Page 1

A JCM Product

© 2017 JCM Global Corporation

Part No. 960-000194R_Rev. A

NOTE: Due to advancements in industry technologies

and future product development, the information in

this guide is subject to change without notice.

Quick Reference Guide

GEN5™ Printer

For more information about product set up, use, testing procedures

and troubleshooting methods, please contact the T echnical Support

Division of Customer Service via the email addresses listed below:

Americas

support@jcmglobal.com

Europe, Middle East, Africa, Russia & UK

support@jcmglobal.eu

Asia & Oceania

asiasupport@jcmglobal.com

Page 2

GEN5™ Printer

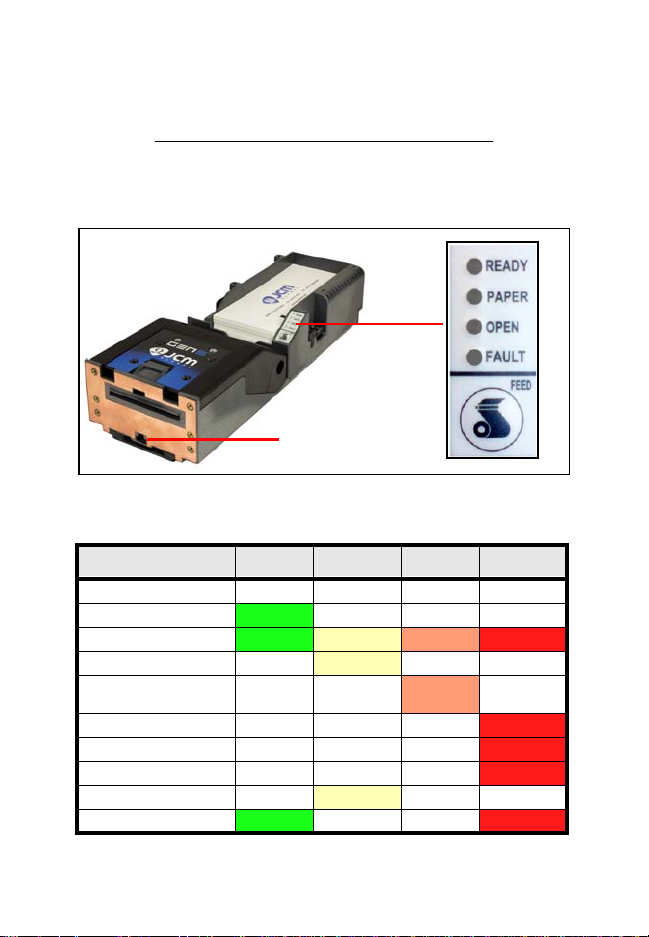

Figure 1 Typical GEN5 Printer

QUICK REFERENCE

TROUBLESHOOTING GUIDE

Introduction

This Quick Reference Guide is designed for use with the GEN5™

line of Printers (Figure 1).

This Guide covers the set-up and use of the following Printer:

PSA-66-ST5.

