Page 1

INSTRUCTION MANUAL

ADS / HDS / DNS

Stands for Handles

Page 2

This manual corresponds to the following references:

AD-SF (for T210 & T245 Handles)

HD-SF (for T470 Heavy Duty Handles)

DN-SF (for T210N/T245N/T470N Nitrogen Handles)

Packing List

Box includes one stand according to purchased reference.

Stand for T210 & T245

Handles ............................ 1unit

Stand Cable 1m ............ 1 unit

Ref. 0 024227

2

Stand for T470 Heavy Duty

Handles ............................ 1unit

Sponge for Modular

Tool Stands ................... 1 unit

Ref. S7034

Brass Wool .................... 1 u ni t

Ref. C L6210

Stand for T210N/T245N/ T470N

Nitrogen Handles ............... 1unit

Manual ............................. 1 unit

Ref . 0 027177

Page 3

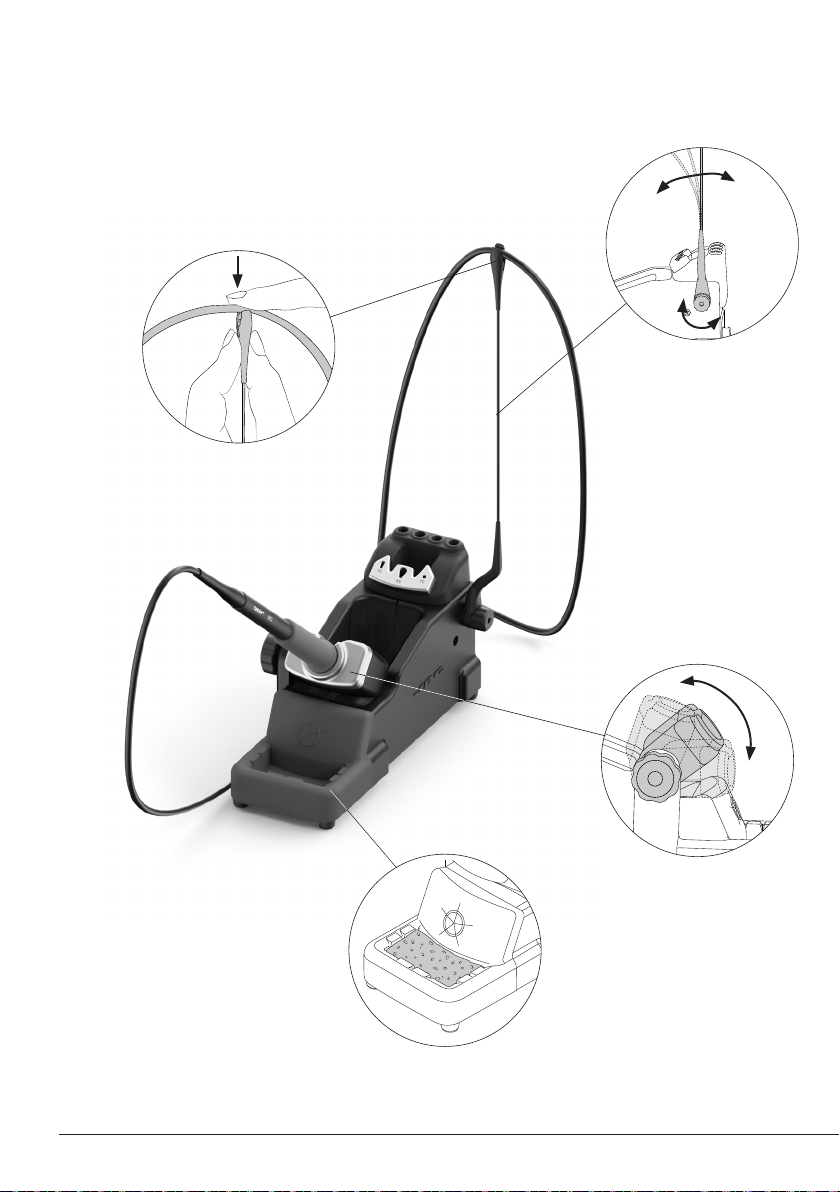

Features and Connections

Cartridge Storage

Quick Tip Changer

Ajustable Tool Holder

Brass Wool

(inside)

www.jbctools.com

Adjustable

Cable Collector

Re f. C C10 01

To Control Unit

(DIU, DDU or DMU)

Sponge

Wiper for

Modular Tool Stand

Ref. C L7899

To To ol

3

Page 4

Assembly

Cable Collector and Adjustable Tool Holder

Insert the cable into the cable

collector clip. Do not leave the

cable longer than necessary to

reach the work area freely.

The cable collector is flexible. It

accomp anies and adapts to the

movements during the soldering

process.

Adjust the tool holder angle to

suit the work position.

