Page 1

1

Instruction Manual

Jupiter 2

jcmseating.co.uk

jcmseating.co.uk

Standard

Deluxe

Page 2

2

Contents

Introduction 3

Measurements & Useful Info 4

Seating System Components 5/6

Important Safety Advice 7

Important Safety Advice - General guidance for use 8

Important Safety Advice - Accessories 9

Important - Chest Harness Adjustment 10

Important - Lap Strap Safety 11

Lap strap fixing points 12

Adjusting Tilt / Prone 13

Push Handle Adjustment 13

Chair Height Adjustment 14

Head Rest Adjustment / Replacement 15

Arm Rest Adjustment 16

Applying / Releasing Brakes 17

Back Height Adjustment 17

Lateral Support Positioning 18

Hip Pad Adjustment 18

Pommel Positioning 19

Footplate Adjustment 20

Leg Rest Adjustment 20

Seat Depth Adjustment 21

Product Labelling 21

Cleaning & Care 22

General Maintenance 22

Servicing via Approved Repairer 23

Service Record Log 24

Warranty 25

Inspecting & Reissuing of Equipment 26

Inspecting & Reissuing of Equipment 27

Page 3

3

Introduction

The Jupiter is designed to provide comfort and postural support. The system

is available in two types Standard and Deluxe to accommodate children from

as young as three years through to adult.

This instruction manual contains very important information about the Jupiter

seating system, how to use it safely and obtain the best results from it. Please

read all the information contained in this manual before using the chair and

retain for future reference. Ensure everyone using the equipment is aware of

the contents of this manual and understands how to use the equipment safely.

These instructions provide guidance on the adjustments for professionals,

but they also give information on how the equipment should be safely used,

maintained, checked, and correctly assembled by anyone who uses the seating

system.

In every case the equipment should be supplied via qualified professionals who

will have adjusted

the equipment, checked its compliance and tested it appropriately.

The seating system should only ever be adjusted by qualified professionals

and persons that are suitably trained. For further information please do not

hesitate to contact us - all contact details are on the back cover of the manual.

The Jupiter 2 is designed, manufactured and CE marked to EN12182

Thank you for purchasing our product, we hope

you enjoy your new seating system.

Page 4

4

Measurements & Useful Info

Jupiter Size 1 Size 2 Standard Size 2 Deluxe Size 3

Number of sizes 1 1 1 1

Age Range 3yrs - 9yrs 8yrs-13yrs 8yrs-13yrs 12yrs-Adult

Chassis Footprint Width 570 660 740 730

Overall Footprint Length 510 710 800 730

Min Max Min Max Min Max Min Max

Overall Height 1070 1265 1160 1365 1160 1365 1090 1165

Seat Depth Single Seat 240 340 360 530 360 530 380 520

Seat Depth Split Seat 240 375 360 530 360 530 N/A

Seat Height (std 100mm Castor) 395 470 425 500 425 500 520 595

Optional Castor Stem Fitted 435 510 N/A N/A N/A

Seat to Top of Back 340 460 470 650 470 650 410 520

Seat Width 360 440 440 450

Seat Width Between Hip Pads 260 360 195 380 195 380 N/A

Seat Width Between Hip Pads

(Optional Hardware)

170 360 N/A N/A N/A

Thigh Giudes Adj.

(30mm per side increments)

300 360 320 440 320 440 N/A

Width Betw

een Trunk Lateral

Supports

170 360 230 340 230 340 N/A

Width Between Trunk Lateral

Supports (Optional Hardware)

N/A 160 270 160 270 N/A

Seat to Footplate 220 370 210 350 210 350 450 525

Footplate Angle -10˚ 15˚ 0˚ 60˚ 0˚ 60˚ 0˚ 35˚

Armrest height from seat 120 230 150 340 160 380 200 380

Armrest Angle 0˚ 36˚ N/A N/A N/A

Armrest height from Floor 600 795 590 780 600 820 690 870

Push Handle Height 850 1050 550 1050 550 1050 1040 1115

Tilt in Space -5˚ 35˚ 0˚ 15˚ 0˚ 15˚ 0˚ 25˚

Back Angle Recline -5˚ 25˚ -5˚ 35˚ -5˚ 35˚ 0˚ 25˚

Leg Rest Elevation -10˚ + 90˚ N/A N/A 0˚ 90˚

Base Footprint W610 x L550 W650 x L680 W650 x L680 W730 x L700

Ground Clearance

(100mm Castor Fitted)

