Page 1

www.jbctools.com

INSTRUCTION MANUAL

Soldering Station

Ref. LC-2SIA

Page 2

Packing List

The following items should be included:

LC Control Unit ........................................ 1 unit

Ref. LC-2SIA (230V)

Power Cord ................................................ 1 unit

Ref. 0019162 (230V)

Manual ......................................................... 1 unit

Ref. 0021003

Precision Purpose Handle .................... 1 unit

Ref. T210-A

Sponge ........................................................ 1 unit

Ref. S2027

www.jbctools.com

INSTRUCTION MANUAL

Soldering Station

Ref. LC-2SIA

2

Page 3

Features

www.jbctools.com

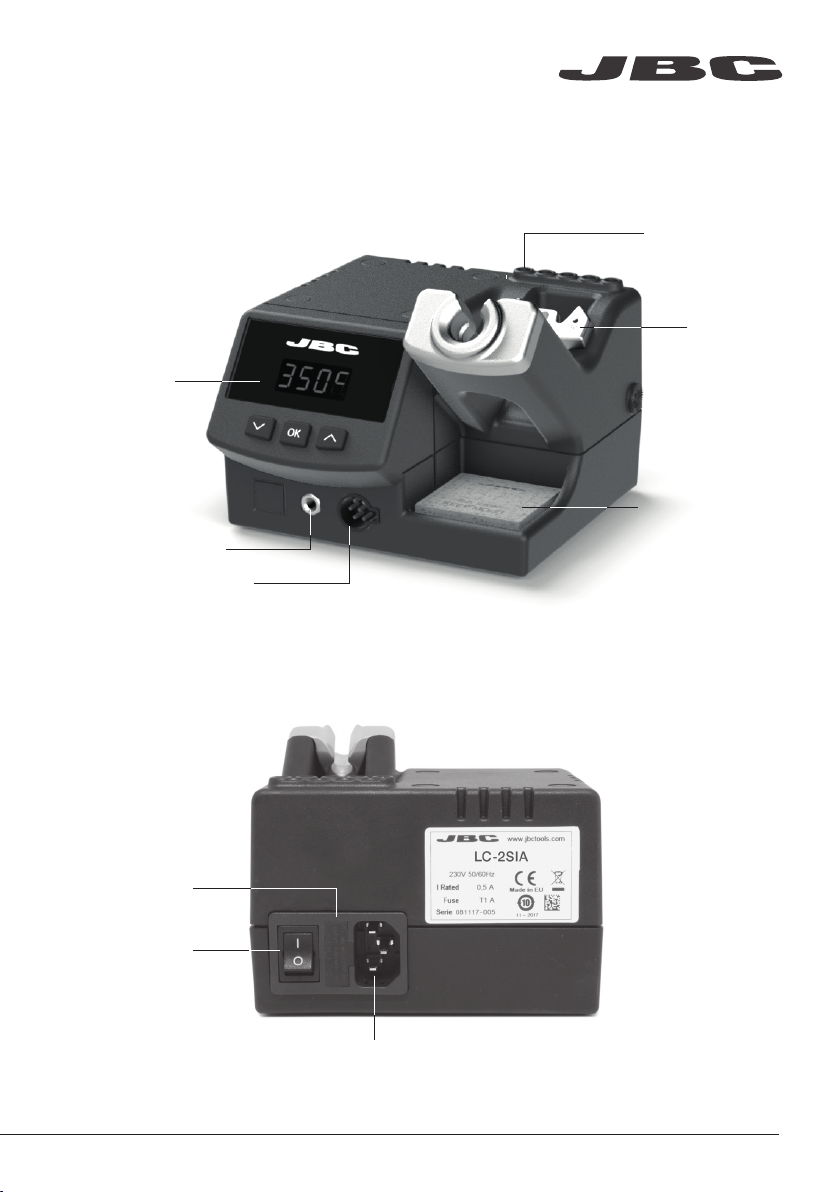

LC Control Unit

Ref. LC-2SA

Process Screen

Equipotential connection

Cartridge storage

Quick Tip

Changer

Sponge

Ref. S2027

to tool

Fuse

Main switch

Power Socket

3

Page 4

ø 1

ø 3,5

A

C

hanging the Grips

Easily replace the Grips for T210-A using the slip-on tabs (Ref. 0016057)

1. Inserting tabs 2. Inserting handle 3. Removing tabs

tabs

new grip

Put the slide-on tabs into the

new grip.

