Page 1

CBT1000 and CBT1000E

Bracket Installation Guide

Rev C

CBT1000

CBT1000E

Page 2

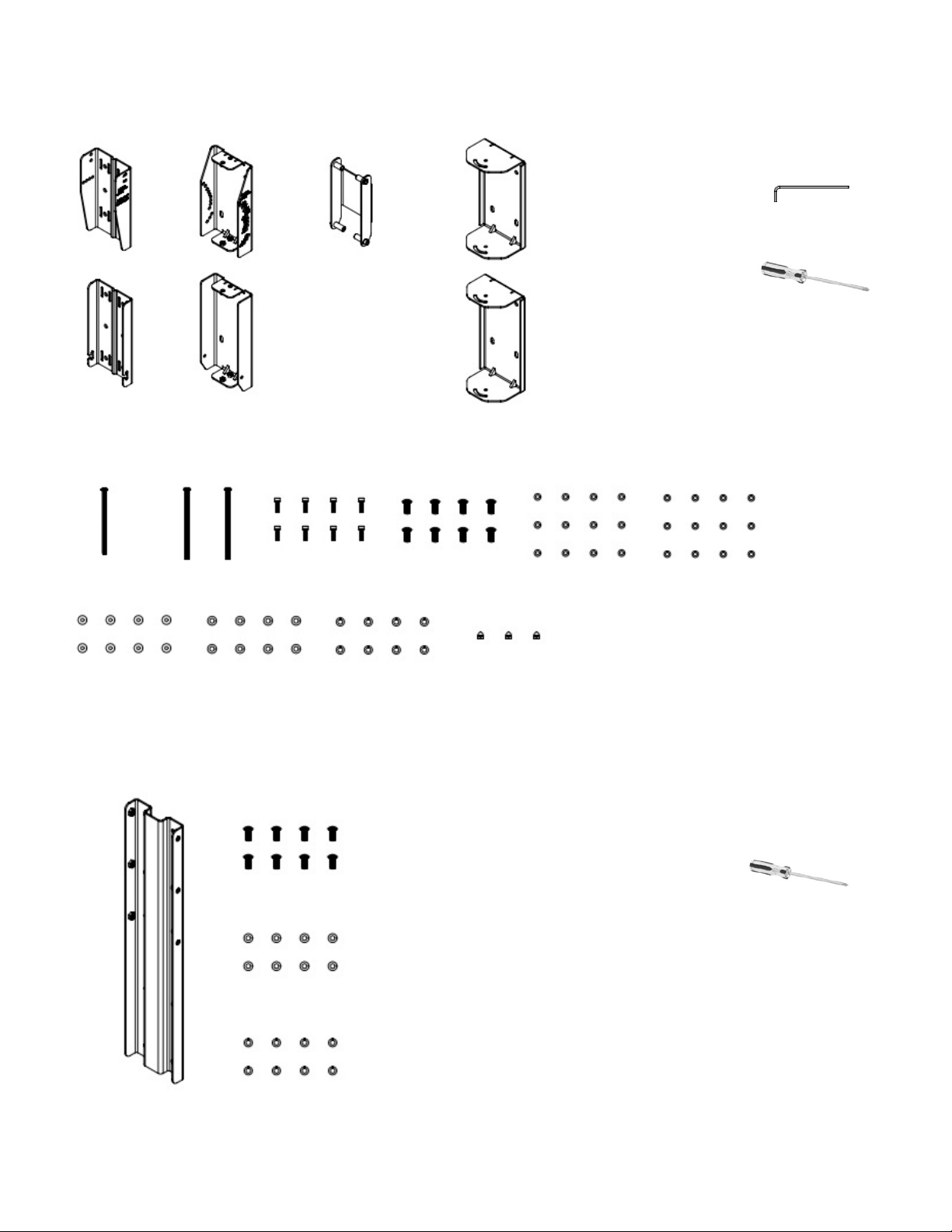

Hardware Included with CBT1000:

WALL

BRACKETS

M6 x 115 mm

PAN HEADS

SPEAKER

BRACKETS

M6 x 125 mm

PAN HEADS

ARM

LINK

M6 x 20 mm

SOCKET HEADS

SWIVEL

BRACKETS

M8 x 20 mm

PAN HEADS

Tools Required:

4 Bracket Parts for UPPER

←

Mounting Position on

Cabinet (when set for 0° or

for down-tilting)

3 Bracket Parts for LOWER

←

Mounting Position on

Cabinet (when set for 0° or

for down-tilting)

Note: When setting system for UP tilting, the UPPER and LOWER

parts get reversed on the cabinet -- see instructions.

M6

FLAT WASHERS

M6 SPLIT

LOCK WASHERS

M6 Hex Wrench

#2 Phillips Head Screwdriver

M6 RUBBER

WASHERS

M8

FLAT WASHERS

M8 SPLIT

LOCK WASHERS

Hardware Included with CBT1000E:

M8 x 20 mm PAN HEADS

M8 FLAT WASHERS

M8 SPLIT LOCK WASHERS

M6

CAP NUTS

Tools Required:

#2 Phillips Head Screwdriver

2

Page 3

Instructions for CBT 1000 Alone (without 1000E):

The BRACKET ASSEMBLY consists of 2 pieces of SPEAKER BRACKETS (the parts that mount on the

speaker), 2 pieces of WALL BRACKETS (the parts that mount on the wall), 2 pcs of SWIVEL BRACKETS

(which get added to the SPEAKER BRACKETS if utilized for horizontal swivel/pan aiming capability), and an

ARM LINK (which is utilized for the larger tilt angles).

1) RUN WIRING -- Run the wiring from the power amplier to the location desired for mounting the JBL

CBT Loudspeakers. Note: Connect wire to speaker terminals at a point in the installation process when

convenient for your installation circumstances.

