Page 1

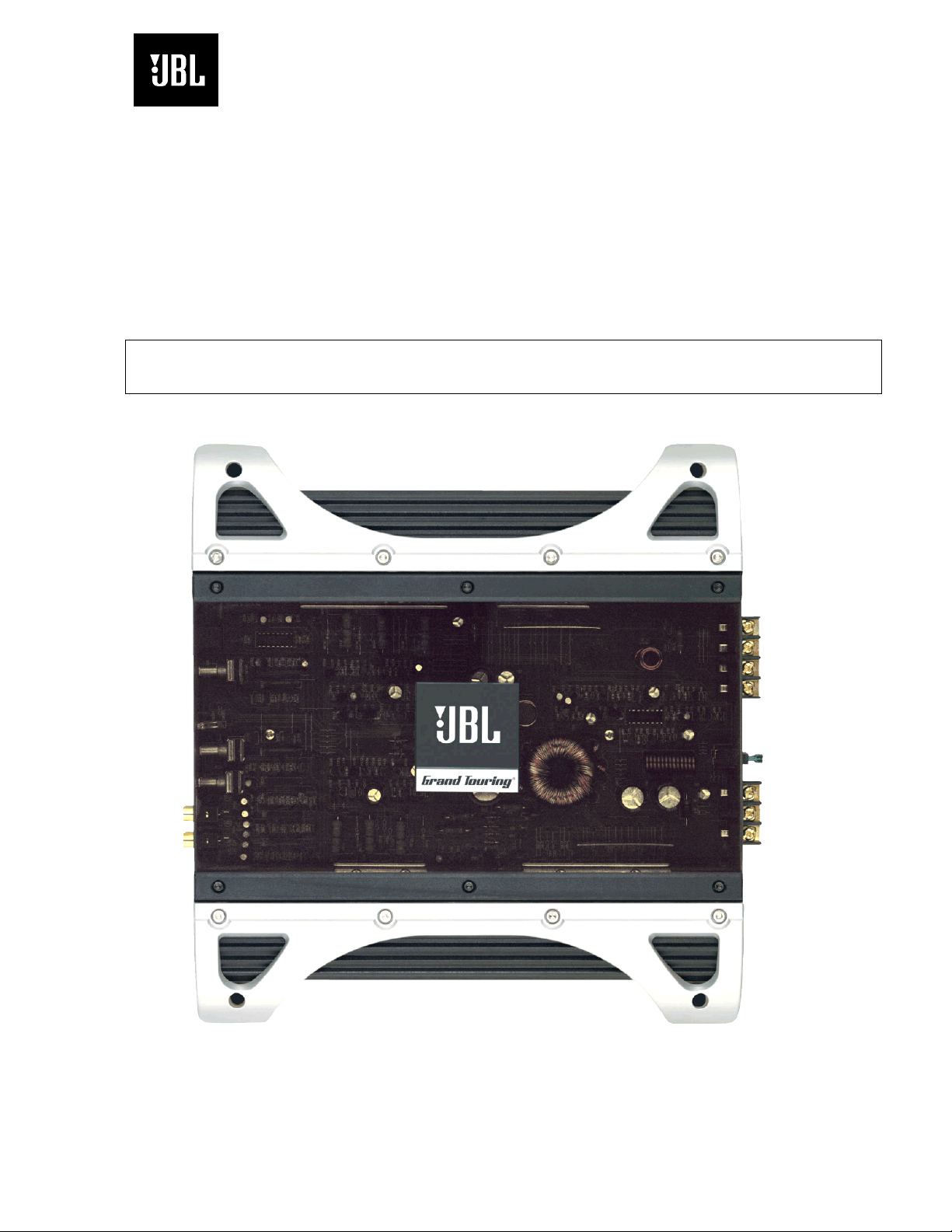

GTO Series

301.1

301.1II

1 CHANNEL POWER AMPLIFIER

SERVICE MANUAL

JBL Consumer Products

250 Crossways Park Dr.

Woodbury, New York 11797 R

ev2AA10/2005

Page 2

1

Power Amplifier GTO 301.1/301.1II

- CONTENTS -

SPECIFICATIONS ………………………………….……..1

FEATURES/TEST CONDITIONS……..…………………2

INSTALLATION………………….……...……..…...…...…3

CONNECTIONS………………….……...……..…...…..…4

SET-UP/CONTROLS ……..………………..…….….…...5

INSTALLING NEON TUBES..…….…….………………..5

BASIC TROUBLESHOOTING..…….…….………………6

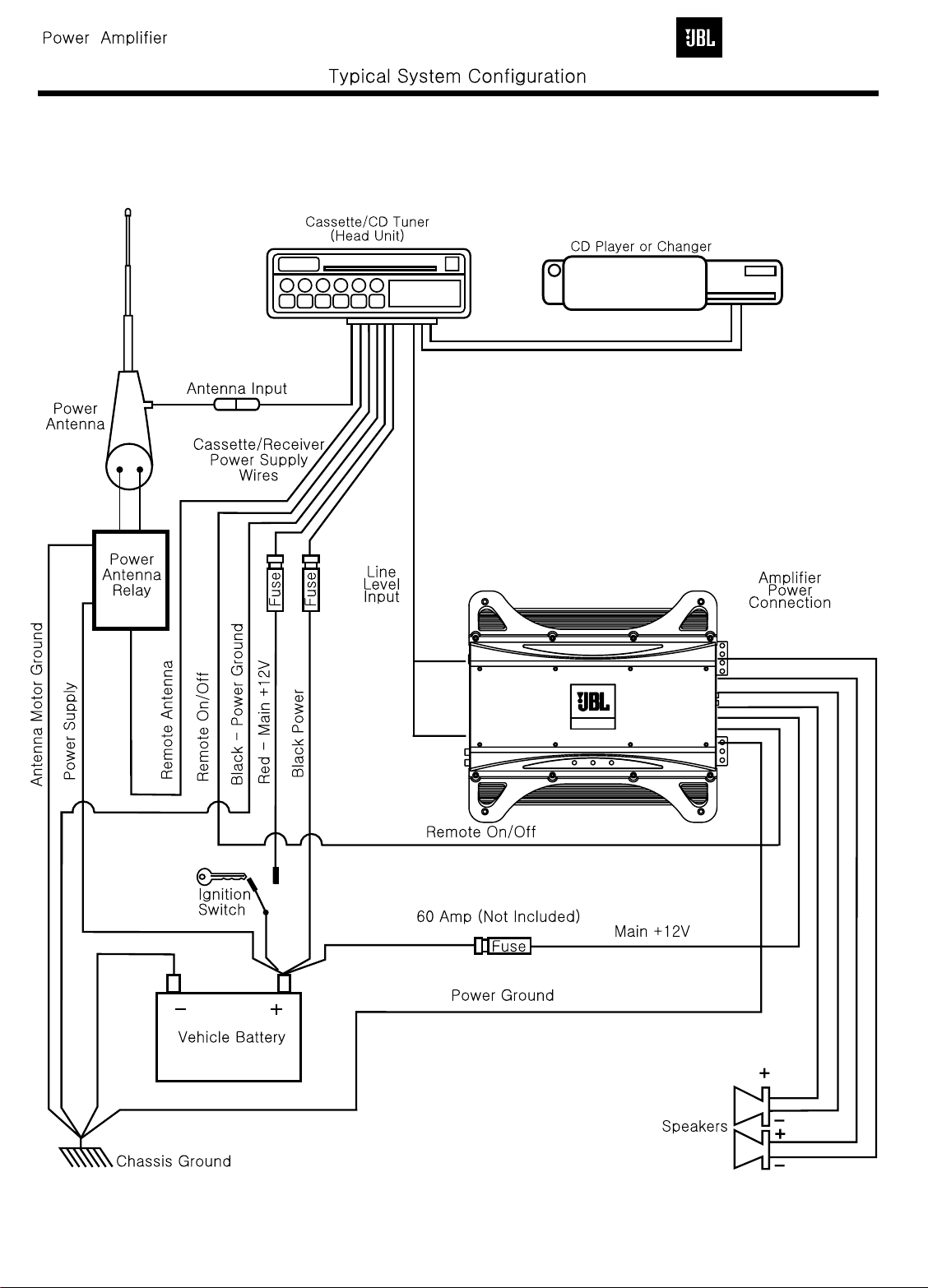

TYPICAL SYSTEM WIRING..…….…….……………..…7

EXPLODED VIEW/PARTS LIST…….….….…………....8

MECHANICAL PARTS LIST..…….…….……………......9

AMPLIFIER BLOCK DIAGRAM…………………….……10

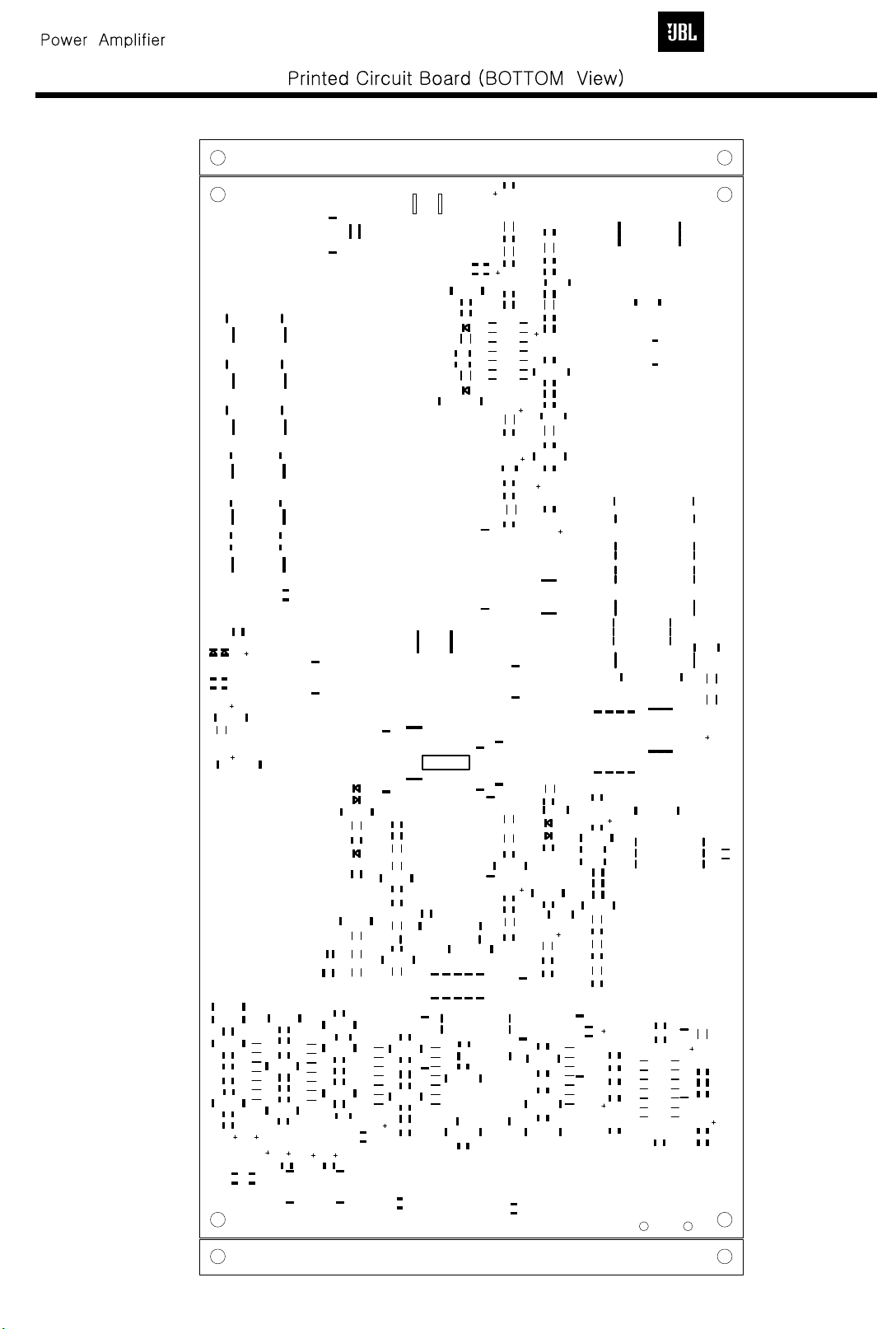

P.C.B. DRAWINGS….……………………………….…….11

ELECTRICAL PARTS LIST ..……….……….…….….…13

VERSION II ELECTRICAL PARTS LIST ADDENDUM….……….16

IC/TRANSISTOR PINOUTS..……..….…….….….….…..17

GTO 301.1 SCHEMATICS………..…………..…..……...20

GTO 301.1II SCHEMATICS………...……….…………...22

PACKING……..……………………………......................24

GTO 301.1/ GTO 301.1II Specifications

Output Power: 204W RMS x 1 channels @ 4 ohms; ≤1% THD + N

(14.4V supply) 294W RMS x 1 channels @ 2 ohms; ≤1% THD + N

Signal-to-noise ratio: 77dBA (reference 1W into 4 ohms)

Dynamic power: 320W @ 2 ohms

Effective damping factor: 6.39 @ 4 ohms

Frequency response: 10Hz – 302Hz (–3dB)

Maximum input signal: 4.7V

Maximum sensitivity: GTO 301.1 - 220mV

GTO 301.1II - 75mV

DC Offset <50mV (-50%)

Output regulation: .098dB @ 4 ohms

Idle Current 0.90A

Input Impedance 22kΩ

Max Current Draw 22A @ 4 ohms

39A @ 2 ohms

Dimensions: 11 5/8 x 12 5/16 x 2 3/8” (L x W x D)

(295mm x 313mm x 60mm)

Fuses: 30A

JBL continually strives to update and improve existing products, as well as create new ones. The specifications and details in

this and related JBL publications are therefore subject to change without notice.

Page 3

GTO 301.1/301.1II

2

Page 4

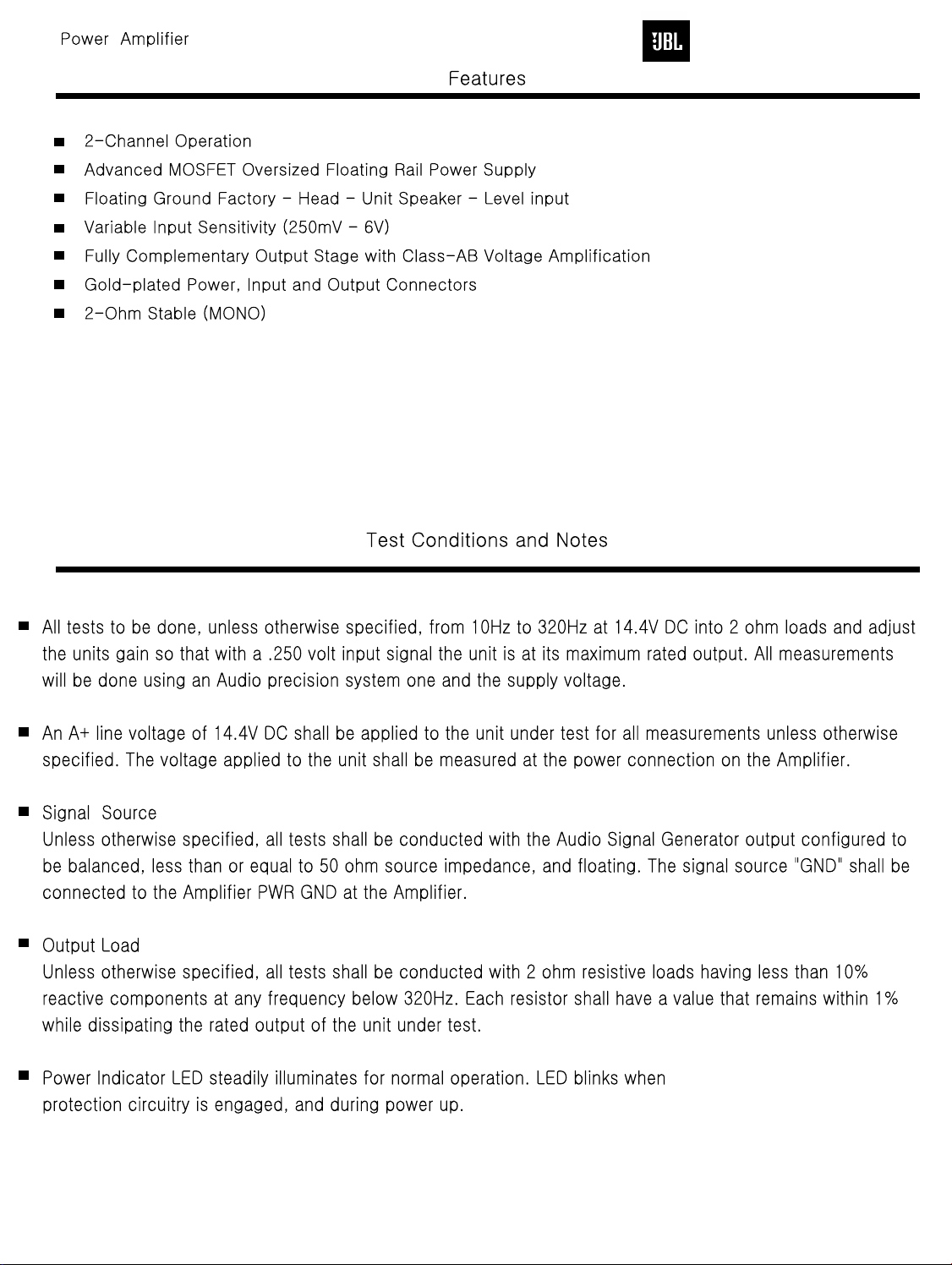

INSTALLATION

3

GTO 301.1/301.1II

WARNING: Playing loud music in an

automobile can hinder your ability to hear

traffic and permanently damage your

hearing. We recommend listening at low or

moderate levels while driving your car. JBL

accepts no liability for hearing loss, bodily

injury or property damage resulting from

