JBL TLXPS-12 Service manual

SERVICE MANUAL

TLX PS12

Discrete Output, High Current

12" Powered Subwoofer

JBL Consumer Products Inc.

250 Crossways Park Drive

Woodbury, N.Y. 11797

A Harman International Company

1112-TLXPS12 Rev A

Powered Subwoofer TLX PS12

TABLE OF CONTENTS

Specifications .................................................................1

Warranty .........................................................................2

Safety Symbols ..............................................................2

Controls and Their Functions.........................................3

Test Procedure ...............................................................4

Trouble Shooting Before Opening .................................5

Removing the Amplifier..................................................5

Trouble Shooting After Removal ...................................5

Components Requiring Exact Replacement..................6

SPECIFICATIONS

Amplifier Power RMS ...........120Watts

Drivers ................12"with high-polymer-laminated cones

Inputs ................Line level and Speaker Level

Outputs* ...............High level with High-Pass filter at 180Hz

Crossover Frequency ...........50-150Hz

(continuosly variable)

Frequency Response ...........23Hz to (50-150Hz)

(-6dB)

Block Diagram ................................................................7

Amplifier Exploded View ................................................8

Cabinet Exploded View..................................................9

Parts Lists.....................................................................10

Packaging and Shipping ..............................................12

Integrated Circuit Diagrams .........................................13

Printed Circuit Boards .................................................14

Schematic Diagrams ...................................................16

External Dimensions (Inches)

Height ................193/4"

Width ................15"

Depth ................163/4"

Weight ................43lbs

Shipping Weight .............49lbs

External Dimensions (mm)

Height ................502mm

Width ................381mm

Depth ................426mm

Weight ................19.5 kg

Shipping Weight .............22.3 kg

* High-Level (speaker) outputs are active only if high-level input are used.

Occasional refinements may be made to existing products without notice, but will always

meet or exceed original specifications unless otherwise stated.

1

Powered Subwoofer TLX PS12

WARRANTY

This amplifier is warranted against defects in material

and workmanship for a period of one year from date of

shipment, when installed in accordance with the owners

manual in a clean, dry, interior home environment. THIS

AMPLIFIER IS NOT SUITABLE FOR OPERATION

OUTSIDE OR IN HARSH ENVIRONMENTS. During the

warranty period, the manufacturer will, at its option, either

repair of replace products which prove to be defective.

For warranty service or repair, this product must be

properly packed and returned to a service facility

designated by the manufacturer. Buyer shall prepay

shipping charges to the designated facility and the

manufacturer shall pay shipping charges to return the

product to buyer. However, Buyer shall pay all shipping

charges, duties and taxes for products returned to the

manufacturer from another country.

The manufacturer does not warrant that the operation of

the product will be uninterrupted or error-free. The Buyer

must determine the suitability of the product for his or her

purposes.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects

resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied interfacing, unauthorized

modification or misuse, operation outside of the

environment specifications for the product including

inadequate ventilation, or improper site preparation,

installation, or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR

IMPLIED. THE MANUFACTURER SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITYAND FITNESS FOR A PARTICULAR

PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYERS

SOLE AND EXCLUSIVE REMEDIES. THE

MANUFACTURER SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

SAFETY SYMBOLS

The following symbols are used throughout this manual

and in the product. Familiarize yourself with each of the

symbols and its meaning before servicing this amplifier.

Instruction manual symbol. The product will be

marked with this symbol when it is necessary for

the user to refer to the instruction manual in order

to protect the unit against damage.

Indicates dangerous voltages are present. Be

extremely careful.

The

CAUTION

hazard. It calls attention to a

procedure which, if not correctly

performed or adhered to, could result in damage to or

destruction of the amplifier. Do not proceed beyond a

CAUTION

understood and met.

result in injury or loss of life. Do not proceed beyond a

sign until the indicated conditions are fully

The

WARNING

hazard. It calls attention to a

procedure which, if not correctly

performed or adhered to could

sign denotes a

sign denotes a

WARNING

understood and met.

sign until the indicated conditions are fully

GENERAL SAFETY CONSIDERATIONS

THIS UNIT DOES NOT HAVE A POWER SWITCH;

HAZARDOUS VOLTAGES ARE PRESENT WITHIN THE

UNIT WHENEVER IT IS PLUGGED IN.

when the over-temperature thermostat opens, as it may

automatically reset at any time.

There are voltages and hot components at many points

in the amplifier which can, if contacted, cause serious injury.

