Page 1

560GTi/660GTi

COMPETITION SPEAKER SYSTEMS

60TH ANNIVERSARY EDITION

OWNER’S GUIDE

Page 2

FOR MORE THAN 60 YEARS, JBL®HAS

DELIVERED PRODUCTS THAT EXEMPLIFY THE TECHNOLOGY

AND EXPERTISE GAINED THROUGH A LEADERSHIP ROLE IN

PROFESSIONAL SOUND REPRODUCTION. THE JBL NAME HAS

BEEN SYNONYMOUS WITH THE PRECISE, NATURALLY

ARTICULATED SOUND FOUND IN MANY OF THE WORLD’S MOST

PRESTIGIOUS LOCATIONS, INCLUDING CLUBS, CINEMAS AND

RECORDING STUDIOS, AND LIVE-MUSIC REINFORCEMENT IN

VENUES RANGING FROM CONCERT HALLS TO OUTDOOR

STADIUMS. JBL LOUDSPEAKERS ARE FOR THOSE WHO WON’T

COMPROMISE – IN THE STUDIO, AT HOME OR ON THE ROAD.

MORE THAN ANY OTHER COMPONENT, SPEAKERS DEFINE

THE SOUND OF AN AUDIO SYSTEM. THEY ARE THE CRITICAL

CHOICE THAT DETERMINES ULTIMATE PERFORMANCE. HOW

DOES A MARKET-LEADING BRAND LIKE JBL BUILD LOUD-

SPEAKERS THAT SATISFY SO MANY PEOPLE? WE USE THE

INDUSTRY’S MOST ADVANCED TESTING METHODS AND

EQUIPMENT, WITH A PANEL OF TRAINED LISTENERS TO

SCIENTIFICALLY QUANTIFY AND QUALIFY THE PERFORMANCE

OF EVERY JBL SPEAKER TO ENSURE THAT IT EXCEEDS EVEN

THE MOST DEMANDING EXPECTATIONS. THE INTRODUCTION

OF THE 560GTi AND 660GTi COMPETITION SPEAKER SYSTEMS

SETS YET A NEW STANDARD IN AUTOMOTIVE SOUND.

2

Page 3

TABLE OF CONTENTS

INTRODUCTION ................................................2

SCIENCE OF JBL SPEAKER DESIGN ................4

PRODUCT FEATURES........................................6

SYSTEM DESIGN ............................................10

SPECIFICATIONS ............................................11

3

ENGLISH

Page 4

THERE ARE THREE STAGES IN ENGINEERING

LOUDSPEAKERS AT JBL:

Computer-aided design and modeling, prototyping and testing. JBL speakers are

thoroughly tested and qualified at each stage to ensure that the finished product

performs flawlessly.

Every speaker design starts with physical dimensions that facilitate installation in

factory locations, along with a complete set of performance targets. Performance

targets include maximum SPL, or how loud the speaker must play at its limits.

From the maximum SPL target, we determine the amount of power required to

drive the speaker to its output limit and set a power-handling target. Sensitivity,

another important performance target, indicates how efficiently the speaker converts electrical input into acoustic output. A frequency-response target is also

included. This target describes not only the shape of the speaker’s response but

also the maximum allowable magnitude of narrow peaks and dips in its response.

Finally, target Thiele/Small parameters are defined to describe the speaker’s

behavior at low-frequency cut-off in its intended application, whether that application is a custom-built enclosure or the interior of a car’s door. A careful analysis

of all these targets determines the excursion and heat dissipation required for the

speaker to produce the necessary frequency response at maximum SPL and maximum input power. With that information, engineers design the motor, choosing

voice coil and magnet dimensions.

COMPUTER-AIDED DESIGN AND MODELING

During this phase of development, the engineers draw intricate diagrams of the

proposed speaker’s construction. Once the computerized drawing is complete,

it is imported into an analysis program. At JBL, we use extensive Finite Element

Analysis (FEA) to model the performance of the speaker’s motor and moving parts.

FEA divides the device being modeled into thousands of small parts or elements,

and predicts performance based on the shape of the design and the materials that

will be used in construction. The motor is analyzed using magnetic and thermal

FEA. This analysis helps to ensure magnetic-field symmetry for low distortion,

proper motor force required to drive the speaker’s moving assembly, and the heat

dissipation needed for high power handling. The moving assembly – composed of

the cone, voice coil and former, spider and surround – is analyzed using structural

FEA, which enables the engineers to observe the movement of the assembly to

guarantee symmetry for low distortion. This analysis also permits the engineers to

determine the proper elasticity of the spider and surround to provide the appropriate

restoring force and perfect performance at the speaker’s excursion limits.

