Page 1

Quick Start Guide

Compact Excavators

18z-1, 19c-1, 19c-1 EP

1

Page 2

Disclaimer Index

Intended Use ......................................................................................................................................4

>

This Quick Reference Guide is to provide quick and simple information to the Operator

and does not include any health and safety aspects. In addition, because of our continual

development of machines, features described in this Quick Reference Guide may differ

from those on your machine. No errors and emissions be entirely ruled out.

Dimensions ........................................................................................................................................5

Tie Down Points ............................................................................................................................ 6-7

Lifting Points .......................................................................................................................................8

>

This Quick Reference Guide DOES NOT replace the Operators Manual. You MUST

read ALL the disclaimers and safety and other instructions in the Operators Manual

before initially operating this product. Accordingly, no legal claims can be entertained on

the basis of the data, illustrations or descriptions in this Quick Reference Guide.

>

This machine should not be operated by any person who isn’t appropriately qualified or

had the appropriate training.

>

Operation of this machine without periodic maintenance could cause it to malfunction.

For more information please contact your JCB Dealer.

Cab Layout & Controls ................................................................................................................. 9-14

Start Up Sequence ...........................................................................................................................15

Hydraulic Hitch Unlock .....................................................................................................................16

Mechanical Hitch Unlock ..................................................................................................................17

Shutdown & Auxiliary Venting ...........................................................................................................18

Maintenance Position ........................................................................................................................19

Service / Maintenance .......................................................................................................................20

Access Covers ............................................................................................................................ 21-2 2

Fluids & Lubricants ............................................................................................................................23

Machine Attachments .......................................................................................................................24

Troubleshooting / FAQs ..............................................................................................................25 -26

Your Notes .......................................................................................................................................27

23Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 3

Intended Use

Dimensions

General

> Machine Type – Compact Excavator

> Self propelled machine with a tracked undercarriage

> 360° revolving upper structure with boom, dipper, bucket and slew mechanism

Intended Use

> Machine intended to be used in normal conditions as detailed in the operators manual

> With bucket fitted, machine work cycle consists of digging, elevating, slewing and discharging

of materials

> Applications include earthmoving, road construction, building and construction, landscaping etc.

> Can be used for object handling if fitted with relevant parts and systems

> Not intended for use in mining and quarrying applications, demolition, forestry, any use

underground and any explosive atmospheres

> Must not be used for forestry, used with attachments of unknown weight, used on sur faces with

unknown stability – list not exhaustive

>

PPE may be required in cer tain applications/environments e.g. high silica concentration or asbestos

> The machine should not be operated by any person without appropriate qualifications, training

or experience of using this type of machine

> Prior to use, the machines suitability should be considered with regards to the intended

applications and any hazards which may be present

Fig 1

F

G

H

L

I

J

D

K

E

N

A

B

C

M

Machine model 18z-1 19c-1 19c-1 EP

A Sprocket idler centres mm 1218

B Track length on ground mm 1220

C Undercarriage overall length – rubber mm 1578

Undercarriage overall length – steel mm 1578

D Kingpost clearance mm 409

E Tailswing radius mm 685 110 3 110 3

F Overall width of superstructure mm 996 996 996

G Height over cab mm 2324

Height over canopy mm 2340 2324 2 324

H Ground clearance mm 162

I Track gauge – Retracted mm 750

Track gauge – Extended mm 1110

J Width over tracks – Retracted mm 980

Width over tracks – Extended mm 133 0

K Transport length with standard dipper mm 3547 3860 3862

L Track height mm 367

M Counterweight clearance mm 434

N Operating mass* kg 1749 1910* * 1943* *

45Please see operator manual for full details.

* Standard machine specification, please see data plate for speci fic machine weight.

* * Cab variant.

