Page 1

8642 - 1

!

WARNING

Study This Handbook Before Starting The Machine

You must understand and follow the instructions in this handbook. You must

observe all relevant laws and regulations. If you are unsure about anything, ask your

JCB distributor or employer. Do not guess, you or others could be killed or

seriously injured.

INT-1-1-1

! CAUTION

Do not fit an attachment to this machine which is not JCB approved. Consult your

JCB distributor before fitting any non approved attachment.

8-4-1-6

In this handbook and on the machine there are safety notices. Each notice starts

with a signal word. The meanings of the signal words are given below.

!

DANGER

Denotes an extreme hazard exists. If proper precautions are not taken, it is

highly probable that the operator (or others) could be killed or seriously

injured.

INT-1-2-1

!

WARNING

Denotes a hazard exists. If proper precautions are not taken, the operator

(or others) could be killed or seriously injured.

INT-1-2-2

!

CAUTION

Denotes a reminder of safety practices. Failure to follow these safety

practices could result in injury to the operator (or others) and possible

damage to the machine.

INT-1-2-3

MACHINE SECURITY

Vandalism and theft of unattended machines is an ever increasing problem and

JCB is doing everything possible to help combat this.

JCB PLANTGUARD is a comprehensive package available to help you safeguard

your machine. It includes such devices as vandal proof covers, window etching,

immobiliser, concealed serial number, battery isolator, Tracker security system

and much more.

Remember that the fitting of any one of these security devices will help to

minimise not only the damage or loss of your machine but also subsequent lost

productivity. It could also result in reduced insurance premiums.

Your JCB Distributor or Dealer will be pleased to provide information on any of

these sensible precautions. ACT NOW!

INT-1-2-4

SAFETY NOTICES

Page 2

8642-1

i i

CONTENTS

Introduction

About this Handbook

Machine model and serial number ...................... 1

Using this handbook ........................................... 1

Units of measurement ......................................... 1

Page numbering .................................................. 1

Left side/right side .............................................. 1

Using the machine............................................... 1

The JCB Backhoe Loader................................. 2

Safety check list

General safety .................................................... 3

Operating safety ................................................. 4

Maintenance safety ............................................. 5

Safety decals...................................................... 7-8

Identifying your machine

Machine identification plate ................................ 9

Typical vehicle number (VIN) ............................... 9

Typical engine identification number................... 9

Serial plates......................................................... 10

Operation

Introduction ....................................................... 11

Before entering the cab ................................... 11

Entering/leaving the cab................................... 12

Control lever locks............................................... 12

Doors and windows

Opening and closing the doors ........................... 13

Opening and closing the rear window................. 13

Seat controls ..................................................... 14

Seat belt

Fasten the seat belt............................................. 15

Check the seat belt is operating correctly........... 15

Release the seat belt ........................................... 15

Engine and drive controls, switches

and instruments

Layout.................................................................. 16

Controls .............................................................. 17-18

Multi-purpose steering column switch ................ 19

Front console switches ....................................... 19

Side console switches......................................... 20

2/4 wheel drive select switch .............................. 21

Starter switch ...................................................... 21

Cab interior light .................................................. 21

Steer mode selector switch ................................ 22

Re-phasing the steer system ............................ 22

Instruments ......................................................... 23-24

Visual warnings.................................................... 24

Audible/visual warnings....................................... 24

Air conditioning and heater controls ............... 25

Power Outlet ...................................................... 25

Loader controls ................................................. 26

Hydraulic speed control .................................... 26

Loader shovel ...................................................... 27-29

Stabiliser controls

Lever controls...................................................... 30

Backhoe controls .............................................. 31

ISO Plus ('+') pattern .......................................... 32-33

Backhoe foot pedal control (if fitted) ................... 34

Kingpost clamps.................................................. 34

Boom and slew locks

Boom lock ........................................................... 35

Slew lock ............................................................. 36

Before starting the engine ............................... 37

Starting the engine ............................................ 38

Inter vehicle start connector ........................... 39

Preparing the machine for travel

Backhoe attachments ......................................... 40

Road travelling position....................................... 41-42

Site travelling position ......................................... 43

Testing the parking brake ................................ 44

Getting the machine moving ............................ 45-46

Stopping and parking the machine ................. 47

Using the attachments and site safety ........... 48-49

Working with the loader

Operating hints .................................................... 50

Filling the loader shovel ...................................... 50

Loading a truck ................................................... 51

Getting the machine unstuck .............................. 51

Working with the backhoe

Operating hints .................................................... 52

Preparing to use the backhoe ............................. 52

Digging ............................................................... 53

Sideshifting the Backhoe .................................... 54

Lifting with the backhoe ...................................... 55

Operating in low and high temperatures ........ 56

Moving a disabled machine

Preparation for towing......................................... 57

Lifting a machine ............................................... 58

Transporting the machine ............................... 59-60

Page Page

Page 3

8642-1

ii ii

CONTENTS

Detachable roof section

Removing .......................................................... 61

Replacing ........................................................... 61

Fire extinguisher

Using the fire extinguisher................................... 62

Maintenance

Lubricants - health and safety ......................... 63

Service requirements

Introduction ......................................................... 64

Maintenance........................................................ 64

Owner/Operator support ..................................... 64

Service/Maintenance agreements....................... 64

Lifting regulations - inspections and tests .......... 64

Cleaning the machine ....................................... 65

Checking for damage........................................ 66

Obtaining replacement parts............................ 66

Service Schedules ............................................. 67-69

Loader arm safety strut

Installing .............................................................. 70

Removing ............................................................ 70

Engine panels

Removing and fitting a side panel ....................... 71

Removing and fitting the access panel ............... 71

Removing and fitting the engine cover................ 71

Seat belt

Checking the seat belt condition and security .... 72

ROPS/FOPS structure

Checking the ROPS/FOPS structure .................. 72

Greasing

Loader arms ........................................................ 73

Backhoe & quick hitch......................................... 74

Front & rear axle .................................................. 75

Driveshafts........................................................... 76

Multi purpose shovel ........................................... 76

Kingpost ............................................................. 76

Loader quick hitch............................................... 77

Backhoe quick-hitch (hydraulic) .......................... 77

Hydraulic pump driveshaft .................................. 78

Tyres and wheels

Tyre inflation ........................................................ 78

Using the Tyre Inflator ......................................... 79

Checking the wheel nut torques.......................... 79

Brakes

Parking brake adjustment ................................... 80

Checking the foot brake fluid level...................... 80

Engine air filter

Changing the elements ....................................... 81

Engine oil and filter

Checking the oil level .......................................... 82

Changing the oil and filter ................................... 82

Engine cooling system

Checking the coolant level .................................. 83

Changing the coolant .......................................... 83

Adjusting the fan belt .......................................... 84

Cleaning the cab heater filter .............................. 84

Fuel system

Types of fuel ........................................................ 85

Fuel standards..................................................... 85

Low temperature fuels......................................... 85

Fatty acid fuels ................................................... 85

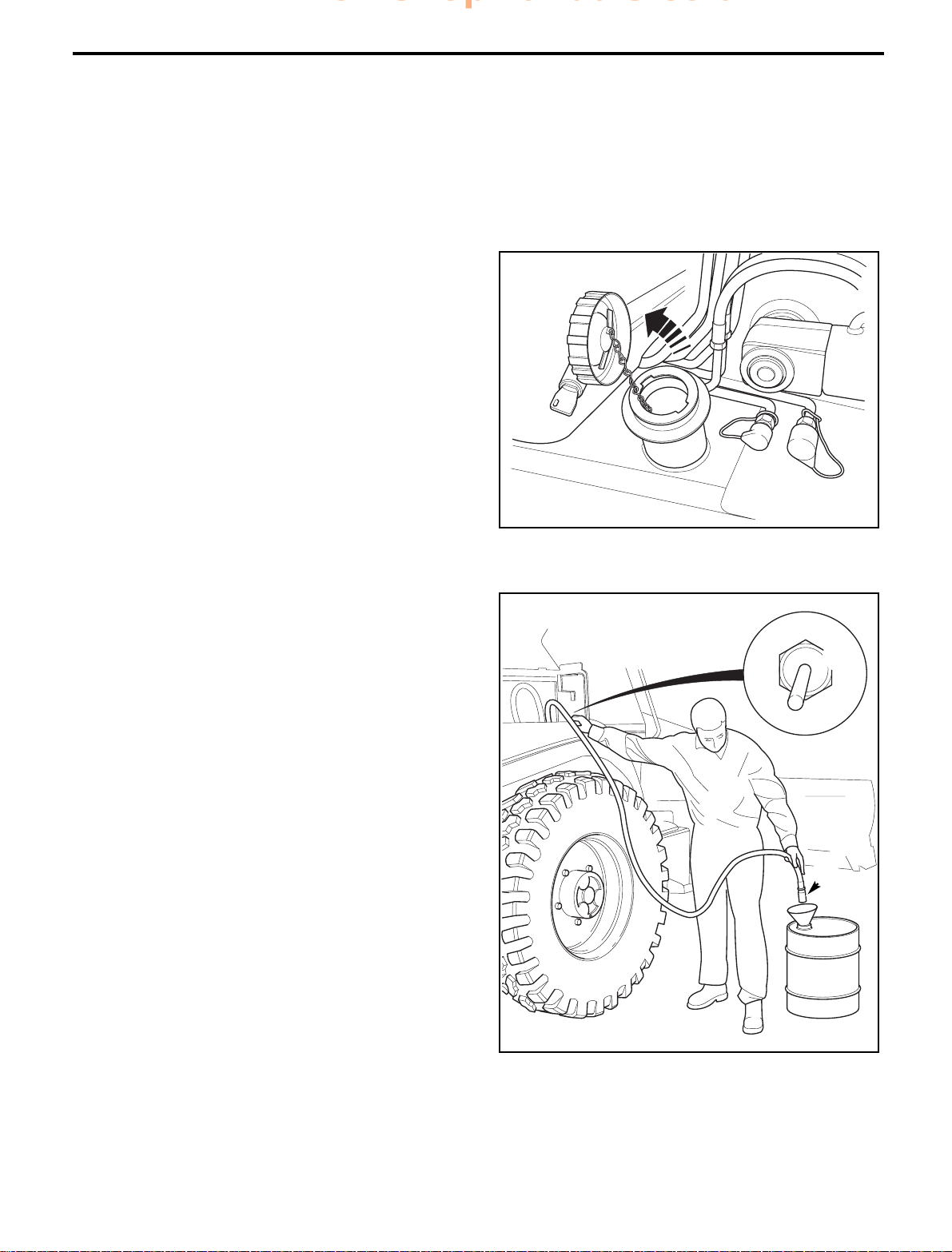

Filling the tank ..................................................... 86

Fuel transfer pump .............................................. 86

Draining the tank ................................................. 87

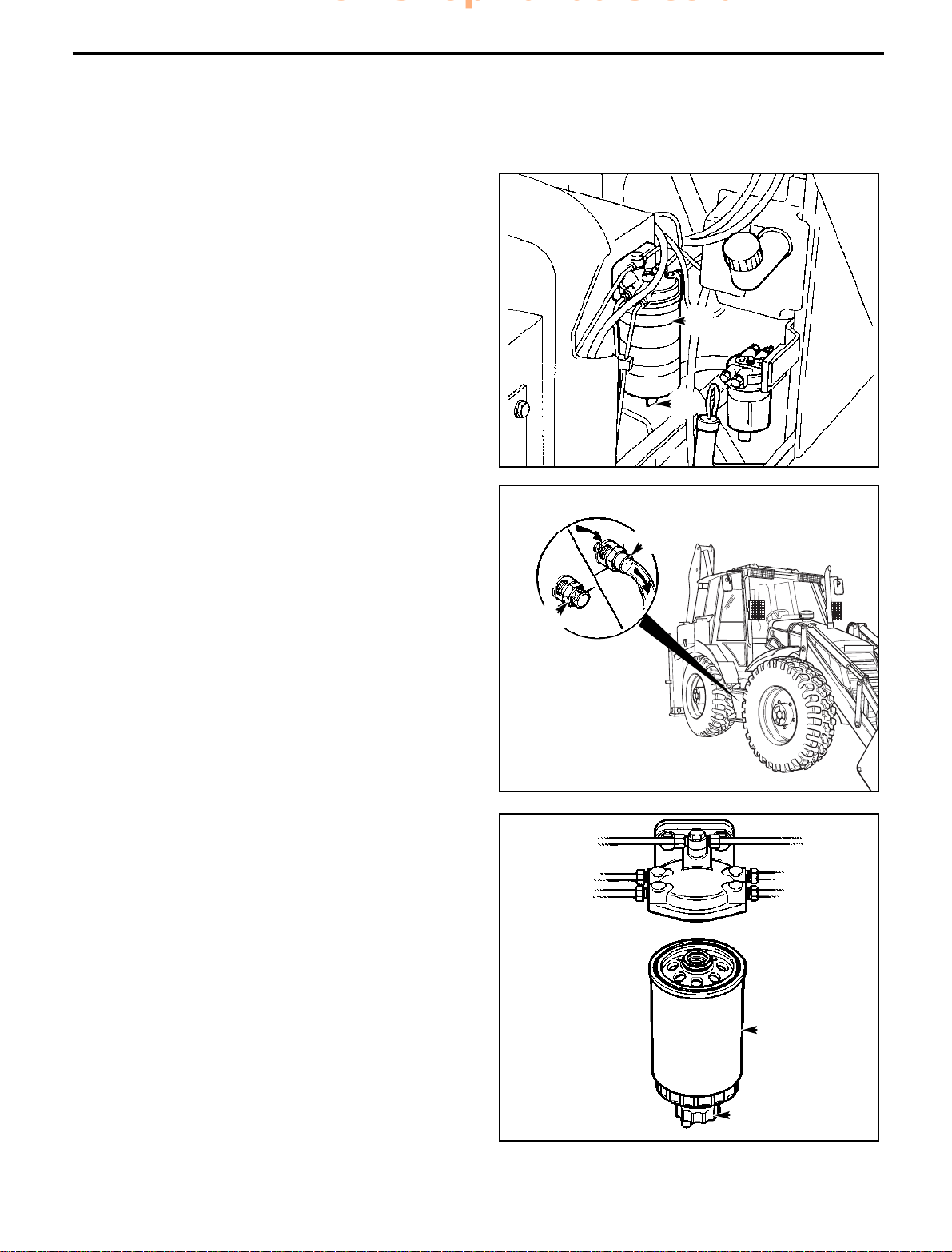

Draining the filter ................................................. 87

Changing the filter element ................................. 87

Draining the sediment bowl................................. 88

Bleed the system................................................. 88

Powershift transmission

Checking the oil level .......................................... 89

Changing the oil and filter ................................... 89

Hydraulic system

Checking the fluid level ....................................... 90

Hydraulic tank cap .............................................. 90

Changing the filter element ................................. 91

Draining the tank ................................................. 92

Changing the suction strainer ............................. 92

Front axle

Checking the differential oil level......................... 93

Changing the differential oil................................. 93

Rear axle

Checking the differential oil level......................... 94

Changing the differential oil................................. 94

Front and rear axle

Checking the hub oil levels ................................. 95

Changing the hub oil ........................................... 95

Electrical system

Fuse identification ............................................... 96

Relay identification .............................................. 96

Relay identification - Powershift transmission .... 97

Link Box Fuses .................................................... 97

Battery

Warning symbols ............................................... 98

First aid - electrolyte............................................ 99

Checking the electrolyte level ............................. 99

Battery removal ................................................... 100

Battery isolator .................................................. 100

Page Page

Page 4

8642-1

iii iii

CONTENTS

Hydraulic oil cooler

Cleaning the tubes/fins........................................ 101

Windscreen washer........................................... 101

Stabiliser legs

Wear pads ........................................................... 102

Wear pad adjustment .......................................... 102

Storage ............................................................... 103

Fire Extinguisher

Checking the fire extinguisher............................. 104

Service Capacities and Lubricants .................. 105-106

Optional Attachments

Introduction........................................................ 107

Backhoe attachment operation

High and low flow attachments........................... 108

Quick release couplings

Quick release couplings - do's & don'ts ............. 109

Connecting quick release couplings ................... 109

Disconnecting quick release couplings............... 109

Loader quick-hitch

Installing the quick-hitch carriage ....................... 110

Removing the quick-hitch carriage ..................... 110

Installing loader quick-hitch attachments ........... 111-112

Removing loader quick-hitch attachments ........ 113

Backhoe quick-hitch (mechanical type)

Installing the quick-hitch ..................................... 114

Removing the quick-hitch ................................... 114

Installing backhoe quick-hitch attachments ....... 115

Removing backhoe quick-hitch attachments...... 116

Sideshift carriage

Operation safety .................................................. 117

Operation............................................................. 117

Installing and removing the carriage ................... 118

Maintenance safety ............................................. 118

Maintenance........................................................ 118

Hydraulic Tool Circuit (HTC)

