Page 1

Support: http://www.jcmglobal.com/en/contact/default.aspx website: http://www.jcmglobal.com

EBA® Series

Banknote Acceptor (EBA-40)

Integration Guide

Revision A, December 4, 2013

P/N 960-000173R_Rev. A {EDP #229278}

Issue #4103-IGE-01-00

© 2013, JAPAN CASH MACHINE CO., LTD.

Page 2

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

or

or or

or

Issue #4103-IGE-01-00

REVISION HISTORY

Rev №. Date Reason for Update Comment

A 12/4/13 Initial Document

International Compliance

• RoHS Directives

• CE Mark

• CB Scheme

NOTE: The above listed compliance confirmations are currently being examined for approval or

certification.

This product document (hereinafter referred to as “Manual”) is fully covered by legal Copyrights owned by the JAPAN

CASH MACHINE CO., LTD. (hereinafter referred to as “JCM”) under Japanese laws and other Foreign Countries.

This Manual contains many copyrighted, patented or properly registered equipment items manufactured by JCM, that

are prohibited and illegal to duplicate, replicate, copy in whole, or in part, without the express authorization by JCM with

the following exceptions:

1. When an authorized JCM agency or distributor duplicates the Manual for sales promotion and/or service

maintenance of the product, or technical service personnel education as required; and

2. When an end user duplicates the Manual to maintain operation of the product or operate the product in general.

JCM retains all rights to amend, alter, change or delete any portion of this Manual in whole, or in part, or add items

thereto without notice regarding the product or its related products.

JCM is a registered trademark of JAPAN CASH MACHINE CO., LTD. All other product names mentioned herein may be

registered trademarks or trademarks of their respective companies. Furthermore,

in each case throughout this publication.

Copyright © 2013 By JAPAN CASH MACHINE CO., LTD.

™, ® and © are not always mentioned

Page 3

i

EBA® Series

Banknote Acceptor (EBA-40)

Table of Contents

Page

1 GENERAL INFORMATION......................................................................................1

Description.......................................................................................................................... 1

EBA-40 Unit ......................................................................................................................

Model Descriptions ............................................................................................................. 2

Type Descriptions ...............................................................................................................2

Software Descriptions......................................................................................................... 2

Precautions.......................................................................................................................

User Cautions ................................................................................................................................. 2

Installation Cautions ..................................................................................................................... 2

Mounting, Dismounting & Transportation...................................................................................... 3

Placing Foreign Objects into the Unit

Preventive Maintenance ..........................................................................................................

Banknote Fitness Requirements....................................................................................................

Primary Features ................................................................................................................4

Component Names............................................................................................................. 5

...........................................................................................3

2 SPECIFICATIONS....................................................................................................6

Technical Specifications...................................................................................................... 6

Environmental Specifications .............................................................................................. 7

Electrical Specifications ...................................................................................................... 7

Structural Specifications...................................................................................................... 7

3 INSTALLATION .......................................................................................................8

Installation Procedure ......................................................................................................... 8

Entire Unit Installation ..................................................................................................................... 8

Acceptor Head Installation .............................................................................................................. 8

Lock Installation .................................................................................................................. 9

DIP Switch Configurations ................................................................................................ 10

4 CONNECTOR PIN ASSIGNMENTS ......................................................................11

CONNECTOR PIN ASSIGNMENTS (Continued 1).......................................................... 12

CONNECTOR PIN ASSIGNMENTS (Continued 2)

CONNECTOR PIN ASSIGNMENTS (Continued 3)

CONNECTOR PIN ASSIGNMENTS (Continued 4)

CONNECTOR PIN ASSIGNMENTS (Continued 5)

CONNECTOR PIN ASSIGNMENTS (Continued 6)

.......................................................... 13

.......................................................... 14

.......................................................... 15

.......................................................... 16

.......................................................... 17

5 PREVENTIVE MAINTENANCE .............................................................................18

Retrieving Banknotes........................................................................................................ 18

Clearing a Banknote Jam.................................................................................................. 18

Cleaning Procedure .......................................................................................................... 18

Sensor and Roller Cleaning Procedure ........................................................................................ 18

Sensor and Roller Locations......................................................................................................

6 STANDARD INTERFACE CIRCUIT SCHEMATICS..............................................20

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 1)................................... 21

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 2)................................... 22

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 3)................................... 23

7 OPERATIONAL FLOWCHART .............................................................................24

Operational Flowchart (Continued 1)................................................................................ 25

8 TROUBLESHOOTING ...........................................................................................26

Introduction ....................................................................................................................... 26

Troubleshooting Overview ................................................................................................ 26

.. 1

.. 2

..... 3

. 4

... 19

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 4

ii

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Table of Contents

Continued

Page

Fault Table Listings ............................................................................................................26

LED Indication Conditions .................................................................................................28

LED Flash Error Code Conditions .................................................................................................28

LED Flash Reject Code Conditions; Banknotes ........

LED Reject Error Code Conditions; Barcode Coupons .................................................................31

....................................................................30

9 UNIT DIMENSIONS ............................................................................................... 33

Entire Unit Outside Dimensions.....................................................................................................33

Head Assembly Outside Dimensions

............................................................................................33

10 TECHNICAL CONTACT INFORMATION ............................................................. 34

Americas .......................................................................................................................................34

JCM American......................................................................................................................

Europe, Africa, Russia & Middle East .......................

JCM Europe GmbH.................................................................................................................

UK & Ireland .....................................................................................................................

JCM Europe (UK Office)..........................................................................................................

Asia and Oceania ................................................................................................................

JCM Gold (HK) Ltd. ..............................................................................................................

JAPAN CASH MACHINE CO., LTD. (HQ)...................................................................................34

....................................................................34

.......34

....34

.............34

....34

..........34

.......34

11 INDEX .................................................................................................................... 35

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 5

iii

EBA® Series

Banknote Acceptor (EBA-40)

List of Figures

Page

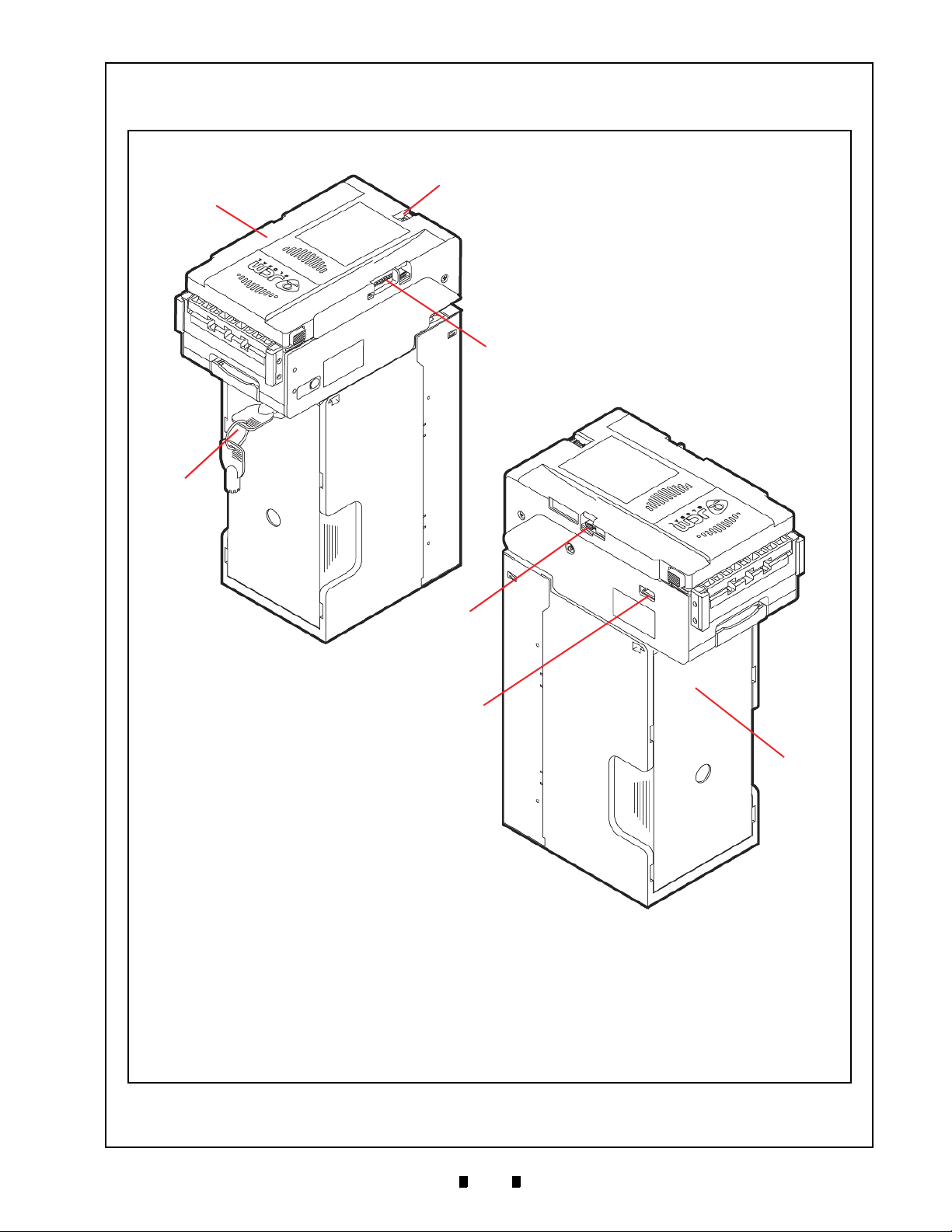

Figure 1 EBA-40 Unit ...............................................................................................1

Figure 2 Precautionary Symbols ..............................................................................2

Figure 3 Unacceptable Banknotes ...........................................................................4

Figure 4 Automatic Centering Mechanism (with the SD3 Stacker) ..........................4

Figure 5 Automatic Centering Mechanism (without the SD3 Stacker) .....................4

Figure 6 EBA-40 Component Names ......................................................................5

Figure 7 M3 Screw Locations (Bottom) ....................................................................8

Figure 8 Key Hole Slot Locations (Rear) .................................................................8

