Page 1

iVIZION® Banknote Validator Operator’s Guide June, 2014 June, 2014

16

1

For the Americas & Oceania, E-mail: support@jcmglobal.com

For the UK, Ireland, Europe, Africa, Russia & Middle East, E-mail: support@jcmglobal.eu

For Asia E-mail: asiapactechsupport@jcmglobal.com

JCM is a registered trademark of JCM American Corporation. All other product names

mentioned herein may be registered trademarks or trademarks of their respective companies.

Furthermore, ™, ® and © are not always mentioned in each case throughout this publication.

Operator’s Guide

• Notes regarding iVIZION Components:

– Sensor locations are shown in yellow.

– Rollers are shown in blue.

– Drive Belts are shown in orange.

– Release levers are shown in green.

– Anti-stringing area is shown in red.

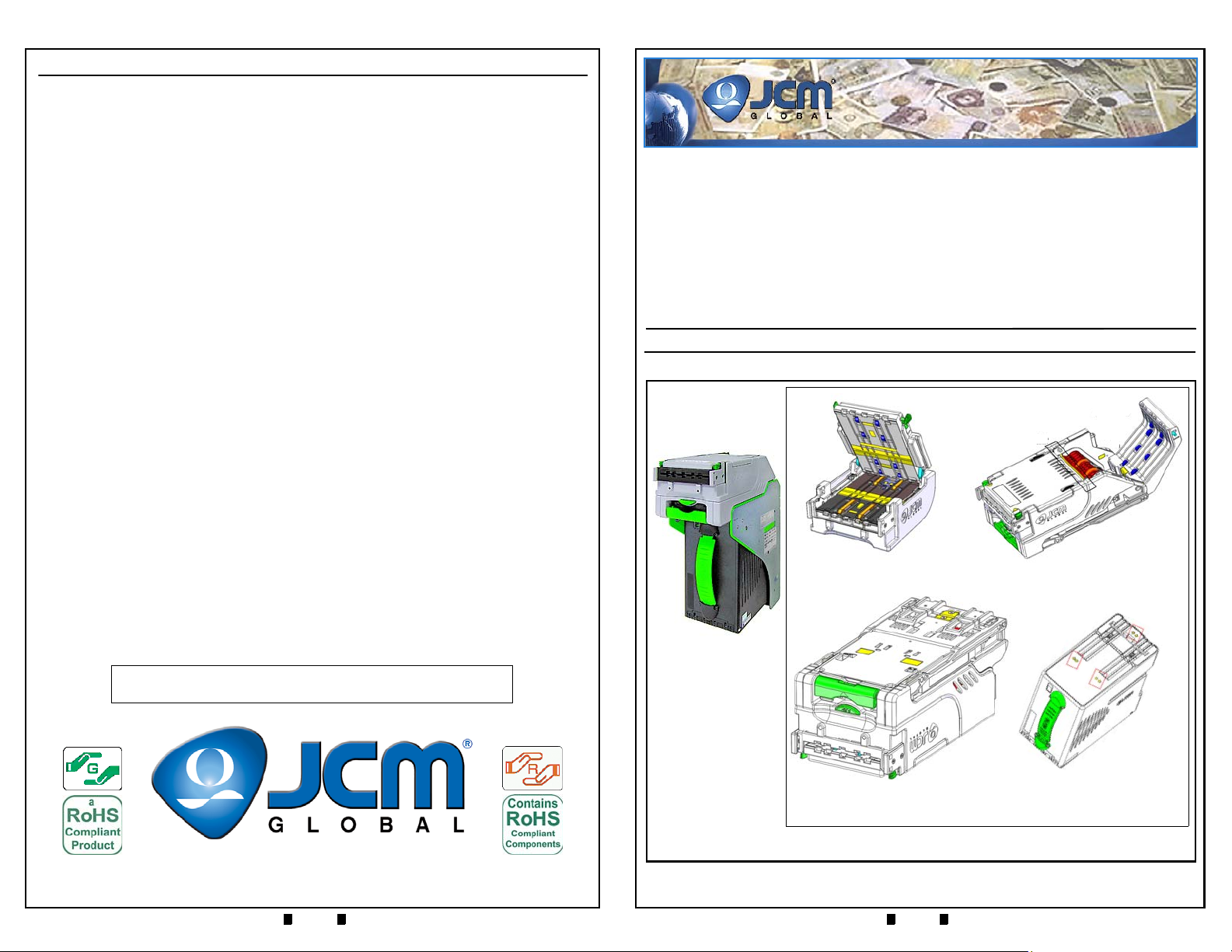

Figure 1 iVIZION Unit, Validator Head, Transport Unit and Cash Box

Typical iVIZION Components

iVIZION Validator Head

Typical iVIZION Unit

(fully assembled)

iVIZION Head and Transport Unit

iVIZION Transport Unit

(inverted)

iVIZION Cash Box

PERSONAL NOTES AND COMMENT AREA

Write any pertinent notes or comments regarding your particular installation

here.