145 220 140 215 140 215 155 230

User W

eight 60kg 80kg 80kg 100kg

Approx. Weight of Seat 36kg 52kg 52kg 73kg

Page 5

5

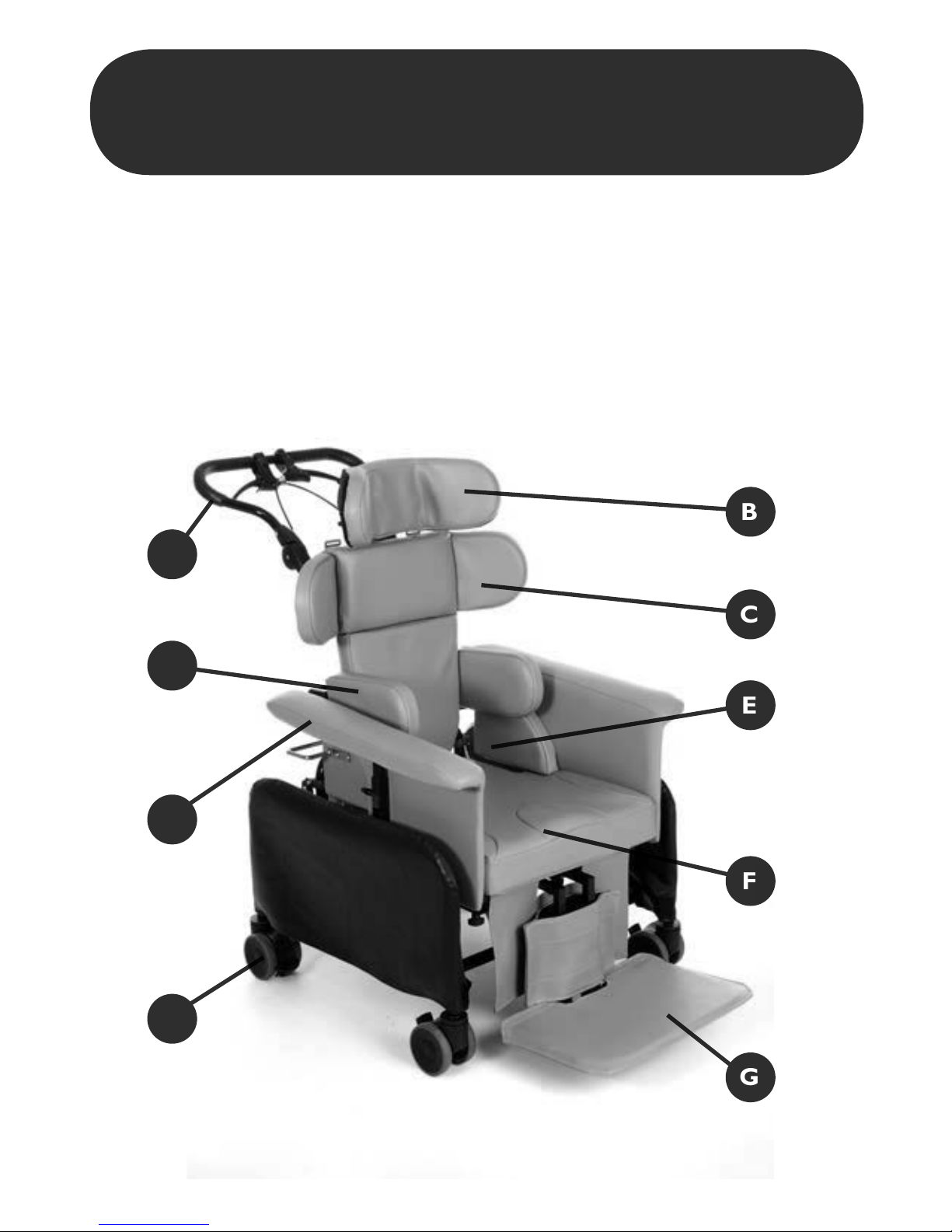

Seating System Components

(Deluxe)

A Push Handle

B Headrest

C Shoulder Protraction Pads

D Lateral Supports

E Hip Pads

F Contoured Seat

G Footrest

H Castors

I Adjustable Arm Rest - Deluxe

A

D E

F

G

I

B

C

H

Page 6

6

A Push Handle

B Headrest

C Shoulder Protraction Pads

D Lateral Supports

E Hip Pads

F Contoured Seat

G Footrest

H Castors

I Adjustable Arm Rest - Std

A

E

F

G

B

C

H

I

D

Seating System Components

(Standard)

Page 7

7

Important Safety Advice

We at JCM are committed to producing products of the highest standard. All

of our products fulfil the essential safety and environmental requirements as

defined in the European Directives. However, improper use of the products will

potentially put the users at risk and therefore JCM strongly suggest that the

following information is strictly adhered to at all times.