Figure 9 M4 Screw Locations (Rear & Bottom) .......................................................8

Figure 10 M3 Screw Locations (Rear & Bottom) .......................................................9

Figure 11 Key Hole Location ......................................................................................9

Figure 12 Lock Dimension & Cylinder Length ............................................................9

Figure 13 Key Unlock Rotation Requirement ...........................................................10

Figure 14 Retrieving Banknotes ...............................................................................18

Figure 15 Clearing an Entrance Banknote Jam .......................................................18

Figure 16 Clearing a Stacker Box Banknote Jam ....................................................18

Figure 17 Sensor Cleaning ......................................................................................19

Figure 18 EBA-40 Sensor and Roller Cleaning Locations .......................................19

Figure 19 EBA-40 TTL Interface Schematic Diagram ..............................................20

Figure 20 EBA-40 MDB Interface Schematic Diagram ............................................20

Figure 21 EBA-40 ccTalk Interface Schematic Diagram ..........................................21

Figure 22 EBA-40 Photo-Coupler Interface Schematic Diagram .............................21

Figure 23 EBA-40 RS232C Interface Schematic Diagram ......................................22

Figure 24 EBA-40 USB Interface Schematic Diagram .............................................22

Figure 25 EBA-40 Bezel LED Interface Schematic Diagram ...................................23

Figure 26 EBA-40 Operational Flowchart (Initializing) .............................................24

Figure 27 EBA-40 Operational Flowchart (Validation) .............................................25

Figure 28 EBA-40 Operational Flowchart (Stacking) ...............................................25

Figure 29 EBA-40 Banknote Acceptor’s Outside Dimensions .................................33

Figure 30 EBA-40 Banknote Acceptor’s Outside Dimensions .................................33

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 6

THIS PAGE INTENTIONALLY LEFT BLANK

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

iv

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 7

v

EBA® Series

Banknote Acceptor (EBA-40)

List of Tables

Page

Table 1 EBA-40 Model Number Specifications ........................................................2

Table 2 EBA-40 Type Number Specifications .........................................................2

Table 3 EBA-40 Software Number Specifications ...................................................2

Table 4 EBA-40 Technical Specifications ................................................................6

Table 5 EBA-40 Environmental Specifications ........................................................7

Table 6 EBA-40 Electrical Specifications .................................................................7

Table 7 EBA-40 Structural Specifications ................................................................7

Table 8 DIP Switch Block 1 Settings .....................................................................10

Table 9 DIP Switch Block 2 Settings .....................................................................10

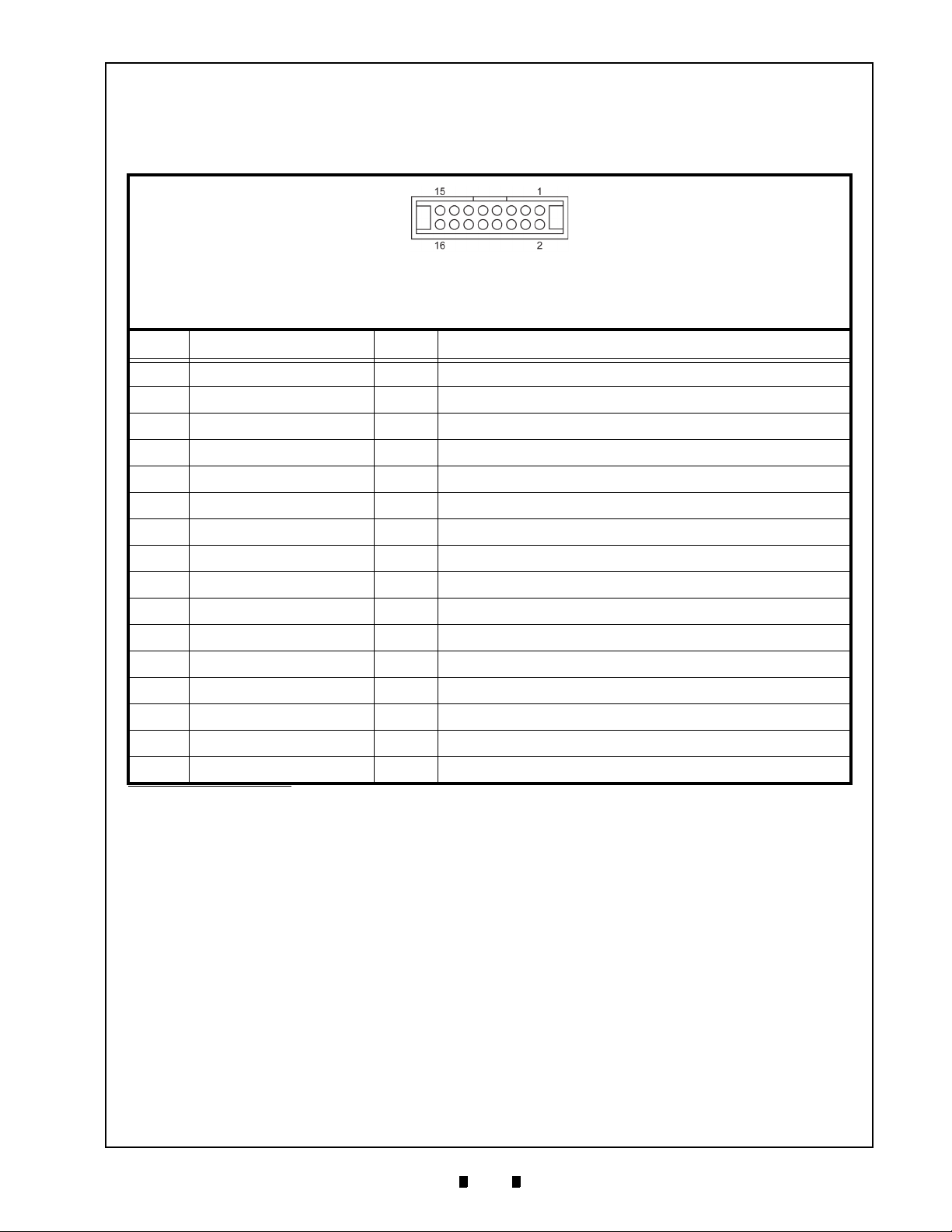

Table 10 EBA-40 TTL Interface Pin Assignments ...................................................11

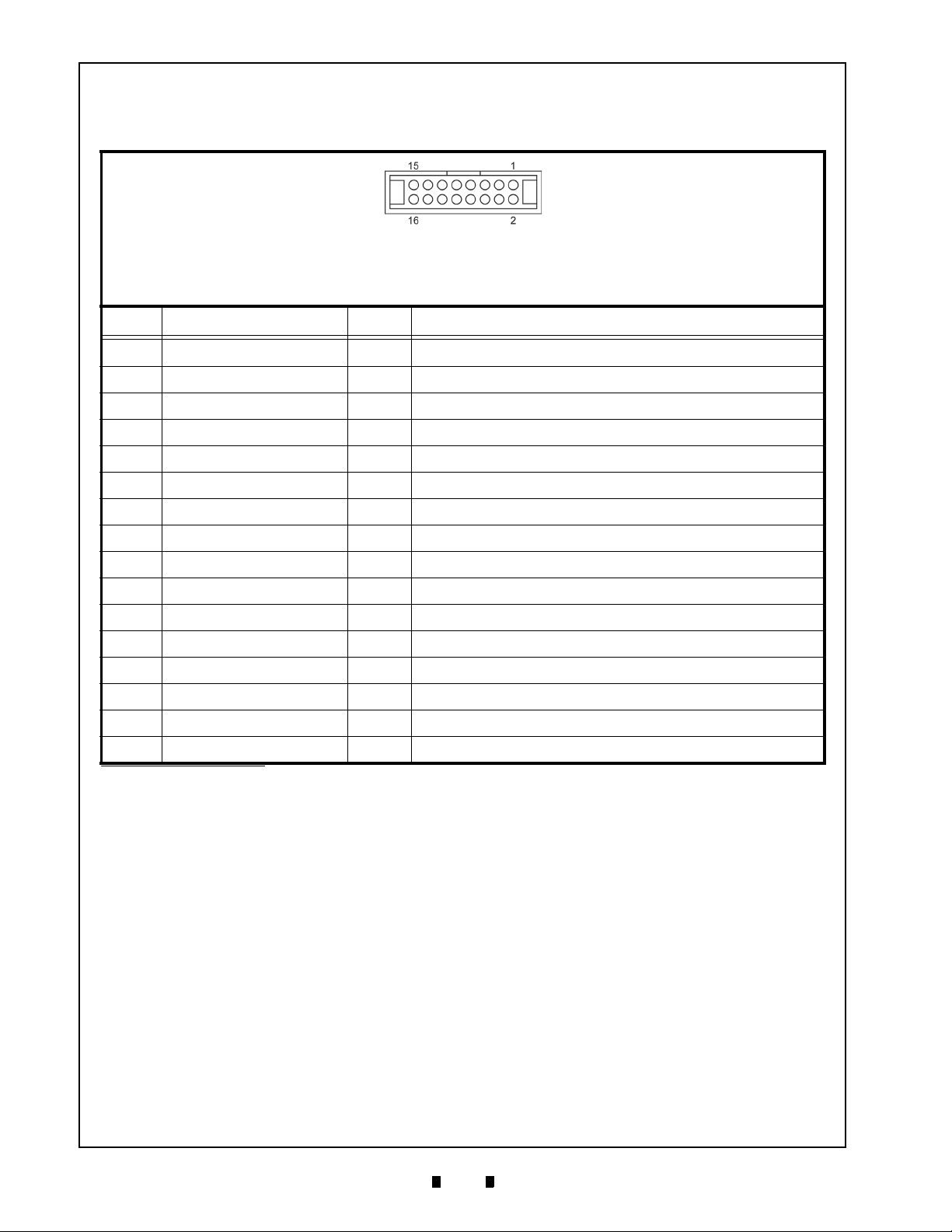

Table 11 EBA-40 MDB Interface Pin Assignments ..................................................12