PROTOTYPING

Once the computer-modeling phase is complete, technicians hand-build prototypes, machining metal parts and attaching them to prototype frames which are

built using a stereo lithography machine. The stereo lithography, or SLA, machine

uses a computer-guided laser to form a speaker basket out of a bath of plastic

resin. Once the basket fit and finish are perfected, off-tool parts are built and then

fully working, production-grade samples are assembled.

AT JBL, SPEAKER DESIGN IS

ALL SCIENCE.

Real-Time FFT Laser Vibrometry: This breakthrough technology uses

scanning infrared-laser impulses that are reflected off a speaker’s

diaphragm and analyzed by a computer. The analysis creates a threedimensional graphic representation of the cone’s movement so that

cone distortion, which contributes to frequency-response aberrations,

can be observed. Improvements to the cone’s shape and composition

can be implemented to ensure that the diaphragm operates as a rigid

piston throughout its usable frequency range, resulting in flat response.

4

Page 5

Anechoic Chambers: JBL’s anechoic chambers are expensive…but

worth the investment. The baffles on the walls of the chamber absorb

sound at all audible frequencies. In this setting, JBL engineers can

assess critical details of the speaker’s performance without the effects

of extraneous noise or reflected sound.

Environmental Test Lab: JBL’s environmental test lab includes machines

that subject speakers to hot and cold temperatures, humidity, ultraviolet

light and vibration. These tests are designed to simulate a lifetime of

abuse in the most adverse environmental conditions.

TESTING

At JBL, we spare no expense in testing loudspeakers. Prototype and production

samples are first tested for frequency-response range and uniformity in one of

our anechoic chambers using MLS and swept sine-wave analyzers. Sine-wave

analysis measures harmonic distortion, which is a critical element in determining

the sonic accuracy of the speaker. MLS, or maximum length sequence, analysis

compares the noise output from the analyzer to the output of the speaker to

determine the speaker’s impulse response, a measure of transient response

accuracy. The speaker’s impulse response measurement is then converted into

a high-resolution frequency-response measurement using a mathematical

operation called Fast Fourier Transform, or FFT. Real-Time Laser Vibrometry is

used to measure the structural behavior of the moving assembly. The Klippel

analyzer measures magnetic field symmetry during the speaker’s operation.

Careful analysis of all these measurements determines the location and causes

of unwanted resonance and distortion in the speaker’s output, enabling the

engineers to refine the speaker’s design to eliminate them.

Once the design is perfected, power handling is verified for production-grade

samples by subjecting them to filtered octaves of pink noise at rated power for

100 hours. That’s right, 100 hours. Finally, samples are tested for longevity in our

environmental test lab, according to the rigorous standards set by the automotive

industry. The last phase in our extensive testing involves the most critical

instruments in our possession – our ears. We listen…and listen…and listen.

Klippel Analyzer: This revolutionary analyzer developed by Klippel GmbH

separates the distortion generated by transducers into two categories:

distortions caused by the speaker’s motor and those caused by the

speaker’s suspension. By analyzing the symmetrical and linear nature of

the measured results, JBL engineers can formulate a cure for almost any

distortion caused by motor or suspension nonlinearity.Klippel analysis

provides accurate Thiele/Small parameter verification at virtually any

input power level.