Connecting the hand held tools .......................... 119

Operating the tool................................................ 119

Disconnecting the hand held tool........................ 120

Ancillary equipment

Stowage of ancillary equipment .......................... 121-124

Removal of stowed ancillary equipment ............. 124

Laser Levelling Equipment

Installing the laser leveller ................................... 125-126

Using the laser leveller ........................................ 127

Introduction ......................................................... 128

Safety .................................................................. 129-130

Production information........................................ 131

Specifications ...................................................... 132-133

Preparation .......................................................... 134

Use ...................................................................... 135

Movement............................................................ 136

Adjusting the laser equipment............................. 136

Levelling .............................................................. 137

Use of tracer........................................................ 137

Stopping and disassembly.................................. 138

Cleaning .............................................................. 139

Transporting ........................................................ 139

Problems/Causes/Solutions................................ 139

Maintenance........................................................ 141-143

Hydraulic diagram ............................................... 144

Electrical diagram................................................ 145

Dual Slope Transmitter

Description .......................................................... 146

Applications......................................................... 146

Features............................................................... 146-147

Grade axis orientation ......................................... 148

Replacement parts .............................................. 149

Elevating Base

Description .......................................................... 150

Applications......................................................... 150

Features/Functions.............................................. 150

Specifications ...................................................... 150

Replacement parts .............................................. 151

Tripod Legs

Description .......................................................... 152

Applications......................................................... 152

Features/Function ............................................... 152

Specification........................................................ 152

Replacement parts .............................................. 153

Omni-Directional Receiver

Applications......................................................... 155

Description .......................................................... 155

Features............................................................... 155

Specifications ...................................................... 155

Earth Drill............................................................ 155

Installing .............................................................. 156

Removing ............................................................ 156

Fitting the auger .................................................. 157

Removing the auger ............................................ 157

Operating hints .................................................... 158

Drilling.................................................................. 158

Transporting ........................................................ 158

Maintenance........................................................ 159-161

Technical specification........................................ 162

360 Hammermaster

Introduction ......................................................... 163

Component Identification .................................... 164

Safety .................................................................. 165-168

Travelling ............................................................. 169

Hydraulic oils, filtering and cooling ..................... 170

Principle of operation .......................................... 171-172

Maintenance........................................................ 173-176

Stowage & Specification .................................... 177-178

Page Page

Page 5

8640 - 1

iv iv

CONTENTS

Sweeper collector

Identification ........................................................ 179

Safety .................................................................. 180-181

Installing/Removing ............................................. 182

Connecting/disconnecting hydraulics................. 183

Preparing for use ................................................. 184

Operation............................................................. 185-186

Fault finding......................................................... 187-188

Travelling with sweeper collector ........................ 189

Routine maintenance........................................... 190-192

Storage ................................................................ 193

Specification........................................................ 194

Multi purpose shovel ........................................ 195

Specifications

Lifting (craning) regulations and safe working loads

Lifting regulations ................................................ 196

Safe working loads.............................................. 196

Safe working loads - Forks

Loader ................................................................. 196

Safe working loads - Craning (No Bucket Fitted)

Backhoe .............................................................. 197

Backhoe bucket weights and dimensions

- general purpose bucket (standard profile) ........ 198

- general purpose bucket (deep profile) .............. 198

- grading bucket .................................................. 198

- jaw bucket ........................................................ 198

- tapered ditching bucket .................................... 198

Static dimensions .............................................. 199

Backhoe/Loader dimensions ........................... 200

Fording depths................................................... 201

Tyre sizes and pressures.................................. 201

Hydraulic hose burst pressures ....................... 202

Noise and Vibration Data .................................. 203

Winterisation and

Waterproofing

Introduction........................................................ 204

Winterisation

Operation ............................................................ 204-205

Snow blind deployment and stowage

- Radiator blind.................................................... 206

- Cab window blinds .......................................... 206

- Door blinds ....................................................... 207

- Fuse identification ............................................ 208

-Relay identification ............................................ 209

Waterproofing

Page Page

Page 6

Page 7

1 1

INTRODUCTION

ABOUT THIS HANDBOOK

Machine Model

This handbook provides information for the 4CX military

Backhoe Loader machine.

Using this Handbook

The illustrations in this handbook are for guidance only.

Where the machines differ, the text and/or the illustration

will specify.

This handbook is arranged to give you a good

understanding of the machine and its safe operation. It

also contains maintenance information and specification

data. Read this handbook from front to back before using

the machine for the first time. Particular attention must be

given to all the safety aspects of operating and

maintaining the machine.

General warnings in this chapter are repeated throughout

the book, as well as specific warnings. Read all the safety

statements regularly, so you do not forget them.

Remember that the best operators are the safest

operators.

Finally, treat this handbook as part of the machine. Keep it

clean and in good condition. Do not operate the machine

without a handbook in the cab. If there is anything you are

not sure about, ask your JCB distributor or employer. Do

not guess, you or others could be killed or seriously

injured.

The manufacturer's policy is one of continuous

improvement. The right to change the specification of the

machine without notice is reserved. No responsibility will

be accepted for discrepancies which may occur between

specifications of the machine and the descriptions

contained in this publication.

INT-1-2-5/1

Units of measurement

In this handbook, the S.I. system of units is used. For

example, liquid capacities are given in litres. The Imperial

units follow in parenthesis () eg 28 litres (6 gal).

Using the machine

To use the JCB Backhoe Loader efficiently and safely you

must know the machine and have the skill to use it. This

handbook instructs you on the machine, its controls and

its safe operation. It is not a training manual on the art of

excavating or loading. If you are a new operator, get

yourself trained in the skills of using a JCB Backhoe

Loader before trying to work with it. If you don't, you will

not do your job well, and you will be a danger to yourself

and others.

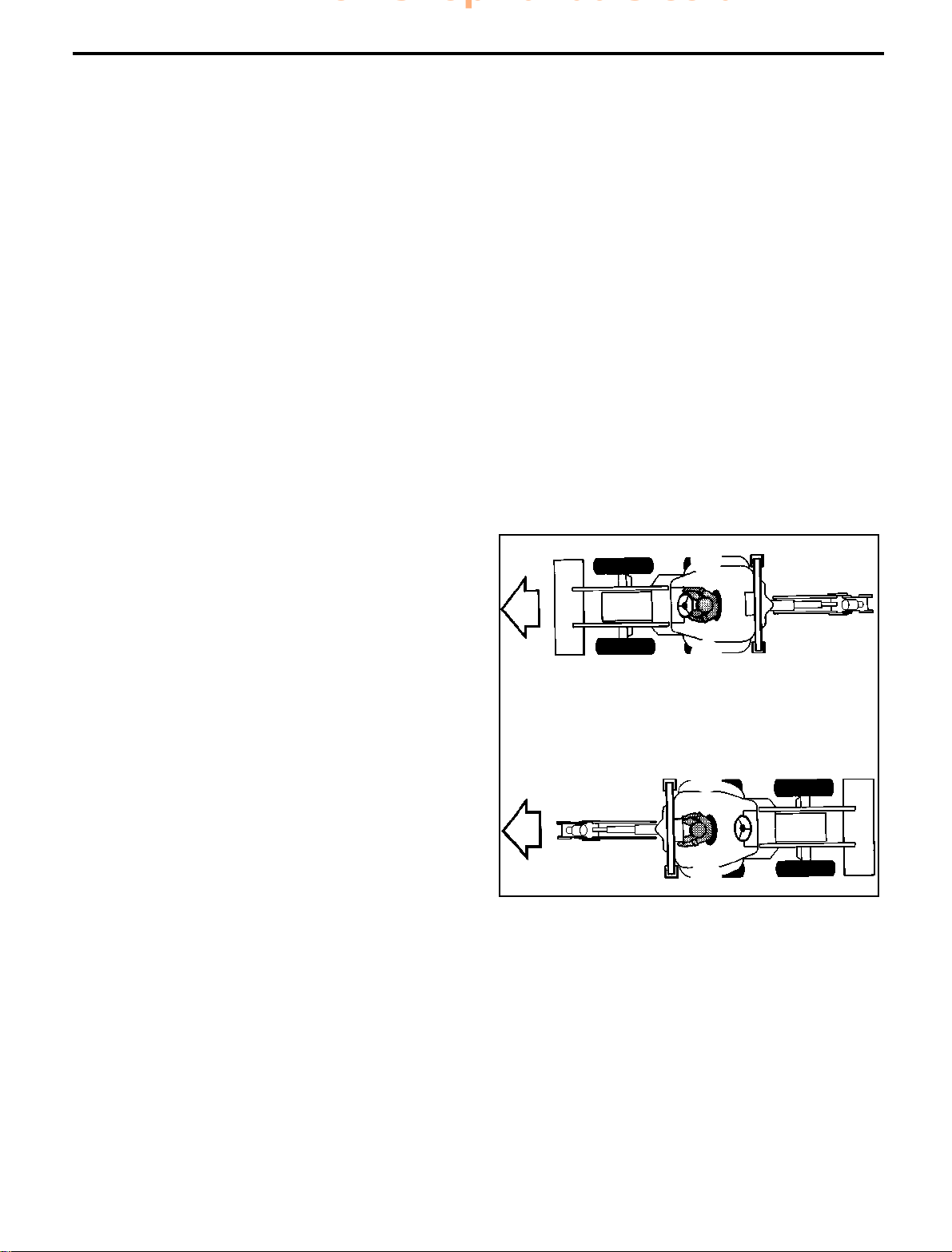

Left Side, Right Side

In this handbook, 'left' A and 'right' B mean your left and

right when you are seated correctly in the machine. This is

so whether you are facing the loader (front) or the backhoe

(rear).

8642-1

S143520

BB

A

B

A

Page 8

2 2

INTRODUCTION

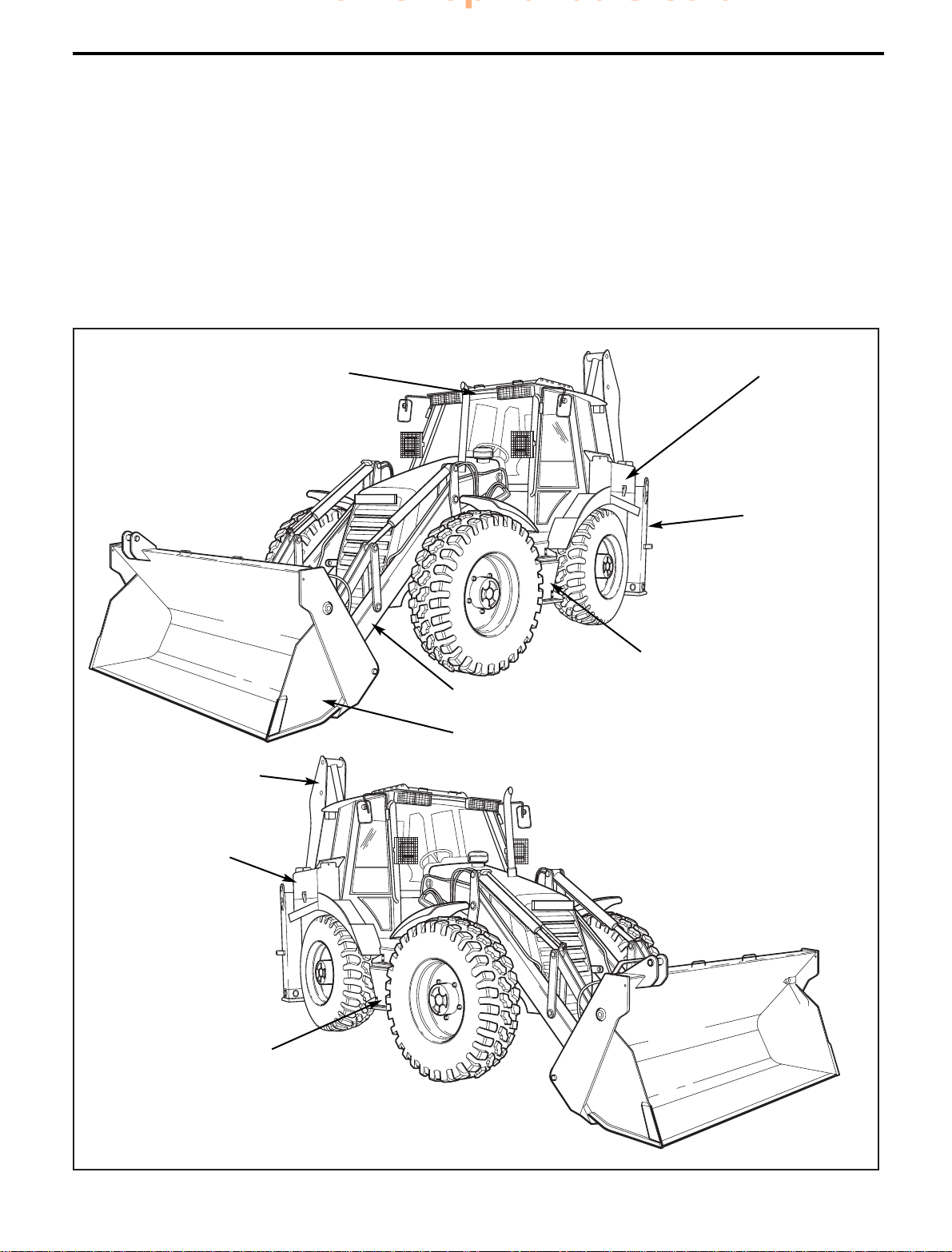

THE JCB BACKHOE LOADER

Machine Description

The backhoe loader is a self propelled wheeled machine with a main structural support designed to carry both a front

mounted bucket loading mechanism and a rear mounted backhoe. When used in the backhoe mode, the machine normally

digs below ground level with bucket motion towards the machine; the backhoe lifts, swings and discharges material while

the machine is stationary. When used in the loader mode, the machine loads or excavates through forward motion of the

machine, and lifts, transports and discharges material.

8642-1

380920

A380920

BATTERY PANNIER

A380910

CLAM

ROPS/FOPS

BACKHOE

TYRE

INFLATOR/FUEL

TRANSFER PANNIER

DIESEL TANK

STABILISERS

LOADER ARM

HYDRAULIC TANK & TOOL BOX

Page 9

3 3

INTRODUCTION

SAFETY - YOURS AND OTHERS

All construction and agricultural equipment can be

hazardous. When a backhoe loader is correctly operated

and properly maintained, it is a safe machine to work with.

But when it is carelessly operated or poorly maintained it

can become a danger to you (the operator) and others.

In this handbook and on the machine you will find warning

messages. Read and understand them. They tell you of

potential hazards and how to avoid them. If you do not

fully understand the warning messages, ask your

employer or JCB distributor to explain them.

But safety is not just a matter of responding to the

warnings. All the time you are working on or with the

machine you must be thinking what hazards there might

be and how to avoid them.

General Safety

!!

WARNING

Handbook

You and others can be injured if you operate or maintain

the machine without first studying this handbook. Read

the safety instructions before operating the machine. If

you do not understand anything, ask your employer or

JCB distributor to explain it. Keep this handbook clean

and in good condition. Do not operate the machine

without a handbook in the cab, or if there is anything on

the machine you do not understand.

INT-1-3-2

!!

WARNING

Clothing

You can be injured if you do not wear the proper clothing.

Loose clothing can get caught in the machinery. Wear

protective clothing to suit the job. Examples of protective

clothing are: a hard hat, safety shoes, safety glasses, a

well fitting overall, ear-protectors and industrial gloves.

Keep cuffs fastened. Do not wear a necktie or scarf. Keep

long hair restrained.

INT-1-3-6

!!

WARNING

Machine Modifications

This machine is manufactured in compliance with

legislative and other requirements. It should not be altered

in any way which would affect or invalidate any of these

requirements. For advice consult your JCB Distributor.

Reference should also be made to Optional Attachments

section where appropriate.

INT-1-3-10

Do not work with the machine until you are sure that you

can control it.

Do not start any job until you are sure that you and those

around you will be safe.

If you are unsure of anything, about the machine or the

job, ask someone who knows. Do not assume anything.

Remember

BE CAREFUL

BE ALERT

BE SAFE

INT-1-3-1/1

!!

WARNING

Alcohol and Drugs

It is extremely dangerous to operate machinery when

under the influence of alcohol or drugs. Do not consume

alcoholic drinks or take drugs before or whilst operating

the machine or attachments. Be aware of medicines which

can cause drowsiness.

INT-1-3-9

!!

CAUTION

Passengers

Passengers in or on the machine can cause accidents.

The JCB Backhoe Loader is a one-man machine. Do not

carry passengers.

INT-2-2-2

!!

WARNING

Raised Attachments

Raised attachments can fall and injure you. Do not walk or

work under raised attachments unless they are safely

blocked.