the use or misuse of this product.

IMPORTANT: To get the best

performance from your JBL Grand Touring

Series amplifiers, we strongly recommend

that installation be entrusted to a qualified

professional. Although these instructions

explain how to install GTO amplifiers in a

general sense, they do not show specific

installation methods that may be required

for your particular vehicle. If you do not

have the necessary tools or experience,

do not attempt the installation yourself.

Instead, please ask your authorized JBL

car audio dealer about professional

installation.

INSTALLATION

WARNINGS AND TIPS

• Always wear protective eyewear when

using tools.

•Turn off the audio system and other

electrical devices before you start.

Disconnect the (–) negative lead from

your vehicle’s battery.

• Check clearances on both sides of

a planned mounting surface before

drilling any holes or installing any

screws. Remember that the screws

can extend behind the surface.

• At the installation sites, locate and

make a note of all fuel lines, hydraulic

brake lines, vacuum lines and electrical

wiring. Use extreme caution when cutting or drilling in and around these areas.

• Before drilling or cutting holes, use a

utility knife to remove unwanted fabric

or vinyl to keep material from snagging

in a drill bit.

• When routing cables, keep input-signal

cables away from power cables and

speaker wires.

•When making connections, make

certain they are secure and properly

®

insulated.

• If the amplifier’s fuse must be replaced,

use only the same type and rating as

that of the original. Do not substitute

another kind.

CHOOSING A LOCATION

AND MOUNTING THE

AMPLIFIER

Choose a mounting location in the trunk

or cargo area where the amplifier will not

be damaged by shifting cargo. Amplifier

cooling is essential for proper amplifier

operation. If the amplifier is to be installed

in an enclosed space, make sure there is

sufficient air circulation for the amplifier

to cool itself.

When mounting the amplifier under a

seat, ensure that it is clear of all moving

seat parts and does not affect the seat

adjustments. Mount the amplifier so it

is not damaged by the feet of backseat

passengers. Make sure that the amplifier

is mounted securely using nuts and bolts

or the supplied mounting screws.

