Page 1

Premium

Micro Desoldering station

Ref. DSS-D

English

www.jbctools.com

Page 2

2

Packing List

The following items should be included:

DI Control Unit .............. 1 unit

Ref. DI-1D (120V)

DI-2D (230V)

DI-9D (100V)

Micro

Desoldering Iron............ 1 unit

Ref. DS360-A

Support Cable

connector ....................... 1 unit

Ref. 0011283

Stand ............................... 1 unit

Ref. DS-SD

Sponge ........................... 1 unit

Ref. S0354

Brush ............................. 1 unit

Ref. CL6217

Electric Desoldering

Module............................. 1 unit

Ref. MS-A

Tip Cleaning

Stand ............................... 1 unit

Ref. CL9885

Power cord ..................... 1 unit

Ref. 0009417 (100V/120V)

0009401 (230V)

Module Cable

connector ...................... 1 unit

Ref. 0010207

Page 3

3

Manual ...........................................................1 unit

Premium

Micro Desoldering station

Ref. DSS-D

Suction Filter ................................................. 1 unit

Ref. 0821830

Cotton Filter .............. 10 units

Ref. 0781046

Filter Box ......................... 1 unit

Ref. 0005966

It contains 50 filters

Cable flange.................. 2 units

Ref. 0010154

Tips

(5 units)

Ref. C360002

Tips

(5 units)

Ref. C360004

Cleaning Rods

Ref. 0008466

Filter

(2 units)

Ref. 0008473

Cleaning brush

Ref. 0008297

Solder Collector

(2 units)

Ref. 0008467

DS360-A Accessories

Ref. 0010259

ww w.j b c tools.com

www .jbc tool s.c om

Page 4

4

Features

Support Cable

connection

Ref. 0011283

DI Control Unit

Ref. DI-1D (120V)

DI-2D (230V)

DI-9D (100V)