5

ENGLISH

Page 6

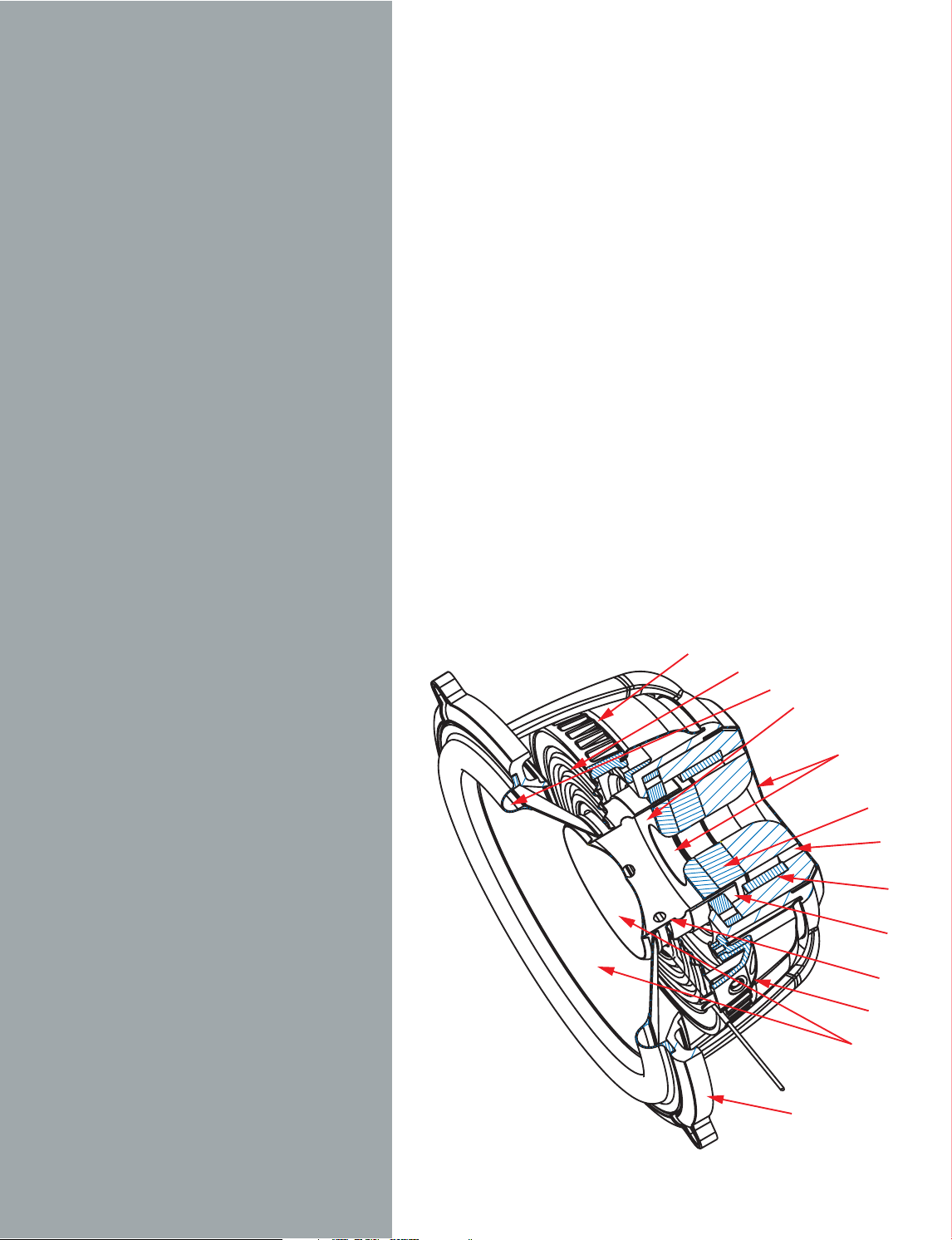

GTi COMPETITION SPEAKER

SYSTEM TECHNOLOGY:

1. Spider-Landing Vents: Minimize distortion from mechanical noise.

2. Nomex

®

Spider: Provides linear force in both movement directions.

3. Nitrile-Butylene Surround: Ensures superior longevity.

4. Copper Polepiece Cap: Provides linear inductance over the full

range of forward voice-coil travel for reduced intermodulation

distortion. Provides crystal-clear vocals and midrange, even

during heavy bass signals.

5. Polished and Flared Polepiece Vent: Provides a low-velocity inlet

and outlet for the movement of air in and out of the motor structure.

Minimizes distortion from mechanical noise.

6. Neodymium Magnet: Provides high flux density. Also allows more

room for larger steel motor components to provide critical heatsink

mass for the voice coil.

7. Vented Gap Cooling

™

Ports: Provide movement of air over the voice

coil for superior power handling.

8. Flux Stabilization Ring: Provides global stabilization of the static

magnetic field and works with the copper cap to minimize

coil inductance during inward movement of the voice coil.

9. Voice Coil: Long, over-hung 2" diameter, aluminum edge-wound

voice coil provides high excursion for improved low-frequency

capability. Reduces distortion at low frequencies and high input

power.

10. Vented Voice Coil Former: Minimizes distortion from mechanical

noise.

11. Screw-Down Terminals: Ensures reliable high-quality

connections.

