Page 1

VTX A12 | User Manual

Page 2

VTX A12 | User Manual

GENERAL INFORMATION

VTX A12 - User Manual

Document Number: 1000297494

Version: D - EN

Distribution Date: December 3, 2020

Copyright © 2020 by HARMAN International; all rights reserved

JBL PROFESSIONAL

8500 Balboa Blvd

Northridge, CA 91329

USA

Page 3

VTX A12 | User Manual

Thank you for purchasing JBL V TX Series products

In more than 75 years of JBL innovations, the VTX Series stands apart as a milestone in the practical application of cre-

ative engineering. VTX products herald the next generation in line array loudspeaker systems: a new era in performance,

system integration and user friendliness. VTX products draw on multiple JBL patents in driver, waveguide, and suspension

technology, as well as custom amplification, DSP, control, and system management designs created in collaboration with

HARMAN Professional sister companies.

VTX loudspeakers marry custom transducer design and in-house manufacture, breakthrough technologies, and a com-

prehensive system approach to deliver a premium experience for all who come into contact with it, from the FOH mixing

engineer to the systems engineer, rigger, road crew, warehouse manager, and, of course, the audience. Designed for

operators of portable and fixed systems alike, the VTX Series features JBL’s legendary sound quality coupled with expert

support and advanced tools that enable optimal specification, configuration, and operation of VTX systems in any venue,

anywhere in the world. The VTX Series delivers a comprehensive solution: the finest sound quality available, plus efficient

and intuitive setup, tuning, networking, and control.

Page 4

VTX A12 | User Manual

TABLE OF CONTENTS

1 - DECLARATION OF CONFORMITY ...........................................................................6

2 - SAFETY .................................................................................................7

2.1 Safety Instructions ....................................................................................7

2.2 General Hardware Information ..........................................................................7

2.4 Important Safety Warning ..............................................................................8

2.5 Are You New to Rigging? ..............................................................................8

2.6 Inspection and Maintenance ............................................................................8

2.7 Symbols ............................................................................................9

3 - SYSTEM COMPONENTS .................................................................................10

4 - COMPATIBLE ACCESSORIES ..............................................................................11

4.1 VTX A12 AF - Array Frame .............................................................................11

4.2 VTX A12 AF EB - Array Frame Extension Bar ..............................................................11

4.3 VTX A12 SB - Suspension Bar ..........................................................................11

4.4 VTX A12 VT - Vertical Transporter .......................................................................12

4.5 VTX A12 VT CVR - Soft Cover ..........................................................................12

4.6 - VTX A12 VT GND - Ground Stack Accessory .............................................................12

4.7 VTX Delta - Delta Plate ................................................................................12

4.8 VTX A12 BP - Base Plate ..............................................................................13

5 - SOFTWARE .............................................................................................14

5.1 Line Array Calculator 3TM ..............................................................................14

5.2 Array LinkTM ........................................................................................14

5.3 Performance ManagerTM ..............................................................................14

6 - INTRODUCTION .........................................................................................15

6.1 VTX A12/VTX A12W ..................................................................................15

6.2 VTX A12 vs VTX A12W ................................................................................16

6.3 Identifying A12 and A12W .............................................................................16

7 - CONNECTIONS .........................................................................................17

7.1 Internal Wiring ......................................................................................17

8 - SYSTEM AMPLIFICATION .................................................................................18

8.1 Using the A12 with Crown I-Tech 4x3500HD ...............................................................18

8.2 Using the A12 with Crown I-Tech 12000HD ................................................................19

8.3 Crown Audio V-Rack .................................................................................19

9 - VTX A12 PRESET LIBRARY ................................................................................20

9.1 VTX A12 Preset Modes and Options .....................................................................20

Page 5

VTX A12 | User Manual

10 - SUBWOOFER OPTIONS .................................................................................21

10.1 SUB/LF Preset Options ...............................................................................21

10.2 Preset Example 1 ...................................................................................22

10.3 Preset Example 2 ...................................................................................22

10.4 Time Alignment .....................................................................................23

11 - FREQUENCY RESPONSE ................................................................................24

12 - LINE ARRAY CONTROL PANEL ...........................................................................25

12.1 Accessing LACP ....................................................................................25

12.2 Filter 1 - Array Size Compensation .....................................................................26

12.3 Filter 2 - Atmospheric Absorption Compensation ..........................................................26

12.4 Filter 3 - HF Throw Distance Compensation ..............................................................26

12.5 Filters 4 & 5 - User PEQ 1 & 2 .........................................................................26

12.6 Example using LACP ................................................................................27

13 - TESTING VTX A12 ......................................................................................28

13.1 Using a DMM (Digital MultiMeter) ......................................................................28

13.2 Using Performance Manager ..........................................................................29

13.3 Performance Manager Readings .......................................................................29

14 - SPECIFICATIONS .......................................................................................30

14.2 VTX A12 Specifications ..............................................................................30

14.2 VTX A12W Specifications .............................................................................31

15 - ACOUSTIC MEASUREMENTS ............................................................................32

15.1 VTX A12 ..........................................................................................32

15.2 VTX A12W ........................................................................................32

16 - DIMENSIONS ..........................................................................................33

17 - CONTACTS INFORMATION ...............................................................................34

Page 6

1 - DECLARATION OF CONFORMITY

BRAND: JBL Professional

FAMILY NAME: VTX A12 loudspeaker and suspension accessories

MODEL NAMES:

VTX A12 | User Manual

• VTX A12

• VTX A12W

• VTX A12 AF

• VTX A12 AF EB

• VTX A12 SB

• VTX A12 VT

We, HARMAN International, declare under our sole responsibility that the product, to which this declaration relates, is in conformity

with the following standards:

STANDARD DESCRIPTION TEST AGENCY

2006/42/EC

MACHINERY DIRECTIVE

• VTX A12 VT GND

• VTX DELTA

Applies to machinery and lays down essential

health and safety requirements

ISO12100

Tested at JBL Professional

2014/35/EC

LOW VOLTAGE DIRECTIVE

Applies to loudspeaker and lays down essential

health and safety requirements.

EN60065

Frank Lacelle

Compliance Manager - Harman International

Tested at JBL Professional

Page 7

VTX A12 | User Manual

2 - SAFETY

2.1 SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not expose the product to direct rain or sea spray.

6. Clean only with a dry cloth.

7. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

8. Only use attachments/accessories specified by the manufacturer.

9. Use only with a cart, stand, tripod, bracket, or table specified by the manufacturer or sold with the apparatus. When a cart is used,

use caution when moving the cart/apparatus combination to avoid injury from tip-over.

10. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as if

liquid has been spilled or objects have fallen into the apparatus, or if the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

11. Contact JBL Professional for advanced servicing issues.

12. CAUTION - DO NOT PERFORM ANY SERVICING UNLESS YOU ARE QUALIFIED TO DO SO.

13. Prolonged exposure to excessive SPL can cause hearing damage. The loudspeaker is easily capable of generating sound pressure

levels (SPL) sufficient to cause permanent hearing damage to performers, production crew, and audience members. Caution should

be taken to avoid prolonged exposure to SPL in excess of 90 dB.

14. Read the System Rigging Manual before installation and use of the product.

2.2 GENERAL HARDWARE INFORMATION

Any hardware used in an overhead suspension application must be load rated for the intended use. Generally, this type of hardware

is available from rigging supply houses, industrial supply catalogs, and specialized rigging distributors. Local hardware stores do not

usually stock these products. Compliant hardware will be referenced with a working load limit (WLL) and a traceability code.