Mount the amplifier so that it remains

dry – never mount an amplifier outside

the vehicle or in the engine compartment.

Figure 1. Terminal connection end plate.

POWER CONNECTIONS

The GTO amplifiers are capable of

delivering extremely high power levels,

and require a heavy-duty and reliable

connection to the vehicle’s electrical system

in order to perform optimally. See Figure 1

for connection location. Please adhere to

the following instructions carefully:

Ground Connection

Connect the amplifier’s Ground (GND)

terminal to a solid point on the vehicle’s

metal chassis, as close to the amplifier

as possible. Refer to the chart below to

determine minimum wire-gauge size. Scrape

away any paint from this location; use a startype lock washer to secure the connection.

Power Connection

Connect a wire (see chart at right for

appropriate gauge) directly to the vehicle’s

positive battery terminal, and install an

appropriate fuse holder within 18" of the

battery terminal.

this time. Route the wire to the amplifier’s

location, and connect it to the amplifier’s

Positive (+12V) terminal. Be sure to use

appropriate grommets whenever routing

wires through the firewall or other sheet

Failure to adequately protect the

metal.

positive wire from potential damage may

result in a vehicle fire.

routing and connecting this wire, you may

install the fuse at the battery.

Remote Connection

Connect the amplifier’s Remote (REM)

terminal to the source unit’s Remote TurnOn lead using a minimum of 18-gauge wire.

NOTE: When using the speaker level

inputs, connect the remote (REM) terminal

to the source unit. If your source unit does

not have a remote turn-on connection,

connect the amplifier’s (REM) terminal to

the vehicle’s accessory circuit.

Do not install the fuse at

When you are done

Speaker Connections

Refer to the application guides on the

pages that follow. Speaker connections

should be made using a minimum of

16-gauge wire.

NOTE: When using the high-level inputs,

the AUX outputs can be used to pass a

line-level signal to another amplifier.

Wire Gauge Chart

Amplifier Maximum Minimum

Model Current Draw Wire Gauge

AWG

AWG

GTO301.1 40A #8 AWG

AWG

These recommendations assume 7' – 10'

wire runs. If your installation differs markedly, you will need to adjust the wire

gauge accordingly.

IMPORTANT NOTE: If you are planning

to use optional neon tubes, install them

before making any electrical connections

to the amplifier (refer to“Installing Neon

Tubes” on page 5).

Page 5

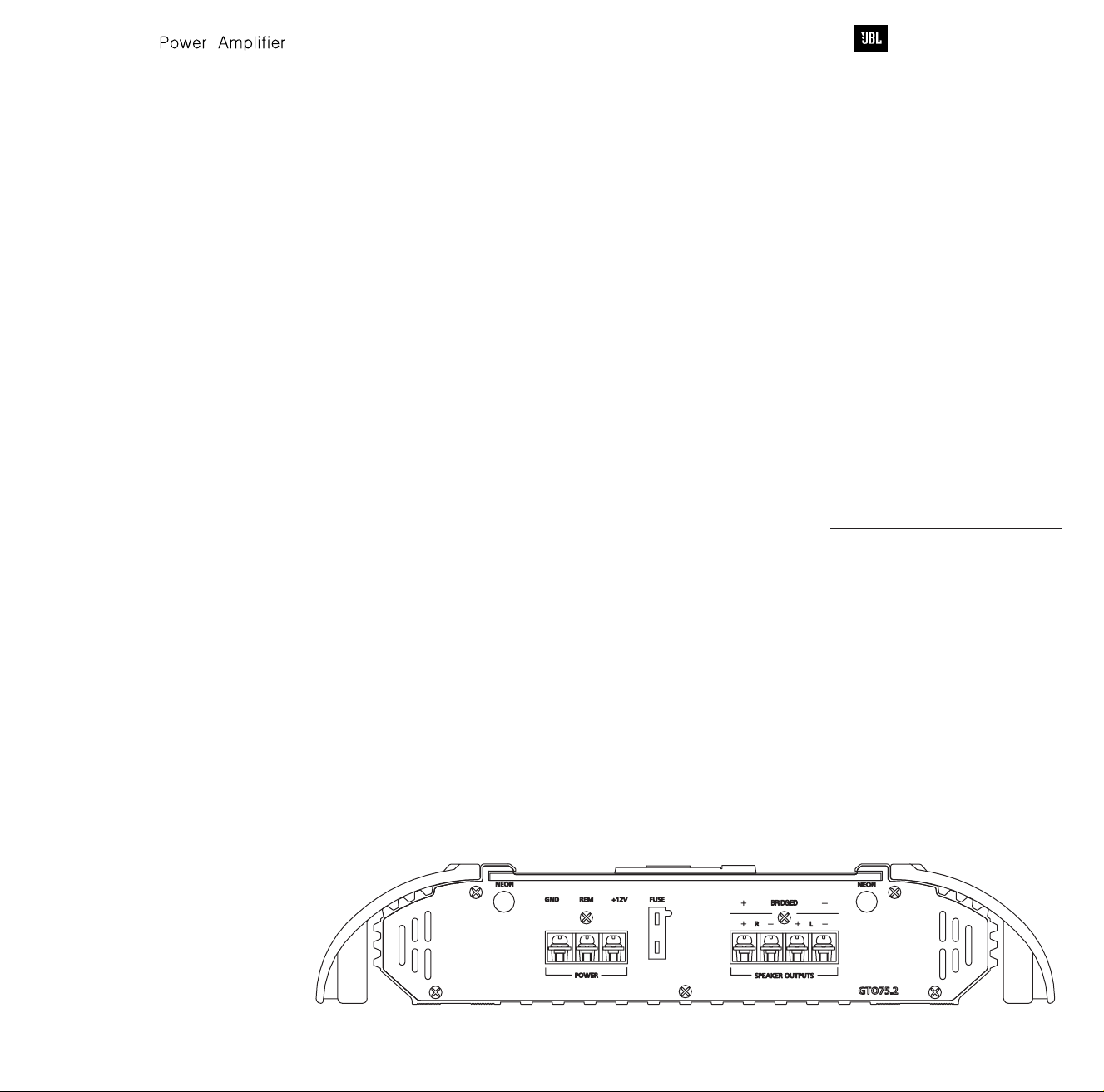

CONNECTIONS – GTO301.1/GTO301.1II

GTO Amplifier

(partial end panel)

Subwoofer

–

+

GTO Amplifier

(partial end panel)

Subwoofer Subwoofer

+

–

–

+

4

The GTO subwoofer amplifiers are

single-channel amplifiers. There are

two sets of terminals to make it easy

to connect multiple woofers. Either

set of (+/–) terminals may be used

when connecting woofers.

To the right are two application

diagrams to help plan your subwoofer

system installation.

show how to configure the GTO

subwoofer amplifiers

Figures 2 and 3

GTO 301.1/301.1II

NOTE: For simplicity, Figures 2 and 3

do not show power, remote and input

connections.

NOTE: Minimum speaker load is

2 ohms.

Figure 2. GTO subwoofer amplifier with two woofer connections.

Figure 3. GTO subwoofer amplifier with one woofer connection.

Page 6

INSTALLATION AND SETUP

SETTING THE

CROSSOVER(S)

SETTING INPUT

SENSITIVITY

1. Initially turn the INPUT LEVEL control(s)

to minimum (counter clockwise).

2. Reconnect the (–) negative lead to the

vehicle’s battery. Apply power to the

audio system and play a dynamic music

track.

3. On the source unit, increase the volume

control to 3/4 volume. Slowly increase

the INPUT LEVEL control(s) toward three

o’clock until you hear slight distortion

in the music. Then reduce the INPUT

LEVEL slightly until distortion is no

longer heard.

NOTE: After the source unit is on, red LEDs

(on the top panel) will light, indicating the

amplifier is on. If not, check the wiring,

especially the remote connection from the

source unit. Also refer to “Troubleshooting”

on the next page.

REMOTE LEVEL CONTROL

SETTING THE BASS BOOST

AUX OUTPUT

NOTE: When using the high-level inputs,

the AUX outputs can be used to pass a

line-level signal to another amplifier.

