper in position BS2. Or to the control panel safety contact input (NC) with jumper in position CS2.

7- AUTOTEST: Common connection safety self-test (-). See Figure and table POLARIZED SELF-TEST.

8- AUTOTEST: Self-test connection for R1. See Figure and table POLARIZED AUTO-TEST.

9- AUTOTEST: Self-test connection for R2. See Figure and table POLARIZED AUTO-TEST.

10, 11- R1: Relay 1 output RADIO receiver

12, 13- R2: Relay 2 output RADIO receiver

LIGHT INDICATORS

Page 3

COD. 1248054-GB / 1.1

3

Configuration of transmitter programming in the receiver.

Led R1

Led R2

Standard Programming (default option,

the receiver is always configured on pluri-channel)

The relays are activated 1st relay by channel 1

and 2nd relay by channel 2 (3rd relay by channel 1

and 4th relay by channel 2)

Flashing

Flashing

Special programming

By pressing any transmitter channel,

relay 1 on the receiver will be activated

ON

OFF

By pressing any transmitter channel,

relay 2 on the receiver will be activated

OFF

ON

By pressing any transmitter channel, the two relays

will be activated at the same time*

ON

ON

In programation

Relay B1 Led

Turned on. It indicates the channel to program.

Relay B2 Led

Turned on. It indicates the channel to program.

RBMOT30 / RBMOT500

OPERATING

The pilot lights are activated every 5 seconds to indicate the correct supply of power to the

equipment.

Upon receiving a code, the receiver checks whether it is in its memory, activating the corresponding

relay R1 and/or R2. The relay activation mode is selected in either impulse or ON/OFF using the

Imp/Bies jumper (only with the relay 2). For adjustment of relay 1, see manual of the programming

tool.

The receiver checks that all the programmed bands are working properly. If a band is activated or if

there is an error in its operation, the receiver activates the appropiated B1 or B2 output relay and

the appropiated B1 or B2 light indicator turns on.

PROGRAMMING

MANUAL PROGRAMMING OF MOTION TRANSMITTERS

Press the receiver programming button for 1 sec. and an acoustic signal will be heard. The

receiver will enter standard programming (see table). If the receiver programming button is

held pressed down, the receiver Hill enter special programming, cyclically passing from one

configuration to the next. Once the programming configuration for the transmitter to be

registered has been chosen, send the code to be programmed by pressing the transmitter.

Every time a transmitter is programmed, the receiver will issue an acoustic signal for 0.5

sec.

*If working in ON/OFF activation mode, relay 1 will act as impulse and relay 2 as ON/OFF. Therefore, on the first

press relay 1 will close and open the contact and relay 2 will only close. On the second, relay 1 will close and

open the contact and relay 2 will open.

N.B.: Each transmitter can be configured independently on the receiver.

MANUAL PROGRAMMING OF RADIOBAND TRANSMITTERS

Makes it possible to store 6 RADIOBAND transmitters (3 Relay B1 and 3 on Relay B2).

Press the receiver programming PROG button for 1s; a sound signal will be heard. The

receiver will enter safety band closing programming mode (BSC). If the programming button

is kept pressed, the receiver will enter safety band opening programming mode (BSO),

moving cyclically from one really to another. Once the programming relay has been chosen

for the transmitter you want to start using, send the programming code by pressing the

RADIOBAND transmitter. Every time a transmitter is programmed, the receiver will emit a

sound signal for 0.5s.

Page 4

COD. 1248054-GB / 1.1

4

Autotest

output in

standby

Autotest

output

activated

Polarity type

Jumper ATEST

POL

ATEST1

ATEST2

Connection to an

equipment with autotest

0V

12/24V

Positive

OFF

Connected*

Connected*

12/24V

0V

inverted

ON

Connected*

Connected*

Connection to an

equipment without

autotest**

---

---

---

OFF

No

connected

No

connected

RBMOT30 / RBMOT500

Note: For proper operation of the system, the transmitter must be programmed into one

receiver only.

In both programming modes, after 10 seconds without programming, the receiver will exit

programming mode, issuing two acoustic signals of 1 sec. If upon programming a transmitter the

receiver memory is full, it will issue 7 acoustic signals of 0.5 sec. and exit programming.

RADIOBAND transmitter replacement

In case you need to replace a RADIOBAND transmitter, it is necessary to reset the system (see

TOTAL RESET on next page) and reprogram all RADIOBAND transmitters used in the installation.