Table 12 EBA-40 ccTalk Interface Pin Assignments ...............................................13

Table 13 EBA-40 Photo-Coupler Interface Pin Assignments ..................................14

Table 14 EBA-40 RS232C Interface Pin Assignments ............................................15

Table 15 EBA-40 CN13 RS232C Connector Pin Assignments ...............................15

Table 16 EBA-40 USB Interface Pin Assignments ..................................................16

Table 17 EBA-40 CN3 mini-B Connector Pin Assignments .....................................17

Table 18 EBA-40 CN2 Bezel Connector Pin Assignments ......................................17

Table 19 EBA-40 Sensor Type Cleaning Methods ..................................................19

Table 20 General Fault Conditions ..........................................................................26

Table 21 Adjustment Fault Conditions .....................................................................27

Table 22 Communication Fault Conditions ..............................................................28

Table 23 LED Flash Error Codes .............................................................................28

Table 24 LED Flash Reject Codes For Banknotes ..................................................30

Table 25 LED Flash Reject Error Codes For Barcode Coupons .............................31

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

vi

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 9

1

EBA® Series

1 GENERAL INFORMATION

EBA-40 Unit

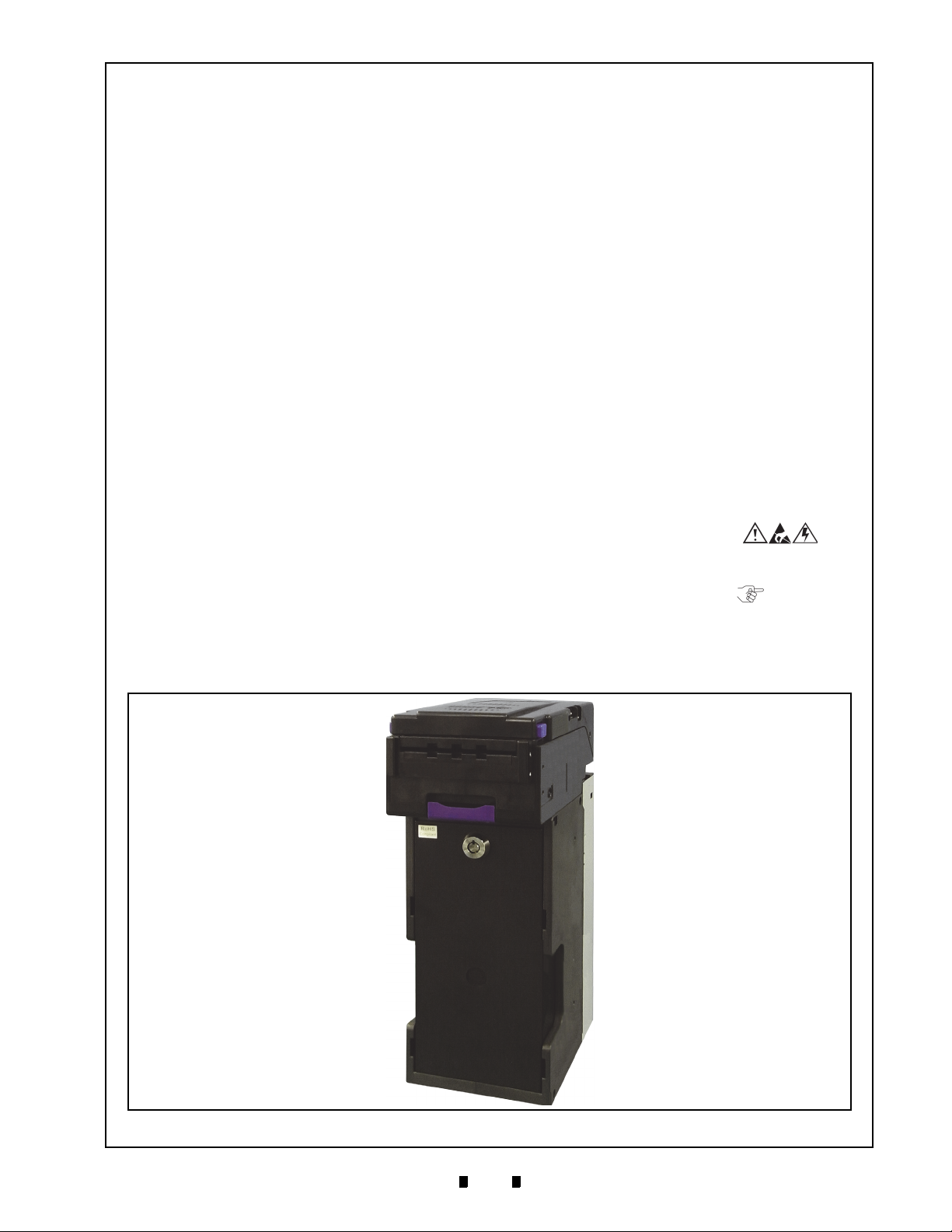

Figure 1 EBA-40 Unit

Banknote Acceptor (EBA-40)

Integration Guide

Revision A

Description

This section provides a general overview of the

®

EBA

Series Banknote Acceptor Unit (EBA-40),

pictured in Figure 1. This section is designed to

help the user navigate through

It includes the following information:

• EBA-40 Unit

• Model Descriptions

• Type Descriptions

• Software Descriptions

• Precautions

• Primary Features

• Component Names

• Specifications

• Installation

• Connector Pin Assignments

• Preventive Maintenance

• Standard Interface Circuit

this guide with ease.

Schematics

• Operational Flowchart

• Troubleshooting

• Unit Dimensions

• International Compliance

• Technical Contact Information

In order to make operating this device and navigating within this manual easier

tions are used:

• Safety Instructions need to be obser

order to protect the operators and the

equipment; these are identified with bold text

and the following pictographs:

pecial Notes affect the use of the Banknote

• S

Acceptor; these are identified with italic text

and the following pictograph:

• St

eps require the operator to perform specific

actions; these are identified with sequential

numbers (1, 2, 3, etc.).

, the following illustra-

ved in

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 10

2

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Type 1 Type 2 Type 3

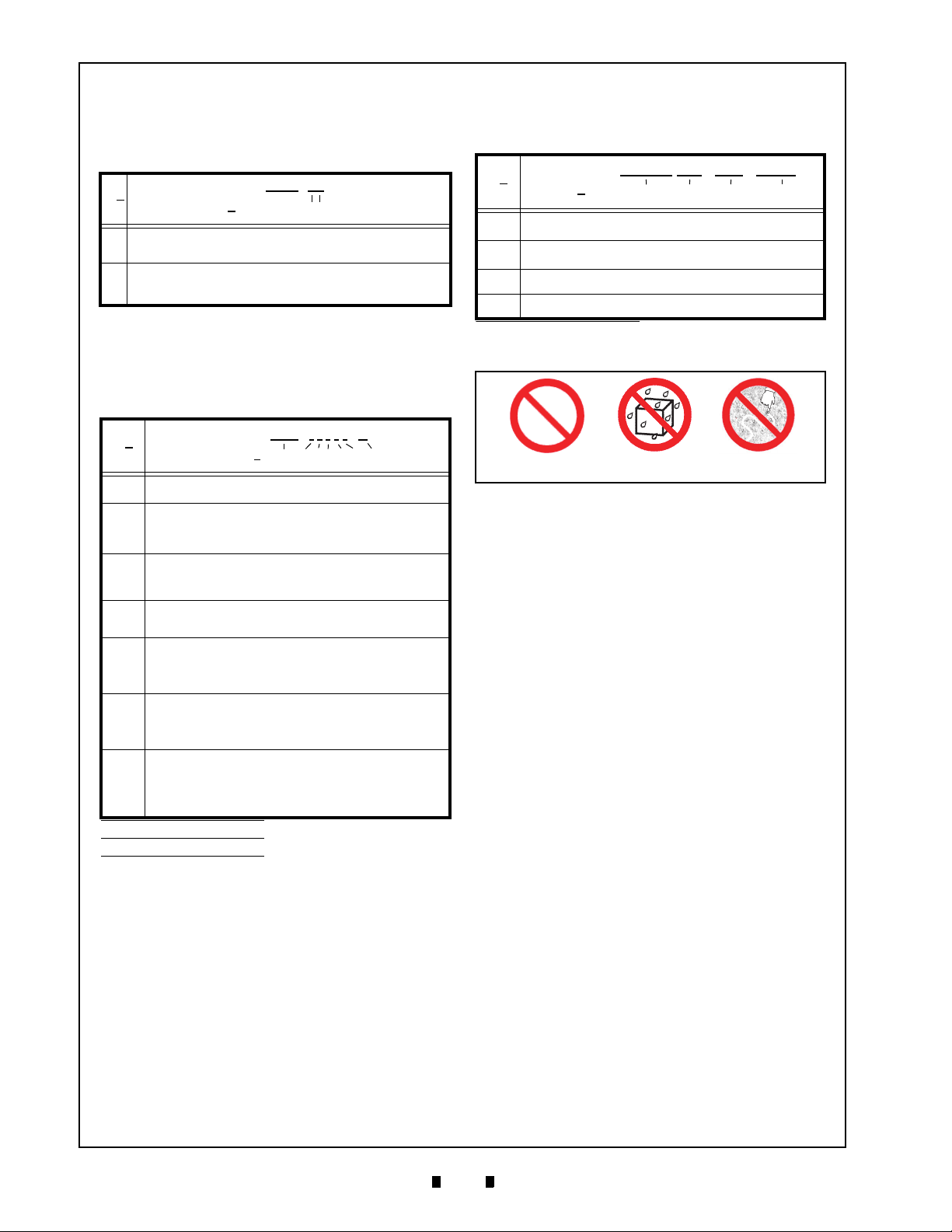

Figure 2 Precautionary Symbols

Model Descriptions

Table 1 lists the product model number

descriptions.

Table 1 EBA-40 Model Number

o

N

N

Model Number

(1)

4 = Standard

Model Series Number

(2)

0 = Standard

1-9 = Reserved

Model: EBA- * * - SD3

o

(1)(2)

Specifications

Type Descriptions

Table 2 lists the product type number descriptions.