© 2017 JCM Global Corporation 2 Part No. 960-000194R_Rev. A

Page 3

GEN5™ Printer

Bezel LED

Connector

Figure 2 GEN5 Printer Keypad, LEDs and FEED Button

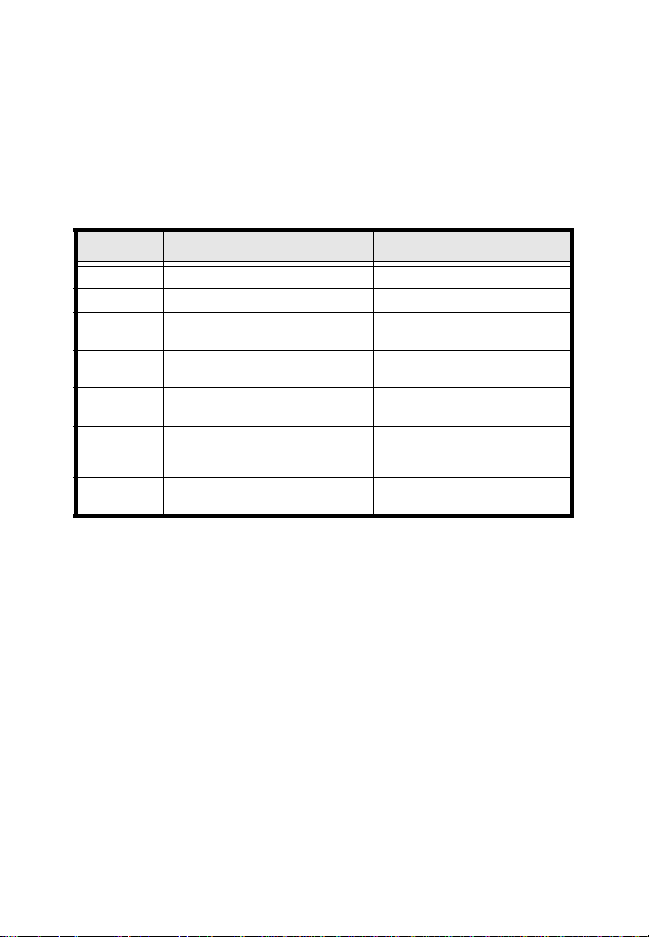

Table 1 GEN5 Keypad LED Status Codes

Condition

Ready

Paper Open Fault

Powered OFF

Ready

Blinking

Flushed

Paper Out

Head Up or Ticket

Module Open

Temperature Error

Voltage Error

Print Head Error

Missing Index Marker

Paper Jammed Blinking

Operator Indicators (LED) And Controls

The GEN5 Printer features a Keypad with LED Status Indicators and

a FEED Button (Figure 2). Printer Status indicators include a Front

Bezel Light and the four (4) Keypad LEDs. Refer to Table 1 below

for GEN5 Keypad LED Status Codes.

© 2017 JCM Global Corporation 3 Part No. 960-000194R_Rev. A

Page 4

GEN5™ Printer

NOTE: For current DIP Switch settings, refer to the

Software Information Sheet for the Firmware version

installed in the GEN5 Printer.

B

EZEL OPERATION

Table 2 identifies the Front Bezel Display indications, which allow

you to determine the Printer Status from a distance.

Table 2 GEN5 Bezel Display Status Indicators

Bezel Display Status

Solid On Printer Idle and Ready

Slow Blink Paper Low or Printer Error

Fast Blink Ticket Printing/Ticket In Chute

OFF Printer Power Off

D

ISABLING/ENABLING THE PAPER LOW SENSOR

To disab le or enable the Paper Low Sensor:

1. Create a Paper Out condition.

2. Create a Paper In Chute condition.

3. Press and hold the FEED button for three (3) seconds.

When the

LED flashes three (3) times. When the

Paper Low Sensor is enabled, the GREEN READY

Paper Low Sensor is

disabled, the RED FAULT LED flashes three (3) times.

GEN5 DIP S

WITCH SETTINGS

The GEN5 Printer has a bank of DIP Switches. The functionality of

the DIP Switch settings is determined by the Firmware loaded into

the GEN5 Printer .