The wiper offers different ways to

clean the cartridge tips. If desired

use the included sponge.

4

Page 5

www.jbctools.com

Quick Tip Changer

Save time and change cartridges safely without switching the station of f. Be careful, the cartridges

may be hot, when placing them in the storage rack.

Ref. AD-SF

1. Removing 2. Inserting

Place the cartridge in the

extractor and pull the handle

to remove it.

Note: It is essential to insert the cartridge as far as the mark for

a proper connection.

Mark

Place the handle on top

of the new car tridge and press

the handle down.

Ref. HD-SF

1. Removing 2. Inserting

Handle Screw

3. Fixing

for ADS and DNS

D

B

A

Use the holes to fix the

cartridge as follows:

A. For curved C210

B. For C245

C. For straight C210

D. cartridge Storage rack

C

3. Fixing

Loosen the handle screw.

Place the Soldering Iron with

the cartridge in the extractor

and pull the handle to remove

it.

Place the handle on top of the

new cartridge and press the

handle down.

Mark

Handle Screw

Note: For T470 handles after

propper cartridge insertion as

far as the mark ,tighten the

handle screw.

5

Page 6

Nozzle Extraction

Ref. DN-SF

The quick tip changer area of DNS stand features both, one slot for cartridge exchange and one

for nozzle exchange. The nozzle exchange works as well as the cartridge exchange.

Use the fixing holes as described for the ADS on page 5.

Cartrige

Extraction Slot

Fixing Holes

Wiper

The integrated wiper offers different ways to clean the cartridge tips.

Tappi n g Wiping Sponge

Tap gently to remove excess

solder.

Use the slots to remove the

remaining particles.

The softest cleaning method.

Keep the sponge damp with

distilled water when working to

avoid tip wear.

Nozzle

Extraction Slot

6

Page 7

www.jbctools.com

Wiper and Brass Wool Replacement

The wiper and brass wool can easily be removed for cleaning or replacement when they are worn.

Lift the wiper at its front edge.

Accessories

Remove the wiper by pulling

it out.

Stand Cable

Replace the brass wool with a

new one when it is worn out.

Place the wiper back o replace

them if desired.