Push the grip with the tabs

onto the handle.

To remove the tabs, hold the

grip and pull. Use a pliers if

necessary.

Quick Tip Changer

Save time and change cartridges safely without switching the station off.

1. Removing 2. Inserting 3. Fixing

Place the handpiece in the

extractor and pull to remove

the cartridge.

*Important

It is essential to insert the

cartridges as far as the mark

for a proper connection.

Place the handpiece on top

of the new car tridge and

press down slightly.

Mark

Use the holes for fixing the

cartridge* as follows:

a. For straight C210.

b. For cur ved C210.

c. For C245.

b

a

c

Compatible cartridges

The LC-2SIA stations work

with C210 cartridges.

Find the model that best suits

your soldering needs in

www.jbctools.com

4

Conical Chisel Conical-bent Bevel Special models

B

Page 5

Accesories*

Wiper LC Ref.CL1170

Placing the Wiper

1

. Insert the wiper in the

cleaning place of the LC Unit

Control.

Dome LC Ref. CL0768

Placing the Dome

2. Press the wiper down to

fix it in place.

www.jbctools.com

3. Make sure that the wiper is

inserted correctly.

1. Put the brass wool in the

dome and insert it in the

cleaning place of the LC Unit

Control.

2. Press the dome to fix it in

place.

Removing the Dome

To remove the dome press the back tab and pull it out .

*These accessories are not included.

3. Make sure that the dome

is inserted correctly.

5

Page 6

Operation

The JBC Exclusive Heating System

This revolutionar y technology is able to recover tip temperature extremely quickly.

This allows the user to work at a lower temperature.

As a result, tip life increases by 5.

1. Wo rk 2. Sleep 3. Hibernation

Long time in

the stand

When the tool is lifted from the

stand the tip will heat up to the

selected temperature.

OK OK OK

· Change temperature

(from 90 to 450ºC)

· Select temperature levels

· Fix one temperature

When the tool is in the stand,

the temperature falls to the

preset sleep temperature.

· Change Sleep temperature

· Set Sleep delay

(from 0 to 9 min or no Sleep)

After longer periods of

inactivity, the power is cut off

and the tool cools down to

room temperature.

· Change Hibernation delay

(from 0 to 35 min)

6

Page 7

Control Process

Menu

- By pressing OK during three seconds will enter in Program.

- Moves by the options with the up and down keys.

www.jbctools.com

Stations settings

Temperature unit Sleep delay* Total hours No Insert new code

Maximum temp. Sleep temperature Work hours Yes

Minimum temp. Hibernation delay Sleep hours

Beep sound Fix temperature Hibernation hours

Go back to menu Te mp. ad ju st

Tool settings Counters Factor y Password

Program version

Extractor cycles

Go back to menu

Sleep cycles

Go back to menu

*

When the tool is in

the stand before

enter into sleep mode

7

Page 8

Parameters

Be careful when using these parameters. They can reduce tip life if not used properly. Please follow

the recommended guidelines:

Temperature unit

Celsius (ºC) or Fahrenheit (ºF)

Maximum temperature

Set the maximum temperature

to work with. Ma x. temp by

default is 400°C (750°F). This

is considered high enough

to work with most lead-free

applications.

Minimum temperature

Set the minimum temperature

to work with. Min. temp. by

default is 200ºC (392ºF). This

is considered to be a proper

starting point for leaded

applications.

Beep

Enable/disable the beep

sound of the keypad.

Sleep delay

Set the time that the tool

will remain at the selected

temperature when in the stand

before entering sleep mode.

The tip temperature will then

drop to the Sleep temperature.

Recommendations Parameter description

N/a

The station temperature

range is 90-450ºC

(190-840ºF). Change the

temperature limits when

working with less common

applications such as low / high

melting point soldering (HMP)

or plastics (e. g. riveting).

N/a N/a

Because our tools reach the

working temperature from

the Sleep mode in a few

seconds, this parameter is

preset to 0 min. Once the tool

is returned to the stand the

temperature will drop to the

sleep temperature, extending

tip life and avoiding oxidation.

Retinning the tip before placing

the tool in the stand will protect

the tip and extend its life.

Warnings

Working with

temperatures over 400°C

(750°F) can damage the

PCB and its components.

Even in short time periods

of tip contact with the

soldering joint, the flux

may not work properly and

could reduce tip life. If the

solder joint requires more

power (e.g. multilayered or

high dissipation boards),

JBC recommends using

other aids like preheaters.

