Page 1

website: http://www.jcmglobal.com

iPRO-RC™ Series

Banknote Recycler

Operation and Maintenance

Manual

(Revision 3)

P/N 960-000164R_Rev. 3 {EDP #213631}

Issue #4088-SME-00-03

© 2018, JAPAN CASH MACHINE CO., LTD.

Page 2

iPRO-RC™ Series Banknote Recycler Operation and Maintenance Manual

or

or or

or

File No. E142330, Subscriber 857947001, Vol. 2

JPULA-04222

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Issue #4088-SME-00-03

REVISION HISTORY

Rev No.

A 6/06/12

1 12/30/13

2 9/16/15

3 2/7/18

Date Reason for Update Comment

Initial Version

Changed Specifications, DIP Switch Settings, Parts List, Copyright

Updated Product Descriptions, Parts Lists

Updated Product Descriptions in Section 1 and updated Parts Lists

in Section 7

International Compliance

• RoHS Directives

• UL & c-UL Marks

• CE Mark

• CB Scheme

• FCC Directives

Electrical Current Symbol

Direct Current: indicates Direct Current values on product labels.

Copyright © 2018 By JAPAN CASH MACHINE CO., LTD.

This product document (hereinafter referred to as “Manual”) is fully covered by legal Copyrights owned by the JAPAN

CASH MACHINE CO., LTD., (hereinafter referred to as “JCM”) under Japanese laws and other foreign countries.

This Manual contains many copyrighted, patented, or properly registered equipment items manufactured by JCM, that

are prohibited and illegal to duplicate, replicate, copy in whole, or in part, without the express authorization by JCM with

the following exceptions:

1. When an authorized JCM agency or distributor duplicates the Manual for sales promotion and/or service

maintenance of the product, or technical service personnel education as required; and

2. When an end user duplicates the Manual to maintain operation of the product or operate the product in general.

JCM retains all rights to amend, alter, change or delete any portion of this Manual in whole, or in part, or add items

thereto without notice regarding the product or its related products.

JCM is a registered trademark of JAPAN CASH MACHINE CO., LTD.. All other product names mentioned herein may be

registered trademarks or trademarks of their respective companies. Furthermore,

in each case throughout this publication.

™, ® and © are not always mentioned

Page 3

i

iPRO-RC™ Series

Banknote Recycler

Table of Contents

Page

1 GENERAL INFORMATION ................................................................................. 1-1

Description ....................................................................................................................1-1

iPRO-RC Unit Assembly ............................................................................................... 1-1

Model Descriptions ....................................................................................................... 1-2

Type Descriptions ......................................................................................................... 1-2

Software Descriptions ................................................................................................... 1-2

Precautions ................................................................................................................... 1-2

User Cautions ...........................................................................................................................1-3

Installation Cautions ..............................................................................................................1-3

Mounting, Dismounting & Transportation ...............................................................................1-3

Preventive Maintenance ............................................................................................... 1-3

Banknote Fitness Requirements ..............................................................................................1-4

Banknote Storage Requirements .............................................................................................1-4

Primary Features .......................................................................................................... 1-4

Component Names ....................................................................................................... 1-5

Specifications ................................................................................................................ 1-6

Technical Specifications ...........................................................................................................1-6

Environmental Specifications ..................................................................................................1-7

Electrical Specifications ............................................................................................................1-7

Structural Specifications ...........................................................................................................1-7

Unit Dimensions ........................................................................................................... 1-8

Entire Unit Outside Dimensions ...............................................................................................1-8

Entire Unit Outside Dimensions (Continued) ............................................................................1-9

Technical Contact Information .................................................................................... 1-10

Americas ................................................................................................................................1-10

JCM American .....................................................................................................................1-10

Europe, Middle East, Africa & Russia ....................................................................................1-10

JCM Europe GmbH ............................................................................................................. 1-10

UK & Ireland ...........................................................................................................................1-10

JCM Europe (UK Office) ......................................................................................................1-10

Asia and Oceania ...................................................................................................................1-10

JCM Gold (HK) Ltd. .............................................................................................................1-10

JAPAN CASH MACHINE CO., LTD.(HQ) ............................................................................1-10

2 INSTALLATION .................................................................................................. 2-1

Installation Procedure ................................................................................................... 2-1

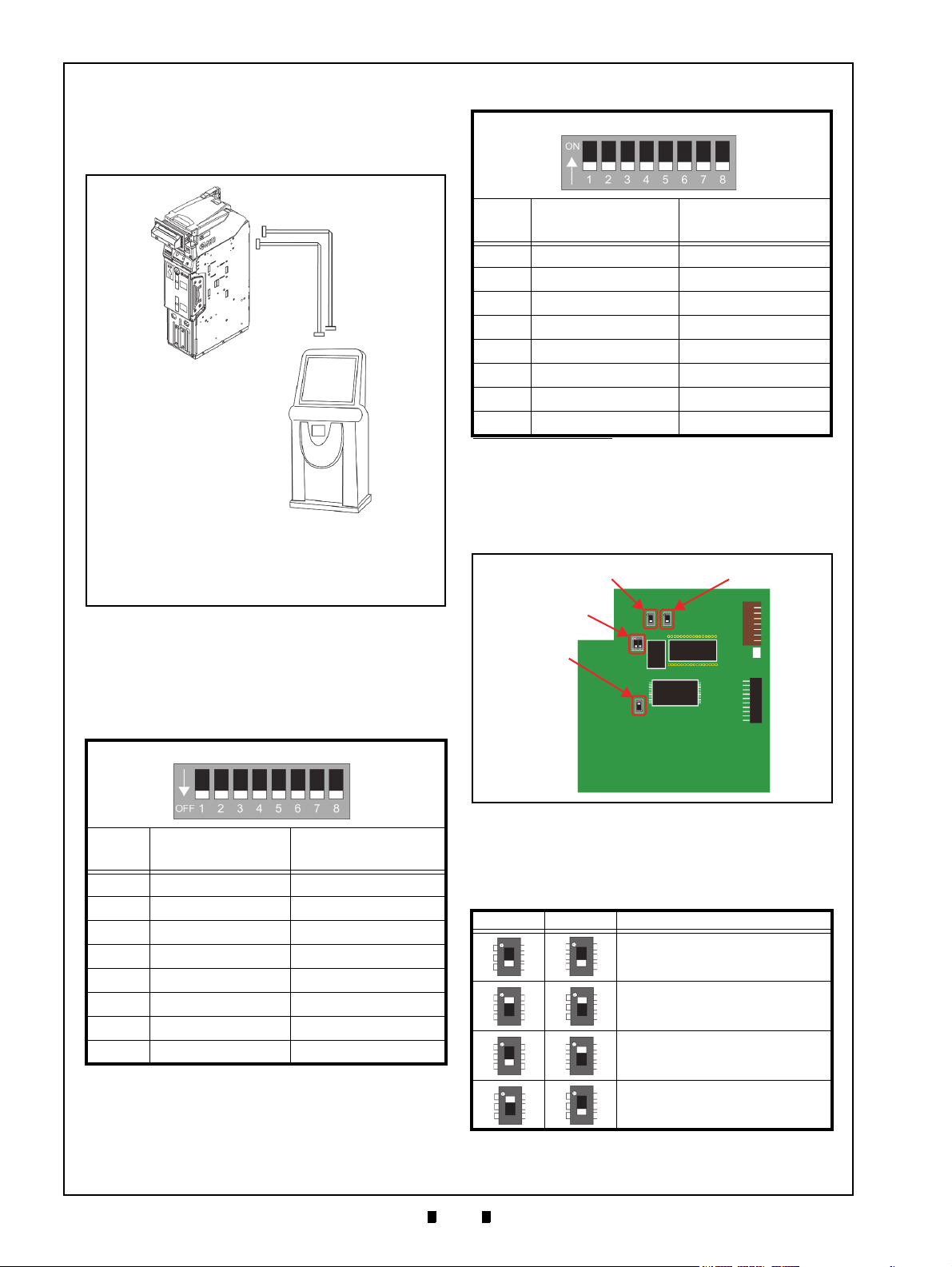

Cable Interconnection ................................................................................................... 2-2

DIP Switch Configuration .............................................................................................. 2-2

Switch Configuration ..................................................................................................... 2-2

Connector Pin Assignments ......................................................................................... 2-4

Connector Pin Assignments (Continued) ................................................................................. 2-5

Connector Pin Assignments (Continued) ................................................................................. 2-6

Connector Pin Assignments (Continued) ................................................................................. 2-7

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 4

ii

iPRO-RC™ Series Banknote Recycler

Table of Contents

Page

Connector Pin Assignments (Continued) ................................................................................. 2-8

Connector Pin Assignments (Continued) ................................................................................. 2-8

Preventive Maintenance ............................................................................................... 2-9

Restoring Banknotes ............................................................................................................... 2-9

Restoring Banknotes using the iPRO Transport Unit ............................................................ 2-9

Restoring Banknotes Directly into the Recycler Unit ............................................................. 2-9

Retrieving Banknotes ................................................................................................... 2-9

Sending Retrieved Banknotes to the Cash Box ....................................................................... 2-9

Sending Retrieved Banknotes to the Cash Box by Command ................................................ 2-9

Retrieving Banknotes Directly ..................................................................................................2-9

Dispense Settings ...................................................................................................... 2-10

Clearing a Banknote Jam ........................................................................................... 2-10

Cleaning Procedure ............................................................................................................... 2-10

Sensor Cleaning Procedure ................................................................................................ 2-10

Sensor and Roller Locations ...................................................................................... 2-12

Standard Interface Circuit Schematics ....................................................................... 2-13

Standard Interface Circuit Schematics (Continued) ............................................................... 2-14

Standard Interface Circuit Schematics (Continued) ............................................................... 2-15

Standard Interface Circuit Schematics (Continued) ............................................................... 2-16

Standard Interface Circuit Schematics (Continued) ............................................................... 2-17

Operational Flowchart ................................................................................................ 2-18

Operational Flowchart (Continued) ........................................................................................ 2-19

Operational Flowchart (Continued) ........................................................................................ 2-20

Operational Flowchart (Continued) ........................................................................................ 2-21

Operational Flowchart (Continued) ........................................................................................ 2-22

Operational Flowchart (Continued) ........................................................................................ 2-23

Operational Flowchart (Continued) ........................................................................................ 2-24

Operational Flowchart (Continued) ........................................................................................ 2-25

3 COMMUNICATIONS ...........................................................................................3-1

Americas .................................................................................................................................. 3-1

JCM American ....................................................................................................................... 3-1

Europe, Middle East, Africa & Russia ...................................................................................... 3-1

JCM Europe GmbH ............................................................................................................... 3-1

UK & Ireland ............................................................................................................................ 3-1

JCM Europe (UK Office) ........................................................................................................ 3-1

Asia and Oceania .................................................................................................................... 3-1

JCM Gold (HK) Ltd. ............................................................................................................... 3-1

JAPAN CASH MACHINE CO., LTD. (HQ) ............................................................................. 3-1

4 DISASSEMBLY/REASSEMBLY .........................................................................4-1

Tool Requirements ........................................................................................................ 4-1

Power Source Board Removal ..................................................................................... 4-1

Lifter Motor Encoder Board Assy Removal .................................................................. 4-1

Recycler CPU Board Assy Removal ............................................................................ 4-2

Emission Side Double Note Sensor Removal .............................................................. 4-2

Lifter Motor Assy Removal ........................................................................................... 4-3

