Page 1

Deutsch 42

Español 22

Premium Rework Station

with Pneumatic Pump

Ref. DDVE-B

English 2

Page

www.jbctools.com

Page 2

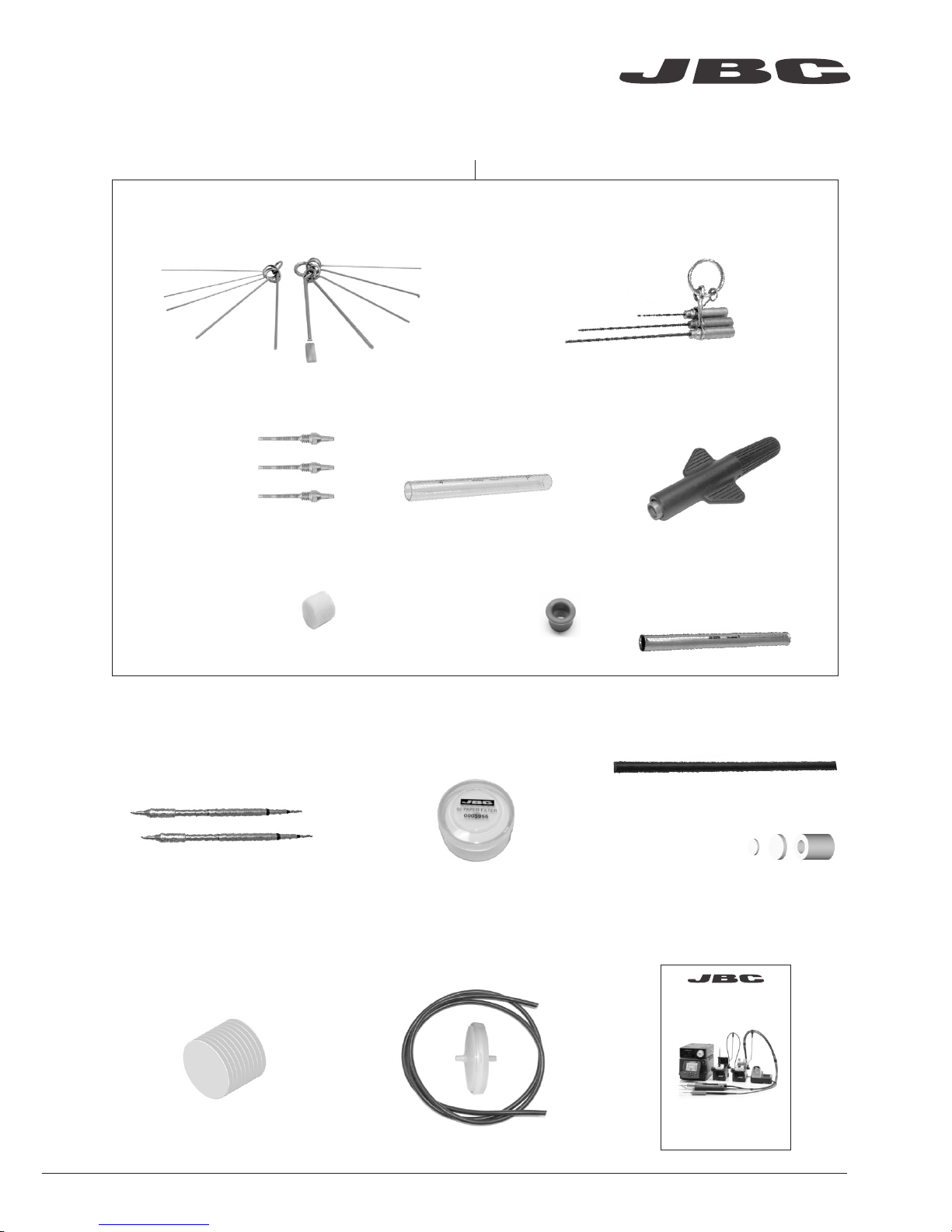

Packing List

The following items should be included:

Stand Cable ................ 2 units

Re f. 0 0112 83

Stand ................ 1 unit

Ref. AD-SD

Sponge ............................ 1 unit

Ref. S0354

Metal Brush .................... 1 unit

Ref. CL6217

Pneumatic Desoldering

Module ............................. 1 unit

Ref. MVE-A

Tip Cleaner ..................... 1 unit

Ref. CL6166

Module Cable ................ 1 unit

Re f. 0 014 874

DDE Control Unit .......... 1 unit

Ref. DDE-1B (120V)

DDE-2B (230V)

DDE-9B (100V)

Union Flanges ............... 1 unit

Re f. 0 0113 56

Desoldering

Iron .................... 1 unit

Ref. DR560-A

Stand ................ 1 unit

Ref. DR-SD

Power cord .................... 1 unit

Ref. 0010569 (230V)

0013671 (100/120V)

General Purpose

Handle .............. 1 unit

Ref. T245-A

2

Page 3

Manual ............................. 1 unit

Ref. 0017356

Premium Rework Station

with Pneumatic Pump

Ref. DDVE-B

Suction Filter ................. 1 unit

Ref. 0821830

Cotton Filter .................... 1 unit

Ref. 0781046

It contains 10 filters

DR560 Accessories

Re f. 0 010211

Internal gasket .......... 1 unit

Ref. 0019208

It contains 2 gaskets

Filter Box .................... 1 unit

Ref. 0780840

It contains 10 filters

Spanner ...................... 1 unit

Ref. 0780550

Glass solder

collector ...................... 1 unit

Ref. 0812620

Metal solder

collector ...................... 1 unit

Ref. 0812630

Tips ............................. 3 units

Ref. C560005

Ref. C560013

Ref. C560004

Cleaning stick ................. 1 unit

Ref. 0786640

Cartridges .................... 2 units

Ref. C245903 (x1)

C245906 (x1)

Filter Box .......................... 1 unit

Ref. 0005966

It contains 50 filters

Venturi Filter ................... 1 unit

Ref. 0008446

Tip cleaning set ................................... 1 unit

Ref. 0965970

Long Tip Cleaning set ....................... 1 unit

Ref. 0965760

www.jbctools.com

3

www.jbctools.com

Page 4

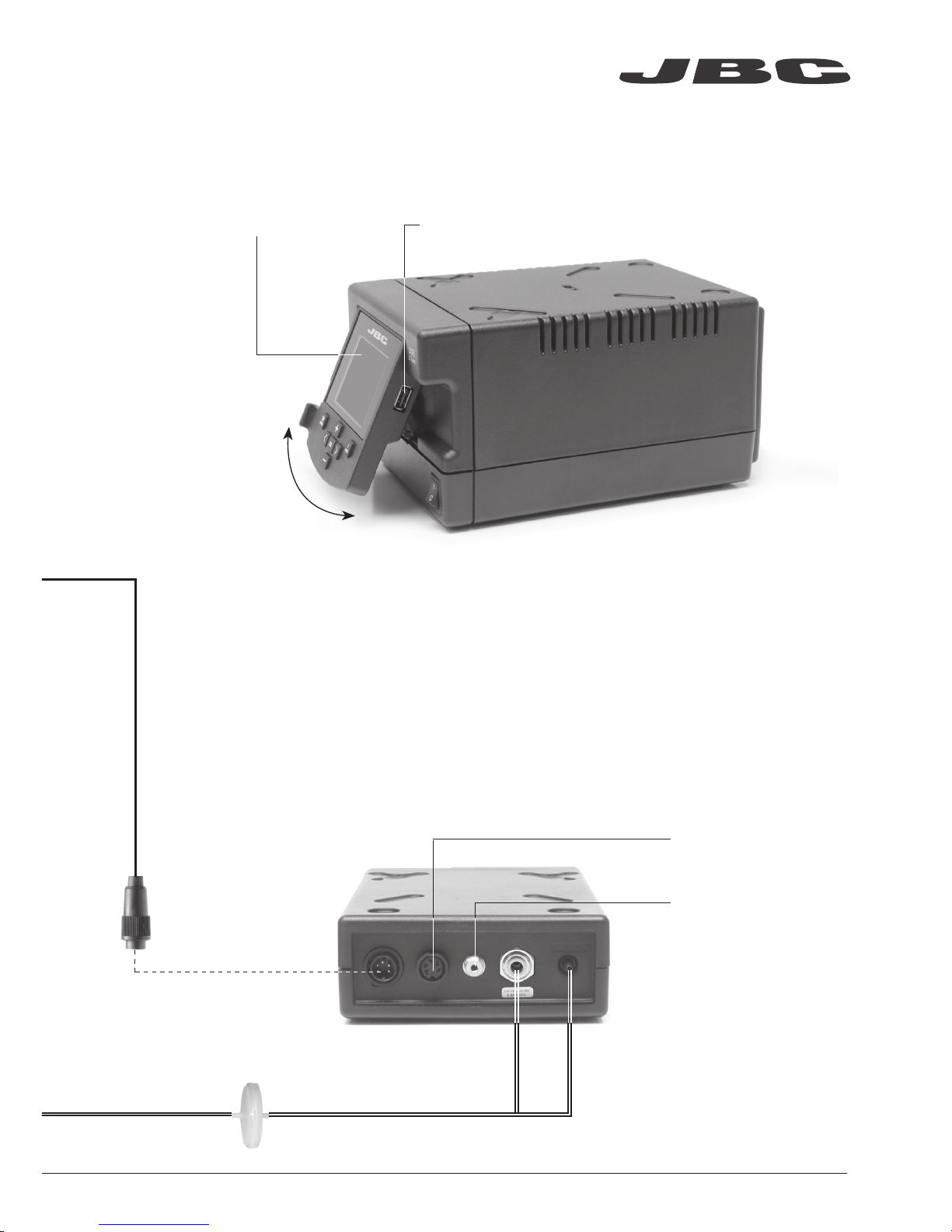

Stand

Ref. DR-SD

Stand Cable

Re f. 0 0112 83

Features

Work simultaneously with up to 2 tools and join each station port with 1 module + 1 pedal (Peripherals).

Stand

Ref. AD-SD

RJ12 connector for Robot

USB-B connector

Equipotential connection

Power Socket

Desoldering Iron

Ref. DR560-A

General

Purpose

Handle

Ref. T245-A

4

Page 5

Suction Filter

Ref. 0821830

Module Cable

Re f. 0 014 874

USB-A connector2,8” Color TFT screen

Tilt the display

for easy reading

Air pressure (4-6 bar)

Pneumatic Desoldering Module

Ref. MVE-A

To another peripheral

To Pedal

Ref. P-005

www.jbctools.com

5

Page 6

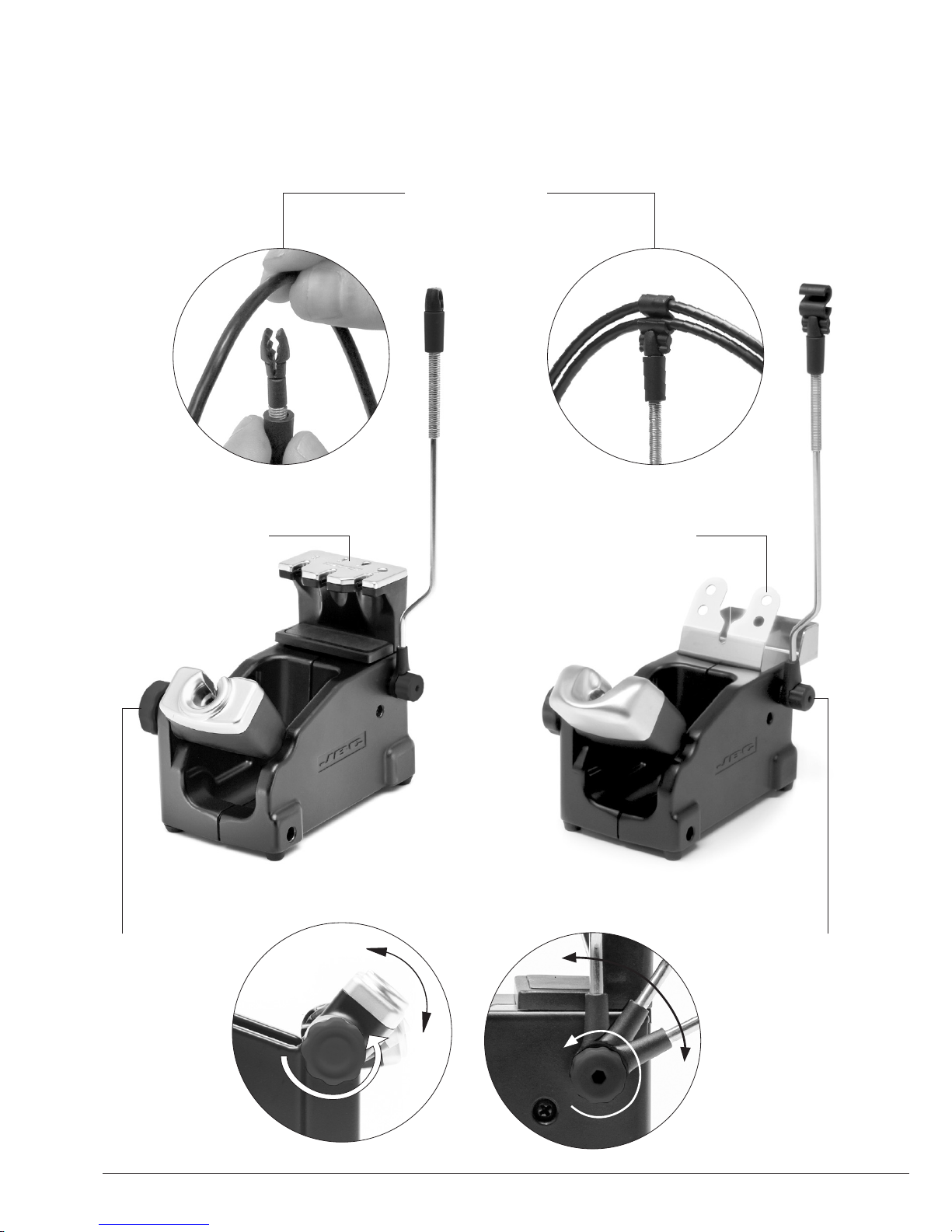

Quick tip changer

Permits switching

cartridges without

interrupting your work.

Adjustable

tool holder

Suits your work

position.

Adjustable

cable collector

Adjustable Stands

Stand

Ref. DR-SD

Quick tip changer

Holding tip system

for easy change.

Cable collector

Keeps working area free of cable.