Be extremely careful. Any adjustments or service

procedures that require operation of the amplifier out of its

enclosure should be performed only by trained service

personnel.

This still applies

2

Powered Subwoofer TLX PS12

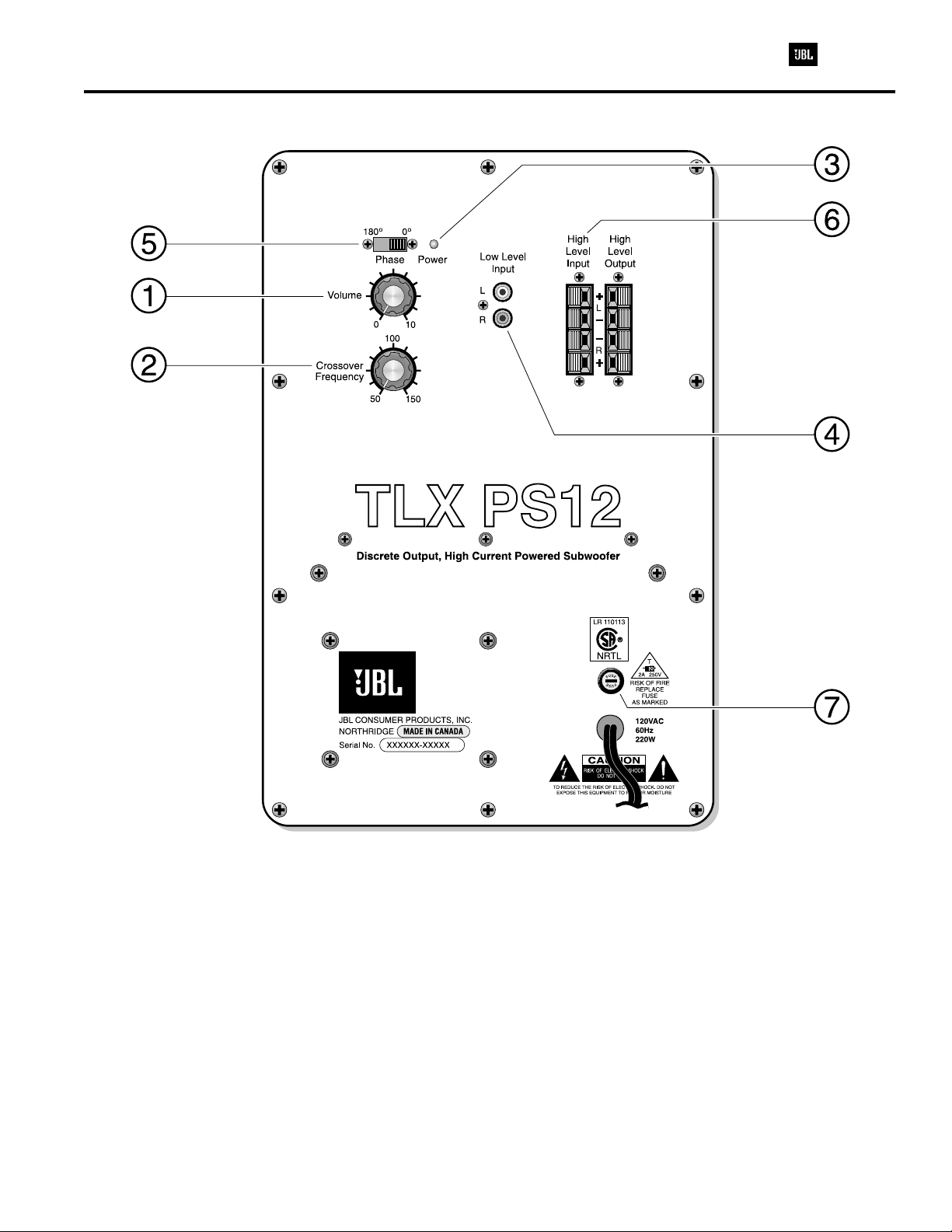

CONTROLS AND THEIR FUNCTION

1. Output Level - The Output Level adjustment

determines volume level strength.

2. Crossover Frequency - The Crossover Frequency

adjustment determines the highest frequency the

TLX PS10 will reproduce. It allows a seamless

transition from the subwoofer to the satellite

speakers.

3. On (LED) - This LED will light green when the unit is

plugged in and is receiving signal. When in

standby mode the LED is red.

4. Low Level Input - These left and right Line Level

Inputs are normally used when the receiver/

processor has line-level “pre-amp out” or subwoofer

out” jacks.