2.3 ATTACHMENT TO STRUCTURES

A licensed Professional Engineer must approve the placement and method of attachment to the structure prior to the installation of any

overhead object. The following performance standards should be provided to the Professional Engineer for design purposes: Uniform

Building Code as applicable, Municipal Building Code as applicable, and Seismic Code as applicable. The installation of the hardware

and method of attachment must be carried out in the manner specified by the Professional Engineer. Improper installation may result in

damage, injury, or death.

7

Page 8

VTX A12 | User Manual

2.4 IMPORTANT SAFETY WARNING

The information in this section has been assembled from recognized engineering data and is intended for informational purposes only.

None of the information in this section should be used without first obtaining competent advice with respect to applicability to a given

circumstance. None of the information presented herein is intended as a representation or warranty on the part of JBL. Anyone making

use of this information assumes all liability arising from such use.

All information presented herein is based upon materials and practices common to North America and may not directly apply to other

countries because of differing material dimensions, specifications, and/or local regulations. Users in other countries should consult with

appropriate engineering and regulatory authorities for specific guidelines.

Correct use of all included hardware is required for secure system suspension. Careful calculations should always be performed to

ensure that all components are used within their working load limits before the array is suspended. Never exceed the maximum recom-

mended load ratings.

Before suspending any speaker system, always inspect all components (enclosure, rigging frames, pins, eyebolts, track fittings, etc.) for

cracks, deformations, corrosion, or missing/loose/damaged parts that could reduce strength and safety of the array. Do not suspend

the speaker until the proper corrective action has been taken. Use only load-rated hardware when suspending JBL suspendable loud-

speaker models.

2.5 ARE YOU NEW TO RIGGING?

If you are new to rigging, you should:

• Know the rules for safe rigging.

• Attend a safe rigging seminar.

• Meet and establish a relationship with a licensed mechanical or structural engineer. Get in the habit of asking them questions in-

stead of assuming their answers. Learn from what they tell you.

• Research and understand the codes, practices and requirements of the venues where you intend to operate your sound system.

2.6 INSPECTION AND MAINTENANCE

Suspension systems are comprised of mechanical devices and, as such, require regular inspection and routine maintenance to ensure

proper functionality. Before suspending or pole mounting any speaker system, always inspect all components (enclosure, suspension

frames or brackets, pins, eyebolts, etc.) for cracks, deformations, corrosion, or missing/loose/damaged parts that could reduce strength

and safety of the array. Do not suspend or pole mount a speaker until the proper corrective action has been taken.

Installed systems should be inspected at least once a year. The inspection must include a visual survey of all corners and load-bearing

surfaces for signs of cracking, water damage, delamination, or any other condition that may decrease the strength of the loudspeaker

enclosure.

Accessory suspension hardware provided with or for VTX systems must be inspected for fatigue at least once a year or as required by

local ordinance. The inspection must include a visual survey of the material for signs of corrosion, bending, or any other condition that

may decrease the strength of the fastener. Additionally, any eyebolts must be checked for possible spin-out of the enclosure.

For all other hardware and fittings, refer to the hardware manufacturer’s inspection and maintenance guidelines for process.

8

Page 9

VTX A12 | User Manual

JBL is not responsible for the application of its products for any purpose or the misuse of this information for any purpose. Furthermore,

JBL is not responsible for the abuse of its products caused by avoiding compliance with inspection and maintenance procedures or

any other abuse.

Prior to suspending the system, an expert, trained and experienced in suspending speaker systems, should inspect all parts and com-

ponents.

2.7 SYMBOLS

The following symbols are used in this document:

CAUTION: This symbol gives notice of a potential risk of harm to the individual or the equipment. Instruction

marked with this symbol must be strictly followed.

TIP: This symbol gives notice of helpful, relevant information about the topic.

INSTRUCTIONS: This symbol gives notice of instructions that must be followed for proper installation and use of

the product.

TOOLS REQUIRED: This symbol gives notice of tools that must be used for proper installation and use of the

product.