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 5

iii

iPRO-RC™ Series Banknote Recycler

Table of Contents

Page

Upper & Lower Full Sensor PT/Upper & Lower End Sensor

LED Removal ............................................................................................................... 4-3

Upper & Lower Full Sensor LED/Upper & Lower End Sensor PT/

Lifter Home Position Sensor LED & PT Removal ......................................................... 4-4

Upper & Lower Flapper Pusher Lever Solenoid Removal ............................................ 4-5

Flapper Open/Close Circuit Board Removal ................................................................ 4-5

Banknote Transaction Sensor/Transport Unit Encoder Board

& Double Note Sensor PT Removal ............................................................................. 4-6

Banknote Transaction Sensor & Box Sensor Board Removal ...................................... 4-6

Recycler Encoder Board Removal ............................................................................... 4-7

Upper & Lower Recycler Transport Motor Assy Removal ............................................ 4-7

Timing Belt Removal ..................................................................................................... 4-8

Pick Roller Removal ..................................................................................................... 4-8

Feed Roller Removal .................................................................................................... 4-9

Impeller and Stop Roller Removal .............................................................................. 4-10

O-Ring (Pusher Plate) Removal ................................................................................. 4-11

Roller Timing Belt and O-Ring Removal ..................................................................... 4-11

Pusher Plate Re-installation ...................................................................................................4-12

5 WIRING DIAGRAMS ........................................................................................... 5-1

Entire System Wiring Diagram ..................................................................................... 5-1

Transport Unit & Frame Unit Wiring Diagram (Partial) ................................................. 5-2

Frame Unit Wiring Diagram (Partial) ........................................................................................5-3

6 PERFORMANCE TESTS .................................................................................... 6-1

Download and Installation

Workbench Tool Requirements .................................................................................... 6-1

JCM Tool Suite Standard Edition Installation ................................................................ 6-1

JCM Tool Suite Standard Edition .................................................................................. 6-3

Firmware Download Procedure .................................................................................... 6-3

Calibration ....................................................................................................................6-5

When to Calibrate .....................................................................................................................6-5

Calibration Tool Requirements .................................................................................................6-5

iPRO-RC Reference Paper ......................................................................................................6-5

Placing the Reference Paper ...................................................................................................6-5

Calibration and Testing Program .............................................................................................. 6-5

Sensor Calibration and Performance Testing ...........................................................................6-5

Model Information Confirmation ...............................................................................................6-8

Reading the Model Information ................................................................................................6-9

Reading the iPRO-RC Maintenance Tool Version ....................................................................6-9

Individual Calibration and Performance Test .............................................................. 6-10

Sensor Test Screen ................................................................................................................ 6-10

Individual Calibration ..............................................................................................................6-10

Load Sensor Data ................................................................................................................6-10

Double Note Detection Sensor Calibration ..........................................................................6-10

RC Full Sensor Button Calibration ....................................................................................... 6-11

Individual Performance Test ................................................................................................... 6-11

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 6

iv

iPRO-RC™ Series Banknote Recycler

Table of Contents

Page

Get All Sensor State ........................................................................................................... 6-13

Performance Test without a PC .................................................................................. 6-14

Performance Test without PC Procedure ............................................................................... 6-15

Banknote Acceptance Test .................................................................................................. 6-15

7 EXPLODED VIEWS AND PARTS LISTS ............................................................ 7-1

Entire iPRO-RC Unit Exploded View ............................................................................ 7-1

Entire iPRO-RC Unit Parts List ................................................................................................ 7-2

iPRO-RC Frame Unit 1 Exploded View ........................................................................ 7-3

iPRO-RC Frame Unit 1 Parts List ............................................................................................ 7-4

iPRO-RC Frame Unit 2 Exploded View ........................................................................ 7-5

iPRO-RC Frame Unit 2 Parts List ............................................................................................ 7-6

iPRO-RC Frame Unit 3 Exploded View ........................................................................ 7-7

iPRO-RC Frame Unit 3 Parts List ............................................................................................ 7-8

iPRO-RC Frame Unit 4 Exploded View ........................................................................ 7-9

iPRO-RC Frame Unit 4 Parts List .......................................................................................... 7-10

iPRO-RC Frame Unit 5 Exploded View .......................................................................7-11

iPRO-RC Frame Unit 5 Parts List .......................................................................................... 7-12

iPRO-RC RC Space 1 Exploded View ........................................................................ 7-13

iPRO-RC RC Space 1 Parts List ............................................................................................ 7-14

iPRO-RC RC Space 2 Exploded View ........................................................................ 7-15

iPRO-RC RC Space 2 Parts List ............................................................................................ 7-16

iPRO-RC RC Space 3 Exploded View ........................................................................ 7-17

iPRO-RC RC Space 3 Parts List ............................................................................................ 7-18

iPRO-RC RC Space 4 Exploded View ........................................................................ 7-19

iPRO-RC RC Space 4 Parts List ............................................................................................ 7-20

iPRO-RC RC Space 5 Exploded View ........................................................................ 7-21

iPRO-RC RC Space 5 Parts List ............................................................................................ 7-22

iPRO-RC Rear Transport Assembly 1 Exploded View ............................................... 7-23

iPRO-RC Rear Transport Assembly 1 Parts List ................................................................... 7-24

iPRO-RC Rear Transport Assembly 2 Exploded View ............................................... 7-25

iPRO-RC Rear Transport Assembly 2 Parts List ................................................................... 7-26

iPRO-RC Rear Transport Assembly 3 Exploded View ............................................... 7-27

iPRO-RC Rear Transport Assembly 3 Parts List ................................................................... 7-28

iPRO-RC Rear Transport Assembly 4 Exploded View ............................................... 7-29

iPRO-RC Rear Transport Assembly 4 Parts List ................................................................... 7-30

iPRO-RC Rear Transport Assembly 5 Exploded View ............................................... 7-31

iPRO-RC Rear Transport Assembly 5 Parts List ................................................................... 7-32

iPRO-RC Rear Transport Assembly 6 Exploded View ............................................... 7-33

iPRO-RC Rear Transport Assembly 6 Parts List ................................................................... 7-34

WBA-SH2 Cash Box Exploded View 1 ....................................................................... 7-35

WBA-SH2 Cash Box Parts List 1 ........................................................................................... 7-35

WBA-SH2 Cash Box Exploded View 2 ....................................................................... 7-36

WBA-SH2 Cash Box Parts List 2 ........................................................................................... 7-37

WBA-SH2 Cash Box Exploded View 3 ....................................................................... 7-38

WBA-SH2 Cash Box Parts List 3 ........................................................................................... 7-38

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 7

v

iPRO-RC™ Series Banknote Recycler

Table of Contents

Page

WBA-SH2 Cash Box Exploded View 4 ....................................................................... 7-39

WBA-SH2 Cash Box Parts List 4 ........................................................................................... 7-40

WBA-SH2 Cash Box Exploded View 5 ....................................................................... 7-41

WBA-SH2 Cash Box Parts List 5 ........................................................................................... 7-42

iPRO-RC Large Cash Box Frame Unit Exploded View .............................................. 7-44

iPRO-RC Large Cash Box Frame Unit Parts List .................................................................. 7-44

Optional Lock Unit Exploded View ............................................................................. 7-45

Optional Lock Unit Parts List ..................................................................................................7-46

8 INDEX ..................................................................................................................8-1

A TROUBLESHOOTING ........................................................................................ A-1

Introduction ...................................................................................................................A-1

Troubleshooting Overview .......................................................................................................A-1

Malfunction LED Error Codes ..................................................................................................A-1

LED Indicator Conditions .........................................................................................................A-1

iPRO-RC Recycler Unit Width and Length Guide Replacement Procedure .................A-4

Length Guide Replacement .....................................................................................................A-4

Length Guide Installation .........................................................................................................A-4

Width Guide Replacement ....................................................................................................... A-5

Maintenance Equipment Requirements ....................................................................... A-6

Additional iPRO-RC Maintenance Equipment .........................................................................A-6

Reference Paper Handling ...................................................................................................... A-6

B GLOSSARY ........................................................................................................ B-1

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

iPRO-RC™ Series Banknote Recycler

vi

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 9

vii

iPRO-RC™ Series

Banknote Recycler

List of Figures

Page

Figure 1-1 iPRO-RC Unit Assembly ...................................................................... 1-1

Figure 1-2 Precautionary Symbols ........................................................................ 1-2

Figure 1-3 Unacceptable Banknotes ..................................................................... 1-4

Figure 1-4 Banknote Storage Insertion Cautions .................................................. 1-4

Figure 1-5 iPRO-RC Component Names .............................................................. 1-5

Figure 1-6 iPRO-RC Banknote Recycler Standard Unit with Bezel

Outside Dimensions ............................................................................. 1-8

Figure 1-7 iPRO-RC Banknote Recycler Standard Unit with Bezel,

Lock Unit and Outside Dimensions ...................................................... 1-8

Figure 1-8 iPRO-RC Banknote Recycler Standard Unit with Bezel

Outside Dimensions ............................................................................. 1-9

Figure 1-9 iPRO-RC Banknote Recycler Standard Unit with Bezel,

Lock Unit and Outside Dimensions ...................................................... 1-9

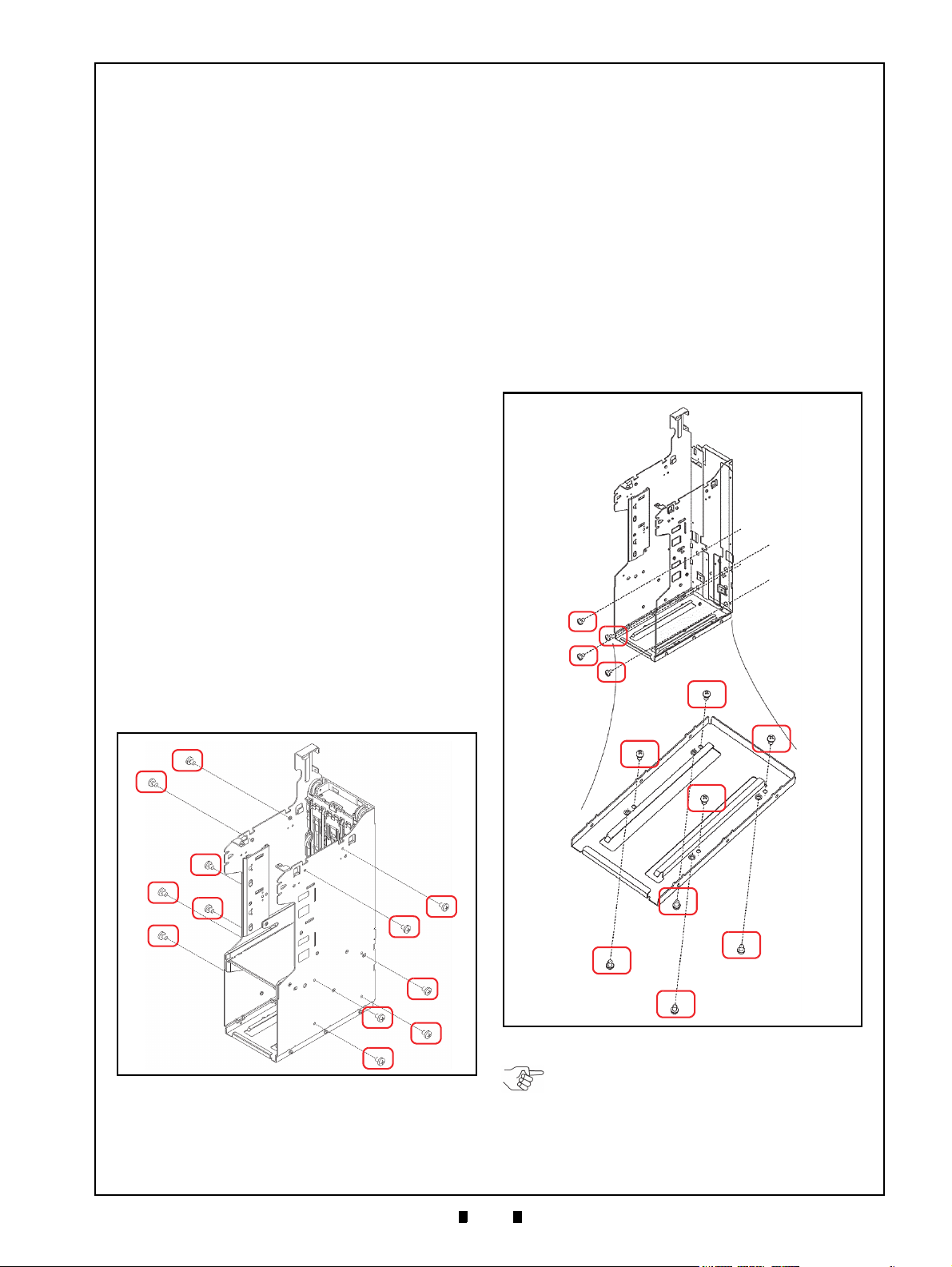

Figure 2-1 M4 Screws Locations (Right/Left) ........................................................ 2-1