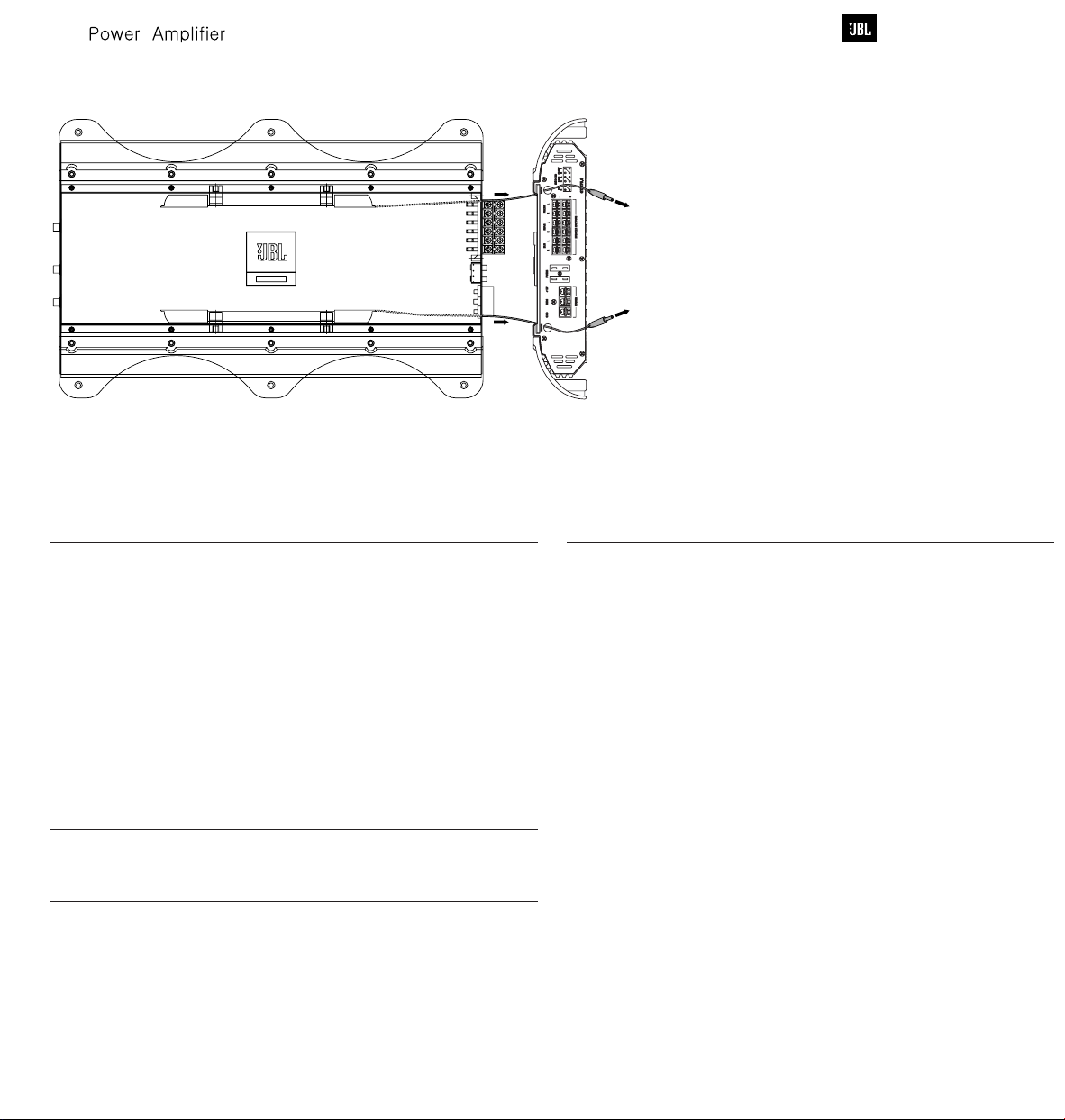

INSTALLING NEON TUBES

(OPTIONAL)

1. Using a Phillips screwdriver, remove all

screws on the amplifier’s output/power

end panel and set them aside.

2. Using a 3⁄ 32-inch Allen wrench, remove

only the screws on the amplifier’s (top)

clear cover and set them aside.

3. Remove the end panel and slide the

cover off. Set both parts aside.

4. Locate the enclosed hardware bag and

remove the four clips. Each clip has a

square end and a larger round end.

Using a round end, press two clips onto

each neon tube (e.g., Street Glow AN9

or equivalent), as shown in

Figure 13.

5. For each tube, align both clips so the

square ends slide onto an exposed

extrusion edge, as shown in Figure 9.

Do not cover any screw holes. When

installed correctly, each neon tube will

sit under an extrusion and not be visible

when viewed from directly above.

6. Route each neon tube’s power cable

through its respective NEON hole on the

end panel (see

Figure 13).

7. Slide the cover back into place and reinstall its screws. Then, replace the end

panel and reinstall its screws.

8. Finish the installation of the neon tubes

as instructed in their owner’s manual.

Figure 12.

5

GTO 301.1/301.1II

Determine your system plans and set the

crossover mode switch accordingly.

Initially set the crossover frequency

control midway. While listening to music,

adjust the crossover for the least

perceived distortion from the speakers,

allowing them to reproduce as much

bass as possible.

Systems using a separate subwoofer set

the crossover mode to HP (high pass) for

your full-range speakers. Adjust the

crossover frequency to limit bass and

provide increased system volume with

less distortion.

For subwoofers, choose the highest

frequency that removes vocal information

from the sound of the subwoofer.

All three GTO subwoofer

amplifiers have inputs for an optional

remote level control (RLC). This will allow

the amplifier’s input level to be adjusted

from the listening position. Connect the

optional remote level control using the

RJ-11 jack on the side of the amplifier.

Install the control module in the front of

the vehicle within easy reach of the driver.

Under the dash or in the center console

are both suitable locations.

All three GTO subwoofer amplifiers

are all equipped with a bassboost control. This allows you to adjust the

bass output of your system at 50Hz up to

12dB and enhance low frequency.

All three GTO subwoofer amplifiers are

equipped with full-range outputs that can

be used to connect additional amplifiers.

Page 7

INSTALLATION AND SETUP

To Neon

Power

Supply

To Neon

Power

Supply

6

Figure 13. Installing neon tubes in a JBL GTO amplifier.

TROUBLESHOOTING

GTO 301.1/301.1II

SYMPTOM LIKELY CAUSE SOLUTION

No audio No voltage at BATT+ Check voltages at

(POWER LED or REM terminals, amplifier terminals

is off) or bad or no ground with VOM

connection

No audio DC voltage on Amplifier may need

(PROTECT LED amplifier output service; see enclosed

flashes every warranty card for

4 seconds) service information

No audio Amplifier is Make sure amplifier

(PROTECT overheated cooling is not blocked

LED is on) at mounting location;

verify speaker system

impedance is within

specified limits (see

“Specifications” on

the next page)

No audio Voltage less than 9V on Check vehicle

(PROTECT BATT+ connection charging system for

and POWER defective voltage

LEDs flash) regulator

SYMPTOM LIKELY CAUSE SOLUTION

No audio Voltage more than 16V Check vehicle

(PROTECT or less than 8.5V on charging system for

LED is on) BATT+ connection defective voltage

Distorted audio Input sensitivity is Check INPUT

Distorted audio Short circuit in Remove speaker leads

and PROTECT speaker or wire one at a time to locate

LED flashes shorted speaker or

Music lacks Speakers are not Check speaker

“punch” connected properly connections for

regulator

not set properly, or LEVEL setting; or

amplifier or source check speaker wires

unit is defective for shorts or grounds

wire, then repair

proper polarity

Page 8

GTO 301.1/301.1II

7

Grand TouringGrand Touring

Page 9

GTO 301.1/301.1II Exploded View

8

GTO 301.1/301.1II

Page 10

Mechanical Parts List

9

GTO 301.1/301.1II

Page 11

GTO301.1/GTO301.1II BLOCK DIAGRAM

10

GTO 301.1/301.1II

Page 12

GTO 301.1/301.1II

11

TH01

FTD5-350

YG225D2

D41

YG225D2

D42

10m/m

Q198

C3198GR

Q199

C3198GR

C199

TIP36C

C3200GR

Q192

Q172

TIP36C

Q191

TIP36C

Q190

PAM629-01

REV.0

J57 10m/m

J58

10m/m

J60 10m/m

J59

10m/m

J56

100/16V

C3198GR

Q219

1/50V

C220

15K

R220

6m/m

J100

10K

R219

4.7/50V

C219

150K

R221

150

R222

104(M)

C197

55m/m

R199

0.1/3W

22m/m

22m/m

22m/m

0.1/3W

0.1/3W

22m/m

J39

J40

J41

680/2W

BJ03

20m/m

56K

15m/m

10

10

10

J101

MOD01

623PCB4-B

4.7/0.5W

19m/m

19m/m

19m/m

J69 15m/m

30K

R215

15K

R216

U105

R223

TER02

DST0014-00

20m/m

20m/m

20m/m

R198

R197

4.7/0.5W

CL-200C

L196

R196

J4225m/m

J43

25m/m

25m/m

J44

25m/m

J45

25m/m

J46

25m/m

J47

25m/m

J48

25m/m

J49

J50

J51

J52

J5325m/m

25m/m

J54

J55

J63

J66

J65

J68

15m/m

15m/m

20m/m

20m/m

R195

J94

R192

J95

J96

J97

R194

R191

R193

R190

NJM13600

X

C61

J61

J62

20m/m

20m/m

910F

R157

100/16V

C159

39KF

R158

C158

100/0.5W

R174

10/0.5W

R175

6m/m

J91

6m/m

J92

6m/m

J93

270P

C175

A1023Y

Q175

R168

A1023Y

Q174

R167

A1023Y

Q173

560

R166

47/16V

C212

10KF

R213

510F

R214

510

R217

10K

R218

47/16V

C223

1K

R227

VR103

20KB

BASSBOOST

C51

470/63V

470/63v

47P

560

560

6m/m

J102

1SS133

J88

J10320m/m

U106

1K

R92

C3198GR

Q90

22K

R91

47K

R90

10

R15

6m/m

J30

A1266GR

Q12

24K

R21

6m/m

J31

100/16V

C12

68K

R25

102(M)

C21

24K

R22

6m/m

J32

910

R16

4.7K

R02

C3198BL

Q21

10K

R14

104P

C22

1K

R31

D11

10/25V

C15

15K

R35

47/25V

C16

12.5m/m

J35

L02

CL-500

C3200GR

Q156

22KF

R171

10m/m

J90

1SS133

D152

1SS133

D151

680

R156

100/63V

C157

473P

C156

120

R172

10m/m

C163

C1027Y

Q171

820

R173

1.5K

R163

R228

NJM2068LD

C228

R232

150K

R230

104(M)

C229

6.8K

R229

104(M)

C227

R04

C11

C3198GR

Q02

R05

A1266GR

Q11

R12

C14 47/16V

R13

J29

10/16V

C06

A1023Y

Q01

R01

100/16V

C13

10/0.5W

R03

R32

R33

A1268GR

Q22

R34

12.5m/m

CL-500

L01

J34

C63

C3200GR

Q153

C3200GR

Q152

22KF

R152

C152

2.2/50V

C151

R151

1/50V

R149

Q151

5.6KF

R150

2.2/50V

20m/m

J89

39K

47P

1K

LED01

R913

TOL-30aSBaCAa-B2

LED02

100/16V

56K

J305

J304

J303

8.2K

R63

R11

4.7K

430K

3.9K

10K

C60

6m/m

R62

U01

10.5KF

R60

1SS133

D03

TL494CN

A1266GR

Q33

220/0.5W

R51

220/0.5W

R41

A1266GR

Q23

1SS133

D04

J28

4.7K

22K

33K

15K

25m/m

J33

473P

C62

J70

15m/m

J71

J7525m/m

68P

10K

100K

J77

J108

J78 25m/m

15m/m

J79

J8010m/m

C150

J104

J105

17.5m/m

J106

17.5m/m

J107

C225

R226

1K

HNRD-3401L

6m/m

6m/m

6m/m

7.5m/m

J08

J07

104P

4.7KF

15m/m

SCREW

4

8

12.5m/m

J36

12.5m/m

J37

12.5m/m

J38

3300/63V"HC"