Operator’s Guide

iVIZION® Banknote Validator

Preventive Maintenance Instructions

This Guide describes procedures for the cleaning and maintenance of the

iVIZION® Banknote Validator. For additional information, refer to Section 2 of

the iVIZION Operation and Maintenance Manual (JCM P/N 960-100929R).

iVIZION REFERENCE DIAGRAMS

Figure 1 identifies the iVIZION™ Validator Head, Transport Unit and Cash Box.

Part No. 960-100932R_Rev. A

© 2014, JCM American, Corporation

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 2

2

15

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

NOTE: In the following procedures, be sure to use only WARM water with a

small amount of liquid dishwashing soap as a cleaning solution.

Alcohol, thinner, solvents, and citrus-based cleaners SHOULD

NEVER be used. These types of chemicals can cause “hazing” of the

imaging and optical sensors, and premature drying out of the Drive

Belts and Rollers.

NOTE: JCM Global does not recommend the use of any Cleaning Card on

the iVIZION Banknote Validator.

iVIZION PREVENTIVE MAINTENANCE INSTRUCTIONS

Instructions for performing a basic cleaning and maintenance of the JCM

iVIZION Banknote Validator are described below.

TOOLS AND EQUIPMENT

The following Tools and Equipment are required to properly clean your

iVIZION Banknote Validator:

– Two clean, dry lint-free cloths (or micro-fiber cloths)

– Cleaning solution: Warm water with a few added drops of mild, non-abrasive

detergent, such as liquid dishwashing soap)

– Canned compressed air, or a clean, moisture-free source of low pressure

(LP) air

– Medium-bristled Technician’s Cleaning Brush (JCM P/N 501-000097R),

nylon brush or acid brush

– Wood or plastic wand

– PS75-002 (or equivalent 12 Volt DC) Power Supply, or a suitable 24 Volt DC

Power Supply

– JCM Tool Suite Installation Guide - Refer to the Support section at

www.jcmglobal.com

PERSONAL NOTES AND COMMENT AREA

Write any pertinent notes or comments regarding your particular installation

here.

REFERENCE MANUALS

– iVIZION Operations and Maintenance Manual - Refer to the Support section at

www.jcmglobal.com

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 3

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

14

3

NOTE: The actual Maintenance Schedule may vary, due to environmental

conditions and/or usage levels.

NOTE: Cash Box Preventive Maintenance should be performed annually

or as needed. Remove the Cash Box from the Game, and then

perform the procedure listed below.