18z-1, 19c-1, 19c-1 EP

Page 4

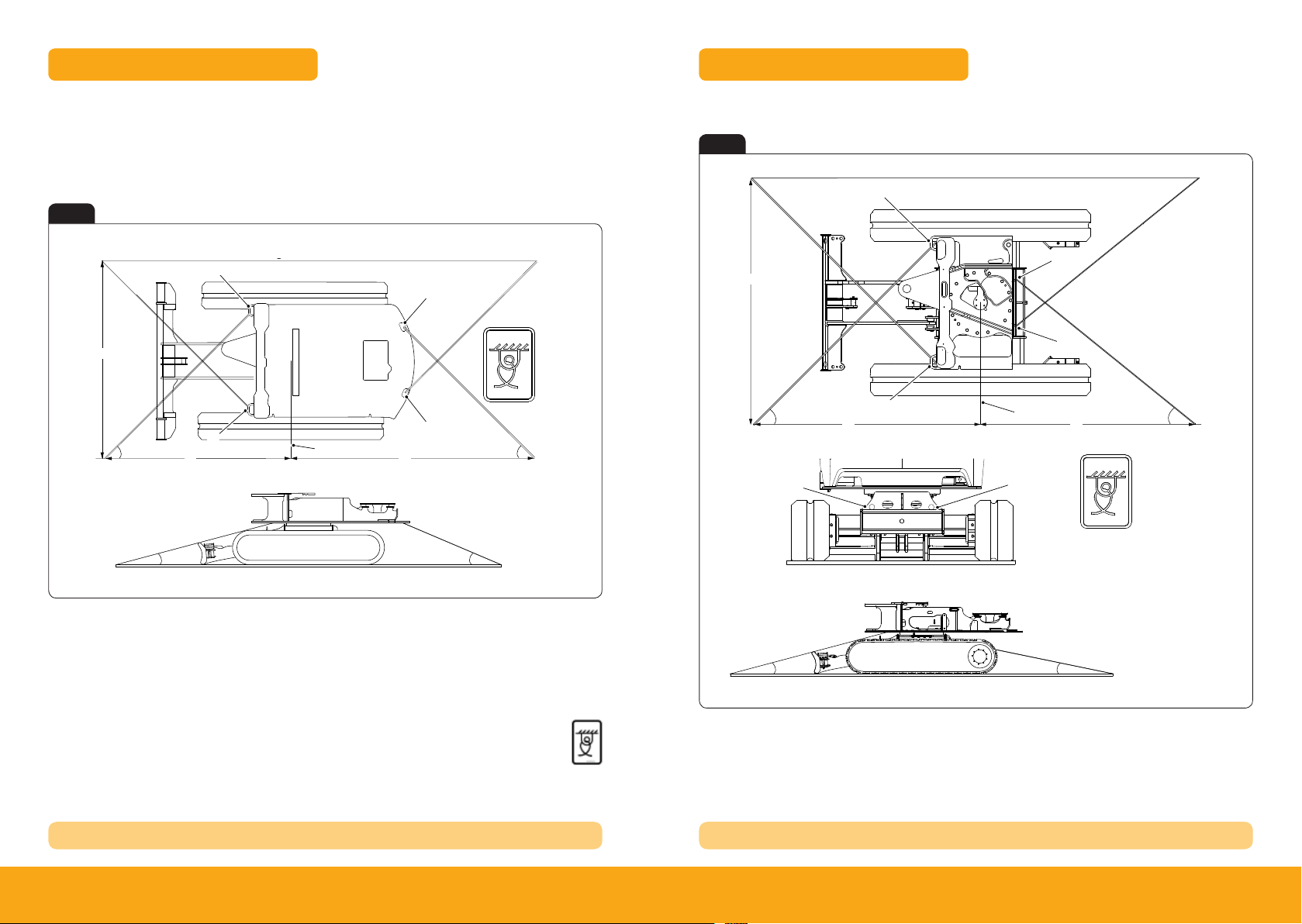

Operation

Transporting the Machine

Figure 90. Method 3

E

E

Tie Down Points

Operation

Transporting the Machine

Figure 89. Method 2

When transporting the machine one of the following three methods should be used:

Method 1

Fig 2

Tie Down Points

Method 2

Fig 3

A

A

H

C D

A

F

E

A Front slew spine tie-down point

C Angle = 35° to 46°

E Angle = 9° to 15°

G Length = 2,720mm to 1,943mm

I Slew ring centre line

I

B Rear slew spine tie-down point

D Angle = 45° to 50°

F Leng th = 2,499mm to 1,846mm

H Length = 2,500mm

J Tie down decal

B

G

J

B

E

Tie Down Posi tion Decal

H

C

B

F

A Front slew spine tie-down point

C Angle = 35° to 46°

E Angle = 9° to 15°

G Length = 2,282mm to 1,670mm

I Slew ring centre line

A

I

B

B Rear slew spine tie-down point

D Angle = 35° to 45°

F Length = 2,499mm to 1,846mm

H Length = 2 ,500mm

J Tie down decal

B

B

G

J

D

REFER TO OPER ATORS MANUAL TRANSPORTING MACHINE REFER TO OPER ATORS MANUAL TRANSPORTING MACHINE

67Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 5

About the Product

Console Switches

Console Switches

Figure 18.

About the Product

Console Switches

About the Product

Console Switches

switch

No LED illumination

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on position.

Position : 1 = Off

Position : 2 = Boom and front cab work light on

Position : 3 = All work lights on

About the Product

Console Switches

switch

No LED illumination

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on position.