9

Page 10

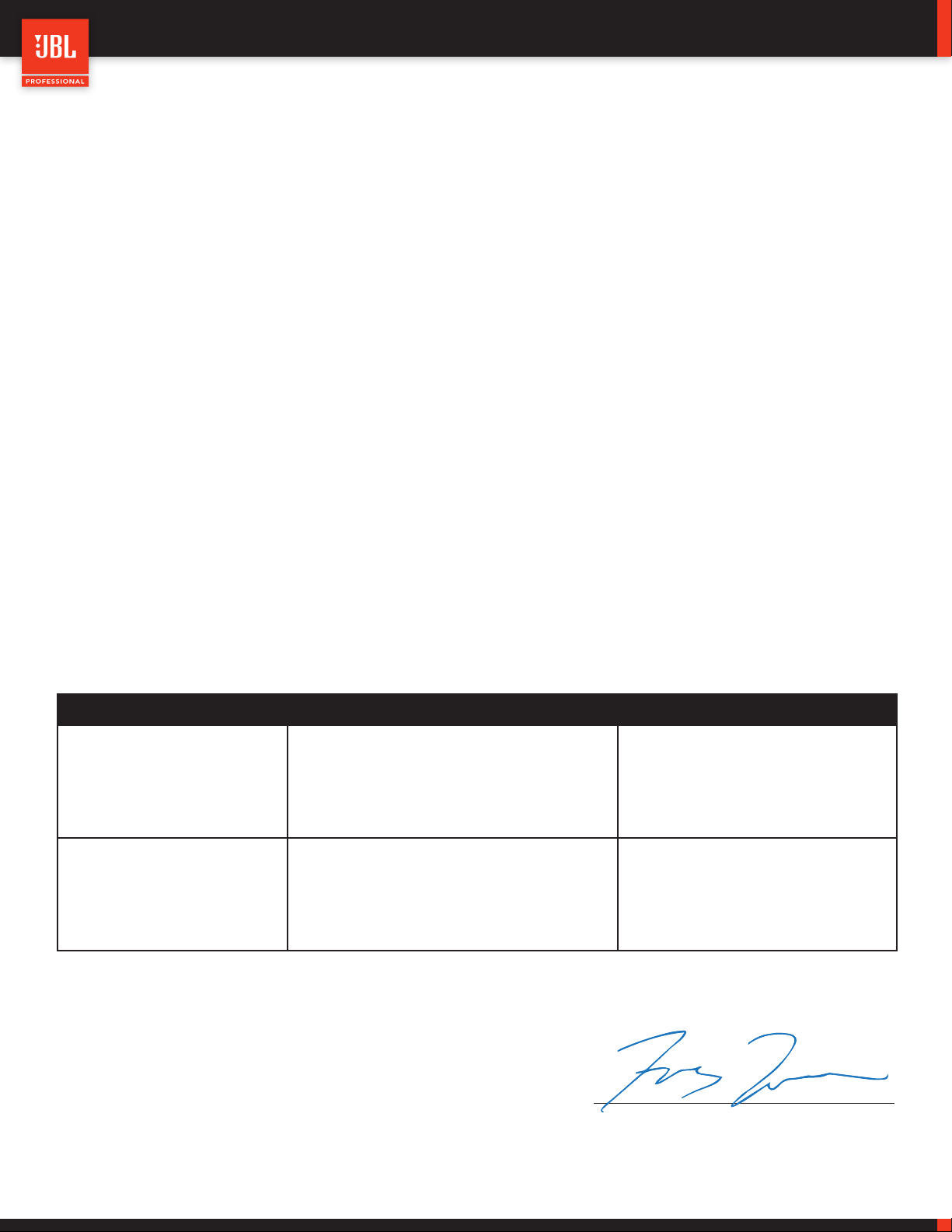

3 - SYSTEM COMPONENTS

VTX A12 | User Manual

VTX A12 / VTX A12W

VTX B28

VTX G28VTX S28

Fault

1

Thermal

1

Clip

-10

-20

Signal

Menu/Exit Prev Next

Ready

Fault

Thermal

1

234

Clip

-10

-20

Signal

Ready

Fault

2

Thermal

2

Clip

-10

-20

Signal

Ready

Menu/Exit

Prev

Next

DRIVECORE SERIES

Power

Bridge 1/2

Bridge 3/4

Data

Power

Bridge 1/2

Bridge 3/4

Data

Crown I-Tech HD Amplifiers Crown V-Rack

10

Page 11

VTX A12 | User Manual

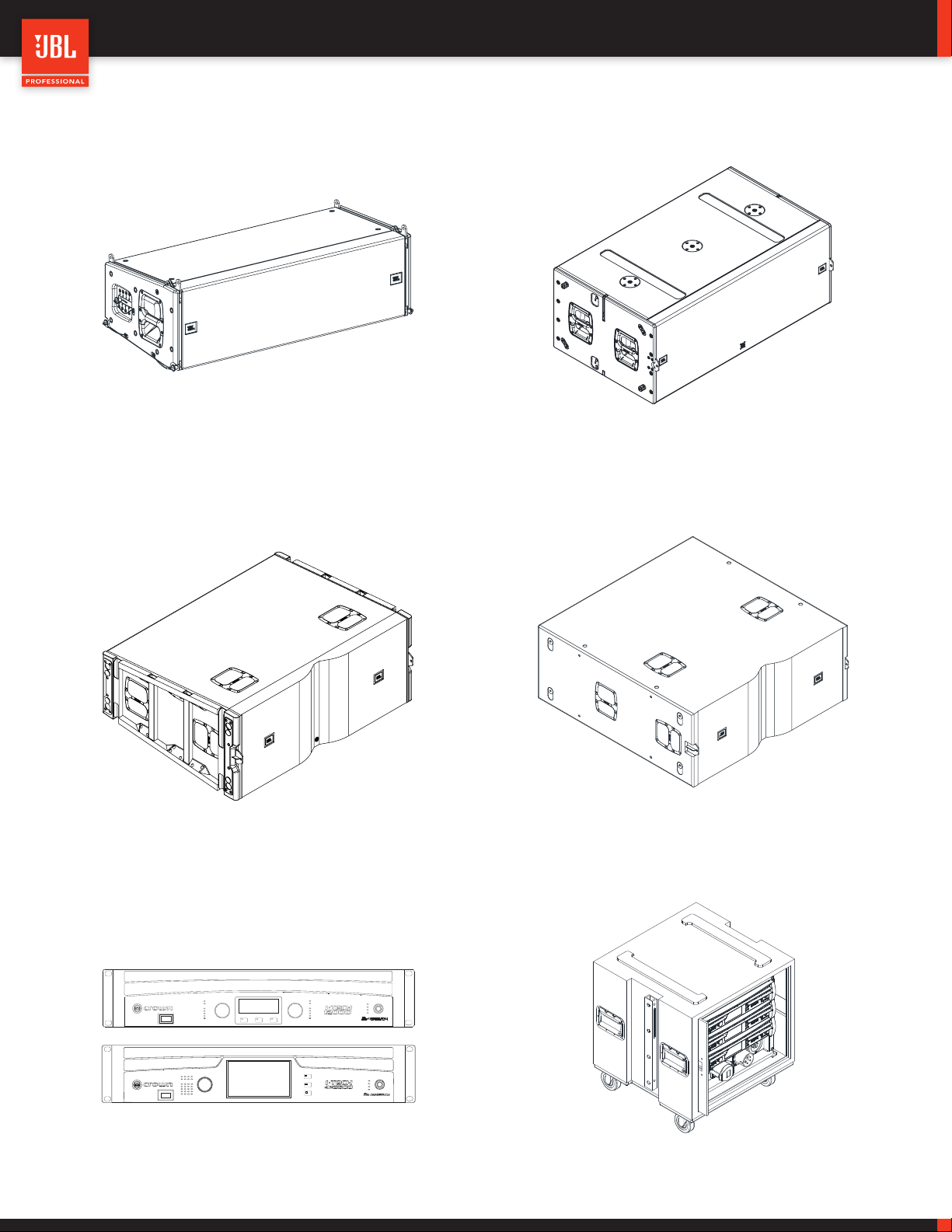

4 - COMPATIBLE ACCESSORIES

All listed accessories are compatible with both the VTX A12 and A12W. For more information on the accessories, refer to the accessory

specification sheets. For more information on usage, refer to the VTX A12 Rigging Manual available at www.jblpro.com.

4.1 VTX A12 AF - ARRAY FRAME

• Array Frame for suspending VTX A12 enclosures

• One Extension Bar included

• Built-in storage position for Extension Bar

• Single, front-to-back and side-by-side suspension points

• High-resolution single-point selection

• Support for up to (24) VTX A12 (array geometry dependent)

