Page 1

1

ELECTRONIC CASH REGISTER

J3500E

SERVICE MANUAL

DOCUMENT No. 5190-02-03

REV.01

TITLE : J3500E SERVICE MANUAL

DRAW CHECK APPR.

PREPARED BY K. SAKAUE 2004/12/6

APPROVED BY

COPY RIGHT 2004 BY JAPAN CASH MACHINE CO., LTD.

Page 2

2

TABLE OF CONTENTS

1 Introduction..................................................................................................................................................................1

2 Installation procedure..................................................................................................................................................1

2.1 unpacking ..............................................................................................................................................................1

2.2 Emergency cash drawer release...........................................................................................................................2

2.3 Preparation for use .............................................................................................................................................2

Dip switch setting....................................................................................................................................................2

Initial reset procedure.............................................................................................................................................2

Diagnostics...............................................................................................................................................................3

3 Theory of operation ......................................................................................................................................................4

3.1 system block diagram............................................................................................................................................4

3.2 circuit description..................................................................................................................................................5

3.2.1 power circuit ...................................................................................................................................................5

3.2.2 PF CIRCUIT ...................................................................................................................................................6

3.2.3 KEY BOARD CIRCUIT..................................................................................................................................7

3.2.4. display circuit ................................................................................................................................................8

3.2.5. printer drive circuit .......................................................................................................................................9

3.2.6. Comparator circuit ........................................................................................................................................9

3.2.7. Motor drive circuit(paper feed motor) ........................................................................................................10

4 Trouble shooting ...................................................................................................................................................... 11

5 CONNECTOR LAYOUT .........................................................................................................................................13

5.1 CONNECTOR TABLE......................................................................................................................................14

5.2 Standard inner cable pin assignment ................................................................................................................16

5.3 Optional cable pin assignment ...........................................................................................................................16

6 Appendix .....................................................................................................................................................................17

Revision table ................................................................................................................................................................18

Page 3

1

1 Introduction

J3500E consist of 5 block

(1)Main CPU board

Main CPU:M16C/80 Renesas device 16 bit MPU

RAM 4M bit (battery back up)

EPROM 4M bit CMOS

(2) Front display unit

(3) Rear display unit

(4) Key board unit

(5) Power supply unit

2 Installation procedure

2.1 unpacking

The ECR packing method is shown fig 2-1.

Unpack the ECR an check that the following items are present.

(1) One roll of thermal rolls 58mm

(2) key set

(3) J3500E owners manual

(4) Dust cover

If the ECR was received in a damaged carton, unpack and inspect for physical damage immediately,

As described in table 2-1. If damage is found, contact the freight carrier and file a claim promptly,.

If any parts are missing, contact JCM within one week of receiving the ECR.

Initial inspection

Perform the appearance and mechanical checks as listed on table 2-1.

The ECR cabinet can be detached by removing the two screw on the back side of the cabinet.

Table 2-1 Check List

Inspection check

Appearance A. surface of cabinet , keyboard, and cash drawer for damage

such as dents and scratches.

B. display windows for damage such as

cracks or scratches.

Mechanical A. all electrical connections for proper seating

B. keys in mode lock for proper operation.

C. Cash drawer for smooth operation when released manually.

See selection 2.3 for release details.