INT-1-3-8

!!

CAUTION

Regulations

Obey all laws, work site and local regulations which affect

you and your machine.

INT-1-3-3

!!

WARNING

Care and Alertness

All the time you are working with or on the machine, take

care and stay alert. Always be careful. Always be alert for

hazards.

INT-1-3-5

8642-1

SAFETY CHECK LIST

Page 10

4 4

INTRODUCTION

SAFETY CHECK LIST

(continued)

Operating Safety

!!

WARNING

Machine Condition

A defective machine can injure you or others. Do not

operate a machine which is defective or has missing parts.

Make sure the maintenance procedures in this handbook

are completed before using the machine.

INT-2-1-2

!!

WARNING

Lifting Equipment

You can be injured if you use faulty lifting equipment.

Make sure that lifting equipment is in good condition.

Make sure that lifting tackle complies with all local

regulations and is suitable for the job. Make sure that

lifting equipment is strong enough for the job.

INT-1-3-7

!!

WARNING

Engine

The engine has exposed rotating parts. Do not open the

engine cover while the engine is running. Do not use the

machine with the cover open.

INT-2-1-6/1

!!

WARNING

Machine Limits

Operating the machine beyond its design limits can

damage the machine, it can also be dangerous. Do not

operate the machine outside its limits. Do not try to

upgrade the machine performance with unapproved

modifications.

INT-2-1-4

!!

WARNING

Controls

You and others can be killed or injured if you operate the

control levers from outside the cab. Operate the control

levers only when you are seated correctly in the cab.

INT-2-1-3

!!

DANGER

Sparks

Explosions and fire can be caused by sparks from the

exhaust or the electrical system. Do not use the machine

in closed areas where there is flammable material, vapour

or dust.

INT-2-2-10

!!

WARNING

Visibility

Accidents can be caused by working in poor visibility.

Keep windows clean and use your lights to improve

visibility. Do not operate the machine if you cannot see

properly.

INT-2-1-11

!!

WARNING

Ramps and Trailers

Water, mud, ice, grease and oil on ramps or trailers can

cause serious accidents. Make sure ramps and trailers are

clean before driving onto them. Use extreme caution when

driving onto ramps and trailers.

INT-2-2-6

!!

WARNING

Safety Barriers

Unguarded machines in public places can be dangerous.

In public places, or where your visibility is reduced, place

barriers around the work area to keep people away.

INT-2-2-8

!!

WARNING

Parking

An incorrectly parked machine can move without an

operator. Follow the instructions in this handbook to park

the machine correctly.

INT-2-2-4

!!

WARNING

Hazardous Atmospheres

This machine is designed for use in normal out door

atmospheric conditions. It should not be used in an

enclosed area without adequate ventilation. Do not use

the machine in a potentially explosive atmosphere, i.e.

combustible vapours, gas or dust, without first consulting

your JCB Distributor.

INT-2-1-14

!!

WARNING

Should the machine start to roll over, you can be crushed

if you try to leave the cab. If the machine starts to roll over,

DO NOT TRY TO JUMP FROM THE CAB. STAY IN THE

CAB, WITH YOUR SEAT BELT FASTENED.

INT-2-1-12

8642-1

Page 11

5 5

INTRODUCTION

SAFETY CHECK LIST

(continued)

Maintenance Safety

!!

WARNING

Modifications and Welding

Non-approved modifications can cause injury and

damage. Parts of the machine are made from cast iron;

welds on cast iron can weaken the structure and break.

Do not weld cast iron. Contact your JCB dealer before

modifying the machine.

INT-3-1-2/1

!!

WARNING

Metal Splinters

You can be injured by flying metal splinters when driving

metal pins in or out. Use a soft faced hammer or drift to

remove and fit metal pins. Always wear safety glasses.

INT-3-1-3

!!

WARNING

Safety Strut

Raised loader arms can drop suddenly and cause serious

injury. Before working under raised loader arms, fit the

loader arm safety strut.

2-1-1-6

!!

WARNING

Communications

Bad communications can cause accidents. If two or more

people are working on the machine, make sure each is

aware of what the others are doing. Before starting the

engine make sure the others are clear of the danger areas;

examples of danger areas are: the rotating blades and belt

on the engine, the attachments and linkages, and

anywhere beneath or behind the machine. People can be

killed or injured if these precautions are not taken.

INT-3-1-5

!!

WARNING

Counterweights

Your machine may be fitted with counterweights. They are

extremely heavy. Do not attempt to remove them.

INT-3-2-5

!!

WARNING

Fires

If your machine is equipped with a fire extinguisher, make

sure it is checked regularly. Keep it in the operator's cab

until you need to use it.

Do not use water to put out a machine fire, you could

spread an oil fire or get a shock from an electrical fire. Use

carbon dioxide, dry chemical or foam extinguishers.

Contact your nearest fire department as quickly as

possible. Firefighters should use self-contained breathing

apparatus.

INT-3-2-7/1

!!

WARNING

Battery Terminals

The machine is negatively earthed. Always connect the

negative pole of the battery to earth.

When connecting the battery, connect the earth (-) lead

last.

When disconnecting the battery, disconnect the earth (-)

lead first.

INT-3-1-9

!!

WARNING

Repairs

Do not try to do repairs or any other type of maintenance

work you do not understand. Get a Service Manual from

your JCB distributor, or get the work done by a specialist

engineer.

INT-3-1-1

!!

WARNING

Hydraulic Pressure

Hydraulic fluid at system pressure can injure you. Before

disconnecting or connecting hydraulic hoses, stop the

engine and operate the controls to release pressure

trapped in the hoses. Make sure the engine cannot be

started while the hoses are open.

INT-3-1-11/1

!!

WARNING

Hydraulic hoses

Damaged hoses can cause fatal accidents. Inspect the

hoses regularly for:

Damaged end fittings

Chafed outer covers

Ballooned outer covers

Kinked or crushed hoses

Embedded armouring in outer covers

Displaces end fittings.

INT- 3-3-2

!!

WARNING

Accumulators

The accumulators contain hydraulic oil and gas at high

pressure. Prior to any work being carried out on the

braking system they must be discharged by a JCB

distributor as the sudden release of the hydraulic oil or gas

may cause injury.

7-1-1-4

!!

WARNING

Soft Ground

A machine can sink into soft ground. Never work under a

machine on soft ground.

INT-3-2-4

8642-1

Page 12

6 6

INTRODUCTION

SAFETY CHECK LIST

(continued)

Maintenance Safety (continued)

!!

WARNING

Fluoroelastomeric Materials

Certain seals and gaskets (e.g. crankshaft oil seal) on JCB

machines contain fluoroelastomeric materials such as

Viton, Fluorel and Technoflon. Fluoroelastomeric materials

subjected to high temperatures can produce highly

corrosive hydrofluoric acid. THIS ACID CAN SEVERELY

BURN.

New fluoroelastomeric components at ambient

temperature require no special safety precautions.

Used fluoroelastomeric components whose temperatures

have not exceeded 300°C require no special safety

precautions. If evidence of decomposition (e.g. charring) is

found, refer to the next paragraph for safety instructions

DO NOT TOUCH COMPONENT OR SURROUNDING

AREA.

Used fluoroelastomeric components subjected to

temperatures greater than 300°C (e.g. engine fire) must be

treated using the following safety procedure. Make sure

that heavy duty gloves and special safety glasses are

worn:

1 Ensure that components have cooled then remove

and place material into plastic bags.

2 Thoroughly wash contaminated area with 10%

calcium hydroxide or other suitable alkali solution, if

necessary use wire wool to remove burnt remains.

3 Thoroughly wash contaminated area with detergent

and water.

4 Contain all removed material, gloves etc. used in this

operation in sealed plastic bags and dispose of in

accordance with Local Authority Regulations.

DO NOT BURN FLUOROELASTOMERIC MATERIALS.

If contamination of skin or eyes occurs, wash the affected

area with a continuous supply of clean water or with

calcium hydroxide solution for 15-60 minutes. Get medical

attention immediately.

INT-3-3-5/1

!!

WARNING

Jacking

A machine can roll off jacks and crush you unless the

wheels have been chocked. Always chock the wheels at

the opposite end of the machine that is to be jacked. Do

not work underneath a machine supported only by jacks.

Always support a jacked-up machine on axle stands

before working underneath it.

INT-3-2-8

!!

WARNING

Under no circumstances must the engine be run with the

transmission in gear and only one driving wheel jacked

clear of the ground, since the wheel on the ground will

move the machine.

INT-3-1-16

!!

CAUTION

Rams

The efficiency of the rams will be affected if they are not

kept free of solidified dirt. Clean dirt from around the rams

regularly. When leaving or parking the machine, close all

rams if possible to reduce the risk of weather corrosion.

INT-3-2-10

!!

CAUTION

Arc Welding

Before carrying out arc welding on the machine,

disconnect the battery and alternator to protect the

circuits and components.

The battery must still be disconnected even if a battery

isolator is fitted.

Make sure that the welding earth return path is kept as

short as possible. This prevents high currents being

induced in the machine chassis or wiring harnesses.

If the machine is equipped with amplifier drivers or

electronic control units (E.C.U.s), then disconnect them

before welding. Failure to disconnect the amplifier drivers

or E.C.U.s could result in irreparable damage to the

electronic components.

INT-3-1-15/1

! WARNING

Oil

Oil is toxic. If you swallow any oil, do not induce vomiting,

seek medical advice. Used engine oil contains harmful

contaminants which can cause skin cancer. Do not handle

used engine oil more than necessary. Always use barrier

cream or wear gloves to prevent skin contact. Wash skin

contaminated with oil thoroughly in warm soapy water. Do

not use petrol, diesel fuel or paraffin to clean your skin.

INT-3-2-3

8642-1

Page 13

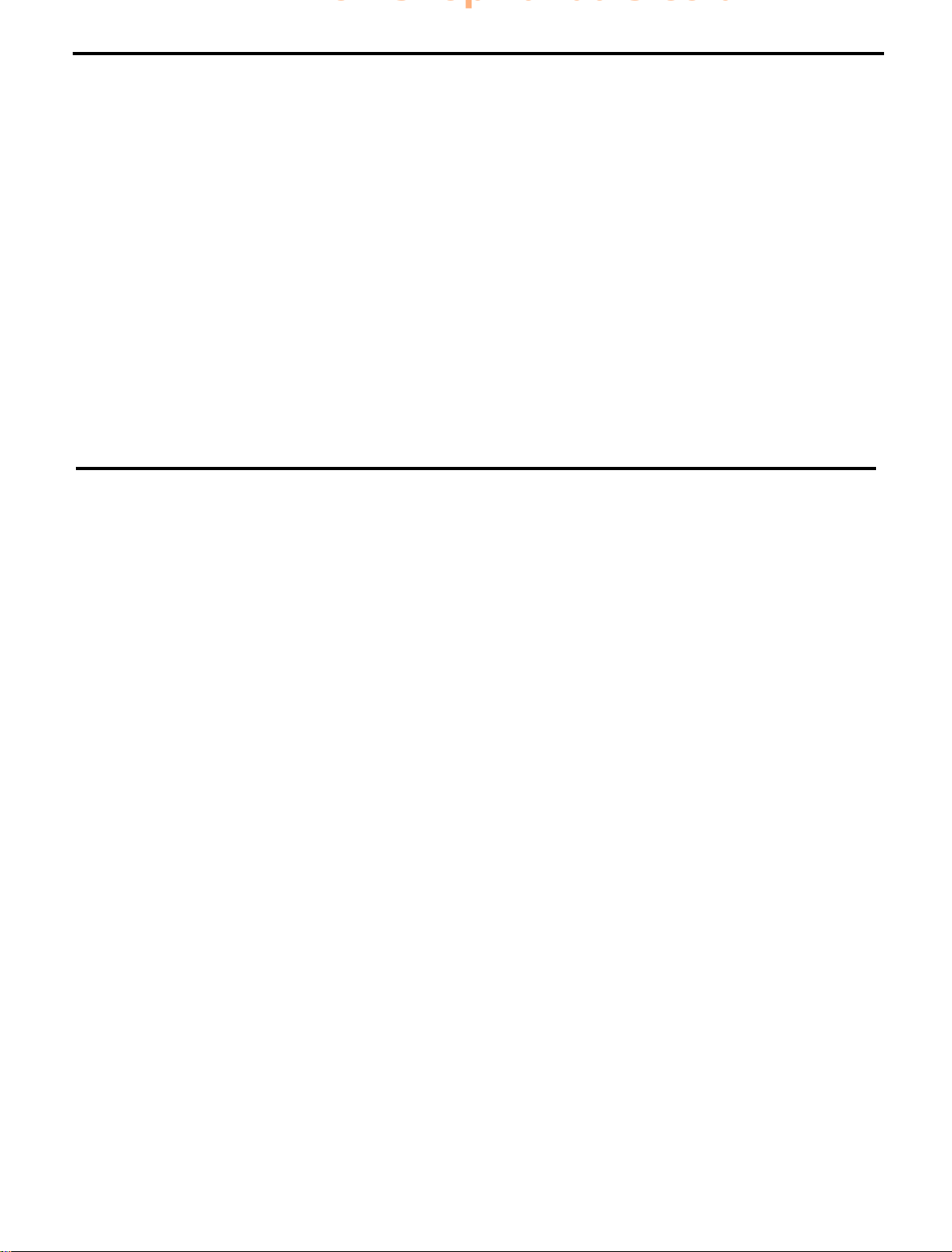

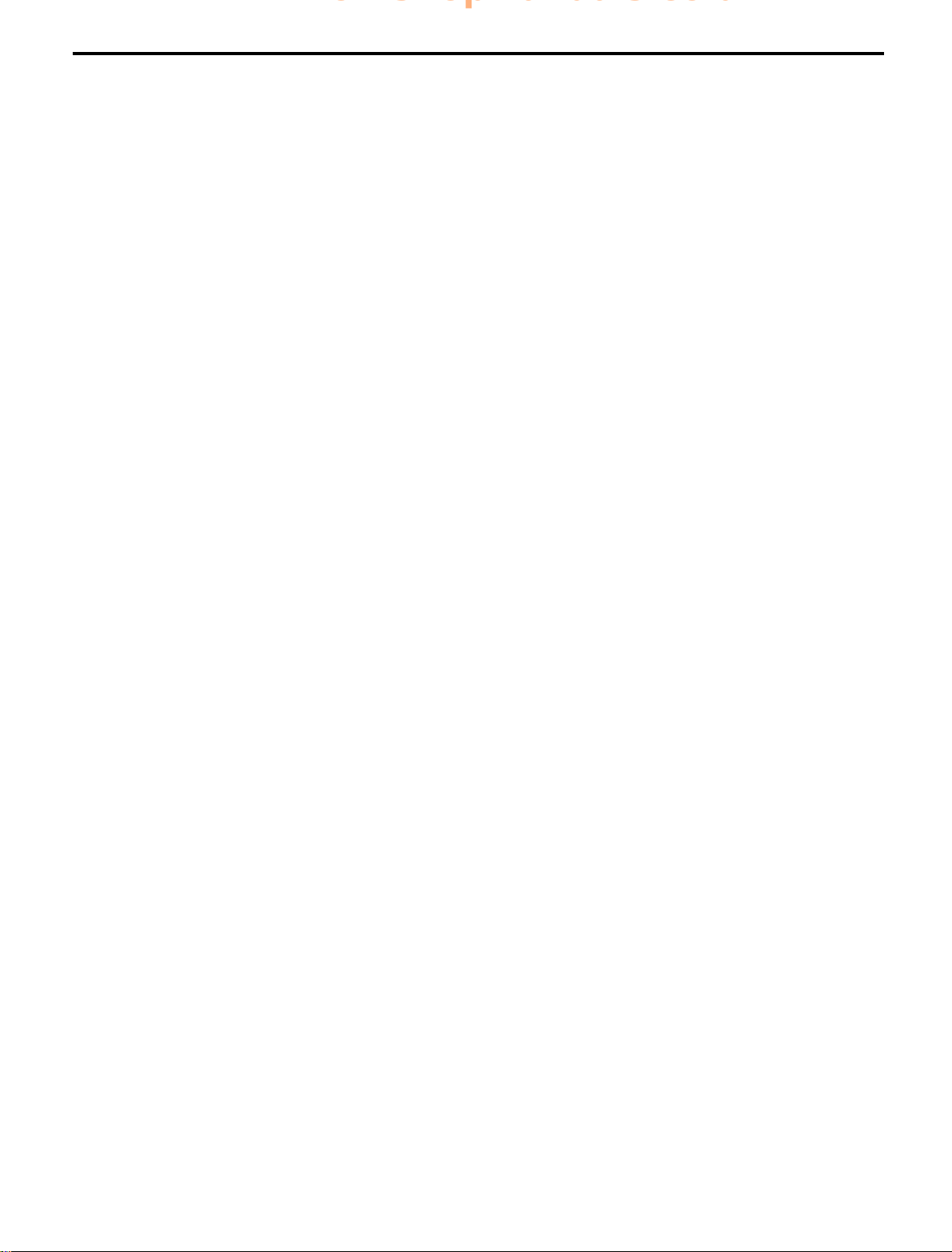

Keep all decals clean and readable. Replace lost or

damaged decals. The decals and their attachment points

are shown on the following pages. Each decal has a part

number printed on it, use this number to order a new

decal from your JCB distributor.