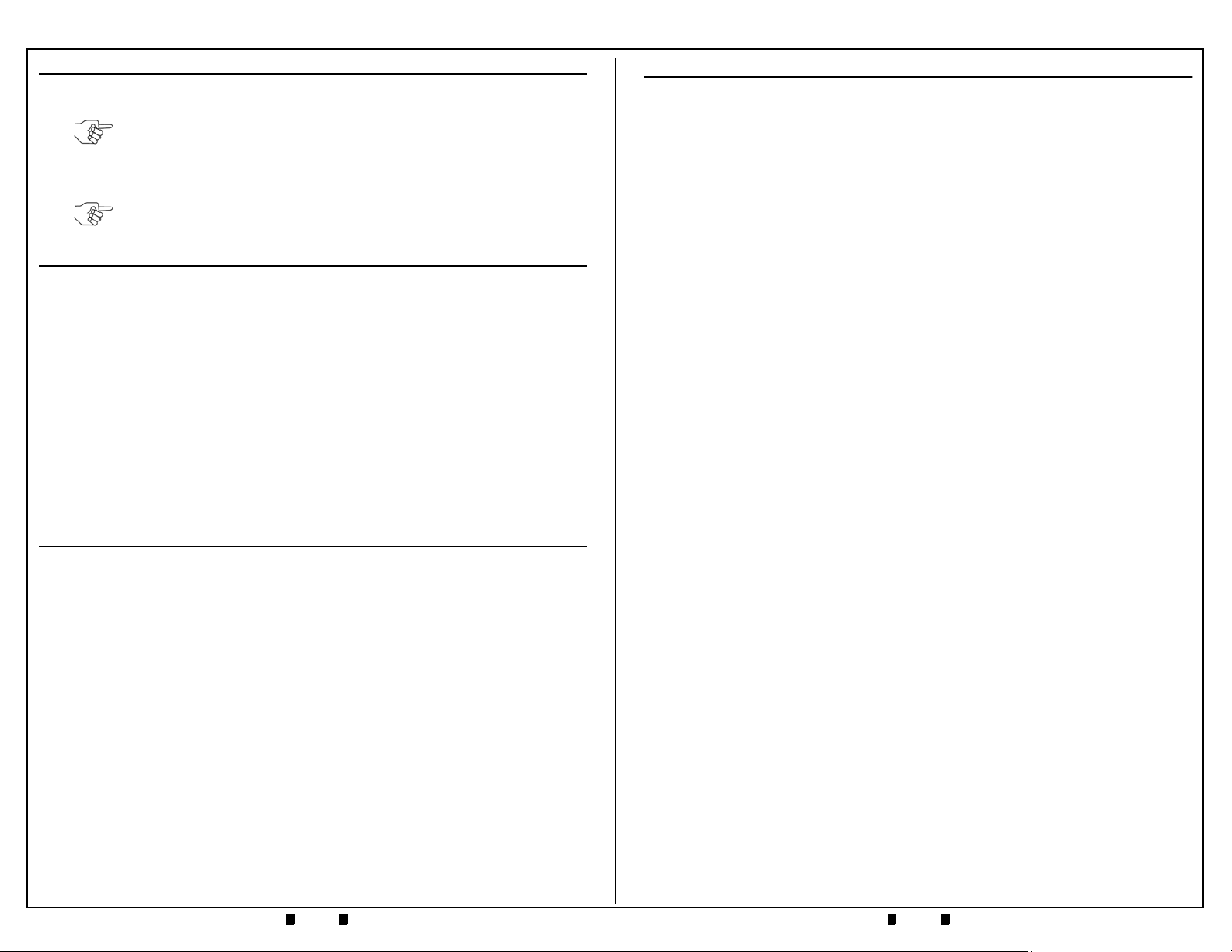

Figure 10 iVIZION Unit and Cash Box

Typical iVIZION Unit

(fully assembled)

CASH BOX PREVENTIVE MAINTENANCE

1. Open the Cash Box and use compressed air or moisture-free low pressure (LP)

air to blow out any dust or debris from inside the Cash Box.

2. Use a damp, lint-free cloth to wipe away any dust, dirt or stains from the Cash

Box Gears.

3. Using a Technician’s Cleaning Brush (JCM P/N 501-000097R), clean any

debris built up on the Cash Box Gears.

4. Using a clean, damp, lint-free cloth, clean the Cash Box Sensors (refer to

10,

yellow areas).

5. Use a dry, clean, lint-free cloth to wipe away any dirt, debris and moisture from

the Cash Box.

Figure

PREVENTIVE MAINTENANCE SCHEDULE

The iVIZION Banknote Validator will perform at optimal levels when regularlyscheduled maintenance is performed. The recommended Preventive Maintenance Schedule should be followed based on time periods or acceptance cycles.

The acceptance cycle can be determined by adding the number of Banknotes

accepted to the number of Tickets accepted for a total estimate of acceptance

cycles.

MONTHLY OR 12,000 CYCLES

Every Month or 12,000 Cycles, the following procedures should be performed at

the Machine (approximate time for completion: 30-60 seconds)

Table 1 Monthly or 12,000 Cycles

Component Procedure Description (Details follow this table)

Validator Head

Transport

Transport

Cash Box

Clean all the Sensor Lenses in the Validator Head (refer to

Figure 2 - iVIZION Validator Head (Yellow Area).

Clean all the Sensor Lenses in the Transpor t Unit (refer to

Figures 3 and 8 - iVIZION Transport Unit (Yellow Areas).

Clean the Transport Feed-In Sensor Lenses (refer to

Figure 3 - iVIZION Transport Unit - Feed-In Sensor).