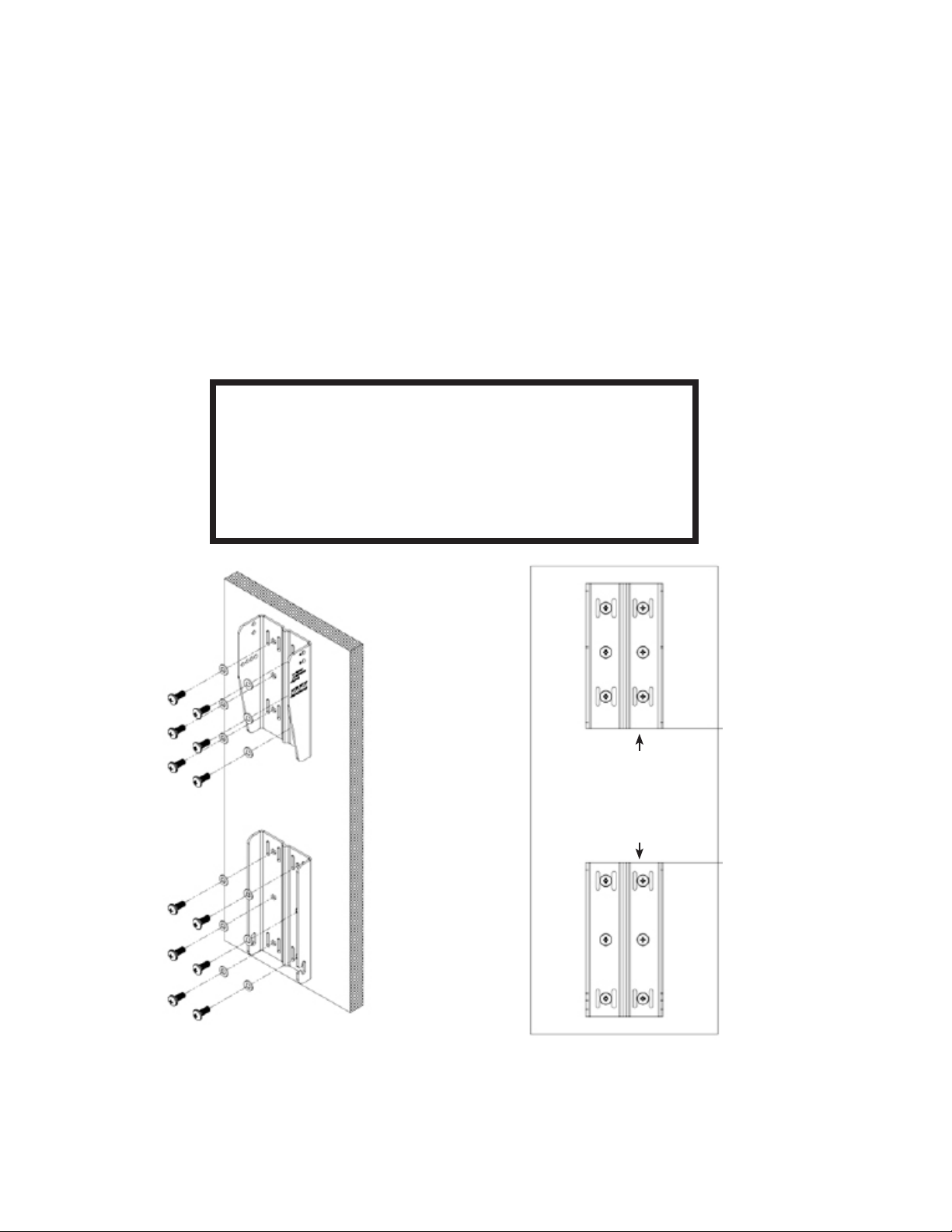

2) ATTACHING WALL BRACKET TO WALL -- Using a level to ensure that the WALL BRACKET is straight,

secure the WALL BRACKET to the wall. Be sure to use the appropriate wall anchors for attaching the

bracket. Use as many of the screw holes as possible for maximum integrity and safety.

CAUTION: Installation must be done by

qualied persons using safe rigging standards.

The installer is responsible for proper selection and use of

mounting hardware to properly and safely wall-mount the

speakers.

(Drawings show upper

and lower bracket

orientation as set for

down-tilt or 0°. Wall

brackets to be reversed

in location and ipped for

up-tilt applications (see

further instructions).

Hardware attaching WALL BRACKET to wall is not included.

Utilize proper hardware for particular wall structure.

Spacing:

181 mm (7-1/8”) for Down-Tilt

197 mm (7-3/4”) for Up-Tilt

Spacing needed between upper and lower

WALL BRACKET parts with CBT1000 depends on

whether speaker will be set with down-tilt or up-tilt.

