Page 1

www.jbctools.com

Reference Guide

CD

SOLDERING

STATION

Page 2

CD

SOLDERING

STATION

Reference Guide

Reference Guide

T210

T245

SOLDERING HANDPIECES

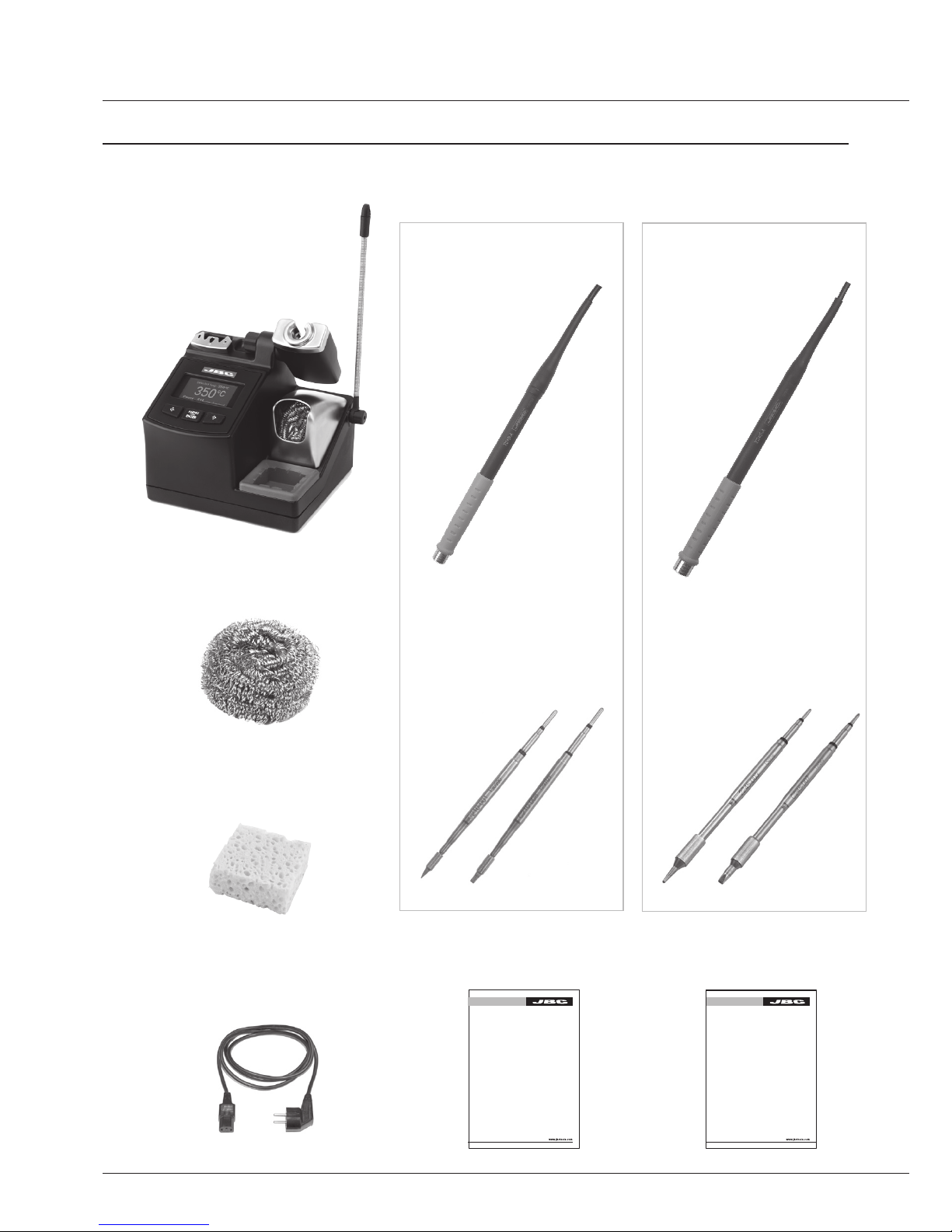

CL6210 Brass Wool

S0331 Sponge

2

CD / SOLDERING STATION

CONTENTS

CONTROL UNIT

T210-A

SOLDERING IRON

C210001

C210008

CARTRIDGES

C245003

C245007