Figure 2-2 M4 Screws Locations (Rear & Bottom) ................................................ 2-1

Figure 2-3 Cable Interconnection .......................................................................... 2-2

Figure 2-4 CPU Board Switch Locations ............................................................... 2-2

Figure 2-5 Banknote Restoration Methods ........................................................... 2-9

Figure 2-6 Retrieving Recycler Banknotes ............................................................ 2-9

Figure 2-7 Clearing a Banknote Jam 1 ............................................................... 2-10

Figure 2-8 Clearing a Banknote Jam 2 ............................................................... 2-10

Figure 2-9 Sensor and Roller Cleaning ............................................................... 2-11

Figure 2-10 iPRO-RC Sensor Cleaning Locations ................................................ 2-12

Figure 2-11 iPRO-RC USB Interface Schematic Diagram .................................... 2-13

Figure 2-12 iPRO-RC Photo-Coupler Interface Schematic Diagram .................... 2-14

Figure 2-13 iPRO-RC RS232C Interface Schematic Diagram .............................. 2-15

Figure 2-14 iPRO-RC ccTalk Interface Schematic Diagram ................................. 2-16

Figure 2-15 iPRO-RC Bezel Circuit Interface Schematic Diagram ....................... 2-17

Figure 2-16 iPRO-RC Operational Flowchart (Primary Sequence) ....................... 2-18

Figure 2-17 iPRO-RC Operational Flowchart (Validation) .................................... 2-19

Figure 2-18 iPRO-RC Operational Flowchart (Stacking/Recycler Unit) ................ 2-20

Figure 2-19 iPRO-RC Operational Flowchart (Stacking/Cash Box) ...................... 2-21

Figure 2-20 iPRO-RC Operational Flowchart (Dispensing) .................................. 2-22

Figure 2-21 iPRO-RC Operational Flowchart (Abnormal Error) ............................ 2-23

Figure 2-22 iPRO-RC Operational Flowchart (Retrieving) .................................... 2-24

Figure 2-23 iPRO-RC Operational Flowchart (Retrieving/Cash Box) ................... 2-25

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 10

viii

iPRO-RC™ Series Banknote Recycler

List of Figures

Page

Figure 4-1 Power Source Circuit Board Removal ..................................................4-1

Figure 4-2 Lifter Motor Encoder Circuit Board Assembly Removal ....................... 4-2

Figure 4-3 Connector & Harness Removals ..........................................................4-2

Figure 4-4 Recycler CPU Circuit Board Removal .................................................. 4-2

Figure 4-5 Emission Side Double Note Sensor Removal ......................................4-3

Figure 4-6 Lifter Motor Bracket Removal ...............................................................4-3

Figure 4-7 Lifter Motor Assy Removal ................................................................... 4-3

Figure 4-8 Rear Frame & Middle Frame Removal ................................................4-3

Figure 4-9 Rear Transport Assy Removal ............................................................. 4-4

Figure 4-10 Left Frame Plate Removal ...................................................................4-4

Figure 4-11 Frame Guide 4 Removal ......................................................................4-4

Figure 4-12 Full Sensor PTs and End Sensor LEDs Removal ................................4-4

Figure 4-13 Frame Guide 3 Removal ......................................................................4-4

Figure 4-14 Full Sensor LEDs, End Sensor PTs and Lifter

Home Position Sensor LED/PT Removal .............................................4-5

Figure 4-15 Upper & Lower Flapper Pusher Lever Solenoid Removal ...................4-5

Figure 4-16 Flapper Open/Close Circuit Board Removals ......................................4-6

Figure 4-17 Banknote Transaction Sensor/ Transport Unit Encoder

Circuit Board & Double Note Sensor Removal ....................................4-6

Figure 4-18 Banknote Transaction Sensor & Box Detection

Circuit Board Removal ......................................................................... 4-6

Figure 4-19 Recycler Encoder Circuit Board Removal ............................................4-7

Figure 4-20 Gear & Shaft Removal .........................................................................4-7

Figure 4-21 Recycler Transport Motors Removal .................................................... 4-7

Figure 4-22 Rear Transport Upper Frame & Shaft Removal ...................................4-8

Figure 4-23 Timing Belt Cover Removals ................................................................ 4-8

Figure 4-24 Timing Belt/Pulley Removal .................................................................4-8

Figure 4-25 RC Centering Guide Removal .............................................................. 4-9

Figure 4-26 End Lever Removal ..............................................................................4-9

Figure 4-27 Pick Roller Removal ............................................................................. 4-9

Figure 4-28 RC Course Assy. Removal ..................................................................4-9

Figure 4-29 Transport Race Shaft Removal ............................................................4-9

Figure 4-30 Feed Roller Removal .........................................................................4-10

Figure 4-31 Flapper Removals .............................................................................. 4-10

Figure 4-32 Spring Removals ................................................................................ 4-10

Figure 4-33 Impeller Shaft Removals .................................................................... 4-10

Figure 4-34 Impeller & Stop Roller Removal ......................................................... 4-11

Figure 4-35 Pusher Mechanism Removal .............................................................4-11

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 11

ix

iPRO-RC™ Series Banknote Recycler

List of Figures

Page

Figure 4-36 O-Ring Removals .............................................................................. 4-11

Figure 4-37 Pusher Plate Removal ....................................................................... 4-11

Figure 4-38 Pusher Drive Gear Removal .............................................................. 4-12

Figure 4-39 Pusher Timing Belt Removal 1 .......................................................... 4-12

Figure 4-40 Pusher Timing Belt Replacement ...................................................... 4-12

Figure 4-41 Pusher Timing Belt Removal 2 .......................................................... 4-12

Figure 4-42 Pulley & O-Ring Removal .................................................................. 4-12

Figure 4-43 Pusher Plate Removal ....................................................................... 4-12

Figure 5-1 iPRO-RC Entire System Wiring Diagram (24V) ................................... 5-1

Figure 5-2 iPRO-RC Transport Unit/Frame Unit System Wiring Diagram (Part 1) 5-2

Figure 5-3 iPRO-RC Frame Unit System Wiring Diagram (Part 2) ....................... 5-3

Figure 6-1 Tool and Harness Connection ............................................................. 6-1

Figure 6-2 setup.exe Location ............................................................................... 6-1

Figure 6-3 Install Shield Wizard Screen ................................................................ 6-1

Figure 6-4 Installation File Extracting Screen ....................................................... 6-2

Figure 6-5 Customer Information Screen .............................................................. 6-2

Figure 6-6 Destination Folder Screen ................................................................... 6-2

Figure 6-7 Current Settings Confirmation ............................................................. 6-2

Figure 6-8 Installation Status Confirmation ........................................................... 6-2

Figure 6-9 Installation Completion Screen ............................................................ 6-2

Figure 6-10 JCM Tool Suite Short-cut Icon ............................................................. 6-3

Figure 6-11 JCM Tool Suite Standard Edition ......................................................... 6-3

Figure 6-12 iPRO-RC DIP Switch Setting ............................................................... 6-3

Figure 6-13 DIP Switch Location ............................................................................. 6-3

Figure 6-14 Select Download .................................................................................. 6-3

Figure 6-15 Invalid File! Dialog Pop-Up Screen ...................................................... 6-3

Figure 6-16 Select Firmware 1 ................................................................................ 6-4

Figure 6-17 Select Firmware 2 ................................................................................ 6-4

Figure 6-18 Select Firmware 3 ................................................................................ 6-4

Figure 6-19 Download Progress Screen ................................................................. 6-4

Figure 6-20 Download Progress Screen ................................................................. 6-4

Figure 6-21 Download Completed Screen .............................................................. 6-5

Figure 6-22 KS-087 Reference Paper ..................................................................... 6-5

Figure 6-23 Reference Paper Insertion ................................................................... 6-5

Figure 6-24 iPRO Transport DIP Switch Setting ..................................................... 6-6

Figure 6-25 DIP Switch Setting ............................................................................... 6-6

Figure 6-26 DIP Switch Location ............................................................................. 6-6

Figure 6-27 Model Information Screen .................................................................... 6-6

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 12

x

iPRO-RC™ Series Banknote Recycler

List of Figures

Page

Figure 6-28 Model Information Screen .................................................................... 6-6

Figure 6-29 iPRO-RC Maintenance Tool Screen 1 .................................................6-6

Figure 6-30 iPRO-RC Maintenance Tool Screen 2 .................................................6-6

Figure 6-31 iPRO-RC Maintenance Tool Screen 3 .................................................6-7

Figure 6-32 iPRO-RC Maintenance Tool Screen 4 .................................................6-7

Figure 6-33 iPRO-RC Maintenance Tool Screen 5 .................................................6-7

Figure 6-34 iPRO-RC Maintenance Tool Screen 6 .................................................6-7

Figure 6-35 iPRO-RC Maintenance Tool Screen 7 .................................................6-7

Figure 6-36 iPRO-RC Maintenance Tool Screen 8 .................................................6-8

Figure 6-37 iPRO-RC Maintenance Tool Screen 9 .................................................6-8

Figure 6-38 Calibration Completed Dialog Box .......................................................6-8

Figure 6-39 Serial No. Screen Button Location ....................................................... 6-8

Figure 6-40 Model Information Saving Screen 1 ..................................................... 6-8

Figure 6-41 Model Information Saving Screen 2 ..................................................... 6-8

Figure 6-42 Model Information Saving Completed Screen ...................................... 6-9

Figure 6-43 Sensor Calibration Screen Button ........................................................6-9

Figure 6-44 Loading Model Information Screen 1 ...................................................6-9

Figure 6-45 Loading Model Information Screen 2 ...................................................6-9

Figure 6-46 Version Information Screen 1 ............................................................... 6-9

Figure 6-47 Version Information Screen 2 ............................................................... 6-9

Figure 6-48 Sensor Test Selection ........................................................................ 6-10

Figure 6-49 Test Function Listing Screen .............................................................. 6-10

Figure 6-50 Calibration Test Function Screen Buttons .......................................... 6-10