12. Kevlar

®

Dustcap and Cone Body: Ultrarigid Kevlar dustcap and

cone body minimize unwanted cone flexing for smooth frequency

response.

13. Cast-Aluminum Basket: Provides a rigid support for motor and

moving assembly.

LOW-DISTORTION WOOFER

Distortion – sound produced erroneously – is the enemy of great speaker

performance. At its worst, distortion makes speakers sound broken. At more

moderate levels, distortion clouds the midrange, making vocals sound muddy

and obscuring the music’s detail. At JBL, we’ve had more practice than any other

speaker company at eliminating distortion, and it shows. GTi competition speaker

systems include the lowest-distortion woofers we’ve ever built.

In a loudspeaker, distortion can be produced by the cone, the motor, the suspension and even the movement of air through the speaker’s assembly. In designing

the 560GTi and 660GTi woofers, JBL engineers have left no stone unturned. The

basket, polepiece and voice coil former all include vents to eliminate any potential

distortion caused by the movement of air trapped within these parts. The ultrarigid Kevlar

®

cone eliminates unwanted cone flexing (also called modal distortion),

which can cause big peaks and dips in the midrange response. The spider and

surround are designed to ensure linear forward and rearward motion, minimizing

distortion caused by the speaker’s suspension. The motor includes a copper polepiece cap and a flux stabilization ring that work together to produce a linear voice

coil inductance that minimizes intermodulation distortion. Finally, an extralong

voice coil ensures that the coil remains in the magnetic gap to minimize distortion

at low frequencies and their harmonics, and during high-output transients. The

result is crystal-clear midrange, snappy mid-bass without any audible ringing or

hang-over, and a smooth frequency response that needs no compensation circuitry

in the crossover (see Figure 1).

Figure 1

1

2

3

4

5

6

7

8

9

10

11

12

13

6

Page 7

TWEETERS, WAVEGUIDES AND OPTIMAL

FREQUENCY RESPONSE

The dispersion pattern of the sound produced by a speaker is different at low

frequencies than at high frequencies. At frequencies with wavelengths greater

than the circumference of the speaker’s cone – the speaker’s piston range – the

sound is radiated in all directions. At higher frequencies, the dispersion pattern

narrows. At frequencies for which the circumference of the speaker is about five

times the sound’s wavelength, the coverage area narrows sharply and the off-axis

sound contains far less high-frequency content. This phenomenon occurs for every

speaker. For multi-way speaker systems, designers have to contend with this

condition for each driver in the system. What makes matters more difficult is

that in the crossover region between a large low-frequency driver and a small

high-frequency driver, the speakers’ behaviors are opposite – the dispersion

pattern of the woofer is narrow and the dispersion pattern of the tweeter is wide

(see Figures 2 and 3). A multi-way speaker that is designed using only measurements of the on-axis response can sound terrible. An analysis of the frequency

response of many speakers designed this way reveals a big hole in the off-axis

response at the crossover frequency, where the woofer’s output is focused into the

forward angles (see Figure 4).

When we listen to speakers, we hear a combination of the sound that comes

directly from the speaker (the on-axis response) and the off-axis response, which

arrives at our ears after being reflected by boundaries and other objects in the

room. In large rooms, the walls and other objects are often located several feet

from the speaker enclosure, so the intensity of the reflected sound is lower than

that of the direct sound. In rooms, the direct sound in the “listening window”

dominates the sound we hear. The off-axis sound is a secondary but important

part of the overall sound of the speaker (see Figure 5).

In cars, the boundaries are much closer to the speaker and to the listener, so the

intensity of the reflections is more similar to the intensity of the direct sound.

Additionally, the reflective surfaces in a car are so close that our brains can’t

distinguish between the direct sound and much of the reflected sound. Reflections

contribute greatly to the quality of the audio experience in cars. Since it isn’t

practical to change the overall shape or size of the car to minimize the effects

of the reflections, closely matching the on- and off-axis responses of the speaker

system can help to ensure a smooth and balanced sound (see Figure 6).

90°

60°

30°

0°

270°

–20

–10

0

–30

Figure 2. Woofer dispersion pattern in the crossover region.

Figure 4. On- and off-axis frequency response of a conventional component system.

Figure 3. Tweeter dispersion pattern in the crossover region.

90°

60°

30°

0°

270°

–20

–10

0

Figure 5. Reflected sounds are attenuated at the listening position

because the boundaries are far from the speakers and the listener.