Setting these

parameters to higher

values will unnecessarily

accelerate oxidation and

shorten tip life especially

when working with

temperatures up to 450°C

(840°F ).

Sleep temperature

This is the set temperature the

tip reaches when returned to

the stand.

8

The sleep temperatures are

set to achieve a balance

between preventing oxidation

and reaching the working

temperature in a few seconds.

Page 9

www.jbctools.com

Recommendations Parameter description Warnings

Hibernation Delay

Set the time the tool will

remain at Sleep temperature

before entering the

Hibernation mode. The power

supply is cut off and the tip

remains at room temperature.

Fix one temperature

Fix a value within the

temperature range of the

station (90 - 450ºC /

190 - 840ºF).

Temp Adjustment

It provides a more precise

adjustment between the

selected temperature and the

actual one.

Protects the tip from oxidation

during long periods of

inactivity while the tool is in the

stand. Retinning the tip before

placing the tool in the stand

helps prevent oxidation and

extends the life of the tip.

Ideal for soldering more than

one component at a specific

temperature. The station will

reject any attempt to change

the temperature.

Set values within ±50°C

(± 90°F) to achieve zero error.

JBC strongly recommends

the use of TID-A or TIA-A

Thermometers to obtain

precise readings.

Increasing the default

value will accelerate

oxidation and shorten the

tip life.

N/a

W

hen you change

the cartridge type, the

parameter should be reset

to 0°C/F or to the value

needed for this cartridge.

E.g. If a correction of

+20°C (+36°F) is set for the

C245966 (thick type) and

you change the cartridge for

a C245030 (which is thinner)

without resetting, they would

be working at a temperature

of +20°C (+36°F) lower for

the C245030.

Change password

Change the default security

password number (0105).

The password must be

entered every time a

parameter is changed.

N/a

9

Page 10

Maintenance

Before carrying out maintenance, always allow the equipment to cool.

- Clean the station screen with a glass cleaner

or a damp cloth.

- Use a damp cloth to clean the casing and the

tool. Alcohol can only be used to clean the

metal parts.

- Periodically check that the metal parts of the

tool and stand are clean so that the station

can detect the tool status.

- Maintain tip surface clean and tinned prior to

storage in order to avoid tip oxidation.

Rusty and dirty surfaces reduce heat transfer

to the solder joint.

- Periodically check all cables and tubes.

- Replace a blown fuse as follows:

Clean

periodically

1. Pull off the fuse holder and remove the

fuse. If necessar y use a tool to lever it off.

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

2. Press the new fuse into the fuse holder

and replace it in the station.

10

Page 11

www.jbctools.com

Safety

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

- Do not use the units for any purpose other than soldering or rework. Incorrect use may cause fire.

- The power cord must be plugged into approved bases. Make sure that it is properly grounded

before use. When unplugging it, hold the plug, not the wire.

- Do not work on electrically live parts.

- The tool should be placed in the stand when not in use in order to activate the sleep mode.

The soldering tip, the metal part of the tool and the stand may still be hot even when the station

is turned off. Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- Do not cover the ventilation grills. Heat can cause inflamable products to ignite.

- Avoid the contact of flux with skin or eyes to prevent irritation

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight and also persons with reduced

physical, sensory or mental capabilities or lack of experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance.

- Maintenance must not be carried out by children unless supervised.

11

Page 12

Specifications

LC-2SIA 230V 50/60Hz. Input fuse: 1A. Output: 23.5V

- Weight: 1,95 kg (4.30 lb)

- Dimensions: 128 x 105 x 130 mm (5.04 x 4.13 x 5.12 in)

- Output Peak Power: 40 W

- Temperature Range: 90 - 450 °C (190 - 840 °F) (± 5%)

- Idle Temp. Stability (still air): ± 1.5 ºC / ± 3 ºF

- Tip to ground resistance: <2 ohms

- Tip to ground voltage: <2 mV RMS

- Ambient operating temp: 10 - 40 ºC (50 - 104 ºF)

Complies with CE standards.

ESD protected housing.

Warranty

JBC’s 2 year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warrant y does not cover product wear or misuse.

In order for the warranty to be valid, equipment

must be returned, postage paid, to the dealer

where it was purchased. Plea se register your

product warranty within 30 days of purchase

in www.jbctools.com/productregistration.

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of its life

must be collected and returned to an authorized recycling facilit y.

www.jbctools.com

0021003-0219

Loading...

Loading...