Page 4

2

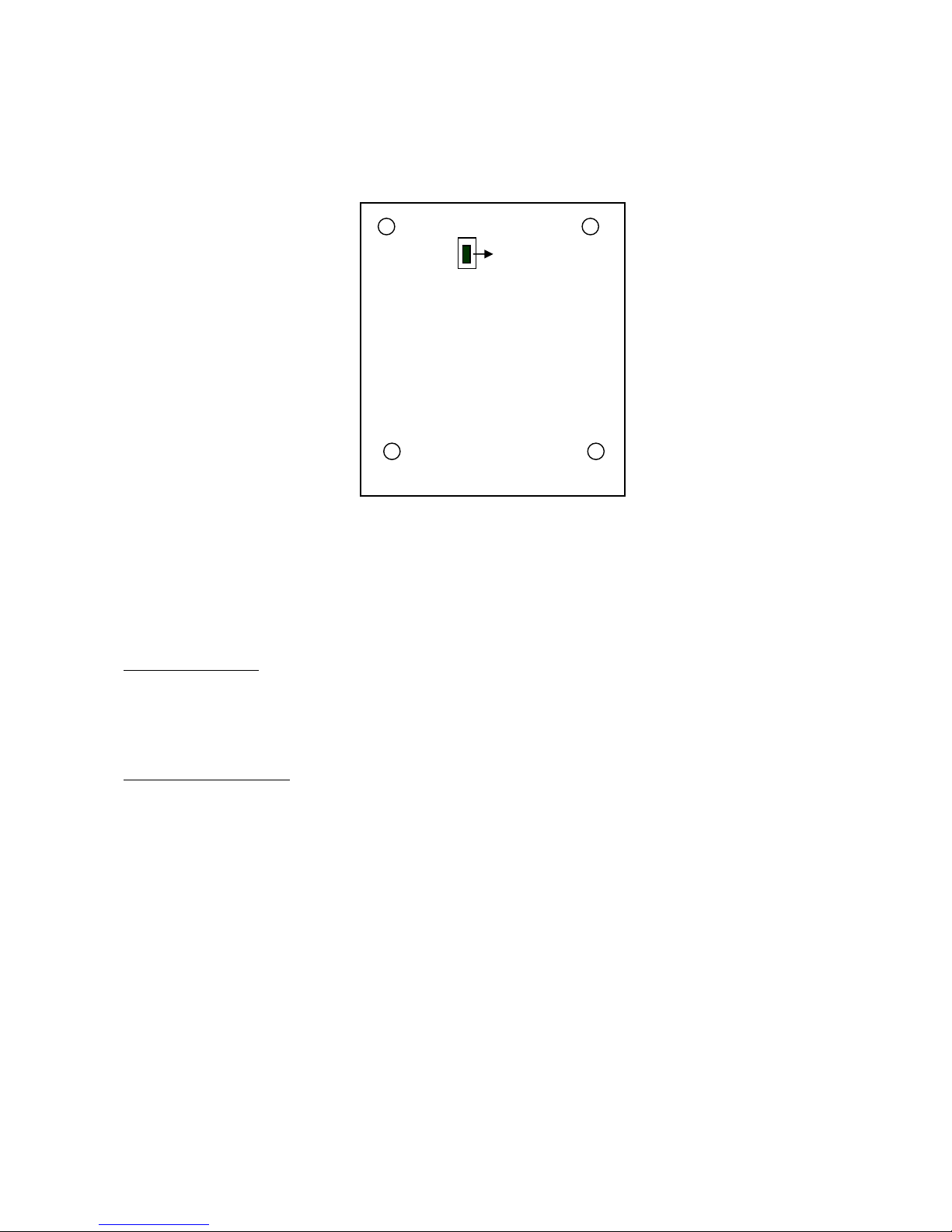

2.2 Emergency cash drawer release

In the unlikely event of a machine malfunction or a prolonged power failure, the model J3500E is

equipped with an emergency cash drawer release.

The release is located on the rear underside of the cash drawer. To manually release the drawer,

carefully lift one side of the ECR with your left hand and push the release tab with the other.

FIGURE 2-2 Emergency Drawer Release

2.3 Preparation for use

Dip switch setting

Dip switch is located on the front center of the main PCB.

It is used for initialization and hardware configuration purposes.

1: ON initial reset

OFF normal operation

Initial reset procedure

(a) Initial reset

(1) set DIP sw1 to ON.

(2) Power ON.

Clears RAM work area only (current transaction)

Does not effect totals/counters or program memory.

Operation mode become “P” mode.

(b) RAM clear(all clear)

(1) Turn the mode lock key to the “P”mode.

(2) Set DIP sw1 to ON

(3) Power ON while depressing the tenkey ”1”.

(4) All clear is displayed.

Clears all Totals/counters and user programmed memory. Loads default operation program

After all clear operation, you must preset the date and time in “X” mode.

The machine does not work without setting date and time.

Rear

BOTTOM VIEW

FRONT

release

Page 5

3

Diagnostics

(1) turn the mode lock key to “P” position, or assign to “P” mode(4---key).

(2) Enter xxxxxxxxx(9digit) --- #/NS

555555555-----#/NS automatic receipt issue at 3 minutes interval.

555555551-----#/NS automatic receipt issue at 5 second interval without cutter.

555555552-----#/NS automatic receipt issue at 5 seconds interval with cutter.

666666666-----#/NS communication port loop back test

check the com. Port from 1 to 3.