Sound from Speakers

Reflected Sound

Figure 6. The intensity of reflected sounds in a car closely match that

of the direct sound, because the boundaries are close to the speakers

and the listeners.

Sound From Speakers

Reflected Sound

7

ENGLISH

On Axis

dBSPL

110

100

90

80

70

60

50

40

30

20

10

20Hz 50 100 200 500 1K 2K 5K 10K 20K

Off Axis

Page 8

THE DIRECTIVITY INDEX (DI): HOW WE MEASURE

THE RELATIONSHIP BETWEEN ON-AXIS RESPONSE

AND OFF-AXIS RESPONSE

The Directivity Index (DI) is the ratio of the intensity of the sound in the listening

window to the average of the intensity of the sound radiated at all angles (sound

power). We make measurements of the speakers in two semicircular patterns

along the horizontal and vertical axes of the speaker (Figure 7). With those

measurements, we determine the size of the optimal listening window and calculate

the sound power of the speaker. We then compare the sound power to the response

in the listening window and plot the directivity index for the speaker system’s

frequency response.

The blue curve at the top in Figure 8 is the Window Response and the curve at the

bottom is the Directivity Index. The Directivity graph indicates the difference in

level of the response in the window and off-axis (sound power, represented by the

green line in the graph). Low-directivity values indicate that the sound is radiated

at all angles and higher directivity values indicate that the sound is more focused

into the listening window. The practical ideal is constant directivity (a flat line) in

the woofer region and a smooth and gradual upward slope in the crossover region

and above.

CONTROLLING THE DIRECTIVITY OF THE TWEETER:

WAVEGUIDES CONTRIBUTE TWO SIGNIFICANT

IMPROVEMENTS TO THE PERFORMANCE OF THE

GTi COMPETITION SPEAKER SYSTEMS

• Waveguides match the directivity of the tweeter to that of the woofer at

the crossover by focusing the tweeter’s output into the listening window.

• Waveguides decrease the directivity of the tweeter at high frequencies through

controlled diffraction along the gentle transition from the waveguide’s conical

center section to the waveguide’s outside edge.

Both of these contributions ensure that the off-axis response reflected by nearby

surfaces more closely resembles the response in the optimal listening window.

That makes speakers sound better in any environment.

In understanding how a waveguide works, it’s useful to think of its shape as a

passageway for sound between the listening window and radiation into full

space; the waveguide can focus the sound into the listening window or allow

it to be spread out over all the angles. At the lowest frequencies the tweeter

plays, the tweeter operates in its piston range and radiates in a spherical pattern.

The conical section in the center of the waveguide (indicated in green in Figure 9)

directs some of the off-axis output back into the listening window. That increases

8

Figure 7. Measurements are made at 10° intervals along the horizontal

and vertical axes.

Figure 8. The directivity index is equal to the window response minus the sound power

response.

Window

dBSPL

100

90

80

70

Directivity Index

Directivity Index

Sound Power

20

10

0

-10

20 Hz 50 100 200 500 1K 2K 5K 10K 20K

Page 9

9

Figure 10.

Figure 12.

the tweeter’s output at low frequencies in the listening window and decreases its output in the off-axis response. That’s a much closer match to the directivity of the woofer,

which is focused into the listening window in the crossover region. The crossover region

is also indicated in dark green in the frequency response plot in Figure 9.

At higher frequencies, the waveguide’s gentle curve (indicated in orange in Figure 9)

spreads the sound over all the angles, increasing the high-frequency content of the

off-axis response and decreasing it in the listening window. This region is also indicated

in light green in the frequency response plot in Figure 9. Essentially, the directivity of

the waveguide is the inverse of the tweeter’s directivity, and the combination of the two

provides nearly constant directivity over the tweeter’s range above the crossover. At the

highest frequencies (to the right of the orange region), the waveguide has no effect

because the dispersion pattern is narrower than the waveguide.

THE CROSSOVER: MORE THAN A DIVIDING NETWORK

The crossover included in GTi competition speaker systems is more than a set of

simple filters. The filter frequencies, slopes and Q values are carefully chosen to

provide a phase-aligned transition between woofer and tweeter with optimally

flat frequency response at the design axis and throughout the listening window.

Additionally, the tweeter’s high-pass filter circuit includes a level control and

frequency contour to optimize the system’s response when the waveguide is used

or when the tweeter is conventionally mounted.