Table 2 EBA-40 Type Number Specifications

o

N

No (1) (2)(3)(4)(5)(6) (7)

(1)

Denomination (Country Code)

(2)

Cash Box Capacity

0 = None (Without Stacker)

4 = 400 notes (Standard)

(3) Bezel (Option)

0 = Without Bezel (Standard)

1 = Bezel Type A

(4) Interface Conversion Board

0 = Without I/F Conversion Board (Standard)

(5) Key Switch

0 = Without Key Switch (Standard)

1 = With Key Switch

2 = OEM Key Switch

(6) Bar Sensor

0 = Without Bar Sensor (Standard)

1 = With Bar Sensor (Up type)

2 = With Bar Sensor (Down type)

(7) Interface

03 = ID-003 (JCM Serial)

D3 = ID-0D3 (MDB)

E3 = ID-0E3 (ccTalk)

** = Other (Last 2 digits of interface ID)

*. The Country Code is indicated following the ISO 3166.

†. The numbers of stacked Notes depends on the Banknote’s condition.

‡. Serial communication protocol developed by MoneyControl is

employed for ccTalk.

Model: ***(*) - * * * * * - **

*

†

‡

Software Descriptions

Table 3 lists the software number descriptions.

Table 3 EBA-40 Software Number Specifications

o

N

(A)

(B)

(C) Interface Protocol Name

(D) Software Version

*. The Country Code is indicated following the ISO 3166.

Software: EBA-40 * * * - 0 * * - V * .**

No (A) (B) (C) (D)

Software Model Name

Denomination (Country Code)

*

Precautions

Symbols in Figure 2 are defined as follows:

1. (Type 1) Do not insert a torn, folded, or wet

Banknote; it may cause a jam inside the unit.

(Type 2) Do not expose the unit to water. The unit

2.

contains several precision electronic devices that

can be damaged if water or any liquid is sprayed

or spilled into the unit.

(Type 3) Do not install the unit in a dusty

3.

environment. Dust may af

sor’s performance.

U

SER CAUTIONS

Careful measures were taken in the design of this

product to ensure its quality; however, the following cautions pertain to all users and should be followed for safe operation.

Installation Cautions

The Installation Cautions are defined as follows:

1. Be sure the Host Machine contains enough

protection to avoid wet or dusty conditions when

installing the

The unit is not designed for outdoor installations.

2. Be sure the Host Machine is designed with

careful consideration for retrieving a Banknote

/or clearing a Banknote jam.

and

3. Be careful not to use excessive outside pressure

the Mounting Plate when removing the Cash

on

Box from the Unit.

4. Avoid exposing the Banknote Insertion Slot to

rect Sunlight and/or Incandescent Lamp

di

illumination having a Gradient Angle of 15

Deg

rees or more, and an illumination index of

3000 Lux or less. Insure that the Host Machine is

also designed to avoid exposing the Banknote

unit in an indoor or open-air space.

fect/degrade the sen-

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 11

3

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

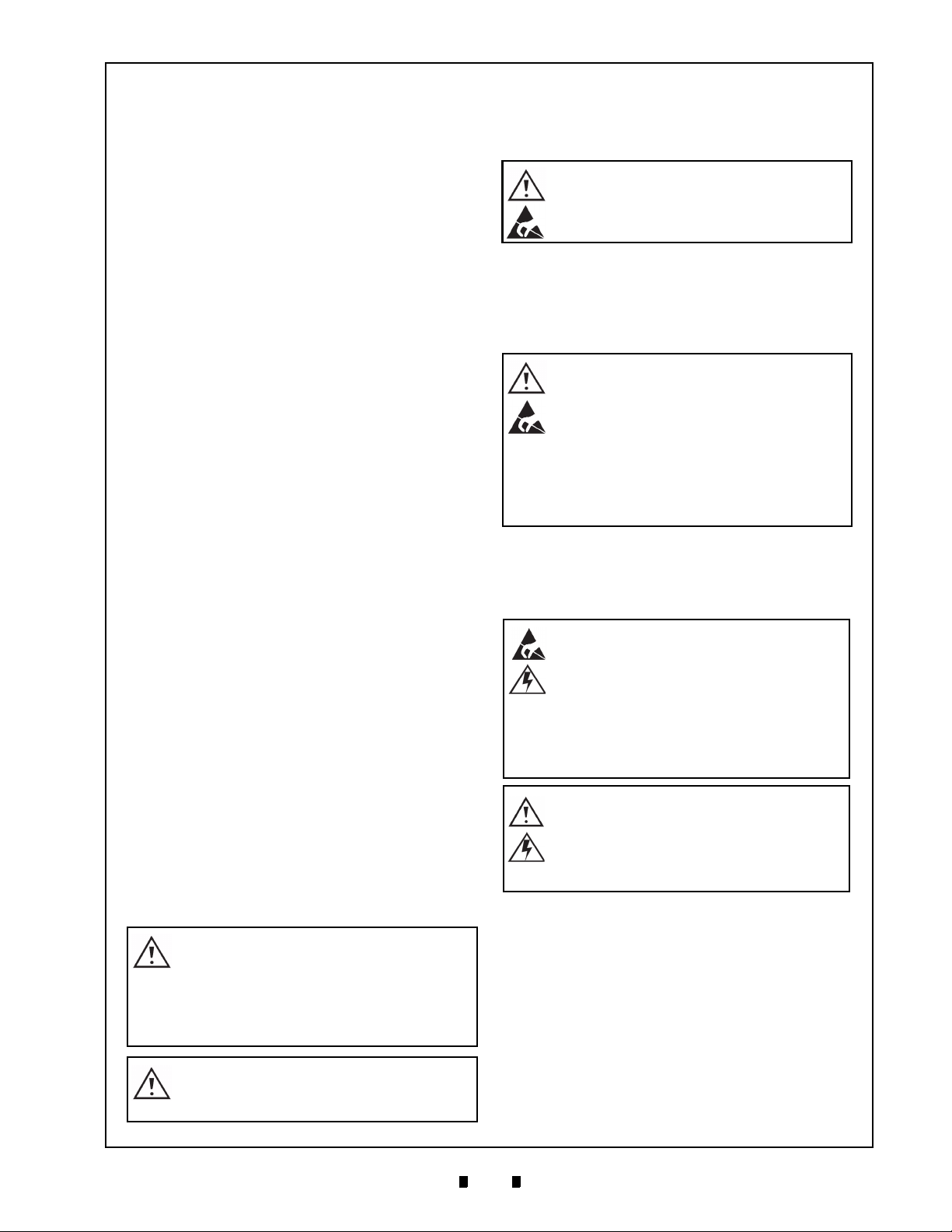

Caution: Turn the EBA-40 Unit’s Power

OFF when opening the Upper Tray;

otherwise, the Rollers may begin

operating and personal injury to fingers

may occur by getting them pulled into

the Unit.

Caution: Be careful to avoid personal

injury to your fingers when closing the

Upper Guide Section.

WARNING: Do not inject water or liquid

agents of any kind into the Acceptor, as

this may cause extreme damage to the

Unit.

WARNING: To minimize risk of damage

to internal printed circuit boards, never

allow excess fluid (e.g., from a wet

cleaning cloth) to drip or leak into the

device. Internal printed circuit boards

may be damaged. Do not use any

alcohol, citrus based cleaners, solvents

or scouring agents that can damage the

plastic surfaces of the device.

Caution: Make sure Interface Harness

connections to the Host Machine are

shorter than 9.84 Feet (3 Meters) in

length. Cut off all unused portions of

the Interface Harness wiring to avoid

static electrical effects or short circuit

possibilities that could cause damage

to the Unit.

WARNING: This Unit is designed for

use with a Current limiting Power

Source! Design the Host Cabinet space

to meet all local related safety

standards.

Insertion Slot to direct Sunlight or incandescent

light.

5. Do not allow the Acceptor to endure a range of

6. Do not use the Acceptor in environments

7. Do not use the Acceptor where it may be exposed

8. Clean and maintain the Acceptor regularly when

perature and humidity beyond the environ-

tem

mental limits specified (See “Environmental

Specifications” on page 7 of this Section).

may be subject to server temperature changes.

to airborne evaporated or s

located in an excess

ment.

poradic chemicals.

ively smoke filled environ-

that

Mounting, Dismounting & Transportation

Methods for mounting, dismounting and transporting the unit:

1. Be sure to turn the Power OFF before mounting

or removing the Unit from its permanent location.

Plugging or unplugging Connector Plugs from

their receptacles while the Power is ON may

cause damage to the Unit.

2. When reassembling a disasse

ensure that the each part is properly replaced in its

correct original location and the Acceptor is not

removed by pulling it forward.

3. Be sure to carry the Unit by both hands when

transportin

cause personal injury if the Unit accidentally

becomes disassembled and drops away.

4. Be careful not to use excessive outside press

on the Unit, or subject it to excessive vibration

during transportation.

g it. Holding the Unit by one hand may

mbled Unit Part,

ure

Placing Foreign Objects into the Unit

Observe the following precautions when placing

foreign objects into the Unit:

1. Do not insert anything except Banknotes into the

Insertion Slot. Inserting Receipts, Stapled Tickets,

Rubber Bands, or Credit Cards into the Unit may

damage the Banknote Transport path.

2. Do not inject liquids into the Banknote Insertion

ot. Injecting water, oil or cleaning agents may

Sl

damage the Sensors within the Banknote Transport path.

Preventive Maintenance

The preventive maintenance requirements are

defined as follows:

1. When closing the Upper Tray of the Acceptor,

ensure that it clicks firmly into place.

2. Do not redesign or disassemble the EBA-40

Acceptor

trained personnel, or use outside the original manufacturer’s intent for operation voids the warranty.

3. Perform routine cleaning and maintenance

once a month to keep the EBA-40 Unit’s performance stable.

4. Use a soft, lint-free clot

pressed air spray to clean dust and debris from the

Rollers.