• Included laser bracket for LAP-TEQ and RECLINE

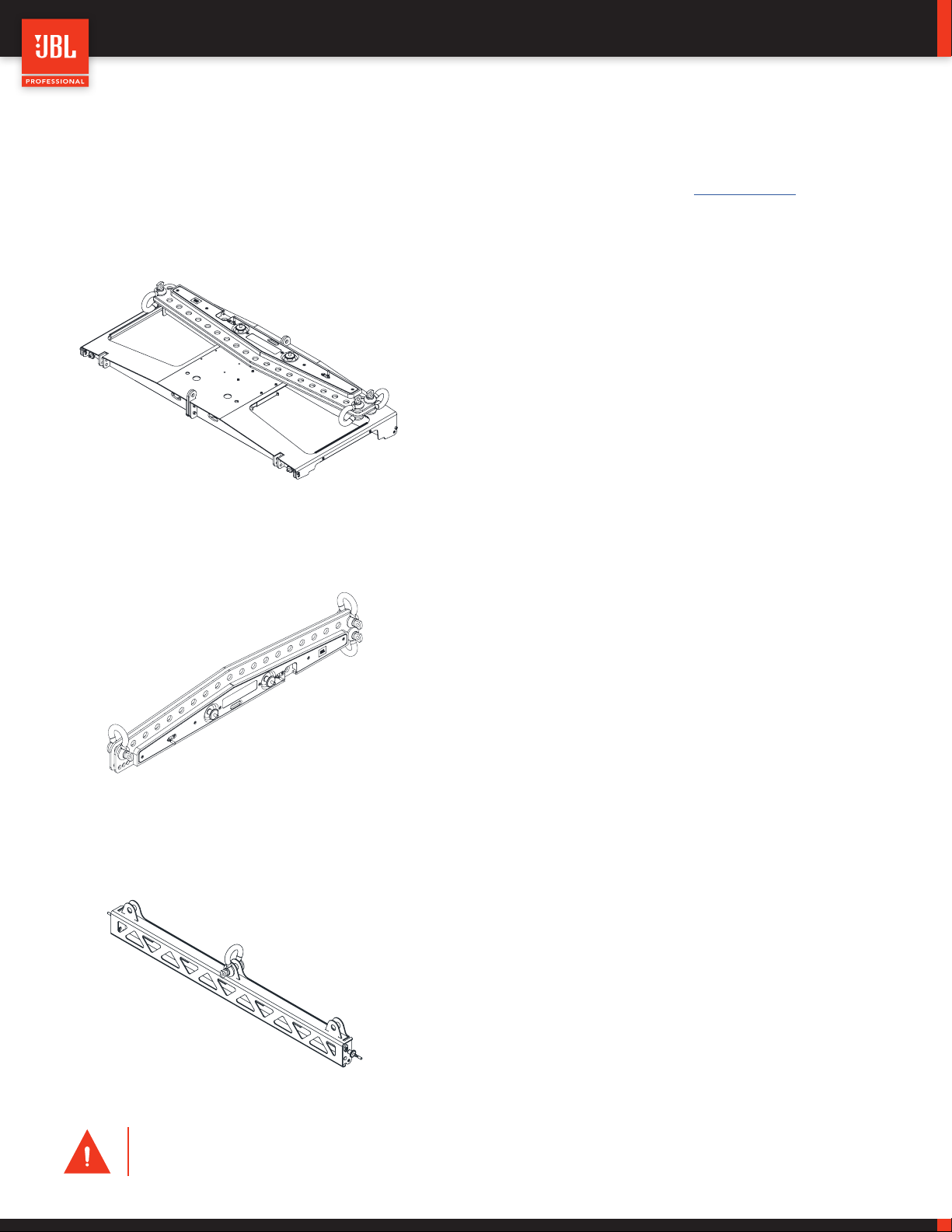

4.2 VTX A12 AF EB - ARRAY FRAME EXTENSION BAR

• Extension Bar for use with the VTX A12 AF

• Two Extension Bars can be used for side-by-side suspension

• Support for up to (24) VTX A12 (array geometry dependent)

• Three 5/8-inch shackles included

• Lightweight design

4.3 VTX A12 SB - SUSPENSION BAR

• Compact suspension bar for VTX A12

• Connects to the top or bottom cabinet of an array

• Used to implement pull-back

• Used for suspending VTX A12 enclosures

• Support for up to (18) VTX A12

• Lightweight design

CAUTION: Always use components and accessories specified and approved by JBL Professional. When a cart is used,

use caution when moving the cart to avoid injury from tip-over.

11

Page 12

4.4 VTX A12 VT - VERTICAL TRANSPORTER

• Vertical Transport cart for four VTX A12 enclosures

• Truck pack-friendly dimensions

• Hard top included for easy stacking and transportation

• Built-in stacking features for easy storage

• Ground stacking support with optional accessory

• Heavy-duty casters

• Constructed from steel and aluminum parts

4.5 VTX A12 VT CVR - SOFT COVER

• Heavy-duty cover for four VTX A12 enclosures

VTX A12 | User Manual

• Includes input panel access flaps for easy testing

• Clear see-through pocket for shipping labels

• Handle cutouts for easy transportation

• Padded front section for grill protection

4.6 - VTX A12 VT GND - GROUND STACK ACCESSORY

• Outrigger system for ground stacking VTX A12

• Support for up to six VTX A12 enclosures

• Four screw jacks are included for adjusting height

• Zero-gravity angle set hinge system

• Range: -15 to +5 degrees

• Connects to the VTX A12 VT

4.7 VTX DELTA - DELTA PLATE

• Universal delta plate accessory for VTX systems

• Support for up to (24) VTX enclosures

• Allows for +/- 10-degree horizontal adjustments

• Includes three 5/8-inch shackles

• Working Load Limit: 2,177 kg (4,800 lbs)

12

Page 13

4.8 VTX A12 BP - BASE PLATE

VTX A12 | User Manual

• Enables ground stacking VTX A12 arrays

• Universal M20 threaded pole mount

• Attaches directly to VTX B28 subwoofer enclosure

• Array angles selectable between -15 degrees and +5 degrees

• Two-part lightweight design

• Support for up to six VTX A12 enclosures

• Connects directly to the VTX B28

13

Page 14

5 - SOFTWARE

VTX A12 | User Manual

5.1 LINE ARRAY CALCULATOR 3TM

LAC-3 is simulation software for designing and predicting VTX Se-

ries systems. LAC-3 predicts the acoustical performance of line

array systems, as well as flown and ground-stacked subwoofer ar-

rays. Subwoofer delay values can be generated for electronic delay

steering (EDS) using the built-in coverage calculator. LAC-3 also

performs mechanical validation of rigging hardware, calculates

weight limits, and generates safety warnings.

www.jblpro.com/lac3

5.2 ARRAY LINKTM

Array Link is a mobile companion app that works in conjunction

with LAC-3 software to assist in deployment of VTX Series sys-

tems. Array Link uses a QR code system to transfer all mechani-

cal array information from the main LAC-3 application to a mobile

phone. All relevant rigging and mechanical options are presented in

an easy-to-understand layout. The application is compatible with

iOS® and AndroidTM and can be obtained from their respective

app stores.

5.3 PERFORMANCE MANAGERTM

Performance Manager is a configuration and control application for

networked audio systems. Performance Manager’s user interface

guides system designers through the complete system design,

configuration, and control processes. A dedicated show mode

provides all monitoring and control functions needed to deliver a

complete picture of the system’s performance in real time.

www.jblpro.com/performancemanager

14

Page 15

6 - INTRODUCTION

6.1 VTX A12/VTX A12W

VTX A12 | User Manual

JBL VTX A12 is a complete tour sound solution for mid- to large-sized touring applications and high-end fixed installations. VTX A12

was designed from scratch to address the unique challenges of rental companies, FOH engineers, and tour sound production crews.

Next-generation JBL transducer technology and waveguide design deliver unmatched performance, efficiency, and coverage. A pat-

ented JBL rigging mechanism and redesigned suspension system streamline deployment and setup. The VTX A12W is acoustically and

mechanically compatible with the A12 and offers a wider (120-degree) horizontal coverage pattern. VTX A12W can be used standalone

for applications that require wide horizontal coverage or in conjunction with A12 for combination arrays. Refinements to the mechanical

design maximize reliability and versatility, while minimizing size and dramatically reducing weight. VTX A12 isn’t just a superior line ar-

ray—it’s a completely new way to approach tour sound.

KEY MESSAGES

PERFORMANCE

JBL Professional is the world’s leading manufacturer of loudspeaker

systems, using custom-designed and built drivers for optimal per-

formance.

VTX A12’s high frequency (HF) section features three uniquely de-

signed drivers that combine the HF phasing plug and waveguide into

one part providing better tolerances and increased sensitivity above

10 kHz, while reducing distortion and overall weight.

The patented Radiation Boundary Integrator incorporates four 5.5-

inch mid frequency drivers into the high frequency waveguide while

providing a smooth surface for the high frequency horn.

A lightweight 12-inch low frequency woofer (LF) features a fourth-gen-

eration Differential Drive design that adds dual magnets to its dual

voice coil/dual gap construction, and a host of proprietary JBL tech-

nologies for increased excursion, power handling, and sensitivity.

INNOVATIVE RIGGING

VTX A12 marks a giant leap forward in how loudspeakers are

rigged and transported. Four array elements are stacked on

the vertical transporter cart for fast deployment. The rigging

features an auto-locking mechanism, which allows the selec-

tion of angles while components are on the ground; once the

system is suspended, the mechanism automatically locks cab-

inet angles in the designated positions. Set angles simply by

pulling and placing a pin—it’s that easy.