Capacitor, inductor and resistor types have been selected to minimize distortion

and maximize power handling. Air-core coils minimize saturation, which can cause

distortion at high input power. Low-loss, low-ESR polypropylene capacitors provide

crystal-clear high frequencies, while wire-wound precision resistors with integral

heatsink ensure filter stability at high input power.

Finally, for systems that will include a separate amplifier channel for each speaker, the

GTi competition system crossover includes bi-amp capability. For instructions in setting

up the crossover for bi-amp systems, see “Adjusting the Crossover” on page 11.

ENGLISH

Figure 9. The waveguide provides a smooth and gradual increase in tweeter directivity in the

crossover region and a reduction in tweeter directivity at higher frequencies.

Figure 11.

Bi-Amp Capable Tweeter Level

Adjustment

Frequency

Contour

Air Core Coils

Polypropylene

Caps

Wire-Wound

Precision Resistors

With Integral Heatsink

Frequency

Contour

–1.5dB

0dB (Reference)

Tweeter Level Adjustment

+1.5dB

Tweeter Without Waveguide

Tweeter With Waveguide

Sound Directed

Into Window

Sound Spread

Into Free Space

Sound Directed Into

Window

Directivity Index

Sound Spread

Into Free Space

dBSPL

20

15

10

5

0

-5

-10

-15

-20

20 Hz 50 100 200 500 1K 2K 5K 10K 20K

1K 2K 5K 10K 20K

Page 10

Many speaker systems are designed for on-axis listening and often include a

listening window that’s ±30° from the speaker’s 0° axis. That’s great for home

audio or other applications where speakers can be easily pointed at a single

listener. In a car, however, the possible speaker mounting locations don’t always

allow for on-axis placement even for a single listener. In many cases, on-axis

placement for two listeners simply isn’t possible because the mounting locations

are too close to the listeners to allow a single 60° window to cover both listeners.

GTi competition speaker systems incorporate a 35° design axis, which provides an

optimal listening window for each front-seat listener.

LISTENING WINDOWS AND MOUNTING LOCATIONS:

CHOOSING THE BEST MOUNTING LOCATION AND

AIMING THE TWEETER

Using the waveguides and planning your installation carefully will help to provide

the best performance from your GTi competition speaker system. Consider the

illustrations that follow and the ones to the left, when determining the best

mounting locations for your woofers and tweeters.

10

SYSTEM DESIGN USING THE

GTi COMPETITION SPEAKER

SYSTEMS.

Figure 13. Listening window illustrated in three dimensions.

The shaded area in Figure 13

indicates the listening window

(the area over which the waveguide is optimized).

The small circle marked 5°

represents one edge of the

listening window and the circle

marked 65° represents the other.

The small white area inside

the 5° circle in the middle

indicates the area considered

to be ”on-axis.”

The circle marked 35° indicates

the design axis, or the center of

the listening window.

Figure 14. Listening windows viewed in two dimensions.

0°

+5°

-5°

+35°

+65°

-65°

-35°

Figure 17. Woofer mounted in the door and waveguide mounted in

the kick panel or A-pillar. Woofer aimed across the car, and tweeter

aimed at a point between the driver and passenger. Woofer coverage

provided by a single window. Tweeter coverage provided by separate

listening windows.

Figure 18. Woofer and tweeter mounted in the door and aimed across

the car. Coverage provided by a single listening window.

Figure 16. Woofer mounted in the kick panel and tweeter mounted in

the A-pillar and aimed at a point between the driver and passenger.

Coverage provided by separate listening windows.

Figure 15. Woofer and tweeter mounted in the kick panel and aimed

at a point between the driver and passenger. Coverage provided by

separate listening windows.

65°

35°

- 65°

-35°

5°

-5°

5°

-5°

-35°

0°

- 65°

Shaded Area = Measurement Window

65°

35°

Design Axis

Page 11

OOFER MOUNTING CONSIDERATIONS

W

• All woofers require a rigid baffle and isolation between the front and back of the

speaker for best low-frequency extension.

The 660GTi woofer may be used in an infinite baffle or in a small sealed enclosure

•

with a volume equal to or larger than 1/8 ft

3

. The 560GTi woofer may be used in

an infinite baffle or in a small sealed enclosure with a volume equal to or larger

han 1/12 ft

t

3

.

• The GTi competition speaker systems include a choice of grille trim. See Figure 19 to

change to the carbon fiber grille trim.

TWEETER MOUNTING CONSIDERATIONS

• Use the waveguides, if possible.