Throughout the manual there are important points to note

identified by the symbol:

• Ensure all adjustment mechanisms are secure and in place before operation. If it is likely that the

hand-wheels will be repeatedly loosened, JCM can supply allen key bolts as an alternative. We

strongly recommend this if there is a danger from those in the vicinity of the user.

• After completing any alterations ENSURE all nuts, bolts, knobs, hand wheels and other fixingsare

securely tightened and in position, and that they are regularly checked as part of the

• Maintenance of the chair. Never over adjust or over tighten moving parts.

• All postural support straps and harnesses should be in place and properly adjusted to the user, prior

to usage of any kind (see pages 10 & 11).

• The Jupiter seating system is designed for Indoor use and should always be positioned on a level, flat

floor. The Jupiter chair can be moved between one working area and another for safety ALWAYS

return the Seat to a neutral position, (level the seat, ensure the back is upright etc.) After the

chair has been moved and during use the chair should be placed in a static position with the brakes

applied.

• Seating system such as the Jupiter are designed to be used inside, however it is acceptable to take

the Jupiter externally for a brief period if transferring the chair from one indoor area to another.

• Heavy items on the tray will aect stability. The fitting of anything other than the standard JCM tray

may substantially aect the stability of the seating system and should therefore be checked before

issue.

• If at any time it is noted that areas of the user’s skin remain reddened after being out of the seating

system for around 10 minutes, urgently contact the qualified professional who performed the

handover of the equipment. This may be a sign of excessive pressure being exerted by the seating.

This might occur in the initial use of a new seat where further adjustment may be required, where

the user has been badly placed, grown or where an underlying medical problem exists. Review may

be necessary in such cases.

• Keep all products away from excessive sources of heat, cigarettes and naked flames.

• If you suspect that the system may be faulty, cease use of the equipment straight away and

• Immediately contact the organization who supplied the system. ( JCM’s contact information can be

found on the back cover).

• The equipment will be labelled with important information. NEVER REMOVE these information

labels or allow them to be defaced, overlaid or altered.

• All modifications, adjustments, reconditioning, repairs, disposal, and servicing of the seating unit

must ONLY be carried out by the agencies who supplied the equipment (see pages 24 - 25)

• The Jupiter size 1, 2 & 3 is designed to be used indoors. For maximum stability the intended use

conditions are indoors on flat surfaces.

!

!

Page 8

8

All JCM seating systems should only be size adjusted by qualified professionals or suitably

trained individuals.

• The Jupiter seating system is intended to be used on a level flat floor only

• The Jupiter seating system can be moved from one working area to another but before moving:

- The seat back should be returned to the vertical or slightly reclined position.

- The seat tilt should be returned to the horizontal position.

- Heavy items on the tray and hanging items from the push handle may aect stability and should be

removed whilst moving the seating system whenever possible

• The Jupiter Seating system is intended for indoor use only although it is acceptable to take the base

externally if transferring from one indoor area to another (Note: this is subject to your own risk

assessment (slope angles, thresholds, surface roughness should be considered).

- If the Jupiter seating system is to be moved down a slope then to avoid tipping forward or running

away then the base must be reversed down.

- If the Jupiter Seating system is to be moved over a threshold then to avoid tipping the base must be

reversed over the threshold.

• After moving and during use, the seating system should be in a static position with the brakes applied.

• Whenever the user transfers themselves or is assisted to transfer forward out of the seat the brakes

must be applied and an assistant must hold the push handle to avoid forward tipping.

• When re-issuing equipment, it is the customer’s responsibility to ensure that the equipment being

supplied is appropriate for the needs of the user taking age, weight, ability, diagnosis, growth and any

other factors into account. JCM are happy by appointment to assist with review or re-assessment of

any client against intended equipment provision.