5. Phase Switch - The Phase switch is used to adjust

the relative polarity of the subwoofer. Normally

this switch is set to “0”.

6. High Level Inputs - These High Level Inputs are for

receivers that don’t have line-level “pre-amp out” or

“subwoofer out” jacks. When a pair of main or

satellite speakers are attached to the OUTPUT

terminals, frequencies below 180 Hz are attenuated

by the high-pass filter.

7. Fuse - Use only a slow-blo 2.0A 250V GMC fuse.

3

Powered Subwoofer TLX PS12

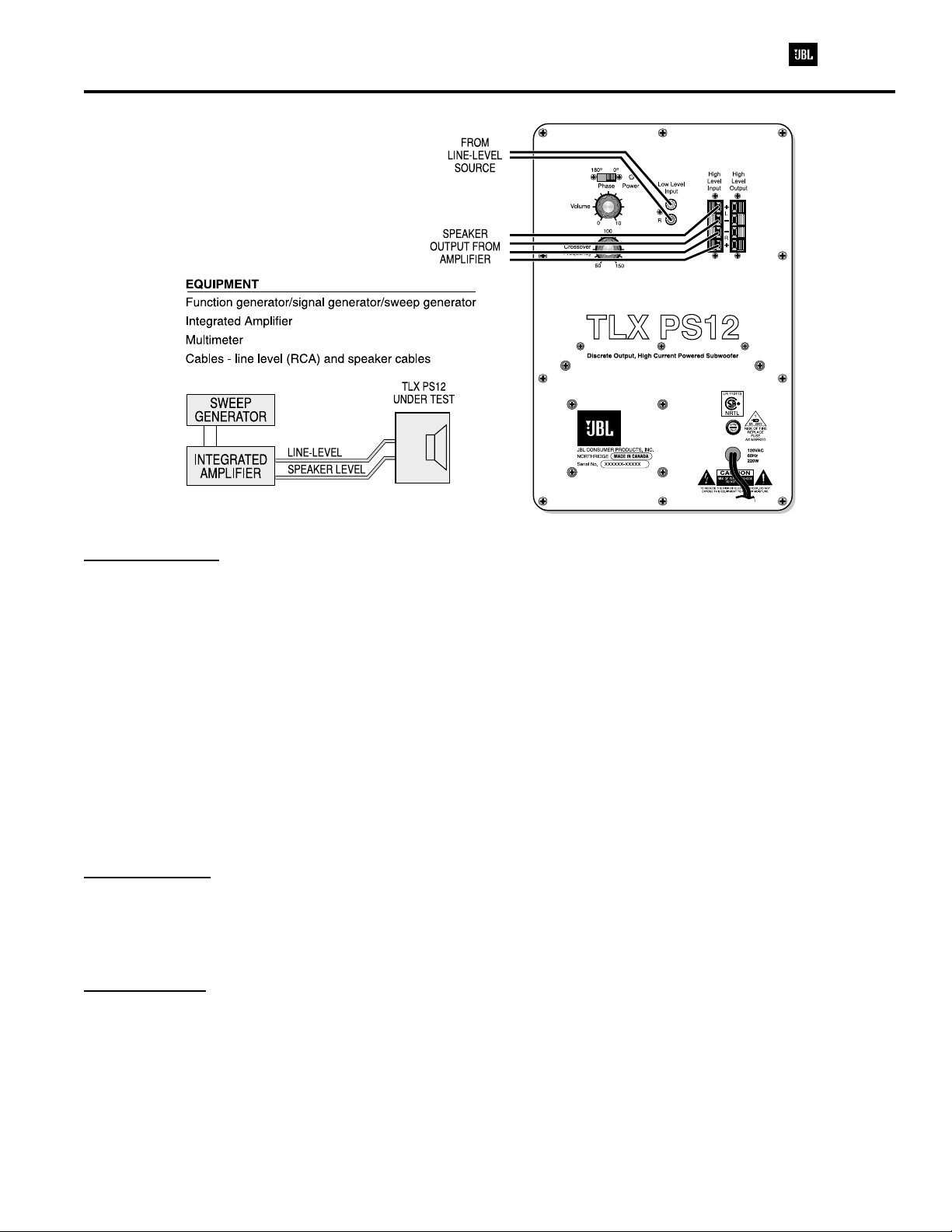

TEST PROCEDURES

General Function

UUT = Unit Under Test

1. Connect both right and left line level inputs (RCA) to signal generator and UUT. Use Y-cable if necessary from

mono source. VOLUME control should be full counterclockwise.