Following result message is printed

Error2 RTS---CTS defect

Error4 RxD ---TxD defect

777777777-----#/NS automatic printing test

All characters are printed on receipt automatically.

You can do a check of printing quality.

It’s terminated by depressing “CL” key

888888888-----#/NS key board test

the display will show the each key’s position number on the right side 2 digit

various signal status will be showed each digit on the display.

It’s terminated by depressing “CASH” key.

For example(display)

P

1 0 1 4 5

Key position code

Blank area

Receipt paper empty

Head up switch

Control key position

999999999-----#/NS version and check sum display

The software version number and checksum of EP-ROM will displayed.

For example(display)

1 - 0 0

E F 1 0 3

check sum

destination spec.

Version number

Page 6

4

Section 2

3 Theory of operation

3.1 system block diagram

SCOM3 is reserved

The ECR circuitry can be broken down into six major sections: MPU, Memory, Display,

Key board, Printer, and power supply.

The heart of this system consists of a M16C/80, Sixteen bit microprocessor

implementing L.S.I, high speed, and low power consumption.

Standard memory includes a 512k x 8 bit EPROM and a 512k x 8 bit static RAM chip.

Printer unit

GTP58

With auto cutter

Front display

9 digit(LED)

SCOM1 SCOM2

Rear display

9 digits(LED)

MPU

M16C/80

E-PROM’(4M)

4M

RAM

232C DRIVER

KEY BOARD

9 X 8 MATRIX

CONTROL LOCK

PRINTER

DRIVER

CIRCUIT

DRAWER

DRAWER

DRIVER

POWER

CIRCUIT

LED driver

(digit)

SCOM3

SWITCHING

POWER SUPPLY

(+24V)

MAIN

LED driver

(segment)

Page 7

5

C46

104C

1011

U12E

SN74LV14APW_VBB

+-

BT1

3/V 280R

R5

122

R43

103

1

TP2

TEST POINT

1

TP3

TEST POINT

R42

103

C47

104C

R44

103

1011

U10E

SN74LV14APW

1213

U12F

SN74LV14APW_VBB

1

2

3

4

CN2

B4P-VH

D2

HZU15B2

VOUT

1

MNURST

2

VCC

3

GND

4

U9

PST591CMT

1213

U10F

SN74LV14APW

C3

104C

R3

122

D3

HZU4.3B2

1

TP1

TEST POINT

nPF

nRESET

VCC

+24V

+24V

VCCVCC

VBB5 VBB5

nRESET-VBB

89

U12D

SN74LV14APW_VBB

65

U12C

SN74LV14APW_VBB

VBB5 VBB5

VOUT1VIN

2

CB

3

FB

6

NC5GND4ON/OFF

7

U1

LM2676S-5.0

C5

103C

D4

EC31QS06

C6

UPW1H471MHH

C7

UPW1V471MPH

L1

SLF12565T-470M2R4

R11

561

R10

221R9OPEN

VOUT8VIN

7

CB

1

FB

4

NC2GND

6

ON/OFF

5

NC

3

U2

LM2675M-5.0

C9

103C

D7

EC31QS06

C8

UPW1H471MHH

C13

UPW1V101MPH

+5VSUB

D6

CMS06

D5

CMS06

R8

100

C4

16V100u LL

VBB

VCC

C10

16V100u LL

RESET-VBB

FL1

DSS9ND31H223

FB5

BLM21PG600SN1

L2

SLF12565T-470M2R4

89

U10D

SN74LV14APW

43

U10B

SN74LV14APW

65

U10C

SN74LV14APW

21

U10A

SN74LV14APW

43

U12B

SN74LV14APW_VBB

3.2 circuit description

3.2.1 power circuit

After passing through the switching regulator. There is a +24V DC power via CN2.

+24V power is supplied to printer circuit. On the other hand, it’s supplied to regulator

circuit too. There are two regulator circuit.

U1(LM2676S-5.0) is used for logic circuit and for memory back up circuit.

+24V pass through U1(LM2676S-5.0) becomes +5V steady.

During normal operation, the voltage of Vbb line is supplied by +5V line.

Rechargeable current is applied to rechargeable battery via R8.

When AC power is removed, the +5V line decreases, and D5 is turn OFF.

Then the battery supplies Vbb line. And back up the memory contents of RAM chip and CPU

Internal RAM

D5 is used to avoid reverse current when power OFF.