Figure 6-51 Load Sensor Data ..............................................................................6-10

Figure 6-52 Double Note Detection Sensor ........................................................... 6-11

Figure 6-53 RC Full Sensor ................................................................................... 6-11

Figure 6-54 Test Function Screen Buttons ............................................................6-11

Figure 7-1 Entire iPRO-RC Unit Exploded View .................................................... 7-1

Figure 7-2 iPRO-RC Frame Unit 1 Exploded View ................................................ 7-3

Figure 7-3 iPRO-RC Frame Unit 2 Exploded View ................................................ 7-5

Figure 7-4 iPRO-RC Frame Unit 3 Exploded View ................................................ 7-7

Figure 7-5 iPRO-RC Frame Unit 4 Exploded View ................................................ 7-9

Figure 7-6 iPRO-RC Frame Unit 5 Exploded View .............................................. 7-11

Figure 7-7 iPRO-RC RC Space 1 Exploded View ............................................... 7-13

Figure 7-8 iPRO-RC RC Space 2 Exploded View ............................................... 7-15

Figure 7-9 iPRO-RC RC Space 3 Exploded View ............................................... 7-17

Figure 7-10 iPRO-RC RC Space 4 Exploded View ............................................... 7-19

Figure 7-11 iPRO-RC RC Space 5 Exploded View ............................................... 7-21

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 13

xi

iPRO-RC™ Series Banknote Recycler

List of Figures

Page

Figure 7-12 iPRO-RC Rear Transport Assembly 1 Exploded View ....................... 7-23

Figure 7-13 iPRO-RC Rear Transport Assembly 2 Exploded View ....................... 7-25

Figure 7-14 iPRO-RC Rear Transport Assembly 3 Exploded View ....................... 7-27

Figure 7-15 iPRO-RC Rear Transport Assembly 4 Exploded View ....................... 7-29

Figure 7-16 iPRO-RC Rear Transport Assembly 5 Exploded View ....................... 7-31

Figure 7-17 iPRO-RC Rear Transport Assembly 6 Exploded View ....................... 7-33

Figure 7-18 WBA-SH2 Cash Box Exploded View 1 ..............................................7-35

Figure 7-19 WBA-SH2 Cash Box Exploded View 2 ..............................................7-36

Figure 7-20 WBA-SH2 Cash Box Exploded View 3 ..............................................7-38

Figure 7-21 WBA-SH2 Cash Box Exploded View 4 ..............................................7-39

Figure 7-22 WBA-SH2 Cash Box Exploded View 5 ..............................................7-41

Figure 7-23 iPRO-RC Large Cash Box Frame Unit Exploded View ......................7-44

Figure 7-24 Optional Lock Unit Exploded View ..................................................... 7-45

Figure A-1 Opening the Recycler Unit Door ..........................................................A-4

Figure A-2 Length Guide Removal ........................................................................A-4

Figure A-3 New Length Guide Installation 1 ..........................................................A-4

Figure A-4 New Width Guide Installation 2 ............................................................A-5

Figure A-5 New Width Guide Installation 3 ............................................................A-5

Figure A-6 New Width Guide Installation 4 ............................................................A-5

Figure A-7 Additional Maintenance Equipment Requirements ..............................A-6

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 14

THIS PAGE INTENTIONALLY LEFT BLANK

iPRO-RC™ Series Banknote Recycler

xii

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 15

xiii

iPRO-RC™ Series

Banknote Recycler

List of Tables

Page

Table 1-1 iPRO-RC Model Number Specifications ............................................... 1-2

Table 1-2 iPRO-RC Type Specifications ............................................................... 1-2

Table 1-3 iPRO-RC Software No. Specifications .................................................. 1-2

Table 1-4 iPRO-RC Technical Specifications ....................................................... 1-6

Table 1-5 iPRO-RC Environmental Specifications ................................................ 1-7

Table 1-6 iPRO-RC Electrical Specifications ........................................................ 1-7

Table 1-7 iPRO-RC Structural Specifications ....................................................... 1-7

Table 2-1 iPRO Transport Unit DIP Switch Settings ............................................. 2-2

Table 2-2 iPRO-RC Unit DIP Switch Settings ....................................................... 2-2

Table 2-3 CPU Board Switch Configurations ........................................................ 2-2

Table 2-4 RC Selection Switch Configuration ....................................................... 2-3

Table 2-5 USB Interface Connection Pin Assignments ........................................ 2-4

Table 2-6 Photo Coupler Interface Connection Pin Assignments ......................... 2-5

Table 2-7 RS232C Interface Connection Pin Assignments .................................. 2-6

Table 2-8 ccTalk Interface Connection Pin Assignments ..................................... 2-7

Table 2-9 Power Supply Pin Assignments ............................................................ 2-8

Table 2-10 Front Panel Bezel Interface Connection Pin Assignments ................... 2-8

Table 2-11 iPRO-RC Sensor Type Cleaning Methods ......................................... 2-12

Table 6-1 Sensor Calibration Configuration ........................................................ 6-11

Table 6-2 Performance Test Configurations ....................................................... 6-12

Table 6-3 Get All Sensor State Configurations ................................................... 6-13

Table 6-4 Non-PC Performance Test Item and Configuration

Table 7-1 iPRO-RC Unit Parts List ....................................................................... 7-2

Table 7-2 iPRO-RC Frame Unit 1 Parts List ......................................................... 7-4

Table 7-3 iPRO-RC Frame Unit 2 Parts List ......................................................... 7-6

Table 7-4 iPRO-RC Frame Unit 3 Parts List ......................................................... 7-8

Table 7-5 iPRO-RC Frame Unit 4 Parts List ....................................................... 7-10

Table 7-6 iPRO-RC Frame Unit 5 Parts List ....................................................... 7-12

Table 7-7 iPRO-RC RC Space 1 Parts List ........................................................ 7-14

Table 7-8 iPRO-RC RC Space 2 Parts List ........................................................ 7-16

Table 7-9 iPRO-RC RC Space 3 Parts List ........................................................ 7-18

Table 7-10 iPRO-RC RC Space 4 Parts List ........................................................ 7-20

Table 7-11 iPRO-RC RC Space 5 Parts List ........................................................ 7-22

Table 7-12 iPRO-RC Rear Transport Assembly 1 Parts List ................................ 7-24

Table 7-13 iPRO-RC Rear Transport Assembly 2 Parts List ................................ 7-26

Table 7-14 iPRO-RC Rear Transport Assembly 3 Parts List ................................ 7-28

............................ 6-14

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 16

xiv

iPRO-RC™ Series Banknote Recycler

List of Tables

Page

Table 7-15 iPRO-RC Rear Transport Assembly 4 Parts List ................................ 7-30

Table 7-16 iPRO-RC Rear Transport Assembly 5 Parts List ................................ 7-32

Table 7-17 iPRO-RC Rear Transport Assembly 6 Parts List ................................ 7-34

Table 7-18 WBA-SH2 Cash Box Parts List 1 ........................................................ 7-35

Table 7-19 WBA-SH2 Cash Box Parts List 2 ........................................................ 7-37

Table 7-20 WBA-SH2 Cash Box Parts List 3 ........................................................ 7-38

Table 7-21 WBA-SH2 Cash Box Parts List 4 ........................................................ 7-40

Table 7-22 WBA-SH2 Cash Box Parts List 5 ........................................................ 7-42

Table 7-23 iPRO-RC Large Cash Box Frame Unit Parts List ................................ 7-44

Table 7-24 Optional Lock Unit Parts List ...............................................................7-46

Table A-1 iPRO Unit LED Code Conditions ...........................................................A-1

Table A-2 RC Unit LED Color Type Error Code Conditions ..................................A-2

Table A-3 Recycler Unit LED Code Conditions .....................................................A-3

Table A-4 Various Recycler Unit LED Flashing Error Code Conditions ................A-3

Table A-5 Additional Maintenance Equipment Parts List .......................................A-6

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 17

1-1

iPRO-RC™ Series

1 GENERAL INFORMATION

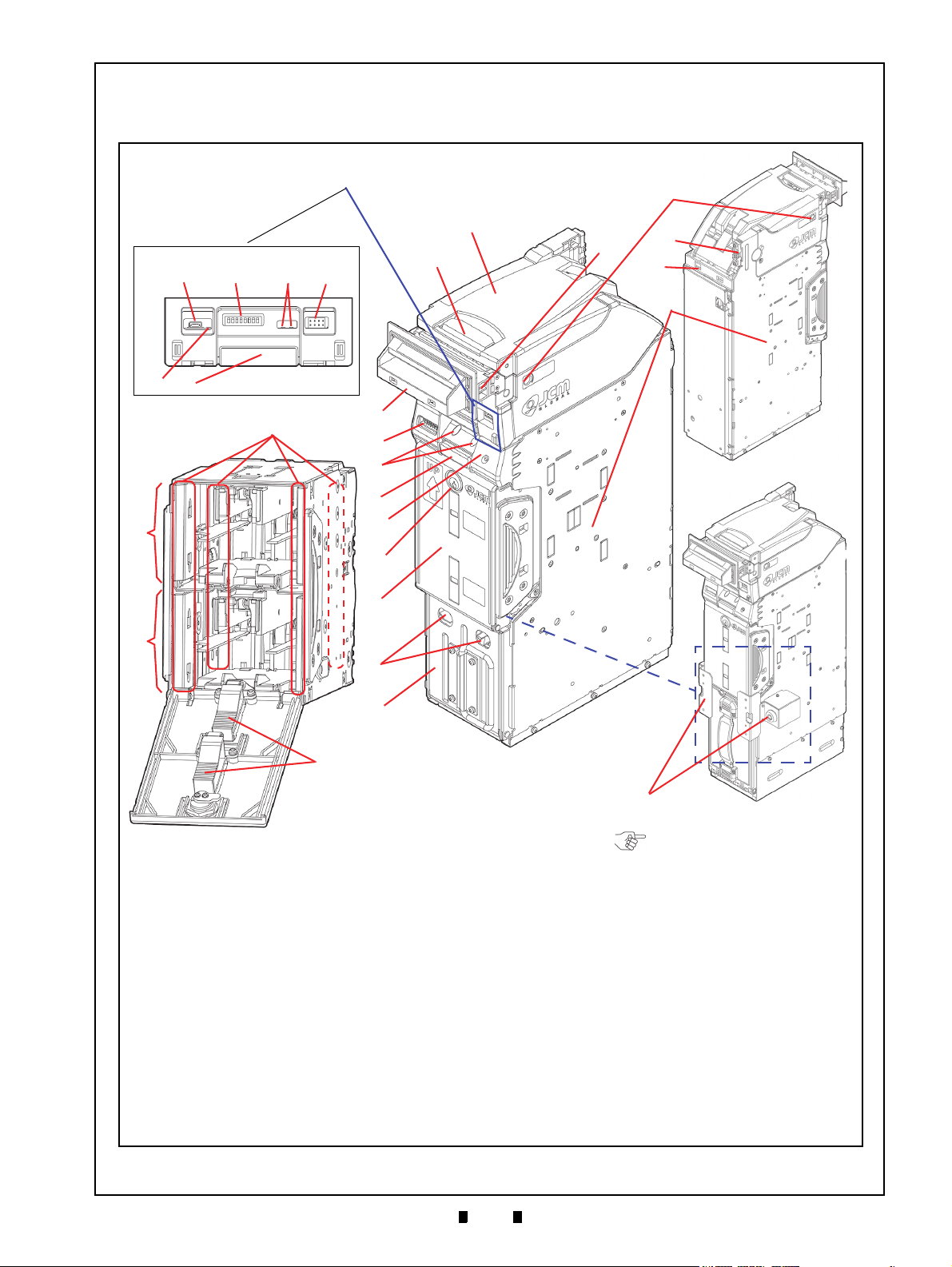

Figure 1-1 iPRO-RC Unit Assembly

iPRO-RC Unit Assembly

Figure 1-1 iPRO-RC Unit Assembly

O

PTIONAL BEZEL

A

SSEMBLY

I

PRO V

ALIDATION

A

SSEMBLY

I

PRO-RC

F

RAME UNIT

I

PRO-RC R

ECYCLER

A

SSEMBLY

I

PRO-RC C

ASH BOX

A

SSEMBLY

(NOT I

NCLUDED

)

NOTE: Cash Box Locks are

Provided Selection

an Optional User

(NOT I

NCLUDED

)

B

EZEL SPACER

(B

EHIND BEZEL

)

Banknote Recycler

Section 1

Description

This section provides a general overview of the

iPRO-RC™ Series Banknote Recycler (iPRO-100SH2-RC; iPRO-RC™) Unit Assembly pictured in

Figure 1-1. This first section is designed to help

you navigate through this guide with ease, and

provides the following information:

• iPRO-RC™ Unit Assembly

• Model Descriptions

• Precautions

• Primary Features

• Component Names

• Specifications

• Unit Dimensions

• Technical Contact Information.

