Page 1

SO53 3LE

Customer Helpline 0845 600 5526

SAFETY AND OPERATING MANUAL

ANGLE GRINDER

JCB-AG2200

ORIGINAL INSTRUCTIONS

Page 2

Page 3

SO53 3LE

Customer Helpline 0845 600 5526

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety

warnings and all instructions.

Failure to follow the warnings and

instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions

for future reference.

The term "power tool" in the

warnings refers to your electric

(corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well

lit.

Cluttered or dark areas invite

accidents.

b) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust.

Power tools create

sparks which may ignite the dust

or fumes.

c) Keep children and bystanders

away while operating a power tool.

Distractions can cause you to

lose control.

2. Electrical safety

a) Power tool plugs must match

the outlet. Never modify the plug

in any way. Do not use any adapter

plugs with grounded power tools.

Unmodified plugs and matching

outlets will reduce risk of electric

shock.

b) Avoid body contact with

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of

electric shock if your body is

grounded.

c) Do not expose power tools

to rain or wet conditions.

Water

entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never

use the cord for carrying, pulling

or unplugging the power tool.

Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use.

Use of

a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a

damp location is unavoidable, use

a residual current device (RCD)

protected supply.

Use of an RCD

reduces the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while

operating power tools may result

in serious personal injury.

b) Use personal protective

equipment. Always wear eye

protection.

Protective equipment

such as dust mask, non-skid

Page 4

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal

injuries.

c) Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to

power source and/or battery pack,

picking up or carrying the tool.

Carrying power tools with your

finger on the switch or energising

power tools that have the switch

on invites accidents.

d) Remove any adjusting key or

wrench before turning the power

tool on.

A wrench or a key left

attached to a rotating part of the

power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of

the power tool in unexpected

situations.

f) Dress properly. Do not wear

loose clothing or jewellery. Keep

your hair, clothing and gloves

away from moving parts.

Loose

clothes, jewellery or long hair can

be caught in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of dust collection can reduce

dust-related hazards.

4. Power tool use and care

a) Do not force the power tool.

Use the correct power tool for

your application.

The correct

power tool will do the job better

and safer at the rate for which it

was designed.

b) Do not use the power tool if

the switch does not turn it on and

off.

Any power tool that cannot

be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from

the power source and/or the

battery pack from the power tool

before making any adjustments,

changing accessories, or storing

power tools.

Such preventive

safety measures reduce the

risk of starting the power tool

accidentally.

d) Store idle power tools out of

the reach of children and do not

allow persons unfamiliar with the

power tool or these instructions

to operate the power tool.

Power

tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check

for misalignment or binding of

moving parts, breakage of parts

and any other condition that may

affect the power tool’s operation.

If damaged, have the power

tool repaired before use.

Many

accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and

clean.

Properly maintained cutting

tools with sharp cutting edges are

less likely to bind and are easier

Page 5

SO53 3LE

Customer Helpline 0845 600 5526

to control.

g) Use the power tool,

accessories and tool bits

etc. in accordance with these

instructions, taking into account

the working conditions and the

work to be performed.

Use of the

power tool for operations different

from those intended could result

in a hazardous situation.

5. Service

a) Have your power tool serviced

by a qualified repair person using

only identical replacement parts.

This will ensure that the safety of

the power tool is maintained.

b) If the replacement of the

supply cord is necessary, this has

to be done by the manufacturer or

its agent in order to avoid a safety

hazard.

Page 6

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

ADDITIONAL SAFETY POINTS FOR YOUR ANGLE GRINDER

Safety Warnings Common for

Grinding or Abrasive Cutting-Off

Operations:

a)

This power tool is intended to

function as a grinder, or cut-off

tool. Read all safety warnings,

instructions, illustrations and

specifications provided with this

power tool.

Failure to follow all

instructions listed below may

result in electric shock, fire and/or

serious injury.

b)

Operations such as sanding,

wire brushing, polishing are not

recommended to be performed

with this power tool.

Operations

for which the power tool was not

designed may create a hazard

and cause personal injury.

c) Do not use accessories which

are not specifically designed

and recommended by the tool

manufacturer.

Just because

the accessory can be attached

to your power tool, it does not

assure safe operation.

d)

The rated speed of the

accessory must be at least equal

to the maximum speed marked

on the power tool.