Position : 1 = Off

Position : 2 = Boom and front cab work light on

Position : 3 = All work lights on

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on and off positions.

Position : 1 = Off

Position : 2 = Beacon on

Controls isolation switch. Two position momentary rocker switch. Press switch to

activate/de-activate the control.

Position : 1 = Rest position.

Position : 2 = Momentary position (activate/de-activate hydraulic controls).

About the Product

Console Switches

switch

No LED illumination

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on position.

Position : 1 = Off

Position : 2 = Boom and front cab work light on

Position : 3 = All work lights on

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on and off positions.

Position : 1 = Off

Position : 2 = Beacon on

Controls isolation switch. Two position momentary rocker switch. Press switch to

activate/de-activate the control.

Position : 1 = Rest position.

Position : 2 = Momentary position (activate/de-activate hydraulic controls).

Three position rocker switch. The switch functions operate when the ignition switch is

in the on position. The wiper will self-park when switched off.

Position : 1 = Off

Position : 2 = On

Position : 3 = Washer on (if installed)

Two position rocker switch. The switch functions operate when the ignition switch is in

the on position and auxiliary has been selected.

Position 1: Bi-directional mode- Double acting attachment

Position 2: Hammer mode- Single acting attachment

About the Product

Console Switches

switch

No LED illumination

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on position.

Position : 1 = Off

Position : 2 = Boom and front cab work light on

Position : 3 = All work lights on

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on and off positions.

Position : 1 = Off

Position : 2 = Beacon on

About the Product

Console Switches

switch

No LED illumination

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on position.

Position : 1 = Off

Position : 2 = Boom and front cab work light on

Position : 3 = All work lights on

Two or three position rocker switch. The switch functions operate when the ignition

switch is in the on and off positions.

Position : 1 = Off

Position : 2 = Beacon on

Controls isolation switch. Two position momentary rocker switch. Press switch to

activate/de-activate the control.

Position : 1 = Rest position.

Position : 2 = Momentary position (activate/de-activate hydraulic controls).

Three position rocker switch. The switch functions operate when the ignition switch is

in the on position. The wiper will self-park when switched off.

Position : 1 = Off

Position : 2 = On

Position : 3 = Washer on (if installed)

