JBL CONTROL 26CT, CONTROL 26C Owner’s Manual

Control Contractor

Ceiling Loudspeakers

Owner’s Manual

Table of Contents

Product Description.........................................................................................2

Product Feature Identification.........................................................................3

Installation Preparations.................................................................................. 4

Step-By-Step Installation and Wiring.............................................................6

Painting the Speaker...................................................................................... 15

Safety Agency Compliance...........................................................................16

Maintenance.................................................................................................. 16

Replacement Parts.........................................................................................17

Contacting JBL.............................................................................................. 17

1

Thank you for purchasing JBL Control Contractor ceiling loudspeakers.

Read through this manual to familiarize yourself with the features, applications and

precautions before you use these products.

Product Descriptions

The JBL Control Contractor ceiling loudspeakers utilize innovative design and

materials to provide premium level performance from compact in-ceiling speakers.

CONTROL 24C & 24CT

24C contains a coaxially mounted 4” woofer and ¾” titanium-coated tweeter,

providing high-fidelity full-range sound over an extremely wide coverage area. The

optional Control 24CT includes a multi-tap transformer for 70V or 100V systems.

CONTROL 26C & 26CT

containing a coaxially mounted 6.5” woofer and ¾” titanium-coated tweeter, able to

deliver maximum sound level over a wide coverage area. The optional Control 26C

includes a multitap transformer for a 70V or 100V line distribution system.

CONTROL 19CS & 19CST Subwoofer

Linear Dynamics port allows powerful low-frequency reinforcement from a

compact in-ceiling enclosure. The Control 19CS is an ideal addition to any system,

resulting in full-fidelity high level sound. The optional Control 19CST includes a

special subwoofer-band transformer for use on 70V or 100V line distribution systems.