Stand

Ref. AD-SD

6

Page 7

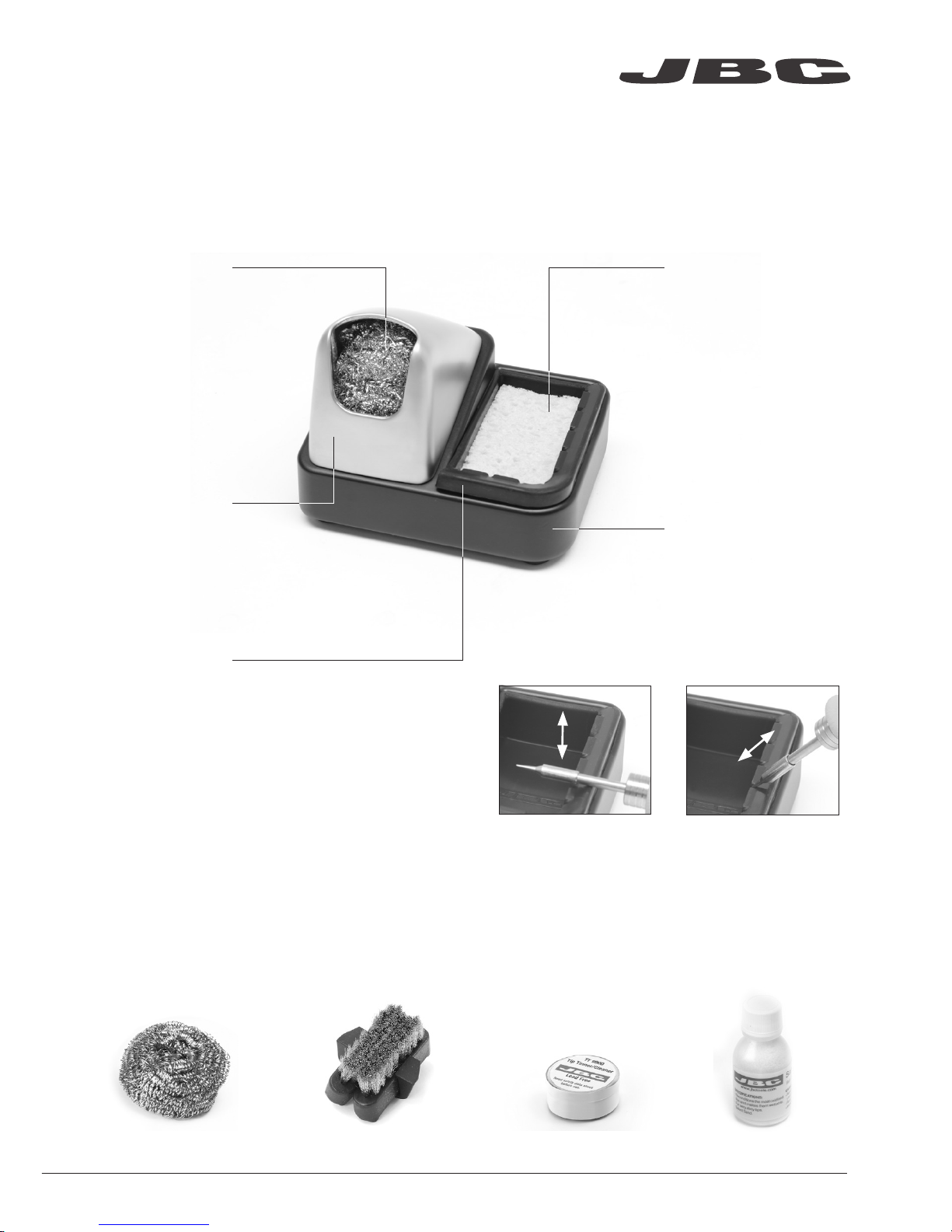

Improve thermal transfer by cleaning the tip after each solder joint.

ESD Tip Cleaner

Optional

Inox wool

Ref. CL6205

Brushes

Ref. CL6220

Tip-tinner

Ref. T T-A

Sand

Re f. C L6211

Brass wool

Ref. CL6210

Splashguard

Non-slip base

Sponge

Ref. S0354

ESD Tip Wiper

Ref. CL0240

Very effective cleaning

method. It leaves a small layer

of solder on the tip to prevent

oxidation between cleaning

and rewetting.

It prevents splashing of

solder particles. Also used

for sponge or brushes.

No need to hold the

base while cleaning tips.

The least harmful

cleaning method.

Keep the sponge damp

with distilled water when

working to avoid tip wear.

A temperature resistant receptacle

lets the operator remove excess

solder by gentle tapping or wiping.

Tapping: Wiping:

Tap to remove excess

solder.

Use the slots to remove

remaining particles.

www.jbctools.com

7

Page 8

ø 1

ø 3,5

A

B

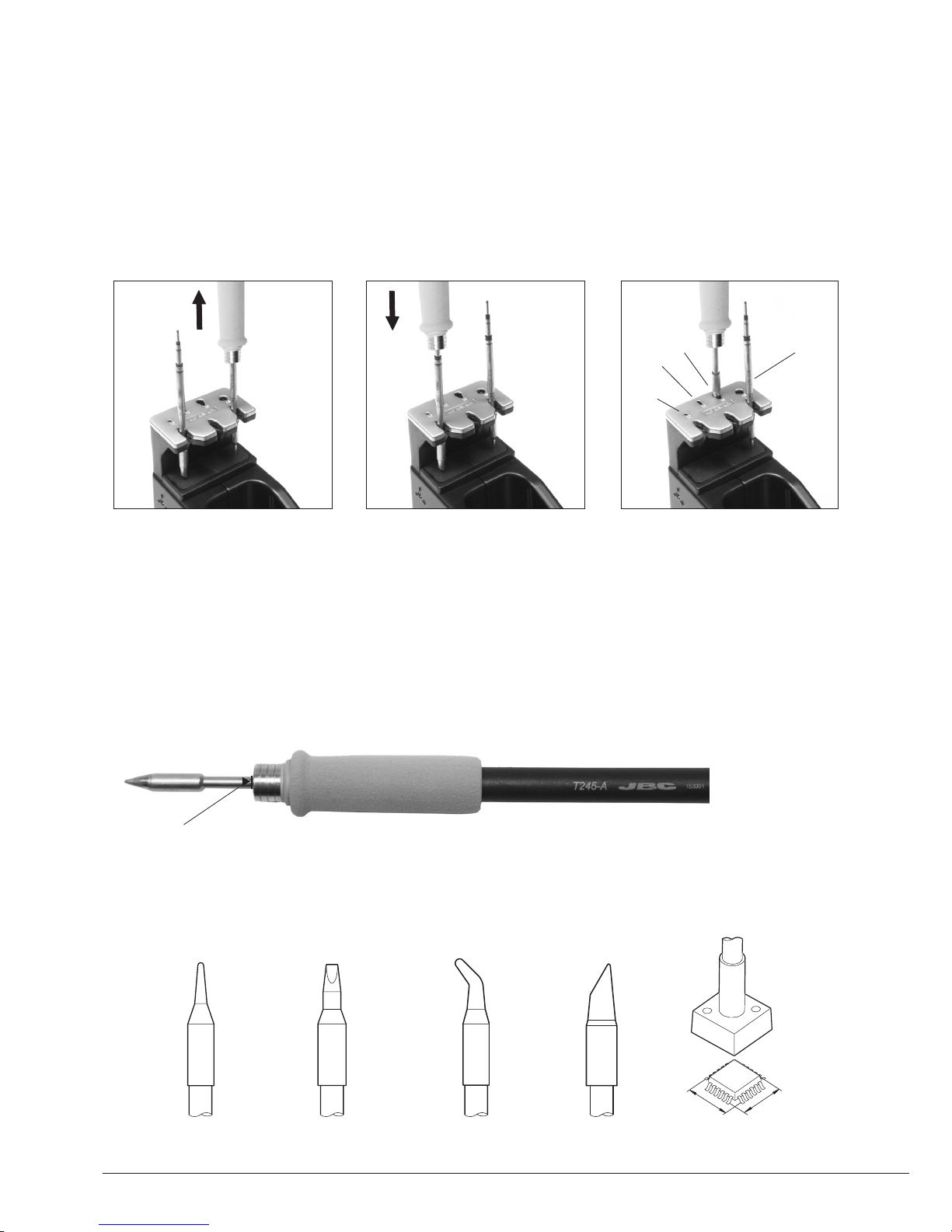

T245 Changing Cartridges

1. Removing 2. Inserting 3. Fixing

Place the handle in the

extractor and pull to remove

the cartridge.

Place the handle on top of

the new cartridge and press

down slightly.

Use the holes for fixing the

cartridge* as follows:

A. For straight C210.

B. For curved C210.

C. For curved C245.

D. For straight C245.

*Important

It is essential to insert the cartridges as far as the mark for a proper connection.

Compatible cartridges

The T245 handle works with C245 cartridges. Find the model that best suits your soldering needs in

www.jbctools.com

Round Chisel Round bent Bevel Special models

Save time and change cartridges safely without switching the station off.

Mark

B

C

A

D

8

Page 9

A ø

B ø

C560-001

C560-002

C560-003

C560-004

C560-009

C560-014

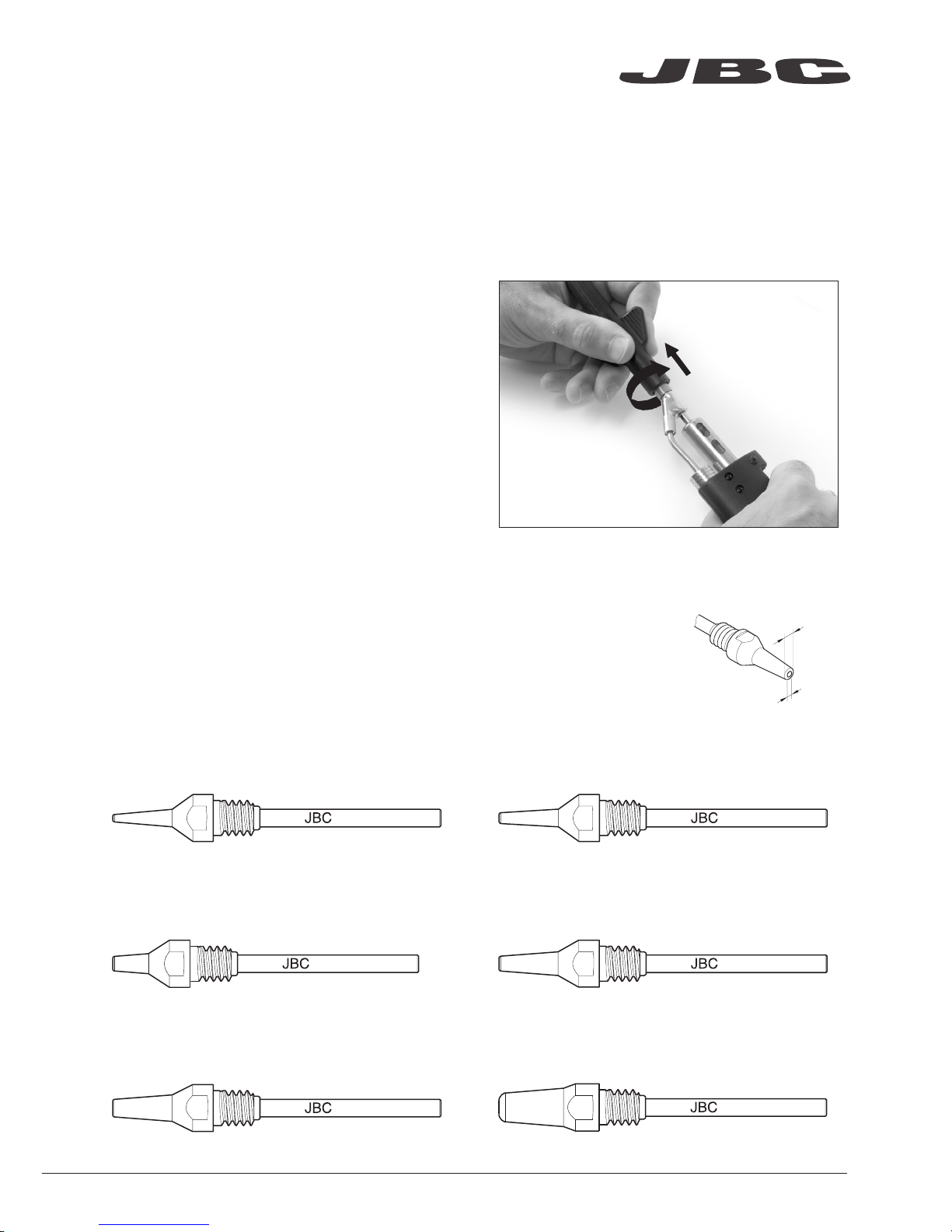

DR560 Changing Tips

This operation should be done while the tip is hot and at a minimum temperature of 250°C, so that

any tin left inside is still molten.

1. Removing

Use the special spanner to unscrew the tip.

2. Inserting

Fit the new tip and tighten with the spanner

to make sure it is air tight.

Compatible Tips

The DR560 uses C560 tips.

Find the model that best suits your soldering needs in www.jbctools.com

Here are some C560 tips in real size:

250ºC minimum

C560-001 A=1,4 B=0,6 max. pin=0,4 mm

(A=0.05 B= 0.02 max. pin= 0.01 in)

C560-002 A=1,8 B=0,8 max. pin=0,6 mm

(A=0.07 B= 0.03 max. pin= 0.02 in)

C560-003 A=2,7 B=1 max. pin=0,8 mm

(A=0.1 B= 0.04 max. pin= 0.03 in)

C560-004 A=3,2 B=1,3 max. pin=1,1 mm

(A=0.12 B= 0.05 max. pin= 0.04 in)

C560-009 A=5 B=1,3 max. pin=1,1 mm

(A=0.19 B= 0.05 max. pin= 0.04 in)

C560-014 A=2,5 B=0,8 max. pin=0,6 mm

(A=0.09 B= 0.03 max. pin= 0.02 in)

www.jbctools.com

9

Page 10

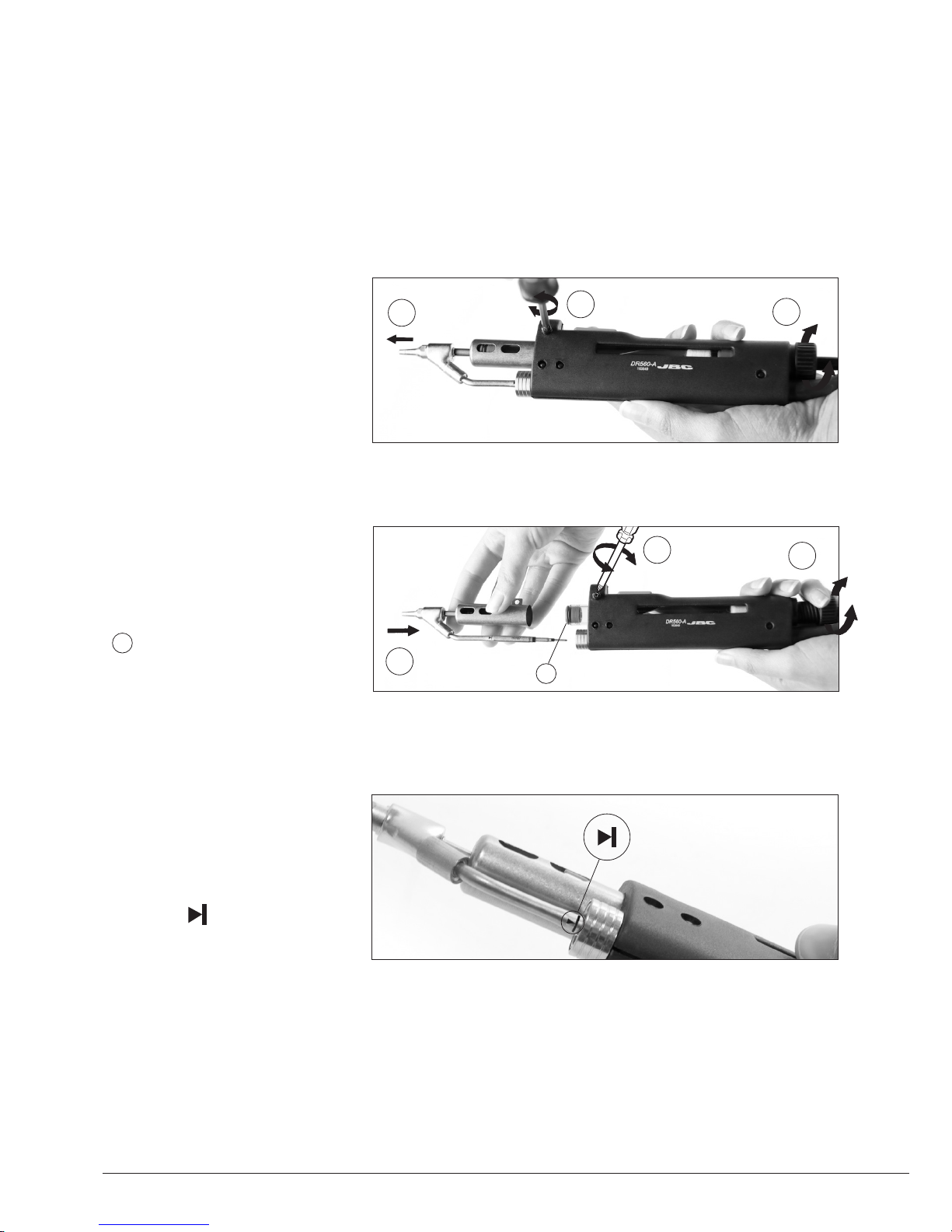

DR560 Changing the Heating Element

1. Removing

Loosen the deposit lid

(a), remove the screw (b)

and withdraw the heating

element (c).