Micro Desoldering Iron

Ref. DS360-A

Suction Filter

Ref. 0821830

Stand

Ref. DS-SD Electric

Desoldering

Module

Ref. MS-A

Main switch

Fuse

Equipotential

connection

Power Socket

Module Cable

connector

Ref. 0010207

Page 5

5

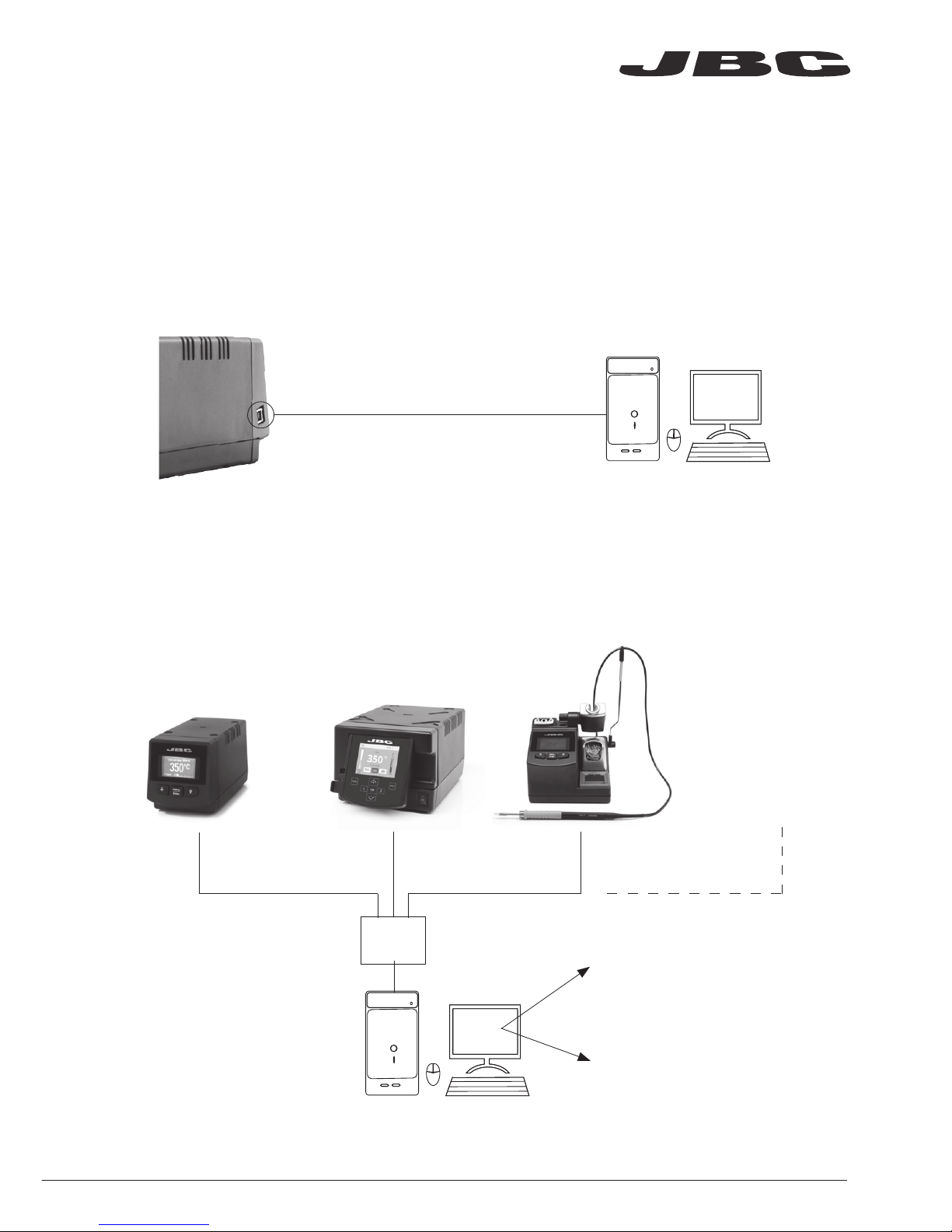

USB Connector

JBC Updater

JBC Manager

Download the latest softwares from our website to improve your soldering station.

www.jbctools.com/software.html

Update the station software via USB connection:

www.jbctools.com/manager.html

Manage and monitor as many stations as your Windows PC supports by using the JBC Manager.

You can export data to another PCs.

Manager Settings

Change settings for a group

of JBC stations at the same

time.

Register Settings

Create graphs of the

soldering process in real time

with power and temperature

data.

Cable USB AB

Cable

USB AB

any JBC

station

USB

Hub

JBC

Manager

ww w.j b c tools.com

Page 6

6

Operation

The JBC Exclusive Heating System

This revolutionary technology is able to recover tip temperature extremely quickly.

This allows the user to work at a lower temperature.

As a result, tip life increases x5 times.

1. Work

Lift tool from the stand and

the tool tip will heat up to the

selected temperature.

2. Sleep

When the tool is in the stand,

the temperature reduces to

Sleep temperature (pre-set

260ºC / 500ºF).

Tool in the stand

A ct u al Te m p. 2 6 0oC

Sleep

Tool in the stand after sleep

No heat

A ct u al Te m p. 2 0oC

Hibernation

0

c

Selected temp.

350 oC

P ow e r 1 0%

350

Long time

in the stand

3. Hibernation

After long periods in the stand

(pre-set 30 min), the power is cut

and the tool cools down to room

temperature.

Change temperature

(from 90 to 450ºC)

Tool Settings:

· Select temperature levels

· Fix one temperature

Tool Settings:

· Set Sleep temperature

(from 180 to 450ºC)

· Set Sleep delay

(from 0 to 9 min or no Sleep)

Tool Settings:

· Set Hibernation delay

(from 0 to 35 min or no

hibernation)

Page 7

7

Menu Screen

Mai n me nu

Cou nt er s

Too l se tt in gs

4 Counters

5

Program version

4

Hibernation hours 0

5

No tool hours 0

6 Sleep cycles

0

7 Desold cycles

0

4

Sleep temp 2600C

5

Hibernation delay 30 min

6

Temp adjust + O OC

Tool DS

Tool

DS

Bac kBac k

Sta ti on set ti ng s

Bac k

Original PIN: 0105

This screen provides

useful information of tool

status in real time.

0

c

Selected temp.

350 oC

P ow e r 1 0%

Fixed temp.

350 oC

Displays a specific fixed temp.

Shown when you have

selected temp. levels.

Work Screen

Process Control

1

Fix one temp -----

2

Temp levels set OFF

3

Sleep delay 0 min

5 Beep ON

6

Change PIN

1 Temp unit

Celsius

2

Maximum temp 4000C

3

Minimum temp 2000C

4

Help text OFF

Levels ºC

270 35 0 4 00

1

Plugged hours 0

2

Working hours 0

3

Sleep hours 0

350

Exit

1 Reset settings

2

Station settings

3

Tool settings

ww w.j b c tools.com

Page 8

8

Cable collector

Keeps working area

free of cable.

Adjustable tool holder

Suits your work position.

Adjustable

cable collector

Stand assembly

Page 9

9

Improve thermal transfer by cleaning the tip after each solder joint.

Tip Cleaning stand

Optional

Brass wool

Ref. CL6210

Inox wool

Ref. CL6205

Brushes

Ref. CL6220

Tip-tinner

Ref. TT-A

Sand

Ref. CL6211

Splashguard

Non-slip base

Sponge

Ref. S0354

Wiper

Ref. CL0236

Very effective cleaning

method. It leaves a small layer

of solder on the tip to prevent

oxidation between cleaning

and rewetting.

It minimises splashing

of solder particles

when using the metal

or brass wool. You don’t need to

hold the base while

cleaning tips

The least harmful cleaning

method. Keep the sponge damp

with destilled water when working

to avoid tip wear.

A temperature resistant receptacle

allows the operator to remove excess

solder by gently tapping or wiping.