– Most compact of the JBL ceiling speakers, the Control

– The Control 26C is a powerhouse ceiling speaker

– The unique Nested Chamber design and

T

2

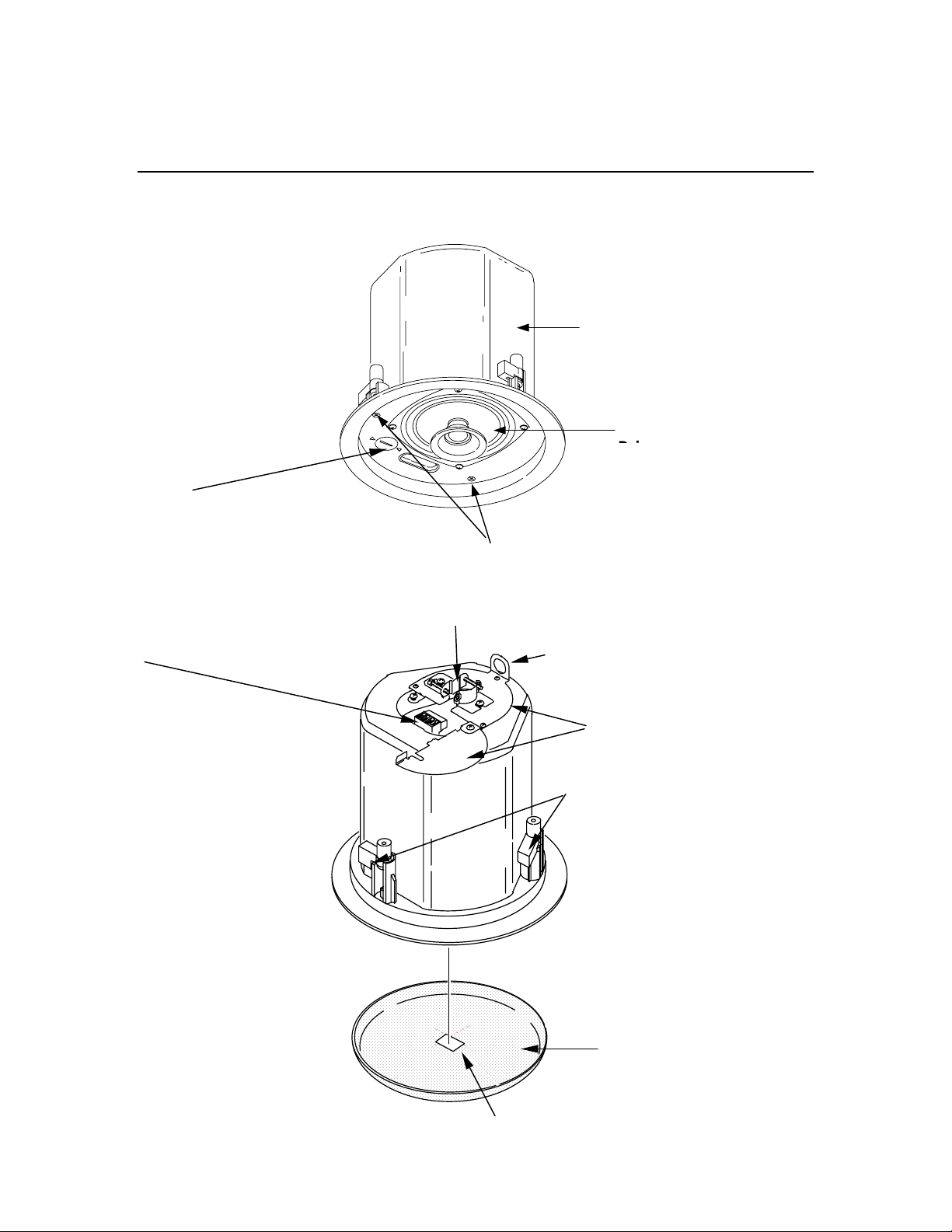

Product Feature Identification

(

Control 24C Shown)

Steel Backcan

Loudspeaker

Tap Selector (on T-versions)

Attachment Screws

Removable Locking Input Connector

Strain Relief Fitting

Seismic Tab

(secondary support point)

Terminal Cover Plate Assembly

Rotating Mounting Tabs

-

JBL Logo

3

Installation Preparations

The entire installation can be accomplished, if necessary, without requiring access

above the ceiling. Bracketry for use with either suspended ceilings or sheetrock

ceilings is included. The speaker is held securely in place via mounting ears which

lock into place. Inputs are attached to a removable locking connector (included)

which can be prewired before installing the speaker for ultra-fast snap-on installation.

OPTIONAL PRE-INSTALLATION BRACKETS

IN MOST CASES, NO BRACKETS OTHER THAN THE ONES INCLUDED WITH

YOUR SPEAKER ARE REQUIRED. Everything needed for most installations of

these loudspeakers is provided with your Control Contractor ceiling speaker.

However, a particular procedure that is sometimes used for installation into sheet rock

(typically gypsum board) can be facilitated by the use of JBL’s optional preinstallation

brackets before the sheetrock is installed. The preinstallation bracket provides a

bracket to which wiring can be tied behind the sheetrock and it can function as a

cutout template when many cutouts are to be made in a production-line style

installation. Two types of pre-installation brackets are available from JBL

Professional as optional accessories:

1) The optional

with wings to attach to the building structure. Holes are drilled for nails or screws at

16 inches (406 mm) and 24 inches (610 mm) on-center. Additional holes can be

drilled by the installer at other spacings up to a maximum of 24-3/4 inches (630 mm)

apart. Sheet rock installs over the bracket, and the bracket provides a template for

blind cutout of the hole in the sheet rock. The sheet rock is typically cut with a routertype cutting tool, using the bracket ring as a cutout guide.

NEW-CONSTRUCTION BRACKET

Figure 1:

Optional New -Construction Bracket

is made of flat sheetmetal,

4

2) The optional

PLASTER-RING BRACKET

(or “mud ring”) contains a circular

offset, forming a edge guide for sheet rock plastering. The bracket has wings that

attach to the building structure. Sheet rock is typically either precut or cut with a

rotary cutting tool using the outside of the plaster ring circle as a guide. The sheet

rock hole is then plastered (or “mudded”) up to the ring to create a seamless cutout.

Figure 2:

Optional Plaster Ring Bracket

New

Mod el

Con structio n

Bra cket

Pla ster- Rin g

Bra cket

Control 24C & 24CT MTC-24NC MTC-24MR

Control 26C & 26CT MTC-26NC MTC-26MR

Control 19CS & 19CST MTC-19NC MTC-19MR

USING INCLUDED C-BRACKET WITH SHEETROCK

For most installations, the INCLUDED C-shaped backing plate to provides adequate

reinforcement to the ceiling material, spreading out the clamping force from the tab

clamps.

CUTOUT SIZES

Packaged with the speakers are cardboard cutout templates for scribing the cutout hole

onto your ceiling surface.

Mod el Cut out S ize

(di amet er)

Control 24C & 24CT 168 mm (6.6 in)

Control 26C & 26CT 220 mm (8.75 in)

Control 19CS & 19CST 305 mm (12.0 in)

5

Loading...

Loading...