© 2017 JCM Global Corporation 4 Part No. 960-000194R_Rev. A

Page 5

GEN5™ Printer

Model Number

System

Communications

Setup

Print Control

Parameters

Amount of

Memory

Resident Ticket

T emplate Packa ge

Version

Firmware Version

Templates, print

regions and fonts

available in the

printer by TCL

page mode

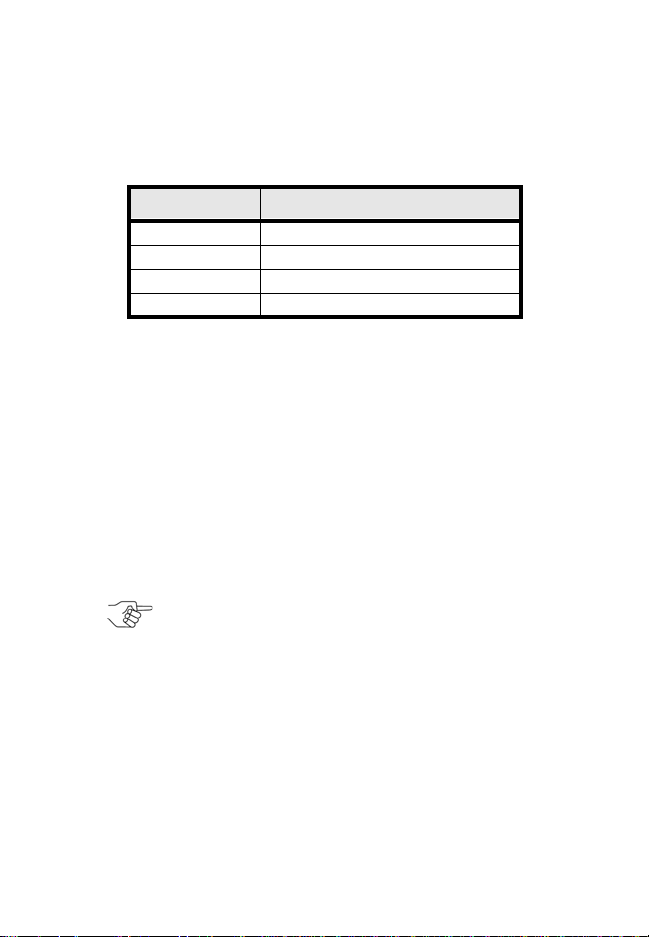

Figure 3 GEN5 Printer Configuration Ticket

Self-Test Procedure

The Self-Test Procedure is used to print a “Configuration T icket” and

verify that the GEN5 Print function operates normally. The Configuration Ticket can be used to check print quality. To print a Configuration Ticket (Figure 3), press the FEED button twice.

© 2017 JCM Global Corporation 5 Part No. 960-000194R_Rev. A

Page 6

GEN5™ Printer

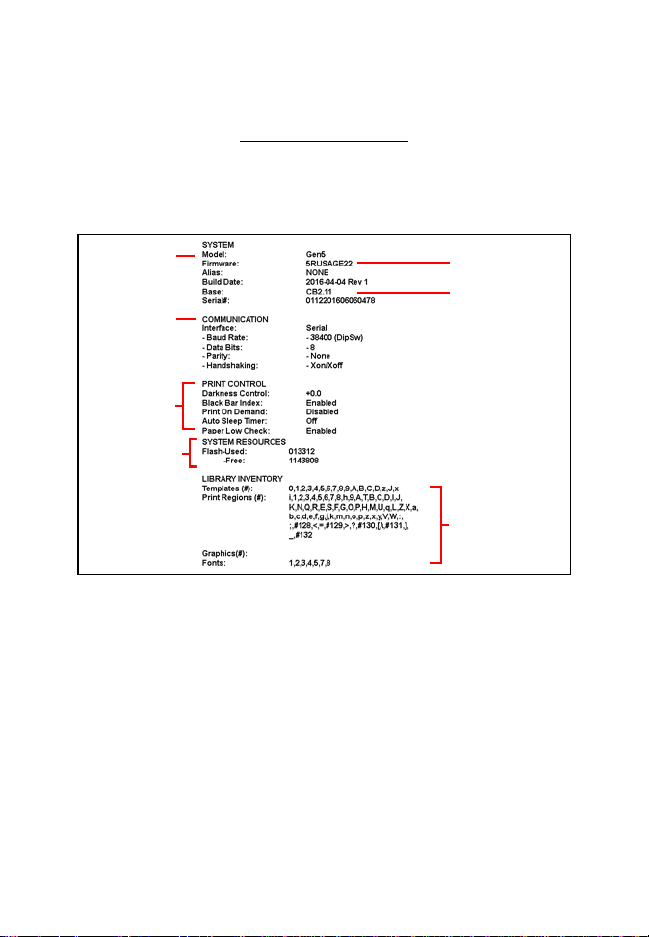

PRINTER SENSOR FUNCTIONS

There are five (5) primary Sensor functions on the GEN5 Printer.