3

Page 4

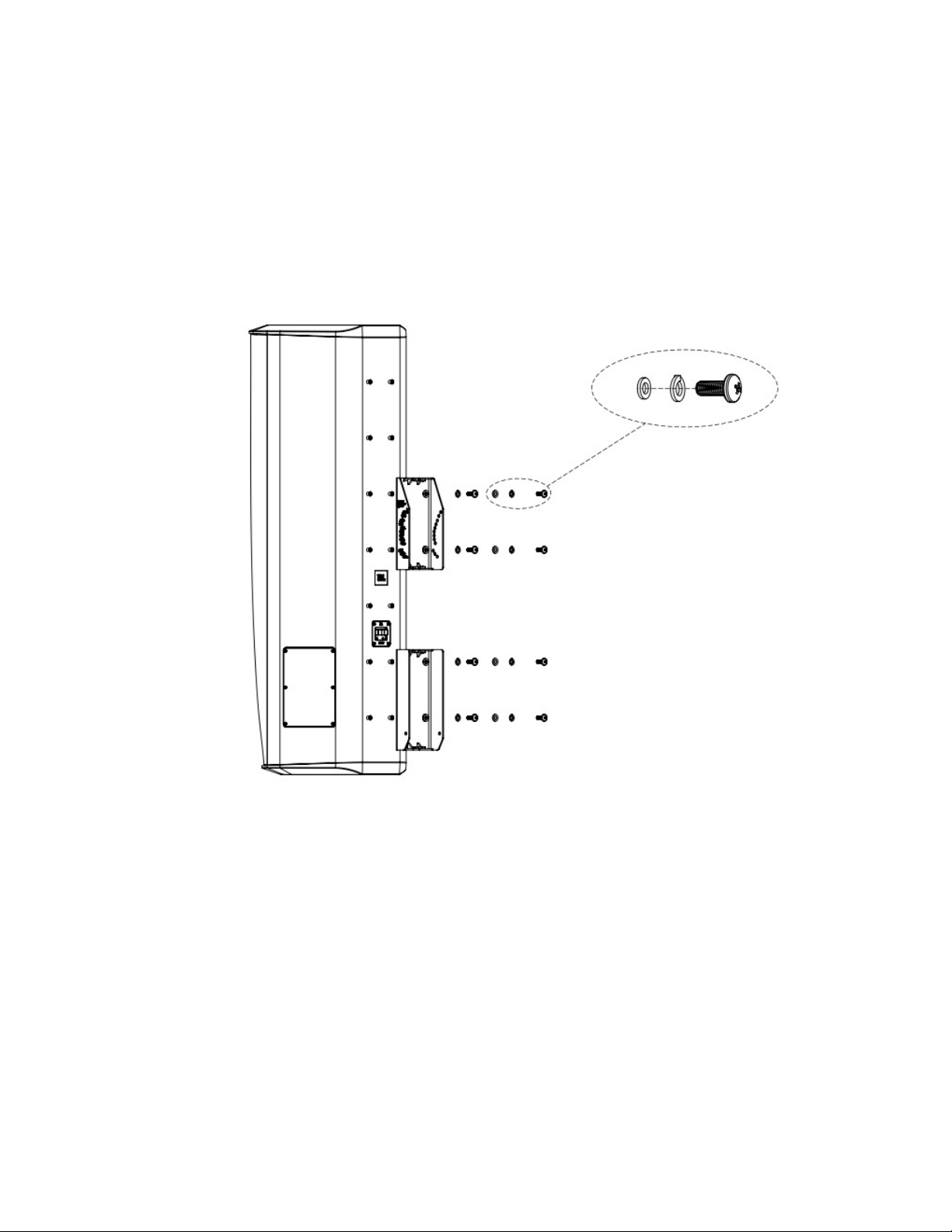

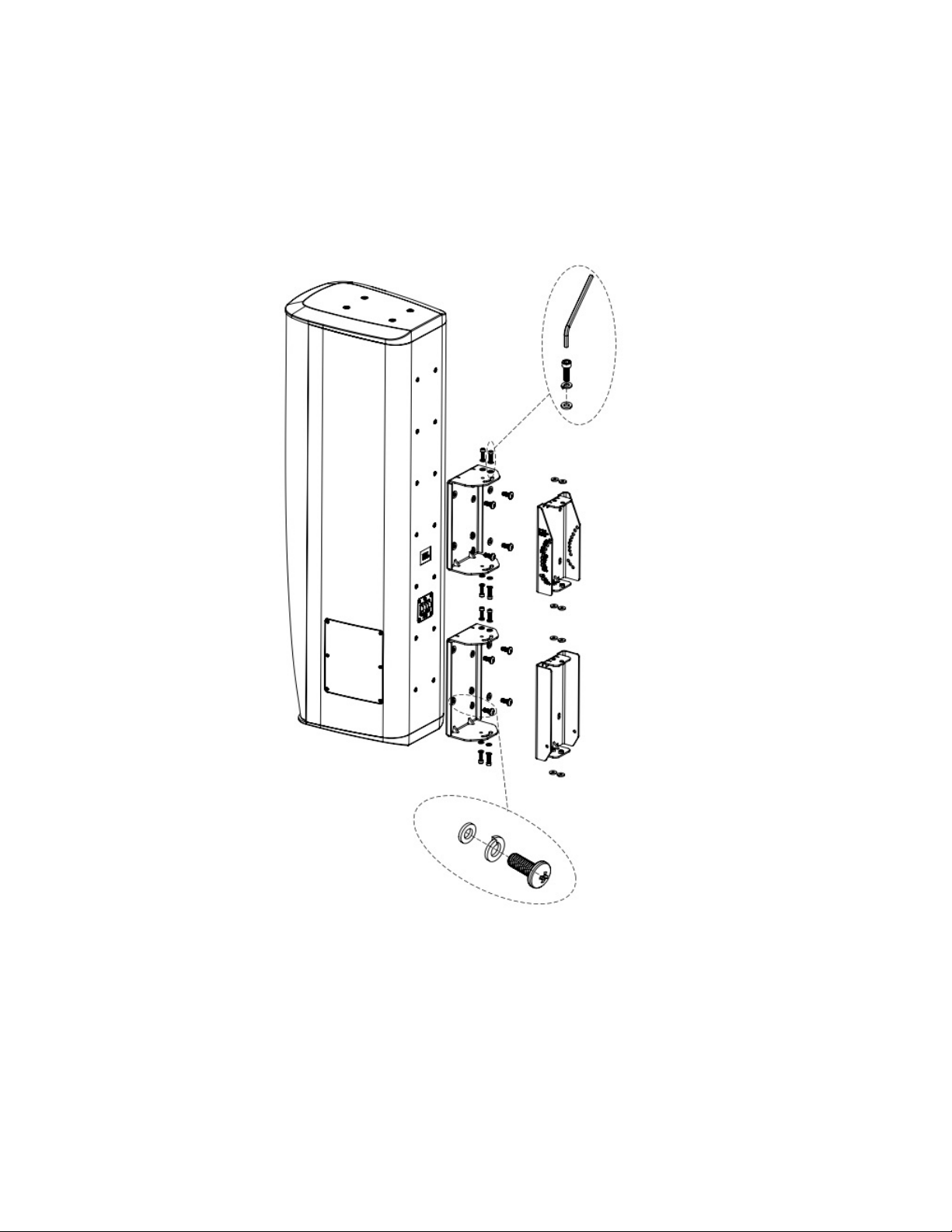

3) ATTACH SPEAKER SIDE OF BRACKET TO SPEAKER

Mount the SPEAKER BRACKET (2 pcs) to the speaker with the provided M8 x20 mm pan-head bolts, in

the locations shown and in the orientation shown in the diagram below.

Option 3a) CBT 1000 with No Swivel (for Down-Tilt Capability [or 0° tilt] and No Horizontal Swivel/Pan).