CARTRIDGES

MANUAL

POWER CORD

T245-A

SOLDERING IRON

MANUAL

SUPPLIED WITH

CD-2SB / CD-1SB / CD-9SB

SUPPLIED WITH

CD-2BB / CD-1BB / CD-9BB

Page 3

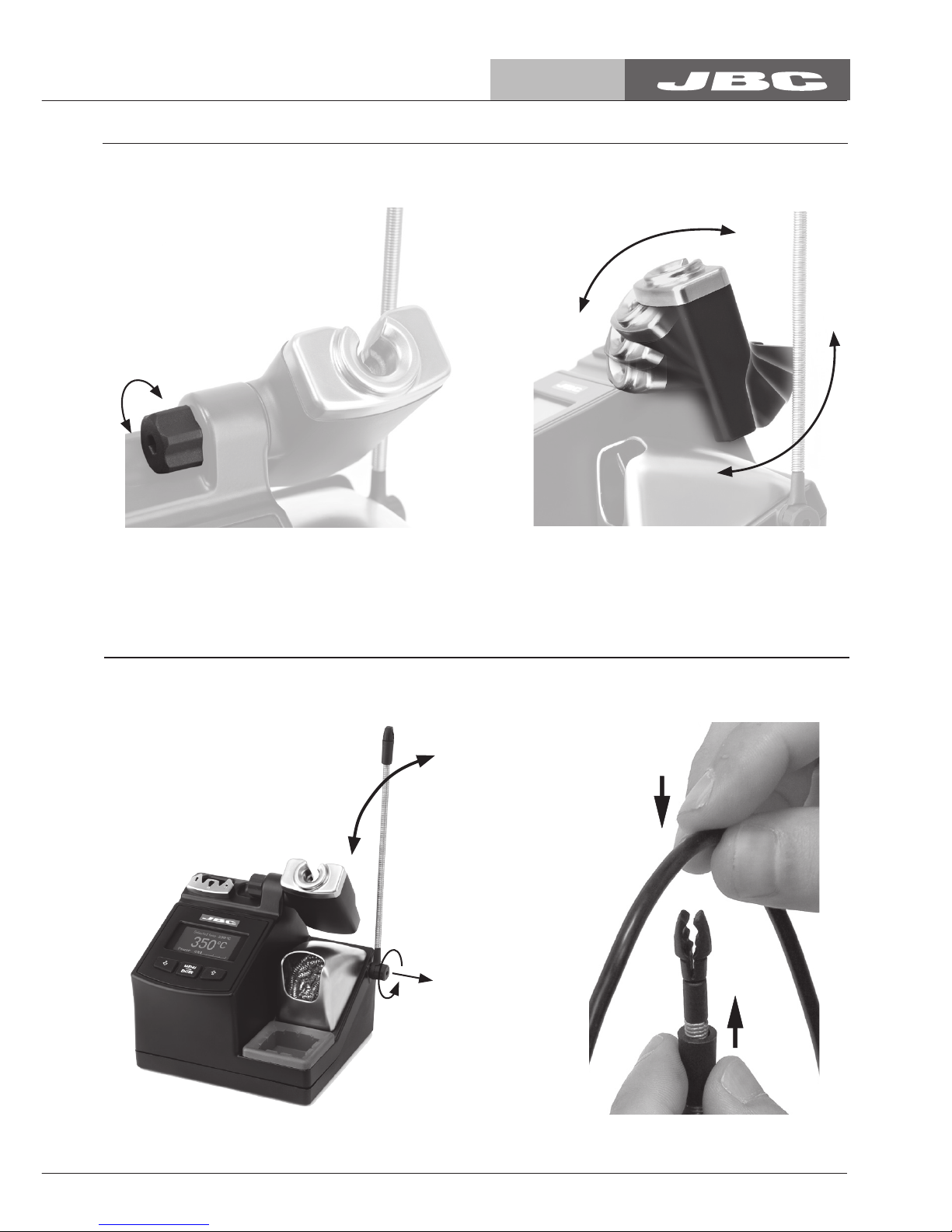

TOOL SUPORT ADJUSTEMENT

CABLE COLLECTOR

3

Page 4

4

SPONGE

The smoothest cleaning method.The sponge has to be kept wet (not soaked) using distilled water.