Accessories

running faster than their rated

speed can break and fly apart.

e)

The outside diameter and the

thickness of your accessory must

be within the capacity rating of

your power tool.

Incorrectly sized

accessories cannot be adequately

guarded or controlled.

f)

The arbour size of discs,

flanges, backing pads or any

other accessory must properly

fit the spindle of the power tool.

Accessories with arbour holes

that do not match the mounting

hardware of the power tool

will run out of balance, vibrate

excessively and may cause loss

of control.

g)

Do not use a damaged

accessory. Before each use

inspect the accessory such as

abrasive discs for chips and

cracks, backing pad for cracks,

tears or excess wear. If power

tool or accessory is dropped,

inspect for damage or install

an undamaged accessory. After

inspecting and installing an

accessory, position yourself and

bystanders away from the plane of

the rotating accessory and run the

power tool at maximum no-load

speed for one minute.

Damaged

accessories will normally break

apart during this test time.

h)

Wear personal protective

equipment. Depending on

application, use face shield,

safety goggles or safety glasses.

As appropriate, wear dust mask,

hearing protectors, gloves

and workshop apron capable

of stopping small abrasive or

workpiece fragments.

The eye

protection must be capable of

stopping flying debris generated

by various operations . The

dust mask or respirator must

Page 7

SO53 3LE

Customer Helpline 0845 600 5526

be capable of filtrating particles

generated by your operation.

Prolonged exposure to high

intensity noise may cause hearing

loss.

i)

Keep bystanders a safe distance

away from work area. Anyone

entering the work area must wear

personal protective equipment.

Fragments of workpiece or of

a broken accessory may fly

away and cause injury beyond

immediate area of operation.

j)

Hold power tool by insulated

gripping surfaces only, when

performing an operation where

the cutting accessory may contact

hidden wiring or its own cord.

Cutting accessory contacting a

“live” wire may make exposed

metal parts of the power tool

“live”and result in operator injury.

k)

Position the cord clear of the

spinning accessory.

If you lose

control, the cord may be cut or

snagged and your hand or arm

may be pulled into the spinning

accessory.

l)

Never lay the power tool down

until the accessory has come to

a complete stop.

The spinning

accessory may grab the surface

and pull the power tool out of

your control.

m)

Do not run the power tool while

carrying it at your side.

Accidental

contact with the spinning

accessory could snag your

clothing, pulling the accessory

into your body.

n)

Regularly clean the power tool’s

air vents.

The motor’s fan will

draw the dust inside the housing

and excessive accumulation

of powdered metal may cause

electrical hazards.

o)

Do not operate the power tool

near flammable materials.

Sparks

could ignite these materials.

p)

Do not use accessories that

require liquid coolants.

Using

water or other liquid coolants may

result in electrocution or shock.

q)

Your hand must hold on the

handle when you are working.

Always use the auxiliary handles

supplied with the tool. Loss of

control can cause personal injury

Further safety instructions

for all operations

Kickback and Related

Warnings

Kickback is a sudden reaction to

a pinched or snagged rotating

disc, backing pad, brush or any

other accessory. Pinching or

snagging causes rapid stalling

of the rotating accessory which

in turn causes the uncontrolled

power tool to be forced in

the direction opposite of the

accessory’s rotation at the point

of the binding.

For example, if an abrasive disc

is snagged or pinched by the

workpiece, the edge of the disc

Page 8

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

that is entering into the pinch

point can dig into the surface of

the material causing the disc to

climb out or kick out. The disc

may either jump toward or away

from the operator, depending on

direction of the disc’s movement

at the point of pinching. Abrasive

discs may also break under these

conditions.

Kickback is the result of power

tool misuse and/or incorrect

operating procedures or

conditions and can be avoided

by taking proper precautions as

given below.

a)

Maintain a firm grip on the

power tool and position your body

and arm to allow you to resist

kickback forces. Always use

auxiliary handle, if provided, for

maximum control over kickback

or torque reaction during start-up.

The operator can control torque

reactions or kickback forces, if

proper precautions are taken.

b)

Never place your hand near

the rotating accessory.

Accessory

may kickback over your hand.

c) Do not position your body in

the area where power tool will

move if kickback occurs.

Kickback

will propel the tool in direction

opposite to the disc’s movement

at the point of snagging.

d)

Use special care when working

on corners, sharp edges etc.

Avoid bouncing and snagging the

accessory.