8 PLACES:

M8

FLAT WASHER

M8 SPLIT

LOCK WASHER

M8 x 20 mm

PAN HEAD

BOLT

Down-tilt range 0° to -15°

4

Page 5

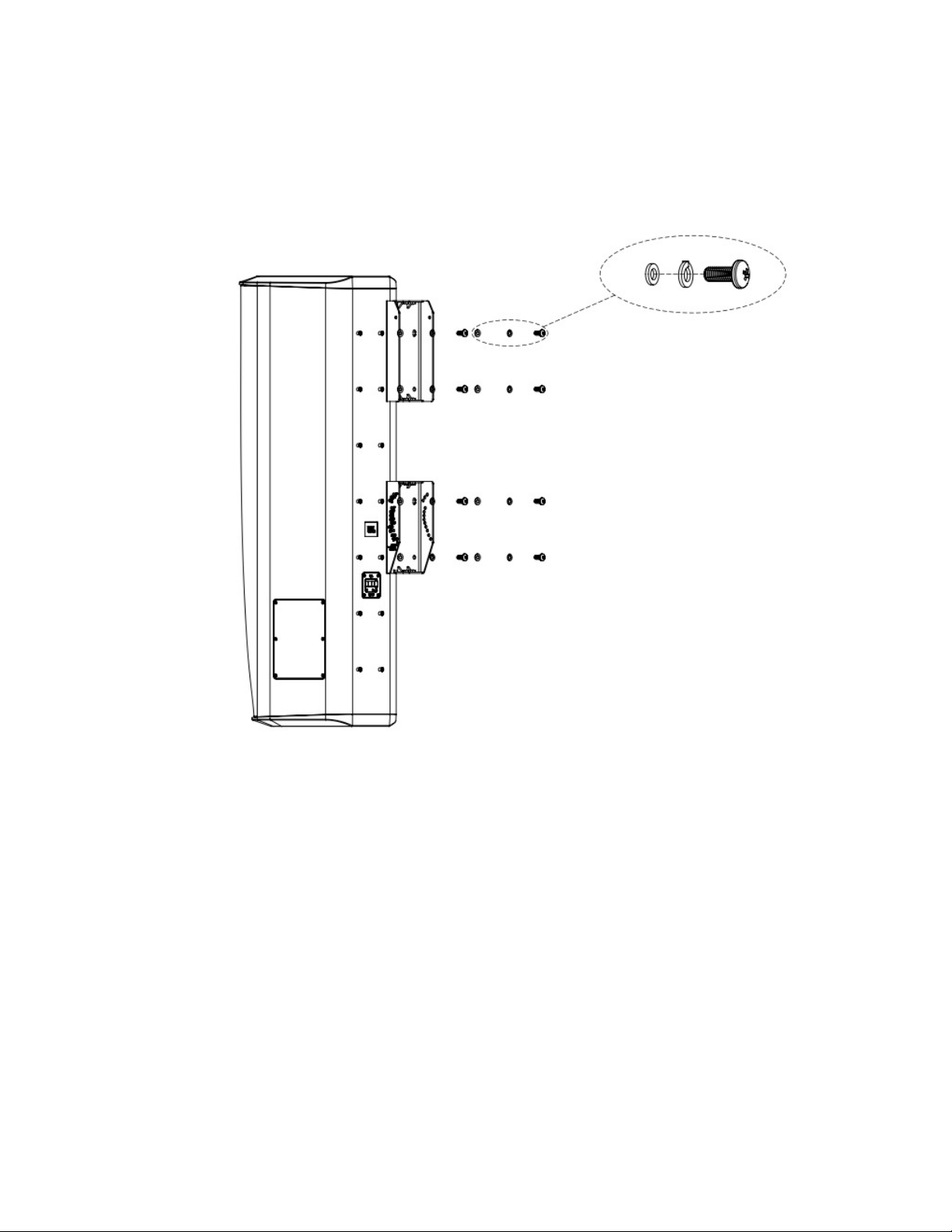

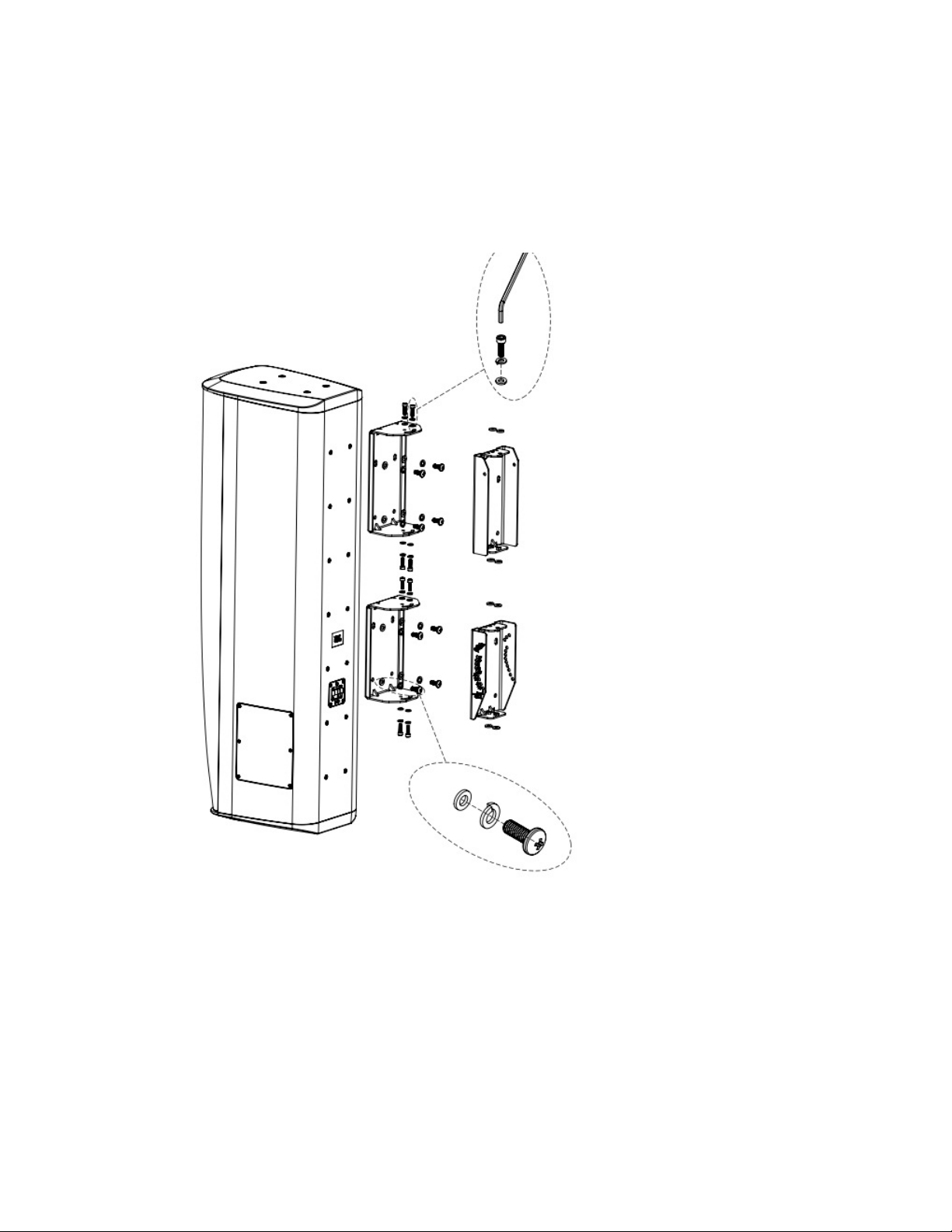

Option 3b) CBT 1000 with Up-Tilt Capability -- No Horizontal Swivel/Pan

8 PLACES:

M8

FLAT WASHER

M8 x 20 mm

PAN HEAD

BOLT

M8 SPLIT

LOCK WASHER

Up-tilt range 0° to +15°

5

Page 6

Option 3c) CBT1000 Mounting with Down-Tilt Capability and SWIVEL BRACKET

(for Horizontal Swivel/Pan aiming capability)

8 PLACES:

M6 Hex Wrench

M6 x 20 mm

SOCKET HEAD BOLT

M6 SPLIT

LOCK WASHERS

M6 FLAT WASHERS

M8

FLAT WASHER

M8 SPLIT

LOCK WASHER

Down-tilt range 0° to -15°

8 PLACES:

M8 x 20 mm

PAN HEAD

BOLT

6

Page 7

Option 3d) CBT1000 Mounting with Up-Tilt Capability and SWIVEL BRACKET

(for Horizontal Swivel/Pan aiming capability)

8 PLACES:

M6 Hex Wrench

M6 x 20 mm