In order to make operation of this device easier and

make navigation within this manual simpler, the

following illustrations were used within the text:

• Safety Instructions, which need to be

observed in order to protect the operators and

equipment, have been written in Bold text and

have been given the following pictographs:

• Special Notes, which affect the use of the

Banknote Recycler have been written in italic

text and have been given the pictograph:

• Steps, requiring the operator to perform

specific actions are given sequential numbers

(1., 2., 3., etc).

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 18

1-2

Section 1 iPRO-RC™ Series Banknote Recycler General Information

0 = None

1 = Width Guide 62 (Gray)

2 = Width Guide 67 (Red)

3 = Width Guide 72 (Blue)

0 = None

1 = Width Guide 62 (Gray)

2 = Width Guide 67 (Red)

3 = Width Guide 72 (Blue)

0 = None

1 = Length Guide 120 (Gray)

2 = Length Guide 127 (Red)

3 = Length Guide 133 (Blue)

4 = Length Guide 140 (Orange)

5 = Length Guide 147 (Green)

6 = Length Guide 152 (Black)

7 = Length Guide 158 (Black)

0 = None

1 = Length Guide 120 (Gray)

2 = Length Guide 127 (Red)

3 = Length Guide 133 (Blue)

4 = Length Guide 140 (Orange)

5 = Length Guide 147 (Green)

6 = Length Guide 152 (Black)

7 = Length Guide 158 (Black)

Figure 1-2 Precautionary Symbols

Type 1 Type 2 Type 3

Figure 1-2 Precautionary Symbols

Model Descriptions

Table 1-1 lists the Product Model Number

descriptions.

Table 1-1 iPRO-RC Model Number Specifications

Model: iPRO

No.

No.

(1)

Product Series Name

Validation Sensor

(2)

1 = Standard (World Wide)

CPU Circuit Board

(3)

0 = Standard

Transport Unit Type

(4)

0 = Standard (World Wide)

Option Unit (Input Section)

(5)

none = Standard

Stacker Type

(6)

SH2 = Horizontal Down (82mm Specification)

SS = Vertical Down (Large Cash Box)

Box Access

(7)

None = Front Access (Standard)

Recycler Function

(8)

RC = Recyclable

o

(1) (2) (3)(4) (5) (6) (7) (8)

Type Descriptions

Table 1-2 lists the Product Type Number

Descriptions.

Table 1-2 iPRO-RC Type Specifications

Type: *

No.

No.o (1,2,3) (4,5) (6,7,8,9,10,11,12,13,14,15,16,17)

Cash Box Capacity

(1)

4 = 400 Notes (New Banknote)

8 = 800 Notes (New Banknote)

Cash Box Type

(2)

0 = Standard

Cash Box Handle

(3)

0 = Standard

Transport Section

(4)

0 = Standard

1 = OEM

Transport Cover

(5)

0 = Standard (Black)

Optional Bezel

0 = None

(6)

1 = Black/Green LED (UBA/iPRO Standard Bezel 85)

2 = Blue/Blue LED (UBA/iPRO Standard Bezel 85)

A = Blue/Blue (2-Line) (UBA/iPRO Standard Bezel 85)

Bezel Spacer

(7)

0 = No

1 = Yes

Optional Power Circuit Board

(8)

1 = Standard (Power Board Featured)

Input/Output Signal

(9)

P = Photo-Coupler Isolation

R = RS232C

0 0 - 0 0 - * * 1 * * * * * * * * *

- 1 0 0 - * SH2 * - RC

Table 1-2 iPRO-RC Type Specifications

Type: *

0 0 - 0 0 - * * 1 * * * * * * * * *

No.

No.o (1,2,3) (4,5) (6,7,8,9,10,11,12,13,14,15,16,17)

External Communication Harness

0 = None

(10)

1 = Standard (with Power Harness)

2 = USB I/F Harness (with Power Harness)

3 = OEM (3441-05-03)

4 = OEM (3441-05-10)

RC1 Recycler Unit Banknote Width Guide

(11)

RC2 Recycler Unit Banknote Width Guide*

(12)

*

†

RC1 Recycler Unit Banknote Length Guide*

(13)

RC2 Recycler Unit Banknote Length Guide*

(14)

Lock Unit

(15)

0 = No (without Lock)

1 = Yes (with Lock)

Anti-Static (Option)

(16)

0 = No (without Anti-Static Sheets)

1 = Yes (with Anti-Static Sheets)

Optional Cash Box Fastener

(17)

0 = None

1 = Thumb Twist Lock Fastener for the Cash Box

*. Contact each region’s local JCM representative for details.

†. Refer to each Country’s “Software Information Sheet”.

Software Descriptions

Table 1-3 lists the Software Number

Specifications.

Table 1-3 iPRO-RC Software No. Specifications

Software: iPRO-100-(*)SH2(*)-RC * * * - 0 * * - V * .**

No.

No.o (A) (B) (C) (D)

(A)

Software Model Name

(B)

Denomination (Country)

(C)

Interface Protocol Name

(D)

Software Version

*. The Country Code is indicated by three (3) Alphabetical Characters

following the JIS Country Standard abbreviation.

*

Precautions

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 19

1-3

General Information iPRO-RC™ Series Banknote Recycler Section 1

Caution: DO NOT use any alcohol,

solvents, abrasive cleaning agents,

or citrus-based cleaners that can

damage the plastic surface of the

device when cleaning it.

Caution: Make Interface Harness

connections to the Host Machine

shorter than 9.84 Feet (3 Meters) in

length. Cut off all unused portions

of the Interface Harness wiring to

avoid static electrical effects or

short circuit possibilities that

could cause damage to the Unit.

WARNING: This Unit is designed

for use with a Current limiting

Power Source! Design the Host

Cabinet space to meet all local

related safety standards.

The Figure 1-2 symbols are defined as follows:

1. (Typ e 1 ) Do not insert a torn, folded, or wet

Banknote into the Unit, as this action may cause a

Banknote jam inside the Unit.

Typ e 2 ) Do not expose the Recycler Unit to

2. (

water or any other liquids. The Unit contains

several precision electronic devices

damaged if water or other liquids are sprayed or

spilled into the Unit.

Typ e 3 ) Do not install the Unit into a dusty

3. (

environment. Dust may affect and degrade the

Recycler’s performance.

User Cautions

Careful measures are taken in the design of this

product to ensure its quality; however, the following cautions should be read and understood by all

users in order to confirm safe operation.

I

NSTALLATION CAUTIONS

The Installation Cautions are defined as follows:

1. Do not allow the Unit to endure or operate at a

high temperature, in high humidity and/or in a

dusty environment.

2. Do not install the Unit

sive vibration or shock are present.

3. The Unit is not designed for outside installation.

4. Avoid exposing the Unit to direct Sunlight and/or

5. Ensure that the Host Machine is designed for

6. When installing the equipment, connect the

7. If an unused Interface

8. Because this equipment is a component product,

9. Do not operate the iPRO-R

10. This Unit is designed to use a current limiting

M

OUNTING

Methods for Mounting, Dismounting, and Transporting the Unit are as follows:

1. Be sure to turn the Power OFF to the iPRO-RC™

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

ure that the Host Machine contains enough

Be s

protection to avoid wet or dusty conditions when

installing in either an indoor or open-air space.

candescent Lamp illumination having a

In

Gradient Angle of 15 Degrees or more, and an

illumination index of 3000 Lux or less.

daily operational access for maintenance

and/or clearing a Banknote jam.

Frame Housing

Machine.

Harness off short to avoid attracting static electricity or a short circuit possibility that may cause

dam

age to the Unit.

close the Ho

Cash Box and/or the Recycler Unit’s door is open.

Personal injury may occur.

Power Source. Be s

cabinet material design meets local safety standards.

, D

Unit before mounting or removing the Recycler

Unit from its permanent location. Attaching or

unplugging Connector Plugs from their Receptacles while the Power is ON may damage the Unit.

st Machine’s door before using it.

ISMOUNTING

that may be

into an area where exces-

to the Frame Ground of the Host

Harness exists, cut the

C™ Unit while the

ure that the Host Machine’s

& T

RANSPORTATION

2. When reassembling a Unit’

each part is replaced in its correct location.

3. Be sure to carry the Unit by both hands when

transportin

cause personal injury if the Unit accidentally

becomes disassembled and falls away from the

Frame housing.

4. Be careful not to use exc

on the Recycler Unit, or subject it to excessive

vibration during transportation.

5. Check that the iPRO™ T

not drop off the Unit Frame while pulling the

Recycler forward from the Frame.

g it. Holding the Unit by one hand may

s Section, ensure that

essive outside pressure

ransport Section does

Preventive Maintenance

The Preventive Maintenance requirements are

defined as follows:

1. Be sure to turn the Power OFF before beginning a

maintenance procedure. The equipment produces

improper operating signals while in maintenance

mode that may cause personal injury.

2. When closing the Recycler Unit, ensure all service door locks click into place.

3. If the iPRO™ Validator Section is dirty due to

st, foreign objects or other such debris adhering

du

to it, the Banknote acceptance rate will degrade.

Clean the Transport Unit once a month to keep its

performance stable.