Bezel light and Keypad LEDs may indicate a Sensor-related error

condition (refer to Table 3).

Table 3 GEN5 Printer Sensor Status

Sensor Location/Description

Paper Out

Paper Low

Paper Taken

Drawer Open

Printer Lid Open

Located in the Print Head, Paper Out indicates that paper is

not loaded in the GEN5 Printer.

Located in the Paper Tray, Paper Low indicates that less

than two (2) Tickets are detect ed in the GEN5 Printer.

Located in the Presenter Chute, Paper Taken indicates that a

Ticket remains in the Presenter Chute.

Located on the CPU Board, Drawer Open indicates that the

Printer is not seated properly in the Host Machine.

Located in the Print Head, Printer Open in d ica te s th a t the

Printer Lid is open.

© 2017 JCM Global Corporation 6 Part No. 960-000194R_Rev. A

Page 7

GEN5™ Printer

P

RINTER ERRORS

Most Printer Errors occur due to paper running out or user intervention. See Table 4 below for Error Descriptions and recommended

solutions. Refer to Figure 2 and T able 1 (Page 3) for Error Indicators.

Table 4 GEN5 Printer Errors

Error Description Remedy

Paper Out Paper is not detected. Load new paper stack.

Lid Open The Printer Lid is open. Close the Printer Lid.

Temperature

Voltage

Print Head

Missing

Black Index

Paper Jam

Operating Temperature exceeds

limits.

Power Supply voltage exceeds

acceptable range.

Error due to connectivity or

interface issue with Print Head.

The Black Index Mark is not

detected.

Error in Paper path as Ticket is

presented.

Determine cause of high

temperature, let unit cool down.

Check cabling, apply correct

power level.

Power cycle and reset printer. If

error recurs, service the printer.

Ensure paper meets

specifications and is loaded

correctly.

Open Printer Head, inspect for

jammed Ticket.

© 2017 JCM Global Corporation 7 Part No. 960-000194R_Rev. A

Page 8

GEN5™ Printer

Figure 4 JCM Device Firmware Upgrade

Downloader UI Window/Closeup

NOTE: A USB Hub is recommended. Connect the

USB Hub between the PC and the GEN5 Printer.

UPDATING FIRMWARE ON THE PRINTER

To update Firmware on the GEN5 Printer using a PC:

1. From your PC Desktop, launch the JCM Device Firmware

Upgrade Downloader (JCM DFU) (Figure 4).

2. Make sure the GEN5 Printer is powered ON.

3. Connect a USB cable from the PC to the Printer’s USB port

(right side).

© 2017 JCM Global Corporation 8 Part No. 960-000194R_Rev. A

Page 9

GEN5™ Printer

a

Figure 5 “Printer Detected” Indicator

a

Figure 6 Click Select Firmware

4. To verify communication between the GEN5 Printer and the

Device Firmware Upgrade Application, look for the Printer

Detected indicator (Figure 5

a) in the window.

5. Click the

Select FIRMWARE button to select the desired

Firmware Upgrade file to be downloaded (Figure 6 a).

© 2017 JCM Global Corporation 9 Part No. 960-000194R_Rev. A

Page 10

GEN5™ Printer

a

b

Figure 7 Select the Firmware File to Download

6. From the Firmware Upgrade window (Figure 7), click on the

desired Firmware update file (Figure 7 a) to be downloaded

to the Printer . Then click the

Open button (Figure 7 b) to con-

tinue.