ACCESSORIES

Multiple accessory options provide flexibility in the VTX A12’s

mounting, integration and installation capabilities. Highlights

include a Base Plate that mounts the A12 on top of ground-

stacked subwoofers such as the B28. The array frame and

vertical transporter cart were purpose-built to meet both U.S.

and international truck pack dimensions for the most efficient

system transportation.

15

Page 16

VTX A12 | User Manual

A12

A12 W

A12

A12 W

A12

A12 W

6.2 VTX A12 VS VTX A12W

The A12 is available in standard and wide-coverage versions. The A12 offers 90-degree horizontal coverage, while the A12W offers

120-degree horizontal coverage. The A12 and A12W are acoustically and mechanically compatible, and can be used to create homog-

enous or combination arrays. The A12W’s wider horizontal coverage pattern can be especially useful in providing additional coverage in

short-throw and medium-throw applications.

Mixed arrays of A12 and A12W cabinets can be built to satisfy specific coverage needs. As the listening distance from an array decreas-

es, so does its coverage width. Depending on the venue geometry, A12W speakers can be used at the bottom of an array for broad near-

field coverage. The use of identical components in the A12 and A12W ensures that the transition between the two models is seamless,

without noticeable discrepancies in voicing or headroom.

Since the A12 and A12W require different processing presets to function correctly, they should never be assigned to the same circuit

group. Plan array circuiting accordingly.

6.3 IDENTIFYING A12 AND A12W

From the front, the A12 and A12W look identical, resulting in a clean and consistent look, even when creating mixed arrays. The A12W

input panel is colored blue to differentiate the two models, even when the system is suspended and/or at a distance.

16

Page 17

VTX A12 | User Manual

7 - CONNECTIONS

The VTX A12 is equipped with two Neutrik NL8 speakON connectors, which are wired in parallel, so that one can be used to receive

input while the other acts as a through connection for daisy-chaining cabinets. The NL8 connectors are installed upside down, so that

the NL8 locking pin position can be seen from under the array.

VTX A12 internal NL8 pinout

NL8 Pin Pin 1 +/- Pin 2 +/- Pin 3 +/- Pin 4 +/-

Transducers LF Left LF Right MF HF

7.1 INTERNAL WIRING

LF

1+

1-

2+

2-

3+

3-

4+

4-

1+

1-

2+

2-

3+

3-

4+

4-

MF

HF

CAUTION: Always use high-quality insulated speaker cables from reputable manufacturers. Use cables with a

wire gauge sufficient for the application and keep cable length as short as possible.

17

Page 18

VTX A12 | User Manual

8 - SYSTEM AMPLIFICATION

Like all VTX systems, the VTX A12 is powered exclusively by Crown I-Tech HD amplifiers for optimum performance and consistency

around the world. Crown I-Tech HD Series amplifiers feature BSS Audio OMNIDRIVEHD™ processing on each amplifier channel, includ-

ing the acclaimed LevelMAX™ Limiter Suite and support for linear-phase FIR filters. All A12 processing is performed by the I-Tech HD’s

internal DSP; no other DSP is required. Crown amplifiers include a user-adjustable input section for room correction equalization, array

size compensation, and circuit adjustments.

Standard A12 presets are available for both the Crown I-Tech 4x3500HD and Crown I-Tech 12000HD. The most up-to-date presets

are available for download from www.jblpro.com, and are always bundled in the latest version of JBL’s Performance Manager control

software.

CAUTION: The A12 and A12W require different presets, as each set of presets is designed for a specific speaker

type. A12 and A12W presets are not interchangeable, so the two models cannot be used within the same circuit

group. Independent amplifier drive is required.

8.1 USING THE A12 WITH CROWN I-TECH 4X3500HD

A Crown I-Tech 4x3500HD amplifier can power up to three A12 loudspeakers. Based on the power demands of the A12, this allows for

optimum power-to-transducer ratio without compromising the maximum SPL capabilities of the system. When finer control of coverage

in a venue is needed, smaller coverage areas can be created by using circuits of two cabinets.

Crown I-Tech 4x3500HD JBL VTX A12

Amplifier Channels

Channel 1 A12 LF

Channel 2 A12 LF

Channel 3 A12 MF

Channel 4 A12 HF

18

Page 19

VTX A12 | User Manual

8.2 USING THE A12 WITH CROWN I-TECH 12000HD

A pair of Crown I-Tech 12000HD amplifiers can power up to three VTX A12 loudspeakers. One Crown I-Tech 12000HD powers the low

frequency section, while the other drives the mid and high frequency sections. Based on the power demands of the A12, this allows for

optimum power-to-transducer ratio without compromising the maximum SPL capabilities of the system. When finer control of coverage

in a venue is needed, smaller coverage areas can be created by using circuits of two cabinets.

Crown I-Tech 12000HD JBL VTX A12

Amplifier 1 - Channels

Channel 1 A12 MF

Channel 2 A12 HF

Amplifier 2 - Channels

Channel 1 A12 LF

Channel 2 A12 LF

TIP: Other channel assignments can be implemented when using two-channel Crown I-Tech HD amplifiers. Use JBL’s Per-

formance Manager control software to assign speaker presets.

CAUTION: Make sure the total number of VTX A12 enclosures per circuit/amplifier does not exceed the recom-

mended maximum.

8.3 CROWN AUDIO V-RACK

VTX A12 systems are compatible with the Crown V-Rack 12000HD and Crown V-Rack 4x3500HD touring racks. The number of sup-

ported cabinets per amplifier and wiring options remain the same as the Crown I-Tech examples illustrated in this document. For more

information on the Crown V-Rack products, refer to the V-Rack User Manuals and documentation.

19

Page 20

VTX A12 | User Manual

9 - VTX A12 PRESET LIBRARY

The VTX A12 preset library includes standard array and fill (FL) operating modes, along with full-range and 80 Hz low frequency proc-

cessing for combinations of the A12 with VTX subwoofers. Presets for cardioid array configurations are included for all VTX subwoofer

models. VTX presets are exclusively developed for Crown I-Tech HD amplifiers and come bundled with Performance Manager control

software. Audio Architect™ presets are also available and can be downloaded from www.jblpro.com. Please see below for a detailed

description of VTX A12 operating modes and subwoofer processing options, and refer to the Preset Library setup sheets for preset

descriptions, memory locations, and output channel assignments.

9.1 VTX A12 PRESET MODES AND OPTIONS

Two preset modes and two low frequency processing options are available:

VTX A12 FL: The FL presets (short for FILL) have a nominally flat frequency response and are designed for situations where one or two

A12 cabinets are appropriate, such as for distributed front fills. With this preset, the acoustical low frequency response of the system

extends down to 45 Hz (full-range).

VTX A12 FL 80: The FL 80 presets have nominally flat frequency response and are to be used in situations where one or two A12 cabi-

nets are appropriate, such as for distributed front fills. With this preset, the acoustical low frequency response of the system is set to 80

Hz and used when subwoofers are available.

VTX A12: This is the standard VTX A12 preset for array use. A high frequency shelving response is applied to offset LF/MF array buildup

for nominally focused arrays (equally spaced impact points over the desired audience coverage area). With this preset, the acoustical

low frequency response of the system extends down to 45 Hz (full-range).

VTX A12 80: This is the standard VTX A12 preset for array use with subwoofers. A high frequency shelving response is applied to offset

LF/MF array buildup for nominally focused arrays (equally spaced impact points over the desired audience coverage area). With this

preset, the acoustical low frequency response of the system is set to 80 Hz. The VTX A12 80 preset will generate the highest A-weighted

maximum sound pressure level.