Wiper can be easily removed to clean it.

Tapping: Wiping:

Tap gently to remove

the excess of solder.

Use the slots to wipe

off any remaining

particles.

ww w.j b c tools.com

Page 10

10

A ø

B ø

C360-003

ØA: 1.4

ØB: 1

Ømax.pin: 0.8

C360-002

ØA: 1.2

ØB: 0.8

Ømax.pin: 0.6

C360-004

ØA: 1.4

ØB: 1

Ømax.pin: 0.8

Important:

Change tips only when the tool is hot, so that

any solder left inside is in molten state.

Ø Inner nozzle

Ø Pin

C360-001

ØA: 1

ØB: 0.8

Ømax.pin: 0.4

C360-007

ØA: 1.9

ØB: 1.4

Ømax.pin: 1.2

C360-006

ØA: 3

ØB: 1.5

Ømax.pin: 1.3

Do not hold the tip on the spring clamp.

Changing the Tip

1. Remove the tip by using a flat-nosed pliers.

Twist the tip and pull.

Compatible tips

The CS and CV desoldering stations work with C360 tip range. Find the model that best suits your

desoldering needs on www.jbctools.com

Tip selection

Remember to select the biggest tip possible for your application: Ø Inner nozzle > Ø Pin.

2. Insert the new tip and follow the same steps

conversely.

Page 11

Spare filters

Ref. 0005966

Cotton filters

Ref. 0781046

Suction filter

Ref. 0821830

Important:

Do not open the

Suction filter with

sharp pointed

objects in order

to avoid damage.

O Ring

Ref. 0007717

Filter cover

Ref. 0004710

11

Changing the Heating Element

Filter

Fixing screw

Heating element

Ref. DSV-DS

1. Disconnect the tool. Pull off the filter and the solder collector.

2. Undo the fixing screw indicated in the picture and remove the heating element.

3. Insert the new heating element following the same steps conversely.

Changing the Pump Filters

Solder Collector

ww w.j b c tools.com

Page 12

12

Remove the fuse by pulling the black cap.

If necessary use a tool to lever it off.

Press the new fuse into the holder and

replace it in the station.

Maintenance

Fuse

Before carrying out maintenance or storage, always allow the equipment to cool.

- Clean the station’s screen with a glass

cleaner or a damp cloth.

- Use a damp cloth to clean the casing and

the tool. Alcohol can only be used when

cleaning the metal parts.

- Periodically check that the metal parts of

the tool/stand are clean so that the station

can detect when the tool is in the stand.

- Maintain tip surface clean and tinned prior

to storage in order to avoid tip oxidation.

Rusty and dirty surfaces reduce heat

transfer to the solder joint.

- Periodically check all cables, tubes and

filters to ensure proper solder suction.

- Replace a blown fuse as follows:

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

Clean periodically

Page 13

13

- Do not use the equipment for any purpose other than soldering or rework. Incorrect use may

cause fire.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded

before use. When removing it, hold the plug, not the wire.

- Do not work on electrically live parts. Antistatic handle of soldering irons is electrically

conductive.

- The tool should be placed in the stand when not in use in order to activate the sleep mode.

The soldering tip, the metal part of the tool and the stand may still be hot even when the station is

turned off. Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- It is necessary to turn the station off before changing tips.

- Do not cover the ventilation grills.

- Heat can cause inflamable products to ignite even when out of sight.

- Use a “non residue” classified flux and avoid contact with skin or eyes to prevent irritation.

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protection glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight and also persons with reduced

physical, sensory or mental capabilities or lack of experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance. Maintenance shall not be carried out by

children unless supervised.

Safety

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

ww w.j b c tools.com

Page 14

14

Exploded View

Page 15

15

ww w.j b c tools.com

Page 16

0014655-0814

Warranty

JBC’s 2 year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear due to use

or mis-use.

In order for the warranty to be valid, equipment

must be returned, postage paid, to the dealer

where it was purchased.

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Specifications

DI-1D 120V 50/60Hz. Input fuse: 2A. Output: 23.5V.

DI-2D 230V 50/60Hz. Input fuse: 1A. Output: 23.5V.

DI-9D 100V 50/60Hz. Input fuse: 2.5A. Output: 23.5V.

- Total unit weight: 4,4 kg (9.6 lb)

- Size: 90 x 105 x 180 mm

- Temperature selection from 90°C (190°F) to 450°C (840°F)

- Output Peak Power: 130W

- Tip to ground resistance: <2 ohms

- Ambient operating temp: 10-40 ºC / 50-104 ºF

- USB connector station-PC

MS-A

- Total weight and size: 1,2 Kg (2.6lb)

- Size: 145 x 55 x 225 mm

- Vacuum: 75% / 570 mmHg / 22.4 inHg

- Flow rate: 9 SLPM

Complies with CE standards

ESD protected housing “skin effect”

www.jbctools.com

Loading...

Loading...