© 2017 JCM Global Corporation 10 Part No. 960-000194R_Rev. A

Page 11

GEN5™ Printer

NOTE: When the ***Printer Successfully Updated***

text line appears, the update is complete.

a

Figure 8 Select the Full Upgrade Button

NOTE: Multiple versions of Firmware can be stored in

the GEN5 System folder.

7. Make sure the Erase User Settings check box is selected.

Then click the Full Upgrade button (Figure 8 a).

8. Press the FEED button twice to print a Configuration Ticket.

9. Verify that the Firmware version printed on the Configuration Ticket matches th e ve rsion downloaded to the Printer.

U

PDATING

GEN5 F

IRMWARE WITH THE BLUEWAVE

™

DX T

To update firmware on the GEN5 Printer using the BlueWaveDX

Tool, perform the following steps:

1. Create a folder in the root directory of the SD Card, named:

GEN5 System.

2. Place the Firmware file for the GEN5 Printer into this new

folder.

OOL

3. Apply power to the GEN5 Printer.

4. Connect a Standard USB Cable between the BlueWaveDX

Tool and the GEN5 Printer USB Download Port.

5. Apply Power to the BlueWa veDX Tool.

© 2017 JCM Global Corporation 11 Part No. 960-000194R_Rev. A

Page 12

GEN5™ Printer

NOTE: When the Firmware has been downloaded,

the GEN5 Printer will reset automatically.

NOTE: The Firmware in the BlueWaveDX Tool must

be Version 2.00 or higher to support the GEN5 Printer

downloading.

6. Select FIRMWARE UPDATE by pressing the OK button on the

BlueW aveDX Tool.

7. Select the Firmware Version by scrolling through the list

using the BlueW av eDX T ool’s UP and DOWN Arrow keys.

8. Press the

OK button to select the required Firmware Version.

9. When

Download Complete appears on the BlueWaveDX Tool

LCD display, press the

CLR button to return to the Main

Menu OR press the OK button to download the selected

Firmware version to another Printer.

A

BOUT THE BLUEWAVE

™

DX PRINTER CONFIG O

PTION

Using the BlueWa veDX Tool, the Bar Code format printed by the

GEN5 Printer can be changed. To do so:

1. Connect the BlueWaveDX Tool to the GEN5 Printer with a

USB Cable.

2. Using the

CONFIG

UP and DOWN Arrow keys, scroll to the PRINTER

option. Press the OK button.

3. Using the UP and DOWN Arrow keys, select the required Bar

Code format from the following options:

a). 4/8 (default)

b). 3/9

c). 4/12

4. Press the OK button to select the Bar Code format.

5. Press the CLR button to return to the Main Menu.

© 2017 JCM Global Corporation 12 Part No. 960-000194R_Rev. A

Page 13

GEN5™ Printer

NOTE: Printers supporting USB Communications also

have RS-232 Active.Test connectivity using an

RS-232 connection.

Figure 9 JCM Printer Basic Driver Opening Screen

ABOUT THE JCM PRINTER BASIC DRIVER

The JCM® Printer Basic Driver allows full testing of a connected

Printer.

C

ONNECTING TO THE

JCM P

RINTER BASIC DRIVER

To connect to the JCM Printer Basic Driver:

1. Click the Start Button on the PC Desktop, then click on Programs.

2. Scroll down to

The

JCM PRINTER BASIC DRIVER Opening Screen appears (Figure 9).

JCM, then click the JCM Printer Basic Driver icon.

3. Select the PROTOCOL (RS-232 or Netplex) and PORT NUMBER.

© 2017 JCM Global Corporation 13 Part No. 960-000194R_Rev. A

Page 14

GEN5™ Printer

a

c

b

d

Figure 10 JCM Printer Basic Driver Main Screen

NOTE: Descriptions of these features appear on

Page 15.