• The waveguide requires a hole 4" in diameter for mounting.

• Aim the tweeters at a point in between the two front-seat positions,

if the waveguides will be mounted in the A-pillars or kick panels.

ADJUSTING THE CROSSOVER

• If you are bi-amping the speakers, remove the jumpers, as illustrated in Figure 20.

• If you are using the waveguides, move the switch to the “Waveguide” position.

• If you are not using the waveguide, move the switch to the “No Waveguide” position.

• After installing the system, set the “Tweeter Level” switch according to your

preference.

See pages 14–19 for dimensions, mounting and wiring diagrams, Thiele/Small

parameters and performance graphs.

SPECIFICATIONS

Figure 19.

Figure 20.

Remover Four Top Cover Screws

Remove Jumpers

ENGLISH

Remove

Top Cover

Model 560GT

i 660GTi

Description 5" 2-Way 6" 2-Way

professional-grade

automotive component

professional-grade

automotive component

speaker system speaker system

Power Handling (W peak) 500 600

Power Handling (W RMS) 125 150

Sensitivity (dB @ 2.83V)

91

92

Frequency Response (Hz) 58–30k 50–30k

Crossover Frequency (Hz)

oice Coil Diameter (mm)

V

2500

50

2500

50

Voice Coil Diameter (in) 2 2

Impedance 4 ohms 4 ohms

11

Page 12

Page 13

ENGLISH

Page 14

14

560GTi

660GTi

102mm

138mm

5-7/16"

176mm

152mm

6"

4"

116.7mm

4-9/32"

160mm

6-5/16"

6-15/16"

41mm

1-5/16"

69mm

2-11/16"

55mm

2-3/16"

69mm

2-11/16"

7-7/8"

200mm

69mm

2-11/16"

116mm

4-9/16"

16mm

59mm

312mm

12-1/4"

5/8"

2-5/16"

12mm

15/32"

81.8mm

3-7/32"

128.1mm

5-1/16"

11/32"

8.7mm

3-1/16"

77.8mm

153mm

6"

121mm

4-3/4"

32mm

1-1/4"

51mm

2"

25mm

1"

32mm

1-1/4"

27mm

1-1/16"

52mm

2-1/16"

300mm

11-13/16"

4-1/2"

114mm

78mm

3-1/16"

4"

102mm

Page 15

15

560GTi

660GTi

2x

2x

2x 2x

2x

2x

2x

12x 8x 8x 4x 8x8x

2x 2x

2x

1x

1x

2x

16x

2x

2x 2x

2x

2x

2x

2x 2x

12x 8x 8x 4x 8x8x

1x

2x

1x

2x

16x

Page 16

16

1

2

3

1

2

4" (102mm)

1

2

3

1

1

2

2

1

2

1

2

Page 17

17

560GTi

Page 18

18

660GTi

Page 19

THIELE/SMALL

560GTi 660GTi

BL (TM) 7.6 7.56

DCR (ohms) 3.07 3.48

MMS(g) 14.84 17.94

SD(sq cm) 86.6 132.7

CMS(µm/N) 312 382

VAS(l) 3.29 9.45

FS(Hz) 74 60.8

Q

ES

0.37 0.42

Q

MS

5.49 10.17

Q

T

0.34 0.4

1wSPL (dB0) 87.5 89

SPL 2.83V 91.7 92.6

HVC(mm) 15.74 17.27

HAG(mm) 6 6

X

MAX

4.87 5.36

V

B

196,000mm

3

288,890mm

3

L

EVC

(mHz) 0.1 0.13

19

Page 20

Harman Consumer Group, Inc.

250 Crossways Park Drive, Woodbury, NY 11797 USA

2, route de Tours, 72500, Château du Loir, France

516.496.3400 (USA only)

www.jbl.com

THE OFFICIAL BRAND

OF LIVE MUSIC.

©2007 Harman International Industries, Incorporated.

All rights reserved.

Part No. 560/660GTiOM Printed 3/07

JBL is a trademark of Harman International Industries, Incorporated, registered in the United States and/or other countries.

Vented Gap Cooling is a trademark of Harman International Industries, Incorporated.

Nomex and Kevlar are registered trademarks of E.I. du Pont de Nemours and Company.

Features, specifications and appearance are subject to change without notice.

Designed, edited and digitally produced by Harman Consumer Group Marketing & Design Center, Woodbury, NY, USA.

Loading...

Loading...