SOCKET HEAD BOLT

M6 SPLIT

LOCK WASHERS

M6 FLAT WASHERS

Up-tilt range 0° to +15°

M8

FLAT WASHER

M8 SPLIT

LOCK WASHER

8 PLACES:

M8 x 20 mm

PAN HEAD

BOLT

7

Page 8

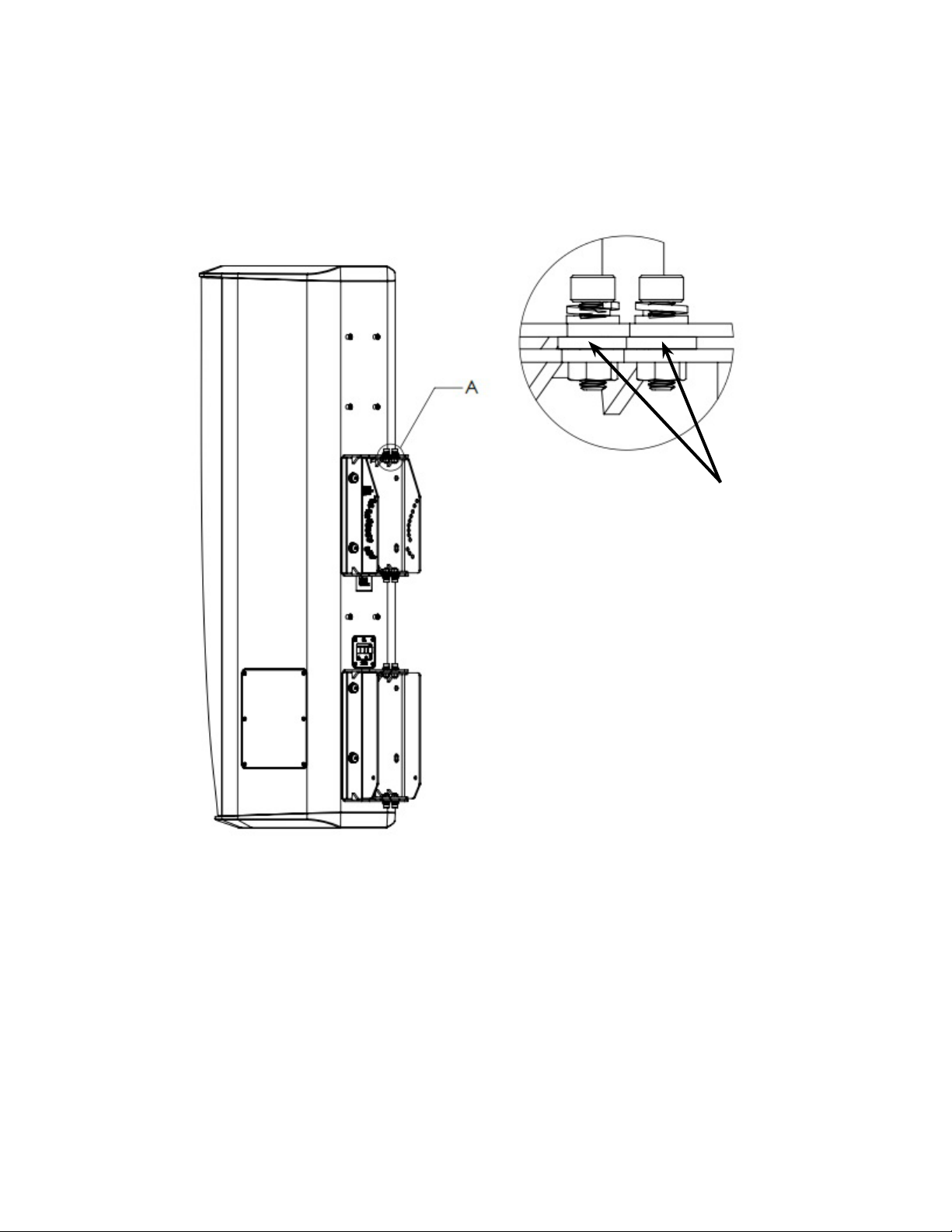

For Options 3c and 3d (congurations that include the SWIVEL BRACKET), place RUBBER

WASHERS as shown when using SWIVEL BRACKET:

RUBBER WASHERS to be placed

between SWIVEL BRACKET and

SPEAKER BRACKET

4) Jump to page 15 for CBT 1000 tilt angling instructions.

8

Page 9

Instructions for CBT 1000+1000E System:

The BRACKET ASSEMBLY consists of 2 pieces of SPEAKER BRACKETS (the parts that mount on the

speaker), 2 pieces of WALL BRACKETS (the parts that mount on the wall), 2 pcs of SWIVEL BRACKETS

(which get added to the SPEAKER BRACKETS if utilized for horizontal swivel/pan aiming capability), and an

ARM LINK (which is utilized for the larger tilt angles).