JCM P

RINTER BASIC DRIVER MAIN SCREEN

The JCM Printer Basic Driver Main Screen (Figu re 10) displays three

main sections:

1. PRINTER CONFIGURATION (Figure 10 a)

2. COMMANDS

3. PRINTER STATUS

(Figure 10 b)

(Figure 10 c)

© 2017 JCM Global Corporation 14 Part No. 960-000194R_Rev. A

Page 15

GEN5™ Printer

NOTE: Any active condition appears highlighted in

RED (Figure 10

d).

PRINTER CONFIGURATION (Figure 10 a)

This section displays the current Printer Configuration, including

Version, Firmware Installed and Communication Setup parameters

COMMANDS (Figure 10 b)

This section provides the following functional checks:

• Reset - Performs a reset of the Printer

• Clear - Clears Warning and Error Status

• Flush - Deletes the Firmware on the Printer

• Feed - Feeds one blank Ticket

• Print Ticket Information - Prints a Test Ticket with Printer

Information, Printer Communication Settings, Character Set

and a Test Barcode

• Get Value - Retrieves the Printer CRC information

• Select File - Use Select File to select a properly-formatted ticket

• Send File - Use Send File to print the sample ticket on the Printer

PRINTER STATUS (Figure 10 c)

This section displays the current status of the Printer.

© 2017 JCM Global Corporation 15 Part No. 960-000194R_Rev. A

Page 16

GEN5™ Printer

NOTE: The Cleaning Cycle may need to be changed,

depending on operating environment conditions.

Smoke-filled and/or dusty environments require more

frequent Cleaning Cycles.

PREVENTIVE MAINTENANCE

To ensure high performance printing quality, the GEN5 Printer must

be cleaned periodically using the following methods:

– Perform the Cleaning Card Method every three (3) months.

– Manual Cleaning should be performed every six (6) months.

Cleaning Supplies

Table 5 Required Supplies

Description Part No.

Cleaning Kit, Bagged

Isopropyl Alcohol (I.P.A.) 99% or greater N/A

Non-Flammable Compressed Air N/A

* Cleaning Kit includes (10) Cleaning Swabs (P/N 350-00291-100), (10) Cleaning Wipes

(P/N 350-00259-100) and (10) Cleaning Cards (P/N 350-00287-100).

C

LEANING THE PRINTER

(C

LEANING CARD METHOD

P/N 350-00292-100

)

To clean the Printer using the Cleaning Card Method:

1. Slide the Printer out of the EGM.

2. Remove Tickets from the Printer’s Paper T r ay (see Figure 11 a on page

17).

3. Verify that the Printer is powered ON.

4. Remove the Cleaning Card from its package.

5. Insert the Cleaning Card into the Ticket-In Slot (see Figure 11 d on page

17). The Cleaning Card will feed into the Slot up to the loading point.

6. Press the FEED button to feed the Cleaning Card through the Paper Path.

7. Remove the Cleaning Card from the Printer.

8. Turn the Cleaning Card over.

9. Repeat Steps 5 through 7 for a second cleaning cycle.

10. Reload the Tickets.

11. Feed at least two (2) Tickets through the Printer to wipe off excess

moisture on the Print Head.

*

© 2017 JCM Global Corporation 16 Part No. 960-000194R_Rev. A

Page 17

GEN5™ Printer

d

a

b

c

Figure 11 Cleaning the Ticket-In Slot

NOTE: Insert the Compressed Air canister’s tube into

the Ticket-In Slot approximately 1 inch from the right

edge of the Slot.

Manual Cleaning

Use the following procedure for Manual Cleaning of the Printer:

1. Slide the Printer out of the EGM.

2. Remove Tickets from the Printer’s Paper Tray (Figure 11 a).

3. Press the Lid Release Lever toward the rear of the Printer to release the lid

(Figure 11 b).

4. Rotate the Lid up in the direction indicated by the red arrow (Figure 11 c

and Figure 12 a on page 18) to access the Printer interior.