For this operation, turn off the station or disconnect the tool and wait until the tool temperature

drops to room temperature.

2. Placing

Insert the new Heating

Element (a), tighten the screw

(b) and then the lid (c).

Important

Before placing, make sure to

insert the internal gasket into

the Glass Solder Collector.

b

a

c

b

c

a

!

!

Important

For a proper connection

it is essential to insert the

cartridge by lining it up to

the mark .

10

Page 11

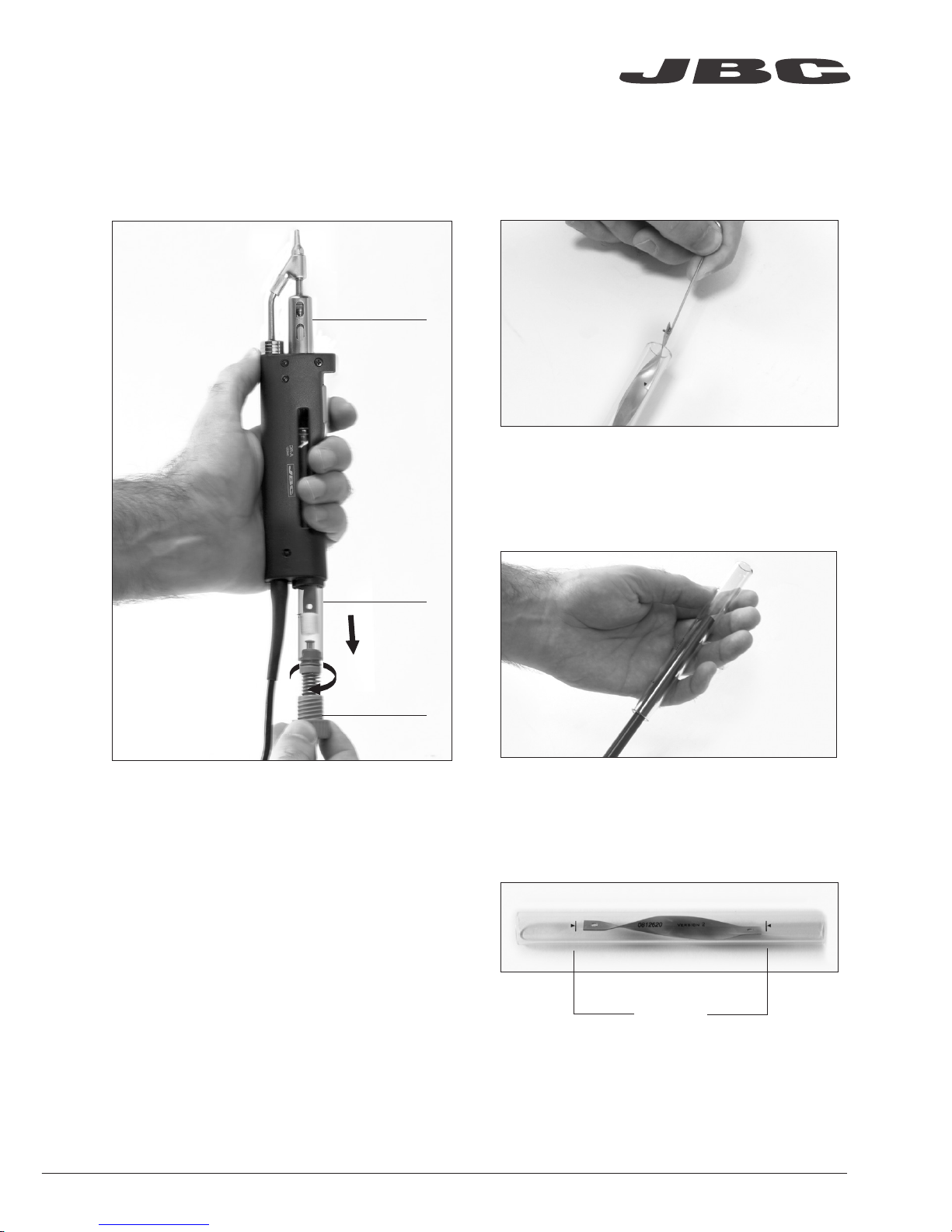

DR560 Glass Solder Collector Cleaning

1. Removing the lid

3. Inserting the glass solder collector

Check filter

Lid

Check

internal joint

2. Cleaning

Check the filter and replace it if it is dirty or

damaged.

Remove the coil and clean the inside of the glass

solder collector with the cleaning stick.

The lid must be unscrewed with the DR560 in a

vertical position.

The glass solder collector must be inserted

with coil filter in place, positioned between the

2 lines marked.

Then the whole unit must be closed by

screwing the lid.

Marks

www.jbctools.com

11

Page 12

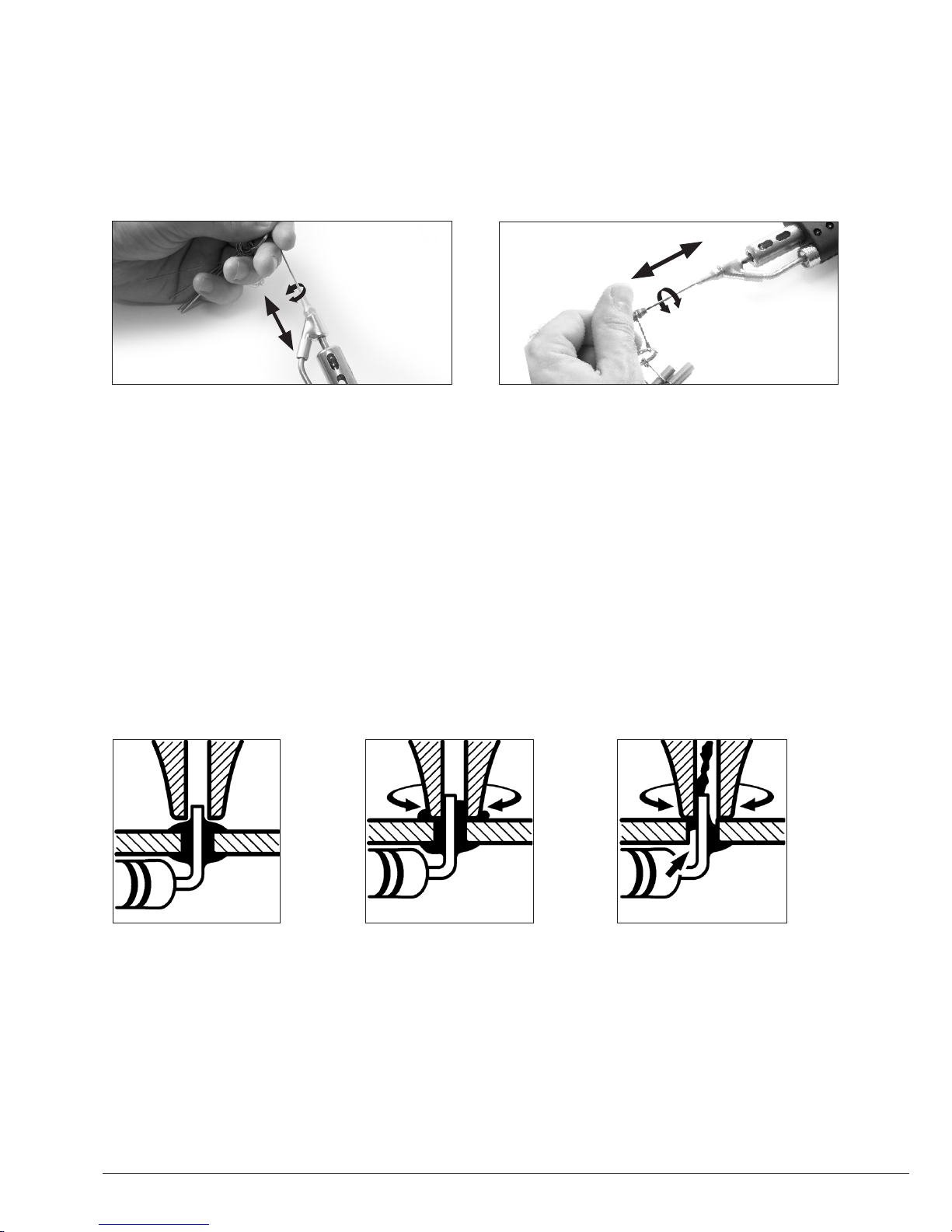

Desoldering process

Use a tip with a larger diameter than the pad to achieve maximum aspiration and thermal efficiency.

Place the tip with the

component terminal in

the hole.

After pressing the desoldering key there is a slight delay until the self-contained vacuum pump

stops. This makes sure that the vacuum circuit is completely empty. If any solder remains are left

on a terminal after desoldering it, resolder it with fresh solder and repeat the desoldering operation.

When the solder liquefies,

gently rotate the tip so that

the compo nent terminal

can be lifted off.

Press the vacuum pump

button long enough to remove

the solder.

3. Aspirating1. Placing 2. Rotating

The intake tube should be periodically cleaned by the largest rod.

DR560 Tip Care

Important

DO NOT press the vacuum pump button while tinning the desoldering tip, as the fumes given off

by the flux would quickly block the ducts and the air filter.

12

Page 13

Peripherals Port 2-DR

17:14

Pedal None

Module None

Module

MVE_a

None

1. Select the module from the list of peripheral

connections. Remember your first connection

is denoted as “a”, the second being “b”, etc.

(e.g. MVE_a, MVE_b,...)

2. Press Menu or Back to save changes.

Once set up, you can change the module

settings by entering the Peripherals Menu.

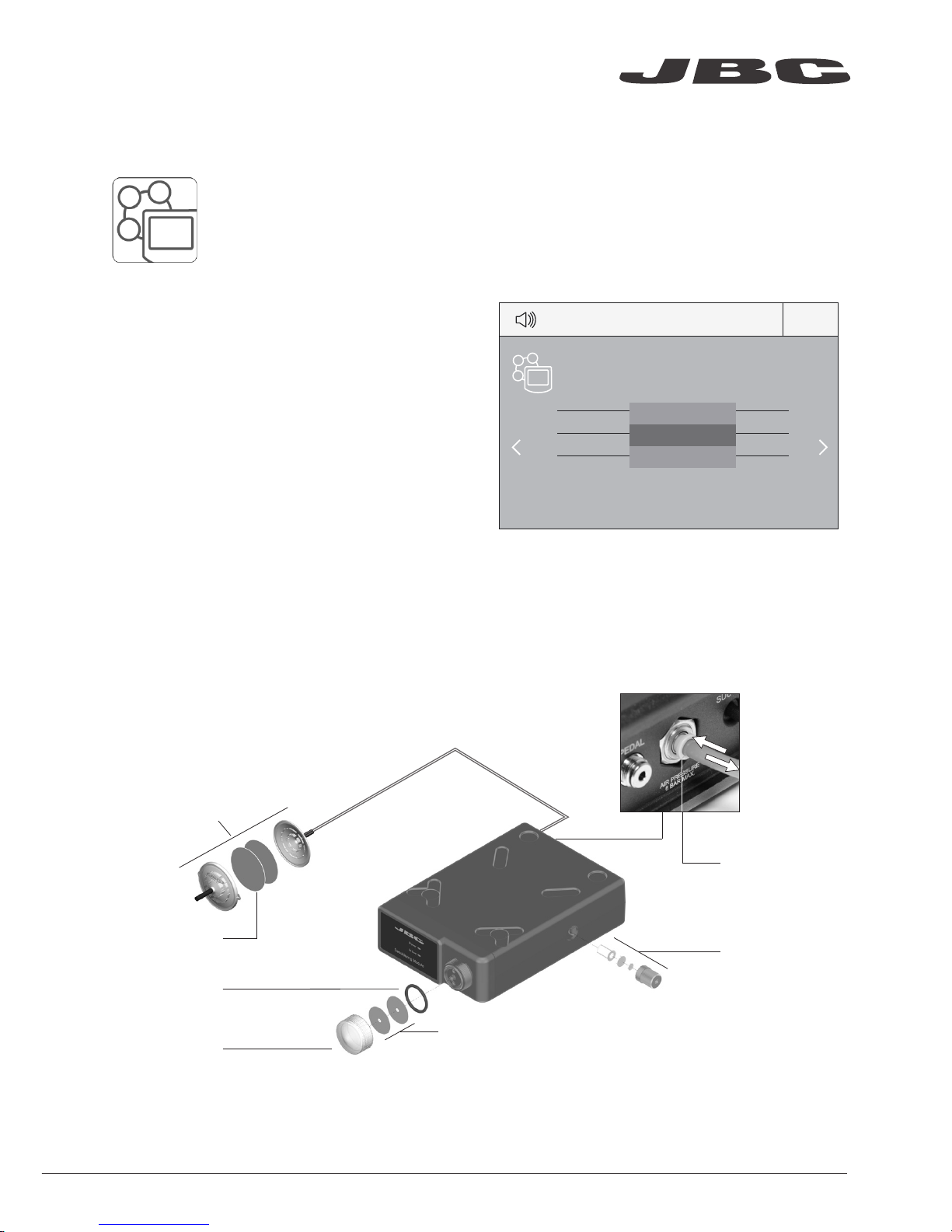

MVE Initial Setup

Peripherals

After connecting the pneumatic desoldering module (MVE-A), enter the

Peripherals Menu and select the port which you want to join with the module.

MVE Changing

the pump filters

- Use a damp cloth to keep the casing clean.

- Periodically check all cable and tube

connections.

- Keep filters clean to ensure proper solder

suction and replace them when

necessary.

Spare filters

Ref. 0005966

Cotton filters

Ref. 0781046

Suction filter

Ref. 0821830

O Ring

Ref. 0007717

Filter cover

Ref. 0004710

Escape filter

Ref. 0008446

Removing the

pneumatic tubing

- Push the release ring to remove the

pneumatic tubing.

Release ring

Important: Do not use sharp pointed objects to open the suction filter.