1) RUN WIRING -- Run the wiring from the power amplier to the location desired for mounting the JBL

CBT Loudspeakers. Note: Connect wire to speaker terminals at a point in the installation process when

convenient for your installation circumstances.

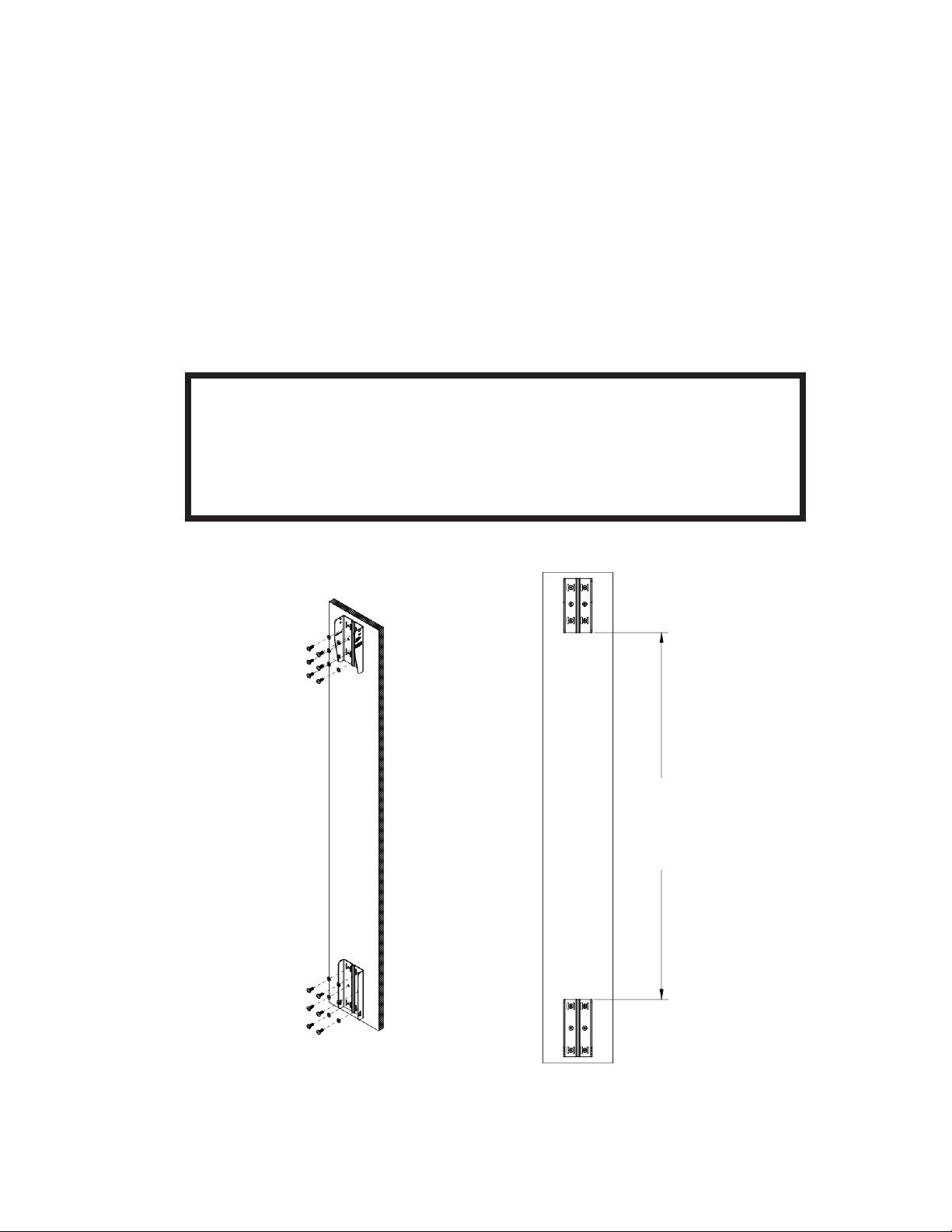

2) ATTACHING WALL BRACKET TO WALL -- Using a level to ensure that the WALL BRACKET is straight,

secure the WALL BRACKET to the wall. Be sure to use the appropriate wall anchors for attaching the

bracket. Use as many of the screw holes as possible for maximum integrity and safety.

CAUTION: Installation must be done by qualied persons

using safe rigging standards.

The installer is responsible for proper selection and use of mounting hardware

to properly and safely wall-mount the speakers.

(Drawings show upper

and lower bracket

orientation as set for

down-tilt or 0°. Wall

brackets to be reversed

in location and ipped for

up-tilt applications (see

further instructions).

Hardware attaching WALL BRACKET to wall is not

included. Utilize proper hardware for particular wall

structure.

Spacing:

1200 mm (47-1/4”) for Down-Tilt

1216 mm (47-7/8”) for Up-Tilt

Spacing needed between upper and lower

WALL BRACKET parts with CBT1000 and

CBT1000E depends on whether speaker will be set

with down-tilt or up-tilt

9

Page 10

3) ATTACHING COUPLER PLATE -- Connect the CBT 1000 and CBT 1000E together by attaching

COUPLER PLATE to bottom four (4) insert points of the CBT 1000 and to top four (4) insert points of

CBT 1000E using 8 pcs M8 x 20 PAN-HEAD PHILLIPS BOLTS with LOCK WASHERS and FLAT

WASHERS. Tighten.

IMPORTANT: WHEN THE CBT 1000E IS LOCATED ON THE TOP VERSUS ON THE BOTTOM

The diagram below shows the COUPLER PLATE attachment method for when the CBT 1000 is on

the top and the CBT 1000E on the bottom. For utilizing with the CBT 1000E on top and the CBT

1000 on the bottom, the depth of the cabinets are different at the junction between them, so it is

necessary to use the optional MTC-CBT-OS3 Offset Bracket (which is part of the CBT1K-ACC1

kit). See Appendix A for attaching together in this orientation utilizing the MTC-CBT-OS3 bracket.

8 PLACES:

M8

FLAT WASHER

LOCK WASHER

M8 x 20 mm

PAN HEAD

BOLT

M8 SPLIT

Hint: One strategy for orienting speakers for

attaching the COUPLER PLATE is to place

both speakers on a non-scratching oor

surface on their sides.