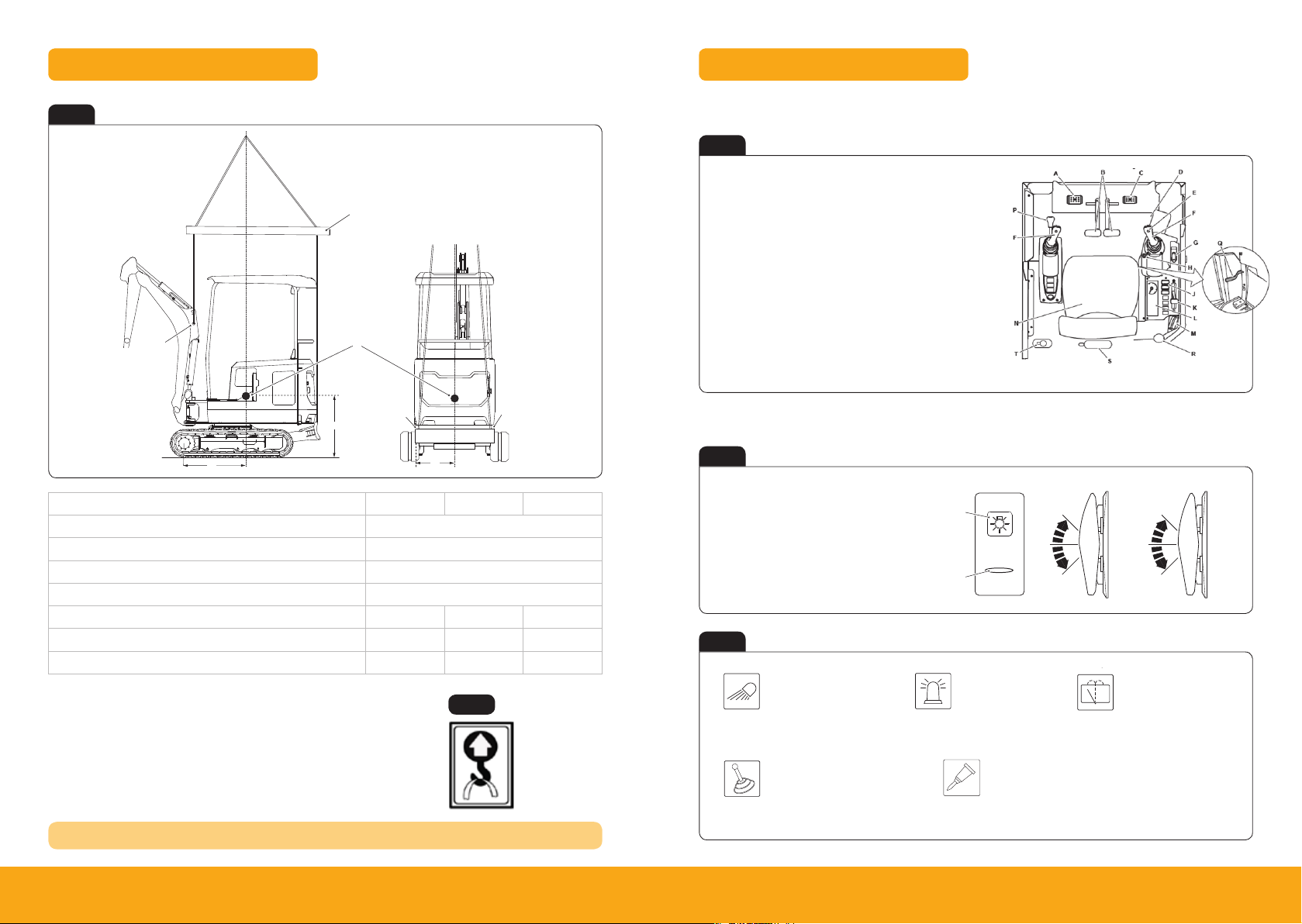

Lifting Points

Operation

Lifting the Machine

7. Check that the lifting eye is positioned directly above the machine centre of gravity.

Figure 84.

E

Cab & Switch Panel

Fig 4

A

Description 18z-1 19c-1 19c-1 EP

A Boom Lif t Point

B Dozer Blade Lift Point

C Spreader Bar

D Centre of Gravity

E mm 632 792 792

F mm 659 639 639

G mm 525 533 533

F

*COG = Centre of Gravity

The correct lifting positions are identified on the machine by their labels:

REFER TO OPER ATORS MANUAL TRANSPORTING MACHINE

C

D

Operator Station Layout – 18z-1, 19c-1

Fig 6

A Auxiliary pedal

B Track Controls

C Swing left/ right

D Heater Controls

E Horn

F Excavator arm controls

G Dozer control lever

H Ignition switch

J Right console switches

L Instrument panel

M Radio (if installed)

N Operator seat

P Control isolation lever

Q Undercarriage track

extension lever

R Fire extinguisher (18z-1)

S Fire extinguisher (19c-1)

T Window washer bottle

K Hand throttle

B

B

Switch Panel – 18z-1, 19c-1

G

Fig 5

Lifting point

Fig 7

A Graphic symbol

B Light bar

C 3 way position switch

D 2 way position switch / momentary switch

Fig 8

Work Lights

1 Off

2 On (Boom)

3 On (Boom & Cab)

A

B

Beacon

1 Off

2 On (Boom)

C D

1

2

3

1

2

3

Window Wipers

1 Off

2 Intermit tent/

continuos/washer

Position label.

Controls Isolation (2GO)

1 Off

2 Activate/de-activate

hydraulic controls

Bi-Directional and Hammer Mode Selector

1 Bi-directional mode – Double acting

2 Hammer mode – Single acting

89Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 6

Operation

Instruments

Instruments

Figure 50.

Figure 50.

B

A

Figure 50.

B

A

Operation

Instruments

Figure 51.

A

B C

D

E

F

G

Operation

Instruments

Figure 51.

A B

C

D

E

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

Operation

Instruments

Figure 52.

A

B

Cab & Switch Panel

About the Product

Console Switches

Figure 19.

G

H

Instrument Panel

Operator Station Layout – 19c-1 EP

Fig 9

A Track controls

B Heater controls

C Excavator arm controls

D Ignition Switch

E Dozer control lever

F Switch panel

G Hand throttle

H Auxillary power socket

K Radio (if installed)

L Instrument panel

M Operator seat

N Control Isolation lever

P Undercarriage track extension lever

Q Fire extinguisher

R Swing lef t/right

S Auxiliary control

T Window washer bottle

Switch Panel – 19c-1 EP

Fig 10

Instrument Panel – 18z-1, 19c-1

Fig 11 Fig 12

A Fuel level guage

B Warning and indicator lamps

A

B

Engine pre-heat

Coolant temperature

Engine oil pressure

Battery charging

Service due warning

Low fuel indicator

Seat belt

High speed travel

SAE active

A Control Isolation Switch (2Go)

B Aux 1 selection switch

C Lift overload switch on/off switch

D Worklights on/off switch

E Wiper/ washer on

F Auto-hydraulic warming switch

G H+ mode selec tion switch

H Aux 2 selec tion switch

I Auto idle on/off switch

J Beacon on/off switch

K Q-hitch sequence switch

1011Please see operator manual for full details.