Stand Extension Cable

Ref. A1286

Le ngth: 1.5m

7

Page 8

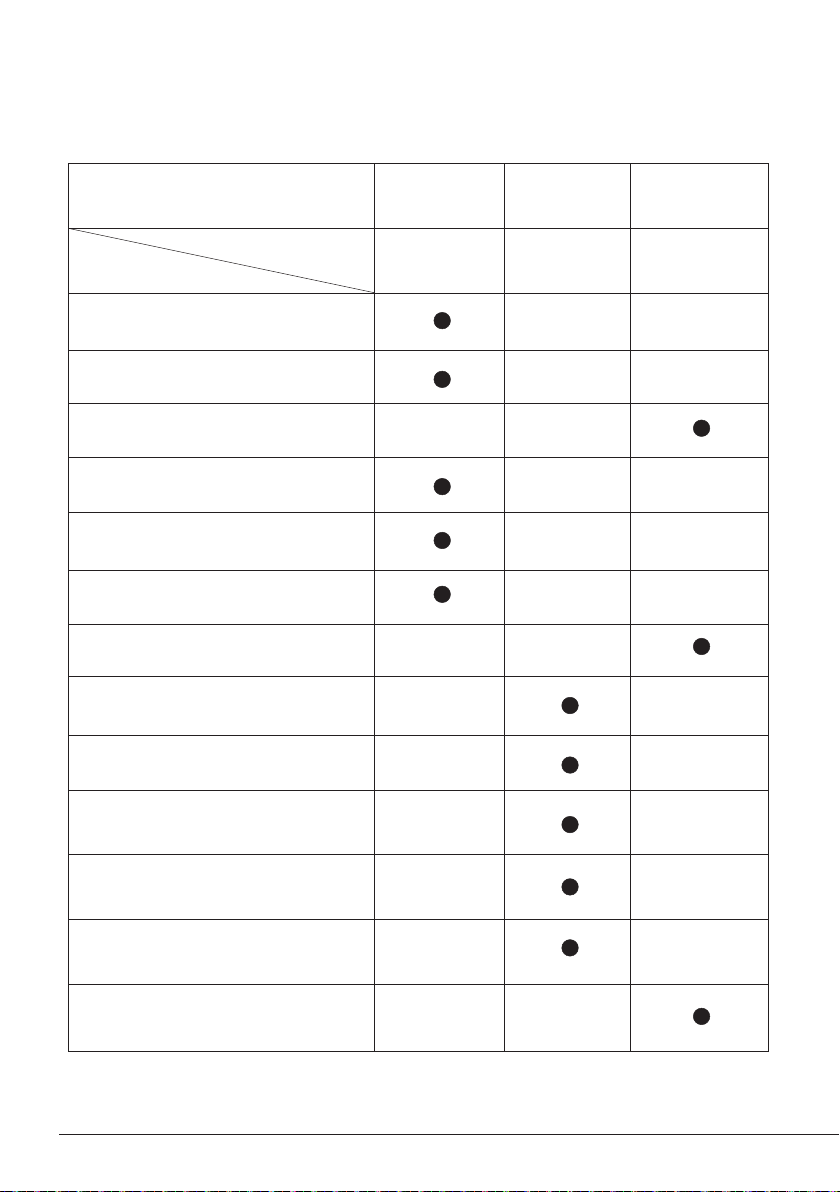

Compatibility - Stand/Tool/Control Unit

Stands

Control

Handles

T210

Presicion Handle

T210P

Blue Grip Precision Handle

T210N

Nitrogen Precision Purpose Handle

T245

General Purpose Handle

T245G

General Purpose Handle with Reinforced

Cable

T245P

Blue Grip General Purpose Handle

T245N

Nitrogen General Purpose Handle

T470

Heavy Duty Handle - 1.5m (4.9ft) cable.

T470S

Heavy DutyHandle - 3m (9.8ft) c able

Units

ADS

for T210 & T245

Handles

DI, DDE , DME HDE DI, DDE , DME

HDS

for T470 Heavy

Duty Handles

DNS

for T210/T245/T470

Nitrogen Handles

T470F

Thermal Insulator Grip Heavy Duty Handle -

1.5m (4.9ft) cable

T470M

Thermal Insulator GripHeavy Duty Handle -

3m (9.8f t) cable

T470Z

Tri-Lobed Grip Heav y Duty Handle -

1.5m (4.9ft) cable

T470N

Nitrogen Heavy Duty Handle -

1.5m (4.9ft) cable

8

Page 9

Maintenance

Before carrying out maintenance or storage,

always unplug the stand from the station and

the tool.

- Use a damp cloth to clean the stand. Alcohol

can be used only when cleaning metal parts.

- Check periodically that the metal parts of the

tool/stand are clean so that the station can

check the tool’s status.

- Periodically check all cables and tube connections.

- Replace any defective or damaged parts. Use

original JBC spare parts only.

- Repairs should only be per formed by a JBC

authorized technical service.

www.jbctools.com

Clean periodically

9

Page 10

Safety

It is imperative to follow safet y guidelines to prevent electric

shock, injury, fire or explosion.

- Do not use the stands for any purpose other than soldering or rework.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded before

use. When unplugging it, hold the plug, not the wire.

- The tool should be placed in the stand when is not in use in order to activate the sleep mode. The

soldering tip, the metal part of the tool and the stand may still be hot even when the station is turned

off. Handle with care, including when adjusting the stand position.

- Avoid the contact of flux with skin or eyes to prevent irritation.

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when working

to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight and also persons with reduced physical,

sensor y or mental capabilities or lack of experience provided that they have been given adequate

supervision or instruction concerning use of the appliance and understand the hazards involved.

Children must not play with the appliance.

- Maintenance must not be carried out by children unless supervised.

10

Page 11

Specifications

ADS

Stand for T210 & T245 Handles

Ref.: AD-SF

- Includes Sleep Mode

- Total Net Weight 1440 g / 3.17 lb

- Package Dimensions / Weight: 342 x 155 x 120 mm / 2002 g

(L x W x H) 13.46 x 6.10 x 4.72 in / 4.41 lb

HDS

Stand for T470 Heavy Duty Handles

Ref.: HD-SF

- Includes Sleep Mode

- Total Net Weight 1514 g / 3.34 lb

- Package Dimensions / Weight: 342 x 155 x 120 mm / 2076 g

(L x W x H) 13.46 x 6.10 x 4.72 in / 4.58 lb

DNS

Stand for T210N / T245N / T470N Nitrogen Handles

Ref.: DN-SF

www.jbctools.com

- Includes Sleep Mode

- Total Net Weight 1510 g / 3.33 lb

- Package Dimensions / Weight: 342 x 155 x 120 mm / 2072 g

(L x W x H) 13.46 x 6.10 x 4.72 in / 4.57 lb

Complies with CE standards

ESD safe.

11

Page 12

Warranty

para manuales - color gris

JBC’s 2 year warranty covers this equipment against

all manufacturing defects, including the replacement

of defective parts and labour.

Warrant y does not cover product wear or misuse.

In order for the warranty to be valid, equipment must

be returned, postage paid, to the dealer where it was

purchased.

Get 1 extra year JBC warranty by registering here:

https://www.jbctools.com/productregistration/

within 3 0 days of purchase.

This product should not be thrown in the garbage.

In accordance with the European directive 2012/19/EU, electronic equipment at the end of its life must

be collected and returned to an authorized recycling facility.

00 2 71 77- 25 112 2

Loading...

Loading...