INT-3-3-6

!!

WARNING

Decals

You can be injured if you do not obey the decal safety

instructions. Keep decals clean. Replace unreadable or

missing decals with new ones before operating the

machine. Make sure replacement parts include warning

decals where necessary.

INT-1-3-4

!!

WARNING

If you need eye-glasses for reading, make sure you wear

them when reading the safety decals. Decals are

strategically placed around the machine to remind you of

possible hazards. Do not over-stretch or place yourself in

dangerous positions to read the decals.

INT-3-3-4

Note: See OPTIONAL ATTACHMENTS Section for

information regarding the decals fitted on attachments.

ROPS/FOPS WILL BE VOID

IF REMOVABLE ROOF IS

NOT IN POSITION AND

FITTED CORRECTLY

TRAVEL HEIGHT

A408070

AA

A=LOADCENTER

7 7

INTRODUCTION

DECALS

8642-1

S255350

Page 14

8 8

INTRODUCTION

DECALS

(continued)

8642 - 1

DIESEL

HYDRAULIC

2.4

BAR

2.4

BAR

NO

STEP

NO

STEP

ON

OFF

24V

INTER VEHICLE

START SOCKET

STOP

20 secs

STOP

20 secs

A408050

Page 15

Machine Identification Plate

Your machine has an identification plate mounted on the

loader tower. The serial numbers of the machine and its

major units are stamped on the plate.

The serial number of each major unit is also stamped on

the unit itself. If a major unit is replaced by a new one, the

serial number on the identification plate will be wrong.

Either stamp the new number of the unit on the

identification plate, or simply stamp out the old number.

This will prevent the wrong unit number being quoted

when replacement parts are ordered.

The machine and engine serial numbers can help identify

exactly the type of equipment you have.

Typical Vehicle

Identification Number (VIN)

SLP 4CX T S R E 0930001

AB

CC DD EE FF GG

A

World Manufacturer Identification

B

Machine Model

C

Steer Type (T= 2WS, F=4WS)

D

Build Type (S=Sideshift, C=Centremount, L=Loader)

E

Year of Manufacture:

1 = 2001

2 = 2002

3 = 2003

4 = 2004

5 = 2005

6 = 2006

7 = 2007

F

Manufacturer Location (E = England)

G

Machine Serial Number:

Typical Engine

Identification Number

AB 50262 U 500405 P

ABCDE

A Engine Type

AB = 4 cylinder turbo

B Build Number

C Country of Origin

D Engine Sequence Number

E Year of Manufacture

9 9

INTRODUCTION

IDENTIFYING YOUR MACHINE

8642-1

A276550

Page 16

10 10

INTRODUCTION

IDENTIFYING YOUR MACHINE

8642-1

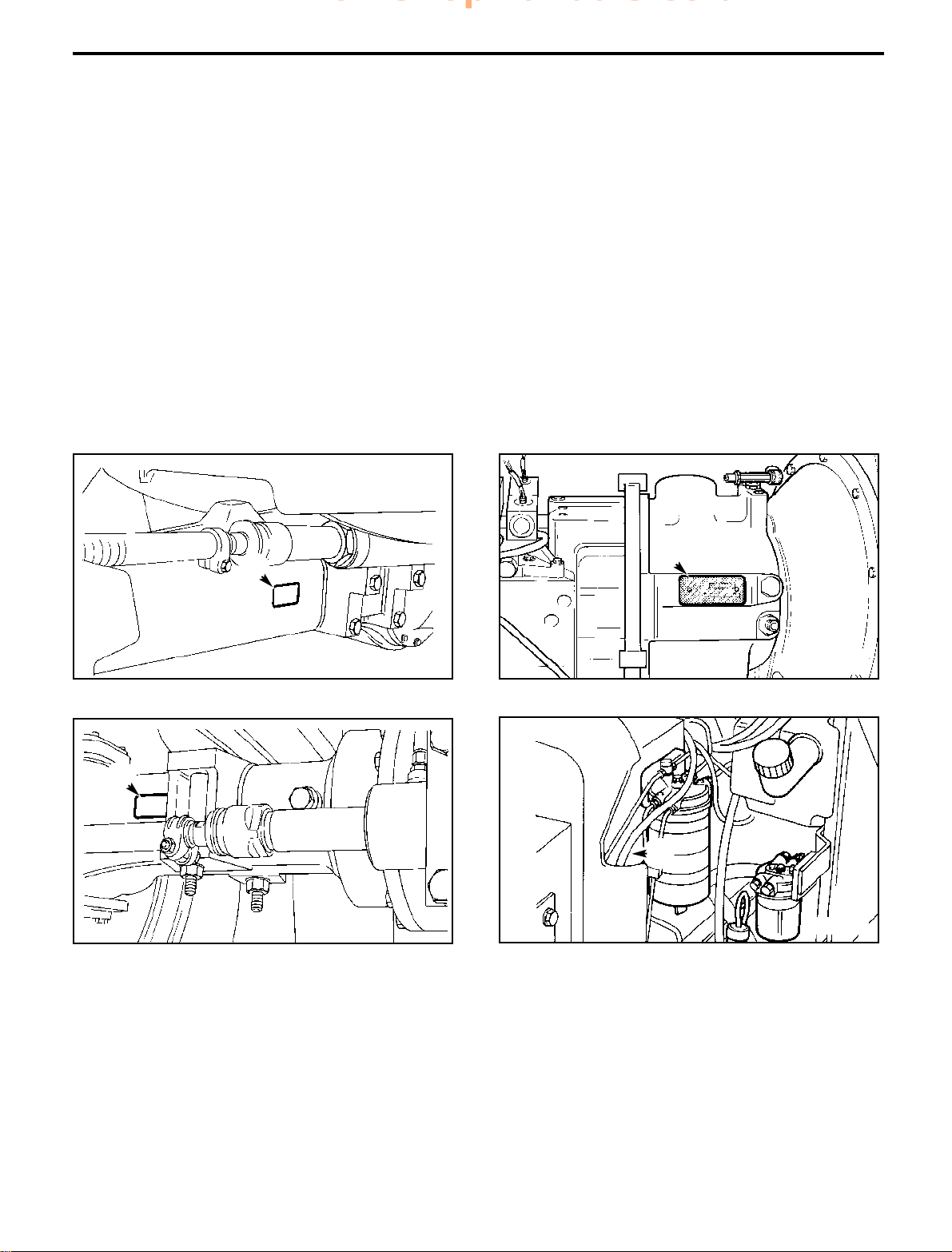

Serial Plates

A Front Axle (4WS machine)

B Rear Axle (4WS machine)

C Powershift Transmission

D Engine

CC

DD

S146790

S260120

AA

S259100

S259110

BB

Page 17

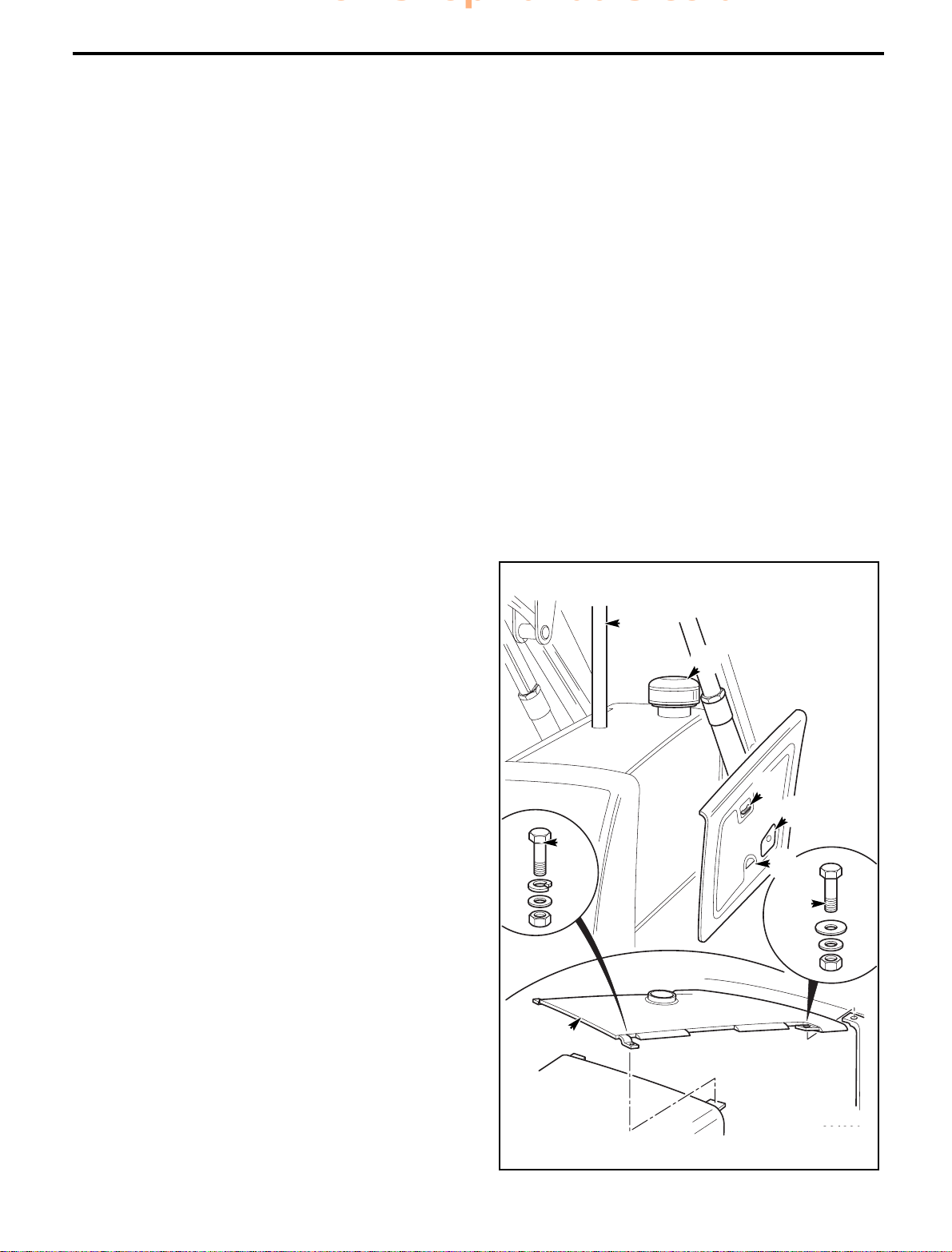

BEFORE ENTERING THE CAB

INTRODUCTION

11 11

OPERATION

8642 - 1

The aim of this part of the handbook is to guide the

operator step-by-step through the task of learning how to

operate the machine efficiently and safely. Read the

OPERATION section through from beginning to end.

Before starting the machine, sit in the drivers seat and

familiarise yourself with the layout of the cab. Use your

handbook to identify each control lever, switch, gauge,

button and pedal. Do not guess. If there is anything you

do not understand, ask your JCB distributor.

The operator must always be aware of events happening

outside the cab as well as inside the cab. Safety must

always be the most important feature when operating the

JCB Backhoe Loader.

The following checks should be made each time you

return to the machine after leaving it for any period of time.

We advise you also to stop the machine occasionally

during long work sessions and do the checks again.

All these checks concern the serviceability of the machine.

Some concern your safety. Get your service engineer to

check and correct any defects.

! WARNING

Walking or working under raised attachments can be

hazardous. You could be crushed by the attachments

or get caught in the linkages.

Lower the attachments to the ground before doing

these checks. If you are new to this machine, get an

experienced operator to lower them for you.

If there is nobody to help you, study this handbook

until you have learned how to lower the attachments.

Also make sure that the parking brake is engaged

before doing these checks.

2-2-1-1

1 Check for Cleanliness

a Clean the windows, light lenses and rear view

mirrors.

b Remove dirt and debris, especially from around

the linkages, rams, pivot points and radiator.

c Make sure the cab step and handholds are clean

and dry.

d Clean all safety decals. Replace any that are

missing or cannot be read.

When you have familiarised yourself with the operating

controls, gauges and switches, practice using them. Drive

the machine in an open space, clear of people. Get to

know the 'feel' of the machine and its driving controls.

Finally, do not rush the job of learning, make sure you fully

understand everything in the OPERATION section. Take

your time and work efficiently and safely.

Remember

BE CAREFUL

BE ALERT

BE SAFE

2 Check for Damage

a Inspect the machine generally for damaged and

missing parts.

b Make sure that the bucket is secure and in good

condition

c Make sure that all pivot pins are secured correctly

in place.

d Inspect the windows for cracks and damage.

Glass splinters can blind.

e Check for oil, fuel and coolant leakages

underneath the machine.

! WARNING

You could be killed or injured if a machine tyre bursts.

Do not use the machine with damaged, incorrectly

inflated or excessively worn tyres.

2-2-1-2

3 Check the Tyres

a Make sure the tyres are correctly inflated.

b Check for cut rubber and penetration by sharp

objects. Do not use a machine with damaged

tyres.

4 Check the Engine Panels, Bonnet and Fuel Cap

a Make sure the engine panels and bonnet catches

are secure.

b Make sure the fuel filler cap is tightly closed and

locked.