5. Use Non-Flammable Compressed Air to blow out excessive dust and dirt

from the following areas within the Printer:

– Ticket-In Slot (Figure 11 d)

– Presenter Assembly (refer to Figure 12 b on page 18)

– Print Head (refer to Figure 13 b on page 18)

– Paper Tray (Figure 11 a)

© 2017 JCM Global Corporation 17 Part No. 960-000194R_Rev. A

Page 18

GEN5™ Printer

a

b

Figure 12 Presenter Assembly

a

b

Figure 13 Print Head Release Lever/Print Head

Clean Print Head (b)

with Cleaning Swab

6. Open the Print Head Release Lever (Figure 13 a).

7. Clean the Print Head (Figure 13 b) using a Cleaning Swab.

© 2017 JCM Global Corporation 18 Part No. 960-000194R_Rev. A

Page 19

GEN5™ Printer

a

d

e

Cleaning Paper

Low Sensor (b) with

Cleaning Swab

b

c

b

Figure 14 Sensor Locations

a Printer Tray (Drawer Open) Sensor

b Ticket Low (Paper Low) Sensor

c Paper Out (Index Mark) Sensor

d Lid Open Sensor

e Ticket Taken (Paper Taken) Sensor

8. Clean each of the Sensors using a clean Cleaning Swab (Figure 14).

© 2017 JCM Global Corporation 19 Part No. 960-000194R_Rev. A

Page 20

GEN5™ Printer

a

b

Figure 15 Platen Roller/Feed Roller

9. Use a Cleaning Wipe to wipe and clean the Platen Roller (Figure 15 a).

Rotate the Roller to clean the Roller’s entire circumference.

10. Close the Print Head Release Lever (refer to Figure 13 a on page 18).

11. Use a Cleaning Wipe to wipe and clean the Feed Roller

(Figure 15 b).

12. Use a clean, dry Micro-fiber cloth to wipe excess liquid from all surfaces.

13. Reload the Tickets.

14. Slide the Printer into the EGM.

© 2017 JCM Global Corporation 20 Part No. 960-000194R_Rev. A

Page 21

GEN5™ Printer

Quick Reference Guide

GEN5™ Printer

JCM International

Offices

Europe, Middle East, Africa & Russia

JCM Europe GmbH

Mündelheimer Weg 60,

D-40472 Düsseldorf Germany

Phone: +49-211-530-645-60

Fax: +49-211-530-645-85

E-mail: support@jcmglobal.eu

UK & Ireland

JCM Europe (UK Office)

Unit B, Third Avenue

Denbigh West Business Park

Bletchley, Milton Keynes

Buckinghamshire MK1 1DH UK

Phone: +44 (0) 190-837-7331

Fax: +44 (0) 190-837-7834

E-mail: info@jcmglobal.eu

© 2017 JCM Global Corporation Part No. 960-000194R_Rev. A

Page 22

GEN5™ Printer

Quick Reference Guide

GEN5™ Printer

JCM International

Offices

Americas

JCM American

925 Pilot Road, Las Vegas, NV 89119

Phone: (702) 651-0000

Fax: (702) 644-5512

E-mail: support@jcmglobal.com

Asia and Oceania

JCM Gold (HK) Ltd.

Unit 1-7, 3/F., Favor Industrial Centre

2-6 Kin Hong Street, Kwai Chung

E-mail: asiasupport@jcmglobal.com

JAPAN CASH MACHINE CO., LTD. (HQ)

N.T. Hong Kong

Phone: +852-2429-7187

Fax: +852-2929-7003

2-3-15, Nishiwaki, Hirano-ku

Osaka 547-0035 JAPAN

Office: +81-6-6703-8400

Fax: +81-6-6707-0348

E-mail: Shohin@jcm-hq.co.jp

© 2017 JCM Global Corporation Part No. 960-000194R_Rev. A

Loading...

Loading...