CAUTION: All preset options are available for both the VTX A12 (90-degree coverage pattern) and the VTX A12W

(120-degree coverage pattern). A12 and A12W presets cannot be used interchangeably. Always use the appropri-

ate preset to guarantee proper system performance.

TIP:

• Both the full-range and 80 Hz presets can be used with subwoofers, depending on the application and subwoofer

arrangement. For more information on subwoofer use, see chapter 10 – Subwoofer Options.

• Mixing FL and standard presets in the same array is not recommended.

• The VTX A12 presets provide a well-balanced tonal starting point for a given array size. The Array Size Compensation

filter in the JBL Line Array Control Panel (LACP) can be used to further fine-tune tonal balance for a given array size

and shape. Please refer to chapter 12 - Line Array Control Panel for more information.

20

Page 21

VTX A12 | User Manual

Frequency (Hz)

SPL (dB)

20

10 - SUBWOOFER OPTIONS

VTX A12 presets are designed for a 3:2 minimum ratio of A12 cabinets to VTX B28 or S28/G28 subwoofers. The 3:2 ratio provides suffi-

cient headroom for both the subwoofers and the A12s to reach their MAX SPL (i.e. limiter threshold) at the same time, while maintaining

a minimum of 10 dB subwoofer to full-range low frequency contour. Other ratios can be used depending on the desired tonal balance

target, MAX SPL, and application.

VT X A12 VT X B28

10.1 SUB/LF PRESET OPTIONS

As mentioned, there are two LF presets available for the A12 system: the VTX A12 (full-range) preset, which extends the frequency re-

sponse of the system down to 45 Hz, and the VTX A12 80 (80 Hz) preset, which extends the frequency response of the system down

to 80 Hz. The VTX A12 (full-range) preset is used when the system is operated without subwoofers or when the application calls for

extended LF response from the main arrays. The VTX A12 80 (80 Hz) preset is used only when subwoofers are available and the highest

A-weighted sound pressure level (SPL) is required. When multiple A12 arrays are used (e.g. main and side arrays), all A12 arrays should

be operated in the same LF mode for headroom consistency and proper summation. Subwoofers are typically set to the mode corre-

sponding to the mode selected for the A12.

Example 1: A12 80 | SUB: 80 Example 2: A12 FR | SUB: 60/80

20

10

10

SUB: 80Hz

0

SPL (dB)

-10

-20

20 100 1000

Frequency (Hz)

21

0

-10

-20

20 100 1000

SUB: 60Hz

Page 22

10.2 PRESET EXAMPLE 1

VTX A12 | User Manual

A12 Full-range or 80 Hz

VTX B28 60 Hz or 80 Hz

10.3 PRESET EXAMPLE 2

A12 Full-range or 80 Hz

VTX B28 60 Hz or 80 Hz

VTX B28 80 VTX B28 80

VTX A12 80 VTX A12 80

VTX A8 FL 80

VTX B28 80

22

Page 23

VTX A12 | User Manual

10.4 TIME ALIGNMENT

The VTX A12 presets provide proper system summation with companion VTX subwoofers in physically coupled configurations (stacked

or suspended), and when used with corresponding subwoofer presets. This pre-alignment is done at the factory, allowing any VTX sub-

woofer to be used with any VTX loudspeaker without the need for subwoofer presets specific to each system and configuration. When

the VTX A12 is operated in full-range mode with companion subwoofers, some additional delay should be applied to the subwoofers to

match the A12.

VTX A12 VTX B28

Additional time alignment delay should be added as needed to account for physical path length differences between suspended A12

arrays and ground-stacked subwoofers. If no acoustic measurement system is available, delay values can be calculated based on the

geometric path difference between a reference point (i.e. FOH position) and each system. This method is effective because every VTX

preset includes a factory pre-delay to correctly align all components. When the latency of a system is unknown, this method is not ef-

fective and should not be used. This can occur when the signal paths of different parts of the system vary in latency.

Path Difference = dFlown Array - dSub

Sub Delay =

Path Diff

Sub Delay =

Path Difference (meters)

343 (meters / second)

or

Path Difference (feet)

1140 (feet / second)

23

dFlown Array

dSub

dSub

Page 24

VTX A12 | User Manual

11 - FREQUENCY RESPONSE

The frequency response of a line array is determined by many factors, including the array size (number of boxes), array curvature (cab-

inet-to-cabinet angles) and listening distance. JBL factory presets are designed to create a well-balanced tonal starting point for given

array conditions. For example, the standard array presets are designed to work optimally with array sizes between eight and 12 cabinets

and equal impact spacing for a flat listening plane. An array with these parameters generates a flat HF frequency response with a grad-

ual rise in LF energy. The frequency at which the response starts rising depends on the array parameters mentioned above. A relatively

short array starts rising at a lower frequency than a longer array. Below are examples of the frequency responses of A12 arrays using the

standard VTX A12 presets with no additional equalization/correction (flat).

Example 1 : A12 Frequency response vs number of cabinets

20

Frequency response of a 12-cabinet A12 array

10

0

SPL (dB)

-10

-20

20 100 1000 10000 20000

Frequency (Hz)

Example 2: Standard preset vs 80 preset

20

10

0

SPL (dB)

-10

-20

20 100 1000 10000 20000

Frequency (Hz)

Frequency response of an eight-cabinet A12 array

Frequency response of a six-cabinet A12 array

Frequency response of a four-cabinet A12 array

Frequency response of a 12-cabinet A12 array

Frequency response of a 12-cabinet A12 array using the

80 Hz preset

Since a factory preset cannot account for all variables and array configurations, user adjustment of certain DSP parameters is neces-

sary to achieve the desired tonal balance for a given array and application. The LF response of any VTX line array system can be easily

adjusted using the Array Size Compensation Filter in the Line Array Control Panel. The Array Size Compensation Filter was specifically

designed to compensate for LF/MF buildup with a single, adjustable parameter. Lowering the gain value of this filter shifts down the

frequency at which LF response starts rising — similar to shortening the length of an array.

24

Page 25

12 - LINE ARRAY CONTROL PANEL

VTX A12 | User Manual

The JBL Line Array Control Panel (LACP) was designed to tailor

the tonal balance of a line array with its five adjustable DSP filters.

Each filter serves a specific purpose and accelerates the system

tuning process. Two filters are global, grouped across the entire

array, while the other three filters are designated for circuit-spe-

cific adjustments.

12.1 ACCESSING LACP

LACP filters can be modeled in Line Array Calculator 3 software and then imported into Performance Manager for deployment to actual

devices. To access LACP within Line Array Calculator 3 use the grouping feature to create circuit groups. The groups should represent

the actual array amplification. This enables realistic and accurate DSP adjustments. After creating the circuit groups, click the LACP

button under the DSP column. Global filters, like Filters 1 and 2, are automatically applied to all circuit groups in the array.

25

Page 26

VTX A12 | User Manual

12.2 FILTER 1 - ARRAY SIZE COMPENSATION

Filter 1 is used to correct for LF/MF buildup when the array size or shape differ from that for which the factory preset was designed.

Filter 1 is automatically applied globally to provide uniform LF adjustments to all cabinets in the array. Filter 1 is a continuously variable

low-shelving filter. Its parameters (corner frequency and slope) are adjusted based on the applied gain value. Array buildup is different

for each configuration, and Filter 1 is optimized to correct for this effect using only one parameter (Gain).