U2(LM2675M-5.0) is used for communication circuit.

+24V pass through U2(LM2675M-5.0) become +5V steady.

Page 8

6

3.2.2 PF CIRCUIT

Power ON

When AC input turn ON, the level of U12-11 rise up to +4.3V.

When input voltage of U12-11 become 3.3V, the output of U12-12(nPF) turn “H”.

Then system goes to operation mode.

Power OFF

When AC input turn OFF, the level of U12-11 fall to 0V.

When input voltage of U12-11 become 2.2V, the output of U12-12(nPF) turn “L”.

Then system goes to standby mode.

+21.6V 24.4V

19.6V

PF signal

+5V

PF signal timing chart

Page 9

7

KR0

1

KR1

2

KR2

3

KR3

4

KR4

5

CN13

W-D0805#01

KS0

1

KS1

2

KS2

3

KS3

4

KS4

5

KS5

6

KS6

7

KS7

8

KS8

9

CN15

W-D0809#01

COM

1

REG

2

X

3

Z

4

P

5

SP

6

CN14

5267-06A

KS[0..3]

KEY SCAN

KEY RETURN

CONTROL

A

1

B

2

C

3

G1

6

G2A

4

G2B

5

Y0

15

Y1

14

Y2

13

Y3

12

Y4

11

Y5

10

Y6

9

Y7

7

U22

SN74LV138APWR

A

1

B

2

C

3

G1

6

G2A

4

G2B

5

Y0

15

Y1

14

Y2

13

Y3

12

Y4

11

Y5

10

Y6

9

Y7

7

U21

SN74LV138APWR

D23 1SS355

D14 1SS355

D20 1SS355

D15 1SS355

D21 1SS355

D16 1SS355

D22 1SS355

D17 1SS355

D18

1SS355

D19

1SS355

VCC

FB75 BLM21AG121SN1

FB76 BLM21AG121SN1

FB77 BLM21AG121SN1

FB78 BLM21AG121SN1

FB79 BLM21AG121SN1

FB80 BLM21AG121SN1

FB81 BLM21AG121SN1

FB82 BLM21AG121SN1

FB83 BLM21AG121SN1

FB64 BLM21AG121SN1

FB66 BLM21AG121SN1

FB68 BLM21AG121SN1

FB70 BLM21AG121SN1

FB72 BLM21AG121SN1

FB74 BLM21AG121SN1

FB65 BLM21AG121SN1

FB67 BLM21AG121SN1

FB69 BLM21AG121SN1

FB71 BLM21AG121SN1

FB73 BLM21AG121SN1

1

2

4

3

DSW1

KSD-02

D13

1SS355

D12

1SS355

R68

473

R66

473

R69

473

R67

473

R64

473

C77

101C

C75

101C

C78

101C

C76

101C

C74

101C

KS0

KS1

KS2

KS3

KR[0..4]

KR[0..4]

KR0

KR1

KR2

KR3

KR4

VCC VCC VCC VCC VCC

2345789

1106

RA6

RA104

VCC VCC

R63

104

R65

104

VCC VCC

KS[0..3]

3.2.3 KEY BOARD CIRCUIT

Input and output signal for key board scanning are passing through CN13~CN15.

The output signals from output port (P140-P143) of U11 are encoded signals.

By passing through U21,U22(74HC138), they are decoded to key scan signals. And they are

applied to key matrix via CN15.

When a certain key is depressed, one of decoded signal is applied to U11(MPU) via CN13.

Thus U11(MPU) recognizes which key is depressed and executes key’s specific operation.

The scanning signal from U26 –Y1 scans control lines KR0-KR4 and they are applied to

U11(MPU) as control signals.

According to the status of control signals, U11(MPU) executes specific operation.

Scan signal

MPU

Data bus

Fig 3-1 key board circuit

Timing chart of key scan signals

P140

P141

P142

P143

Y0

Y1

Y2

Y7

5.48msec

Page 10

8

3.2.4. display circuit

Display signals are applied to display circuit board via CN3.

The display signals for digit indication are supplied from P120 to P127 and P145,P146 of CPU ports.

The digit indication signals are amplified at 9 FETs.(2SJ208) And they are supplied to LED common

terminal on FD and supplied to RI ones.

The segment data signals are amplified at U14’(M54583) and supplied to segment line of FD and RI

circuit board.