5. If the Unit is exposed to water or liquids, use a

clean, dry

absorb excess liquids immediately. Any remaining liquids or fluids may affect and degrade the

Sensors and V

. Unauthorized use by inadequately

at least

h, cotton swab or com-

micro-fiber cloth to wipe off and

alidation component performance.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 12

4

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Damaged Banknotes

Wrinkled Banknotes

Curled Banknotes

Folded or Partial Banknotes

Figure 3 Unacceptable Banknotes

6

2

m

m

-

8

5

m

m

Figure 4 Automatic Centering Mechanism

(with the SD3 Stacker)

Figure 5 Automatic Centering Mechanism

(without the SD3 Stacker)

6

0

m

m

-

8

5

m

m

B

ANKNOTE FITNESS REQUIREMENTS

The following Banknote types may not validate

correctly, or worse, can cause a jam and/or damage

to the unit’s Transport Path.

Banknotes exhibiting the following conditions

illustrated in Figure 3 should be avoided:

• torn

• excessive folds or wrinkles

• dirty

• wet

• containing foreign objects and/or oil

Primary Features

The EBA-40 Banknote Acceptor Unit contains the

following primary features:

•

Proven Anti-Pullback Technology – This JCM

patented Anti-Pullback Mechanism provides

powerful protection against Banknote

stringing.

Automatic Centering – The Centering

•

Mechanism (See Figure 4 & Figure 5) allows

the unit to read Banknote without using speci

Banknote Guides. It helps to improve the

overall acceptance rate:

– With the SD3 Stacker: 62mm to 85mm in width

– Without the SD3 Stacker: 60mm to 85mm in

width.

al

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 13

5

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Figure 6 EBA-40 Component Names

a) Acceptor Unit

b) DIP Switch Block 2

c) DIP Switch Block 1

d) Coin Lock

e) Interface Connector

f) External Display Connector

g) SD3 Stacker Box

b

c

d

e

f

g

a

Component Names

Figure 6 illustrates the EBA-40 component names and locations.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 14

6

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

2 SPECIFICATIONS

Technical Specifications

Table 4 EBA-40 Technical Specifications

98% or greater

Note: The following banknote types are excluded:

• Banknotes with excess or poor magnetism or unclear graphics

Acceptance Rate

*

:

Banknote Types Accepted:

Barcode Coupon†:

Insertion Direction: Refer to the Specific Country’s “Software Information Sheet”

Processing Speed‡:

Validation Method: Validation Sensor and Magnetic Sensor

Diagnostic Indicators: LED (Green/Red), External Display Output

Escrow: 1 Note

Anti-stringing Mechanism: Pull-Back (PB) Unit (Anti-pullba

Cash Box Capacity

**

:

Cash Box Access: Front Access

††

Interface

*. Refer to the specific Country’s “Software Information Sheet” for each Country’s particular Banknote acceptance rate.

†. Refer to the specific Country’s “Bar Code Coupon Specification” for more details.

‡. Excluding Host Communication time lag (Power Supply: +12V DC, Temperature: 25º C ±5º C, Humidity: 30%-60%).

**.The number of Notes stacked depends on the Banknote’s condition.

††.The Interface Harness connecting to the Host should be less than 3m(9.84 ft).

:

• Double (dual) Notes

• Worn, dirty, wet, stained, torn or excessively wrinkled Banknotes

• Banknotes having folded corners or edges

• Banknotes having the wrong cut dimensions or printing displacement

• Returned Banknotes because of incorrect or failed insertion.

With the SD3 Stacker

• Long side: 120-160mm (4.72-6.29 in.)

• Short side: 62-85mm (2.44-3.34 in.)

Without the SD3 Stacker

• Long side: 110-181mm (4.33-7.12 in.)

• Short side: 60-85mm (2.36-3.34 in.)

Standard Specification

• Read code interleaved: 2 of 5

• Narrow Bar: 0.5-0.6mm (0.019-0.023 in.)

• Wide Bar to Narrow Bar ratio = 3:1

• Characters: 18 Characters

• Print Position: Middle (Divides a Coupon equally from the left, right, top and

bottom of the Coupon’s center)

• Print Width: Wider than 10mm (0.39 in.)

Approximately 1.8 seconds

(from Banknote insertion to sending Vend Signal)

Approximately 3.5 seconds

(from Banknote insertion t

o stacking completion)

ck System - JCM Patented)

Approximately 400 notes (new Banknotes)

TTL Serial Interface

MDB Interface

ccTalk

RS232C

USB (USB Specification Rev. 2.0 Co

mpliance) (Full Speed/12Mbps)

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 15

7

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Hydrothermal Condition Table

Humidity [%RH]

Temperature [ºC]

Allowable

and Humidity Range

Operating

Temperature

50ºC/40RH%

35ºC/80RH%

Environmental Specifications

Table 5 EBA-40 Environmental Specifications

Operating Temperature:

Storage Temperature:

5ºC to +50ºC (41ºF to 122ºF)

-20ºC to +60ºC (-4ºF to 140ºF)

Relative Operating Humidity: 30% to 85% RH (non-condensed)

Relative Storage Humidity: 30% to 85% RH (non-condensed)

Visible Light Sensitivity:

Avoid contact with direct sunlight

Radiant Angle of 15 Degrees or more having an Illu

Installation: Indoors Only

*. Depends on hydrothermal conditions.

*

*

(Interior lighting must be incandescent with a

mination index of 3000 Lux or less)

Electrical Specifications

pecifications

*

Supply Voltage:

Current Consumption:

*. Use a Current Source Limiting Power Supply

Table 6 EBA-40 Electrical S

12V DC ±5% (Greater than 3A)

24V DC ±5% (Greater than 1.6A)

12V DC

• Standby = 180mA

• Operation = 1.0A

• Peak = 3.0A

24V DC

• Standby = 110mA

• Operation = 0.6A

• Peak = 1.6A

Structural Specifications

Tab le 7 EBA-

Weight:

With the SD3 Stacker: Approximately 2.5kg (5.51lbs.)

Without the SD3 Stacker: Ap

Mounting: Horizontal

Outside Dimensions: See “Entire Unit Outside Dimensions” on page 33 of this Manual

40 Structural Specifications

proximately 1kg (2.2lbs.)

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 16

8

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

84mm

60mm

50mm

a

1

a

2

a

3

a

4

84mm

60mm

50mm

a

1

a

2

a

3

a

4

60mm

50mm

a

1

a

2

a

3

a

4

Figure 7 M3 Screw Locations (Bottom)

WARNING: The maximum length of the

M3 Screws should be selected

considering the Cabinet or Mounting

Bracket thickness. The Mounting

Screws’ length should not extend more

than 8mm upward from the bottom of

the SD3 Stacker Box Frame.

Key

84mm

Ø6

Ø

1

0

74mm

Rear View

9.5mm

Hole Slots

Figure 8 Key Hole Slot Locations (Rear)

1

0

5

m

m

9

1

.

7

m

m

a

1

a

2

a

3

a

4

c

1

c

2

b

Figure 9 M4 Screw Locations (Rear & Bottom)

3 INSTALLATION

This section provides installation and operating

instructions for the EBA-40 Banknote Acceptor

unit. The information within this section contains

the following features:

• Installation Procedure

• Lock Installation

• DIP Switch Configuration

Installation Procedure

The EBA-40 Frame Unit provides installation holes

for each surface.

E

NTIRE UNIT INSTALLATION

Perform the following steps to install the EBA-40

Unit:

1. Place the EBA-40 Unit Frame in its intended

mounting location.

2. Bolt the bottom side of the EBA-40 Frame into its

tended location using four (4) M3 Screws

in

(See Figure 7 a

the Frame when this mounting configuration is

preferred.

through a4) from the outside of

1

3. Hang the EBA-40 Frame onto shafts which fit in

place for

the proper width and length of the Key

Hole Slots on the rear side of the Frame when this

mounting configuration is preferred (See Figure

8).

A

CCEPTOR HEAD INSTALLATION

Perform the following steps to install the EBA-40

Acceptor Head Assembly using the Mounting

Bracket:

1. Place the EBA-40 Acceptor Head in its intended

mounting location.

2. Install the Mounting Bracket into its intended

cation using four (4) M4x6 Screws (See Figure

lo

9 a

through a4) provided with the Mounting

1

Bracket.

3. Slide and install the EBA-40

Assembly (See Figure 9 b) onto the Mounting

Bracket while simultaneously sliding the “Pedestal Rail

” (See Figure 9 c

this mounting configuration is preferred.

Acceptor Head

& c2) in place when

1

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 17

9

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Bottom View

3

7

m

m

2

5

m

m

c1-c

6

1

2

m

m

4

0

m

m

4

2

m

m

Attention

Do not use screws

longer than 5mm

JCM GLOBAL

b

a1-a

6

Figure 10 M3 Screw Locations (Rear & Bottom)

WARNING: The maximum length of the

M3 Screws should be selected

considering the Cabinet or Mounting

Bracket thickness. The Mounting

Screws’ length should not extend more

than 4mm upward from the bottom of

the SD3 Stacker Box Frame and the

Lower Cover.

Figure 11 Key Hole Location

Key Hole

1

7

.

4

m

m

15.8 mm

Ø1

9

.

5

Tan g

(Front)

Figure 12 Lock Dimension & Cylinder Length

NOTE: Make sure the Tang is correctly installed,

as illustrated in Figure 12.

Perform the following steps to install the EBA-40

Acceptor Head Assembly without the Mounting

Bracket:

1. Confirm the six (6) installation holes (See Figure

10 a

through a6) on the Lower Cover (See Figure

1

10 b) located on the

Acceptor Head Assembly.

2. Place the EBA-40 Acceptor Head Assembly in its

ended mounting location.

int

3. Bolt the Lower Cover of the

Head Assembly into its intended location using

six (6) M3 Screws (See Figure 10 c

from the bottom side of the Frame when this

unting configuration is preferred.

mo

bottom side of the EBA-40

EBA-40 Acceptor

through c6)

1

Lock Installation

One security lock can be installed onto the EBA-40

SD3 Stacker. When installing a security lock, the

following attachment accessories may be required:

• Tang

Choose a Lock that fits a standard 17.4 mm cylinder length format. This is the only format that

supported. (See Figure 12).

is

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 18

10

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

NOTE: There are many lock designs. Locks vary

greatly in price, security, keying policies, etc..