S0331 Sponge S0354 Sponge

CL6210 Brass Wool

Very effective clea n i ng

method. Leaves a small

layer of solder on the tip so

it prevents from oxidizing

between cleaning and re-

wetting.

Depending on your needs you can choose

between 3 diferent cleaning methods , Sponge,

Metal wool (brass or Inox) and brush.

TIPS CLEANING

Page 5

5

CL6205 Inox Wool

A bit more agressive on the tip than the brass

wool.

Provides a deeper cleaning on the tip.

TAPING

Tap smoothly the cartridge on the wiper profile

to remove the excess of solder

WIPING

Use the slots to wipe any posible particle

sticked on the tip

WIPER

OPTIONAL TIPS CLEANING

CL6220 Brushes

More agressive on the tip than the wool.

It cleans the tip very well but it should be used

gently.

Page 6

6

INSTALLATION

JBC stations intelligently manage the tool temperature:

Work mode: When the tool is used, pre-set work temperature is 350º C.

Sleep mode: When the tool is in the stand, the temperature goes down to 180º C (depending of the configuration).

Hibernation mode: After longer periods of inactivity (pre-set i.e 30 minutes), the power is cut off and the

tool cools down to room temperature.

Heat management increase tip life which reduces cost of ownership.

HEAT MANAGEMENT

Power Cord

Socket

Main switch

Equipotential

connection

CONTROL UNIT

T210-A or T245-A

SOLDERING IRON

Page 7

SETTINGS

0

c

Selected temp.

350 oC

P ow e r 1 0%

350

Decrease & move down Increase & move up

Tip temperature

% Instant power supplied to the tool

Access Menu

&

Confirm

Selection

WORKING

Main me nu

Count er s

Tool se tt in gs

Exit

1 Reset settings

2

Station settings

3

Tool settings

1

Plugged hours 0

2

Working hours 0

3

Sleep hours 0

1

Fix one temp -----

2

Temp levels set OFF

3

Sleep delay 0 min

4 Counters

5

Program version

4

Hibernation hours 0

5

No tool hours 0

6 Sleep cycles

0

4

Sleep temp 1800C

5

Hibernation delay 30 min

6

Temp adjust + O OC

Tool 245

Tool 245

Back

Back

ORIGINAL PIN: 0105

Stati on set ti ng s

1 Temp unit

Celsius

2

Maximum temp 4000C

3

Minimum temp 2000C

4

Help text OFF

5 Beep ON

6 Power limit 130W

7

Change PIN

Back

7

Page 8

WARRANTY

JBC’s 2 years warranty guarantees this equipment against all manufacturing defects, covering the replacement of defective parts

and all necessary labour.

Warranty does not cover product wear due to use or mis-use.

In order for the warranty to be valid, equipment must be returned,

postage paid, to the dealer where it was purchased enclosing this

fully filled in, sheet.

MORE INFORMATION

www.jbctools.com

SERIAL Nº

STAMP OF DEALER

DATE OF PURCHASE

0010333-0211

TECHNICAL SPECIFICATIONS

- Temperature selection from 90 to 450°C (±5%).

- Power: 75W.

- Safety transformer, mains separator and double isolation, with temperature protection fuse.

- CD-2BB / CD-2SB 230V control unit. Input: 230V 50/60Hz. Output: 24V.

- CD-1BB / CD-1SB 120V control unit. Input: 120V 50/60Hz. Output: 24V.

- CD-9BB / CD-9SB 100V control unit. Input: 100V 50/60Hz. Output: 24V.

- Total weight of unit: 2,6 Kg.

- Complies with CE standards on electrical safety, electromagnetic compatibility and ESD protected housing

“skin effect”.

- RoHS compliant.

- Equipotential connector and the tool tip are connected to station mains ground supply for ESD protection.

This product should not be

thrown in the garbage.

Loading...

Loading...