• Periodic Re-Assessment.

- Many of the features of JCM products are designed to be adjustable.

- Healthcare providers/prescribers should consider the need for periodic (re) assessment of users and

their equipment to ensure that the settings of any adjustable features or the complete product where

changes in the user, e.g. growth or other changes, or the intended use are still eective.

• Please note the stability is aected by the following, all of which should be considered during use

and when undertaking a risk assessment:

- User weight

- Seat depth

- Recline angle

- Seat tilt angle

- Seat height

- Environment (slopes and thresholds).

If you have any concerns regarding stability of your chair then please contact JCM.

Important Safety Advice

!

Page 9

9

Important Safety Advice

(Accessories)

Multi adjustable head support

Wings on the head support are ideally set at 45 degrees. Do NOT

bring the wings in tight to the head. Ensure that the head support

is set in such a way that the child cannot loop their head around

the wings and get stuck.

Flexi-supports and lateral supports

Ensure the straps do not infringe on any feeding tubes the child

may have.

Pommel

Should only be fixed when the user is wearing shoes or boots.

Tr ay

Do NOT use the tray as a way of securing children in a chair always

ensure that the lap strap and any other straps supplied are used.

Ensure that the tray clips are secure on both sides of the tray. If the

tray is damaged, ensure that this will not be a hazard to the user.

Never leave hot items on the tray while children are unattended.

!

Page 10

10

Important - Chest

Harness Adjustment

GREAT CARE should be taken when fitting a chest harness and the

following points should always be followed:

• The straps on the harness should never be allowed to move

close to or in any way cause an obstruction to the child’s neck.

• The straps should never be fitted too tightly and should be clear

from any obstruction.

• The sternum straps (A) on the chest harness should always be

adjusted prior to use to ensure that it is no higher than the

middle of the user’s chest.

• A lap strap (B) should always be fitted if a harness is being used

to ensure the child cannot slide down onto the sternum strap.

• Always ensure that the belts oer your child both comfort and

support. If the child’s clothing has been adjusted (i.e. a jumper

removed) the straps should be re-adjusted accordingly.

Fixing onto chair

• The Jupiter comes with guide plates for the top straps which

are located either side of the upper back (A). The webbing

strap should be fed through these guides and then adjusted and

secured in place using the cam buckle clasps directly beneath the

guide plates.

• The straps at the bottom of the harness should be fed through,

adjusted for fit and then locked using the Cam Buckle Clasp (B)

located on the hip pad rail.

Fastening of belts

• Feed the fabric belt through the buckle on the strap.

• The belts should be pulled through enough to suitably support

your child whilst still being comfortable.

• When this has been achieved the buckle should be snapped

closed to secure the strap in place

The same precautions highlighted here should be adhered to when

using any form of trunk supports or flexi supports with straps.

!

!

If there is any possible chance of the child getting the straps caught

around their neck, REMOVE THE HARNESS IMMEDIATELY.

A

A

B

B

Page 11

11

Important

Lap Strap Safety

Incorrect fitting of lap straps can put the user at serious risk. When using lap

straps we recommend the following points should always be adhered to:

Lap Strap Fitting

• The angle that the hip belt is attached to

the seating system has a direct eect on

the angle of pull on the pelvis.

Considerations:

• A 60° angle of attachment to the seat rail

positions the hip belt anterior and inferior

to the ASIS, which reduces the tendency of

the client with a posterior pelvic tilt to slip

underneath the belt.

• A higher angle of attachment of the primary

straps encourages a posterior pelvic tilt,

which assists in positioning clients with an

anterior pelvic tilt.

• The secondary straps of a 4-point hip belt

are attached to the seat post between 45°

and 90° to hold the primary padded strap

in place and to prevent the belt from riding

into the abdomen or twisting.

• The angle of attachment may have to be

compromised in order to accommodate

such situations as wounds in the pelvic

area, unstable hip joints or gastric tubes.

Tightening the belt

• Keep belt tightened at adjustment straps

during fitting and daily use to ensure

correct pad placement. For padded hip

belts the pads are to be touching when

correctly tightened. For non-padded hip

belts the Adjustment strap at the buckle

should be approximately 3” (76mm) long.

Education of the care giver is essential for

correct hip belt positioning.