The customer is responsible for selecting a lock

that is appropriate for the intended purpose.

JCM does not test or endorse any commercially

available brand of lock for its security

characteristics.

Figure 13 Key Unlock Rotation Requirement

Unlock

DS1

DS2

DIP Switch Configurations

This section provides the denomination DIP Switch

Block 1 (DS1) and 2 (DS2) Settings for the

EBA-40 Unit.

Tab le 8 DIP Switch Block 1 Settings

Switch

No.

1

2

3

4

5

6

7

8

Table 9 DIP Switch Block 2 Settings

Switch ON Switch OFF

VEND 1 INHIBIT VEND 1 ACCEPT

VEND 2 INHIBIT VEND 2 ACCEPT

VEND 3 INHIBIT VEND 3 ACCEPT

VEND 4 INHIBIT VEND 4 ACCEPT

VEND 5 INHIBIT VEND 5 ACCEPT

VEND 6 INHIBIT VEND 6 ACCEPT

VEND 7 INHIBIT VEND 7 ACCEPT

TEST MODE FUNCTION

Switch

No.

1

2

3

4

5

6

7

8

Switch ON Switch OFF

With SD3 Stacker Without SD3 Stacker

Key Switch Enabled Key Switch Disabled

ccTalk (Encrypted) ccTalk (Non-Encrypted )

RS232C Interface Other Interface

With Barcode Sensor

Board

Reserved Reserved

Reserved Reserved

Reserved Reserved

Without Barcode Sensor

Board

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 19

11

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

4 CONNECTOR PIN ASSIGNMENTS

Table 10 through Table 18 list the EBA-40 Unit’s pin assignments.

Table 10 lists the EBA-40 TTL Interface Pin Assignments.

Table 10 EBA-40 TTL Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

Pin No. Signal Name

I/O

*

1 +12V/+24V -

2 GND

3 +12V/+24V

4 GND

5 TTL - TXD

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

9 MDB - TXD

10 MDB - RXD

11 MDB COM

-

-

-

OUT

-

IN

IN/OUT

OUT

IN

-

12 I/F 12V No Connection

OR

Power Supply

GND

Power Supply

GND

TTL Communication Output Signal Line

Signal GND

TTL Communication Input Signal Line

No Connection

No Connection

No Connection

No Connection

Function

13 PC - TXD

OUT

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

No Connection

No Connection

-

No Connection

IN

No Connection

IN

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 20

12

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 1)

Table 11 lists the EBA-40 MDB Interface Pin Assignments.

Table 11 EBA-40 MDB Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

Pin No. Signal Name

I/O

*

1 +12V/+24V -

2 GND

3

+12V/+24V

4 GND

5 TTL - TXD

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

9 MDB - TXD

10 MDB - RXD

11 MDB COM

-

-

-

OUT

-

IN

IN/OUT

OUT

IN

-

12 I/F 12V No Connection

13 PC - TXD

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

OUT

-

IN

IN

OR

Function

Power Supply

GND

Power Supply

GND

No Connection

No Connection

No Connection

No Connection

MDB Communication Output Signal Line

MDB Communication Input Signal Line

MDB Common Signal Line

No Connection

No Connection

No Connection

No Connection

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 21

13

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 2)

Table 12 lists the EBA-40 ccTalk Interface Pin Assignments.

Table 12 EBA-40 ccTalk Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Pin No. Signal Name

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

*

I/O

OR

Function

1

+12V/+24V

2 GND

3

+12V/+24V

4 GND

5 TTL - TXD

OUT

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

IN/OUT

9 MDB - TXD OUT

10 MDB - RXD

11 MDB COM

Power Supply

-

GND

-

Power Supply

-

GND

-

No Connection

Signal GND

-

No Connection

IN

ccTalk Communication Input/Output Signal Line

No Connection

No Connection

IN

No Connection

-

12 I/F 12V No Connection

13 PC - TXD

OUT

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

No Connection

No Connection

-

No Connection

IN

No Connection

IN

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 22

14

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 3)

Table 13 lists the EBA-40 Photo-Coupler Interface Pin Assignments.

Table 13 EBA-40 Photo-Coupler Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Pin No. Signal Name

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

*

I/O

OR

Function

1 +12V/+24V -

2 GND

3

+12V/+24V

4 GND

5 TTL - TXD

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

IN/OUT

9 MDB - TXD

10 MDB - RXD

11 MDB COM

OUT

OUT

Power Supply

GND

-

Power Supply

-

GND

-

No Connection

No Connection

-

No Connection

IN

No Connection

No Connection

No Connection

IN

No Connection

-

12 I/F 12V Photo-Coupler Communication Interface Power Supply 12V

13 PC - TXD

OUT

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

Photo-Coupler Communication Output Signal Line

Photo-Coupler Communication Interface GND

-

No Connection

IN

Photo-Coupler Communication Input Signal Line

IN

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 23

15

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 4)

Table 14 lists the EBA-40 RS232C Interface Pin Assignments.

Table 14 EBA-40 RS232C Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Pin No. Signal Name

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

*

I/O

OR

Function

1 +12V/+24V -

2 GND

3 +12V/+24V

4 GND

5 TTL - TXD

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

IN/OUT

9 MDB - TXD

10 MDB - RXD

11 MDB COM

OUT

OUT

Power Supply

GND

-

Power Supply

-

GND

-

No Connection

No Connection

-

No Connection

IN

No Connection

No Connection

No Connection

IN

No Connection

-

12 I/F 12V No Connection

13 PC - TXD

OUT

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

No Connection

No Connection

-

No Connection

IN

No Connection

IN

Table 15 lists the EBA-40 CN13 RS232C Connector Pin Assignments.

Table 15 EBA-40

Pin No. Signal Name I/O Function

1 RS232C - TXD OUT

2 RS232C - RXD

3 SG

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

CN13 RS232C Connector Pin Assignments

Header: 53426-0310 (MOLEX)

Housing: 51103-0300 (MOLEX)

Recommended Wire: UL1007 AWG#22-28

Contact: 50351-8000

RS232C Communication Output Signal Line

RS232C Communication Input Signal Line

IN

Signal GND

-

Page 24

16

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 5)

Table 16 lists the EBA-40 USB Interface Pin Assignments.

Table 16 EBA-40 USB Interface Pin Assignments

Header: XG4C-1634 (OMRON)

Housing: XG5M-1635-N Slit Wire (OMRON)

Pin No. Signal Name

Recommended Wire: UL1007 AWG#26-28

Housing: XG4M-1630-T Flat Cable (OMRON)

Recommended Wire: UL2651 AWG#28

*

I/O

OR

Function

1 +12V/+24V -

2 GND

3 +12V/+24V

4 GND

5 TTL - TXD

6 SG

7 TTL - RXD

8 ccTalk TXD/RXD

IN/OUT

9 MDB - TXD

10 MDB - RXD

11 MDB COM

OUT

OUT

Power Supply

GND

-

Power Supply

-

GND

-

No Connection

No Connection

-

No Connection

IN

No Connection

No Connection

No Connection

IN

No Connection

-

12 I/F 12V No Connection

13 PC - TXD

OUT

14 I/F GND

15 SW - IN

16 PC - RXD

*. I/O (input/output) is the terminal as viewed from the Banknote Acceptor’s backside.

No Connection

No Connection

-

No Connection

IN

No Connection

IN

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 25

17

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONNECTOR PIN ASSIGNMENTS (Continued 6)

Table 17 lists the EBA-40 CN3 mini-B Connector Pin Assignments.

Table 17 EBA-40 CN3 mini-B Connector Pin Assignments

Header: MNC20-5K5P10 [USB mini-B Type] (ACON)

Housing: USB mini-A Type

Pin No. Signal Name I/O Function

1 Vbus -

2 D-

3 D+

4 -

IN/OUT

IN/OUT

5 USB GND

USB Communication Vbus Signal Line

USB Communication Input/Output Signal Line

-

USB Communication Input/Output Signal Line

No Connection

USB Communication GND

-

Table 18 lists the EBA-40 CN2 Bezel Connector Pin Assignments.

Table 18 EBA-

Pin No. Signal Name I/O Function

1 +12V -

2 GND

3 BZLED_1

4 BZLED_2

5 BZLED_3

6 BZLED_4

7 BZLED_5

40 CN2 Bezel Connector Pin Assignments

Header: S7B-ZR-3.4 (JST)

Housing: ZHR-7 (JST)

Contact: SZH-002T-P0.5 (MOLEX)

Recommended Wire: UL1061 AWG#26-28

Power Suppl

GND

-

LED Drive Line (Cathode)

-

LED Drive Line (Cathode)

-

LED Drive Line (Cathode)

-

LED Drive Line (Cathode)

-

LED Drive Line (Cathode)

-

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 26

18

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

5 PREVENTIVE MAINTENANCE

a

b

Figure 14 Retrieving Banknotes

a

b

c

Figure 15 Clearing an Entrance Banknote Jam

a

b

Figure 16 Clearing a Stacker Box Banknote Jam

NOTE: If a Banknote jam occurs when the

Centering Mechanism is closed, the cover

will not open. To un-jam the Unit, rotate the

Centering Guide Shaft out of the way by

using a Hex Nut Driver, and then open the

Top Cover and remove the jam.

Caution: Do not use Alcohol, thinner or

Citrus based products for cleaning any

Banknote transport Sensors or

surfaces. The lenses can become

clouded by chemical evaporation

residue that may cause acceptance

errors.

Retrieving Banknotes

To retrieve Cash Box deposited Banknotes, perform

the following steps:

1. Unlock the Stacker Box lock using the supplied

Coin Key (See Figure 14 a).

2. Pull the Stacker Box out

(See Figure 14 b) and ret

of the Frame Housing

rieve the Banknotes.

Clearing a Banknote Jam

To retrieve a jammed Banknote located inside the

Banknote Acceptor, proceed as follows:

1. Pull the Tabs (See Figure 15 a) located on the

both sides of the Acceptor As

Unit’s Front Cover (See Figure 15 b).