TOTAL RESET

In programming mode (PROG RADIO or PROG RBAND, depending the memory which wants to be

erased), the programming button is held down and the “MR” reset jumper is bridged for 3 secs. The

receiver will issue 10 short acoustic warning signals followed by others at a faster pace to indicate

that the operation has been successful. The receiver is now in programming mode.

After 10 seconds without programming or quickly pressing the programming button, the receiver

will exit programming mode, issuing two acoustic signals of 1 sec.

OTHER RADIOBAND1G FUNCTIONS

POLARIZED AUTO-TEST

Check the auto-test output on the control panel, in standby, to see whether the voltage is

0V (inverted test input) or 12/24V AC/DC (positive polarity). The auto-test signal of the

panel must remain at its maximum for 2 seconds.

* N.B.: Only connect the auto-test output to be used.

** Where the auto-test is not used, the system is not checked at the start of the

operation, which means that security normative EN 12453 regarding the use of

motorised garage doors is, in some cases, not complied with.

SYSTEM CHECK

This function has to be used to check the operation and range of all the devices once the

installation has been carried out.

Press the receiver‟s CHECK button for at least 1 second to enter check mode. The indicator

light will come on and four beeps will be heard.

Perform a complete door opening and closing manoeuvre. During the system check a beep

will be heard every 1,5 seconds.