0 1

A

2 3

B

4 5

C

D

E

F

7

6

8 9

I

J

K

Key

Black Text = Standard equipment

Blue Text = Not Used

Master warning

Immobilisers active

Hydraulics active

Aux 1 – single acting

18z-1, 19c-1, 19c-1 EP

Page 7

Operation

Operating Levers/Pedals

Figure 62. 16C-1 and 18Z-1

A B

B

A

Operation

Operating Levers/Pedals

Figure 65.

B

C

B

B

C C

A

Figure 66. 16C-1 and 18Z-1

Operation

Operating Levers/Pedals

Figure 64.

Operation

Operation

Operating Levers/Pedals

Figure 65.

B

C

B

B

C C

A

Instrument Panel

Operation

Instruments

Figure 52.

Operation

Instruments

Instruments

Figure 50.

B

A

Operation

Instruments

Figure 50.

B

A

Operation

Instruments

Figure 52.

A

Operation

Instruments

Figure 52.

A

B

Operation

Instruments

Figure 52.

A

B

Operation

Instruments

Figure 52.

A

B

Operation

Instruments

Figure 51.

A B

C

D

E

F

G

Operation

Instruments

Figure 51.

A B

C

D

E

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

Figure 51.

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

E

F

G

Operation

Instruments

Operation

Instruments

A

Operation

Instruments

Figure 52.

A

Foot Controls & Dozer Lever

Instrument Panel – 19c-1 EP

Fig 13 Fig 14

A Fuel level guage

B Warning and indicator lamps

1213Please see operator manual for full details.

A

B

Engine pre-heat

Coolant temperature

Engine oil pressure

Battery charging

Service due warning

Low fuel indicator

Seat belt

High speed travel

SAE active

Master warning

Immobilisers active

Hydraulics active

Quick hitch unlock

Lift overload warning

Aux 1 – double acting

Aux 1 – single acting

Aux 2 – low flow

Swing active

Swing Controls – 18z-1, 19c-1 Auxiliary Controls – 18z-1, 19c-1

Fig 15 Fig 16

A Swing left

A Auxiliary pedal

B Swing right

A

Dozer Lever Retracting Undercarriage Lever

Fig 17 Fig 18

A

B

A Lower the dozer

B Raise the dozer

C Control lever

C

B

A

A Track Extension Lever

B Upward - Retract

C Downward - Extend

B

C C

18z-1, 19c-1, 19c-1 EP

B

Page 8

Maintenance

Service Points

Service Points

Figure 112.

B

C

D

A

H

Operation

Entering and Leaving the Operator Station

Figure 20.

Operation

Seat Belt

Seat Belt

Figure 34.

About the Product

Interior Switches

Figure 16.

Operation

Working with the Excavator Arm

Figure 71.

Figure 72.

Operation

Starting the Engine

Figure 40.

About the Product

Interior Switches

Figure 16.

Joystick & Dozer Lever

Operation

Operating Levers/Pedals

Figure 62. 16C-1 and 18Z-1

A

B

B

A

Figure 63. 19C-1

A

B

B

A

Operation

Operating Levers/Pedals

Figure 67. 19C-1

Operation

Operating Levers/Pedals

Figure 64.

Operation

Operation

Operating Levers/Pedals

Figure 65.

B

C

B

B

C C

A

Swing Controls – 19c-1 EP Auxiliary Controls – 19c-1 EP

Start Up Sequence

Fig 19 Fig 20

A Swing left

B Swing right

C Swing thumb wheel control

D Change over button

D

A

C

B

A Lower the dozer

B Raise the dozer

C Control lever

Dozer Lever Retracting Undercarriage Lever

Fig 21 Fig 22

1415Please see operator manual for full details.

B

A

C

A Tilt/grab changeover for tilt-rotator

B Boom swing/Aux change over button

C Thumb wheel control – Aux 2 (Low flow)

D Continuous flow button – Hammer circuit

E Thumb wheel control – Aux 1 (High flow)

Note: A & D located underside of joystick

C

A

B

E

D

B

C C

A Track Extension Lever

B Upward - Retract

C Downward - Extend

1

Insert Isolator Key

Insert isolator key (A) and

turn in a clockwise direction.

A

4

Engine Pre Heat

Turn ignition to position 1 (A)

to pre-heat engine before star t.