15m/m

GTO301.1

330/16V

C921

1N4744

D921

330/16V

C913

20m/m

J8110m/m

J8210m/m

J8310m/m

22m/m

22m/m

5.6K

R225

10K

R224

683(M)

C226

SCREW

823(M)

5.6K

50KC

1K

R923

FH01

J01

J02

7.5m/m

WF-9402

7.5m/m

7.5m/m

7.5m/m

7.5m/m

7.5m/m

7.5m/m

D911

VR102

LPF

J03

7.5m/m

J06

J05

J04

J330

J300

J301

7.5m/m

7.5m/m

7.5m/m

J302

J306

J307

J308

CL-300

L03

2200/25V"WL"

C04

C03 104P

J09

J11

J12

J13

J10

10m/m

10m/m

10m/m

10m/m

10m/m

2200/25V"WL"

C05

37PHI

J73

17.5m/m

17.5m/m

330/16V

22K

6m/m

A1268GR

A1268GR

100P

1.5K

473P

A1268GR

1K

102P

A1268GR

10KF

R211

102P

C211

2KF

R212

6m/m

J109

4.7KF

R208

470P

C108

4.7KF

R108

6m/m

J110

15K

R250

VR101

R210

C52

47

750F

T01

J74

U103

C210

20KB

VOLUME

20m/m

D161

D160

R187

D187

C155

2

6

1SS133

C187

C3200GR

Q187

1SS133

J120

C165

C1027Y

Q165

C1027Y

Q164

C1027Y

Q163

330/16V

C923

NJM2068LD

47/16V

R209

3

5(0.7x9):17(0.7x4):10(0.7x1)

7

J72

C911

R160

1N4744

J85

Q162

Q161

C160

R162

R161

6m/m

J76

C154

Q154

R153

C153

J8410m/m

Q155

17.5m/m

J108

NJM2068LD

U104

DST0013-00

3

6m/m

X

6m/m

6m/m

C01

D01

2

2

1

5

100/2W

R30

3300/63V"HC"

1SS133

100P

15K

6m/m

100/63V

270P

5m/m

J86

6m/m

J87

47KF

R106

22P

C106

9.4KF

R207

10P

C104

47KF

R103

47KF

R102

47KF

R105

22P

C105

6m/m

J111

9.4KF

R107

100

22/16V

C103

C102

22KF

R101

C101

102P

R

IN4004

D02

C801

473P

1N5404

BJ01

47

BJ02

47

25m/m

1K

47

17.5m/m

17.5m/m

17.5m/m

222(M)

C08

473P

C33

R6110K

3RD

FR154

D54

FR154

FR154

D52

D53

473P

C53

220/2W

220/2W

R921

R911

10

1.5K

0.1/3W

10

R164

100/0.5W

R165

10/0.5W

0.1/3W

10

0.1/3W

22P

C205

47KF

R205

10KF

R240

NJM2068LD

47KF

R202

10P

C204

6m/m

J112

47KF

R203

10KF

R140

22P

U101

C206

47KF

22/16V

R206

22/16V

22/16V

C202

C203

22KF

R201

C201

102P

LL

R

DJB-554A

TER01

J1417.5m/m

J1517.5m/m

R54

J1617.5m/m

J1717.5m/m

R53

J18

J19

47

J2017.5m/m

J2117.5m/m

47

J22

J2317.5m/m

1K

47

J2417.5m/m

J2517.5m/m

105(M)"TL"

C31

3RD.

6m/m

J26

C67

FR154

D51

C57

C82

Q82

C83

15m/m

J27

R182

R186

R185

R181

R184

R180

R183

NJM2068LD

U102

4.7/50V

C143

R144

100K

55m/m

R55

R52

R45

R44

R42

R43

105(M)"TL"

W01

D81

47/50V

R81

47/50V

22P

10/50V

Q182

Q181

Q180

104P

C912

104P

C922

6m/m

J113

22P

C241

10KF

R241

1K

R242

1K

R142

1K

R243

22P

C141

10KF

R141

1K

R143

C243

R244

100K

RCA101

FQP50N06

Q55

FQP50N06

Q54

FQP50N06

Q53

FQP50N06

Q45

FQP50N06

Q44

FQP50N06

C32

Q43

WIRE

X

1SS133

1SS133

220K

10K

J108

TIP35C

1

TIP35C

1

TIP35C

1

4.7/50V

3

D80

R80

C182 220P

C180 220PC181 220P

Page 13

GTO 301.1/301.1II

12

Q55

Q54

Q53

Q45

Q44

Q43

Q182

Q181

Q180

C210

FH01

L03

J28

T01

J73

J72

GTO301.1

J74

C921

C911

R160

D911

R210

D921

C913

J76

J77

J78

J83

J84

J108

U104

VR102

R923

Q162

Q161

C160

R161

C154

Q155

R162

R153

C153

J85

Q154

C211

R212

J109

R208

C108

R108

J110

R250

R51

C62

R224

C226

C225

R41

R225

R04

C11

Q02

R92

R05

Q90

Q11

R91

R12

R63

R11

C60

R62

R60

D03

Q33

Q23

D04

J33

J71

J75

J79

J80

J81

J82

J104

J105

J106

J107

R226

LED01

LED02

J70

Q153

Q152

R33

R152

C152

C151

R151

R149

Q151

R150

C150

R90

R15

C14

J30

R13

J29

Q12

U01

R21

J31

C12

R25

C21

R22

J32

C06

R16

R02

Q01

R01

Q21

R14

C13

C22

R03

R31

D11

R32

C15

R35

Q22

R34

C16

L01

J34

J35

C63

L02

Q156

R171

J90

D152

D151

R156

C157

C156

R172

J88

C163

Q171

R173

R163

J89

R228

C228

R232

R230

C229

U106

R229

C227

R913

TER02

J39

J40

J41

R198

R197

C197

R196

L196

BJ03

J42

J43

J44

J45

J46

J47

J48

J49

R157

C159

R158

C158

C175

Q175

R168

Q174

R167

Q173

R166

J102

VR103

J50

J51

J52

J53

J54

J55

R199

J69

J68

R213

R214

R217

R218

C223

R227

C212

J66

J65

J62

J63

R195

J94

R192

J95

J96

J97

R194

R191

R193

R190

R215

R216

U105

R223

MOD01

J61

C51

C61

R174

R175

J91

J92

J93

J103

J101

Q219R211

C220

R220

J100

R219

C219

R221

R222

TH01

J58

J57

D41

D42

J59

J60

J56

Q198

Q199

C199

Q192

Q172

Q191

Q190

TER01

C01

D02

J301

J302

C801

D01

C04

BJ01

R55

R54

C32

C31

W01

D80

R80

R81

C912

C922

J113

C241

R241

R242

R142

R243

C141

R141

R143

R244

3RD.