4. Use a soft, lint-free cloth,

pressed air spray to clean dust and debris from the

Banknote

5. Do not redesign or disassemble the Recycler Unit.

Unauthorized us

personnel, or use outside the original manufacturer’s intent for operation voids the warranty.

path and inside areas of the Recycler.

e by inadequately trained

cotton swab or a com-

Page 20

1-4

Section 1 iPRO-RC™ Series Banknote Recycler General Information

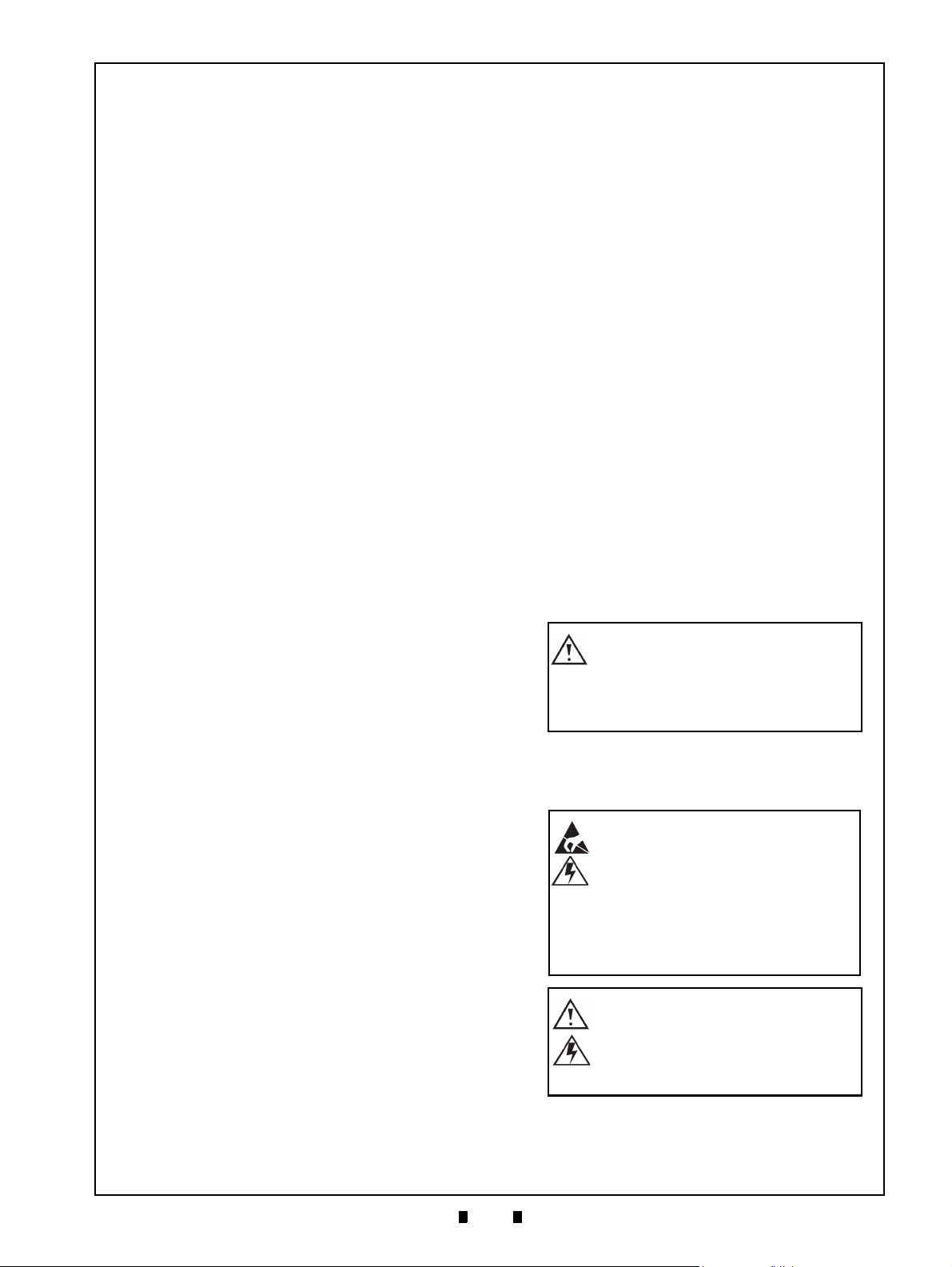

Figure 1-3 Unacceptable Banknotes

Figure 1-3 Unacceptable Banknotes

Damaged Banknotes

Wrinkled Banknotes

Curled Banknotes

Folded or Partial Banknotes

NOTE: Do not insert more than the

above recommended recyclable

Banknotes.

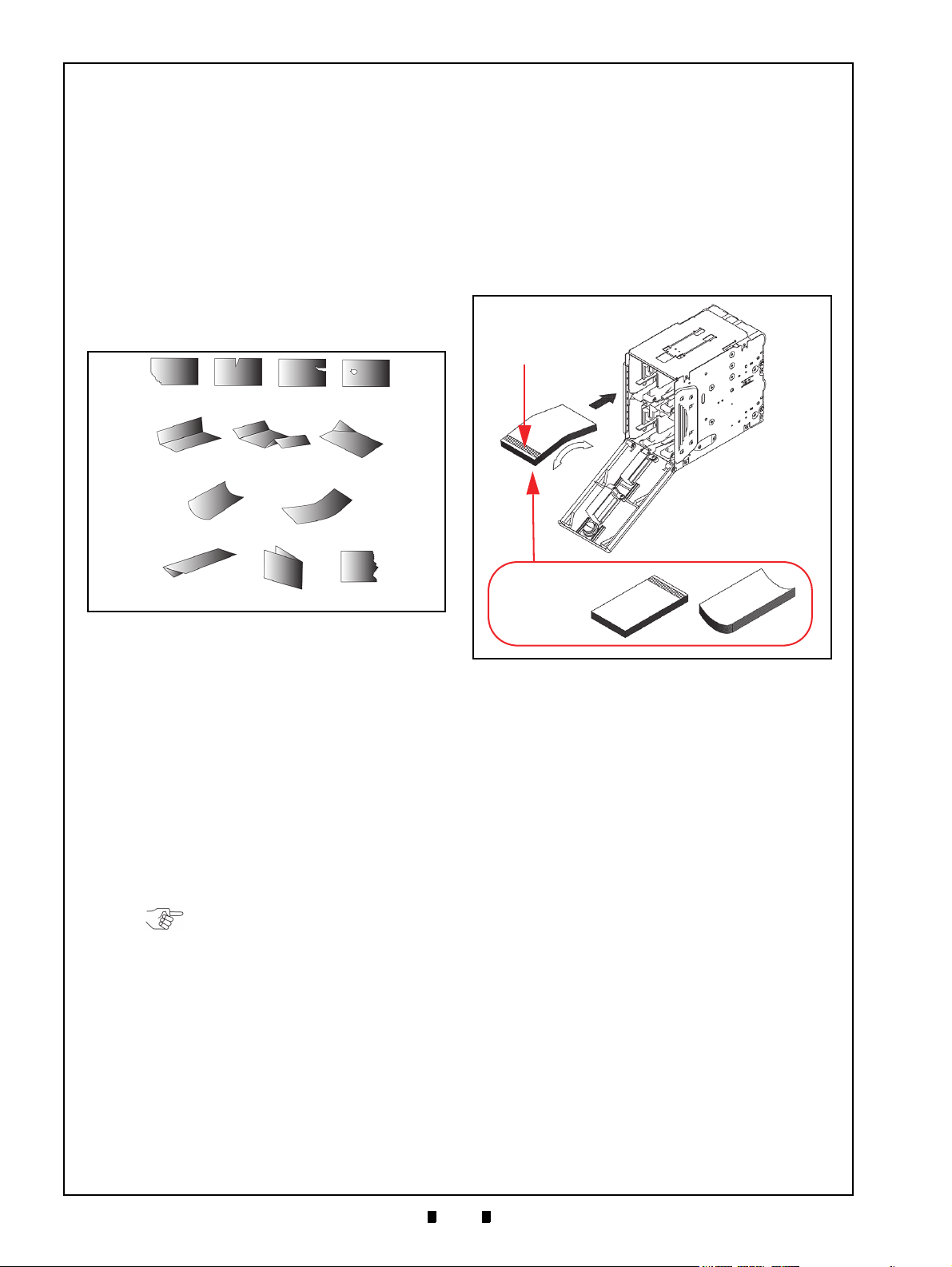

Figure 1-4 Banknote Storage Insertion Cau-

tions

Figure 1-4 Banknote Storage Insertion Cautions

x

Adjust shapes

before restoring

recyclable

Banknotes.

x

a

Hologram

End

aaa

b

Banknote Fitness Requirements

The following Banknote types may not validate

correctly, or can cause a Banknote jam and/or damage to the Unit’s Transport path. Banknotes exhibiting the conditions listed below and illustrated in

Figure 1-3 should be avoided:

• Torn

• Having excessive folds

• Dirty

• Wet

• Having excessive wrinkles

• Adhering foreign objects and/or oil

7. Make sure the denomination of each Banknote

bundle ins

direction.

8. Make sure the Banknote bundle inserted is of the

same deno

when restoring by hand.

9. Insert the Banknotes being recycled into the

Recycler Unit’

reaches the very back of the Bin.

10. Verify that the bottom Note of a Banknote bundle

not curled or folded when inserting the Bank-

is

note bundle into a Recycler Unit’s Bin.

erted is correctly placed in the same

mination and from the same Country

s Bins carefully until the bundle

Banknote Storage Requirements

The following conditions are required when placing

Banknotes directly into the Recycler Unit’s Bins.

1. Replace the minimum Banknote count as required

for Recycler initialization, so the Banknotes will

be available for use during a standard recycle

function.

• The maximum number of recyclable Banknotes

in a Recycler

Unit’s Bin should be:

– Approximately 100 Notes if the Banknotes are

all new

– Approximately 70 Notes if the Banknotes are

a mixed Street Grade level.

2. Do not use any Banknotes indicated in Figure 1-3

“Unacceptable Banknotes ” shown on this page.

3. Make one edge of the Banknote bundle smooth.

4. Verify that no curled or folded Banknotes

5. Before placing Banknotes into the Recycler Bins

6. Verify that the Holograp

ally new Notes), Flip-over and Fan-Flip

(especi

the Banknote bundle; then curve the middle of the

Banknote bundle to form a downward angled

structure (Figure 1-4 a).

hic image portion of a

Banknote is always at the front end of the insertion direction (Figure 1-4 b).

exist.

Primary Features

The iPRO-RC™ Series Banknote Recycler

contains the following primary features:

• Allows a high capacity, compact size,

Recycling Unit available for two (2) different

Banknote denominations

• The Friction Roller System eases operation and

maintenance of the Recycler Unit

• The Automatic Centering Mechanism allows

the Unit to read Banknotes ranging from 62mm

to 82mm in width, and a maximum of 158mm

in length. It will automatically center

Banknotes inserted at an angle to help improve

the acceptance rate

• A secure Recycler Unit containing a Key Lock

is composed of durable, impact-resistant

plastic construction to assure safe and secure

cash handling.

• The JCM patented Anti-Pullback Mechanism

provides powerful protection against Banknote

stringing operations.

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 21

1-5

General Information iPRO-RC™ Series Banknote Recycler Section 1

Figure 1-5 iPRO-RC Component Names

Figure 1-5 iPRO-RC Component Names

A.iPRO Transport Unit

(User Supplied)

B.iPRO Unit Upper Guide Access Lever

C.Front Panel Access

1.USB mini-B Type Receptacle

(for performing

Software downloads and adjustments)

2.8 Position DIP Switch Block

3.iPRO Transport Unit LEDs (Green & Red)

4.Front Bezel Receptacle (for the Optional Bezel

Assembly Plug)

5.Centering LED

6.Transport Unit Release Lever

D.RC Unit DIP Switch Block

E.RC Unit LEDs

(Green, Red & Yellow)

F. Recycler Unit Release Pushbutton

G.Restore Pushbutton (for moving Banknotes from the

Recycler Unit into the Cash Box)

H.Recycler Unit Lock (Supplied with Key)

I. Recycler Unit

J. Cash Box Lock Holes

(Locks are User Supplied

Options)

K.Cash Box

L. Bezel Accessory

(One of 3 Options Available)

M.Bezel Spacer

N.Centering Guide Release Port

O.Interface Connector

(Connects to the Host Machine)

P. Housing Frame

Q.RC1-Bin Assembly Banknote Space

R.RC2-Bin Assembly Banknote Space

S.Banknote Width Guide

T. Banknote Length Guide

U.Power Connector

V.Optional Lock Unit

(Right or Left side)

A

B

E

G

H

I

L

M

D

F

N

J

K

12354

C: Front Panel Access

6

Recycler Unit Assembly

Rear Side

Front Side

Optional Lock

O

U

P

Q

R

T

C

S

V

NOTE: The Optional Lock is

available for installation on

either the right or left side of an

iPRO-RC Unit.