Page 18

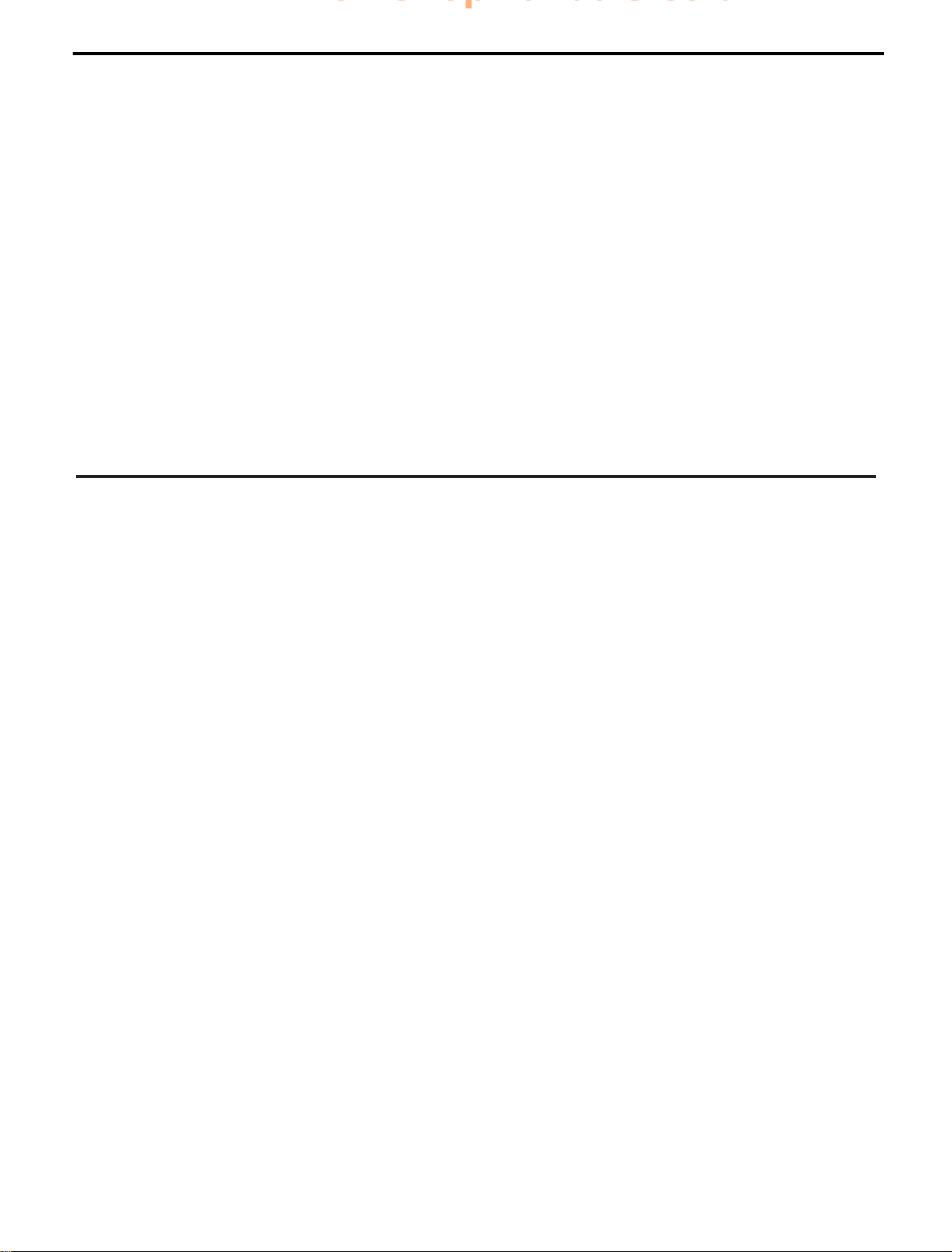

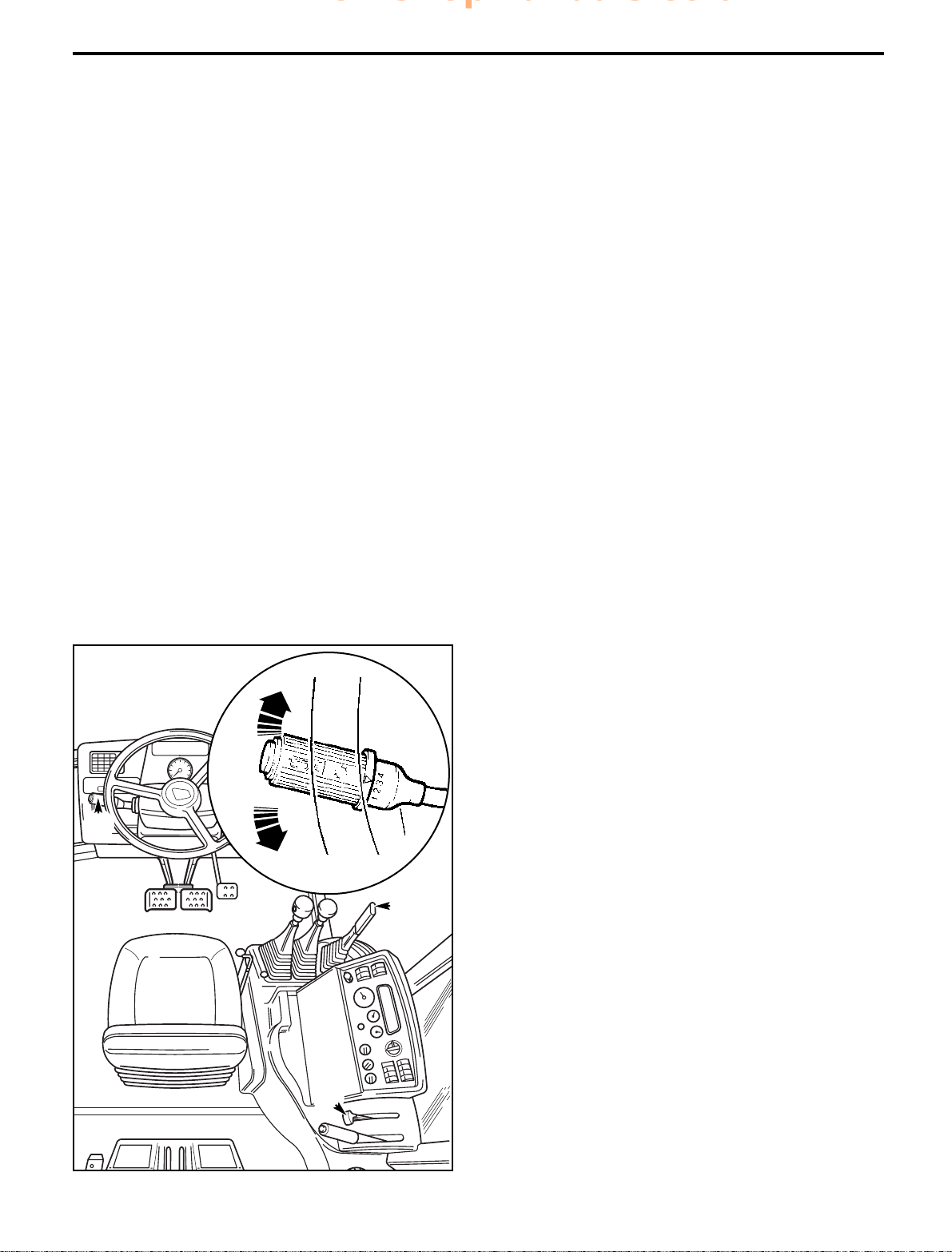

Control Lever Locks

To prevent the loader arms and the backhoe from being

accidentally operated when the driver is entering or

leaving the cab, or driving on the highway, safety locking

pins B can be installed.

Always fit the locking pin before leaving the cab. Only

remove the locking pin when you are correctly seated

inside the cab. Put the pins in their stowage position

during machine operation. This will prevent the pin from

being misplaced.

12 12

OPERATION

ENTERING AND LEAVING THE CAB

8642 - 1

Entering & Leaving the Cab

! WARNING

Entering or leaving the cab or canopy must only be

made where steps and handrails are provided. Always

face the machine when entering and leaving. Make

sure the step(s), handrails and your boot soles are

clean and dry. Do not jump from the machine. Do not

use the machine controls as handholds, use the

handrails.

INT-2-1-7/1

Make sure the machine is stopped and correctly parked

before entering or leaving the cab. When you get on and

off the machine always maintain a three point contact with

the handrails and step as shown at A. Do not use the

machine controls or steering wheel as handholds.

380930

A

A380930

S247091

B

B

Page 19

A

B

D

390160

13 13

OPERATION

DOORS AND WINDOWS

8642 - 1

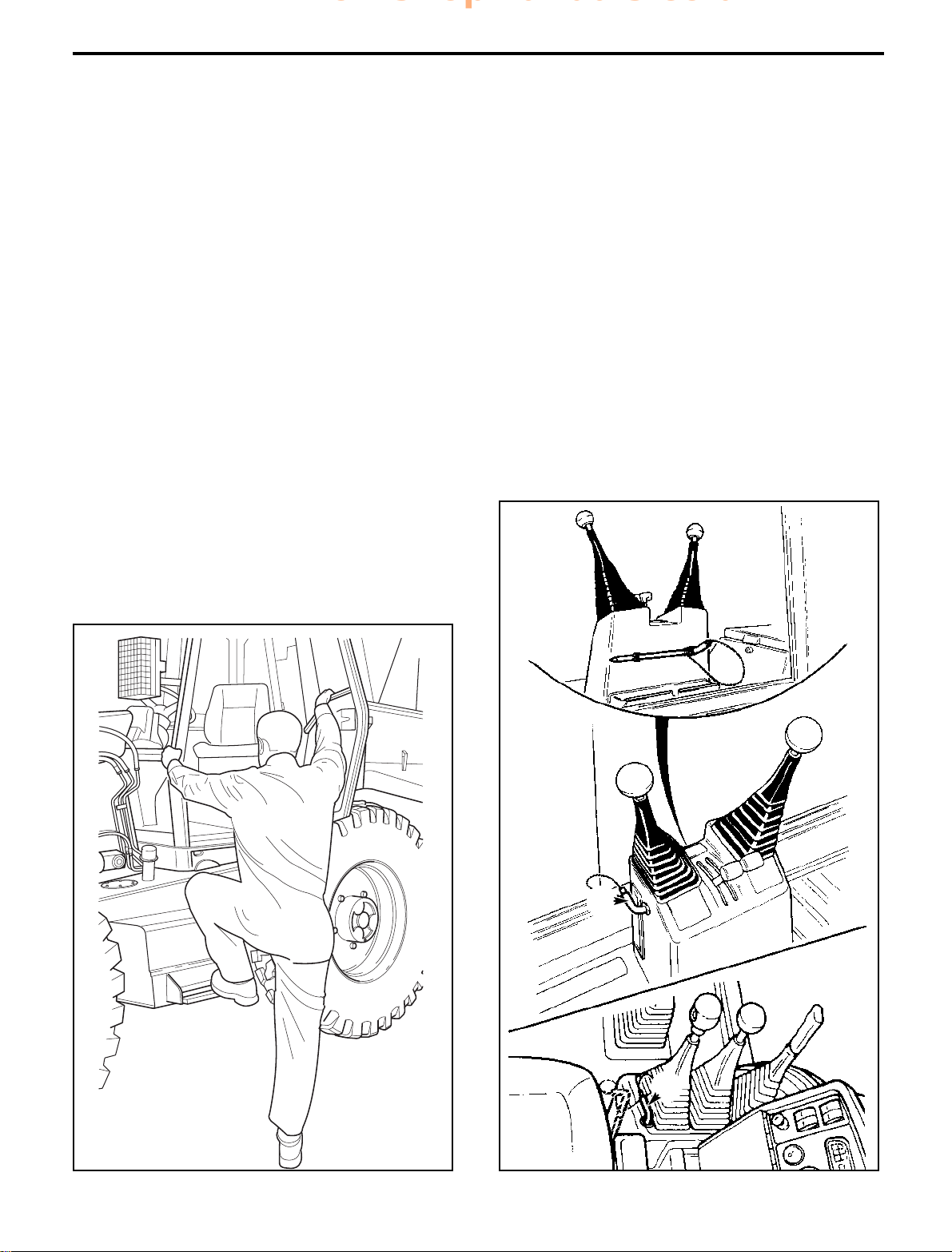

Opening and Closing the Doors

To open a door from the outside, unlock it with the key

provided and press the lock barrel. The door is fitted with

an assister which will spring it open and hold it open.

Close the door from the inside by pulling it firmly; it will

latch itself. To open the door from the inside, operate lever

A.

If extension rod B is fitted, the door can be latched partly

open; swing extension rod B towards the door and hold it

there while you pull the door onto it. Make sure the door

latches fully onto the extension rod.

Note: Do not drive the machine with the doors unlatched.

Otherwise they could swing open.

Opening and Closing the Rear Window

To open the rear window, press locking levers A. Lower

the window to the required position, release locking levers

to lock in required position.

To close the rear window, press locking levers A. Raise

the window, release locking levers to lock.

380940

A380940

AA

AA

Page 20

14 14

OPERATION

SEAT CONTROLS

The operator's seat can be adjusted for your comfort. A

correctly adjusted seat will reduce operator fatigue.

Position the seat so that you can comfortably reach the

machine controls. For driving the machine, adjust the seat

so that you can depress the brake pedals fully with your

back against the seat back. The Operator's Handbook and

Parts Book are located in the pouch X at the rear of the

seat.

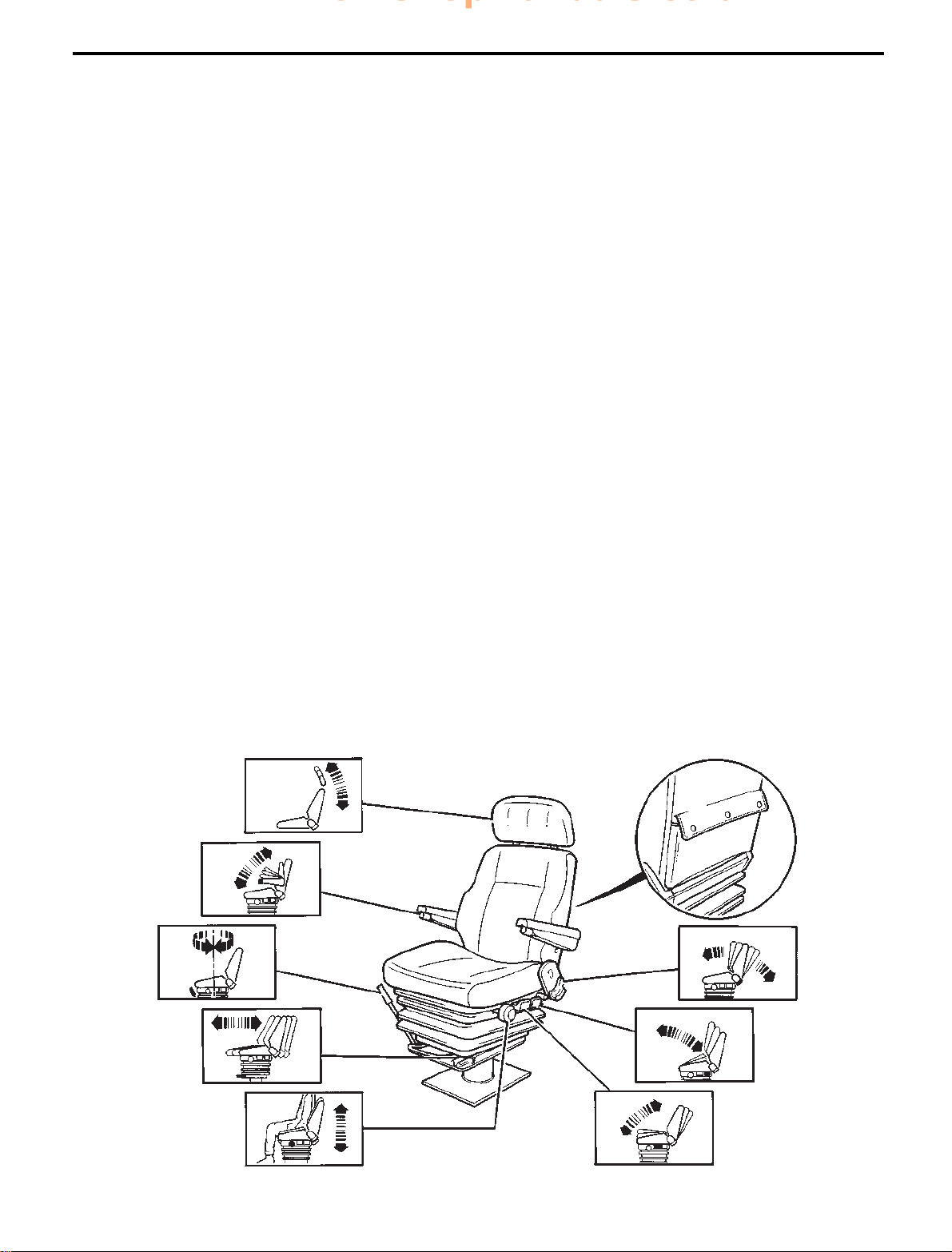

Headrest A(optional)

The headrest can be adjusted to suit, take hold of the rest

and lift or lower as required.

Armrest B(optional)

The angle of the armrest can be adjusted, rotate the

control knob clockwise to rise the armrest and anticlockwise to lower the armrest.

Swivel

C

Important Note: Before swiveling the seat, move the seat

fully forward, see Fore/Aft below. The side console can be

damaged if the seat is not fully forward.

To swivel lift the lever, swivel the seat all the way around

to face the opposite direction then release lever. Make

sure the seat fully latches into position.

Fore/Aft

D

To move the seat fore and aft, lift the bar and slide the

seat to the position you want, release the bar to lock the

seat. Make sure the seat is locked in position.

! WARNING

Whilst seated, adjust the dial on the left of the seat

until your weight in kgs appears in the red shaded

area. Failure to set the weight adjustment dial will

reduce the beneficial isolation effect of the seat

suspension and may result in personal discomfort or

injury.

2-2-1-12

Weight

E

Whilst seated, turn the weight adjustment dial until your

weight is shown in the red shaded area of the dial. This

will set the seat to the most suitable support for your

weight. The dial is calibrated in kilograms (kg).

Backrest Angle

F

Press your back firmly against the backrest. Lift the

control lever and position the backrest as required. When

the backrest is in position release the control lever. Make

sure the backrest has locked in position.

Height and Slope G(rear)

To raise or lower the rear of the seat lift the control lever.

Allow the seat to move into position and then release the

lever. Make sure the seat has locked in position.

Height and Slope H(front)

To raise or lower the front of the seat lift the control lever.

Allow the seat to move into position and then release the

lever. Make sure the seat has locked in position.