Page 5

COD. 1248054-GB / 1.1

5

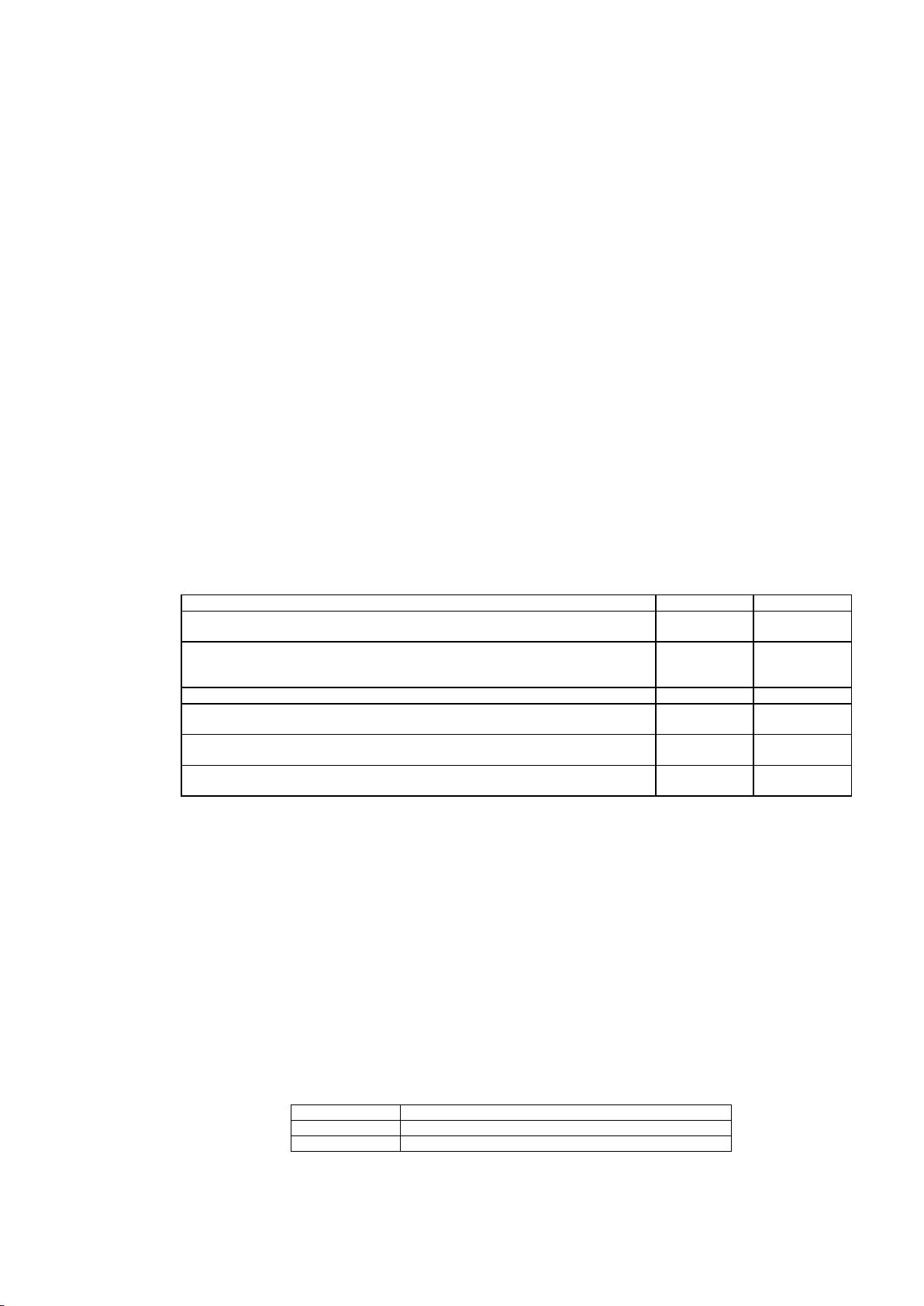

Number of check LED flashes

Coverage

Result of check

1

Very weak

Band failure

2

Weak

OK

3

Normal

OK

4

Good

OK

5

Very good

OK

CORRECT OPERATION OF THE SYSTEM

If no other acoustic signal is heard on completing the manoeuvre, the system is operating

correctly. Either press the CHECK button again or wait 5 minutes and the RADIOBAND

receiver will exit checking automatically, indicating with two beeps that the check has been

correct. The check indicator light will go out.

DETECTION OF BAND FAILURE

If the communication with a RADIOBAND transmitter fails during checking, or the

communication is deficient (for instance, too many communication retries or poor

coverage), the RADIOBAND receiver emits three consecutive beeps, indicating that an

error has occurred. Halt the door manoeuvre and press the safety bands installed to

detect what has failed.

If a single beep is heard on pressing a band, this means that the band is correct.

If three consecutive beeps are heard on pressing the band, this means that the band has

failed.

In this event, it is recommended changing the orientation of the transmitting-receiving

aerials to ensure the desired range.

On exiting check mode, seven consecutive beeps will be heard and the indicator light will

flash continuously.

Perform another system check until the result is correct.

SIGNAL COVERAGE

After pressing one of the installed bands, continuous flashes, ranging from 1 to 5, indicate

the signal coverage for this band at the time it was pressed.

RBMOT30 / RBMOT500

TRANSMITTER BATTERY LOW INDICATOR

If the battery of a RADIOBAND transmitter programmed into the receiver becomes low, the

receiver will beep 4 times every 20 seconds. If there is more than one transmitter

programmed, each safety edge should be activated to identify, hearing the 4 beeps, which

transmitter has a low battery. If the battery power is low, replace it immediately.

In RBMOT500, you can use the second relay on the receiver as an indicator for low battery,

the output will activate when a transmitter with low battery is detected. Jumper B2/LB

must be ON for this operation.

Page 6

COD. 1248054-GB / 1.1

6

RBMOT30 / RBMOT500

OTHER MOTION FUNCTIONS

MOTION GROUPS

This equipment can work with the group identification of the system FREE. Receivers can

be configured with a group (from 0 to 7) that allows management of up to 28 doors

independently.

C=channel

G=group

N.B. Group 0 enables all groups.

GROUP CONFIGURATION

After the receiver has been totally reset, it will be configured with the group of the first

radio-programmed transmitter by enabling the hands free mode.

On powering the receiver, the led R1 will flash the same number of times as the group

number with which it is configured.

INSTALLATION ADVISES

Page 7

COD. 1248054-GB / 1.1

7

>20 cm

RBMOT30 / RBMOT500

USE OF THE EQUIPMENT

This equipment is intended to be used for remote control and be installed with a safety edge in

automatic doors installations. Their use is not guaranteed for directly activating any other equipment

different to that specified.

The manufacturer reserves the right to modify equipment specifications without prior notice.

IMPORTANT ANNEX

Disconnect the power supply before handing the unit.

In compliance with the European Directive low-voltage electrical equipment, we hereby inform users

of the following requirements:

· For units which are permanently connected, an easily accessible circuit-breaker device must be

built into the wiring system.

· This unit must always be installed in a vertical position and firmly fixed to the structure of the

building.

· This unit must only be handled by a specialised installer, by his maintenance staff or by a duly

trained operator.

· The instruction manual for this unit must always remain in the possession of the user.

· Terminals of maximum section 3,8mm2 must be used for the power supply connections.

· Use time delayed fuses.

· The two working frequencies does not interfere each other.

Hereby, JCM TECHNOLOGIES, S.A., declares that this RBMOT30, RBMOT500 is in compliance

with the essential requirements and other relevant provisions of 2004/108/CEE Directive, insofar as

the product is used correctly and 2006/95/CE low voltage directive, only if the usage is the

appropriate.

CE DECLARATION OF CONFORMITY

See web www.motion-line.com

Loading...

Loading...