Sizing

• Measure hip width to determine the belt

size required. The suggested method for

measuring hip width is from trochanter to

trochanter. If this is not possible, measure

from ASIS to ASIS and add a couple of

inches. The correct belt size for the

individual has padding that covers all of the

bony prominences.

• Always check that the child’s pelvis is

symmetrical and positioned securely at

the back of the seat.

• Always ensure that the lap straps and

chest harness hold the child securely

and are comfortable. Ensure they

provide a snug fit, a simple rule of thumb

is to allow two fingers to be inserted

between the belt and the child’s body.

• Never leave a child in a chair unattended

without the lap strap being fastened.

• A lap strap should always be fitted if a

harness is being used.

• When altering the angle between the

seat and the back of the chair always

re-adjust the chest harness and lap

strap accordingly to ensure all safety

recommendations are followed.

!

Page 12

12

Lap Strap Fixing Points

Harness and Lap Strap Positioning

This diagram shows the recommended positioning of the chest harness and lap straps:

Ensure all belt straps are secured over the lock bar (C) and clamp is closed down in its locked position

(B) & (A).

All straps & harnesses

must be securely fitted to

the back of the chair.

The cross strap on the

chest harness must be

fitted no higher than the

sternum (mid chest).

Four-point lap strap

Chest Harness Fitting

Primary Lap Strap

Fitting

Secondary Lap Strap Fitting

AB

C A

Page 13

13

Adjustment Tilt / Prone

Push Handle Adjustment

The chair has been designed to oer a substantial variation of positioning and support, which

the Tilt / Prone angle and back recline mechanism can help to demonstrate. The chair can be

positioned at any point within this range to suit any situation.

Tilt / Prone Angle

• Pulling and holding lever (A) inwards whilst controlling the chair by the Push handle enables

you to alter the seats tilt / prone angle.

• Pulling and holding lever (B) inwards whilst controlling the chair by the Push handle

enables you to alter the seats back recline angle.

• Once a suitable position has been achieved, the lever should be released to lock the chair

in position.

• Push Buttons and hold in. The angle of the

push handle can then be altered which has the

secondary function of adjusting the handle height.

When the required position has been achieved

release buttons ensuring the mechanism “clicks”

into place.

• This may also be used for folding the handle away.

A

B

Page 14

14

Chair Height Adjustment

The height of the chair can be adjusted

by removing pin (A) from the chair leg

and pulling the castor away from the

frame. This will reveal extra holes in

the chrome work (B), which enable

the chair to sit at dierent heights.

When a suitable height has been

achieved re-align the relevant hole and

re-insert the pin to lock the caster leg

into the chair frame. The C ring that

the pin is attached to (C) will lock the

pin into place.

Repeat this process for all four legs.

Always ensure that all four legs are set

at identical height – this will ensure the

chair is level.

A

C

B

Page 15

15

Head Rest Adjustment /

Replacement

Head Rest Height / Replacement

• Turning hand wheel (A) anti-clockwise enables

you to adjust the height of the head rest by

moving it up or down. Re-tighten the hand

wheel to secure into place.

Head Rest Forward / Rearward & Angle

Adjustment.

• Turn levers (B) anti-clockwise to move the

head rest forwards and backwards, allowing

the required head rest angle and position to

be achieved.

• Re-tighten the levers (B) to secure into place.

Head Rest Lateral Wing Adjustment

• To Increase or decrease the angle of the

Head rest lateral wing, turn lever (C) anticlockwise. Rotate the Headrest lateral wing

(D) by pushing forward or backwards until the

required position has been achieved.

• Re-tighten the lever (C) to secure into place.

A

B

C

D

Page 16

16

Arm Rest Adjustment

Arm rest width adjustment Deluxe model only.

• Un-tighten bolts (B) Adjust the arm by

either: pulling it outwards, away from

the seat frame to expand the seat

width or pushing it inwards towards

the frame to narrow the seat width.

• Once a suitable position has been

achieved tighten screws (B) Securely.

Arm Rest Height Adjustment

Un-tighten bolts (A) Adjust the arm by

pulling it Upwards, downwards Once

a suitable position has been achieved

tighten screws (A)

A

A

A

B

Page 17

17

• Turning both levers (A) anti-clockwise

releases the lock and allows height adjust of

the back rest. Lift up to increase the height

or push down to lower the height.