12.3 FILTER 2 - ATMOSPHERIC ABSORPTION COMPENSATION

Filter 2 compensates for atmospheric conditions such as large variations in temperature and humidity, which can impact overall HF

energy. Filter 2 is applied globally and can be used to quickly brighten or darken an array. This filter can also be used to adjust overall

system tonal balance to taste.

12.4 FILTER 3 - HF THROW DISTANCE COMPENSATION

Filter 3 is used to correct for distance offsets between different sections of an array. The Type, Frequency, and Q parameters are linked

across the entire array, but the Gain parameter is adjustable per circuit group. This filter can be used to reduce HF energy delivered close

to an array and increase HF energy reaching further areas, where air absorption has a bigger impact.

12.5 FILTERS 4 & 5 - USER PEQ 1 & 2

Filters 4 and 5 are User parametric EQs, which can be applied to individual circuit groups. As the Frequency and Q parameters are not

linked across circuits, it is recommended that User PEQ 1 & 2 be used only for moderate gain changes of frequencies above 1kHz.

26

Page 27

VTX A12 | User Manual

12.6 EXAMPLE USING LACP

This example is for a 12-cabinet VTX A12 array. The standard A12 preset is used, with the Array Size Compensation filter set to –3 dB

to offset LF buildup and achieve a flatter frequency response. As seen from the illustration below, Array Size Compensation is globally

applied to all array circuits. The HF Throw Distance compensation filter (Filter 3) on the bottom circuit can apply HF attenuation to correct

for proximity differences. Simple adjustments to the LACP filters can get an A12 system to a very good staring point. Further required

adjustments will depend on the room and specific application.

TIP: The LACP parameters used in LAC-3 to predict an array can be easily applied to an actual array in Performance

Manager. For information on how to import LACP parameters into Performance Manager, please refer to the Performance

Manager documentation.

27

Page 28

VTX A12 | User Manual

13 - TESTING VTX A12

Speakers need to be periodically checked and maintained to assure long-term performance and reliability. While the VTX A12 is designed

for the utmost reliability, it is important to confirm that the system is operating within specified tolerances to ensure optimal performance

for years to come. Below are two methods that can be used to check and verify proper transducer performance in a VTX A12 system.

13.1 USING A DMM (DIGITAL MULTIMETER)

This method is best suited for when the speaker system is in the shop. A DCR (DC resistance) test with a multimeter can give a very

accurate reading of how many transducers are properly wired together and within their standard operating tolerances. This test is ap-

propriate for individual cabinets and not groups.

With the A12 speaker unconnected to any amplifiers, set a DMM to the resistance (Ω) setting and place the probes across the 1+/-, 2+/-,

3+/-, and 4+/- leads. Record the values indicated on the DMM for each pair of leads and refer to the chart below to either confirm correct

readings or investigate out-of-tolerance DCR readings.

HF Section (Pin 4)

DCR Tolerance

All drivers functioning 7.0 Ω +/- 0.2 Ω

1 x HF Driver open 10.3 Ω +/- 0.2 Ω

2 x HF Drivers open 20.5 Ω +/- 0.2 Ω

3 x HF Drivers open OL -

Any driver shorted 0.2 Ω -

MF Section (Pin 3)

DCR Tolerance

All woofers functioning 5.4 Ω +/- 0.2 Ω

1 x woofer open 10.8 Ω +/- 0.2 Ω

LF Section (Pin 1 / 2)

DCR Tolerance

Functioning woofer 5.5 Ω +/- 0.2 Ω

Shorted 0.2 Ω -

Notes:

• The DCR values listed above assume room temperature transducers. If measurements are taken right after use, when the transduc-

ers are warm, the values will vary. For best results, test the speakers cold.

• The DCR value of a transducer gives an accurate representation of its electrical state, but mechanical defects are not characterized

by this test. Refer to the VTX A12 Service Manual for instructions on performing a rub-and-buzz test with a sine wave generator.

28

Page 29

VTX A12 | User Manual

13.2 USING PERFORMANCE MANAGER

When in the field, the Test System Mode in Performance Manager can be used to test an A12 system. This test method is quick and

especially useful for determining whether all the speaker cables, including cabinet-to-cabinet NL8 jumpers, are properly functioning.

To perform the test, Performance Manager uses the I-Tech HD’s built-in noise generator, in conjunction with the amplifier’s current draw

and voltage-sensing capabilities, to generate a nominal load impedance reading for each amplifier output channel. Since broadband

pink noise is used as the test stimulus, the returned value is considered to be an impedance value, and it will differ from the resistance

values given earlier in this document (which are taken using DC voltage as the stimulus). `

STEPS:

1

• Make sure Performance Manager is online and connected to the devices.

2

• Navigate to the Test System Mode and make sure all speakers are muted.

3

• Switch the Noise Generator to the ON position and set the level to a value between -30 dB and -10 dB. Values lower than -30

dB may not be sufficient to trigger a reading.

4

• Unmute the speaker or a bandpass to start the measurement. The measured value is displayed on the speakers.

13.3 PERFORMANCE MANAGER READINGS

Below are the expected impedance values for a single VTX A12, a circuit of two A12 cabinets, and a circuit of three A12s. The measure-

ments below were taken at room temperature with a cable length of 25 m (82 ft). Acceptable tolerance is +/- 0.5 Ω.

1 x VTX A12 2 x VTX A12 3 x VTX A12

Variances in temperature, cable length, wire gauge, and usage can make the measurements recorded by Performance Manager more

susceptible to drift. However, variations in conditions like temperature are common across all similar circuits of a system. More important

than the individual component values is consistency across similar circuits. For example, all three-cabinet circuits for an array should

measure similarly. If one is off by several ohms, there is likely something wrong with that specific circuit.

29

Page 30

14 - SPECIFICATIONS

SYSTEM

14.2 VTX A12 SPECIFICATIONS

Frequency Range (-10 dB):

46 Hz - 19 kHz (Preset: VTX A12)

VTX A12 | User Manual

Coverage Pattern (-6 dB)

Horizontal:

Vertical:

System Input Power Rating

MF:

HF:

Maximum Peak Output²:

System Amplification:

Required Amplifier Channels:

Number of Cabinets per Circuit:

System Impedance:

TRANSDUCERS

Low Frequency :

Mid Frequency :

High Frequency :

90 degrees nominal (250 Hz - 18 kHz)

Varies with array size and configuration

1

2x 800W Continuous (IEC/100 hour)

LF:

400W Continuous (IEC/100 hour)

150W Continuous (IEC/100 hour)

146 dB (Preset: VTX A12)

Crown I-Tech 9000HD

Crown I-Tech 12000HD

Crown I-Tech 4x3500HD

(4) channels (LF|LF|MF|HF)

(3) VTX A12

LF: 2x 8 ohms | MF: 8 ohms | HF: 8 ohms

(2) JBL 2264H, 12 in diameter, dual 3 in diameter voice coil, Neodymium Differential Drive®

(4) JBL 2165H, 5.5 in diameter, dual 2 in diameter voice coil, Neodymium Differential Drive®

(3) JBL 2423K, 2 in diameter annular diaphragm, 2 in diameter voice coil, Neodymium compression drivers

ENCLOSURE

Construction :

IP Rating3 :

Suspension :

15 mm 11-ply Finnish birch plywood, Black DuraFlexTM finish, four integral recessed handles

IP55 EN (60529)

High-grade steel with anti-corrosion coating, captive suspension plates, quick release pins, auto-locking mechanism for setting angles

Inter-enclosure Angle (deg) :