1

2

www.jbctools.com

13

Page 14

Port

2

T245

17:14

Sleep

Tool in the stand

Actual Temp. 180ºC

Delay to hibernation: 29:30

Port

2

T245

17:14

Hibernation

Actual Temp. 25ºC

350

ºC

Port

2

Power

45%

T245

17:14

Selected 350ºC

3. Hibernation

Operation

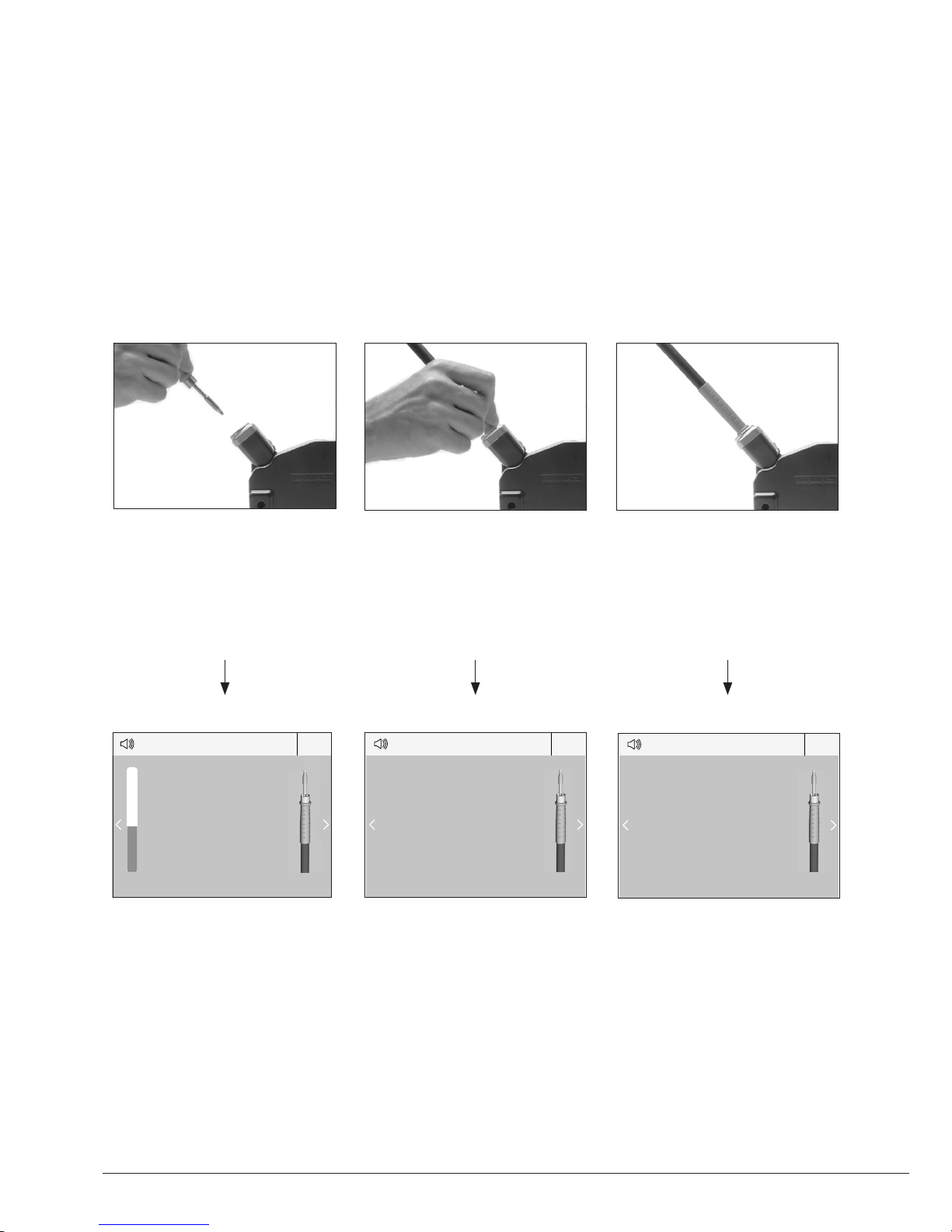

The JBC Exclusive Heating System

Our revolutionary technology is able to recover tip temperature extremely quickly. It means the user

can work at a lower temperature and improve the quality of soldering. The tip temperature is further

reduced thanks to the Sleep and Hibernation modes which increase the tip life by 5.

1. Work

2. Sleep

When the tool is lifted from the

stand the tip will heat up to the

selected temperature.

When the tool is in the stand,

the temperature falls to the

preset Sleep temperature.

After longer periods of

inactivity, the power is cut off

and the tool cools down to

room temperature.

Tools Menu:

· Set temperature limits

· Select temperature levels

Tools Menu:

· Set Sleep temperature

· Set Sleep delay

(from 0 to 9 min or no Sleep)

Tools Menu:

· Set Hibernation delay

(from 0 to 60 min or no

hibernation)

Long time in

the stand

14

Page 15

350

ºC

Port

2

Power

45%

Temp. Levels

T245

250 350 380

17:14

USB flash drive is connected.

Station is controlled by a PC.

Station is controlled by a robot.

Station software update.

Press INFO to start the process.

Warning.

Press INFO for failure description.

Error. Press INFO for failure description,

the type of error and how to proceed.

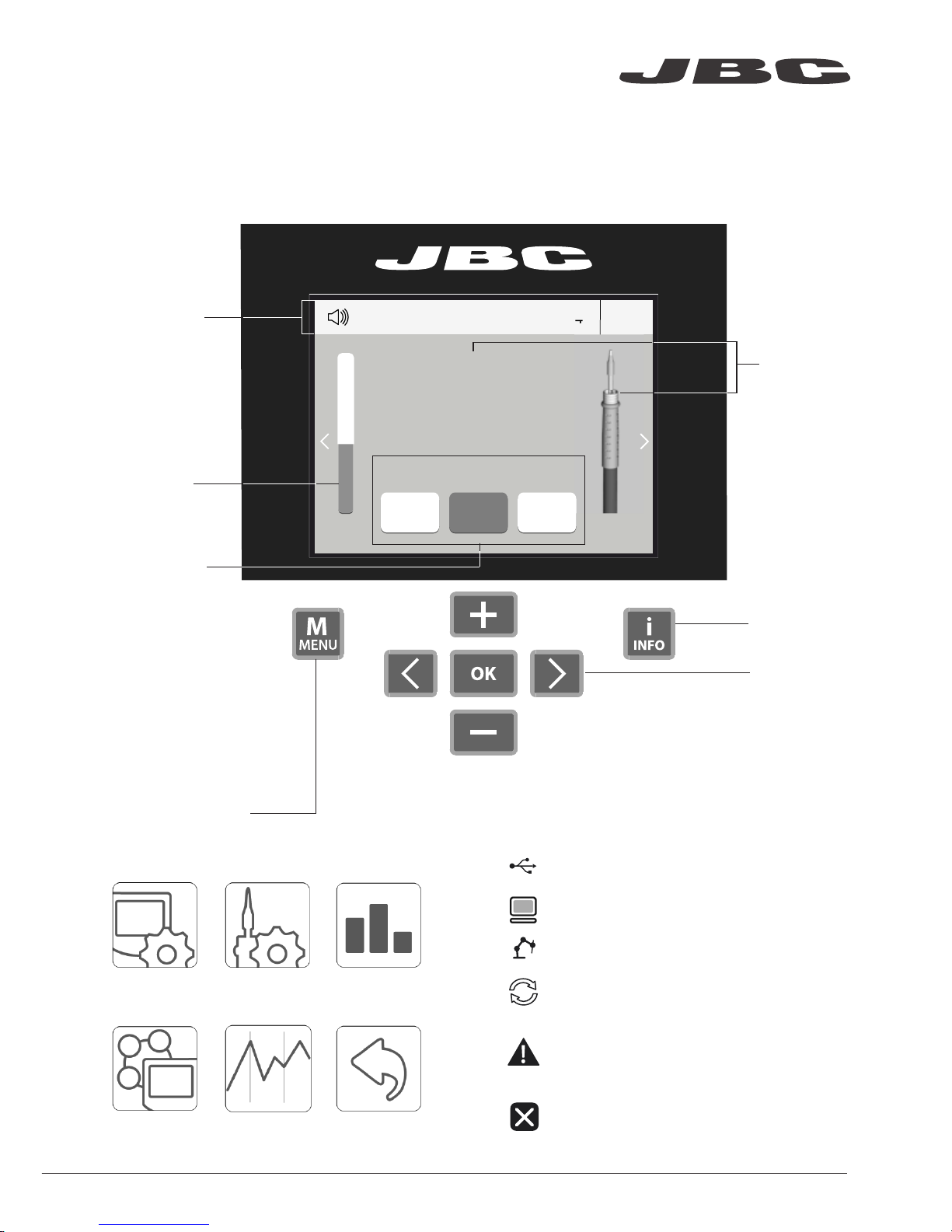

System notifications (Status Bar)Menu Options

Station

Information

Power

indicator

Tool

in use

Work Screen

Status bar

The DDE offers an intuitive user interface which provides quick access to station parameters.

Original PIN: 0105

Change port

Displayed if

temperature

levels are

activated

Station Tools Counters

ResetGraphicsPeripherals

Press INFO for each parameter description.

www.jbctools.com

15

Page 16

Port 1 - T245

450

400

350

300

250

150

100

50

200

Power Temp

17:14

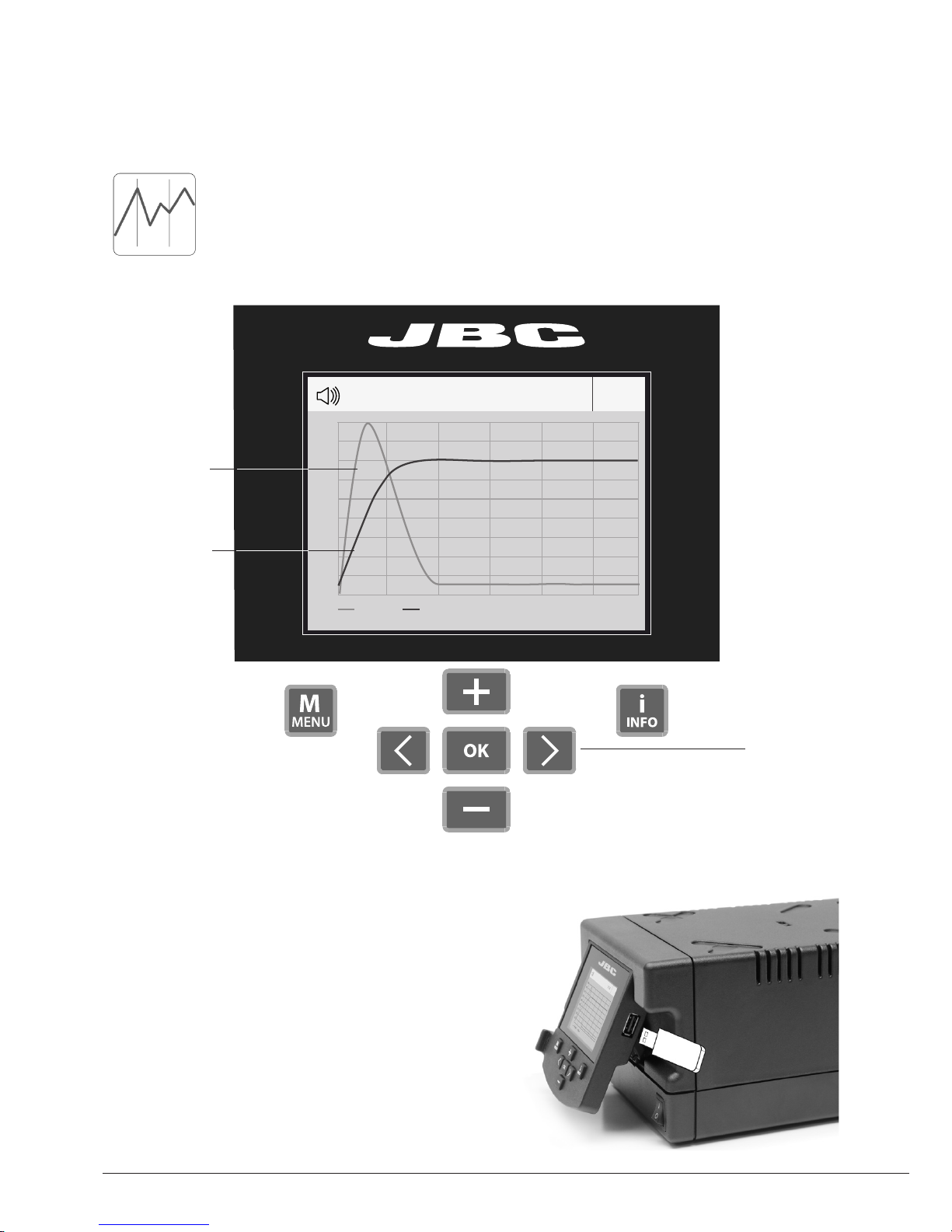

By pressing Graphics in the main MENU, temperature and power figures in real

time are displayed for each port. This helps you decide which tip to use to obtain

the best quality solder joints.

Process analysis

Export graphics

Insert a USB flash drive into the USB-A connector

to save your soldering process in csv format.

Graphics

Temperature

Power (%)

See other

port graphic

16

Page 17

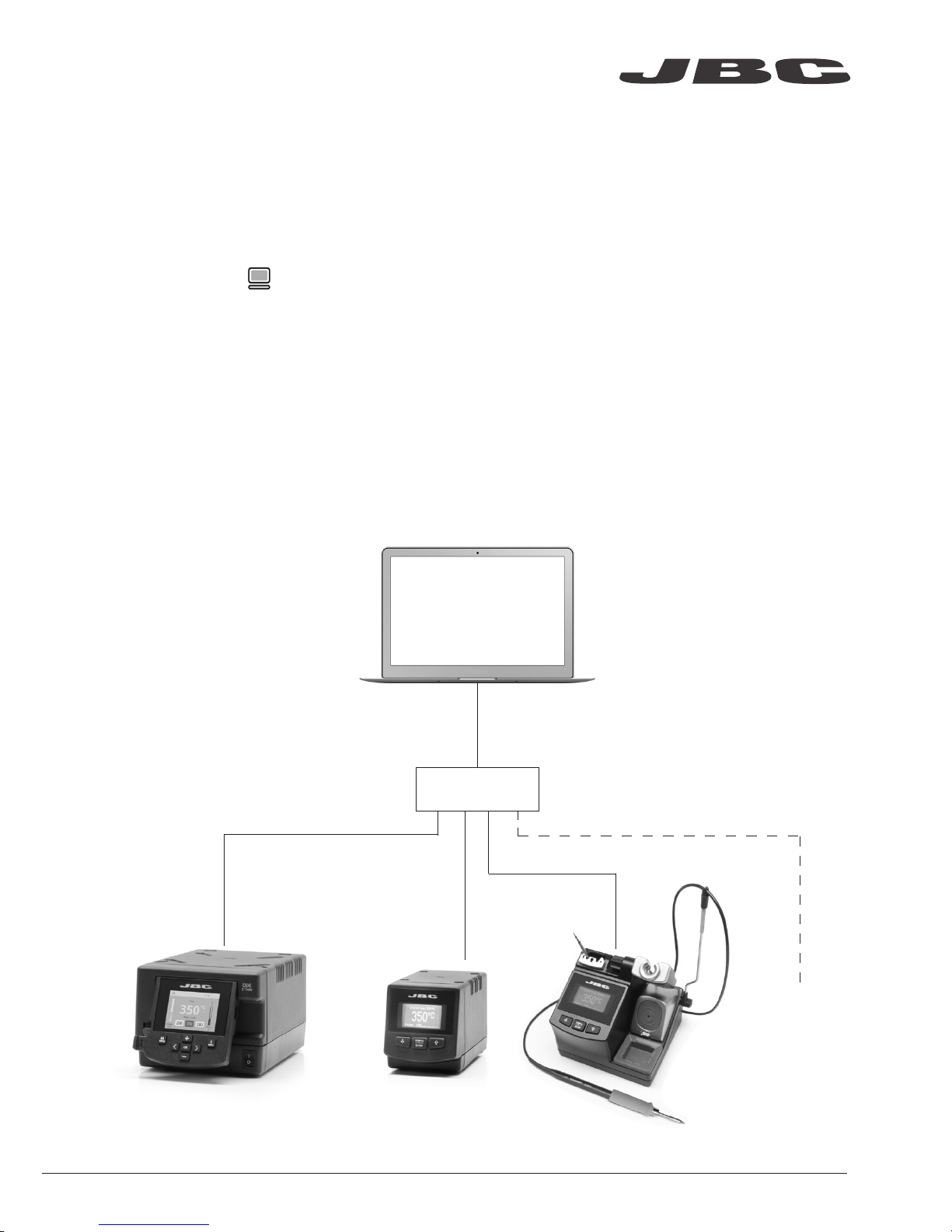

Soldering Net

Remotely manage and monitor as many stations as your PC can handle.