Corners, sharp edges

or bouncing have a tendency to

snag the rotating accessory and

cause loss of control or kickback.

e)

Do not attach a saw chain

woodcarving blade or toothed

saw blade.

Such blades create

frequent kickback and loss of

control.

Additional safety instructions

for grinding and cutting-off

operations

Safety Warnings Specific for

Grinding and Abrasive Cutting-Off

Operations:

a)

Use only disc types that are

recommended for your power tool

and the specific guard designed

for the selected disc.

Discs for

which the power tool was not

designed cannot be adequately

guarded and are unsafe.

b)

The guard must be securely

attached to the power tool and

positioned for maximum safety,

so the least amount of disc is

exposed towards the operator.

The

guard helps to protect operator

from broken disc fragments and

accidental contact with disc.

c)

Discs must be used only for

recommended applications. For

example: do not grind with the

side of cut-off disc.

Abrasive

cut-off discs are intended for

peripheral grinding, side forces

applied to these discs may cause

them to shatter.

d)

Always use undamaged disc

Page 9

SO53 3LE

Customer Helpline 0845 600 5526

flanges that are of correct size

and shape for your selected disc.

Proper disc flanges support the

disc thus reducing the possibility

of disc breakage. Flanges for cutoff discs may be different from

grinding disc flanges.

e)

Do not use worn down discs

from larger power tools.

Disc

intended for larger power tools

are not suitable for the higher

speed of a smaller tool and may

burst.

Additional safety instructions

for cutting-off operations

Additional Safety Warnings

Specific for Abrasive Cutting-Off

Operations:

a)

Do not “jam” the cut-off disc

or apply excessive pressure. Do

not attempt to make an excessive

depth of cut.

Overstressing

the disc increases the loading

and susceptibility to twisting or

binding of the disc in the cut and

the possibility of kickback or disc

breakage.

b)

Do not position your body in

line with and behind the rotating

disc.

When the disc, at the point

of operation, is moving away from

your body, the possible kickback

may propel the spinning disc and

the power tool directly at you.

c)

When disc is binding or when

interrupting a cut for any reason,

switch off the power tool and hold

the power tool motionless until the

disc comes to a complete stop.

Never attempt to remove the cutoff disc from the cut while the disc

is in motion otherwise kickback

may occur.

Investigate and take

corrective action to eliminate the

cause of disc binding.

d)

Do not restart the cutting

operation in the workpiece. Let

the disc reach full speed and

carefully reenter the cut.

The disc

may bind, walk up or kickback if

the power tool is restarted in the

workpiece.

e)

Support panels or any oversized

workpiece to minimize the risk of

disc pinching and kickback.

Large

workpieces tend to sag under

their own weight. Supports must

be placed under the workpiece

near the line of cut and near the

edge of the workpiece on both

sides of the disc.

f)

Use extra caution when making

a “pocket cut” into existing

walls or other blind areas.

The

protruding disc may cut gas or

water pipes, electrical wiring or

objects that can cause kickback.