From CPU

board

segment

signal

for RI

digit signal

for RI

DET1

1

DSP A

2

DSP B

3

DSP C

4

DSP D

5

DSP E

6

DSP F

7

DSP G

8

DSP P

9

DSP G1

10

DSP G2

11

DSP G3

12

DSP G4

13

DSP G5

14

DSP G6

15

DSP G7

16

DSP G8

17

DSP G9

18

DSP G10

19

DET2

20

CN3

52045-2010

1110

2

3

4

5

6

7

8

9

19

18

17

16

15

14

13

12

U14

M54583FP

VCC

VCC

VCC

2345789

1106

RA1

RA103

R7

103R6103

VCC

R39

102

R38

102

R37

102

R36

102

R35

102

R34

102

R33

102

R32

102

R30

102

R29

102

DSPG1

DSPG2

DSPG3

DSPG4

DSPG5

DSPG6

DSPG7

DSPG8

DSPG9

DSPG10

DSPG[1..10]

DSPG[1..10]

FB62 BLM21AG121SN1

FB47 BLM21PG600SN1

FB46 BLM21PG600SN1

FB49 BLM21PG600SN1

FB48 BLM21PG600SN1

FB51 BLM21PG600SN1

FB50 BLM21PG600SN1

FB53 BLM21PG600SN1

FB52 BLM21PG600SN1

FB55 BLM21PG600SN1

FB54 BLM21PG600SN1

FB57 BLM21AG121SN1

FB56 BLM21AG121SN1

FB59 BLM21AG121SN1

FB58 BLM21AG121SN1

FB61 BLM21AG121SN1

FB60 BLM21AG121SN1

FB63 BLM21AG121SN1

DSPS[1..8]

DSPS[1..8]