Functions:

- Set all the station parameters from your PC.

- Organize groups of stations and set all their parameters at the same time.

- Store specific configurations for later uses.

- Analyze the soldering graphics of the stations on your PC and export them.

1. Download the JBC Manager software and the user manual from www.jbctools.com/manager.html

2. Connect the stations via USB-B connector and the PC will automatically detect them.

3. The notification will be displayed on the station.

any JBC

station

USB Hub

JBC

Manager

Software

www.jbctools.com

17

Page 18

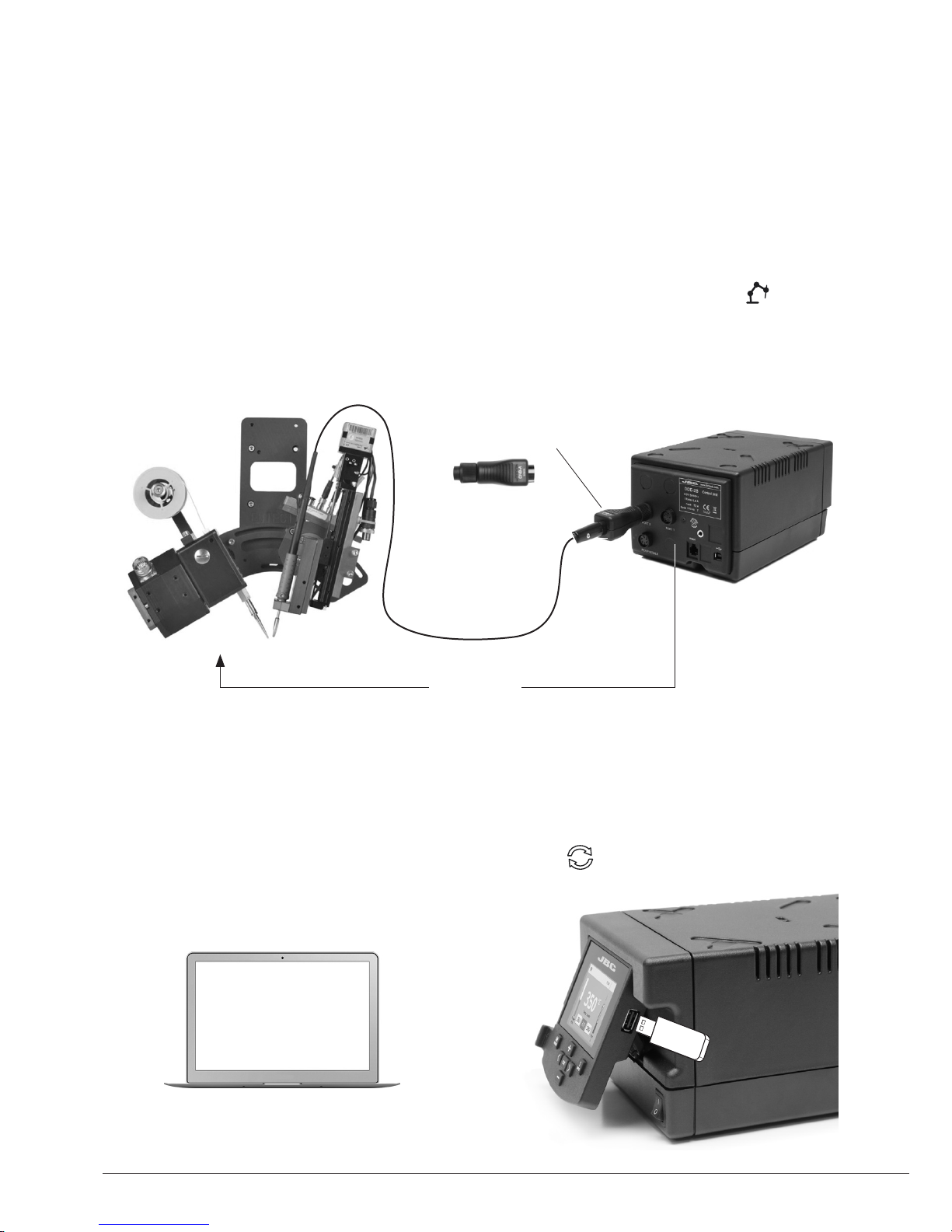

1. Connect the tool to the station port by means of the CHB-A Converter.

2. Connect your Robot system to the Robot connector (RJ12) of the station.

DB9-RJ12 Adapater available only if necessary (Ref: 0013772).

3. Enable the Robot option in the station settings and the notification will be displayed:

4. Set your Robot’s commands according to the Robot Communication Protocol, available on the

website www.jbctools.com/jbcsoftware-menu-115.html.

Manage and monitor the station using a Robotic system.

Working with Robots

Control

Unit

Robot

Update the station software

1. Download the JBC Update File from

www.jbctools.com/software.html and save

it on a USB flash drive. Preferably one with no

other files.

CHB-A

Converter

Ref. CHB-A

2. Insert the USB flash drive to the station.

The icon is diplayed while updating.

RS-232

connection

JBC

Update File

18

Page 19

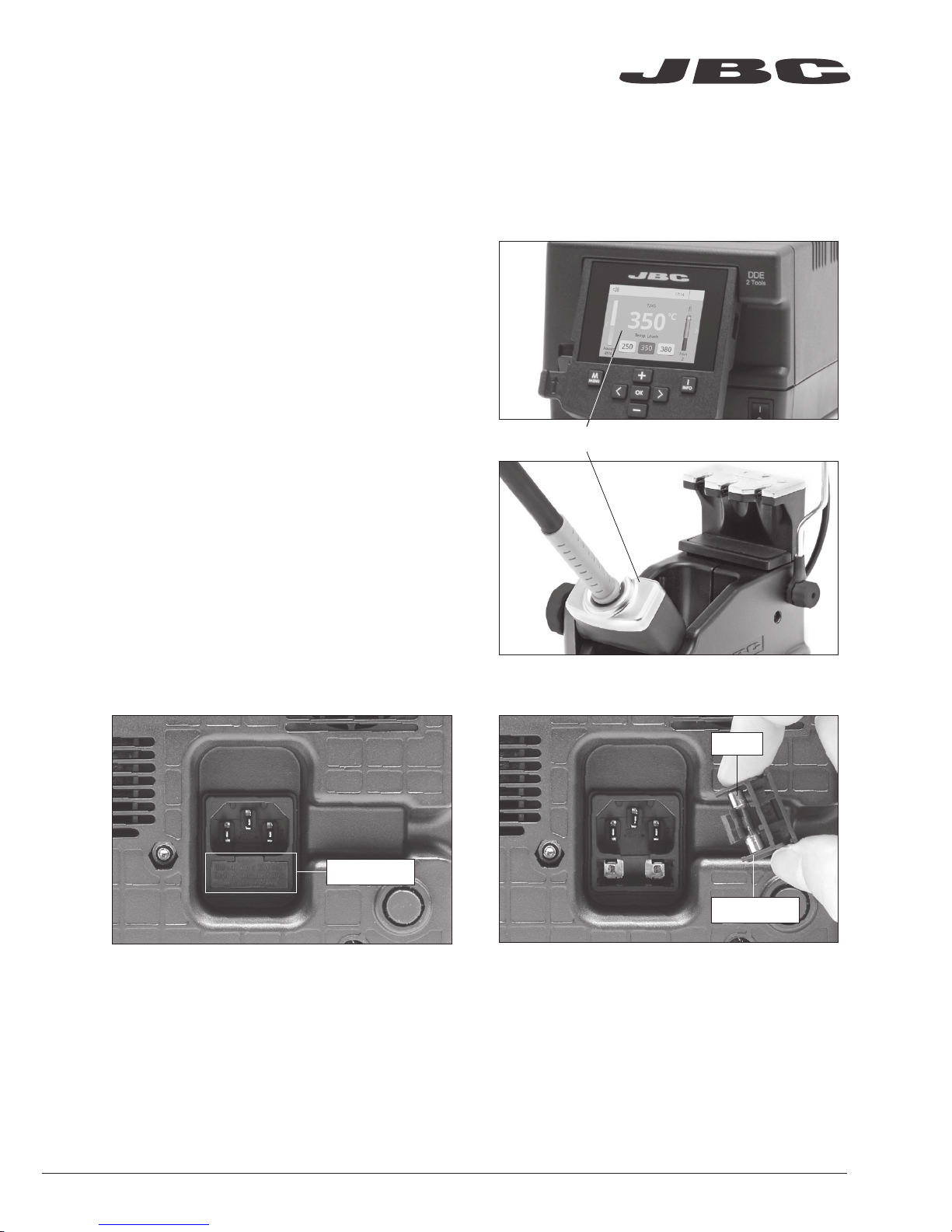

Clean periodically

Maintenance

Before carrying out maintenance or storage, always allow the equipment to cool.

- Clean the station screen with a glass cleaner

or a damp cloth.

1. Pull off the fuse holder and remove the

fuse. If necessary use a tool to lever it off.

2. Press the new fuse into the fuse holder

and replace it in the station.

- Use a damp cloth to clean the casing and the

tool. Alcohol can only be used to clean the

metal parts.

- Periodically check that the metal parts of the

tool and stand are clean so that the station

can detect the tool status.

Fuse holder

Fuse holder

- Maintain tip surface clean and tinned prior to

storage in order to avoid tip oxidation. Rusty

and dirty surfaces reduce heat transfer to the

solder joint.

- Periodically check all cables and tubes.

Fuse

- Replace a blown fuse as follows:

- Replace any defective or damaged pieces. Use original JBC spare parts only.

- Repairs should only be performed by a JBC authorized technical service.

www.jbctools.com

19

Page 20

Safety

- Do not use the units for any purpose other than soldering or rework. Incorrect use may cause fire.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded

before use. When unplugging it, hold the plug, not the wire.

- Do not work on electrically live parts.

- The tool should be placed in the stand when not in use in order to activate the sleep mode.

The soldering tip, the metal part of the tool and the stand may still be hot even when the station is

turned off. Handle with care, including when adjusting the stand position.

- Do not leave the appliance unattended when it is on.

- Do not cover the ventilation grills. Heat can cause inflamable products to ignite.

- Avoid flux coming into contact with skin or eyes to prevent irritation.

- Be careful with the fumes produced when soldering.

- Keep your workplace clean and tidy. Wear appropriate protective glasses and gloves when

working to avoid personal harm.

- Utmost care must be taken with liquid tin waste which can cause burns.

- This appliance can be used by children over the age of eight and also persons with reduced

physical, sensory or mental capabilities or lack of experience provided that they have been given

adequate supervision or instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance.

It is imperative to follow safety guidelines to prevent electric

shock, injury, fire or explosion.

20

Page 21

Specifications

Premium Rework Station with Pneumatic Pump

DDVE-1B / DDVE-2B / DDVE-9B

- Total weight: 8.3 Kg (18.4 lb)

DDE-1B 120V 50/60Hz. Input fuse: 4A. Output: 23.5V

DDE-2B 230V 50/60Hz. Input fuse: 2A. Output: 23.5V

DDE-9B 100V 50/60Hz. Input fuse: 5A. Output: 23.5V

- Weight: 3.8 Kg (8.4 lb)

- Dimensions: 148 x 120 x 232 mm (5.83 x 4.72 x 9.13 in)

- Output Peak Power: 150W per tool

- Temperature Range: 90-450°C (190-840 ºF)

- Idle Temp. Stability (still air) ±1.5 ºC (±3 ºF)

- Tip to ground resistance: <2 ohms

- Tip to ground voltage: <2mV RMS

- Ambient Operating Temperature: 10-40 ºC (50-104 ºF)

- USB-A / USB-B / Peripherals connectors

- RJ12 connector for Robot

MVE-A

- Weight: 0.7 Kg (1.54 lb)

- Dimensions: 145 x 55 x 225 mm (5.71 x 2.17 x 8.86 in)

- Air Pressure supply range: 4-6 Bar

- Vacuum at 6 Bar: 90% / 680 mmHg / 26.8 inHg

- Flow rate: 15 SLPM

Complies with CE standards

ESD protected

www.jbctools.com

21

Page 22

Composición

Los siguientes artículos deberían estar incluidos:

Stand Cable.......... 2 unidades

Cable del soporte

Re f. 0 0112 83

Stand ..................... 1 u

Soporte

Ref. AD-SD

Sponge ...................... 1 unidad

Esponja

Ref. S0354

Metal Brush .............. 1 unidad

Cepillo metálico

Ref. CL6217

Pneumatic Desoldering

Module ................................. 1 u

Módulo desoldador neumático

Ref. MVE-A

Tip Cleaner ......................... 1 u

Limpiador de puntas

Ref. CL6166

Module Cable .......... 1 unidad

Cable del módulo

Re f. 0 014 874

DDE Control Unit .............. 1 u

Unidad de Control DDE

Ref. DDE-1B (120V)

DDE-2B (230V)

DDE-9B (100V)

Union Flanges ......... 1 unidad

Bridas de unión

Re f. 0 0113 56

Contiene 2 bridas

Desoldering Iron .. 1 u

Desoldador

Ref. DR560-A

Stand ..................... 1 u

Soporte

Ref. DR-SD

Power cord ............... 1 unidad

Cable de Red

Ref. 0010569 (230V)

0013671 (100/120V)

General Purpose

Handle ...................... 1 u

Mango para

aplicaciones generales

Ref. T245-A

22

Page 23

Manual ....................... 1 unidad

Ref. 0017356

Suction Filter ........... 1 unidad

Filtro de aspiración

Ref. 0821830

Cotton Filter .............. 1 unidad

Filtros de algodón

Ref. 0781046

Contiene 10 filtros

DR560 Accessories

Accesorios del DR560

Re f. 0 010211

Internal gasket .... 1 unidad

Casquillo junta interior

Ref. 0019208

Contiene 2 casquillos

Filter Box .............. 1 unidad

Caja de filtros

Ref. 0780840

Contiene 10 filtros

Spanner ................. 1 unidad

Llave

Ref. 0780550

Glass solder

collector ................ 1 unidad

Depósito de estaño

Ref. 0812620

Metal solder

collector ................ 1 unidad

Depósito de metal para estaño

Ref. 0812630

Tips ..................... 3 unidades

Puntas

Ref. C560005

Ref. C560013

Ref. C560004

Cleaning stick ........... 1 unidad

Baqueta de limpieza

Ref. 0786640

Cartridges ............ 2 unidades

Cartuchos

Ref. C245903 (x1)

C245906 (x1)

Filter Box .................... 1 unidad

Caja de filtros

Ref. 0005966

Contiene 50 filtros

Venturi Filter ................... 1 unit

Filtro Venturi

Ref. 0008446

Tip cleaning set ............................. 1 unidad

Juego de limpieza de puntas

Ref. 0965970

Long Tip Cleaning set .................. 1 unidad

Juego de limpieza de puntas largo

Ref. 0965760

Premium Rework Station

with Pneumatic Pump

Ref. DDVE-B

www.jbctools.com

23

www.jbctools.com

Page 24

Stand

Soporte

Ref. DR-SD

Stand Cable

Cable del soporte

Re f. 0 0112 83

Características

Trabaje simultáneamente con 2 herramientas y enlace cada puerto con 1 módulo + 1 pedal (Peripherals).