Page 10

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

SYMBOLS

To reduce the risk of injury, user must read

instruction manual

Warning

Double insulation

Wear ear protection

Wear eye protection

Wear dust mask

Waste electrical products must not be

disposed of with household waste. Please

recycle where facilities exist. Check

with your local authorities or retailer for

recycling advice

Page 11

SO53 3LE

Customer Helpline 0845 600 5526

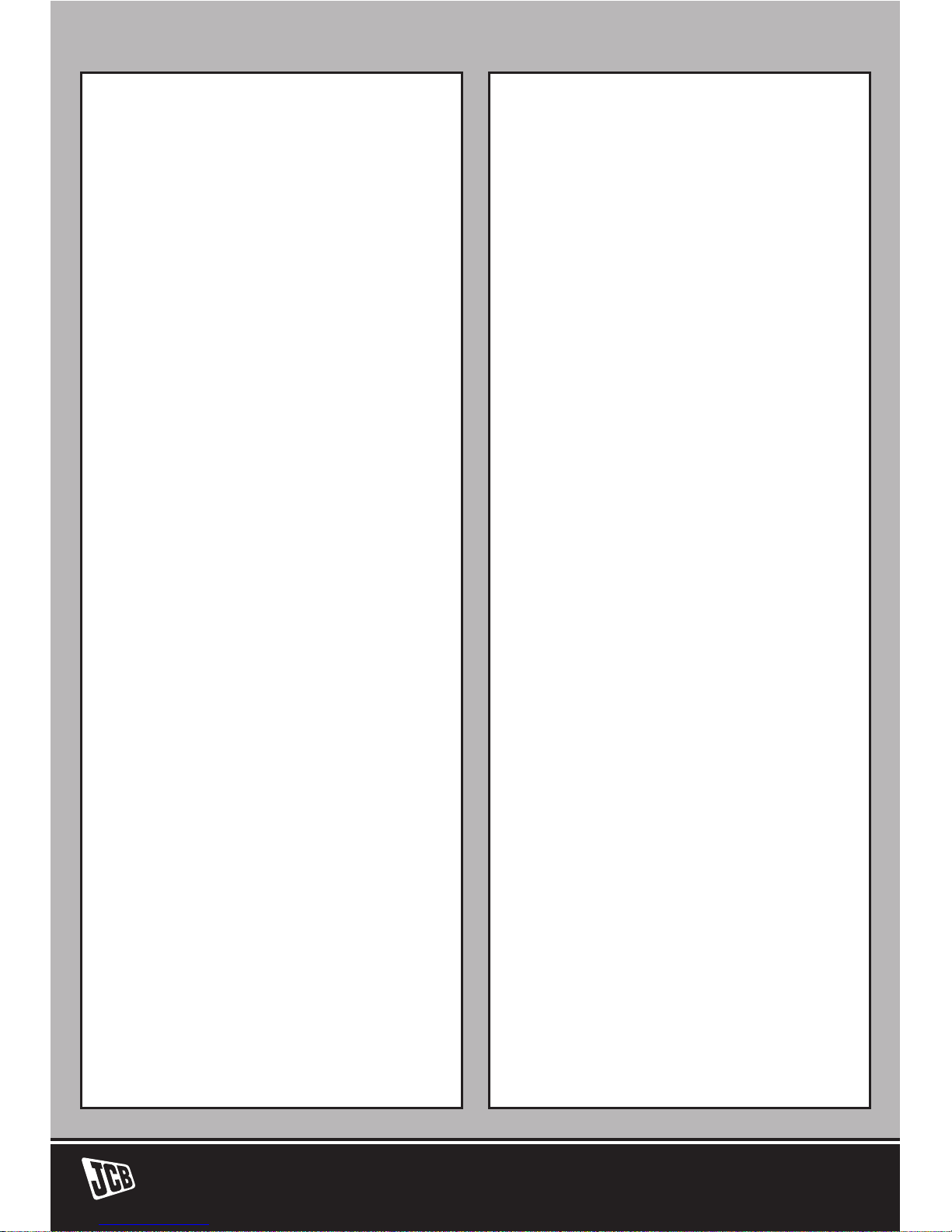

1. LOCK-OFF & LOCK-ON SWITCH

2. HAND GRIP AREA

3. ANTI-VIBRATION AUXILIARY HANDLE

4. SPINDLE LOCK BUTTON

5. OUTER FLANGE

6. INNER FLANGE

7. SPINDLE

8. DISC *

9. SPANNER

10.PROTECTION GUARD FOR GRINDING

11.CLAMPING SCREW

12.RAISED PROJECTION

13.PROTECTION GUARD FOR CUTTING *

14.INSULATING TIP (See

7

)

15.CARBON BRUSH (See

7

)

16.COMMUTATOR (See

7

)

17.CARBON BRUSH CAP (See

8

)

*

Not all accessories illustrated are included as standard.

COMPONENT LIST

10

13

11

12

2

1

3

4

5 6 7 98

Page 12

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

TECHNICAL DATA

Voltage 230-240V~50Hz

Power input 2200W

Rated speed 6500/min

Protection class

/II

Spindle thread M14

Disc size 230mm

Disc bore 22.2mm

Machine weight 4.7kg

NOISE INFORMATION

VIBRATION INFORMATION

Vibration total values (triax vector sum) determined according to EN 60745:

Typical weighted vibration

Vibration emission value a

h

= 4.6m/s²

Uncertainty K = 1.5m/s²

A weighted sound pressure LpA:98.5dB (A)

A weighted sound power LwA :109.5dB (A)

KpA & KwA= 3.0dB (A)

Wear ear protection when sound pressure is over: 80dB (A)

WARNING:

The vibration emission value during actual use of the power tool

can differ from the declared value depending on the ways in which the tool is

used dependant on the following examples and other variations on how the tool is

used:

How the tool is used and the materials are cut.