Clean all the Sensor Lenses in the Cash Box (refer to

Figure 4 - iVIZION Cash Box (Yellow Area).

Reinstall and verify proper operation.

:

INSPECTION

1. Remove the iVIZION Validator from the Machine, and place it on a suitable

work surface.

2. Perform a visual inspection of the entire iVIZION Unit. Look for any broken or

damaged parts that need to be repaired or replaced.

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 4

4

13

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

NOTE: Be sure to wipe down the entire Bill Path in both the upper and lower

sections of the Validator Head.

Figure 2 iVIZION Validator Head

NOTE: Refer to Section 6 of the iVIZION Operation and Maintenance Manual

(JCM P/N 960-100929R) for calibration instructions.

NOTE: Initialization resets the performance numbers to Zero (0) and stores

the date from the PC on the iVIZION Unit for future reference.

NOTE: Repeat the Monthly, 6 Month and Annual Procedures for the next

Preventive Maintenance cycle.

Figure 9 iVIZION Unit (Fully Assembled)

CLEANING THE VALIDATOR HEAD (MONTHLY/12,000 CYCLES)

1. Remove the iVIZION Validator Head (refer to Figures 1 and 2) from the

Transport Unit. To do so:

a). Press the green release (“PUSH”) button on the front of the Validator Head.

b). Pull the Validator Head off and away from the Transport Unit.

2. Open the Validator Head cover by pressing the green-colored release latches on

the left and right sides (refer to

3. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off any dirt and stains from the surfaces of the Imaging and Optical Sensors.

4. Use a clean, dry Micro-Fiber cloth to perform a second wipe-down of the Bill

Path area, to remove any excess cleaning solution, moisture, residue or haze from

the Imaging and Optical Sensor Lenses. Make sure the entire Bill Path is free of

any smudges, streaks or residue.

Figure 2).

GENERAL (ANNUAL/144,000 CYCLES)

1. After cleaning, reassemble the iVIZION Validator Head and the Transport Unit,

so that the iVIZION Unit is fully assembled.

2. Calibrate the iVIZION Unit.

3. Using the JCM Tool Suite application, initialize the iVIZION Statistics.

4. If a repair or firmware change is not required, then the iVIZION Cleaning and

Preventive Maintenance procedure is complete. The iVIZION Unit may be

returned to service.

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 5

12

5

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

NOTE: Be sure to wipe down the entire Bill Path in both the upper and lower

sections of the Transport Unit.

Figure 3 iVIZION Transport Unit

NOTE: Perform at least 5 Aging Cycles. If necessary, replace the Motor Gear

Assembly.

NOTE: Refer to Section 4 of the iVIZION Operation and Maintenance Manual

(JCM P/N 960-100929R) for removal instructions.

NOTE: If necessary, replace the Motor Drive Gear Assembly.

Figure 8 iVIZION Transport Unit (Inverted)

CLEANING THE TRANSPORT (ANNUAL/144,000 CYCLES)

1. Perform the Monthly Transport Cleaning Procedures (refer to Page 5).

2. Perform the 6 Month Transport Cleaning Procedures (refer to Page 9).

3. Use the JCM Tool Suite application to run the Aging Test. Listen for excessive or

unusual noise.

4. The Transport Unit uses light pipes for the transfer of some optical signals in the

unit. Remove the bottom cover of the Transport Unit to clean the Lenses on the

inside of the Transport Cover where these signals cross over (refer to

yellow areas).

5. Clean the Sensor components on the Processor PCB, using compressed air or

moisture-free low pressure (LP) air to blow out any dust.

6. Remove the Motor Gear Assembly.

7. Remove the Encoder PCB from the Motor Gear Assembly.

8. Use compressed air or moisture-free low pressure (LP) air to blow out any dust or

debris from the gears.

9. Inspect the Motor Drive Gear Assembly for damaged or worn gears.

10. Reinstall the Motor Drive Gear Assembly in the Transport Unit, and then reinstall

the bottom cover.

11. Use a clean, dry, lint-free Microfiber cloth to wipe down the Transport Unit and

remove any cleaning solution, moisture or residue that may remain on the Optic al

Sensor Lenses.