Stand

Soporte

Ref. AD-SD

Conector RJ12 para Robot

Conector USB-B

Conexión equipotencial

Toma de corriente

Desoldering Iron

Desoldador

Ref. DR560-A

Ref. DR560-A

General

Purpose Handle

Mango para

aplicaciones

generales

Ref. T245-A

24

Page 25

Suction Filter

Filtro de succión

Ref. 0821830

Module Cable

Cable del módulo

Re f. 0 014 874

Conector USB-APantalla color TFT de 2,8”

Incline la

pantalla para

una mejor

lectura

Presión de aire (4-6 bar)

Pneumatic Desoldering Module

Módulo desoldador neumático

Ref. MVE-A

A otro periférico

Al Pedal

Ref. P-005

www.jbctools.com

25

Page 26

Cambio rápido

de cartuchos

Cambie cartuchos

sin interrumpir

su trabajo.

Soporte de

herramienta

ajustable

Se adapta a

su posición de

trabajo.

Recogecable

ajustable

Soportes ajustables

Stand

Soporte

Ref. DR-SD

Cambio rápido

de puntas

El sistema de sujeción

de puntas

facilita el cambio.

Recogecable

Mantiene el área de trabajo ordenada sin cable

Stand

Soporte

Ref. AD-SD

26

Page 27

Mejore la transferéncia térmica limpiando la punta después de cada soldadura.

Limpiador de Puntas

Opcional

Inox wool

Lana inoxidable

Ref. CL6205

Brushes

Cepillos de metal

Ref. CL6220

Tip-tinner

Reestañador de puntas

Ref. T T-A

Sand

Arena

Re f. C L6211

Brass wool

Lana de latón

Ref. CL6210

Método de limpieza muy

eficaz. Deja una fina capa

de estaño en la punta

para prevenir la oxidación

entre la limpieza y la

rehumectación.

Splashguard

Protector

anti-salpicaduras

Protege la estación de

las salpicaduras cuando

se utiliza la lana de latón.

Non-slip base

Base antideslizante

No es necesario sujetar

la base al limpiar.

Sponge

Esponja

Ref. S0354

El método de limpieza

menos dañino. Mantenga

la esponja húmeda con

agua destilada cuando

trabaje para evitar el

desgaste de la punta.

ESD Tip Wiper

Limpiador ESD

Ref. CL0240

Receptáculo resistente a la

temperatura que permite que

se pueda eliminar el exceso

de soldadura golpeando

la punta suavemente. Se

puede extraer fácilmente

para su limpieza

Golpeteo: Limpieza:

Golpee suavemente

para retirar el exceso

de soldadura.

Use las ranuras para

retirar las partículas

restantes.

www.jbctools.com

27

Page 28

ø 1

ø 3,5

A

B

Cambiar cartuchos del T245

1. Retirar 2. Insertar 3. Fijar

Coloque el soldador en el

extractor y tire para retirar el

cartucho..

Coloque el mango soldador

en la parte superior del

nuevo cartucho y presione

ligeramente.

Fije el cartucho* utilizando

los agujeros:

A. Para los C210 rectos.

B. Para los C210 curvados.

C. Para los C245 curvados.

D. Para los C245 rectos.

*Importante

Es necesario insertar el cartucho hasta la marca para una conexión correcta.

B

C

A

D

Cartuchos compatibles

El mango para soldador T245 funciona con cartuchos C245. Encuentre el modelo que mejor se

adapte a sus necesidades de soldadura en www.jbctools.com

Redondo Cincel

Redondo

curvado

Bisel

Modelos

especiales

Ahorre tiempo cambiando los cartuchos de forma rápida y segura sin apagar la estación.

Marca

28

Page 29

A ø

B ø

C560-001

C560-002

C560-003

C560-004

C560-009

C560-014

Cambiar puntas del DR560

Esta operación debe realizarse con la punta caliente (por encima de los 250°C) para que el estaño

de su interior se mantenga fundido.

250ºC minimo

1. Retirar

Desenrosque la punta utilizando la llave

suministrada.

2. Insertar

Coloque la punta nueva y enrósquela

con la llave para asegurarse que queda

hermético.

Puntas compatibles

El DR560 funciona con puntas C560.

Encuentre el modelo que mejor se adapte a sus necesidades de desoldadura

en www.jbctools.com

Algunas de las puntas C560 en tamaño real (mm):

C560-001 A=1,4 B=0,6 max. pin=0,4 mm

(A=0.05 B= 0.02 max. pin= 0.01 in)

C560-002 A=1,8 B=0,8 max. pin=0,6 mm

(A=0.07 B= 0.03 max. pin= 0.02 in)

C560-003 A=2,7 B=1 max. pin=0,8 mm

(A=0.1 B= 0.04 max. pin= 0.03 in)

C560-004 A=3,2 B=1,3 max. pin=1,1 mm

(A=0.12 B= 0.05 max. pin= 0.04 in)

C560-009 A=5 B=1,3 max. pin=1,1 mm

(A=0.19 B= 0.05 max. pin= 0.04 in)

C560-014 A=2,5 B=0,8 max. pin=0,6 mm

(A=0.09 B= 0.03 max. pin= 0.02 in)

www.jbctools.com

29

Page 30

Cambio del elemento calefactor del DR560

1. Retire

Desenrosque el tapón del

depósito (a), retire el tornillo

(b) y extraiga el elemento

calefactor (c).

Para realizar esta operación debe apagar la estación o desconectar la herramienta y esperar

que la punta esté a temperatura ambiente.

2. Coloque

Inserte el nuevo elemento

calefactor (a), apriete el tornillo

(b) y luego el tapón del

depósito (c).

Importante

Antes de colocar el depósito,

asegúrese que la junta interna

esté colocada.

b

a

c

b

c

a

Importante

Para una buena conexión, es

imprescindible introducir el

cartucho hasta la marca .

!

!

30

Page 31

Limpieza del depósito de estaño del DR560

1. Retire la tapa

3. Inserte el depósito de estaño

Compruebe

el filtro

Tap a

Compruebe

la junta interna

2. Limpieza

El filtro y la junta interna deben supervisarse

para reemplazarlos si fuera necesario, ya sea

por exceso de suciedad o por algún daño.

Retire el espiral para limpiar el interior del

depósito con la baqueta suministrada.

La tapa se debe retirar con el desoldador en

posición vertical.

El depósito se debe insertar con el espiral ya

colocado entre las dos marcas.

Concluya el proceso cerrando el depósito con

la tapa.

Marcas

www.jbctools.com

31

Page 32

Proceso de desoldadura

La punta elegida debe tener un diámetro más grande que el pad para conseguir la máxima

aspiración posible y el mejor rendimiento térmico.

Coloque la punta con el

terminal del componente

en el orificio.

Tras pulsar el botón del desoldador hay un ligero retraso hasta que la bomba de succión se

detiene. Esto asegura que el conducto de succión está completamente vacío.

Si se quedaran restos de soldadura en algun terminal después de desoldarlo, vuelva a soldarlo

con estaño nuevo y repita el proceso de desoldadura.

Cuando la soldadura se

liqüe, gire la punta con

suavidad para que el terminal

del componente se suelte.

Pulse el botón de la bomba

de succión hasta retirar

por completo los restos de

soldadura.

3. Aspirar1. Coloca r 2. Rotar

El conducto de entrada se debe limpiar periódicamente con la baqueta más larga.

Mantenimiento de puntas del DR560

Importante

NO pulse el botón de la bomba de succión mientras estaña la punta, ya que los humos producidos

por el flux bloquearían rápidamente los conductos y el filtro de aire.

32

Page 33

Peripherals Port 2-DR

17:14

Pedal None

Module None

Module

MVE_a

None

1

2

1. Seleccione el módulo del listado de

conexiones periféricas. Recuerde que su

primera conexión se indica como “a”, la

segunda como “b”, etc. (MVE_a, MVE_b,...)

2. Pulse Menu o Back para guardar los

cambios. Una vez configurado podrá

modificar cambios desde el menú Peripherals.

Puesta en marcha de la bomba MVE

Peripherals

Tras conectar el módulo desoldador neumático (MVE-A), entre en el menú de

Peripherals y seleccione el puerto con el que desee enlazar el módulo.

Cambiar los filtros

de la bomba MVE

- Limpie la carcasa con un paño húmedo.

Asegúrese utilizar un paño suave para el

frontal.

- Revise periódicamente los cables y tubos.

- Mantenga los filtros limpios para garantizar

una correcta aspiración y reemplácelos si

fuera necesario.

Filtros

Ref. 0005966

Filtros de algodón

Ref. 0781046

Filtro de aspiración

Ref. 0821830

Anillo

Ref. 0007717

Tapa de filtros

Ref. 0004710

Filtro

de escape

Ref. 0008446

Cambiar el tubo del módulo

- Presione el anillo de liberación para extraer

el tubo del módulo.

Anillo

de liberación

Importante: No utilice objetos punzantes para abrir el filtro de aspiración.

www.jbctools.com

33

Page 34

Port

2

T245

17:14

Sleep

Tool in the stand

Actual Temp. 180ºC

Delay to hibernation: 29:30

Port

2

T245

17:14

Hibernation

Actual Temp. 25ºC

350

ºC

Port

2

Power

45%

T245

17:14

Selected 350ºC

3. Hibernación

Funcionamiento

El exclusivo sistema calefactor de JBC

Nuestra tecnología revolucionaria es capaz de recuperar la temperatura de la punta de forma

extremadamente rápida. Esto significa que el usuario puede trabajar a una temperatura más baja

y mejorar la calidad de la soldadura. Esta temperatura se reduce aún más gracias a los modos de

Sleep e Hibernation que incrementan hasta 5 veces la vida de las puntas.

1. Tra bajo 2. Sleep

Al levantar la herramienta

del soporte, la punta se

calienta hasta la temperatura

seleccionada.

Si la herramienta permenece

en el soporte, la temperatura

se reduce a la temperatura

predefinida.

Luego de largos períodos de

inactividad, el suministro de

energía se corta y la punta

se enfría hasta temperatura

ambiente.

Menu To ols:

· Configure límites de

temperatura.

· Seleccione niveles de

temperatura.

Menu To ols:

· Configure la temperatura

de Sleep

· Configure el tiempo de

retraso de Sleep (de 0 a 9

min o ninguno)

Menu To ols:

· Configure el retraso de

Hibernación (de 0 a 60 min

o ninguno)

Mucho tiempo

en el soporte

34

Page 35

350

ºC

Port

2

Power

45%

Temp. Levels

T245

250 350 380

17:14

Unidad de memoria USB conectada.

Estación controlada por un PC.

Estación controlada por un robot.

Actualización del software de la estación.

Pulse INFO para iniciar el proceso.

Aviso.

Pulse INFO para la descripción del fallo.

Error. Pulse INFO para la descripción del

fallo, el tipo de error y cómo proceder.

Notificaciones (Barra de estado)Opciones de Menú

Ayuda de

la estación

Indicador de

potencia

Herramienta

en uso

Pantalla de trabajo

Barra

de estado

La DDE-B presenta una interfaz de usuario intuitiva y ofrece un rápido acceso a los parámetros.

PIN original: 0105

Cambio

de puerto

Se muestra si

los niveles de

temperatura

están activos

Station Tools Counters

ResetGraphicsPeripherals

Pulse INFO para la descripción de parámetros.

www.jbctools.com

35

Page 36

Port 1 - T245

450

400

350

300

250

150

100

50

200

Power Temp

17:14

Pulsando sobre Graphics en el menú principal, se muestran las respuestas de

temperatura y potencia en tiempo real de cada puerto. Esto le ayudará a decidir cuál

es la punta más adecuada para obtener la mejor calidad en sus soldaduras.

Análisis del proceso

Exporte gráficos

Inserte una unidad de memoria USB para guardar

su proceso de trabajo en formato csv.

Graphics

Temperatura

Potencia (%)

Vea el gráfico del

otro puerto

36

Page 37

Red de soldadura

Gestione y monitorice tantas estaciones como soporte su PC.

Funciones:

- Configure todos los parámetros de la estación desde su PC.

- Organice grupos de estaciones y configure todos sus parámetros al mismo tiempo.

- Guarde configuraciones específicas para usos posteriores.

- Analice gráficos del proceso de soldadura de las estaciones desde su PC y expórtelos.

1. Descargue el software JBC Manager y el manual de usuario de www.jbctools.com/manager.html

2. Conecte las estaciones a través del conector USB-B y el PC las detectará automáticamente.

3. La notificación se mostrará en la estación.

cualquier

estación

JBC

USB Hub

JBC

Manager

Software

www.jbctools.com

37

Page 38

1. Conecte la herramienta a la estación utilizando el convertidor CHB-A.

2. Conecte su sistema robotizado al conector Robot de la estación (RJ12).

Si lo necesita, el adaptador DB9-RJ12 está disponible (Ref: 0013772).

3. Active la opción de robot en la estación y se mostrará la siguiente notificación:

4. Configure su sistema robotizado según el Protocolo de Comunicación para Robots,

que encontrará en www.jbctools.com/jbcsoftware-menu-115.html.

Gestione y monitorice la estación por medio de un sistema robotizado.

Trabajar con Robots

Unidad

de Control

Robot

Actualice el software de la estación

1. Descargue el archivo de actualización de

www.jbctools.com/software.html cuando

esté disponible y guá rdelo en una unidad de

memoria USB (preferentemente una sin

otros archivos).

Convertidor

CHB-A

Ref. CHB-A

2. Inserte la unidad de memoria USB.

La notificación se muestra mientras

se actualiza el software.

Conexión

RS-232

JBC

Update File

38

Page 39

Mantenga limpio

Mantenimiento

Antes de realizar tareas de mantenimiento o almacenar, desconecte el equipo y déjelo enfriar.

1. Tire del portafusible para retirar el fusible.

Si lo precisa, utilice una pequeña palanca.

2. Sustituya el fusible y coloque de nuevo el

portafusibles en su sitio.

- Use un paño húme do para limpiar la pantalla

del equipo, la carcasa y la herramienta.

Puede utilizar alcohol solamente en las

partes metálicas.

- Compruebe periódicamente que las partes

metálicas de la herramienta y del soporte

están limpias. Así la estación puede detectar

el estado de la herramienta y activar los

modos de Sleep o Hibernation.

- Mantenga la punta limpia y estañada la

para evitar su oxidación. Las superfícies

sucias reducen la transferencia térmica a la

soldadura.

- Revise periódicamente los tubos y cables.