The tool being in good condition and well maintained

The use the correct accessory for the tool and ensuring it is sharp and in good

condition.

The tightness of the grip on the handles and if any anti vibration accessories are

used.

And the tool is being used as intended by its design and these instructions.

Page 13

SO53 3LE

Customer Helpline 0845 600 5526

This tool may cause hand-arm vibration syndrome if its use is not adequately

managed.

WARNING:

To be accurate, an estimation of exposure level in the actual

conditions of use should also take account of all parts of the operating cycle

such as the times when the tool is switched off and when it is running idle but not

actually doing the job. This may significantly reduce the exposure level over the total

working period.

Help to minimize your vibration exposure risk.

Maintain this tool in accordance with these instructions and keep well lubricated (where

appropriate)

If the tool is to be used regularly then invest in anti vibration accessories.

Avoid using tools in temperatures of 10oC or less

Plan your work schedule to spread any high vibration tool use across a number of

days.

ACCESSORIES

We recommend that you purchase your accessories from the same store that

sold you the tool. Use good quality accessories marked with a well-known brand

name. Choose the type according to the work you intend to undertake. Refer to the

accessory packaging for further details. Store personnel can assist you and offer

advice.

Anti-vibration auxiliary handle 1

Spanner 1

Page 14

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

INTENDED USE

NOTE:

Before using the

tool, read the the safety and

operating manual carefully.

INTENDED USE

The machine is intended for

cutting, roughing and brushing

metal and stone materials without

using water. For cutting metal, a

special protection guard for cutting

(accessory) must be used.

ASSEMBLY AND

ADJUSTMENT

MOUNTING THE

PROTECTIVE DEVICES

1. AUXILIARY HANDLE

The auxiliary handle MUST be

fitted all times.

Screw the auxiliary handle (3)

into the head of the machine

according to the working

method. (See

1

)

Warning!

Do not make any

alterations to the auxiliary

handle.

Do not continue to use

an auxiliary handle if it is

damaged.

MOUNTING THE GRINDING

DISC

Before any work on the machine

itself, pull the mains plug.

Grinding and cutting discs become

very hot while working; do not

1

Page 15

SO53 3LE

Customer Helpline 0845 600 5526

touch until they have cooled.

1. SPINDLE LOCK BUTTON

Clean the grinder spindle and all

parts to be mounted. For clamping

and loosening the grinding tools,

lock the grinder spindle (7) with the

spindle lock button (4).

Actuate the spindle lock button (4)

only when the grinder spindle is

at a standstill!

2. GRINDING/CUTTING DISC

Pay attention to the dimensions

of the grinding disc. The

mounting hole diameter must fit

the inner flange (6) without play.

Do not use reducers or adapters.

When using a diamond cutting

disc, take care that the directionof-rotation arrow on the diamond

cutting disc and the direction of

rotation of the machine (direction-ofrotation arrow on the machine head)

agree.

For mounting, see the Component

list illustration page.

Screw on the outer flange (5) and

tighten with the two-pin spanner (9).

(See

2

)

3. ADJUSTABLE OUTER

FLANGE CLAMPING

The outer flange (5) should be

adjusted to suit different disc

thickness. For thinner cutting or

diamond discs the raised part of

the outer flange is fitted facing away

from the disc (See

3

). For thicker

2

3

Page 16

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

grinding discs the raised part of the

outer flange is fitted facing towards

the disc to provide improved

support for the disc hole (See

4

).

Always ensure your disc is securely

clamped.

ADJUSTING THE

PROTECTION GUARD

Before any work on the machine

itself, pull the mains plug.

For work with grinding or cutting

discs, the protection guard must

be mounted.

The coded projection (12) on the

protection guard (10/13) ensures

that only a guard that fits the

machine type can be mounted.

Loosen the clamping screw (11), if

necessary.

Place the protection guard (10/13)

with coded projection (12) into the

coded groove on the spindle collar

of the machine head and rotate

to the required position (working

position).

The closed side of the protection

guard (10/13) must always point

to the operator.

Tighten clamping screw (11).