DSPS1

DSPS2

DSPS3

DSPS4

DSPS5

DSPS6

DSPS7

DSPS8

FB45

BLM21PG600SN1

C54

103C

C52

103C

C48

103C

C63

103C

C26

103C

C62

103C

C73

103C

C72

103C

C70

103C

74LV00A 74LV14A 74LV14A 74LV32A 74LV32A 74LV123A 74LV138A 74LV138A LMV358

C66

103C

LM393

VBB VBB VCC VCC VCC VCC VCC VCC VCC VCC

8PIN

7PIN 7PIN 7PIN 7PIN 7PIN 8PIN 8PIN 8PIN 4PIN

8PIN

4PIN

16PIN 16PIN16PIN14PIN 14PIN14PIN14PIN14PIN

2

13

Q14

2SJ208

2

13

Q6

2SJ208

2

13

Q13

2SJ208

2

13

Q5

2SJ208

2

13

Q12

2SJ208

2

13

Q4

2SJ208

2

13

Q11

2SJ208

2

13

Q3

2SJ208

2

13

Q10

2SJ208

2

13

Q2

2SJ208

Page 11

9

G

D

S

Q8

2SK2569

R

CX

RX/CX

&

1

2

3

14

15

4

13

U16A

SN74LV123APW

S

2

D

6

D

7

S

3

G

4

S

1

D

5

D

8

Q9

IRF7424

D25

1SS226

R52 153

C69

104C

R57 472

1

2

3

U5A

SN74LV32APW

-

+

3

2

1

U19A

LM393M

R14

472

R60

103

R

CX

RX/CX

&

9

10

11

6

7

12

5

U16B

SN74LV123APW

R58

222

C28

101C

R53

473

9

10

8

U5C

SN74LV32APW

C61

35V 1000u

R54

103

C25

471C

R12

472

-

+

5

6

7

U19B

LM393M

12

13

11

U5D

SN74LV32APW

R51

103

R50

103

4

5

6

U5B

SN74LV32APW

C64

104F

C35

471C

R56

472

R49

103

C33

101C

R13

103

C23

471C

PRI_EN

PRSTB1

PRSTB2

TH

PR/LAT0

PRCLK0

PRDIO

nRESET

VCC

VCC

+24V

VCC

VCC VCC VCC

VCC

VCC

TH

TH

VH

28

VH

27

TM1

19

TM2

9

DO

24

GND

18

GND

17

GND

16

GND

15

VDD

8

/STB3

7

/LAT

22

CLK

23

/STB2

6

VH

4

VH

3

VH

26

VH

25

VH

2

VH

1

DI

5

NC

21

/STB1

20

GND

14

GND

13

GND

12

GND

11

GND

10

CN7

28FE

VCC

1

2 12

13

U17A

SN74LV10APW

PRSTB3

FB28

BLM21AG121SN1

FB31

BLM21AG121SN1

FB29

BLM21AG121SN1

C29

101C

4

5

6

U15B

SN74LV32APW

12

13

11

U15D

SN74LV32APW

1

2

3

U15A

SN74LV32APW

9

10

8

U15C

SN74LV32APW

FB26 BLM21AG121SN1

FB27 BLM21AG121SN1

FB32 BLM21AG121SN1

FB30

BLM21PG600SN1

C32

104C

C60

35V 1000u

C30

50V 10u

C27

50V 10u

C22

50V 10u

C24

50V 10u

4

5

6

3

U17B

SN74LV10APW

9

10 8

11

U17C

SN74LV10APW

3.2.5. printer drive circuit

Printer drive circuit consists of U11(MPU), U15,U16,U17 and U18 (driver), U19 (comparator)

Usually, P73 outputs “L” level. When one of department key is depressed, CPU outputs printer power

Signal “H”(PRI_EN) from output port P73 of U11. Q8and Q9 turn ON. Thus the thermal head

On the printer mechanism is activated.

Serial print data input from “PRDIO” is transferred to the shift register synchronously with the

Clock ”PR_CLK0”, then stored in the latch register at the timing of the latch ”PR/LAT0” signal.

The heat elements which correspond to the latched print data are activated while each gate is on.

The gates are on while each head activation signal (PRSTB1-PRSTB3) is low.

3.2.6. Comparator circuit

The thermal head has a thermistor for detect the head temperature.

The level of the “TH” is changed according to head temperature.

When head is heated too high temperature, the output level of comparator goes to “H” level.

Thus thermal head will be non-activity.

This status is released when the head become cool.

Page 12

10

F2

CCP2E25

PH1

PH2

DA0

+24V

OUT1A

17

OUT2A

20

OUT1B

14

OUT2B

23

VCC

8

VBB

24

VREF1

10

VREF2

4

GND

6

GND

7

GND

18

GND

19

RC2

5

RC1

9

SENSE1

15

E1

16

SENCE2

22

E2

21

PHASE1

11

PHASE2

3

I01

13

I02

1

I11

12

I12

2

U18

UDN2916LB

1B

3

1A

1

2B

4

2A

2

M

CN8

B04B-PASK-1

-

+

3

2

1

U20A

LMV358M

R59

563

R55

563

R18

102

R15

102

R17

1W 0R82

R16

1W 0R82

C36

471C

C34

471C

C67

471C

C68

471C

R62

106

R61

OPEN

FB36 BLM21PG600SN1

FB34 BLM21PG600SN1

FB35 BLM21PG600SN1

FB33 BLM21PG600SN1

C31

50V100u

C65

104C

VCC

MOT_I0

MOT_I1

D8

SS16D9SS16

D10

SS16

D11

SS16

3.2.7. Motor drive circuit(paper feed motor)

After PF_I0,PF_I1 set to “L” level, the signal PF_PH1,PF_PH2 are sequentially changed

for to feed the receipt paper. Similarly after JF_I0,JF_I1 set to “L” level, the signal JF_PH1,

JF_PH2 are sequentially changed for to feed the journal paper.

Page 13

11

+

4 Trouble shooting

Phenomenon condition Considerable cause Check point/method Remedy

AC power is not supplied

AC power is not applied to

switching power supply.

Is AC power plug connected to outlet?

Is outlet voltage normal?

Is fuse (primary side of switching

Power supply?

Is 24V output from secondary side of

switching power supply?

Connect the plug to outlet.

Replace the fuse

Replace the switching power supply.

Is DC power voltage

normal?

+5V is not generated.

Is D6 defect?

Is U1 defect?

Replace D6

Replace U1.

Crystal is not oscillating. Check wave form pin 20 and

Pin 22 of U11(frequency 20MHz)

Replace crystal(x1)

Replace U11

Machine

doesn’t work

at all

Printer doesn’t work

after power on

The levels of PF lines don’t

become “H”

Is D2 defect?(open)

Is U12 defect?

Is D3 defect?(short)

Replace D2

Replace U12

Replace D3

Date/time

data fails.

Date doesn’t

increment.

Date /time data

doesn’t increment

correctly

Crystal(x2:32.768kHz) is

not oscillating properly.