2. Remove the jammed Banknote (See Figure 15 c).

sembly to open the

4. Remove any jammed Banknote found there

(See Figure 16 b).

Cleaning Procedure

To clean the EBA-40 Validation Section, gently rub

the Sensors and Rollers clean using a dry, soft,

lint-free, Micro-fiber Cloth ONLY.

Do not use any Alcohol, solvents, Citrus based

products or scouring agents that may cause damage

the Validation Section Sensors and/or Rollers.

to

S

ENSOR AND ROLLER CLEANING PROCEDURE

To clean the EBA-40 Unit’s Sensors and Rollers,

proceed as follows:

1. Turn the EBA-40 Unit and the Host Machine’s

Power Supply’s OFF.

2. Open the EBA-40 Units Front and Rear Guide.

3. Clean the appropriate path

Sensor.

and Lens of each

3. If the Banknote jam location is still not evident,

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

and pull the Stacker Box out of the Frame

unlock

Unit (See Figure 16 a).

Page 27

19

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Lens

Roller

Lint-free Cloth Cotton Swab Air Jet

Before

Cleaning

After

Cleaning

Belt

Figure 17 Sensor Cleaning

NOTE: Calibration is recommended after

cleaning.

Figure 18 EBA-40 Sensor and Roller Cleaning Locations

h

e

g

a

d

f

b

a

b

e

c

Anti-Pullback System

c

Note: Clean Rollers using a damp, lint-free, Micro-fiber Cloth.

Note: Clean the Anti-pullback

System with Compressed Air.

h

g

S

ENSOR AND ROLLER LOCATIONS

Figure 18 illustrates the various EBA-40 Unit’s

sensor cleaning locations. Table 19 lists the

EBA-40 sensor type cleaning methods.

Table 19 EBA-40 Sensor Type Cleaning Methods

Sym. Sensor/Roller Type Sym. Sensor/Roller Type Cleaning Method

a

Entrance Sensor

b Centering Guide Timing Sensor f Magnetic Sensor

c Validation Sensor g Anti-Pullback Exit Sensor

d Anti-Pullback Entrance Sensor h Exit Sensor

*. Either the Upper or Lower Barcode Sensor is required.

e

Barcode Sensor (Option)

*

Wipe clean using a

soft lint-free cloth or

blow clean using

compressed air.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 28

20

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONTROLLER SIDE

EBA SIDE

Figure 19 EBA-40 TTL Interface Schematic Diagram

CONTROLLER SIDE

EBA SIDE

Figure 20 EBA-40 MDB Interface Schematic Diagram

6 STANDARD INTERFACE CIRCUIT SCHEMATICS

Figure 19 illustrates the EBA-40 TTL Interface Schematic Diagram.

Figure 20 illustrates the EBA-40 MDB Interface Schematic Diagram.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 29

21

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONTROLLER SIDE

EBA SIDE

Figure 21 EBA-40 ccTalk Interface Schematic Diagram

CONTROLLER SIDE

EBA SIDE

Figure 22 EBA-40 Photo-Coupler Interface Schematic Diagram

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 1)

Figure 21 illustrates the EBA-40 ccTalk Interface Schematic Diagram.

Figure 22 illustrates the EBA-40 Photo-Coupler Interface Schematic Diagram.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 30

22

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONTROLLER SIDE

EBA SIDE

Figure 23 EBA-40 RS232C Interface Schematic Diagram

CONTROLLER SIDE

EBA SIDE

Figure 24 EBA-40 USB Interface Schematic Diagram

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 2)

Figure 23 illustrates the EBA-40 RS232C Interface Schematic Diagram.

Figure 24 illustrates the EBA-40 USB Interface Schematic Diagram..

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 31

23

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

CONTROLLER SIDE

EBA SIDE

Figure 25 EBA-40 Bezel LED Interface Schematic Diagram

STANDARD INTERFACE CIRCUIT SCHEMATICS (Continued 3)

Figure 25 illustrates the EBA-40 Bezel LED Interface Schematic Diagram.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 32

24

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

b) Initializing

c) Stand-by

d) Enable Acceptance?

f) External LED Display shows Enable Accept

Pattern

g) Inserted the Banknote?

h) Intake the Banknote

i) Centering the Banknote

j) Start Transporting the Banknote

k) Sampling the Banknote Data

A) To “Validation” Flow (See Figure 27)

l) Stop Transporting the Banknote

C) Return from “Stacking” Flow (See Figure 28)

a) Apply Power to the Unit.

e) External LED Display shows No Accept

Pattern

Figure 26 EBA-40 Operational Flowchart (Initializing)

7 OPERATIONAL FLOWCHART

Figure 26 depicts Part One of a typical EBA-40 Initialization Banknote acceptance flow process.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 33

25

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

a) Is the Banknote Authentic?

b) Is the Banknote acceptable?

d) Has STACK Command been received?

D) To “f” function on this chart

e) Return the Banknote

h) Retried Acceptance Operation three times?

i) VEND Signal Output?

j) Stop operation (Abnormal Signal Output)(*1)

A) From “Initialize” Flow (See Figure 26)

c) Denomination Signal Output?

g) Is the Banknote transported to Stacker?

D) To “f” function on this chart

f) Transporting the Banknote

B) To “Stacking” Flow (See Figure 28)

*1). When an abnormal signal is received, remove and reapply Power to the EBA-40 Unit after resolving the problem, or send

a RESET Command from the Host Machine.

Figure 27 EBA-40 Operational Flowchart (Validation)

a) Stack the Banknote

b) Is the Cash Box full?

c) Stop operation (Stacker Full Signal Output)(*2)

B) From “Validation” Flow (See Figure 27)

C) To “Initializing” flow (See Figure 26)

*2). When a “Cash Box Full” Signal is received, retrieve the Banknotes from the Cash Box and re-seat the Cash Box back into

the Unit. The EBA-40 Unit will automatically perform its re-initialization movement operation.

Figure 28 EBA-40 Operational Flowchart (Stacking)

Operational Flowchart (Continued 1)

Figure 27 depicts Part Two of a typical EBA-40 Validation Banknote acceptance flow process.

Figure 28 depicts Part Three of a typical EBA-40 Stacking Banknote acceptance flow process.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 34

26

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

8 TROUBLESHOOTING

This section provides troubleshooting instructions

for the EBA-40 Banknote Acceptor Units, including the following information:

• Introduction

• Troubleshooting Overview

• Fault Table Listings

• LED Indication Conditions

Introduction

Most Banknote Acceptor failures result from minor

causes. Before replacing any parts, be sure that all

assembly and circuit board connectors are properly

fitted, with their harnesses properly connected.

Poor performance by the EBA-40 Banknote Acceptor is often caused when dust or foreign objects

adhere to the

Banknote insertion section first, then carefully

observe the operating state of the Acceptor when

re-initializing power. This observation is important

Symptoms/Error

Me

Banknote Acceptor is

not working

(does not accept any

Ba

Banknote jams occur

sensors or transport belt. Clean the

ssages

nknotes)

often

Possible Fault Causes Corrective Action Required

No external Power is applied to

he Banknote Acceptor

t

(+12/24V DC & GND)

Wrong or inappropriate

connections

Corrupted Software.

CPU Board failure.

A pressure Roller is dirty or

A pressure Roller Spring is

A foreign object is lodged in

the Transport path and/or

properly seated all the way

(the Acceptor Unit’s Latch

Release Levers are not locked

Banknote is wider than 85 mm

or narrower than 62mm (60mm

without the Stacker) (out of the

damaged.

loose or missing.

inside the Cash Box.

The Acceptor Unit is not

into the Frame

onto the Frame).

EBA Banknote width

specifications).

Table 20 General Fault Conditions

Verify that the Power Supply +12/24V DC and Ground Cables are connected

to their appropriate Pins on the main connector.

NOTE: The small LED to the left of the DS1 DIP Switches indicates power

available when lit.

Verify that all Harness Connectors are properly seated.

Check for any bent, missing or damaged Pins in the Connector Plugs and

mating Receptacles.

Re-download the correct Software.

Conduct an Initial Operational Test. If the test result is Negative (NG), replace

the CPU Board. Make sure to re-calibrate the Sensors after CPU Board is

replaced.

Clean all Pressure Rollers.

Replace as necessary.

Check all Pressure Roller Springs using a finger pressure test.

Replace as necessary.

Clean the Transport path and remove any foreign object discovered.

Re-seat the Acceptor Unit back into the Frame so it is firmly seated all the

way back into the Frame so the Acceptor Unit Release Lever Latches

securely lock onto the Frame.

Use only Banknotes widths having the correct EBA Unit’s size specifications.

in locating any causes of failure and the possible

fault location.

Perform all repairs by referring to Calibration and

esting in Section 6 of the EBA-40 Service Man-

T

ual, and the Disassembly/Reassembly instructions

Section 4 of the EBA-40 Service Manual.

in

Troubleshooting Overview

This product allows the operator to perform fault

diagnosis by checking various Fault Table Listings

against the symptoms. Survey the cause(s) of any

failure occurrences during the process.

After determining the cause of the failure, execute

rformance Test, and then repair the unit

the Pe

replacing any appropriate parts deemed necessary.

Fault Table Listings

Table 20 lists the various possible EBA-40 Unit

fault conditions that can occur and

actions required to correct them.

the necessary

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 35

27

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Table 20 General Fault Conditions (Continued)

Symptoms/Error

Messages

Acceptance rates

Upper Guide can not

be opened

All Banknotes being

rejected

Motor

continues to run

Can not enter the

TEST mode

Possible Fault Causes Corrective Action Required

Dirt and/or stains on the

Rollers, Belts and Lenses.

The Unit has been

disassembled, and calibration

adjustments have not

occurred following a

reassembly.

The wrong Software version

or an older Software version

is being used.

Software not designed to

accept current Banknotes

Centering Guides are not at

their Home position.

Incorrect software

different Currency type).

(

Banknotes are not being

accepted by the Software.

Incorrect DIP Switch settings.

Banknote acceptance is being

inhibited by a Host Controller

command.