Wait until pre-heat symbol (B)

2

Raise LH Arm Rest

Ensure the hydraulic isolation

lever (left hand arm rest) is in

the raised position.

B

A

A Handle B LH arm rest

5

Disarm Immobiliser

If fitted disarm by entering PIN

code using one of the below

methods.

3

Engage Seat Belt

Engage seat belt (A) into latch

(B) before starting machine.

B

A

6

Start Machine

From ignition position 1 turn

ignition to position 3 (A) to star t

the machine.

on instrument panel goes off.

A

B

7

A

B

Lower LH Arm Rest

Lower the LH arm rest to

activate the hydraulics.

Note: If 2 GO enabled go to step 8,

if not go to step 9

A Handle

B LH arm rest

B

8

Press 2 GO Button

If enabled press 2 GO button

(A) to activate hydraulics.

Instrument panel will illuminate

(B) when active.

A B

A

A

B

9

Operate Machine

All controls are now active

and the machine is now ready

to use.

18z-1, 19c-1, 19c-1 EP

Page 9

Attachments

Quickhitch

Figure 104.

Attachments

Quickhitch

Figure 103.

B

Attachments

Quickhitch

Figure 105.

Hydraulic Hitch Unlock Sequence (19c-1 EP only)

Mechanical Hitch Unlock System

Standard Attachments

1

Start Unlock Process

To start quick hitch unlock

process ensure hydraulics are

live then press quick hitch

sequence button (A).

4

Remove Attachment

To disengage the pivot pin,

crowd attachment for 3 seconds

then remove attachment.

Standard Attachments

2

Confirm Process

Instrument panel will indicate

need to confirm process (A).

To confirm process press 2 GO

button (B).

A

B

A

5

Change Attachment

Operate the machine to

engage

the jaw (A) with the

attachment

(B) and then full

crowd the attachment

to align latch.

3

Boom LED Indicator

When the sequence is

confirmed the LED on the

boom will flash red (A).

A

6

Lock Quick Hitch

To engage the lock on the quick

hitch press one of the following

two but tons and visually check

hitch is locked.

A

B

1

Park Machine Up

Park the machine on firm level

ground. Position the attach-

ment (A) just above the ground

and dozer (B) on the ground.

4

Release Attachment

Apply downward pressure to

the tommy bar to release the

buckets rear pivot.

A

2

Disconnect Attachment

Stop the engine, remove any

connected hydraulic hoses and

remove the locking pin.

5

Restart Machine

Start the engine, rest

attachment on the ground

and engage the hydraulics.

3

Insert tommy bar

Insert the tommy bar into the

hole of the latch hook.

A Latch Hook B Tommy Bar

C Hole

A

C

6

Remove Attachment

Slowly roll the quickhitch in the

direction of the arrow whilst

raising the dipper to release the

front pivot (A).

B

A

A

1617Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 10

Maintenance

Maintenance Positions

Maintenance Positions

Figure 111.

Shutdown and Auxiliary Venting

About the Product

Console Switches

Figure 19.

G

H

0 1

Operation

Operating Levers/Pedals

Figure 67. 19C-1

E

D

C

Operation

Instruments

Figure 52.

A

Operation

Instruments

Figure 52.

A

B

Operation

Operating Levers/Pedals

Figure 67. 19C-1

E

D

C

Maintenance Position

Shutdown Sequence

1

Park Machine Up

Park machine on solid level

ground with the attachment (A)

and dozer (B) on the ground.

2

Leave & Secure

Switch off all switches. Leave

machine using the handrails

and footholds.

Close & lock

all doors and

windows to

secure machine.

Auxiliary Venting (Within 1 Minute of Shutdown)*

1

Lower LH Arm Rest

While sitting in the operating

station with engine off lower

LH arm rest.

A Handle

B LH arm rest

4

Select Aux Circuit

Enable aux function on top of

the left control lever (A). Ensure

symbol (B) or (C) is displayed.

B

A

*19c-1 EP only please refer to the operators manual for 19c-1 and 18z-1

1819Please see operator manual for full details.

C

2

Turn Ignition On

Turn ignition to position 1 (A) so

that the instrument panel and

switches become active.

5

Switching Circuits

Change Aux mode between

Aux1 (A) and Aux 2 (B) using

mode select switch on the right

hand console.

A

A

2 3

B

3

Isolate Machine

Turn isolator key anti-clockwise

and remove key.

3

Press 2 GO Button

A

Press 2 GO but ton (A) to

activate hydraulics. Instrument

panel will illuminate (B)

when active.

A B

6

Venting Aux Circuit

Operate the roller switch fully

in both directions to release

stored pressure. Right hand

(A) for Aux 1 and left hand (B)

for Aux.