Check wave form of pin 17 and pin 18 of

U11(frequency:32.768kHz)

Replace crystal(X2)

Buzzer

doesn’t sound

Trouble in buzzer circuit. When pin 10(P144)of U11 output “H”,

buzzer is driven.

Is Q7 defect?.

Replace the buzzer.

Replace Q7

Drawer is not

opened

Drawer solenoid

doesn’t operate.

Trouble in drawer circuit When pin 114(P114)of U11 output “H”,

drawer solenoid is driven.

Is Q1 defect?.

Replace Q1

Abnormal

print out

Printed character is

Not desired.

The level of thermister

signal is not stable.

Printer is defect.

Is the signal level of pin 1(U19) stable? Replace U19

Replace printer

Page 14

12

PHENOMEN

ON

CONDITION CONSIDERABLE

CAUSE

CHECK POINT/

METHOD

REMEDY

Is the head unit over heat? When the head is over heated, printing is

stop.

Wait for head becomes cool.

Printer

doesn’t work

at all

Printer motor doesn’t

rotate

Stepping signal does not

generated.

Is the stepping signal output from

P11X(U11)?

Is the stepping signal output from U18

Replace U11

Replace U18

Printer feed

the paper

without

printing

Printer motor does

work correctly

DC power for print head

unit is not output

When pin12(P142) of U11 outputs “H” ,

the head become active.

Replace Q3,Q4.

The FPC for CPU and FD

units connection is broken

Check conduction of FPC. Replace FPC

Segment signal is not

generated

Is U14 defect? Replace U14

Check the voltage between VF1 and

VF2(tolerance3.46Vrms)

Replace converter transformer

Is the cathode voltage of PD14-23.5V? Replace PD14.

Abnormal

display

Display doesn’t light

Display PCB is broken. Is the display PCB cracked? Replace the display unit

Specific digit

is not lit

correctly

Key input correct Trouble in FD digit driver. Check the condition of the FPC

Check the FET of digit driver.

Replace FPC

Replace FET(Q2~Q6,Q10~Q14

Specific

segment is

not lit

correctly

Display data and time

data are correct.

Trouble in segment drive. Check the condition of the FPC.

Check the output of U14

Replace FPC

Replace U14

2 key are depressed

together

Check whethe r any key keeps depressing. Replace key board unit.

Control mode is lock

position

When control lock is released, lock signal

is applied to KR lines(KR0-KR4)

Replace D10

Check conduction of the control key.

Diodes (D14-D23)

are defect.

Check the diode on the output line of

specific key’s key matrix.

Check diode on key

Matrix output.

Key input

cannot be

accepted

Specific key input

cannot be accepted.

Key depressing section is

defect.