Validation Sensor failure.

Unit was disassembled and

calibration did not occur

following reassembly.

Upper Guide is open.

A foreign object or a jammed

Banknote is stuck in the

Transport path.

Motor Driver failure.

Incorrect DIP Switch settings.

Dip Switch failure.

CPU Board failure.

Clean the Transport path. Refer to “Preventive Maintenance” on page 18.

Calibrate the Sensors after reassembling the EBA Unit.

Make sure that the programmed Software is the latest version, and it

supports the Currency values and specific Country allowing acceptance.

Check the particular specifications for the required Banknote Type

Acceptance, and make sure the Banknotes will be accepted by the Software

loaded (e.g., check denomination/issuing year).

Turn the Power OFF and ON again. This action should tell the Host Machine

to send a Reset Command to re-initialize the Unit.

If power cannot be applied, use a Hexagonal Nut Driver to open the Upper

Guide, and manually reset the Guide.

Download the correct Software for Currency being accepted.

Make sure the Banknote values required are included in the Software

Specifications (e.g., denominations/issuing year).

Enable all denominations by setting all DIP Switches to OFF.

Enable Banknote acceptance for the required Host Command.

Change the CPU Board and Sensor Board.

Calibrate all EBA Sensors following reassembly.

Firmly close the Upper Guide.

Open the Upper Guide, remove the foreign object or jammed Banknote, and

close the Cover.

Conduct a Forward/Reverse Motor Rotation Test.

Set the DS1 DIP Switch No. 8 to ON, and reapply power to the EBA Unit.

See “DIP Switch Configurations” on page 10 regarding the DIP Switch Test,

and conduct a DIP Switch TEST to check if the specific DIP Switch Block

contains a failure.

Exchange the CPU Circuit Board with a known good Circuit Board.

Table 21 Adjustment Fault Conditions

Symptoms/Error

Me

ssages

Can not start the EBA

Calibration Tool for

Maintenance.exe

program by double-

clicking on its Icon

Communication Error

Adjustment Error

Possible Fault Causes Corrective Action Required

PC Operating System (OS) is

not compatible.

The Program Files are

corrupted.

Wrong or inappropriate

nections

con

EBA Switch settings are

incorrect.

DIP Switch failure.

CPU Board failure.

Incorrect Reference

Paper t

ype.

Validation Sensor failure.

The current Adjustment program only supports the Windows 2000/XP/

Windows 7 Operating System.

Request the correct programs from JCM.

Check the PC Harness connections and the related EBA Interface

Connectors for damage. Check for any bent, missing or damaged Pins in the

Connector Plug and/or Receptacle.

Set the DS1 DIP Switch No. 8 to ON, and reapply power to the EBA Unit.

See “DIP Switch Configurations” on page 10 regarding DIP Switch settings

and conduct a DIP Switch Test.

Exchange the CPU Circuit Board with a known good Circuit Board.

Follow the instructions provided in the “EBA Calibration Tool for

Maintenance.exe” Program and use the correct recommended

Reference Paper.

Change the CPU Board and Sensor Board.

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 36

28

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

LED Indication Conditions

Table 22 Communication Fault Conditions

Symptoms/Error

Me

ssages

Cannot

communicate with the

Host Machine

Possible Fault Causes Corrective Action Required

DIP Switch settings are

incorrect.

Connectors are disconnected

or loosely connected.

Damaged Connector Pins.

CPU Board is corrupted.

Incorrect Interface.

Set all DIP Switches to OFF.

Firmly re-seat all of the Communication Connectors.

Check for any bent, missing or damaged Pins in the Connector Plugs and

mating Receptacles.

Exchange the CPU Circuit Board with a known good Circuit Board.

Verify that the correct interface between the Host Machine and the Banknote

Acceptor is being used.

The External LED Display indicates various combinations of solid or alternating Color light flashing

conditions when any

of the Standard Error and

Reject Codes listed in Table 23 through Ta b l e 25

occur.

Identify the cause and solution for an i

ndicated

error by comparing it against each listing in Table

Table 23 LED Flash Error Codes

LED

Sequence

Red

(1)

Red

(2)

Red

(3)

Red

(4)

Red

(5)

Red

(6)

Red

(7)

LED Color

State

Green Lit

Green Lit

Green Lit

Green Lit

Green Lit EEPROM Error

Green Lit

Green Lit

Error Causes and Solutions

External Flash

ROM Boot Program

ROM Check Error

External Flash

ROM Bo

ROM Main Program

CPU Internal RAM

ot I/F Area

ROM Check Error

External Flash

ROM Check Error

C

heck Error

External SD-RAM

Error

Downloading File

Error

Magnetic Sensor

tting Abnormal

Se

The Boot Program that is supposed to run after Power is supplied is not correctly

written in ROM, or it cannot be read.

[Solution] Check that the following part is properly assembled and/or Harness

connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

The Boot Interface Area was not written correctly or cannot be read.

[Solution] Re-download the Program. If the error is not resolved, check that the

following part is assembled and/or Harness connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

The Main Operating Program is not written into the ROM correctly, or cannot be

read.

[Solution] Re-download the Program. If the error is not resolved, check that the

following part is properly assembled and/or Harness connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

RAM reading or writing was not properly performed.

[Solution] Check that the following part is properly assembled and/or Harness

connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

External SD-RAM reading or writing was not properly performed.

[Solution] Check that the following part is properly assembled and/or Harness

connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

EEPROM reading, writing and/or saving was not properly performed.

[Solution] Perform the Sensor Calibration procedure. If the error is not resolved,

check that the following part is properly assembled and/or Harness connected.

[Relative Parts] CPU Circuit Board.

If the error is not resolved, change the above related part or parts.

Downloading files does not proceed.

[Solution] Select a file supported by the EBA Unit.

An abnormal Magnetic Sensor setting is detected.

[Solution] Check that the following part is properly assembled and/or Harness

connected. Clean the following Sensor.

[Relative Parts] Magnetic Sensor.

If the error is not resolved, change the above related part or parts.

23. Ensure that the relative Assemblies are properly

connected and/or harnessed, and all of the Unit’s

sen

sors are clean before proceeding to troubleshoot

the error condition.

LED F

LASH ERROR CODE CONDITIONS

Table 23 lists the various LED Flash Error Code

causes & solutions for Banknotes

P/N 960-000173R_Rev. A {EDP #229278} © 2013, JAPAN CASH MACHINE CO., LTD.

Page 37

29

EBA® Series Banknote Acceptor (EBA-40) Integration Guide

Table 23 LED Flash Error Codes (Continued)

LED

Sequence

Red

(8)

Red

(1)

Red

(2)

Red

(3)

Red

(4)

Red

(5)

Red

(6)

Red

(7)

Red

(8)

Red

(9)

Red

(10)

LED Color

State

Error Causes and Solutions

Green Lit I2C Access Error

OFF Cash Box Full

Pusher Mechanism

OFF

OFF

OFF

OFF

OFF

OFF

Ho

me Position

Error

Banknote Jam

(C

ash Box)

Banknote Jam

(T

ransport Unit)

Feed Motor Speed

Err

or

Feed Motor

L

ock-Up

Stacker Motor

L

ock-Up

OFF Reserved

OFF PB Unit Error

OFF Cash Box Removal

While communicating with each device on the CPU Board, Sensors detect an

abnormal operating condition.

[Solution] Check that the following part is properly assembled and/or Harness

connected. Clean the following part.

[Relative Parts] Stacker.

If the error is not resolved, change the above related part or parts.

Sensors detected that the Cash Box is full.

[Solution] Remove Banknotes from the Cash Box.

Check that the following parts are properly assembled and/or Harness connected.

Clean or adjust the following parts and Sensors.

[Relative Parts] Pusher Mechanism, Stacker Motor, Stacker Home Sensor, Stacker

Motor Encoder.

If the error is not resolved, change the above related part or parts.

When stacking Banknotes, the Pusher Mechanism is not returning to the Home

position.

[Solution] Check that the following parts are properly assembled and/or Harness

connected. Clean or adjust the following parts and Sensors.

[Relative Parts] Pusher Mechanism, Stack Motor, Stack Home Sensor, Stack Motor

Encoder.

If the error is not resolved, change the above related part or parts.

When transporting a Banknote in the Cash Box, the Sensors are not detecting a

Banknote present condition when the time interval is too long, or the pulse number

is greater than specified value for the function.

[Solution] Remove Banknotes from the Cash Box.

Check that the following parts are properly assembled and/or Harness connected.

Clean or adjust the following parts and Sensors.

[Relative Parts] Exit Sensor, Pusher Mechanism, Stack Motor, Stack Home Sensor,

Stack Motor Encoder.

If the error is not resolved, change the above related part or parts.

When transporting or returning a Banknote in the Transport Unit, the Sensors did

not detect a Banknote present condition when the time interval was too long, or the

pulse number is greater than specified value for the function.

[Solution] Check that the following parts are properly assembled and/or Harness

connected. Clean or adjust the following parts and Sensors.

[Relative Parts] Entrance Sensor, Centering Timing Sensor, Validation Sensor, PB

Entrance Sensor, Exit Sensor, Feed Motor, Feed Motor Encoder.

If the error is not resolved, change the above related part or parts.

While Initializing, no pulse inputs exist greater than the specified value.

[Solution] Remove Banknotes from the EBA Unit.

Check that the following parts are properly assembled and/or Harness connected.

Clean or adjust the following parts and Sensors.

[Relative Parts] Feed Motor, Feed Motor Encoder.

If the error is not resolved, change the above related part or parts.

While operating the Feed Motor, no pulse inputs occurred greater than the

specified value.

[Solution] Check that the following parts are properly assembled and/or Harness

connected. Clean or adjust the following parts and Sensors.

[Relative Parts] Feed Motor, Feed Motor Encoder

If the error is not resolved, change the above related part or parts.

While operating the Stacker Motor, no pulse inputs occurred greater than the

specified value.

[Solution] Check that the following parts are properly assembled and/or Harness

connected. Clean or adjust the following parts and Sensors.

[Relative Parts] Stacker Motor, Stacker Encoder.