10

Page 11

4) ATTACH SPEAKER SIDE OF BRACKET TO SPEAKER

Option 4a) CBT 1000+1000E System with No Swivel

(for Down-Tilt Capability [or 0° tilt] and No Horizontal Swivel/Pan)

8 PLACES:

M8

FLAT WASHER

LOCK WASHER

M8 x 20 mm

PAN HEAD

BOLT

M8 SPLIT

Down-tilt range 0° to -5.25°

11

Page 12

Option 4b) CBT1000+1000E System with Up-Tilt Capability

(No Horizontal Swivel/Pan)

8 PLACES:

M8

FLAT WASHER

M8 x 20 mm

PAN HEAD

BOLT

M8 SPLIT

LOCK WASHER

Up-tilt range 0° to +5.25°

12

Page 13

Option 4c) CBT1000+1000E System with Down-Tilt Capability and Horizontal Swivel/Pan

8 PLACES:

M8 SPLIT

LOCK WASHER

M8

FLAT WASHER

M8 x 20 mm

PAN HEAD

BOLT

SWIVEL BRACKET attaches to speaker

via M8 x 20 mm PAN HEAD BOLTS (with

lock washers and atwashers).

SPEAKER BRACKET attaches to

SWIVEL BRACKET via M6 x 20 SOCKET

HEAD BOLTS inserted from the top and

bottom of the SWIVEL BRACKET, with

RUBBER WASHERS between the two

brackets.

See pages 6 and 7 for detailed drawings

of SPEAKER BRACKET / SWIVEL

BRACKET connection (as shown on CBT

1000 alone).

Down-tilt range 0° to -5.25°.

Horizontal ±45° Swivel (Pan)

13

Page 14

Option 4d) CBT1000+1000E System with Up-Tilt Capability and Horizontal Swivel/Pan

M8

FLAT WASHER

M8 SPLIT

LOCK WASHER

8 PLACES:

M8 x 20 mm

PAN HEAD

BOLT

SWIVEL BRACKET attaches to speaker

via M8 x 20 mm PAN HEAD BOLTS (with

lock washers and atwashers).

SPEAKER BRACKET attaches to

SWIVEL BRACKET via M6 x 20 SOCKET

HEAD BOLTS inserted from the top and

bottom of the SWIVEL BRACKET, with

RUBBER WASHERS between the two

brackets.

See pages 6 and 7 for detailed drawings

of SPEAKER BRACKET / SWIVEL

BRACKET connection (as shown on CBT

1000 alone).

Up-tilt range 0° to +5.25°.

Horizontal ±45° Swivel (Pan)

14

Page 15

The following instructions apply to both the CBT1000 by itself and

to the CBT 1000+1000E System.

(For simplicity, drawings are shown with CBT1000 only.)

5) SLIDE SPEAKER WITH SPEAKER BRACKET ONTO WALL BRACKET

Make sure the PIVOT BOLT is installed in-place in the SPEAKER BRACKET. The PIVOT BOLT

ASSEMBLY consists of the M6 x 125 mm bolt with lock washer and at washer on the head and secured

in place with at washer, lock washer and M6 cap nut. IMPORTANT: Leave the nut loose (do not tighten).

Slide the speaker forward so that the SPEAKER BRACKET engages into the WALL

BRACKET, dropping the PIVOT BOLT ASSEMBLY into the hook slot of the WALL BRACKET.

For Down-Tilt or 0°

For Up-Tilt

For Down-Tilt or 0° Tilt

Hook Slot

Install PIVOT BOLT before dropping

speaker into WALL BRACKET

Install PIVOT BOLT before dropping

speaker into WALL BRACKET

Hook Slot

Drop PIVOT BOLT into

hook slot of WALL BRACKET

Bolt Installed

Bolt Installed

Drop PIVOT BOLT into

hook slot of WALL BRACKET

15

Page 16

6) SET THE TILT ANGLE

6a) For Setting Shallow Tilt Angles (0° to -3° for CBT1000; 0° to -0.9° for CBT1000+1000E System),

do NOT use ARM LINK.

Slide the M6 x 125 mm BOLT into labeled hole for desired down-tilt angle. Use LOCK WASHER

and FLAT WASHER on head and FLATWASHER, LOCK WASHER, and CAP NUT on end of bolt.

For clarity, shown without loudspeaker (or

SWIVEL BRACKET, if utilized), and shown with

brackets in the down-tilt orientation.

M6 CAP NUT

M6 LOCK WASHER

M6 FLAT WASHER

ARM LINK is not to be used for tilt angles from 0° to 3°

(CBT1000) or 0° to 0.9° (CBT 1000 + 1000E System)

See full size Tilt Angle Settings Diagram for

detail of markings and settings

M6 FLAT WASHER

M6 LOCK WASHER

M6 x 125 mm BOLT

CBT 1000: 0°

CBT 1000 + 1000E: 0°

Use Points “C”

CBT 1000: 1°

CBT 1000 + 1000E: 0.3°

CBT 1000: 2°

CBT 1000 + 1000E: 0.6°

16

CBT 1000: 3°

CBT 1000 + 1000E: 0.9°

Page 17

6b) For Setting Larger Tilt Angles (-4° to -15° for CBT1000; -1.25° to -5.25° for CBT1000+E

System), Use ARM LINK.

Loosely attach the ARM LINK to the WALL BRACKET using the M6 x 115 mm bolt in hole A or B

(depending on desired tilt angle -- refer to TILT ANGLE SETTINGS DIAGRAM). Use LOCK WASHER

and FLAT WASHER on head and FLATWASHER, LOCK WASHER, and CAP NUT on end of bolt.

IMPORTANT: Do not tighten yet (leave loose).

Attach the other end of ARM LINK to SPEAKER BRACKET. Slide the M6 x 125 mm BOLT into

labeled hole for desired down-tilt angle through the holes in the lower end of the ARM LINK. Use

LOCK WASHER and FLAT WASHER on head and FLATWASHER, LOCK WASHER, and CAP NUT

on end of bolt.

For clarity, shown without SPEAKER BRACKET

Tighten all bolts.

M6 x 115 mm BOLT

(and SWIVEL BRACKET, if used), and shown

with brackets in the down-tilt orientation.