J26

D81

D51

C67

C57

C82

Q82

C83

J27

R184

R183

U102

C243

C143

R144

R185

BJ02

J14

J15

J16

J17

R52

R53

J18

J19

R45

J20

J21

R44

J22

J23

R42

R43

J24

J25

C08

R61

C33

3RD

D54

D53

D52

R921

R911

R182

R186

R181

R164

R165

R180

C205

R205

R240

R202

C204

J112

R203

R140

U101

C206

R206

C203

C202

R201

C201

RCA101

C03

C05

R30

C52

C53

D161

D160

C187

Q187

R187

D187

J120

C155

C165

Q165

J86

Q164

J87

Q163

R106

C923

C106

R207

C104

R103

R102

R105

C105

J111

U103

R107

R209

C103

C102

R101

VR101

C101

Page 14

13

GTO 301.1/301.1II

FET-00-00045 F.E.T MUTTING J-FET J108 Q82,151 2

TRS-00-00087 TRANSISTOR SMALL SIGNAL PNP KTA1023Y Q01,173,174,175 4

TRS-00-00088 TRANSISTOR SMALL SIGNAL NPN KTC1027Y Q163,164,165,171 4

TRS-00-00091 TRANSISTOR SMALL SIGNAL PNP KTA1268GR Q22,154,155,161,162 5

TRS-00-00111 TRANSISTOR SMALL SIGNAL NPN KTC3200GR Q152,153,156,187 4

TRS-00-00090 TRANSISTOR SMALL SIGNAL PNP KTA1266GR Q11,12,23,33 4

TRS-00-00110 TRANSISTOR SMALL SIGNAL NPN KTC3198GR Q02,90,198,199,219 5

TRS-00-00109 TRANSISTOR SMALL SIGNAL NPN KTC3198BL Q21 1

DIO-00-00108 DIODE FAST RECOVERY FR154 D51,52,53,54 4

DIO-00-00003 DIODE RECTIFIER IN4004 D02 1

DIO-00-00006 DIODE SWITCHING SIGNAL 1SS133 /1N4148 D03,04,11,80,81,151,152,160,161,187 10

RES-00-00549 RESISTOR METAL FILM 1/5WF 510 OHM R214 1

RES-00-00577 RESISTOR METAL FILM 1/5WF 750 OHM R210 1

RES-00-00590 RESISTOR METAL FILM 1/5WF 910 OHM R157 1

RES-00-00482 RESISTOR METAL FILM 1/5WF 2K OHM R212 1

RES-00-00523 RESISTOR METAL FILM 1/5WF 4.7K OHM R62,108,208 3

RES-00-00545 RESISTOR METAL FILM 1/5WF 5.6K OHM R150 1

RES-00-00589 RESISTOR METAL FILM 1/5WF 9.4K OHM R107,207 2

RES-00-00402 RESISTOR METAL FILM 1/5WF 10K OHM R140,141,211,213,240,241 6

RES-00-00399 RESISTOR METAL FILM 1/5WF 10.5K OHM R60 1

RES-00-00467 RESISTOR METAL FILM 1/5WF 22K OHM R101,152,171,201 4

RES-00-00517 RESISTOR METAL FILM 1/5WF 39K OHM R158 1

RES-00-00537 RESISTOR METAL FILM 1/5WF 47K OHM R102,103,105,106,202,203,205,206 8

RES-00-00610 RESISTOR CARBON FILM 1/5WJ 10 OHM R15,180,181,182,190,191,192 7

RES-00-00716 RESISTOR CARBON FILM 1/5WJ 47 OHM R43,44,45,53,54,55,162 7

RES-00-00606 RESISTOR CARBON FILM 1/5WJ 100 OHM R209 1

RES-00-00615 RESISTOR CARBON FILM 1/5WJ 120 OHM R172 1

RES-00-00622 RESISTOR CARBON FILM 1/5WJ 150 OHM R222 1

RES-00-00723 RESISTOR CARBON FILM 1/5WJ 510 OHM R217 1

RES-00-00728 RESISTOR CARBON FILM 1/5WJ 560 OHM R166,167,168 3

RES-00-00741 RESISTOR CARBON FILM 1/5WJ 680 OHM R156 1

RES-00-00756 RESISTOR CARBON FILM 1/5WJ 820 OHM R173 1

RES-00-00761 RESISTOR CARBON FILM 1/5WJ 910 OHM R16 1

RES-00-00633 RESISTOR CARBON FILM 1/5WJ 1K OHM R31,42,52,92,142,143,153,227,232,242 13

R243,913,923

RES-00-00598 RESISTOR CARBON FILM 1/5WJ 1.5K OHM R161,163,186 3

RES-00-00676 RESISTOR CARBON FILM 1/5WJ 3.9K OHM R12 1

RES-00-00702 RESISTOR CARBON FILM 1/5WJ 4.7K OHM R01,02,11 3

RES-00-00720 RESISTOR CARBON FILM 1/5WJ 5.6K OHM R225,226 2

RES-00-00734 RESISTOR CARBON FILM 1/5WJ 6.8K OHM R229 1

RES-00-00751 RESISTOR CARBON FILM 1/5WJ 8.2K OHM R05 1

RES-00-00608 RESISTOR CARBON FILM 1/5WJ 10K OHM R13,14,61,81,151,218,219,224 8

RES-00-00623 RESISTOR CARBON FILM 1/5WJ 15K OHM R34,35,187,216,220,250 6

RES-00-00658 RESISTOR CARBON FILM 1/5WJ 22K OHM R32,91,160 3

RES-00-00663 RESISTOR CARBON FILM 1/5WJ 24K OHM R21,22 2

RES-00-00680 RESISTOR CARBON FILM 1/5WJ 30K OHM R215 1

RES-00-00687 RESISTOR CARBON FILM 1/5WJ 33K OHM R33 1

RES-00-00697 RESISTOR CARBON FILM 1/5WJ 39K OHM R228 1

RES-00-00714 RESISTOR CARBON FILM 1/5WJ 47K OHM R90 1

RES-00-00730 RESISTOR CARBON FILM 1/5WJ 56K OHM R04,199 2

Page 15

14

GTO 301.1/301.1II

RES-00-00742 RESISTOR CARBON FILM 1/5WJ 68K OHM R25 1

RES-00-00604 RESISTOR CARBON FILM 1/5WJ 100K OHM R144,149,244 3

RES-00-00620 RESISTOR CARBON FILM 1/5WJ 150K OHM R221,230 2

RES-00-00654 RESISTOR CARBON FILM 1/5WJ 220K OHM R80 1

RES-00-00706 RESISTOR CARBON FILM 1/5WJ 430K OHM R63 1

RES-00-00053 RESISTOR METAL FILM 1/2WJ 4.7 OHM R196,197 2

RES-00-00018 RESISTOR METAL FILM 1/2WJ 10 OHM R03,165,175 3

RES-00-00016 RESISTOR METAL FILM 1/2WJ 100 OHM R164,174 2

RES-00-00038 RESISTOR METAL FILM 1/2WJ 220 OHM R41,51 2

ELC-00-00218 CAPACITOR ELECTROLYTIC "SMS" 1/50V C163,220 2

ELC-00-00223 CAPACITOR ELECTROLYTIC "SMS" 2.2/50V C150,151 2

ELC-00-00229 CAPACITOR ELECTROLYTIC "SMS" 4.7/50V C143,219,243 3

ELC-00-00195 CAPACITOR ELECTROLYTIC "SMS" 10/16V C06 1

ELC-00-00203 CAPACITOR ELECTROLYTIC "SMS" 10/25V C15 1

ELC-00-00220 CAPACITOR ELECTROLYTIC "SMS" 10/50V C83 1

ELC-00-00197 CAPACITOR ELECTROLYTIC "SMS" 22/16V C102,103,202,203 4

ELC-00-00198 CAPACITOR ELECTROLYTIC "SMS" 47/16V C14,210,212,223 4

ELC-00-00205 CAPACITOR ELECTROLYTIC "SMS" 47/25V C16 1

ELC-00-00227 CAPACITOR ELECTROLYTIC "SMS" 47/50V C57,67 2

ELC-00-00199 CAPACITOR ELECTROLYTIC "SMS" 100/16V C11,12,13,159,199 5

ELC-00-00201 CAPACITOR ELECTROLYTIC "SMS" 330/16V C911,913,921,923 4

MYC-00-00020 CAPACITOR MYLAR 5% 100V 102(M) J C21 1

MYC-00-00031 CAPACITOR MYLAR 5% 100V 222(M) J C08 1

MYC-00-00044 CAPACITOR MYLAR 5% 100V 683(M) J C226 1

MYC-00-00045 CAPACITOR MYLAR 5% 100V 823(M) J C225 1

MYC-00-00094 CAPACITOR MYLAR 5% 100V 104(M) J C197,227,229,35 4

MYC-00-00085 CAPACITOR MYLAR 5% 63V "TL" 105(M) J C31,32,36 3

CEC-00-00074

CEC-00-00077 CAPACITOR CERAMIC DISK 50V 10P F C104,204 2

CEC-00-00090 CAPACITOR CERAMIC DISK 50V 22P F C82,105,106,141,205,206,241 7

CEC-00-00103 CAPACITOR CERAMIC DISK 50V 47P F C158,228 2

CEC-00-00108 CAPACITOR CERAMIC DISK 50V 68P F C152 1

CEC-00-00073 CAPACITOR CERAMIC DISK 50V 100P F C160,187 2

CEC-00-00092 CAPACITOR CERAMIC DISK 50V 270P F C165,175 2

CEC-00-00101 CAPACITOR CERAMIC DISK 50V 470P F C108 1

CEC-00-00074 CAPACITOR CERAMIC DISK 50V 102P F C101,153,201,211,37 5

CEC-00-00102 CAPACITOR CERAMIC DISK 50V 473P F C33,53,63,154,156,801 6

CEC-00-00076 CAPACITOR CERAMIC DISK 50V 104P F C03,22,60,912,922 5

CEC-00-00086 CAPACITOR CERAMIC DISK 50V 220P F C180,181,182 3

JUP-00-00051 JUMPER 0OHM JUMPER 5m/m J86 1

JUP-00-00043 JUMPER 0OHM JUMPER 6m/m J26,29,30,31,32,76,85,87,91,92 25

J93,100,102,109,110,111,112,113,120,300

J301,302,303,304,305

JUP-00-00044 JUMPER 0OHM JUMPER 7.5m/m J01,02,03,04,05,06,07,08,306,307 12

J308,330

JUP-00-00045 JUMPER 0OHM JUMPER 10m/m J09,10,11,12,13,56,57,58,59,60 17

J80,81,82,83,84,88,90

JUP-00-00046 JUMPER 0OHM JUMPER 12.5m/m J34,35,36,37,38 5

JUP-00-00047 JUMPER 0OHM JUMPER 15m/m J27,28,66,68,69,70,71,79,94 9

JUP-00-00048 JUMPER 0OHM JUMPER 17.5m/m J14,15,16,17,18,19,20,21,22,23 17

J24,25,72,73,106,107,108

JUP-00-00074 JUMPER 0OHM JUMPER 19m/m J50,51,52 3

JUP-00-00049 JUMPER 0OHM JUMPER 20m/m J39,40,41,55,61,62,63,65,74,77 12

J89,103

Page 16

15

GTO 301.1/301.1II

JUP-00-00075 JUMPER 0OHM JUMPER 22m/m J95,96,97,101,104,105 6

JUP-00-00042 JUMPER 0OHM JUMPER 25m/m J33,42,43,44,45,46,47,48,49,53 13

J54,75,78

ICO-00-00022 I.C PWM I.C TL494CN U01 1

ICO-00-00170 I.C ELECTRIC VOLUME I.C NJM13600D U105 1

ICO-00-00112 I.C DUAL OP AMP (SIP-08P) NJM2068LD U101,102,103,104,106 5

FET-00-00023 F.E.T N-CH MOSFET FQP50N06 Q43,44,45,53,54,55 6