Portafusible

Portafusible

Fusible

- Cambie cualquier pieza defectuosa o dañada. Utilice solamente recambios originales de JBC.

- Cualquier reparación sólo se podrá realizar por un servicio técnico oficial JBC.

- Cambie el fusible fundido de la siguiente manera:

www.jbctools.com

39

Page 40

Seguridad

- No utilice el equipo para otros fines que no sea la soldadura o reparación. El uso incorrecto

puede causar fuego.

- El cable de red debe enchufarse en bases homologadas. Asegúrese de que está conectado a

tierra correctamente antes de su uso. Al retirarlo, tire del conector, no del cable.

- No trabaje con tensión.

- La herramienta debe permanecer en el soporte mientras no está en uso con el fin de activar el modo

de Sleep o Hibernación. El cartucho y las partes metálicas de la herramienta o del soporte pueden

estar calientes incluso cuando con la estación apagada. Manipule con cuidado, incluso cuando se

ajusta la posición del soporte.

- No deje el aparato desatendido cuando está en funcionamiento.

- No cubra las rejillas de ventilación. El calor puede causar que los productos inflamables se enciendan.

- Evite el contacto del Flux con la piel o los ojos para prevenir la irritación.

- Tenga cuidado con el humo producido al trabajar.

- Mantenga su lugar de trabajo limpio y ordenado. Use gafas y guantes de protección adecuados.

Así evitará cualquier daño.

- Tenga cuidado con los restos de estaño líquido. En contacto con la piel, puede causar quemaduras.

- Este aparato puede ser utilizado por personas a partir de 8 años y también por aquellas

personas con movilidad reducida o capacidades físicas, sensoriales o mentales limitadas o

con falta de experiencia y conocimientos siempre y cuando reciban supervisión o instrucciones

relativas al uso del aparato de una manera segura y entiendan los riesgos que implica. Los niños

no deben jugar con el aparato.

- Los niños no deberán realizar tareas de mantenimiento sin supervisión.

Es necesario cumplir estas normas de seguridad para prevenir cualquier

choque eléctrico, heridas, fuego o explosiones.

40

Page 41

Especificaciones

Premium Rework Station with Pneumatic Pump

Estación de reparación con bomba neumática

DDVE-1B / DDVE-2B / DDVE-9B

- Peso total: 8,3 Kg (18.4 lb)

DDE-1B 120V 50/60Hz. Fusible de entrada: 4A. Salida: 23.5V

DDE-2B 230V 50/60Hz. Fusible de entrada: 2A. Salida: 23.5V

DDE-9B 100V 50/60Hz. Fusible de entrada: 5A. Salida: 23.5V

- Peso: 3,8 Kg (8.4 lb)

- Dimensiones: 148 x 120 x 232 mm (5.83 x 4.72 x 9.13 in)

- Potencia máxima de pico: 150W por herramienta

- Rango de temperatura: 90-450°C (190-840 ºF)

- Estabilidad de temperatura en reposo: ±1.5 ºC (±3 ºF)

- Resistencia punta a tierra: <2 ohms

- Tensión en punta: <2mV RMS

- Temperatura ambiente de trabajo: 10-40 ºC (50-104 ºF)

- Conectores USB-A / USB-B / Peripherals (periféricos)

- Conector RJ12 para Robot

MVE-A

- Peso: 0,7 Kg (1.54 lb)

- Dimensiones: 145 x 55 x 225 mm (5.71 x 2.17 x 8.86 in)

- Rango de presión de aire: 4-6 Bar

- Vacío a 6 Bar: 90% / 680 mmHg / 26.8 inHg

- Caudal: 15 SLPM

Cumple con las normativas CE

Seguridad ESD

www.jbctools.com

41

Page 42

Packliste

Die folgenden Artikel sollten enthalten sein:

Stand Cable................ 2 Stück

Anschlusskabel

Re f. 0 0112 83

Stand .................. 1 St.

Ablageständer

Ref. AD-SD

Sponge ........................ 1 Stück

Schwamm

Ref. S0354

Metal Brush ................ 1 Stück

Metallbürste

Ref. CL6217

Pneumatic Desoldering

Module ......................... 1 Stück

Druckluft Entlöt Modul

Ref. MVE-A

Tip Cleaner ................. 1 Stück

Lötspitzenreiniger

Ref. CL6166

Module Cable ............ 1 Stück

Modulkabel

Re f. 0 014 874

DDE Control Unit ...... 1 Stück

DDE Versorgungseinheit

Ref. DDE-1B (120V)

DDE-2B (230V)

DDE-9B (100V)

Union Flanges ........... 1 Stück

Kabelclips

Re f. 0 0113 56

Sie enthält

2 Kabelclips

Desoldering Iron .. 1 St.

Entlötkolben

Ref. DR560-A

Stand .................. 1 St.

Ablageständer

Ref. DR-SD

Power cord ................. 1 Stück

Netzkabel

Ref. 0010569 (230V)

0013671 (100/120V)

General Purpose

Handle ................... 1 St.

Universal-Handstück

Ref. T245-A

42

Page 43

Handbuch ................... 1 Stück

Ref. 0017356

Suction Filter ............. 1 Stück

Saugfilter

Ref. 0821830

Cotton Filter ................ 1 Stück

Baumwollfilter

Ref. 0781046

Sie enthält 10 filter

DR560 Accessories

DR560 Zubehör

Re f. 0 010211

Internal gasket ...... 1 Stück

Dichtung für Entlötkolben

Ref. 0019208

Sie enthält 2 dichtung

Filter Box ................ 1 Stück

Ref. 0780840

Sie enthält 10 filter

Spanner ...................... 1 Stück

Entlötspitzen-Wechselwerkzeug

Ref. 0780550

Glass solder

collector .................. 1 Stück

Glasrohr

Ref. 0812620

Metal solder

collector .................. 1 Stück

Metallrohr für Entlötkolben

Ref. 0812630

Tips ........................... 3 Stück

Spitzen

Ref. C560005

Ref. C560013

Ref. C560004

Cleaning stick ............. 1 Stück

Reinigungsstab

Ref. 0786640

Cartridges ................... 2 Stück

Kartuschen

Ref. C245903 (x1)

C245906 (x1)

Filter Box ...................... 1 Stück

Ref. 0005966

Sie enthält 50 filter

Venturi Filter ................ 1 Stück

Filtro Venturi

Ref. 0008446

Tip cleaning set ............................... 1 Stück

Lötspitzen-Reinigungsset

Ref. 0965970

Long Tip Cleaning set .................... 1 Stück

Reinigungswerkzeug, Nadeln

Ref. 0965760

Premium Rework Station

with Pneumatic Pump

Ref. DDVE-B

www.jbctools.com

43

www.jbctools.com

Page 44

Stand

Ablage

Ref. DR-SD

Stand Cable

Anschlusskabel

Re f. 0 0112 83

Merkmale

Arbeiten Sie gleichzeitig mit bis zu 2 Werkzeugen und verbinden Sie jeden Stationsport mit 1 Modul

+ 1 Fußschalter (Peripheriegeräte).

Stand

Ablage

Ref. AD-SD

RJ12-Buchse für Roboter

USB-B-Anschluss

Potenzialausgleichsbuchse

Netzkabelbuchse

Desoldering Iron

Entlötkolben

Ref. DR560-A

Ref. DR560-A

General

Purpose Handle

Universal-Handstück

Ref. T245-A

44

Page 45

Suction Filter

Saugfilter

Ref. 0821830

Module Cable

Modulkabel

Re f. 0 014 874

USB-A Anschluss2,8” Farb TFT Bildschirm

Das Display

zum einfachen

Ablesen kippen

Luftdruck (4-6 bar)

Pneumatic Desoldering Module

Druckluft Entlöt Modul

Ref. MVE-A

Zu einem anderen

Peripheriegerät

Zum Fußschalter

Ref. P-005

www.jbctools.com

45

Page 46

Spitzen-Schnellwechsler

Ermöglicht Ihnen

Spitzenwechsel ohne

Arbeitsunterbrechung.

Verstellbarer

Werkzeughalter

Optimiert Ihre

Arbeitsposition.

Verstellbarer

Kabel-ausleger

Verstellbare Ablagen

Stand

Ablage

Ref. DR-SD

Spitzen-Schnellwechsler

Spitzenfixiersystem

für einfachen Wechsel.

Kabelausleger

Sorgt für einen kabelfreien Arbeitsbereich

Stand

Ablage

Ref. AD-SD

46

Page 47

Verbessern Sie die Wärmeübertragung durch Reinigung der Lötspitze nach jeder Lötverbindung.

Spitzenreiniger

Wahlweise

Inox wool

Edelstahlwolle

Ref. CL6205

Brushes

Bürstenl

Ref. CL6220

Tip-tinner

Lötspitzenverzinner

Ref. T T-A

Sand

Re f. C L6211

Brass wool

Messinggeflecht

Ref. CL6210

Sehr wirksame

Reinigungsmethode. Lässt

eine dünne Lotschicht auf

der Spitze zurück, wodurch

die Oxidation zwischen

Reinigung und Rückfeuchten

vermieden wird.

Splashguard

Spritzschutz

Verhindert Lötpartikelspritzer.

Auch für Schwamm oder

Bürsten benutzt.

Non-slip base

Rutschfeste

Bodenauflage

Während der

Lötspitzenreinigung ist

es nicht notwendig, die

Bodenauflage festzuhalten.

Sponge

Schwamm

Ref. S0354

Die schonendste

Reinigungsmethode.

Halten Sie den

Schwamm bei der

Arbeit mit destilliertem

Wasser feucht, um

Spitzenverschleiß zu

vermeiden.

ESD Tip Wiper

ESD-Lötspitzenabstreifer

Ref. CL0240

Ein temperaturfester Behälter

ermöglicht dem Bediener

durch leichtes Abklopfen oder

Abstreifen überschüssiges

Lot zu entfernen.

Abklopfen: Abstreifen:

Klopfen Sie ab, um

überschüssiges Lot zu

entfernen.

Benutzen Sie die

Aussparungen, um noch

vorhandene Partikel zu

entfernen.

www.jbctools.com

47

Page 48

ø 1

ø 3,5

A

B

T245 Auswechseln der Kartuschen

1. Entfernen 2. Einsetzen 3. Fixieren

Positionieren Sie das Handstück im Abzieher und ziehen

Sie zum Entfernen der

Kartusche.

Positionieren Sie das

Handstück auf der neuen

Kartusche und drücken Sie

mit leichtem Druck nach

unten.

Benutzen Sie die

Aussparungen zur Fixierung

der Kartusche* wie folgt:

A. Für gerade C210.

B. Für bogenförmige C210.

C. Für bogenförmige C245.

D. Für gerade C245.

*Wichtig

Es ist wichtig, die Kartuschen für eine einwandfreie Verbindung genau bis zur Markierung einzustecken.

B

C

A

D

Kompatible Kartuschen

Der Lötkolben T245 arbeitet mit C245 Spitzen. Finden Sie das passende Modell für Ihren Lötbedarf

unter www.jbctools.com

Rund Meißelförmig

Rund

gebogen

Abgeschrägt Spezialmodelle

Sparen Sie Zeit und wechseln Sie sicher Kartuschen, ohne die Station auszuschalten.

Markierung

48

Page 49

A ø

B ø

C560-001

C560-002

C560-003

C560-004

C560-009

C560-014

DR560 Tipps zum Auswechseln

Diese Operation sollte ausgeführt werden, solange die Spitze heiß ist, bei mindestens 250 °C,

sodass jegliches darin befindliche Zinn im geschmolzenen Zustand ist.

1. Entfernen

Schrauben Sie die Spitze mit dem

Wechsel-Werkzeug los.

2. Einsetzen

Passen Sie die neue Spitze ein, ziehen

Sie sie mit dem Wechsel-Werkzeug an,

um ihre Luftundurchlässigkeit zu

gewährleisten.

Kompatible Spitzen

Der Entlötkolben DR560 arbeitet mit C560 Spitzen.

Finden Sie das passende Modell für Ihren Lötbedarf unter

www.jbctools.com

Hier sehen Sie einige C560-Spitzen maßstabsgetreu (mm):

250ºC mindest

C560-001 A=1,4 B=0,6 max. pin=0,4 mm

(A=0.05 B= 0.02 max. pin= 0.01 in)

C560-002 A=1,8 B=0,8 max. pin=0,6 mm

(A=0.07 B= 0.03 max. pin= 0.02 in)

C560-003 A=2,7 B=1 max. pin=0,8 mm

(A=0.1 B= 0.04 max. pin= 0.03 in)

C560-004 A=3,2 B=1,3 max. pin=1,1 mm

(A=0.12 B= 0.05 max. pin= 0.04 in)

C560-009 A=5 B=1,3 max. pin=1,1 mm

(A=0.19 B= 0.05 max. pin= 0.04 in)

C560-014 A=2,5 B=0,8 max. pin=0,6 mm

(A=0.09 B= 0.03 max. pin= 0.02 in)

www.jbctools.com

49

Page 50

DR560 Wechsel des Heizelements

1. Entnehmen

Schrauben Sie die

Abdeckung ab (a), öffnen

Sie die Schraube (b)

und entnehmen Sie das

Heizelement (c).

Um diese Operation durchzuführen, die Station ausschalten oder das Werkzeug vom Netz trennen.

2. Einsetzen

Setzen Sie das neue

Heizelement ein (a), befestigen

Sie die Schraube (b) und

schrauben Sie die Abdeckung

wieder fest (c).

Wichtig

Bevor Sie das Glasrohr

einsetzen, stellen Sie sicher,

daß die innere Dichtung

eingesetzt ist.

b

a

c

c

b

a

!

!

Wichtig

Setzen Sie das Heizelement

bis zur Markierung ein, um

eine korrekte Verbindung zu

gewährleisten .

50

Page 51

DR560 Reinigung des Glasrohrs

1. Abdeckung entfernen

3. Einsetzen des Glasrohrs

Filter prüfen

Abdeckung

Innendichtung

prüfen

2. Reinigung

Der Filter und die Innendichtung müssen

geprüft werden und bei Verschmutzung oder

Beschädigung ausgetauscht werden.

Entnehmen Sie die Spirale, um das Innere

des Glasrohrs mit dem zum Lieferumfang

gehörenden Stab zu reinigen.

Die Abdeckung muss entfernt werden, wenn

der Entlötkolben DR560 in senkrechter

Position steht.

Das Glasrohr muss mit korrekt ausgerichtetem

- zwischen den 2 auf dem Glasrohr markierten

Linien - Spiralfilter eingesetzt werden.

Dann muss die ganze Einheit durch

Einschrauben der Abdeckung verschlossen

werden.

Markierungen

www.jbctools.com

51

Page 52

Entlöt-Verfahren

Benutzen Sie eine Spitze mit einem größeren Durchmesser als das Lötauge, um so maximale

Saugleistung und thermische Effizienz zu erzielen.

Platzieren Sie die

Spitze mit dem

Baugruppenterminal

innerhalb der Öffnung.

Nach Betätigung der Entlöttaste tritt eine kurze Verzögerung ein, bis die eigenständige Vakuumpumpe abschaltet. Dies gewährleistet, dass der Vakuumkreislauf vollständig leer ist. Falls nach

dem Entlöten irgendein Lotrest auf einem Terminal zurückbleiben sollte, mit frischem Lot löten

und den Entlöt-Vorgang wiederholen.

Wenn das Lot flüssig wird,

drehen Sie vorsichtig

die Entlötspitze, sodass

das Baugruppenterminal

angehoben werden kann.

Drücken Sie lang genug den

Pumpenknopf, um das Lot zu

entfernen.