Component Names

Figure 1-5 illustrates the iPRO-RC™ component names and locations.

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 22

1-6

Section 1 iPRO-RC™ Series Banknote Recycler General Information

Specifications

Technical Specifications

Table 1-4 iPRO-RC Technical Specifications

98% or greater

The following Banknote Types are excluded:

Acceptance Rate:

a) Banknotes with excess or poor magnetism or unclear graphics

b) Double (dual) Banknotes

c) Worn, dirty, wet, stained, torn or excessively wrinkled Banknotes

d) Banknotes having folded corners or edges

e) Banknotes having the wrong cut dimensions or a printing displacement.

Recycler Unit

• Length: 120-158mm (4.72-6.22 in.)

Banknote Types Accepted†:

• Width: 62-82mm (2.44-3.22 in.)

Cash Box

• Length: 120-170mm (4.72-6.69 in.)

• Width: 62-82mm (2.44-3.22 in.)

Standard Specification

a) Interleaved Barcode Read: 2 of 5

b) Narrow Bar Width: 0.5mm-0.6mm (0.019-0.023 in.)

Barcode Coupon**:

Insertion Direction:

c) Wide Bar to Narrow Bar ratio = 3:1

d) Characters: 18 Characters

e) Print Position: Middle (Divides a Coupon equally to the left, right, top and

bottom of the Coupon’s center line)

f) Print Width: Wider than 10mm (0.39 in.)

Banknote:

Barcode Coupon: Two-way (with Barcode Surface Facing Upward)

From Banknote insertion to Vend signal output:

• Approximately 2 seconds

From Banknote insertion to stacking operation completion:

• Approximately 5 seconds (to Recycler Unit)

Processing Speed††:

• Approximately 6 seconds (to Cash Box)

From dispense beginning to dispensing operation completion:

• Approximately 3 seconds

From retrieve beginning to retrieving operation completion:

• Approximately 7 seconds

Escrow: 1 Note

Transport Unit: Two Single-Color LEDs

Diagnostic Indicators:

Cash Box‡‡:

Cash Box Capacity:

Recycler Unit: Key Lockable, 2 Denomination Integral Recycler (Friction Roller System)

Recycler Unit Capacity: 100 Notes (New Banknotes Only)

Recycle Unit Storage Method:

Interfaces:

*. Refer to the “Software Information Sheet” for each Country’s Acceptance Rate parameters.

†. Banknote size widths are limited by the specific Guide Types inserted.

‡. Contact each region’s local JCM representative if the Banknote length is over 165mm (6.49 in.).

**.Refer to the specific Country’s Barcode Coupon Specification for more details.

††.Excludes the time lag associated with Host Communication (Power Supply: +24V DC, Temperature: 25º C ±5º C).

‡‡.Cash Box Lock(s) and Key(s) are provided by User (2 Key Hole Caps are fitted in place to cover existing holes when shipped).

RC Unit: Two Tri-Color LEDs (Red/Green/Yellow)

Centering Home Position Indicator: LED (Red)

Steel: Secure Type (WBA-SH2 Cash Box Design)

Plastic: Secure Type (UBA/iPRO Large Cash Box Design)

400 Notes

800 Notes (New Banknotes Only) (UBA/iPRO Large Cash Box Design)

Stores Banknotes from the Acceptor

Stores Banknotes directly

USB (USB Specification Rev.2.0/Full Speed Transmission 12Mbps)

Photo-Coupler Isolation, TTL & RS232C

*

‡

Refer to the specific Country’s “Software Information Sheet”

(Red/Green)

(New Banknotes Only) (WBA-SH2 Cash Box Design)

(Recommended)

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 23

1-7

General Information iPRO-RC™ Series Banknote Recycler Section 1

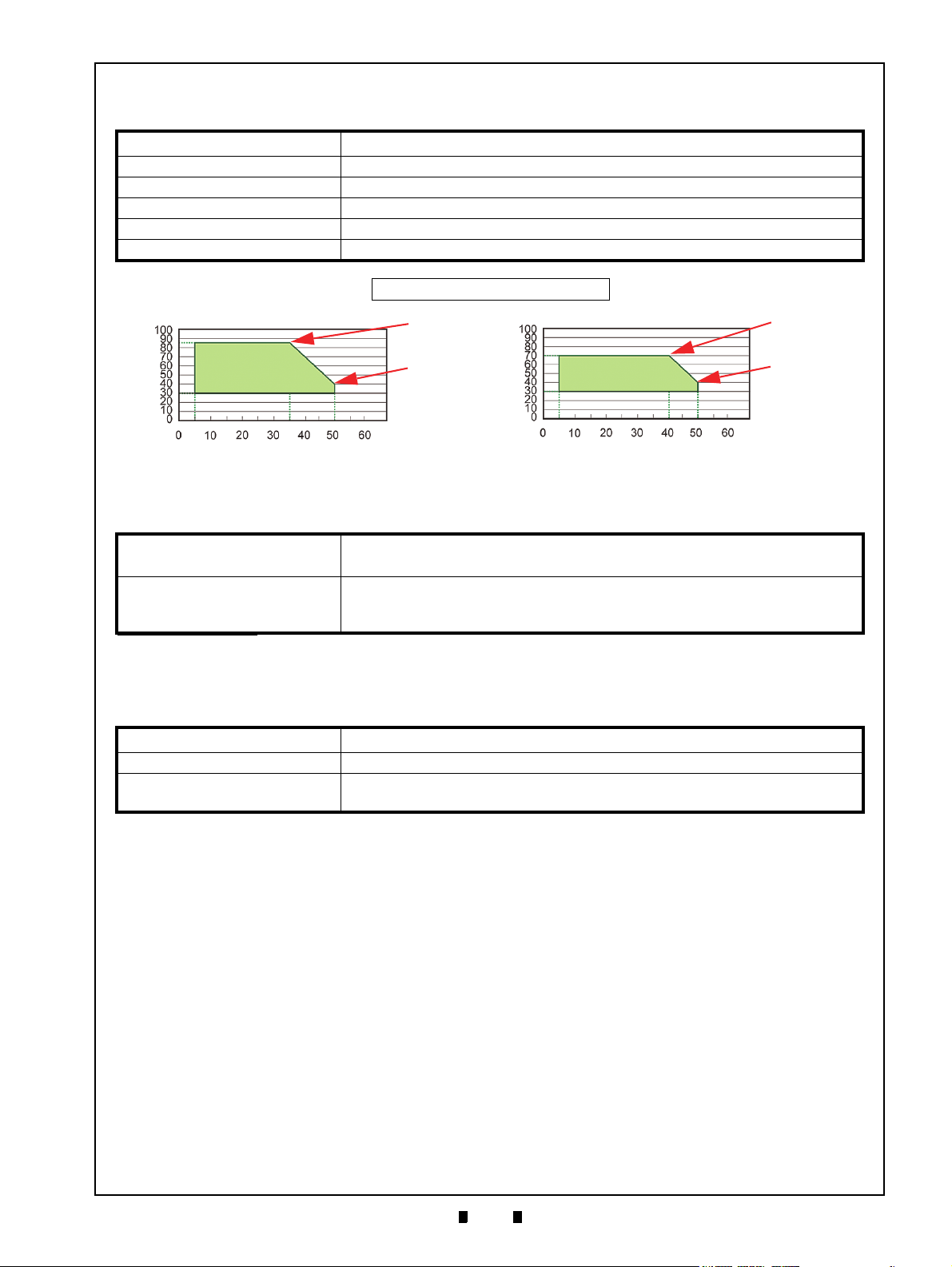

Hydrothermal Condition Table

[°C]

[RH%]

35°C/85%

50°C/40%

[°C]

[RH%]

40°C/70%

50°C/40%

Normal Banknote

Polymer Banknote

Allowable Operating

Temperature and

Humidity Range

Allowable Operating

Temperature and

Humidity Range

Environmental Specifications

Table 1-5 iPRO-RC Environmental Specifications

Operating Temperature: 5ºC to +50ºC (41ºF to 122ºF)

Storage Temperature: -20ºC to +60ºC (-4ºF to 140ºF)

Relative Operating Humidity: 30% to 85% RH (non-condensing)

Relative Storage Humidity: 30% to 85% RH (non-condensing)

Visible Light Sensitivity: Avoid contact with direct Sunlight

Installation: Indoors Only

Electrical Specifications

Table 1-6 iPRO-RC Electrical S

pecifications

Supply Voltage

*

:

24V DC (±5%) (Greater than 3.5A Recommended)

(Use a Current Limiting Power Source)

Standby: 230mA

Current Consumption:

Operation: 1.5A

Peak: 2.5A

*. Use a Limited Power Source.

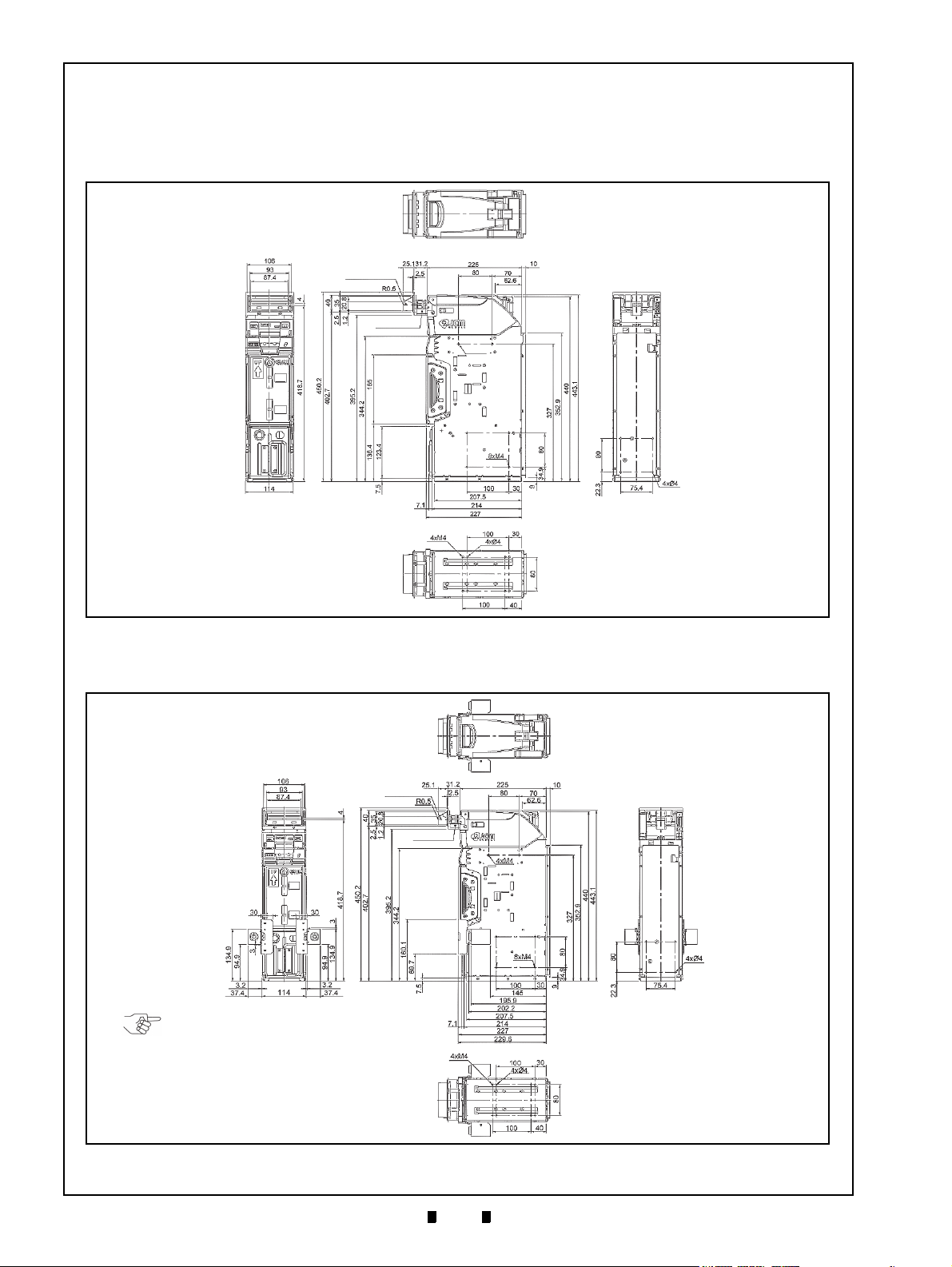

Structural Specifications

Table 1-7 iP

Weight Empty: Approximately 9kg (19.8lbs)