Replace key depressing section

Page 15

13

5 CONNECTOR LAYOUT

OF CPU BOARD

CN4CN5CN6

CN17

CN16

CN15

CN13

CN14

CN3

CN11CN10

CN9

CN8

CN7

PRO M

RAM

CPU

CN2

BATT

CN1

CN12

1 2

PRINT HEAD

MOTOR

SCO M 0

SCOM 1

SCO M 2

DISPLAY

PO WER

DRW

Page 16

14

5.1 CONNECTOR TABLE

CN1 CN2 CN4 CN5 CN6

DRAWER POWER SCOM0 SCOM1 SCOM2

PIN signal PIN signal PIN signal PIN signal PIN signal

1 +24V 1 GND 1 SG 1 SG 1 SG

2 DRW 2 GND 2 TxD 2 TxD 2 TxD

3 DRW SOL 3 +24V 3 RxD 3 RxD 3 RxD

4 SG 4 +24V 4 RTS 4 RTS 4 RTS

5 CTS 5 CTS 5 CTS

6 Vcc 6 DTR 6 DTR

7 DSR 7 DSR

CN3 CN8 CN9 CN10

display MOTOR Paper end Head up SW

PIN signal PIN signal PIN signal PIN PIN signal

1 DET1 11 DSP G2 1 1A 1 LED 1 HS

2 DSP A 12 DSP G3 2 2A 2 SG 2 SG

3 DSP B 13 DSP G4 3 1B 3 NEND 3 NC

4 DSP C 14 DSP G5 4 2B 4 SG

5 DSP D 15 DSP G6 CN13

6 DSP E 16 DSP G7 CN11 CN12 key return

7 DSP F 17 DSP G8 CUTTER SW Paper NEND PIN signal

8 DSP G 18 DSP G9 PIN signal PIN signal 1 KR0

9 DSP P 19 DSP G10 1 CTSW 1 LED 2 KR1

10 DSP G1 20 DET2 2 SG 2 SG 3 KR2

3 NEND 4 KR3

5 KR4

CN7

HEAD CN14 CN15 CN16

PIN signal PIN signal control lock key scan down load

1 VH 15 GND PIN signal PIN signal PIN signal

2 VH 16 GND 1 COM 1 KS0 1 Vcc

3 VH 17 GND 2 REG 2 KS1 2 BUSY

4 VH 18 GND 3 X 3 KS2 3 CLK1

5 DI 19 TM1 4 Z 4 KS3 4 RxD1

6 /STB2 20 /STB1 5 P 5 KS4 5 CE

7 /STB3 21 NC 6 SP 6 KS5 6 EPM

8 VDD 22 /LAT 7 KS6 7 GND

9 TM2 23 CLK 8 KS7 8 RESET

10 GND 24 DO 9 KS8 9 CNVSS

11 GND 25 VH 10 TxD1

12 GND 26 VH

13 GND 27 VH

14 GND 28 VH

Page 17

15

CONNECTOR TABLE (continued)

CN17

3rd DISPLAY

PIN Signal

1 GND

2 Vcc

3 NC

4 L RS

5 L WR

6 L RD

7 L DB0

8 L DB1

9 L DB2

10 L DB3

11 L DB4

12 L DB5

13 L DB6

14 L DB7

Page 18

16

5.2 Standard inner cable pin assignment

COM1 5120-05-03 (for DOS/V pin assign hand scanner)

CN4 signal Direction Dsub 9pin(male) Signal

1 SG GND 5 SG

2 TxD Output 3 TxD

3 RxD Input 2 RxD

4 RTS Output 7 RTS

5 CTS Input 8 CTS

6 Vcc Power 9 Vcc

COM2 5120-05-04 (for DOS/ V PC communication)

CN5 signal Direction Dsub 9pin(male) Signal

1 SG GND 5 SG

2 TxD Output 3 TxD

3 RxD Input 2 RxD

4 RTS Output 7 RTS

5 CTS Input 8 CTS

6 NC

7 NC

8 NC

It can be connected with scanner which have DOS/V pin assign connector directly.

5.3 Optional cable pin assignment

Interface cable for between J3500 and the hand scanner ZE84RMD4JK(Panasonic)

WI-1370

SCOM

side(female)

Signal Dsub 9pin(female) Signal

9 Vcc 9 Vcc

8 CTS 1 CTS

7 RTS 4 RTS

2 RxD 2 RxD

3 TxD 3 TxD

5 GND 7 GND

Interface cable for between J3500 and the GP965

WI-1369

SCOM

side(female)

Signal Dsub 9pin(female) Signal

9 Vcc 6 Vcc

8 CTS 5 CTS

7 RTS 4 RTS

2 RxD 3 RxD

3 TxD 2 TxD

5 GND 1 GND

Application case

1. J3500-----DOS/V scanner

It can be connected directly.

2. J3500-----Panasonic scanner (ZE84RMD4JK)

please use the interface cable WI-1370.

5120-05-03+WI-1370

Page 19

17

3. J3500-----DOS/V PC

It can be connected directly by the cross cable.

4. J3500-----GP965

Case2 : please use the interface cable WI-1369.

5120-05-03+WI-1369 (COM1)

or 5120-05-04+WI-1369 (COM2)

6 Appendix

number of PLU & PB actually maximum occupation.

Standard Memory 256KB Mem. Occ.

PLU 12 char+P-T-D

5349

41 Bytes

PLU 20 char.+P-T-D 4599 49 Bytes

PLU 15 char+stock+P-T-D 4599 49 Bytes

PLU 12 char 6898 30

PLU 20 char 5698 38

PLU 15chrar+stock 5698 38

PB 5698 38 Bytes

Second Lang. The second language have fix

occupation.

16384 Bytes

Electronic journal 5000line x 35 175k Bytes

HARD RESET

It is executed automatically when power is ON.

Page 20

18

Revision table

date description Rev.

Number

Rom ver

2004/12/07 1st edition .01 1.00-3

Loading...

Loading...