A

1. Park the machine on solid, level ground

I. Release the two track levers

II. Set the hand throttle lever to the idle position

2. Lower the dozer blade (A)

3. Lower the excavator so the attachment is flat on the ground

Fig 23

B

A

A Attachment flat on the ground

B Dozer blade lowered to ground

4. Stop the engine

5. Discharge the hydraulic pressure (see aux venting operation)

B

6. Isolate the controls and remove ignition key

7. Isolate the battery to prevent accidental operation of the engine

18z-1, 19c-1, 19c-1 EP

Page 11

Maintenance

Service Points

Service Points

General

The following illustrations identify the service points for the operator to perform the daily and weekly

maintenance tasks.

Engine Compartment

Figure 112.

F

B

C

A

H

Maintenance

Access Apertures

Access Apertures

Figure 114.

Maintenance

Electrical System

Figure 133.

Service/Maintenance

Access Covers – Service Items and Relays

Daily Checks (10h) Check

Check engine for leaks and oil level Visual check

Check engine coolant for leaks, contamination and level Visual check

Check condition of cooling pack and system Visual check

Check hydraulic oil level Visual check

Check the condition of welded structure Visual check

Check window washer fluid level Visual check

Check condition of bodywork and framework Visual check

Check condition of attachments / optional equipment Visual check

Grease attachments / optional equipment as required Lubricate

Check for excessive exhaust smoke Visual check

Check fuel system for leaks & contamination Visual check

Check operation of all services i.e. excavator, dozer etc. Operate

Check operation of all electrical equipment i.e horn, alarms etc. Operate

Check the track and running gear operation Operate

Check operation of the hour meter Viual check

Weekly Checks (50h) Check

Clean cooling pack Clean

Drain water from water separator on fuel filter Clean

Check condition of drive belt Visual check

Check hydraulic hoses / pipework for leaks and damage Visual check

Check condition of the rams Visual check

Check the condition of the electrical wiring Visual check

Clean the battery terminals Clean

Check condition and tension of tracks Visual check

Check presence of all pivot pin retaining bolts Visual check

Grease slew ring bearing Lubricate

Grease window and door hinges Lubricate

Fig 24 Fig 25

A Lock

B Engine compartment cover

A Fixings

B Relay access cover

C Handle

A

C

Fig 26

B

A Air filter

B Water separator

C Oil filler cap

D Coolant expansion bottle

E Battery

F Engine oil dipstick

G Battery isolator

H Fuel pre filter

G

A

B

E

A

D

2021Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 12

Access Covers – Fluid Levels and Fill

Maintenance

Access Apertures

Figure 115.

A B

Maintenance

Service Points

Figure 113.

Fluids and Lubricants

Fig 27

A Hydraulic compartment cover

B Lock

Fig 28

A Radiator cap

B Hydraulic tank filler cap

C Fuel filler cap

D Hydraulic oil level indicator

A

B

Item Capacity Fluid/lubricant

JCB Part

Number

Container

Size

Fuel Tank 20.5L Diesel oil – –

Engine Oil

(Stage 3A Perkins 403D-07)

2.5L

-30°C (-22°F) to 40°C (104°F):

JCB Extreme performance 5W40

4001/ 2 70 5 20L

Engine Coolant (Cab) 4.7L JCB Antifreeze HP / Coolant / Water 4 00 6 /112 0 20L

Engine Coolant (Canopy) 4.2L JCB Antifreeze HP / Coolant / Water 4 0 06 / 1120 20L

Track Gearbox (each) 0.3L

JCB Engine Oil HP SAE 30

(Not Multigrade)

4001/ 0305 20L

Track Idler Wheels 0.3L JCB HP90 Gear Oil 4000/0305 20L

Track Rollers (bot tom) 0.025L JCB HP90 Gear Oil 4000/0305 20L

Hydraulic System 28L

Hydraulic Tank 15 L

C

Slew Ring Bearing

Slew Ring Gear Teeth

All Other Grease

JCB par t numbers are liable to change and may also vary by region.

D

For the latest information, always check with your dealer/distributor.