4

Page 17

SO53 3LE

Customer Helpline 0845 600 5526

STARTING OPERATION

Your switch is locked off to prevent

accidental starting. To switch on

your tool, push the safety switch

lever (B) forward and depress on/

off switch (A) fully. Now your tool is

switched on. To switch off your tool,

just release the On/Off switch.

If you wish to use the tool

continuously, push the safety switch

lever (B) forward and depress on/

off switch (A) fully, then push the

safety switch lever (B) forward again

and release the On/Off switch. Now

your switch has been locked on for

continuous use. To switch off your

tool, simply depress On/Off switch

fully, the safety On/Off switch will

automatically release. (See

5

)

ACCIDENTAL

RESTARTING FEATURE.

The restarting protection feature

prevents accidental restarting of the

machine after an interruption in the

power supply.

To restart the operation, switch the

On/Off switch (A) to the Off position

and start the machine again.

SOFT START MOTOR

Internal electronic components

allow the motor speed to increase

slowly, which reduces the “twisting”

effect on your wrists due to the high

power motor.

OPERATION

5

B A

Page 18

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

OPERATING

INSTRUCTIONS

●

Clamp the workpiece if it does

not remain stationary due to its own

weight.

●

Do not strain the machine so

heavily that it comes to a standstill.

●

Grinding and cutting discs

become very hot while working; do

not touch until they have cooled.

●

Remove the plug from the

socket-outlet when not using the

machine. With the plug inserted

and mains voltage existing, the

power tool still has low power

consumption even when it switched

off.

1. HAND GRIP AREAS

Always hold your angle grinder

firmly with both hands when

operating (See

6

).

2. ROUGH GRINDING

The best roughing results are

achieved when setting the machine

at an angle of 30° to 40°. Move

the machine back and forth with

moderate pressure. In this manner,

the workpiece will not become too

hot, does not discolour and grooves

are not formed.

Warning!

Never use a

cutting disc for roughing.

3. CUTTING

Warning!

For cutting metal,

always work with the wheel

6

Page 19

SO53 3LE

Customer Helpline 0845 600 5526

guard for cutting.

When cutting, do not press, tilt or

oscillate the machine. Work with

moderate feed, adapted to the

material being cut.

Do not reduce the speed of running

down cutting discs by applying

sideward pressure.

The direction in which the cutting is

performed is important.

The cutting disc must always

be used in an upward motion.

NEVER move the cutting disc in

other directions otherwise it may

be pushed out of the cut in an

uncontrolled way.

AUTO-STOP CARBON

BRUSHES

After prolonged use the carbon

brushes will wear. This machine

is fitted with Auto Stop Carbon

Brushes that will automatically shut

down the motor when the brushes

become worn.

When this occurs, both carbon

brushes should be replaced. Keep

the carbon brushes clean and free

to slip in the holders. Both carbon

brushes should be replaced at

the same time. Use only identical

carbon brushes. (See

7

)

7

16

14

15

Page 20

SO53 3LE

Customer Helpline 0845 600 5526

REPLACE THE CARBON

BRUSH AS FOLLOWS: (See

8

& 9)

Unscrew the brush cap (17),

remove the carbon brush (15), if the

carbon has worn down to 6mm it

should be replaced. Always replace

both brushes at the same time, insert

the new brush and replace the brush

cap. Check that the tool is working.

Before use, allow it to run for a few

minutes to enable the brushes to

settle.

9

15

17

8

Page 21

SO53 3LE

Customer Helpline 0845 600 5526

WORKING HINTS FOR YOUR ANGLE GRINDER

If your angle grinder becomes too hot, run no load for 2-3 minutes to cool the motor.

Never start your angle grinder with the disc/ accessory in contact with the workpiece.

Always start at no load to achieve maximum speed then start working.

Do not force the disc to work faster, reducing the Disc’s moving speed means longer

working time.

When grinding, always work with a 30° to 40° angle between disc and workpiece.

Larger angles will cut ridges into the workpiece and affect the surface finish. Move the

angle grinder across and back and forth over the workpiece.

When using a cutting disc never changes the cutting angle otherwise you will stall the

disc and angle grinder motor or break the disc.

When cut, only cut in the opposite direction to the disc rotation. If you cut in the same

direction as the disc rotation the disc may push itself out of the cut slot.

When cutting very hard material best results can be achieved with a diamond disc.

When using a diamond disc it will become very hot. If this happens you will see a

full ring of sparks around the rotating disc. Stop cutting and allow cooling at no load

speed for 2-3 minutes.