Figure 8,

CLEANING THE TRANSPORT (MONTHLY/12,000 CYCLES)

1. Open the Rear Transport Cover on the Transport Unit. To do so, pull forward on

the green release catch on the top of the Transport Unit, to expose the rear section

of the Transport Unit for cleaning (refer to

2. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off any dirt and stains from the Optical Sensors (refer to the yellow areas in

Figure 3).

3. Locate the Feed-In Optical Sensor Lenses, directly in front of the Anti-Stringing

Mechanism (refer to the red areas in

channel in the molding that can collect dust in dirty environments.

4. Use a clean, lint-free Micro-Fiber cloth to wipe the grooved channel clean, and

reduce the risk of false “Bill Jam” errors.

5. Using a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution),

clean and dry the Feed-In Optical Sensor Lenses located on each side of the

Transport Path.

Figure 3).

Figure 3). This area features a grooved

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 6

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

6

11

NOTE: The Cash Box Optical Sensors can be accessed while the Cash Box is

mounted in the Frame.

Figure 4 iVIZION Cash Box

NOTE: Refer to Appendix A in the iVIZION Operation and Maintenance

Manual (JCM P/N 960-100929R) for Error Codes.

CLEANING THE CASH BOX (MONTHLY/12,000 CYCLES)

The three sets of Cash Box Optical Sensors (refer to the yellow areas in Figure 4)

are not flush-mounted, and often tend to collect dust.

1. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe away any dust, dirt or stains from the Optical Sensor Lenses on the Cash

Box (refer to the yellow areas in

2. Use a dry, clean, lint-free Micro-Fiber cloth to wipe down the Cash Box to

remove any excess cleaning solution, moisture or residue that may remain on the

Optical Sensor Lenses.

3. Reassemble the Validator Head and Transport Unit.

4. Rei nstall the iVIZION Un it into the Machine.

5. Verify proper operation.

Figure 4).

ANNUAL OR 144,000 CYCLES

Every 12 Months or 144,000 Cycles, the following procedures should be

performed in a Service Area (approximate time for completion: 20 Minutes):

Table 3 12 Months or 144,000 Cycles

Component Procedure Description (Details follow this table)

All Perform the Monthly cleaning procedures (refer to Page 3).

All Perform the 6 Month cleaning procedure (refer to Page 7).

Remove the Transport Unit’s bottom cover, then clean the

Transport

inside lens surfaces (refer to Figure 8 - iVIZION Transport

Unit (Yellow Area).

Transport

Complete Unit

Inspect for gear damage or dirt build-up on the Motor Gear

Assembly and clean as needed.

Run the Aging Test to check for excessive noise, squealing

or errors.

Transport Verify Software Version and update, if necessary.

Complete Unit Calibrate the Unit.

Complete Unit Run the Acceptance Test and verify proper operation.

INSPECTION

1. Using JCM Tool Suite, check the Statistics for information on performance.

Be sure to note the three most common Error Codes for Banknotes and Tickets.

During the Maintenance Procedure, check areas of the iVIZION Validator that

might generate the noted Error Codes.

2. Perform a visual inspection of the entire iVIZION Unit (Validator Head and

Transport Unit). Look for any broken or damaged parts that need to be repaired

or replaced.

CLEANING THE VALIDATOR HEAD (ANNUAL/144,000 CYCLES)

Perform the Monthly Validator Head Cleaning Procedures (refer to Page 4).

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A ©2014, JCM American, Corporation

Page 7

iVIZION® Banknote Validator Operator’s Guide Operator’s Guide June, 2014

10

7

NOTE: Initialization resets the performance numbers to Zero (0) and stores

the date from the PC on the iVIZION Unit for future reference.