As

required

As

required

As

required

-20°C (-4°F) to 46°C (114.7°F):

JCB Hydraulic Fluid OP46

-20°C (-4°F) to 46°C (114.7°F):

JCB Hydraulic Fluid OP46

4002/2005 20L

4002/2005 20L

JCB HP Grease 40 03 / 2 017 0.4kg

JCB Special Slew Pinion Grease 4003/1619 0.4kg

JCB MPL-EP Grease 4 0 03/1501 0.4 kg

2223Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 13

Machine Attachments

Troubleshooting/FAQs

Description

Mechanical Quickhitch 13. 7 Quick change of attachments None

Hydraulic Quickhitch 22 Quick change of attachments Quickhitch circuit

Bucket GP 150mm 20.2

Bucket GP 230mm 22.2

Bucket GP 300mm 24.4

Bucket GP 400mm 28.7

Bucket GP 460mm 30.3

Grading / Ditching Bucket

760 mm

Grading / Ditching Bucket

1000mm

Earth Drill – 1500Nm 63.8 Drilling 160mm – 900mm holes

Breaker – HM012T 107 Breaking up tarmac, concrete, rock

Breaker –HM100Q 12 9 Breaking up tarmac, concrete, rock

Weight

(kg)

General excavation / Bulk loading loose

General excavation / Bulk loading loose

General excavation / Bulk loading loose

General excavation / Bulk loading loose

General excavation / Bulk loading loose

36.8 Grading, finishing, landscaping and ditching None

44.9 Grading, finishing, landscaping and ditching None

Intended Use

material

material

material

material

material

Hydraulic

Requirements

None

None

None

None

None

1 Hi-Flow aux

service

1x single acting

aux service

1x single acting

aux service

Issue / FAQ Resolution/Answer

My machine will not start

I can’t activate the Hydraulics

Why is there an audible buzzer in

the cab when I’m lifting a large load?

EP

(19c-1

Can I disable the lift overload

warning indicator when not object

handling? (19c-1 EP only)

500hrs Greasing – Does it matter

if greased every day?

only)

Ensure the start up sequence has been followed (Page 14).

If machine still will not star t contact dealer

Here are some of the possible reasons:

• When the machine hydraulics are live and you lift the left hand pod

you will need to re-select ‘2-GO’ when the pod is returned to the

down position.

• The left hand pod is in the raised position.

• There is a fault on the keypad.

• Engine isn’t switched on.

• If there is an error on the machine and an error code is displayed

on the LCD screen – which would inhibit the hydraulics.

If hydraulics still won’t activate contact dealer

The lift overload warning system has detected a load that is near the

limits of the machine, reduce load to prevent machine overturning

To disable lift overload warning indicator when not object handling

press but ton ‘C’ on the switch panel (refer to page 9)

No, there is no impact on life of the pivot pins or bushes

ATTACHMENT WEIGHTS AR E A GUIDE ONLY, ALWAYS CHECK YOUR OWN ATTACHMENTS

2425Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 14

Issue / FAQ Resolution/Answer

Your NotesTroubleshooting/FAQs

500hrs Greasing – Do the bushes

need to be replaced at 500hrs?

500hrs Greasing – After the first

500hrs do the bushes then need

greasing daily?

500hrs Greasing – Without daily

greasing what cleans all the dirt

out of the bush?

How do I switch from ISO to SAE

control patterns?

How do I activate continuous

auxiliary flow? (19c-1 EP only)

What are the max flows and

pressures of the Auxiliary circuits?

No, just grease and continue work

No, the bushes wont need greasing until the next 500hrs

Machine is fitted with one way seals stopping dirt entering the bush

but allowing old grease out when greasing

The control pattern change-over switch is located under the operator

station station.

Position 1 = SAE

Position 2 = ISO

Always refer to the in cab display for confirmation of control

pattern selection.

To activate constant flow, select right hand finger but ton on the right

hand joystick. Please refer to page 14 for joystick control layout.

Aux Flow L/min Aux Pressure bar (psi)

L1 32 200 (2898.5)

L2 32 200 (2898.5)

L3 32 200 (2898.5)

2627Please see operator manual for full details.

18z-1, 19c-1, 19c-1 EP

Page 15

JCB Sales Limited, Rocester, Staffordshire, Uni ted Kingdom ST14 5JP

Tel: +44 1889 590312 Email: salesinfo@jcb.com

Download the very latest information on this product range at: w ww.jcb.com

All right s reserved. No p art of this pub lication may be rep roduced, stored i n a retrieval sys tem, or transmi tted in any form or by any other means, el ectronic, mech anical, photoco pying

or other wise, without p rior permissi on from JCB Sales . All references in t his publicati on to operating wei ghts, sizes, capa cities and other performance m easurements a re provided

for guida nce only and may var y dependant upo n the exact spec ification of the machine. They shou ld not therefore b e relied upon in rel ation to suitab ility for a par ticular applic ation.

Guidance and advice shoul d always be sought f rom your JCB Deale r’. JCB reserves the r ight to change spec ifications wit hout notice. Ill ustrations an d specificatio ns shown may

include op tional equipm ent and accessori es.

9818/290 0

Loading...

Loading...