M6 x 125 mm BOLT

M6 LOCK WASHER

M6 LOCK WASHER

M6 FLAT WASHER

M6 FLAT WASHER

M6 LOCK WASHER

M6 CAP NUT

M6 FLAT WASHER

ARM LINK is to be used for tilt angles greater than 3° (CBT 1000)

or 0.9° (CBT 1000 + 1000E System). ARM LINK is to be installed

to WALL BRACKET rst before setting angle.

17

Page 18

Tilt Angle Settings Diagram

+

+

Shown set in the 13° tilt setting for CBT1000, or 4.5°

tilt setting for CBT 1000 + 1000E System

(Marked A-13° in black and A-4.5° in orange, so other

end of LINK ARM is at Point “A”)

18

Page 19

See full size Tilt Angle Settings Diagram on previous

page for detail of markings and settings

ARM LINK Not Utilized

“System” = CBT 1000 + 1000E

+

= Bolt Setting Location(s)

+

Use

Point “C”

CBT 1000: 0°

System: 0°

CBT 1000: 1°

System: 0.3°

ARM LINK Utilized

Use

Point “B”

CBT 1000: 4°

System: 1.25°

+

+

+

+

CBT 1000: 2°

System: 0.6°

“System” = CBT 1000 + 1000E

+

+

CBT 1000: 5°

System: 1.75°

+

+

CBT 1000: 6°

System: 2.0°

+

CBT 1000: 3°

System: 0.9°

+

= Bolt Setting Location(s)

Use

Point “A”

Use

Point “A”

+

+

CBT 1000: 7°

System: 2.5°

+

CBT 1000: 12°

System: 4.0°

+

+

CBT 1000: 8°

System: 2.75°

+

CBT 1000: 13°

System: 4.5°

+

CBT 1000: 9°

System: 3.0°

+

19

+

++

+

CBT 1000: 14°

System: 5.0°

+

CBT 1000: 10°

System: 3.5°

+

+

+

CBT 1000: 11°

System: 3.75°

+

CBT 1000: 15°

System: 5.25°

+

+

Page 20

7) SETTING HORIZONTAL SWIVEL (PAN) AIMING – With the 8 M6 x 20 mm SOCKET HEAD

swivel screws loose (4 on top bracket and 4 on bottom bracket), set the horizontal swivel (pan)

aiming angle. Tighten all 8 swivel screws.

Once all components have been

installed, use HEX WRENCH to

loosen SWIVEL BRACKET and

the speaker will be able to pan to

+45°.

2 M6 x 20 mm SOCKET BOLTS

2 M6 x 20 mm SOCKET BOLTS

2 M6 x 20 mm SOCKET BOLTS

2 M6 x 20 mm SOCKET BOLTS

20

Page 21

BRACKET PARTS DIMENSIONAL DIAGRAMS

WALL BRACKET TOP/BOTTOM SECTIONS

48

50

[2.0]

[1.9]

196

[7.7]

M6 Bolt

Clearance

Holes

Narrow

Pole-Strap

Slots

Wide

Pole-Strap

Slots

184

[7.3]

104

[4.1]

24

[1.0]

50

[2.0]

29

[1.1]

209

[8.2]

Center Recessed

Channel for

Improved

Pole-Mount

Stability

21

Dims in mm [in]

Page 22

SPEAKER BRACKET TOP/BOTTOM SECTIONS

208

[8.2]

70

[2.8]

111

[4.4]

M8 Bolt Clearance

Holes

172

[6.8]

45

[1.8]

4 x M6 Threaded Inserts

44

[1.7]

M6 Bolt Clearance Holes

228

[9.0]

70

[2.8]

111

[4.4]

44

[1.7]

200

[7.9]

73

[2.9]

4 x M6 Threaded Inserts

M6 Bolt Clearance Hole

Dims in mm [in]

22

Page 23

SWIVEL BRACKET TOP/BOTTOM SECTIONS

70

[2.8]

87

[3.4]

220

[8.7]

113

[4.4]

123

[4.8]

[2.1]

70

[2.8]

180

[7.1]

53

82

[3.2]

37

[2.2]

87

[3.4]

239

[9.4]

110

[4.3]

120

[4.7]

81

[3.2]

57

[2.2]

23

206

[8.2]

82

[3.2]

Dims in mm [in]

Page 24

LINK ARM

90

[3.6]

96

[3.8]

103

[4.1]

33

[1.3]

172

[6.8]

24

Page 25

APPENDIX A - MTC-CBT-OS2 Offset Bracket

MTC-CBT-OS3 Offset Bracket must be used when the CBT 1000E (extender) is located on the top

versus on the bottom of the CBT 1000 (full-range speaker).

The optional MTC-CBT-OS3 bracket is part of the CBT1K-ACC1 kit.

Hardware Included with MTC-CBT-OS3:

MTC-

CBT-OS3

BRACKET

Tool Required:

M8 x 20 mm

PAN HEAD

BOLTS

M6

FLAT WASHERS

M6 SPLIT

LOCK WASHERS

#2 Phillips Head

Screwdriver

25

Page 26

1) Attach MTC-CBT-OS3 to bottom 4

inserts of CBT 1000E using M8 PAN

HEAD BOLTS with LOCKWASHERS

AND FLATWASHERS

2) Attach top of COUPLER PLATE to

MTC-CBT-OS3 BRACKET by inserting

bolts through holes in MTC-CBT-OS3

BRACKET (3 on left side; 3 on right

side) and thread into captured nuts in

COUPLER PLATE

(6 places)

3) Attach bottom of COUPLER

PLATE to CBT 1000 via the normal

method, using M8 PAN HEAD BOLTS

with LOCK WASHERS and FLAT

WASHERS

(4 places)

4) Insert 2 bolts through middle holes

in the back panel of the COUPLER

PLATE and thread into captured

nuts at the bottom of MTC-CBT-OS3

bracket.

M8 x 20 mm

PAN HEAD BOLTS with

LOCK WASHERS and

FLAT WASHERS

6 PLACES:

3 on left side,

3 on right side

M8 x 20 mm

PAN HEAD BOLTS with

LOCK WASHERS and

FLAT WASHERS

4 PLACES

Make sure all bolts are tight.

M8 x 20 mm

PAN HEAD BOLTS with

LOCK WASHERS and

FLAT WASHERS

6 PLACES

26

Page 27

Completed Assembly

27

Page 28

JBL Professional

8500 Balboa Blvd.

Northridge, CA 91329

U.S.A.

CBT1000 Brkt RevC

10/17

Loading...

Loading...