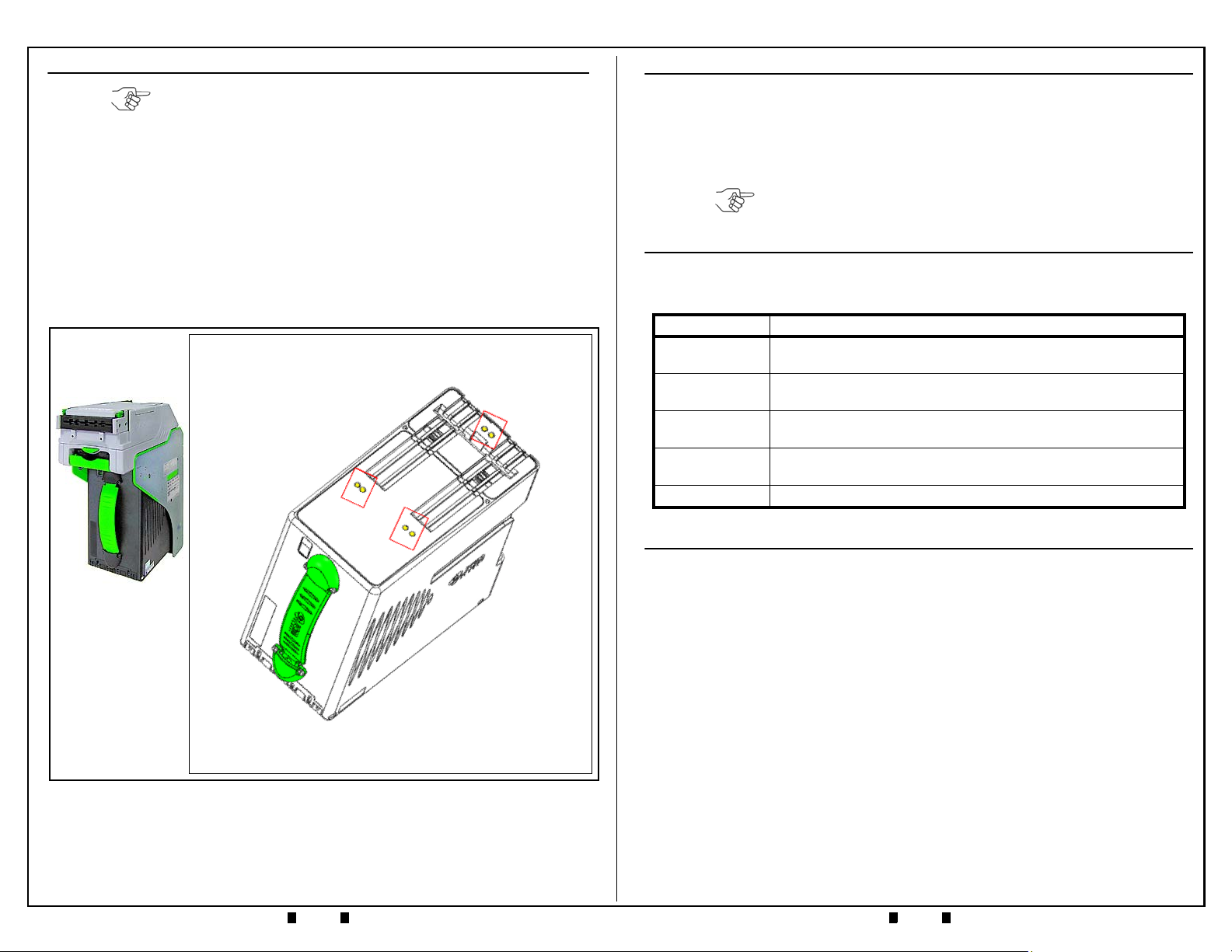

Figure 7 iVIZION Unit and Cash Box

Typical iVIZION Unit

(fully assembled)

NOTE: Refer to Appendix A in the iVIZION Operation and Maintenance

Manual (JCM P/N 960-100929R) for Error Codes.

GENERAL (6 MONTHS/72,000 CYCLES)

1. Reassemb le the iVIZION Validator Head and the Transport Unit, so that the

iVIZION Unit is fully assembled.

2. Using the JCM Tool Suite application, initialize the iVIZION Statistics.

3. If a repair, calibration or firmware change is not required, then the iVIZION

Cleaning and Preventive Maintenance procedure is complete. The iVIZION Unit

may be returned to service.

6 MONTHS OR 72,000 CYCLES

Every 6 Months or 72,000 Cycles, the following procedures sho uld be performed in a Service Area (approximate time for completion: 10-15 Minutes):

Table 2 6 Months or 72,000 Cycles

Component Procedure Description (Details follow this table)

Inspection

Inspection

Inspect for damaged or broken parts - repair or replace as

required.

Inspect Belts for wear or damage in the Validator Head and

Transport Unit - Repair or replace as required.

Inspect Optical Sensor Lenses for damage in the Validator

Inspection

Head, Transport Unit and Cash Box - Replace Lenses if

scratched, cracked, discolored or damaged.

General Complete the monthly cleaning procedure (refer to Page 3) .