8642 - 1

S214190

A

X

F

G

H

B

C

E

D

Page 21

15 15

OPERATION

SEAT BELT

8642 - 1

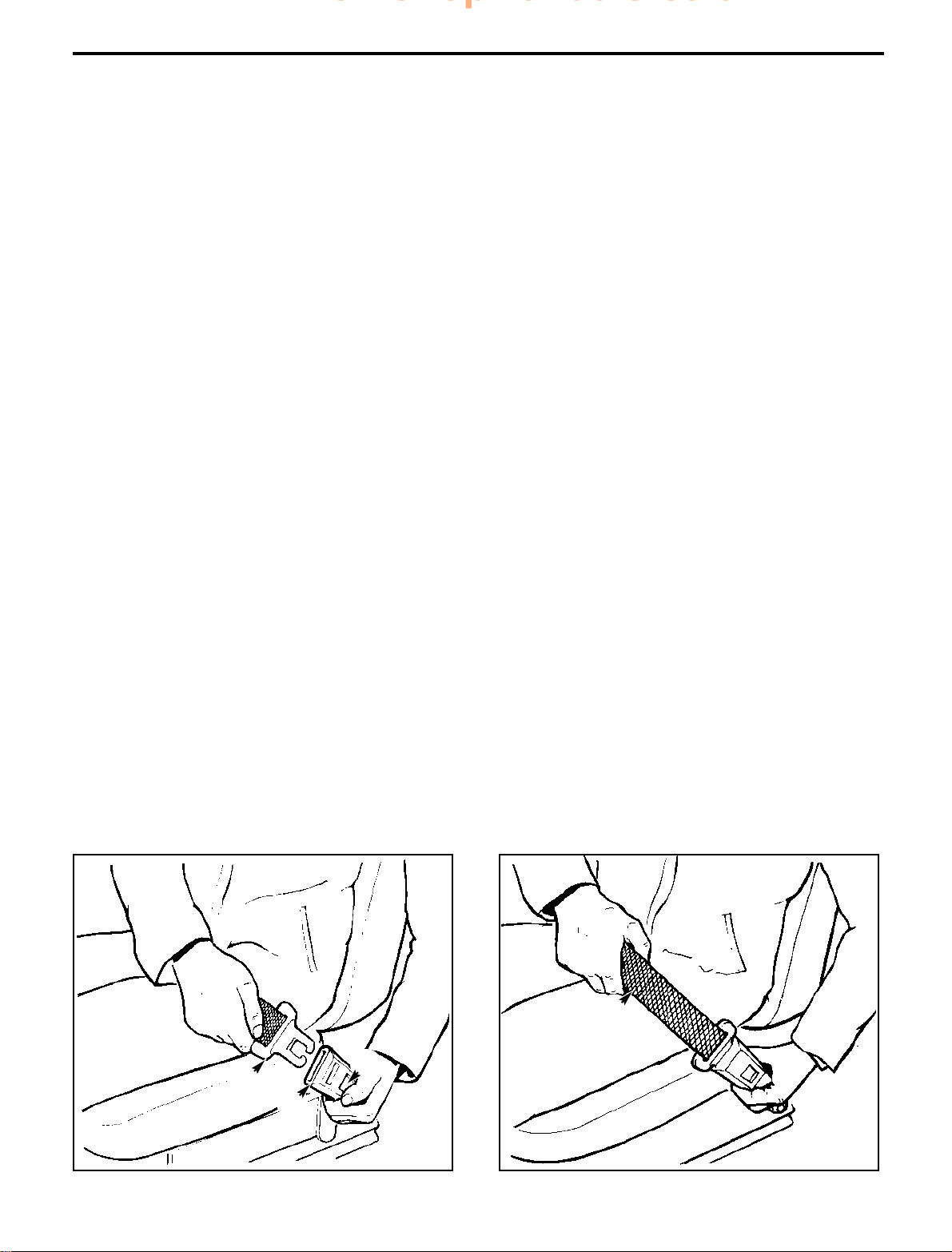

Check the Seat Belt Is Operating

Correctly

1 Sit correctly in the seat and fasten the seat belt as

described.

2 Hold the middle of the seat belt as shown at D and

tug. The seat belt should 'lock'.

!WARNING

If the seat belt does not 'lock' when you check if the

seat belt is operating correctly, do not drive the

machine. Get the seat belt repaired or replaced

immediately.

2-2-2-1

Release the Seat Belt

1 Press button C and pull the male fitting A from the

buckle.

2 Let the seat belt retract into its reel holder.

!WARNING

The ROPS cab is designed to give you protection in an

accident. If you do not wear your seat belt you could

be thrown about inside the cab, or thrown out of the

machine and crushed. You must wear a seat belt when

using the machine. Fasten the seat belt before starting

the engine.

2-2-1-9

!WARNING

Do not use a seat belt which is damaged or

excessively worn.

Do not use a seat belt that has been in an accident.

A worn, damaged or already stressed seat belt could

break or give way in a collision. If that happens you

could be killed or injured.

2-2-3-8

Fasten the Seat Belt

1 Sit correctly in the seat. Pull the belt from its reel

holder in one continuous movement.

2 Push the male fitting A into the buckle B until it latches

into position. Make sure the seat belt is not twisted

and that it is over your hips not your stomach.

Note: If the belt 'locks' before the male fitting A has been

engaged, allow the belt to fully retract in its reel holder and

then try again. The inertia mechanism may lock if you pull

the belt too sharply or if the machine is parked on an

incline. In such cases, ease the belt gently from its reel

holder.

S187810

S187820

A

B

C

D

Page 22

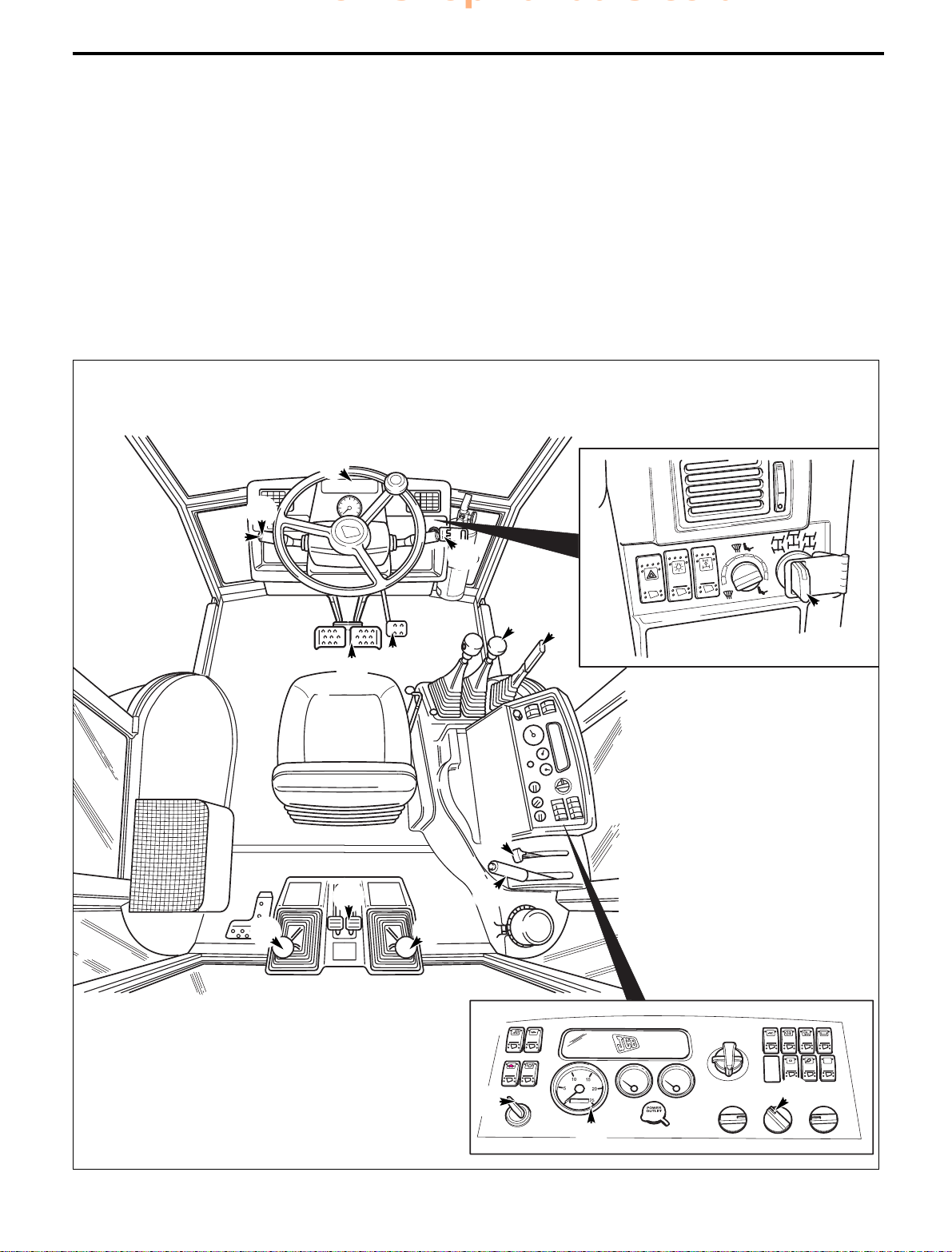

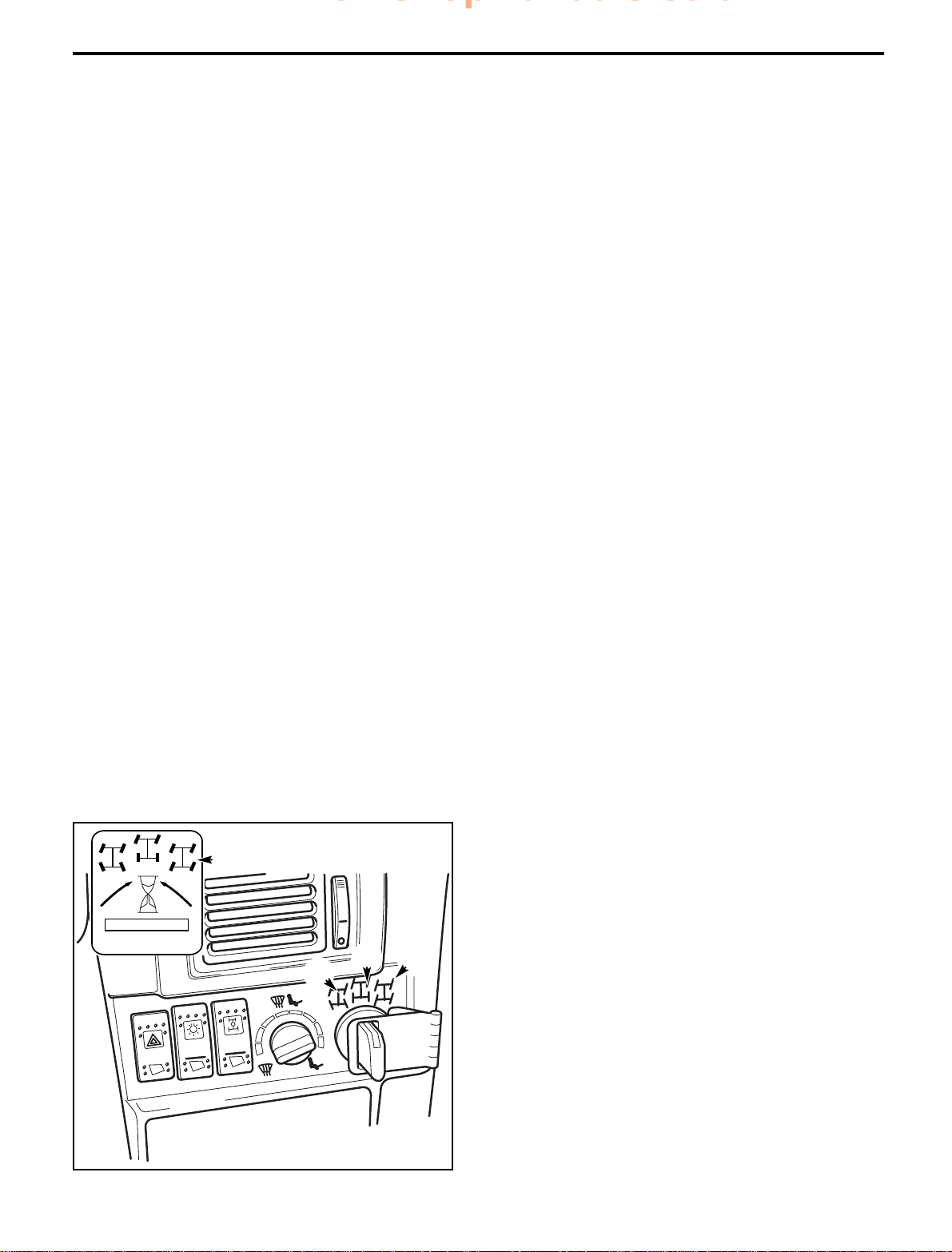

1 Gear select switch

2 Forward/reverse lever & horn

3 Front instrument panel

4 Front console switches

5 Multi-purpose steering column switch

6 Accelerator pedal

7 Brake pedals and locking bar

8 Loader controls

9 Parking brake lever

10 Side console switches

11 Starter switch

12 Side console gauges

13 Heater controls

14 Hand throttle lever

15 Remote boom lock

16 Stabiliser controls

17 Backhoe controls

18 Steer mode select switch

16 16

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

8642 - 1

6

7

A380900

5

1

8

9

&

£

^^

22

33

44

00

!!

@

%%

$$

&&

**

Page 23

17 17

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

Controls

1 Accelerator Pedal

Push this pedal down to increase engine speed. Let

the pedal up to reduce engine speed. With your foot

off the pedal the engine will idle.

! WARNING

When driving the machine, use only the accelerator

pedal to control the engine speed. Do not use the hand

throttle lever to set the engine speed while driving.

2-2-2-2

2 Brake Pedal

Push down on the brake pedal to slow or stop the

machine. Use the brakes to prevent overspeeding

down a slope. The stop lights should come on when

the brakes are applied. Do not drive the machine

unless both stop lights work correctly.

There are two brake pedals. The left rear brake is

operated by the left pedal. The right rear brake is

operated by the right pedal. The pedals can be

locked together by a steel locking bar.

! WARNING

You and others can be killed or injured if the brake

pedal locking bar is not engaged as recommended. If

only one brake is applied for a quick stop, the machine

could swerve out of control.

2-2-2-3

Separate the pedals only when driving in first gear (1)

off the road. Lock the pedals together when driving in

any other gear off the road. Lock the pedals together

when driving on the road in any gear.

3 Gear Select Switch

! WARNING

Do not change from a high gear to a low gear (for

instance, 4th to 1st) in one sudden movement whilst

the machine is moving. Otherwise the machine will

rapidly decelerate, you or others could be killed or

seriously injured. When selecting lower gears, allow

the engine speed to drop before each gear change.

2-1-1-9/1

When moving or stationary, to select a gear, rotate

the barrel so that the arrow marked on the barrel

aligns with the required gear.

When selecting lower gears, allow the engine speed

to drop before each gear change. Take notice of the

warning above, do not change from a high gear to a

low gear in one sudden movement whilst the

machine is moving. Otherwise the machine will

rapidly decelerate.

8642 - 1

1

2

A380900

33

Page 24

18 18

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

Controls (cont’d)

4 Forward/Reverse Lever & Horn

! WARNING

You and others can be killed or injured if you operate

the forward/reverse lever while travelling. The machine

will immediately reverse direction without warning to

others. Follow the recommended procedure for proper

use of this selector.

2-2-2-4

Stop the machine before moving this lever. To select

forward, reverse or neutral, 'lift' and move the lever to

the required position. All four gears are available in

both forward and reverse. The engine will only start if

the lever is at neutral.

To reverse direction:

a Stop the machine: keep the foot brakes applied.

b Let the engine speed drop to idle.

c Select the new direction.

d Release the foot brakes and accelerate away.

Press the button on the end of the lever to operate

the horn. Functions only with the starter switch at

position I.

5 Hand Throttle Lever

Move this lever to increase or decrease the engine

speed. Pushing the accelerator pedal fully down will

return the hand throttle to its idle position.

6 Parking Brake Lever

Use this lever to engage the parking brake before

leaving the machine.

Note also that the transmission drive is automatically

disconnected when the parking brake is engaged.

! CAUTION

The parking brake must not be used to slow the

machine from travelling speed, except in an

emergency, otherwise the efficiency of the brake will

be reduced. Whenever the parking brake has been

used in an emergency, always renew the brake pads.

4-2-1-1/1

To engage the parking brake, pull the lever up

(vertical). Check that the indicator light comes on.

To release the parking brake, lower the lever as far as

it will go (horizontal). Check that the indicator light

goes out.

8642 - 1

4

55

44

66

Page 25

Front Console Switches

Each switch has an insert with a graphic symbol, this

symbol and the switch descriptions are detailed below.

Side Lights and Headlights

Press once to switch on the side lights. Press

again to switch on the headlights.

Hazard Warning Lights

Press to switch on the hazard warning lights.

A light on the instrument panel flashes with

the outside lights.

2/4 Wheel Drive Select Switch

Refer to 2/4 Wheel Drive Select Switch, this

section. Illuminates when 2 wheel drive is

selected.