Mounting: Horizontal

Outside Dimensions:

Refer to Figure 1-6 “iPRO-RC Banknote Recycler Standard Unit with

Bezel Outside Dimensions” on page 1-8 of this Service Manual Section.

RO-RC Structural Specifications

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 24

1-8

Section 1 iPRO-RC™ Series Banknote Recycler General Information

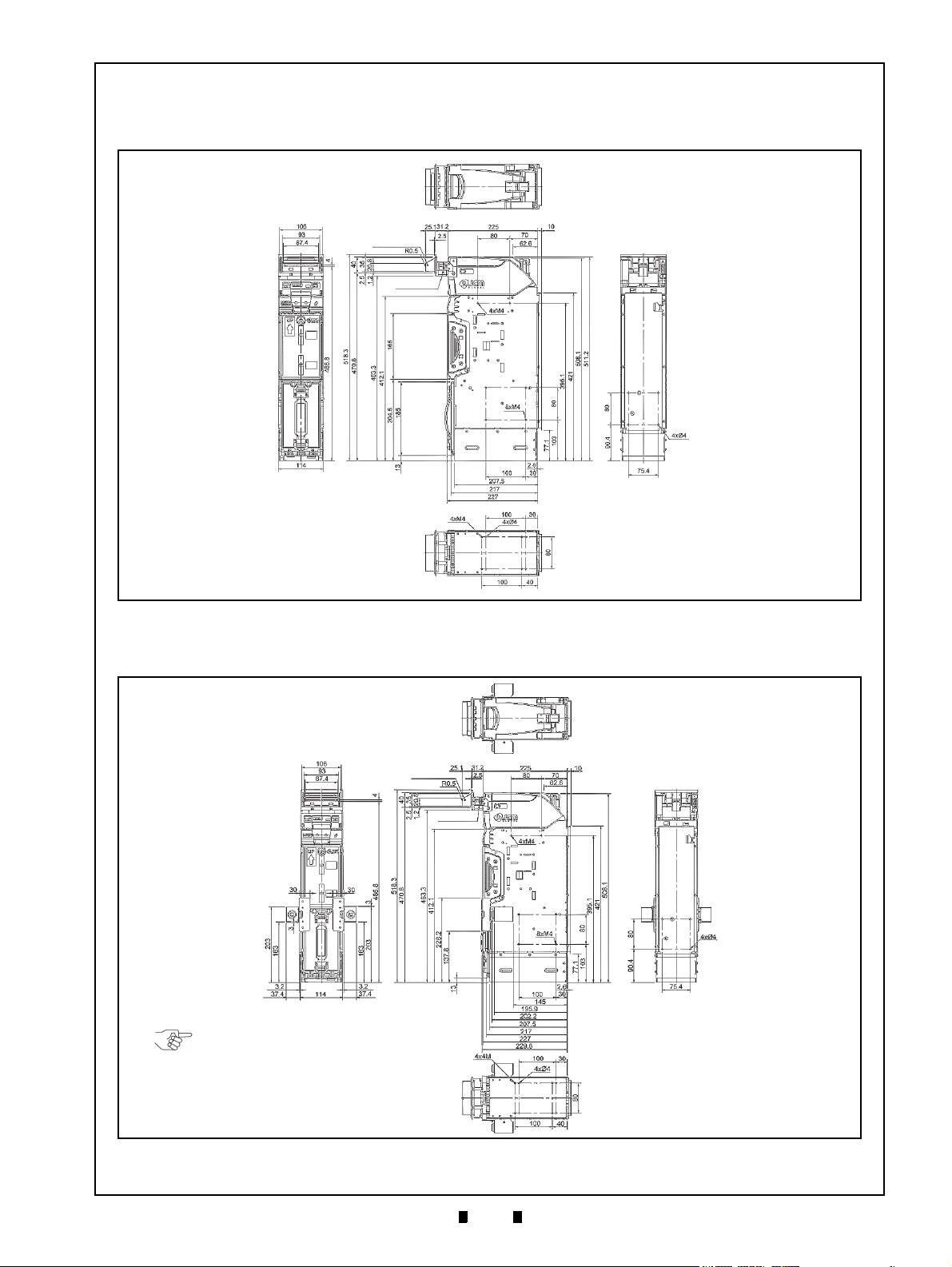

Figure 1-6 iPRO-RC Banknote Recycler Stan-

dard Unit with Bezel Outside Dimensions

Figure 1-6 iPRO-RC Banknote Recycler Standard Unit with Bezel Outside Dimensions

UBA/iPRO Bezel Unit

Bezel Spacer

MAX DEPTH7mm

NOTE: All dimension are in millimeters

MAX DEPTH7mm

Figure 1-7 iPRO-RC Banknote Recycler Stan-

dard Unit with Bezel, Lock Unit and Outside

Dimensions

Figure 1-7 iPRO-RC Banknote Recycler Standard Unit with Bezel, Lock Unit and Outside Dimensions

UBA/iPRO Bezel Unit

Bezel Spacer

MAX DEPTH7mm

NOTE: The Lock Unit is available

for installation on either the right

or left side of the Unit.

NOTE: All dimension are in millimeters

Unit Dimensions

Entire Unit Outside Dimensions

Figure 1-6 illustrates the iPRO-RC™ Unit with the Bezel, Bezel Spacer and 400 Note Cash Box outside

dimensions.

Figure 1-7 illustrates the iPRO-RC™ Unit with the Bezel, Bezel Spacer, Lock Unit and 400 Note Cash

Box outside dimensions.

P/N 960-000164R_Rev. 3 {EDP #213631} © 2018, JAPAN CASH MACHINE CO., LTD.

Page 25

1-9

General Information iPRO-RC™ Series Banknote Recycler Section 1

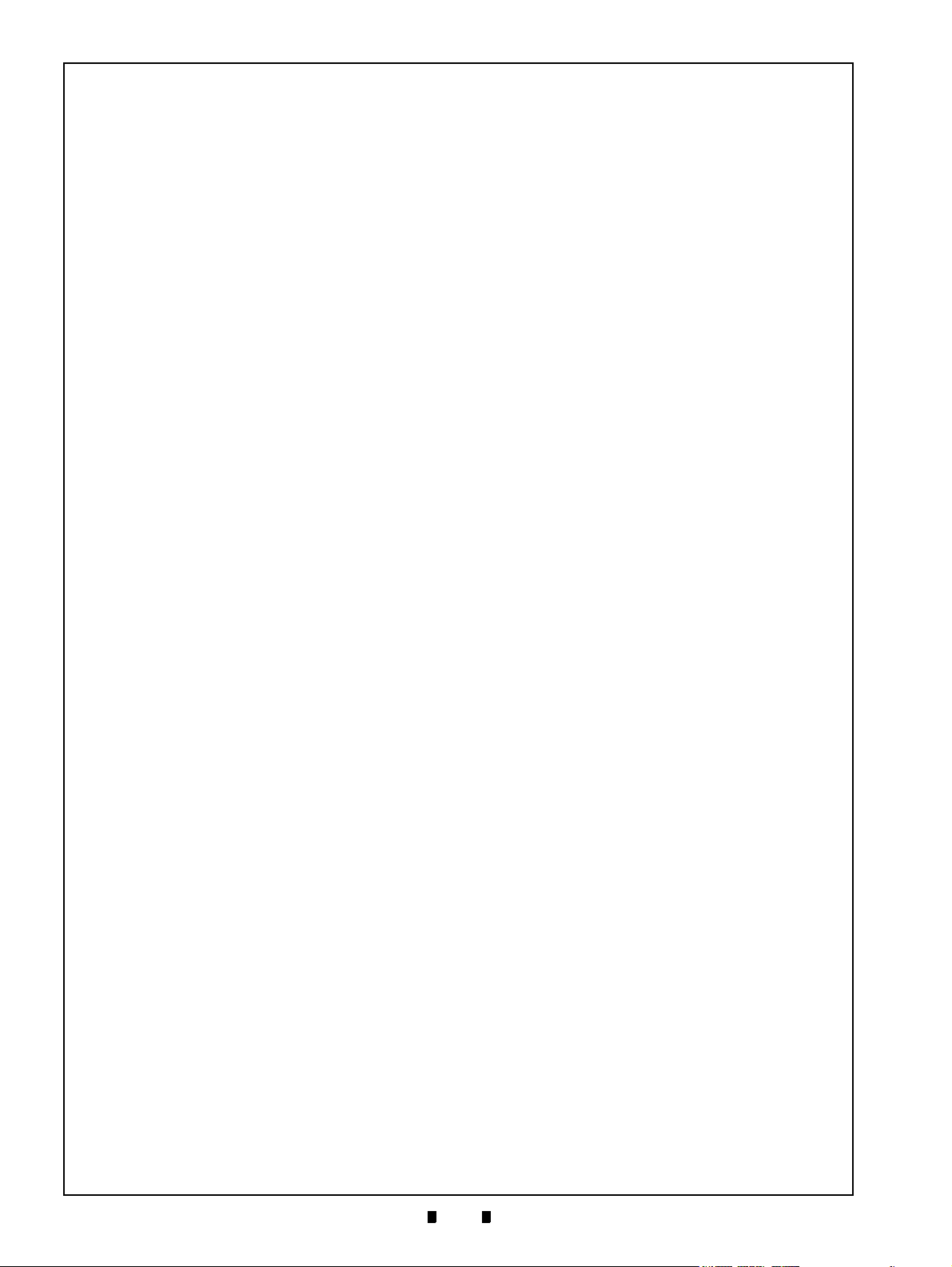

Figure 1-8 iPRO-RC Banknote Recycler Stan-

dard Unit with Bezel Outside Dimensions

Figure 1-8 iPRO-RC Banknote Recycler Standard Unit with Bezel Outside Dimensions

UBA/iPRO Bezel Unit

Bezel Spacer

MAX DEPTH7mm

MAX DEPTH7mm

NOTE: All dimension are in millimeters