Always ensure the workpiece is firmly held or clamped to prevent movement.

MAINTENANCE

Remove the plug from the socket before carrying out any adjustment, servicing

or maintenance.

Your power tool requires no additional lubrication or maintenance.

There are no user serviceable parts in your power tool. Never use water or chemical

cleaners to clean your power tool. Wipe clean with a dry cloth. Always store your power

tool in a dry place. Keep the motor ventilation slots clean. Keep all working controls

free of dust. Occasionally you may see sparks through the ventilation slots. This is

normal and will not damage your power tool.

If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

ENVIRONMENTAL PROTECTION

Waste electrical products must not be disposed of with household waste.

Please recycle where facilities exist. Check with your local authorities or retailer

for recycling advice.

Page 22

SO53 3LE

Customer Helpline 0845 600 5526

SO53 3LE

Customer Helpline 0845 600 5526

PLUG REPLACEMENT (UK & IRELAND ONLY)

If you need to replace the fitted plug then follow the instructions below.

IMPORTANT

The wires in the mains lead are colored in accordance with the following code:

Blue – Neutral

Brown – Live

As the colors of the wires in the mains lead of this appliance may not correspond

with the coloured markings identifying the terminals in your plug, proceed as

follows. The wire which is coloured blue must be connected to the terminal which

is marked with N. The wire which is coloured brown must be connected to the

terminal which is marked with L.

Warning:

Never connect live or neutral wires to the earth terminal of the plug. Only fit

an approved BS1363/A plug and the correct rated fuse.

Note:

If a moulded plug is fitted and has to be removed take great care in

disposing of the plug and severed cable, it must be destroyed to prevent

engaging into a socket.

13 Amp fuse approved

to BS1362

Connect

Blue to N

(neutral)

Outer sleeve

rmly clamped

Brown L(live)

Cable grip

Page 23

SO53 3LE

Customer Helpline 0845 600 5526

WARRANTY STATEMENT

Cutting edge construction technology in your hands

In 1945 JCB began producing construction equipment. Today, we build the world’s

number one diggers, each one the product of our unswerving focus on innovation,

quality and engineering. JCB power tools are built to give you the same world

beating standards of performance. The same innovation, to always get the job

done better, the same quality, to never let you down, the same engineering

heritage and expertise that you can trust 100%.

JCB power tools are guaranteed against manufacturing defects for a period of 5

years from the date of purchase. If your JCB power tool becomes defective within

this warranty period, we guarantee to:

• Replaceorrepairalldefectiveparts,freeofcharge,or

• Repairproductsfreeofcharge,or

• Replacetheunitwithaneworre-conditionedunit,freeofcharge.

Conditions

Your 5 year guarantee does not cover defects caused by or resulting from:

• overload,misuse,orneglect

• normalwearandtear,includingaccessorywear

• tradeorhireuse

• repairsattemptedbyanyoneotherthananauthorisedagent

• damagecausedbyforeignobjects,substancesoraccidents

Your 5 year guarantee does not cover:

• batterypacksastheyareguaranteedfora12monthperiod

• accessoriessuppliedwiththepowertool.

Warranty claims

For guarantee claims, please contact JCB Customer Services. You will be required

to submit proof of purchase.

JCB CUSTOMER HELPLINE 0845 600 5526

Terms

This guarantee does not affect your statutory rights. JCB SO53 3LE (Registered in

England under No. 973387).

Page 24

SO53 3LE

Customer Helpline 0845 600 5526

EC DECLARATION OF CONFORMITY

We,

Positec Power Tools RG24 8AL, UK

Declare that the product

Description

JCB Angle Grinder

Type

(JCB-AG2200)

Function

Peripheral and lateral grinding

Complies with the following Directives,

EC Machinery Directive

2006/42/EC

EC Low Voltage Directive

2006/95/EC

EC Electromagnetic Compatibility Directive

2004/108/EC

Standards conform to

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

EN 60745-1

EN 60745-2-3

The person authorised to compile the technical file,

Name: Russell Nicholson

Address: Positec Powertools(Europe) LTD

Pinewood, Chineham Business Park,

Basingstoke, Hampshire, RG24 8AL, United Kingdom

2010/07/15

Jacky Zhou

Quality Manager POSITEC

Page 25

Page 26

Page 27

Page 28

Loading...

Loading...