19 19

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

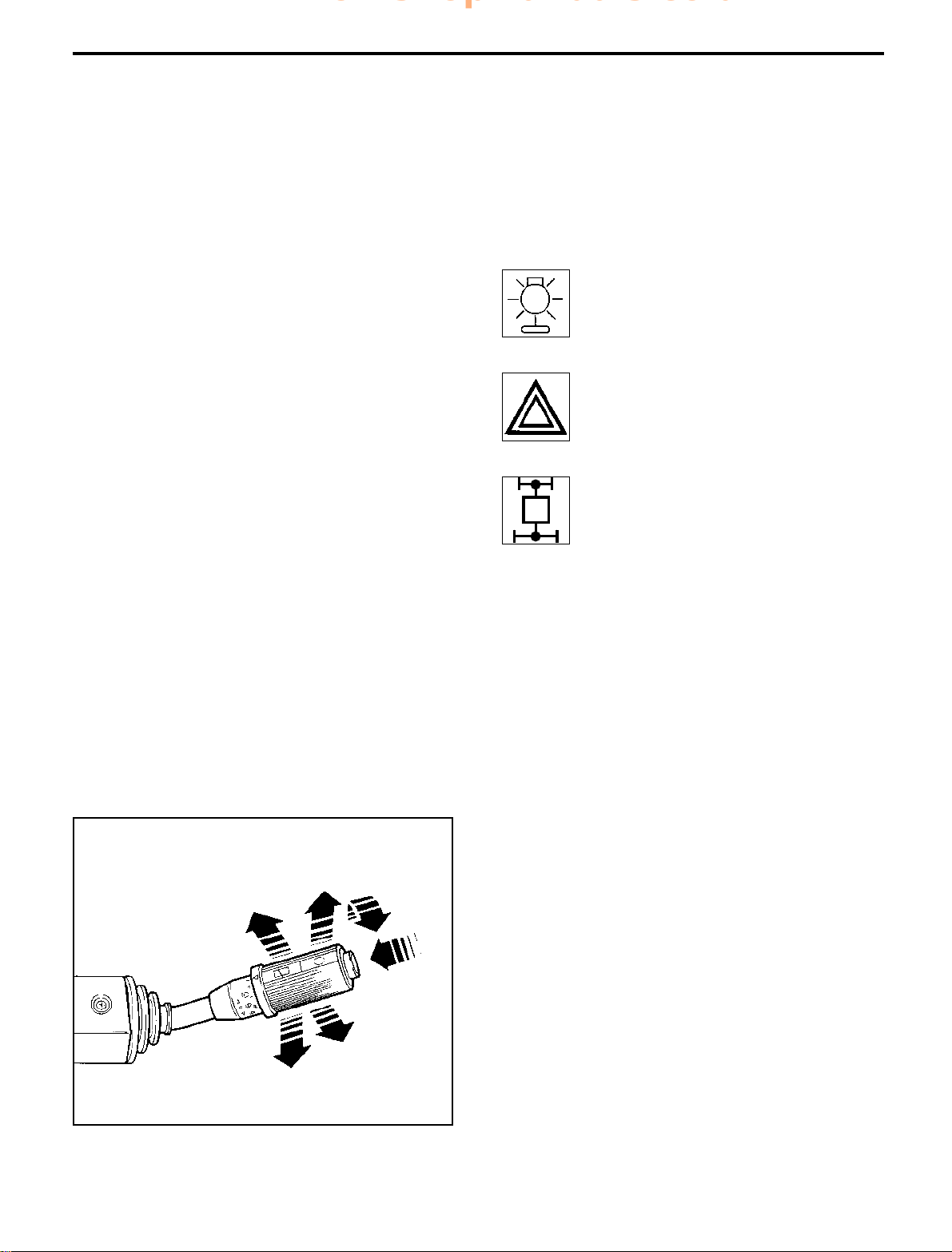

Multi-Purpose Steering Column Switch

1 Direction Indicators (Right)

Pull the lever towards you to indicate a right turn.

Switch the indicators off when you have completed

the turn. Functions only with the starter switch at

position I.

2 Direction Indicators (Left)

Push the lever away from you to indicate a left turn.

Switch the indicators off when you have completed

the turn. Functions only with the starter switch at

position I.

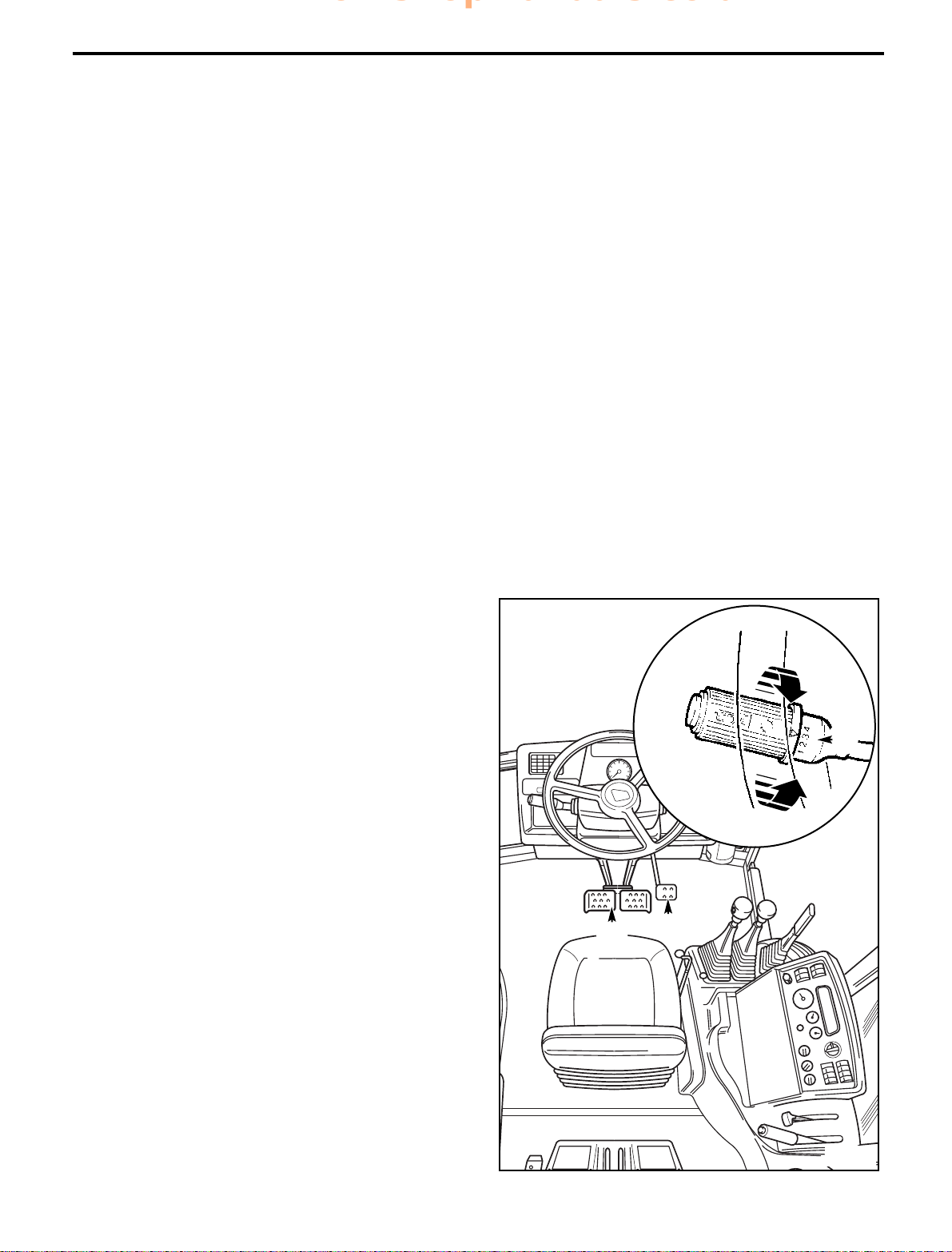

3 Windscreen Wiper

Rotate the lever barrel to switch the windscreen

wipers on and off. The following functions are

available (only with the starter switch turned on).

I On 0 Off

The wipers will self-park when switched off.

4 Windscreen Washer

Push the button towards the steering wheel to

operate the windscreen washer. Functions only with

the starter switch at position I.

5 Headlights Flash

Lift the lever to flash the headlights. Functions only

with the starter switch at position 1.

6 Headlight/Mainbeam

Push the lever down for high beam. Centre position is

dipped beam. Functions only with the side/head

lights on.

8640 - 1

1

5

4

6

2

3

240130

Page 26

20 20

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

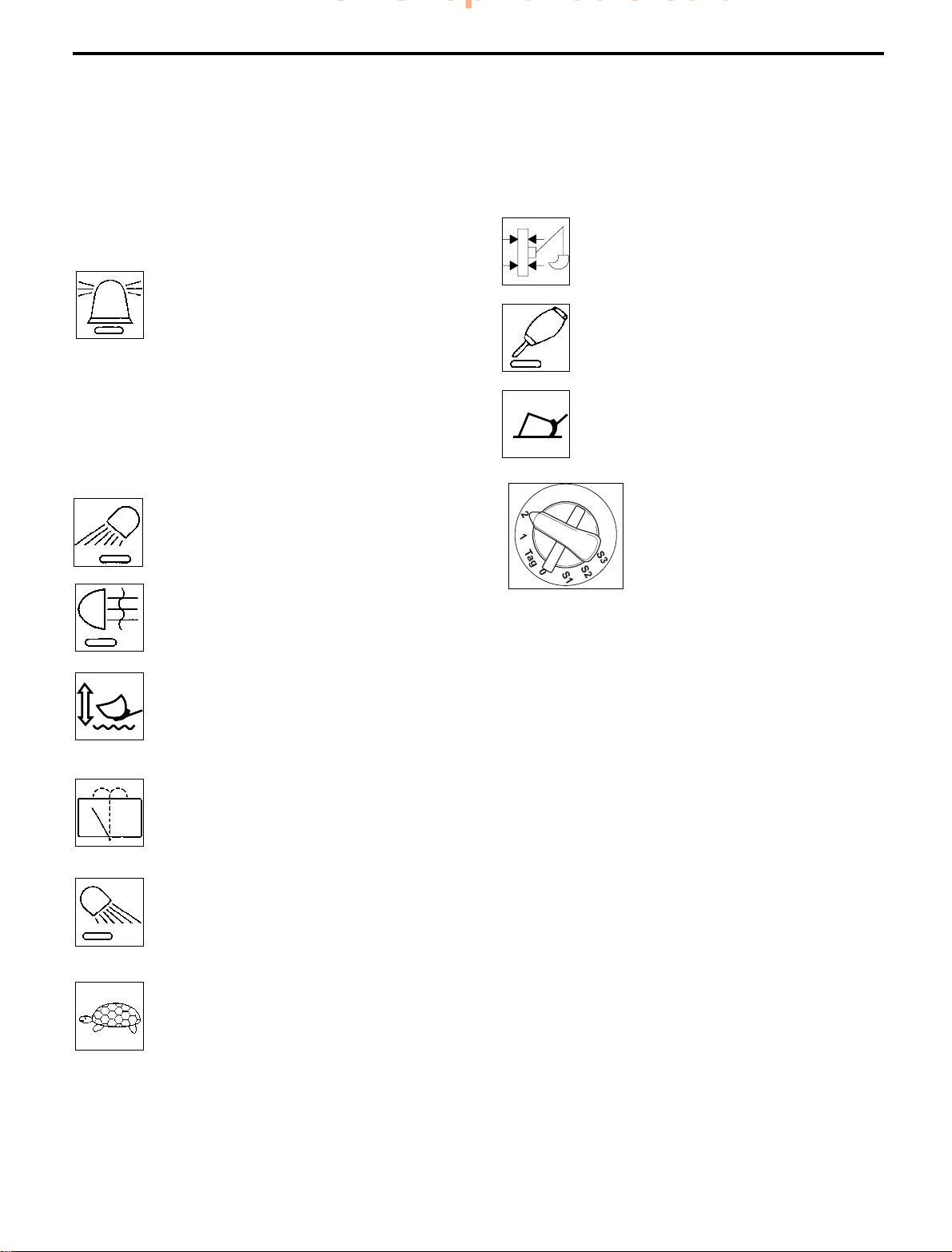

Side Console Switches

Each switch has an insert with a graphic symbol, this

symbol and the switch descriptions are detailed below.

Beacon

Press to switch on the flashing beacon.

Front Work Lights

! WARNING

Do not drive on the road with the work lights switched

on. You can dazzle other drivers and cause an

accident.

2-2-2-5

Press to switch on the front work lights. The

work lights will work independently of the

main lights circuit (see note).

Rear Fog Light

Press down to switch on high intensity fog

light. Functions only with side and headlights

on.

Smooth Ride System

Press down to switch on Smooth Ride

System. The switch is illuminated when ON.

Refer to Preparing The Machine For Travel,

this section.

Rear Window Wiper (if fitted)

Press to switch on the rear window wiper.

Press again to operate the washer (if fitted).

Note that the wiper will self-park when

switched off.

Rear Work Lights

Press down to switch on the rear work lights.

The work lights will work independently of the

main lights circuit.

Hydraulic Speed Control

Refer to Hydraulic Speed Control, this

section.

Hydraclamps

Refer to Sideshifting the Backhoe -

Powered, this section.

Auxiliary Circuit Enable Switch (if fitted)

Refer to Hydraulic Tool Circuit, OPTIONAL

ATTACHMENT section.

Return To Dig Enable Switch (if fitted)

Refer to Loader Controls, OPERATION

section.

Master Blackout Switch

The master black out switch is fitted

allowing illumination, including

reversing and stop lights and any

audible alarms, to be extinguished as

required. The switch will not deactivate the hour meter or warning

lights that indicate equipment failure.

Switch position

2 All functions normal.

1 As 2 but isolates headlights and fog lights.

TAG Only hazard, steer mode warning, direction

indicators and rear brake lights function.

0 Only engine warning lights function.

S1 Only engine warning lights and convoy lights

function.

S2 As S1 but with front side lights.

S3 As S2.

380950

8642 - 1

Page 27

21 21

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

2/4 Wheel Drive Select Switch

Press rocker switch A UP for 4-wheel drive, the light will

go OFF.

Note: With 2-wheel drive selected, when the brake pedal

is pressed, the machine will automatically go into 4-wheel

drive and the indicator light on the switch will come on.

Cab Interior Light

Plug the interior light into the 24 volt auxiliary socket C

and press rocker switch D on the side of the light to

switch ON/OFF.

Starter Switch

This is operated by the starter key B. It has four positions.

The key can be removed only with the switch set to 'O'.

00 Off/Stop Engine

Turn the key to this position to stop the engine. Make

sure the transmission is in neutral, the attachments

have been lowered and the parking brake is engaged

before stopping the engine.

II 'IGN' On

Putting the switch to this position connects the

battery to all the electrical circuits except the lights

and the 4-way flashers warning circuit. (The lights

and hazard warning circuits are permanently live.)

The starter key will spring back to this position when

it is released from II or III.

IIII Heat Position

Holding the key in the heat position warms the engine

induction manifold for cold weather starting. Do not

hold in this position for more than 15 seconds.

IIIIII Start Position

Operates the starter motor to turn the engine.

Note: Do not operate the starter motor for more than 20

seconds at one time. Let the starter motor cool for at least

two minutes between starts.

8642 - 1

B

A380900

A259220

0

I

II

III

389093

AA

C

DD

Page 28

22 22

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

Steer Mode Selector Switch

This is a three-position rotary switch, equipped with a

hinged lockplate. The lockplate enables the selector

switch to be locked into the 2-wheel steer mode, when the

machine is driven on public roads.

Indicator lights on the instrument panel tell you what steer

mode the machine is in. If you have any doubt about the

steer mode the machine is in, always remember that it is

the indicator light which is correct.

Never change steer mode on the move, the machine

should be stationary. Only change the steer mode when

the engine is at low engine rpm/idling. Never change from

4 wheel steer to crab steer (or vice versa) without first

selecting 2 wheel steer for approximately 5 seconds (as

shown by the decal A).

1 2-Wheel Steer

The front wheels only are controlled by the steering

wheel. This position must be used for driving on

public roads. Make sure the hinged lockplate is

engaged.

2 4-Wheel Steer

The front wheels steer one way and the rear wheels

steer in the opposite direction. This position provides

the tightest turning circle.

3 Crab Steer

The front and rear wheels steer in the same direction.

This position improves manoeuverability in confined

spaces.

Re-phasing the Steer System

4 Wheel Steer Machines Only

! WARNING

Failure to phase 4-wheel steer at least once per day

may mean a reduction in steering effectiveness.

5-2-1-6

The steering must be re-phased:

i At the start of each working period

ii At least once per day.

ii If having difficulty in steering.

Follow the procedures below for re-phasing the steer

system:

1 Select 2-wheel steer.

Sensors on the axles prevent the steer mode from

changing until the wheels straighten up or pass

through the 'straight ahead' position. Because of this,

there will be a short period when the indicator lights

do not agree with the switch position.

2 Operate the machine until the rear wheels

straighten up.

When the rear wheels straighten up the machine will

go into 2-wheel steer. The indicator light will show

when 2-wheel steer has engaged.

3 Select 4-wheel steer again

The front and rear wheels are now back in phase.