• The height of the back should be adjusted to

fit the size of child and seat them in comfort.

• Once a suitable position has been found the

levers should be re-tightened by turning clock

wise ensuring they are tight.

Shoulder Protraction Pad

• Turn soft touch hand wheel (B) anti-clockwise

to loosen and Swing-away.

• Re-tighten clockwise to secure.

A

B

Back Height Adjustment

Applying / Releasing Brakes

Applying Brakes

Depress lever (A) with your foot. To secure the chair

in place you should suppress all the brakes fitted to

the wheels on the base.

Releasing Brakes

To release the brakes you should flick the levers up

using the top of your foot. When all brakes are released

the chair will be free to travel in any direction.

A

Page 18

18

Lateral Support Width & Height

• Using the 4mm Allen Key T bar supplied, turn

bolts (A) 1/2 a turn anti-clockwise to release

the lateral support.

• Move the lateral support in, out, up or down

until the required position has been achieved.

• Once the required position has been achieved,

turn bolts (A) clockwise until tight. Ensure

the Lateral support is secure and positioned

correctly for the users’ needs and comfort.

• Pull out locking pin (B) to disengage the lateral

support. Hold the locking pin out and move

the lateral pad in an outward direction to swing

away.

• Repeat in reverse to swing the Lateral support

back into position, ensuring the locking pin

clicks securely into place.

• Ensure the Lateral support is secure and

positioned correctly for the users’ needs and

comfort.

• Turn hand wheel (C) anti-clockwise to release

the friction lock.

• The hip pad can be moved in, out and can be

angled up or down as required.

• Once the required position has been achieved,

turn hand wheel (C) clockwise until tight.

• Ensure the Pelvic Support is secure and positioned

correctly for the users’ needs and comfort.

A

Lateral Support Adjustment

Hip Pad Adjustment

B

C

Page 19

19

Horizontal Positioning

• Turn lever (A) anti-clockwise to adjust the height positioning of the pommel.

(The pommel can be completely removed from the frame using this method

and then re-inserted once the child is seated.)

• Turn the lever clockwise to fix the pommel securely into place.

Vertical Positioning

• Turn lever (B) anti-clockwise to adjust the vertical positioning of the

pommel.

• Once a suitable position has been achieved re-tighten the lever by turning

it clockwise.

Pommel Positioning

A

B

Page 20

20

Vertical position of footplate

• Turn levers (A) anti-clockwise to

adjust the vertical position.

• Extended the footplate to suit the

child and provide suitable support

and comfort.

• Re-tighten the levers to secure into

place.

Footplate angle

• The footplate can be flipped out of

the way by pushing it up towards

the frame. Lever (B) shown acts as a

stop to position the footplate at the

desired angle.

• Screw the lever clockwise to increase

angle, anti-clockwise to decrease.

Footplate extension

• Un-tighten levers (C) and pull down

the footplate to extend or pull

upwards to shorten.

• Re-tighten the levers to secure into

place.

Footplate Adjustment

A C

A

B

Page 21

21

• Turn bolts (A) anti-clockwise with the

5mm T bar Allen key provided.

• Move the backrest forward or

backwards until the required seat

depth has been achieved.

• Turn bolts (A) clockwise to tighten,

ensure the bolts are secure and tight.

Seat Depth Adjustment

A

• Located on the lower horizontal backrest rail.

• Lift back rest cushion to reveal.

Product Labelling

Page 22

22

We recommend the following points for successful cleaning of your equipment. (It is possible that some

surface wrinkling may occur following these processes)

Fabric Upholstery Care

Refer to JCMs fabric cleaning guide which can be found on their website www.jcmseating.co.uk

Do not use bleach, acidic, solvent, abrasive, biological or phenolic based cleaners.

Metal Framework

• If all upholstery is removed the metal framework can be cleaned with hot soapy water and detergent

or it can be steam cleaned. (Labelling may need to be replaced following steam cleaning).

• Ensure that the framework is thoroughly dried after cleaning.

• Always ensure that any moving or adjustable parts are re-lubricated.

General maintenance should be carried out by a competent, professional person who is well informed

on how to use the equipment (see warranty - page 25) if there is no such person available or a more

thorough check is needed, a service via an approved repairer (see opposite) should be booked. The

person who carries out the maintenance check or service should always fill out the service history log

record (page 24) in order to ensure the warranty remains valid.