3. Saugen1. Einsetzen 2. Drehen

Die Ansaugleitung sollte regelmäßig mit dem größten Stab gereinigt werden.

DR560 Spitzenpflege

Wichtig

Betätigen SIE NICHT den Druckknopf der Vakuumpumpe, während die Entlötspitze verzinnt

wird, da der aus dem Flussmittel entweichende Rauch schnell die Leitungen und den Luftfilter

blockieren würde.

52

Page 53

Peripherals Port 2-DR

17:14

Pedal None

Module None

Module

MVE_a

None

1. Wählen Sie das Modul aus der Liste der

Anschlüsse von Peripheriegeräten aus.

Denken Sie daran, dass Ihr erster

Anschluss als “a”, der zweite als “b”, usw.

bezeichnet werden (d.h. MVE_a, MVE_b,...)

2. Drücken Sie Menu oder Back, um die

Änderungen zu speichern. Nach

vorgenommener Konfiguration, können Sie

die Moduleinstellungen ändern, indem Sie

in das Menü Peripherals gehen.

MVE Startkonfiguration

Peripherals

Nachdem die Druckluft Entlöt Modul (MVE-A) angeschlossen wurde, gehen Sie

in das Menü Peripherals und wählen den Port aus, den Sie mit dem Modul

verbinden möchten.

MVE Wechsel der

Pumpenfilter

- Halten Sie das Gehäuse sauber, indem Sie

einen feuchten Lappen benutzen. Bitte darauf

achten dass Sie ein weiches Tuch für die

Vorderseite benutzen.

- Überprüfen Sie regelmäßig alle Kabel und

Schlauchanschlüsse. Halten Sie die Filter sauber,

um einwandfreie Lotabsaugung zu gewährleisten

und tauschen Sie sie bei Bedarf aus.

Ersatzfilter

Ref. 0005966

Baumwollfilter

Ref. 0781046

Saugfilter

Ref. 0821830

O-Ring

Ref. 0007717

Filterdeckel

Ref. 0004710

Ausströmfilter

Ref. 0008446

Herausziehen des

Druckluftschlauchs

- Üben Sie Druck auf den Ausrückring aus, um

den Druckluftschlauch herauszuziehen.

Ausrückring

Wichtig: Zum Öffnen des Ansaugfilters keine Gegenstände mit scharfer Spitze verwenden.

1

2

www.jbctools.com

53

Page 54

Port

2

T245

17:14

Sleep

Tool in the stand

Actual Temp. 180ºC

Delay to hibernation: 29:30

Port

2

T245

17:14

Hibernation

Actual Temp. 25ºC

350

ºC

Port

2

Power

45%

T245

17:14

Selected 350ºC

3. Hibernation

Betrieb

Das exklusive Heizsystem von JBC

Unsere revolutionäre Technik ist dazu in der Lage, außerordentlich schnell die Spitzentemperatur zu

erreichen. Dies bedeutet, dass der Benutzer bei geringerer Temperatur arbeiten und die Lötqualität

verbessern kann. Die Spitzentemperatur wird zudem dank der Betriebsarten Sleep und Hibernation

weiter gesenkt, wodurch die Spitzenstandzeit verfünffacht wird.

1. A rbeit

2. Sleep

Wenn das Werkzeug aus der

Ablage genommen wird, wird

die Spitze auf die ausgewählte

Temperatur aufgeheizt.

Wenn sich das Werkzeug in

der Ablage befindet, wird die

Temperatur auf voreingestellte

Sleep-Temperatur abgesenkt.

Nach längeren Zeiträumen

der Untätigkeit wird die

Stromversorgung abgeschaltet

und das Werkzeug kühlt auf

Raumtemperatur ab.

Menü Werkzeuge:

· Temperaturgrenzwerte

einstellen

· Temperaturstufen auswählen

Menü Werkzeuge:

· Sleeptemperatur einstellen

· Sleepverzögerung einstellen

(von 0 bis 9 Min. oder kein

Sleepzustand)

Menü Werkzeuge:

· Hibernationverzögerung

einstellen (von 0 bis 60 Min.

oder keine Hibernation)

Lange Zeit in

der Ablage

54

Page 55

350

ºC

Port

2

Power

45%

Temp. Levels

T245

250 350 380

17:14

USB-Flashspeicher ist angeschlossen.

Station wird von einem PC gesteuert.

Station wird von einem Roboter gesteuert.

Aktualisierung Stationsoftware. Drücken

Sie INFO, um den Prozess zu starten.

Warnung. Drücken Sie INFO zur

Störungsbeschreibung.

Fehler. Drücken Sie INFO zur

Störungsbeschreibung, des Fehlertyps

und emp-fohlenen Vorgehensweise.

Systemmeldungen (Statusleiste)Menüoptionen

Station

Informationen

Leistungsanzeige

Angeschlossenes

Werkzeug

Arbeitsbildschirm

Statusleiste

Die DDE-B bietet eine intuitive Benutzerschnittstelle, die schnellen Zugriff auf die Stationsparameter

gewährt. Original-PIN: 0105

Port ändern

Angezeigt, wenn

Temperaturstufen

aktiviert sind

Station

Werkzeuge Zähler

ResetGraphics

Peripheriegeräte

Drücken Sie INFO für jede ParameterBeschreibung.

www.jbctools.com

55

Page 56

Port 1 - T245

450

400

350

300

250

150

100

50

200

Power Temp

17:14

Beim Drücken von Graphics im Haupt-MENU, werden für jeden Port in Echtzeit

Temperatur- und Leistungsangaben eingeblendet. Dies hilft Ihnen bei der

Entscheidung, welche Spitze Sie für die beste Qualität der Lötverbindungen

benutzen müssen.

Prozessanalyse

Grafiken exportieren

Stecken Sie einen USB Flashspeicher in den

USB-A-Anschluss, um mit dem Speichern Ihres

Lötprozesses im csv-Format zu beginnen.

Graphics

Temperatur

Leistung (%)

Siehe andere

Portgrafik

56

Page 57

Lötnetz

So viele Stationen, wie Ihr PC bewältigen kann, aus der Ferne steuern und überwachen.

Funktionen:

- Alle Stationsparameter von Ihrem PC aus einstellen.

- Stationsgruppen organisieren und alle ihre Parameter zur selben Zeit einstellen.

- Spezifische Konfigurationen für spätere Anwendungen speichern.

- Die Lötgrafiken der Stationen auf Ihrem PC analysieren und sie exportieren.

1. Laden Sie die JBC Manager Software und das Benutzerhandbuch herunter unter

www.jbctools.com/manager.html

2. Schließen Sie die Stationen per USB-B-Anschluss an und der PC wird sie automatisch erkennen.

3. Die Meldung wird auf der Station angezeigt werden.

irgendeine

JBC

Station

USB Hub

JBC

Manager

Software

www.jbctools.com

57

Page 58

1. Schließen Sie das Werkzeug mit einem CHB-A Konverter an den Stationsport an.

2. Verbinden Sie Ihr Robotersystem mit der Roboterbuchse (RJ12) der Station. DB9-RJ12 Adapter

nur bei Bedarf verfügbar (Ref. 0013772).

3. Aktivieren Sie die Roboteroption in den Stationseinstellungen und die Mitteilung wird angezeigt

werden:

4. Gestalten Sie Ihre Roboter-Befehle gemäß dem Roboter-Kommunikations-Protokoll, verfügbar

auf der Website www.jbctools.com/jbcsoftware-menu-115.html.

Steuern und Überwachen der Station unter Nutzung eines Robotersystems.

Arbeit mit Robotern

Steuer-gerät

Roboter

Stationssoftware aktualisieren

1. Laden Sie den JBC Update File herunter

unter www.jbctools.com/software.html und

speichern Sie ihn auf einem USB-Flashspeicher.

Möglichst einer ohne andere Dateien.

CHB-A

Konverter

Ref. CHB-A

2. Stecken Sie den USB-Flashspeicher in die

Station. Das Symbol wird während des

Aktualisierens angezeigt.

RS-232

Buchse

JBC

Update File

58

Page 59

Wartung

Vor der Durchführung von Wartungsarbeiten oder Einlagerung die Geräte immer erst auskühlen lassen.

1. Ziehen Sie die Sicherungshalterung

heraus und entnehmen Sie die Sicherung.

Falls notwendig, benutzen Sie ein

Werkzeug, um sie herauszudrücken.

2. Drücken Sie die neue Sicherung in die

Halterung und setzen Sie sie erneut in die

Station ein.

- Reinigen Sie den Bildschirm der Station mit

einem Glasreiniger oder mit einem feuchten

Lappen.

- Benutzen Sie einen feuchten Lappen, um

das Gehäuse und das Werkzeug zu reinigen.

Alkohol darf nur zur Reinigung der Metallteile

benutzt werden.

- Regelmäßig überprüfen, dass die metallischen

Teile des Werkzeugs/der Ablage sauber

sind, damit die Station den Werkzeugstatus

erkennen kann.

- Halten Sie die Oberfläche der Spitze vor

der Aufbewahrung sauber und verzinnt, um

Spitzenoxidation zu vermeiden. Angerostete

und verschmutzte Oberflächen mindern den

Wärmedurchgang zur Lötstelle.

- Überprüfen Sie regelmäßig alle Kabel und

Schläuche.

Sicherungshalterung

Sicherungshalterung

Sicherung

- Jedes defekte oder schadhafte Teil austauschen. Nur Original-Ersatzteile von JBC verwenden.

- Reparaturen dürfen nur von dem Vertragskundendienst von JBC durchgeführt werden.

- Eine durchgebrannte Sicherung wie folgt

austauschen:

Regelmäßig reinigen

www.jbctools.com

59

Page 60

Sicherheit

- Die Anlagen für keinen anderen Zweck verwenden als zum Löten oder Reparieren. Unsachgemäße

Verwendung kann Feuer hervorrufen.

- Das Netzkabel muss in zugelassene Steckdosen eingesteckt werden. Vergewissern Sie sich vor

der Benutzung, dass sie korrekt geerdet ist. Beim Herausziehen am Stecker ziehen, nicht am Kabel.

- Nicht an aktiven Bauteilen arbeiten.

- Das Werkzeug sollte bei Nichtgebrauch in der Ablage abgestellt werden, um die Betriebsart

Ruhe auszulösen. Die Lötspitze, der metallische Teil des Werkzeugs und die Ablage können

noch heiß sein, wenn die Station ausgeschaltet ist. Gehen Sie vorsichtig vor, sogar wenn Sie die

Ständerposition justieren.

- Das eingeschaltete Gerät niemals unbeaufsichtigt lassen.

- Die Kühlungsgitter nicht abdecken. Hitze kann entzündliche Stoffe entzünden.

- Um Irritationen zu vermeiden keinen Flussmittelkontakt mit der Haut oder den Augen.

- Sich vor dem beim Löten entstehenden Rauch in Acht nehmen.

- Ihren Arbeitsplatz sauber und aufgeräumt halten. Bei der Arbeit geeignete Schutzbrille und

Handschuhe tragen, um gesundheitliche Schäden zu vermeiden.

- Im Umgang mit flüssigen Zinnrückständen muss äußerste Sorgfalt walten.

- Dieses Gerät kann von Kindern über acht Jahren und auch Personen mit körperlicher, sinnlicher

oder geistiger Behinderung oder mangelnder Erfahrung benutzt werden, nachdem ihnen

angemessene Überwachung oder Einweisung hinsichtlich der Verwendung des Geräts und der

damit verbundenen Risiken gegeben worden ist. Kinder dürfen mit dem Gerät nicht spielen.

- Wartung darf nicht von Kindern durchgeführt werden, wenn sie hierbei nicht beaufsichtigt werden.

Die Sicherheits-Leitlinien müssen unbedingt eingehalten werden, um

elektrischen Schlag, Verletzung, Feuer oder Explosion zu vermeiden.

60

Page 61

Spezifikationen

Premium Rework Station with Pneumatic Pump

Löt-/Entlötstation mit Druckluftpumpe

DDVE-1B / DDVE-2B / DDVE-9B

- Gesamtgewicht: 8,3 kg (18.4 lb)

DDE-1B 120 V 50/60 Hz. Eingangssicherung: 4 A. Ausgang: 23,5 V

DDE-2B 230 V 50/60 Hz. Eingangssicherung: 2 A. Ausgang: 23,5 V

DDE-9B 100 V 50/60 Hz. Eingangssicherung: 5 A. Ausgang: 23,5 V

- Gewicht: 3,8 kg (8.4 lb)

- Abmessungen: 148 x 120 x 232 mm (5.83 x 4.72 x 9.13 in)

- Spitzenausgangsleistung: 150 W pro Werkzeug

- Temperaturbereich: 90-450 °C (190-840 ºF)

- Temperaturstabilität ohne Last (stillstehende Luft) ±1,5 ºC (±3 ºF)

- Spitze-Erde-Widerstand: <2 Ohm

- Spitze-Erde-Spannung: <2 mV RMS

- Umgebungsbetriebstemperatur: 10-40 ºC (50-104 ºF)

- USB-A / USB-B / Peripheriegeräte-Buchsen

- RJ12-Buchse für Roboter

MVE-A

- Gewicht: 0,7 kg (1.54 lb)

- Abmessungen: 145 x 55 x 225 mm (5.71 x 2.17 x 8.86 in)

- Druckluftversorgungsbereich: 4-6 bar

- Vakuum bei 6 bar: 90 % / 680 mmHg / 26,8 inHg

- Durchflussrate: 15 slpm

Erfüllt EG-Normen

ESD-gerechtes Gehäuse “skin effect”

www.jbctools.com

61

Page 62

Exploded View · Despiece · Explosionszeichnung

62

Page 63

www.jbctools.com

63

Page 64

0017356-051

7

Garantie

Die 2-Jahres-Garantie von JBC

ersteckt sich auf das Gerät bei

Herstellungsfehlern, einschließlich

Fehlern der Verarbeitung und dem

Ersatz defekter Teile und deren

Austausch.

Die Garantie gilt nicht für

Produktverschleiß durch normale

Nutzung oder durch falsche

Anwendung.

Damit die Garantie Gültigkeit

erlangt, muß das Gerät an den

Händler, bei dem es gekauft

wurde, zurückgesand weden

(Porto bezahlt).

Dieses Produkt sollte nicht mit dem Hausmüll entsorgt werden.

In Übereinstimmung mit der europäischen Richtlinie 2012/19/EU müssen elektronische Geräte am

Ende ihrer Lebensdauer eingesammelt und einem autorisierten Recyclingbetrieb zugeführt werden.

Garantía

Esta garantía de 2 años cubre este

equipo contra cualquier defecto

de fabricación, incluyendo la

sustitución de partes defectuosas

y mano de obra.

La garantía no cubre el desgaste

del producto por uso o mal uso.

Para que esta garantía sea válida,

el equipo debe ser devuelto, a

portes pagados, al distribuidor

donde se compró.

Este producto no debe desecharse en la basura.

De acuerdo a la directiva europea 2012/19/UE, los equipos electrónicos al final de su vida se deberán

recoger y trasladar a una planta de reciclaje autorizada.

Warranty

JBC’s 2 year warranty covers

this equipment against all

manufacturing defects, including

the replacement of defective parts

and labour.

Warranty does not cover product

wear or misuse.

In order for the warranty to be

valid, equipment must be returned,

postage paid, to the dealer where

it was purchased.

This product should not be thrown in the garbage.

In accordance with the European directive 2012/19/EU, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

www.jbctools.com

Loading...

Loading...