8642 - 1

389093

11

33

22

A

00 : 00 : 05

817/04091

Page 29

Side Console

1 Tachometer

Indicates the engine speed in revolutions per minute

(RPM). A green band on the scale indicates the RPM

which gives best fuel economy. Operate within that

band whenever possible.

2 Hourmeter

Records the total running time of the engine. Use it to

keep a check of running hours during maintenance

intervals.

3 Fuel Gauge

Indicates the level of diesel fuel in the tank. Do not let

the tank run dry, or air will enter the fuel system.

4 Coolant Temperature Gauge

Indicates the temperature of the engine coolant. The

gauge pointer will gradually swing upwards as the

coolant temperature rises.

Note: The 2 wheel steer, 4 wheel steer and crab steer

indicator lights are provided with a night combat shade as

shown at X. When the shade is lowered, the indicator

lights are visible through the small pin-holes Y.

A407840

23 23

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

Instruments

All instruments power down when the starter switch is set

to O, apart from the hazard warning lights indicator.

Front Console

The driving indicators and gauges are located at the side

of the driver's seat.

On the front console A the master warning light B will

illuminate when any of the following warning lights on the

side console are illuminated:

Air Filter Blocked; Water Temperature; Transmission Oil

Temperature; Engine Oil Pressure; Parking Brake

Engaged; Transmission Oil Pressure.

1 Speedometer

Indicates the road speed, the outer ring is MPH and

the inner ring is kph.

Note: The 2 wheel steer indicator light is provided with a

night combat shade as shown at C. When the shade is

lowered, the indicator light is visible through the small pinhole D.

8642 - 1

A407840

10 20 30

40

A407850

A407850

A

22

11

33

44

BB

11

X

D

C

Y

Page 30

24 24

OPERATION

ENGINE AND DRIVE CONTROLS, SWITCHES AND INSTRUMENTS

(continued)

Instruments (cont'd)

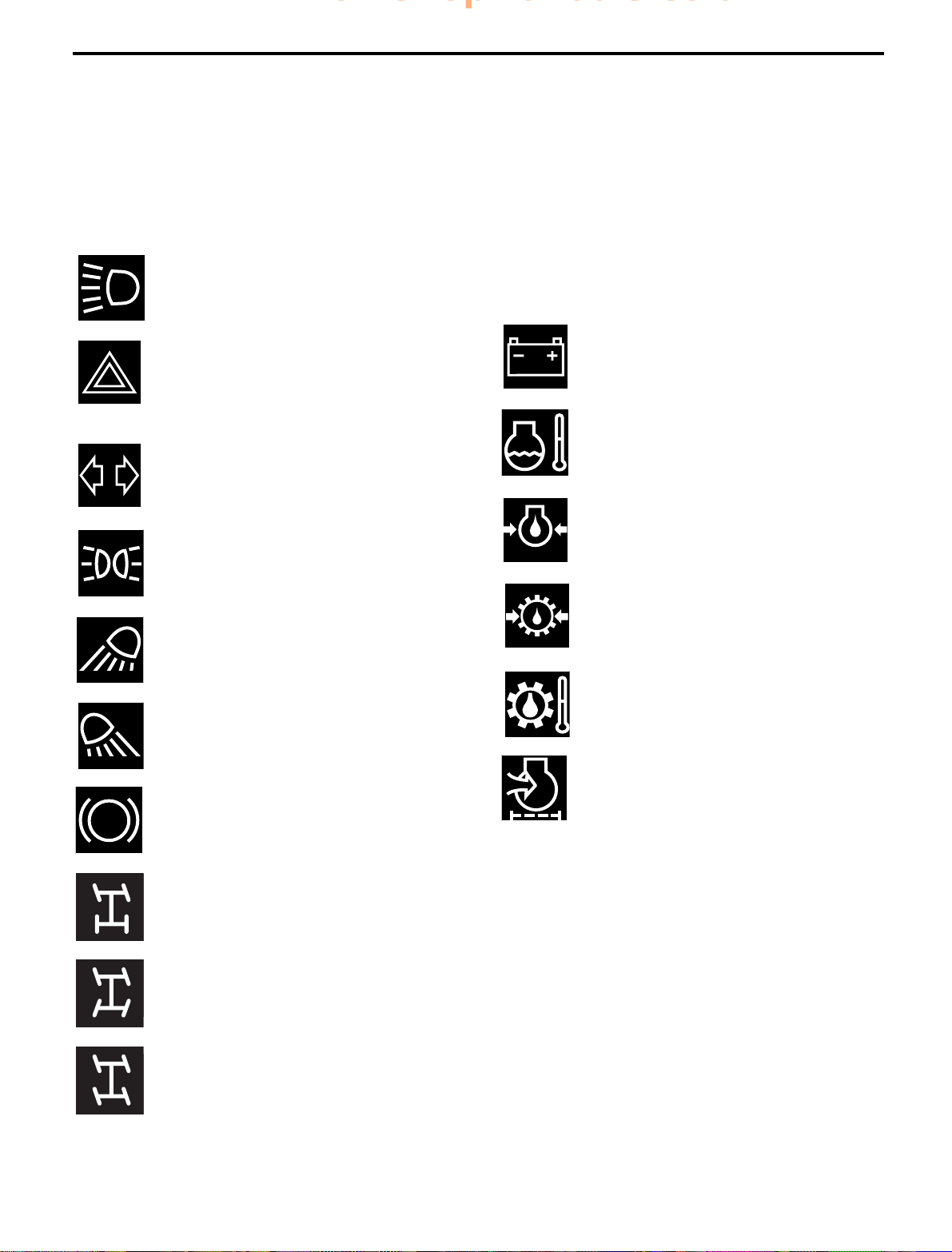

Warning Lights

Main Beam On

Lights up when the headlight main beams are

switched on. Switch the main beams off for

on-coming vehicles.

Hazard Warning

Flashes with the hazard warning lights (even

with the starter switch at O). Switch the

flashers on whenever your machine is a

possible hazard.

Direction Indicators

Flashes with the direction indicators. Use the

indicators to signal before turning the

machine.

Sidelights

Lights up when the sidelights are switched on.

Front Work Lights

Lights up when the front work lights are

switched on.

Rear Work Lights

Lights up when the rear work lights are

switched on.

Parking Brake Engaged

Lights when the parking brake is engaged

with the machine in forward or reverse.

2 Wheel Steer Engaged

Lights up when 2 wheel steer is selected.

4 Wheel Steer Engaged

Lights up when 4 wheel steer is selected.

Crab Steer Engaged

Lights up when crab steer is selected.

Warning Lights with Audible Alarm

Note: If any of the following lights come on while the

engine is running, stop the engine as soon as it is safe to

do so. Do not use the machine until the fault is put right.

No Charge

Lights if the battery charging circuit fails while

the engine is running. The light should go out

a few seconds after the engine is started.

Water Temperature High

Lights if the engine coolant overheats.

Engine Oil Pressure Low

Operates if the engine oil pressure drops too

far. The light should go out when the engine is

started.

Transmission Oil Pressure Low

Lights if the transmission oil pressure drops

too far. The light should go out when the

engine is started.

Transmission Oil Temperature High

Lights if the transmission oil temperature rises

too far.

Air Filter Blocked

Lights if the engine air filter clogs up.

8642 - 1

P

Page 31

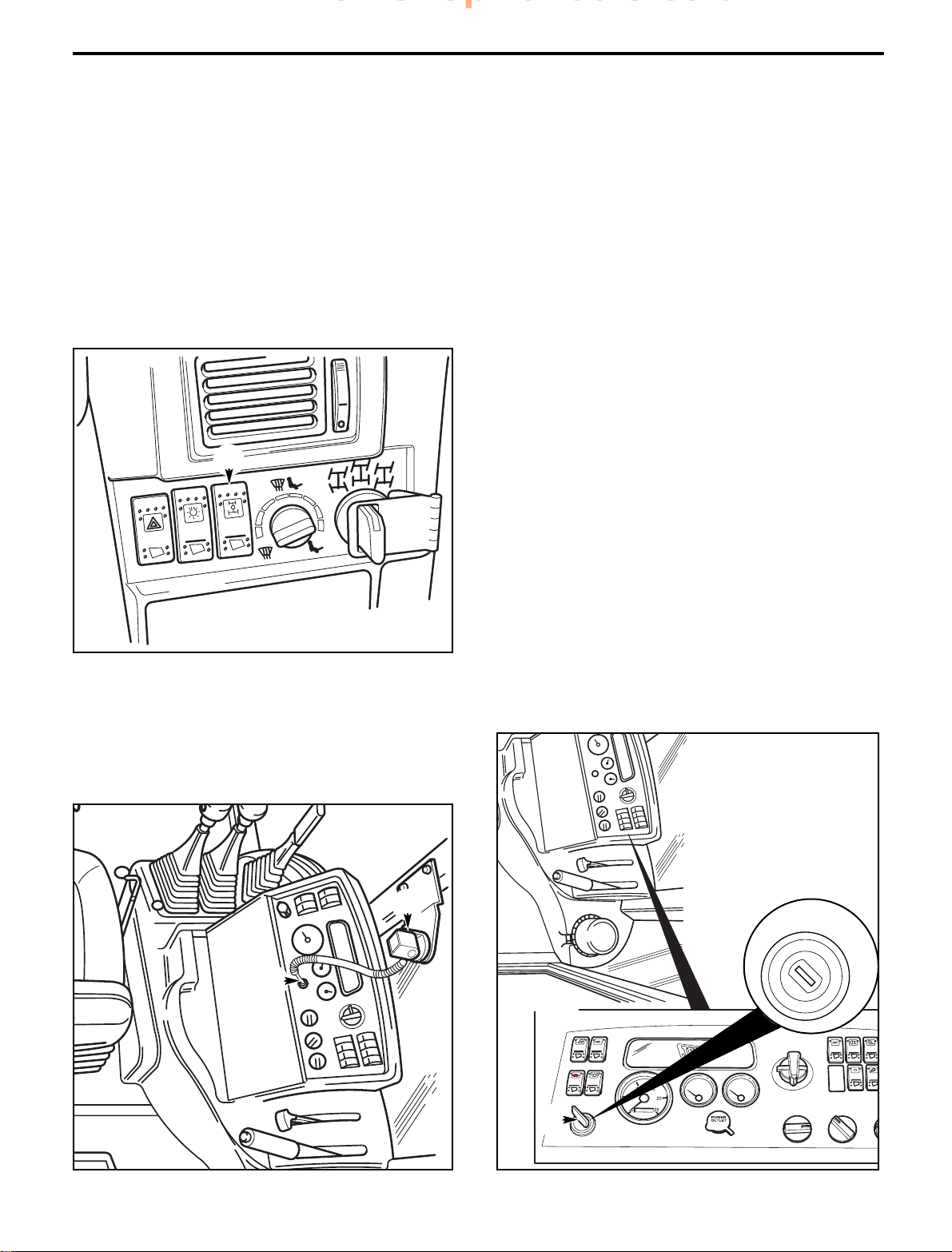

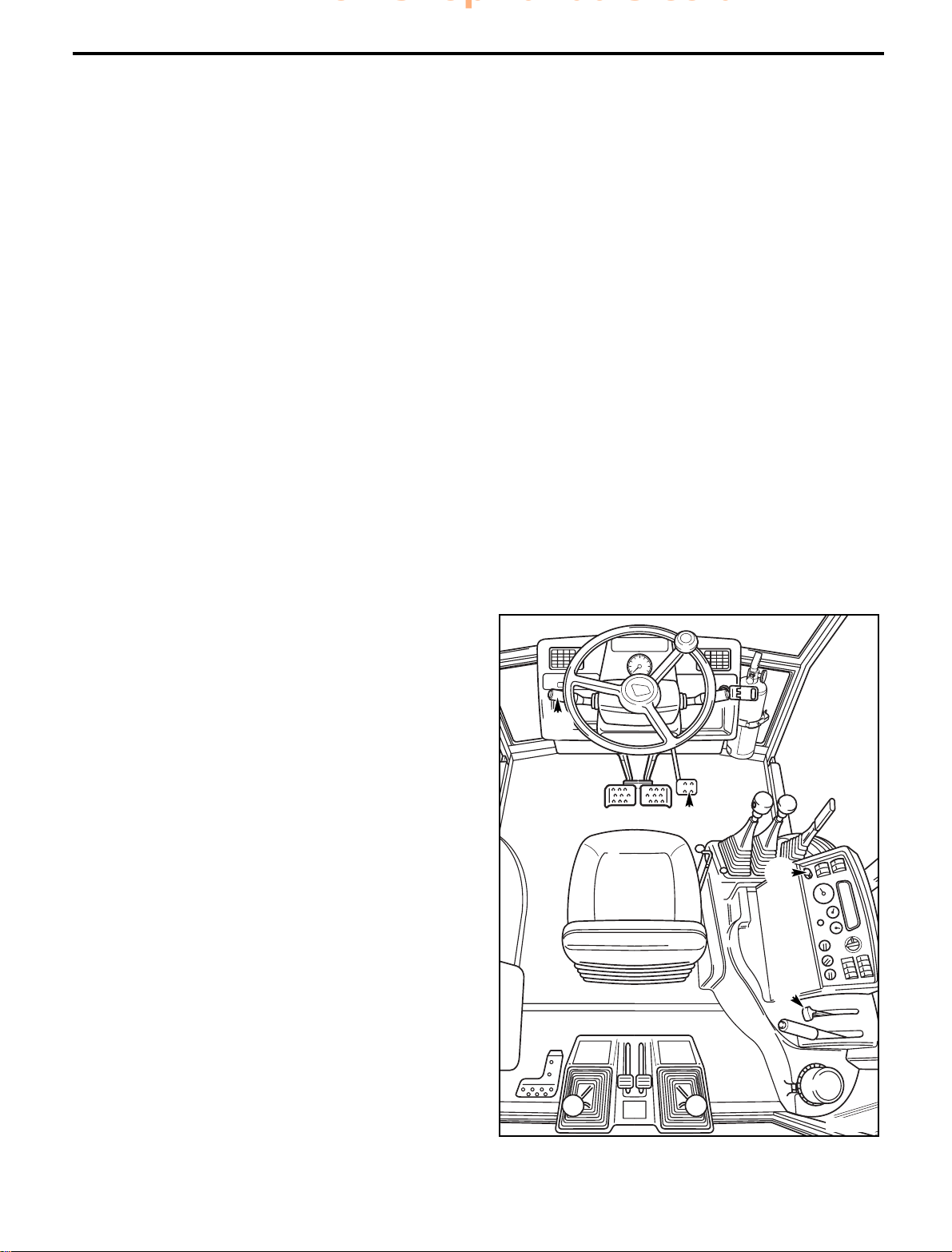

25 25

OPERATION

HEATER CONTROLS

The heater system is controlled by the following switches:

A - Re-circulation Switch

B - Three Speed Fan Switch

C - Temperature Control Switch

E - Air Distribution Control Switch

Heater Controls

Hot air can be directed to the front windscreen (for

demisting) and/or the cab floor by operating control E. The

temperature can be adjusted by operating control C. A

heater control switch B controls a three speed heater fan.

Air Control

Rotate control E anti-clockwise to direct more air to the

front windscreen. Rotate clockwise to direct more air to

the cab floor. With the control in the middle, air is directed

to both areas.

Rotate control A to position 1 to allow fresh air to enter the

cab. Position 2 gives re-circulated air and should be used

when operating in a dusty working environment. Position 2

can also be used to increase the heater performance

during cab warm up, and whilst operating the machine on

light duties.

Heat control

Rotate control C clockwise to increase the temperature.

Rotate anti-clockwise to decrease the temperature.

Heater Fan (Three Speeds)

Rotate control B to switch on the cab three speed heater

fan. Functions only with the starter switch at IGN.

Air Conditioning Controls

To operate the air conditioning, press switch D to the ON

position (the switch will be illuminated).

The air conditioning controls operate in the same manner

as described for 'Heater Controls', except cool dehumidified air is directed via vents into the cab (not heated

air).

Rotate the control C anti-clockwise to decrease the

temperature from ambient to cold. To obtain best results

from the air conditioning system ensure that all doors and

windows are closed.

Air conditioning performance is improved when the recirculation switch A is in position 2.

8642 - 1

E

A

B

C

2

11

Power Outlet

A power outlet socket F is located on the side console.

Auxiliary electrical eqiupment such as a light can be

connected to the socket. Note that the power supply from

the socket is 24V, DO NOT connect 12V equipment.

S247101

F

D

Page 32

26 26

OPERATION

LOADER CONTROLS

Loader Shovel

On standard machines the loader shovel is operated from

a single control lever C. Pressing the transmission dump

pushbutton D on the lever knob quickly disconnects the

transmission from the engine. This gives more power to

the loader.

For individual loader movements (raise, lower, roll forward,