As documented opposite, the degree of maintenance required is dependent on various factors relating

to the use of the product. In addition to the specific functional adjustment warnings specified in this

manual, it should be ensured that a thorough inspection of the following should be completed at no

greater than 6 month intervals:

Points listed here are generic across the JCM range and do not apply to all products.

Cleaning & Care

General Maintenance

!

Castors

Lift base and check each wheel to ensure it is not damaged, loose or worn.

Brakes

• Removing any grease or dirt that has built up on the wheels, check that the brakes stop the wheels

rotating.

•

Chec

k they are securely fixed in place & that there are no signs of damage or wear & tear.

Pushing Handles

• Ensure handles are functioning correctly.

• Check there are no signs of damage or wear and tear.

•

Ensur

e push handle grips are secure.

Seat Tilt in Space

Mechanism

• With the tilt lock released check for free movement with no signs of damage or wear to the mechanism,

lever or cables.

• Tighten the lock and ensure it holds the seat angle.

Seat / Backrest Upholsters

• Check the attachment points of the seat and backrest upholstery are tight.

• Check for worn covering. Rough worn upholstery can cause discomfort and would be dicult to

• keep hygienically clean, which may cause skin irritation.

Frame

With correct maintenance the

frame should provide at least

5 years trouble free use but,

depending on conditions of use,

wear will occur and a thorough

inspection is recommended.

• Check all metal parts to ensure there are no signs of damage or wear and tear, paying particular attention

to adjustable or moving parts.

•

Chec

k there are no signs of failure in joints and welds.

•

Chec

k tightness & security of all fixings, bolts, nuts, spring loaded pegs, & other fitments.

•

Chec

k for signs of fatigue wears, replace parts that show signs of wear or repeatedly becoming loose.

Fixtures

Check arm pads and headrest, replace if worn.

Page 23

23

What should be completed during a service?

A service is a comprehensive combination of inspection, maintenance and repair or replacement of

worn, faulty or missing components. The growth and any changes of the occupants needs since the

original assessment is taken into account when performing the service. This is in contrast to general

maintenance (opposite), where only straightforward checks, inspections and adjustments take place and

primary services are planned.

What happens if a fault is found?

If any faults are found that could prove to be a risk to either the user or the operator then all use of the

equipment should be ceased immediately until the product has been repaired.

Who should carry out the service?

It is stressed that only a JCM approved repairer or a person with competent training of a Class 1 medical

device should carry out this work.

Any modifications must not be carried out without prior agreement of JCM Seating Solutions Ltd. It

must be understood that unauthorised modifications may pose a risk to all users and attendants, as well

as potentially invalidate the warranty.

Any new parts required should be genuine JCM Seating Solutions Ltd. approved parts, fitted to JCM

specifications.

Frequency of Service

JCM recommend that a service of this product is completed once every 6 months as a minimum.

However, the frequency of inspection and service must be altered depending upon the severity of use. If

the system is used in any of the following ways then the use could be said to be fairly heavy and constant.

Therefore we would recommend the service interval be reduced to once every three months;

• Daily for around 8 to 10 hours.

• Weekly for at least 6 days out of 7.

• Monthly for at least 11 months a year.

• By an active user or somebody who is very active voluntarily or involuntarily.

• By a user who is above 80% of the maximum user weight recommended.

• Transported in a moving vehicle twice or more in a day.

If the usage exceeds the amount highlighted above it is possible that services every six weeks or less

might be needed.

How to book a service

JCM have specified technicians trained to service our products. If you would like JCM to service

your chair or for further information please contact us on 01733 405830.

Alternatively, contact the person who issued you with the product.

Servicing via Approved

Repairer

Page 24

24

This log is an important record of usage and care of the product. It is a primary tool in predicting the

need for further service and maintenance. It should be completed each time an inspection, service

or any other significant manipulation has taken place. JCM Seating Solutions Ltd. will require proof of

service for any warranty claims or orders.

Please contact JCM if additional log sheets are required.

Service Record Log

DAT E SERVICE PERFORMED ORGANISATION

PRINT NAME &

SIGN

SERIAL NUMBER

___________________

DATE DELIVERED

______/______/______

Page 25

25

Products manufactured by JCM are covered with a manufacturer’s 3 year warranty.

What it covers

The warranty covers all aspects of product failure due to faulty workmanship or

manufacturing.