Validator Head

Validator Head

Transport

Transport

Clean the Validator Head Rollers (refer to Figure 5 iVIZION Validator Head (Blue Area).

Clean the Validator Head Belts (refer to Figure 5 - iVIZION

Validator Head (Orange Area).

Clean the Transport Rollers (refer to Figure 6 - iVIZION

Transport Unit (Blue Area).

Clean the Transport Belts (refer to Figure 6 - iVIZION

Transport Unit (Orange Area).

Run the Acceptance Test and verify proper operation.

INSPECTION

1. Using JCM Tool Suite, check the Statistics for information on performance.

Be sure to note the three most common Error Codes for Banknotes and Tickets.

During the Maintenance Procedure, check areas of the iVIZION Validator that

might generate the noted Error Codes.

2. Perform a visual inspection of the entire iVIZION Unit (Validator Head and

Transport Unit). Look for any broken or damaged parts that need to be repaired

or replaced.

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Page 8

iVIZION® Banknote Validator Operator’s Guide June, 2014

8

9

NOTE: If the Drive Belts are heavily frayed, worn out, or damaged, the belts

should be replaced.

Minor fraying along the left and right edges of the drive belts may

result in “Belt Strings” extending out from the sides of the belts. These

strings can be snipped away with a small pair of scissors. Drive belts

do not need to be replaced if only minor fraying is evident.

NOTE: If a lens has any of these conditions, the lens should be replaced.

NOTE: Use a wood or plastic wand to apply pressure to the side of a Roller, to

keep it from turning during cleaning.

Be careful not to scratch the Rollers! Scratched Rollers will collect dirt

faster, and may require more frequent cleaning.

Figure 5 iVIZION Validator Head

NOTE: If a lens has any of these conditions, the lens should be replaced.

NOTE: If the Drive Belts are heavily frayed, worn out, or damaged, the belts

should be replaced.

Minor fraying along the left and right edges of the drive belts may

result in “Belt Strings” extending out from the sides of the belts. These

strings can be snipped away with a small pair of scissors. Drive belts

do not need to be replaced if only minor fraying is evident.

NOTE: Be sure to blow out the Anti-Stringing Mechanism and the grooved

channel in front of it (refer to

Figure 6).

NOTE: If necessary, use a Technician’s Cleaning Brush (JCM P/N 501-

000097R) to remove residue build-up from the Belts in the Transport

Unit. The Drive Belts can easily be moved by hand, in order to clean

the entire belt.

Figure 6 iVIZION Head and Transport Unit/Inverted Unit

Feed-In

Sensor

Stacker

Sensor Lens

CLEANING THE VALIDATOR HEAD (6 MONTHS/72,000 CYCLES)

1. Perform the Monthly Validator Head Cleaning Procedures (refer to Page 4).

2. Inspect the Drive Belts in the Validator Head (refer to Figure 5, orange areas).

2. Inspect the Imaging and Optical Sensor Lenses on the Validator Head (refer to

Figure 5, yellow areas) for scratches, chips, cracks or discoloration.

3. Using canned, compressed air or a clean, moisture-free source of low pressure

(LP) air, blow out any dust, debris, or paper fibers from the Validator Head.

4. Clean the Rollers in the Validator Head using a Technician’s Cleaning Brush

(JCM P/N 501-000097R) to remove the dirt and any build-up

5. Clean the Drive Belts in the Validator Head using a clean cloth dampened with

cleaning solution. The Drive Belts in the iVIZION Validator Head can easily be

moved by hand, to allow cleaning of the entire belt.

.

CLEANING THE TRANSPORT (6 MONTHS/72,000 CYCLES)

1. Perform the Monthly Transport Cleaning Procedures (refer to Page 5).

2. Inspect the Optical Sensor Lenses on the Transport Unit (refer to Figure 6, yellow

areas) for scratches, chips, cracks or discoloration.

3. Inspect the Drive Belts in the Transport Unit (refer to

4. Using canned, compressed air or a clean, moisture-free source of low pressure

(LP) air, blow out any dust, debris, or paper fibers from the Transport Unit.

5. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off the Rollers in the Transport Unit (refer to

6. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off the Belts in the Transport Unit (refer to

.

Figure 6, orange areas).

Figure 6, blue areas).

Figure 6, orange areas).

Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation Part No. 960-100932R_Rev. A © 2014, JCM American, Corporation

Loading...

Loading...