2. Turn on generator, adjust to 50mV, 50 Hz.

3. Plug in UUT; red LED should be ON. Turn VOLUME control full clockwise.

4. LED should turn Green; immediate bass response should be heard and felt from port tube opening.

5. Turn off generator, turn VOLUME control fully counterclockwise, disconnect RCA cables.

6. Connect one pair of speaker cables to either high level input terminal on UUT. Cables should be connected to

an integrated amplifier fed by the signal generator.

7. Turn on generator and adjust so that speaker level output is 2.0V, 50 Hz. Turn VOLUME control full clockwise.

8. Green LED should light, immediate bass response should be heard and felt from the port tube opening.

Sweep Function

1. Follow steps 1-4 above, using a sweep generator as a signal source.

2. Sweep generator from 20Hz to 300Hz. Listen to the cabinet and drivers for any rattles, clicks, buzzes or any

other noises. If any unusual noises are heard, remove driver and test.

Driver Function

1. Remove driver from cabinet; detach + and - wire clips.

2. Check DC resistance of driver; it should be 3.3 ohms.

3. Connect a pair of speaker cables to driver terminals. Cables should be connected to an integrated amplifier fed by

a signal generator. Turn on generator and adjust so that speaker level output is 5.0V.

4. Sweep generator from 20Hz to 1kHz. Listen to driver for any rubbing, buzzing, or other unusual noises.

4

Powered Subwoofer TLX PS12

BEFORE THIS AMPLIFIER IS PLUGGED IN, make sure its rated voltage corresponds to the voltage of the AC power

source to be employed. Failure to use the correct voltage could cause damage to the amplifier when the AC power cable is

plugged in. Do not exceed the rated voltage by more than 10%; operation below 90% will degrade performance or cause the

unit to shut off.

1. TROUBLE SHOOTING BEFORE OPENING

Check connections, control settings, driver and other

possible external problems. If there is Output, determine if

all controls and Inputs function properly. Rotate Pots over

full range while applying lateral and vertical oscillating

forces to locate possible intermittent function. High Level

Inputs should be tested individually both differentially

(signal from "-" to "+" with normal output) and in common

mode (signal from low level ground to both "+" and "-"

shorted together, giving virtually no output). While passing

a signal, corner drop the enclosure a few inches to expose

possible intermittent problems. Check woofer for rubbing of

voice coil or tears in cone or surround. Check cabinet for

loose extraneous articles which may have been pushed

into front port.

If line core, its strain relief, or the AC switch are

replaced, it is necessary to seal them completely to panel

with an approved conformal coating to prevent air

"whistling" through any openings from woofer pressure.

To reduce the risk or electric shock and/or

fire, replace items as marked on schematic

with the safety marking only with the exact

replacements listed in the safety component

list, section 5. If exact replacements are not available,

order them from the factory or an authorized service center.

2. REMOVING THE AMPLIFIER.

There are voltages and hot components at many points

in the amplifier which can, if contacted, cause personal

injury. Be extremely careful. Any adjustments or service

procedures that require operation of the amplifier out of its

enclosure should be performed only by trained service

personnel. Refer to PCB drawings for locations of hazards

and familiarize yourself with their locations before starting.

3. TROUBLE SHOOTING AFTER REMOVAL

Verify AC plug is disconnected See WARNINGS in

section 2.

To prevent loose hardware from reducing safety

spacings, it is essential that all hardware be replaced in the

same manner as it was removed, with lock washers under

all nuts, proper torque on screws and thread locking sealer

on the transformer nuts.

A.) Check fuse F1. If blown visually check transformer

for discoloration, and large capacitors (C36, C37) for

bulges or venting. Check for shorts in Q3-Q7 with

an Ohmmeter, (see schematic).

B. With ohmmeter, verify contacts of thermostat are

closed, voice coil of woofer is 3.3 ohms, and

windings of transformer are continuous.

C. Examine board and wiring for obvious damage,

broken or poorly soldered connections, or

discoloration.

D. Repair or replace items identified above. Procedures

for replacing power transistors and removing PCB

are as follows:

Use low power, grounded temperature regulated iron

with small tip such as Weller PTA7 and ESD control.

Use SN63/37 solder 0.032" diameter with "no clean"

flux core, Alpha Metals P2 or equal.

I) Replacing power transistors:

near body of transistor. Remove screw and

discard device (keep hardware and insulator).

Holding each lead in turn with needle nose

Clip all 3 leads

5

Loading...

Loading...