TRS-00-00188 TRANSISTOR AUDIO POWER NPN TIP35C Q180,181,182 3

TRS-00-00207 TRANSISTOR AUDIO POWER PNP TIP36C Q190,191,192 3

TRS-00-00111 TRANSISTOR SMALL SIGNAL NPN KTC3200GR Q172 1

DIO-00-00152 DIODE FAST RECOVERY YG225D2 D41,42 2

DIO-00-00048 DIODE RECTIFIER 1N5404 D01 1

DIO-00-00206 DIODE ZENER 1W 15V 1N4744A D911,921 2

DIO-00-00278 LED RED COLOR 3PHI HNRD-3401L LED01 1

DIO-00-00303 LED BLUE COLOR 3PHI TOL-30aSBaCAa-B2 LED02 1

RES-00-01223 RESISTOR

RES-00-01270 RESISTOR

RES-00-01041 RESISTOR

RES-00-00895 RESISTOR

ELC-00-00235 CAPACITOR ELECTROLYTIC "SMS" 100/63V C155,157 2

ELC-00-00276 CAPACITOR ELECTROLYTIC "SMS" 470/63V C51,61 2

ELC-00-00727 CAPACITOR ELECTROLYTIC "WL" 2200/25V C04,05 2

ELC-00-00618 CAPACITOR ELECTROLYTIC "HC" 3300/63V C52,62 2

THS-00-00013 THERMISTOR 50K NTC RESISTOR FTD5-350 TH01 1

VOL-00-00335 VOLUME

VOL-00-00336 VOLUME

COR-TF-00384 CORE 37PHI ISU T01 [5T(0.7x9):17T(0.7x4):10T(0.7x1)] 1

COI-00-00034 INDUCTOR DRUM COIL CL-500 L01,02 2

COI-00-00023 INDUCTOR BAR COIL CL-300 L03 1

COI-00-00019 INDUCTOR AIR COIL CL-200C L196 1

JAC-00-00043 RCA JACK DJB-554A RCA101 1

JAC-00-00050 MODULAR 623PCB4-B MOD01 1

TER-00-00241 TERMINAL GOLD PLATED(3P) DST0013-00 TER01 1

TER-00-00242 TERMINAL GOLD PLATED(4P) DST0014-00 TER02 1

JUP-00-00005 JUMPER METAL JUMPER 55m/m BJ01,03 2

JUP-00-00002 JUMPER METAL JUMPER 25m/m BJ02 1

WIR-00-00015 WIRE ASS'Y

HOD-00-00009 FUSE HOLDER WF-9402 FH01 1

TUB-00-00008 TEFLON TUBE 0.7PHI 10m/m Q172, TH01 3

TUB-00-00009 TEFLON TUBE 0.7PHI 15m/m LED02 2

TUB-00-00006 TEFLON TUBE 0.7PHI 20m/m LED01 2

FUS-AT-00006 AUTO FUSE 30A SET1+ASS'Y1 2

HEAT TUBE 2PHI 15m/m W02,03,04 3

MOR/S 2WJ

MOR/S 2WJ

MOR/S 2WJ

WIRE WOUND 3WJ

V12L5(9x5)G(PH2D)N15S

V12L5(9x5)G(PH2D)N15S

AWG #22 BLACK 3.2PHI RING RUG

100 OHM R30 1

220 OHM R911,921 2

680 OHM R198 1

0.1 OHM R183,184,185,193,194,195 6

3B20KB 2! VR101,103 2

15C50KC 2! VR102 1

60m/m W02,03,04 3

Page 17

GTO 301.1/301.1II

GTO 301.1 Version II Electrical Parts List Addendum

The following chart below represents the only electrical parts

differences in Version I and II models:

MODEL PART NAME PART NO SPEC DESIGNATOR

GTO 301.1 RESISTOR RES-00-00577 1/5WF 750 OHM R210 1

GTO 301.1II RESISTOR RES-00-00474 1/5WF 240 OHM R210

GTO 301.1 RESISTOR RES-00-00482 1/5WF 2K OHM R212 2

GTO 301.1II RESISTOR RES-00-00554 1/5WF 560 OHM R212

GTO 301.1

3

GTO 301.1II

GTO 301.1

4

GTO 301.1II

POWER TERMINAL

POWER TERMINAL

SPEAKER TERMINAL

SPEAKER TERMINAL

TER-00-00238 (3P) DST0013-00 TER01

TER-00-00277 (3P) DK-03B03-AG-1-DN TER01

TER-00-00239 (4P) DST0014-00 TER02

TER-00-00275 (4P) DK-04A03-AG-1-DN TER02

16

Page 18

17

GTO 301.1/301.1II

Page 19

GTO 301.1/301.1II

18

Page 20

GTO 301.1/301.1II

19

Page 21

20

GTO 301.1 Page1 Schematic

6.17V

R12

3.9K

R11

4.7K

4.94V

4.94V

C14

47/16V

Q11

A1266GR

C11

100/16V

0V

4.93V

Q21

C3198BL

R14

10K

R13

10K

C12

100/16V

Q12

A1266GR

R21

24K

C22

104P

Q55

FQP50N06

Q45

FQP50N06

14.4V

1

C05

2200/25V"WL"

C04

1

2200/25V"WL"

C03

104P

L03

CL-300

5T:17T:10T

(0.7X9:0.7X4:0.7X1)

T01

37PHI

D01

1N5404

FH01

30A

D41

YG225D2

R30

100/2W

C08

222(M)"100V"

D42

YG225D2

D80

1SS133

D81

1SS133

W1

14.4V

R80

220K

R81

10K

REM

C51

470/63V

C61

470/63V

L01

CL-500

L02

CL-500

TER01

DST0013-00

C82

22P

-27.8V

DC14.4V

REMOTE

GND

D51 FR154

D52 FR154

D53 FR154

D54 FR154

49V

C52

3300/63V"HC"

C62

3300/63V"HC"

-49V

Q82

J108

C53

473P

C63

473P

C83

10/50V

C57

47/50V

C67

47/50V

-20.2V

+VCC1

-VCC1

+VCC

-VCC

MUTE

13.55V

Q01

A1023Y

C06

10/16V

13.88V

D02

REM

1N4004

C801

473P

4.45V

R62

4.7KF

C60

104P

R15

10

4.94V

TH01

50KTH

0V

0.07V

R311KR32

R16

910

R60

10.5KF

16 15 14 13 12 11 10 9

R25

R90

68K

47K

D11

1SS133

0V

22K

C15

10/25V

U01

TL494CN

R91

22K

R33

33K

C21

102(M)

R63

430K

R04

56K

R05

8.2K

87654321

Q22

A1268GR

48.8V

0

R22

24K

C3198GR

R34

100/16V

Q90

15K

C13

R02

4.7K

R92

1K

0V

220/0.5W

PROTECTION

C16

47/25V

R35

15K

R01

4.7K

Q02

C3198GR

0.7V

R51

220/0.5W

R41

3.63

13.06V

LED01

HNRD-3401L

13.65V

R03

10/0.5W

12V

D03

1SS133

D04

1SS133

PROTECTION

12.92V

0V

Q33

A1266GR

Q23

A1266GR

12V

R52

R42

R55

47

R54

47

R53

47

1K

1K

R43

47

R44

47

R45

47

Q53

FQP50N06

Q43

FQP50N06

Q54

FQP50N06

Q44

FQP50N06

W02

2

C35

104(M)

60m/m#22

W03

C31

R61

10K

2

C36

60m/m#22

2

C37

102P105(M)"TL"

W04

#22 60m/m

C33

473P

C32

105(M)"TL"

105(M)"TL"

Page 22

21

GTO 301.1 Page2 Schematic

LOW INPUT R-CH

RCA101-A

DJB-554A

C101

LOW INPUT L-CH

RCA101-B

DJB-554A

RCA101-C

DJB554A

RCA101-D

DJB-554A

102P

C201

102P

R-OUT

L-OUT

C102

22/16V

R101

22KF

C103

22/16V

C202

22/16V

R201

22KF

C203

22/16V

C143

4.7/50V

R144

100K

C243

4.7/50V

R244

100K

R102

47KF

R103

47KF

R202

47KF

R203

47KF

R143

R243

IN_PUT

C104

10P

C204

10P

1K

1K

-20.2V

1

U102-A

NJM2068LD

1

U102-B

NJM2068LD

C150

2.2/50V

2

3

R106

47KF

6

5

R206

47KF

Q151

J108

R151

10K

C105

22P

R105

47KF

-

+

U101-A

NJM2068LD

C205

22P

R205

47KF

-

+

NJM2068LD

C141

22P

R141

10KF

-

+

C241

22P

R241

10KF

-

+

R150

5.6KF

1

C106

22P

7

U101-B

C206

22P

2

3

2

3

MUTE

R142

R242

R140

10KF

1K

1K

R240

10KF

R149

100K

R107

9.4KF

R207

9.4KF

0V

C151

2.2/50V

48.2V

C154

R152

22KF

473P

C208

4.7KF

C155

100/63V

Q152

C3200GR

C108

470P

R108

4.7KF

2

-

+

3

C152

68P

-47.4V

1

U103-A

NJM2068LD

Q154

A1268GR

Q156

C3200GR

R156

680

C156

473P

R209

100

VR101

20KB

R210

750F

A1268GR

47.4V

R1531KC153

102P

Q153

C3200GR

0V

Q155

C210

47/16V

R250

D152

1SS133

D151

1SS133

C157

100/63V

15.5V

D911

C912

C913

330/16V

15.5V

+15V

U103-B

NJM2068LD

5

+

-

6

R211 10KF

15K

C211 102P

R212

2KF

47/16V

7

C212

14.5V

12.6V

R213

10KF

R214

510F

R215

30K

R217

510

R216

15K

16 15 14 13 12 111210 9

U105

NJM13600

876543

0.8V

R223

1N4744

104P

C223

47/16V

R224

R218

10K

10K

X

REMOTE CONTROL

C220

R219

10K

47P

12.6V

10/0.5W

C1027Y

R167

560

A1023Y

10/0.5W

C3198GR

4.7/50V

C923

330/16V

R165

Q164

Q174

R175

Q219

C219

-15V

C922

104P

Q165

C1027Y

R168

560

R190

Q175

A1023Y

R180

12.6V

D921

1N4744

49V

220P

C180

10

1

R181

10

Q180

TIP35C

R183

0.1/3W

R193

0.1/3W

Q190

TIP36C

10

R191

10

-49V

R157

910F

C159

100/16V

R161

1.5K

D161

1SS133

D160

1SS133

R160

22K

-46.9V

R171

22KF

-47.5V

44.5V

44.8V

C3200GR

0.7V

45V

C160

100P

Q172

R162

47

Q161

A1268GR

Q162

A1268GR

R163

1.5K

R173

820

Q171

C1027Y

R172

120

R100

2K

VR100

20KB

-48.1V

47.8V

44.4V47.1V

-47.4V

C163

1/50V

MOD01

0.3V

0.3V

0.7V

R220

15K

R221

150K

R222

150

R164

100/0.5W

C165

270P

C175

270P

R174

100/0.5W

1/50V

C158

R158 39KF

Q163

C1027Y

R166

560

Q173

A1023Y

330/16V

U104-A

NJM2068LD

5

+

-

6

330/16V

220P

1

C181

C911

-15.9V

C921

R182

TIP35C

R184

0.1/3W

R194

0.1/3W

TIP36C

R192

7

10

Q181

Q191

10

R911

220/2W

R921

220/2W

220P

C182

R225

5.6K

1

0.1/3W

0.1/3W

+VCC1

32Hz-320Hz/12dB oct LPF

823(M)