0.25, 0.5, 1, 1.5, 2, 2.5, 3, 4, 6, 8, 10

Powder coated 1.8 mm (14-guage), hex-perforated steel with acoustically transparent black cloth backing

Grill :

Connectors

(2) Neutrik® speakON® NL-8

Type :

Pin Assignments :

Pins 1 ± (LF), Pins 2 ± (LF),

Pins 3 ± (MF), Pins 4 ± (HF)

Dimensions (H x W x D) :

330 mm x 1118 mm x 495 mm

13 in x 44 in x 19.5 in

Net Weight :

Footnotes:

1: IEC Standard: IEC shaped noise with 6 dB crest factor based on nominal impedance and a duration of 100 hours

2: Peak, unweighted SPL, measured under full-space conditions at 1 meter using broadband pink noise with a 12dB crest factor and specified preset

3: Front face at 0 degree or greater down angle to allow the cabinet to drain water. Suspension components fully weather rated for indoor or covered outdoor conditions where humidity is nominally under 50% and not local

to bodies of corrosive materials. Unused speakON connectors must be sealed using silicone to protect against water and moisture

JBL continually engages in research related to product improvement. Some materials, production methods and design refinements are introduced into existing products without notice as a routine expression of that

philosophy. For this reason, any current JBL product may differ in some respect from its published description, but will always equal or exceed the original design specifications unless otherwise stated.

60.8 kg (134 lbs)

30

Page 31

14.2 VTX A12W SPECIFICATIONS

SYSTEM

Frequency Range (-10 dB):

46 Hz - 19 kHz (Preset: VTX A12W)

VTX A12 | User Manual

Coverage Pattern (-6 dB)

Horizontal:

Vertical:

System Input Power Rating

MF:

HF:

Maximum Peak Output²:

System Amplification:

Required Amplifier Channels:

Number of Cabinets per Circuit:

System Impedance:

TRANSDUCERS

Low Frequency :

Mid Frequency :

High Frequency :

120 degrees nominal (250 Hz - 18 kHz)

Varies with array size and configuration

1

2x 800W Continuous (IEC/100 hour)

LF:

400W Continuous (IEC/100 hour)

150W Continuous (IEC/100 hour)

146 dB (Preset: VTX A12W)

Crown I-Tech 9000HD

Crown I-Tech 12000HD

Crown I-Tech 4x3500HD

(4) channels (LF|LF|MF|HF)

(3) VTX A12W

LF: 2x 8 ohms | MF: 8 ohms | HF: 8 ohms

(2) JBL 2264H, 12 in diameter, dual 3 in diameter voice coil, Neodymium Differential Drive®

(4) JBL 2165H, 5.5 in diameter, dual 2 in diameter voice coil, Neodymium Differential Drive®

(3) JBL 2423K, 2 in diameter annular diaphragm, 2 in diameter voice coil, Neodymium compression drivers

ENCLOSURE

Construction :

IP Rating3 :

Suspension :

15 mm 11-ply Finnish birch plywood, Black DuraFlexTM finish, four integral recessed handles

IP55 EN (60529)

High-grade steel with anti-corrosion coating, captive suspension plates, quick release pins, auto-locking mechanism for setting angles

Inter-enclosure Angle (deg) :

0.25, 0.5, 1, 1.5, 2, 2.5, 3, 4, 6, 8, 10

Powder coated 1.8 mm (14-guage), hex-perforated steel with acoustically transparent black cloth backing

Grill :

Connectors

(2) Neutrik® speakON® NL-8

Type :

Pin Assignments :

Pins 1 ± (LF), Pins 2 ± (LF),

Pins 3 ± (MF), Pins 4 ± (HF)

Dimensions (H x W x D) :

330 mm x 1118 mm x 495 mm

13 in x 44 in x 19.5 in

Net Weight :

Footnotes:

1: IEC Standard: IEC shaped noise with 6 dB crest factor based on nominal impedance and a duration of 100 hours

2: Peak, unweighted SPL, measured under full-space conditions at 1 meter using broadband pink noise with a 12 dB crest factor and specified preset

3: Front face at 0 degree or greater down angle to allow the cabinet to drain water. Suspension components fully weather rated for indoor or covered outdoor conditions where humidity is nominally under 50% and not local

to bodies of corrosive materials. Unused speakON connectors must be sealed using silicone to protect against water and moisture

JBL continually engages in research related to product improvement. Some materials, production methods and design refinements are introduced into existing products without notice as a routine expression of that

philosophy. For this reason, any current JBL product may differ in some respect from its published description, but will always equal or exceed the original design specifications unless otherwise stated.

60.8 kg (134 lbs)

31

Page 32

15 - ACOUSTIC MEASUREMENTS

Frequency (Hz)

20 180

-180

SPL (dB)

20000

Frequency (Hz)

360

-6 dB Beamwidth (degrees)

Frequency (Hz)

20 180

-180

SPL (dB)

20000

Frequency (Hz)

360

-6 dB Beamwidth (degrees)

15.1 VTX A12

VTX A12 | User Manual

FREQUENCY RESPONSE

10

0

-10

-20

20 100 1000 10000 20000

VTX A12 FL VTX A12 FL 80 VTX A12 Phase

15.2 VTX A12W

FREQUENCY RESPONSE

10

0

BEAMWIDTH

90

0

-90

100

10

20 100 1000

Horizontal Beamwidth

BEAMWIDTH

90

0

100

-10

-20

20 100 1000 10000 20000

VTX A12W FL VTX A12W FL 80 VTX A12W Phase

-90

10

20 100 1000

Horizontal Beamwidth

32

Page 33

16 - DIMENSIONS

VTX A12 | User Manual

1091 mm (43 in)

330 mm (13 in)

1117 mm (44 in)

165 mm (6.5 in)

203 mm (7.9 in)

10.00°

493 mm (19.4 in)

33

Page 34

17 - CONTACTS INFORMATION

UNITED STATES OF AMERICA

VTX A12 | User Manual

HARMAN Professional Solutions

8500 Balboa Blvd.

Northridge, CA 91329

USA

+1 (844) 776-4899

www.jblpro.com

PROFESSIONAL CONTACTS OUTSIDE THE U.S.A.:

Contact the JBL Professional distributor in your area. A complete list of JBL Professional international distributors is provided at our

U.S.A. website: www.jblpro.com

HARMAN Professional EMEA

Westside

London Road

Hemel Hempstead

HP3 9TD

United Kingdom

www.pro.harman.com

www.jblpro.com/support

U.S.A. Technical Support

+1 (800) 852-5776

HProTechSupportUSA@Harman.com

www.jblpro.com

HARMAN Professional APAC

108 Pasir Panjang Road

#02-08 Golden Agri Plaza

Singapore 118535

+65 6870-5000

www.pro.harman.com

www.jblpro.com/support

HARMAN Professional China

20F, China Merchants Port Plaza, #1

Gongye 3rd Road, Shekou, Nanshan

Dist.

Shenzhen, 518067, China

400 166 7806

www.harman.com/China

HARMAN Professional India

Prestige Technology Park

Jupiter 2A Block, 4th Floor

Marathahalli Ring Road

Bangalore 560103, India

+1 (800) 208-8880

www.harman.com/India

India In-Country Support

www.harman.com/india/india-service-center

China In-Country Support

ChinaPRO.Service@harman.com

HARMAN Professional Brazil

Br386, Km435 92480-000

Nova Santa Rita Rs

Brazil

+55 51 34794000

www.harman.com/Brasil

www.jblaudio.com.br

Brazil In-Country Support

tecnica@harman.com

34

Page 35

Loading...

Loading...