Period of Cover

The period of the warranty runs for 3 years from the date that the product is

dispatched.

The Work JCM is obliged to Complete

JCM’s obligation under this warranty is to replace or repair any defective goods

within the period of the warranty free of charge.

What the Warranty Does Not Cover

• Items that are damaged or fail due to natural wear and tear, extreme usage, neglect

or misuse.

• Accidental damage, modifications or repairs carried out by a third party

unauthorized by JCM or non-professional healthcare representative.

Customer Responsibility

To ensure the warranty remains valid, customers are advised that servicing,

maintenance and re-issuing guidelines must be followed and documented as stated

in the manual.

JCM will require proof of service (see opposite) for any warranty claims or orders.

When making a claim JCM reserve the right to inspect the product and all necessary

documentation.

Only valid for products purchased after 1st April 2006. Applies only to products exclusively manufactured by JCM.

3 YEAR WARRANTY

Important

JCM Seating Solutions Ltd. will not be held responsible for any damage or injury caused by

incorrect use of this product. For any information or guidance on the use of this product please

call our oce who will put you through to your local representative or send you any additional

information you may require.

Tel: 01733 405830

!

Page 26

26

Inspecting & Reissuing of Equipment

Most JCM Seating Solutions Ltd. products are individually assessed for a client

prior to issue. They are handed over in a controlled way to ensure optimum fit and

specification, checks are completed and any additional individual verbal instructions

given. We therefore recommend the following points are adhered to prior to any reissue of equipment:

Cleaning

Follow a rigorous process of cleaning in

order to decontaminate the product and

eliminate the chance of cross infection.

Assessment of Fabrics / Foams

Carefully assess the condition of fabrics

and foams in the seating product, and have

these replaced partially or even completely

if need be. In severe cases if the chassis is

worn and the seating in poor condition

it may be necessary to have the product

re-furbished by the manufacturer. In very

severe cases if the chassis is badly worn and

the seating in very poor condition then the

product should be decommissioned and

disposed of.

Electrical and Electronic Equipment

Decomissioning

If your product is set up with an electrical

function you should always contact JCM

or your authorised representative for decomissioning information.

Appropriateness of Equipment

Check that the equipment supplied is

appropriate for the needs of the user

taking age, weight, ability, diagnosis, and

any other important factors into account.

For instance, JCM Seating Solutions Ltd.

products may not be suitable for persons

with severe challenging patterns of

behaviour. Also ensure safe specified limits

for use are not exceeded by the new user.

Your sales representative can advise on the

suitability of the equipment.

Manuals and Records

Ensure this instruction manual and any

additional manuals for the seating unit

are handed over to the new user with

the equipment and ensure the servicing

log history is up to date. Records on the

new user must be updated to maintain

traceability.

Inspection

The equipment should have a rigorous

inspection prior to the reissue, to

include the points covered in the six

monthly routine check, regardless of if

the checks were recently completed. The

equipment should be free of excessive

wear or distortion in any aspect of its main

construction or accessories.

Condition

Wheels, tyres and brakes must be in good

working condition, properly adjusted and

inflated as appropriate.

Page 27

27

Accessories

Check all accessories carefully for damage

and potential shortcomings which may

pose a risk to the user.

Function

Ensure that all the functions of the chair

are working correctly e.g. tilt in space,

height adjustment, back recline, folding

etc.

Fixings

Check that any knobs, hand wheels,

nuts, bolts, levers and fixings are in good

condition and fitted in place securely.

Modifications

Any special modifications, adaptations,

alterations or other such procedures

including added accessories may require

review. If they are found inappropriate,

remedial action (if considered safe and

practical) should be taken to reverse them

if possible.

Labelling

Any labelling specific to the previous user

should be removed and replaced with

labelling specific to the new user.

Adjustment

Adjustment of the equipment to the

new user must be carried out by suitably

qualified and experienced professionals.

These adjustments along with the other

appropriate checks and tests should be

completed with the owners knowledge

and agreement.

Hand Over

Competent handing over of the

equipment to the new user or attendant

must include proper training and

advice in safe use, particularly regarding

transportation issues.

Packaging

Always ensure that the chair is packaged

correctly before delivery.

Page 28

Q.A.90 (March 2016)

© 2016 JCM Seating all rights reserved.

www.jcmseating.co.uk

Loading...

Loading...