VR102-A

50KC

R226

5.6K

VR102-B

50KC

C226

683(M)

-VCC1

+VCC

Q182

R186

TIP35C

1.5K

R185

L196

CL-200C

R196

R195

4.7/0.5W

0V

Q192

TIP36C

-VCC

C225

R187

15K

D187

1SS133

R197

4.7/0.5W

C197

104(M)"100V"

U104-B

NJM2068LD

3

+

-

1

2

0V 48.8V

R199

R198

680/2W

0V

C199

100/16V

Q187

C3200GR

C187

100P

56K

R227

R232

1K

1K

VR103

20KB

C227

104(M)

C229

104(M)

R230

150K

R913

1K

LED02

TOL-30aSBaCAa-B2

R923

1K

Q198

C3198GR

Q199

C3198GR

50Hz 0~12dB BASS BOOST

U106-B

NJM2068LD

5

+

-

7

6

R228 39K

C228 47P

R229 6.8K

3

+

-

1

2 NJM2068LD

+15V

-15V

PROTECTION

DST0014-00

U106-A

TER02

OUTPUT

4P

IN_PUT

+

-

+

-

Page 23

Power Amplifier GTO 301.1II

22

Q01

A1023Y

10/0.5W

C06

R01

10/16V

4.7K

R02

R63

4.7K

430K

D02

REM

1N4004

C801

473P

R62

4.7KF

C60

104P

C14

47/16V

16 15 14 13 12 11 10 9

R11

4.7K

Q11

A1266GR

R12

3.9K

100/16V

R13

10K

C11

R14

C12

10K

100/16V

Q21

C3198BL

Q12

A1266GR

C22

104P

R15

10

R21

24K

TH01

50KTH

R311KR32

R16

910

R25

68K

1SS133

10/25V

D11

C15

R04

56K

R05

8.2K

R60

10.5KF

U01

TL494CN

87654321

C21

R22

102(M)

R90

47K

22K

24K

R91

C3198GR

22K

Q22

A1268GR

R33

33K

Q02

C3198GR

R51

220/0.5W

R41

220/0.5W

C13

100/16V

PROTECTION

R92

LED01

Q90

1K

HNRD-3401L

R34

C16

15K

47/25V

R35

15K

GTO 301.1II Page1 Schematic

R03

Q55

D03

1SS133

D04

1SS133

PROTECTION

Q33

A1266GR

Q23

A1266GR

R55

47

R54

47

R53

R52

47

1K

R42

1K

R43

47

R44

47

R45

47

Q53

FQP50N06

Q43

FQP50N06

Q54

FQP50N06

Q44

FQP50N06

FQP50N06

Q45

FQP50N06

1

C05

2200/25V"WL"

C04

1

2200/25V"WL"

C03

104P

L03

CL-300

(0.7X9:0.7X4:0.7X1)

T01

37PHI

5T:17T:10T

1N5404

FH01

30A

D01

D41

YG225D2

R30

100/2W

C08

222(M)"100V"

D42

YG225D2

1SS133

1SS133

W1

REM

TER01

DST0013-00

L01

CL-500

CL-500

C52

3300/63V"HC"

3300/63V"HC"

L02

C82

22P

C51

470/63V

C61

470/63V

D80

R80

220K

D81

R81

10K

DC12V

REMOTE

GND

D51 FR154

D52 FR154

D53 FR154

D54 FR154

C62

Q82

J108

+VCC1

C57

47/50V

C67

47/50V

-VCC1

+VCC

C53

473P

C63

473P

-VCC

MUTE

C83

10/50V

C31

R61

10K

2

2

C35

104(M)

W02

W03

60m/m#22

2

C36

C37

102P105(M)"TL"

W04

#22 60m/m

60m/m#22

C32

C33

473P

105(M)"TL"

105(M)"TL"

Page 24

23

LOW INPUT R-CH

RCA101-A

DJB-554A

10/16V

LOW INPUT L-CH

RCA101-B

DJB-554A

RCA101-C

DJB554A

RCA101-D

DJB-554A

Power Amplifier GTO 301.1II

C105

22P

C102

C101

3

C201

10/16V

R102

22/16V

47KF

R101

22KF

C103

R103

22/16V

47KF

C202

R202

22/16V

47KF

R201

22KF

C203

R203

22/16V

R-OUT

L-OUT

C143

4.7/50V

R144

100K

C243

4.7/50V

R244

100K

47KF

R143

R243

3

IN_PUT

R105

47KF

2

C104

-

10P

+

1

3

U101-A

NJM2068LD

R106

C106

47KF

22P

C205

22P

R205

47KF

6

C204

-

10P

+

7

5

U101-B

NJM2068LD

R206

C206

47KF

22P

C141

22P

R140

R141

10KF

10KF

U102-A

NJM2068LD

U102-B

NJM2068LD

C150

2.2/50V

2

-

1

+

3

R142

1K

C241

22P

R241

R240

10KF

10KF

2

-

1

+

3

R242

1K

R150

5.6KF

Q151

J108

R151

10K

2.2/50V

R149

100K

MUTE

1K

1K

C108

R107

470P

9.4KF

R108

4.7KF

R209

2

100

-

+

3

NJM2068LD

C208

4.7KF

R207

9.4KF

C154

A1268GR

473P

C155

100/63V

Q152

C151

C3200GR

R152

C152

22KF

68P

C3200GR

Q156

U103-A

Q154

R156

680

C156

473P

1

VR101

20KB

R210

240F

A1268GR

R1531KC153

C3200GR

C210

47/16V

R250

15K

2

Q155

102P

Q153

D152

1SS133

D151

1SS133

C157

100/63V

GTO 301.1II Page2 Schematic

C912

C913

104P

330/16V

R217

+15V

510

R216

15K

R214

510F

C163

1/50V

R215

30K

MOD01

16 15 14 13 12 111210 9

R220

15K

R221

150K

R222

150

R158 39KF

R164

100/0.5W

C165

270P

Q163

C1027Y

R166

560

Q173

A1023Y

C175

270P

R174

100/0.5W

U105

NJM13600

C220

1/50V

R219

C158

R223

X

876543

Q219

C3198GR

C219

10K

4.7/50V

-15V

C922

C923

104P

330/16V

47P

R165

10/0.5W

Q165

C1027Y

Q164

C1027Y

R180

R167

R168

560

560

R190

Q174

A1023Y

Q175

A1023Y

R175

10/0.5W

R213

10KF

R157

910F

C159

100/16V

5

+

-

6

R211 10KF

C211 102P

R212

560F

2

R161

1.5K

D161

1SS133

D160

1SS133

R160

22K

R171

22KF

U103-B

NJM2068LD

C160

100P

Q172

C3200GR

7

C212

47/16V

REMOTE CONTROL

R100

2K

VR100

20KB

R162

47

Q161

A1268GR

Q162

A1268GR

R163

1.5K

R173

820

Q171

C1027Y

R172

120

R911

220/2W

+VCC1

D911

C911

1N4744

330/16V

32Hz-320Hz/12dB oct LPF

C225

C223

47/16V

R218

10K

D921

1N4744

R224

10K

U104-A

NJM2068LD

5

+

-

6

330/16V

823(M)

VR102-B

50KC

C226

683(M)

U104-B

NJM2068LD

3

+

-

2

1

VR102-A

50KC

R226

R225

5.6K

5.6K

7

R921

220/2W

C921

-VCC1

R227

R232

1K

1K

C227

104(M)

C229

104(M)

R230

150K

LED02

TOL-30aSBaCAa-B2

50Hz 0~12dB BASS BOOST

NJM2068LD

5

VR103

6

20KB

R228 39K

C228 47P

R229 6.8K

3

2 NJM2068LD

+15V

R913

1K

R923

1K

-15V

+VCC

R182

220P

1

C182

R181

TIP35C

R183

0.1/3W

R193

0.1/3W

TIP36C

10

220P

1

C181

10

Q180

Q190

R191

10

TIP35C

R184

0.1/3W

R194

0.1/3W

TIP36C

R192

Q182

R186

TIP35C

0.1/3W

R195

0.1/3W

TIP36C

1.5K

R187

15K

R185

CL-200C

4.7/0.5W

Q192

D187

L196

1SS133

R196

R197

4.7/0.5W

C197

104(M)"100V"

Q181

Q191

10

220P

C180

1

10

10

R198

680/2W

R199

C199

100/16V

C3200GR

C187

100P

56K

Q187

Q198

C3198GR

Q199

C3198GR

PROTECTION

-VCC

U106-B

+

-

+

-

7

1

OUTPUT

DST0014-00

IN_PUT

U106-A

TER02

+

-

4P

+

-

Page 25

GTO 301.1/301.1II

24

Item Part Number Description Qty

BOX-36-145AB GTO 301.1 Gift box carton 1

1

BOX-36-145AD GTO 301.1II Gift box carton 1

2 INN-42-004A0 End Pads 2

MAN-00-0195A

3

MAN-01-0195Z

MAN-00-0196A

CAR-WA-004A Warranty Card 1

4 FUS-AT-00006 Fuse 30A 2

SC4-NP-40250 Mounting screw STT1 PH

BKT-14-523A0 Bracket lamp SK-5/BK 4

5 Pair Pack carton 1

GTO 301.1 Owner’s manual

(USA)

GTO 301.1II Owner’s

manual (USA)

GTO 301.1 Owner’s manual

(Europe)

4X25 NI

1

1

1

4

Loading...

Loading...