Page 1

Index Page

English 1

Español 25

Français 49

Deutsch 73

Italiano 97

0780448-0

AM 6000

REWORK STATION

Instructions manual

CE Version

Page 2

ENGLISH

1

We appreciate the confidence you have placed in JBC in purchasing this station.

It is manufactured to the most stringent quality standards in order to give you the

best possible service. Before turning on your station, we recommend you to read

these instructions carefully.

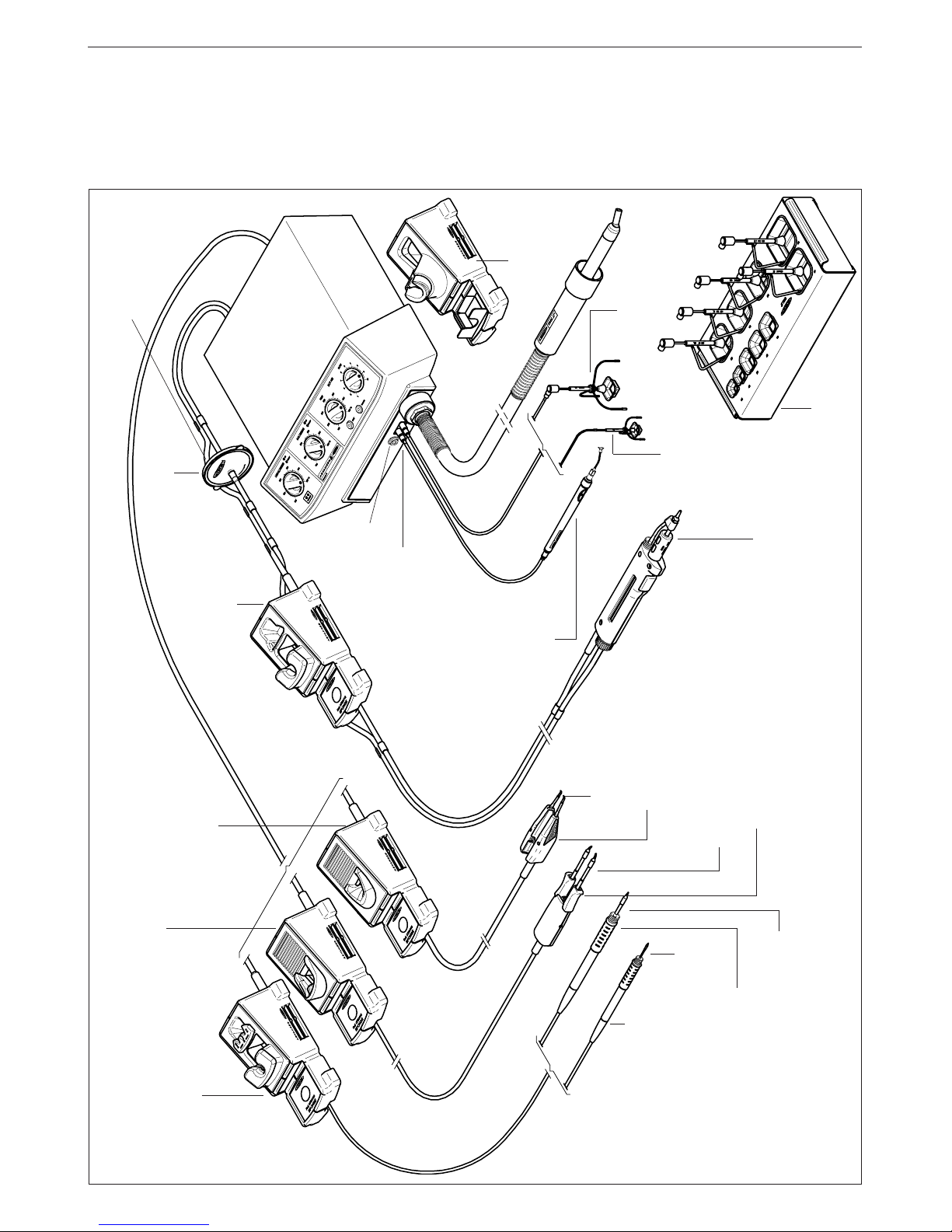

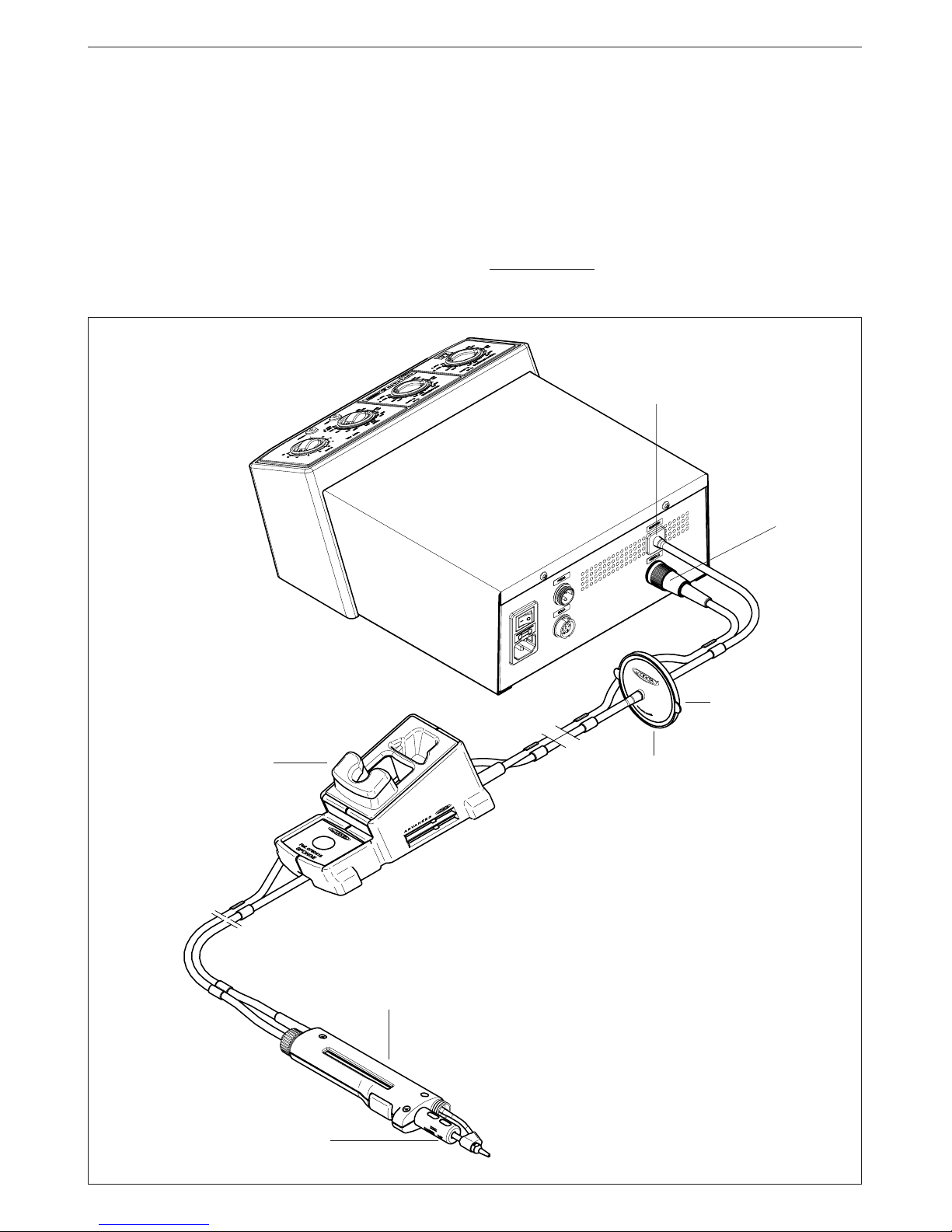

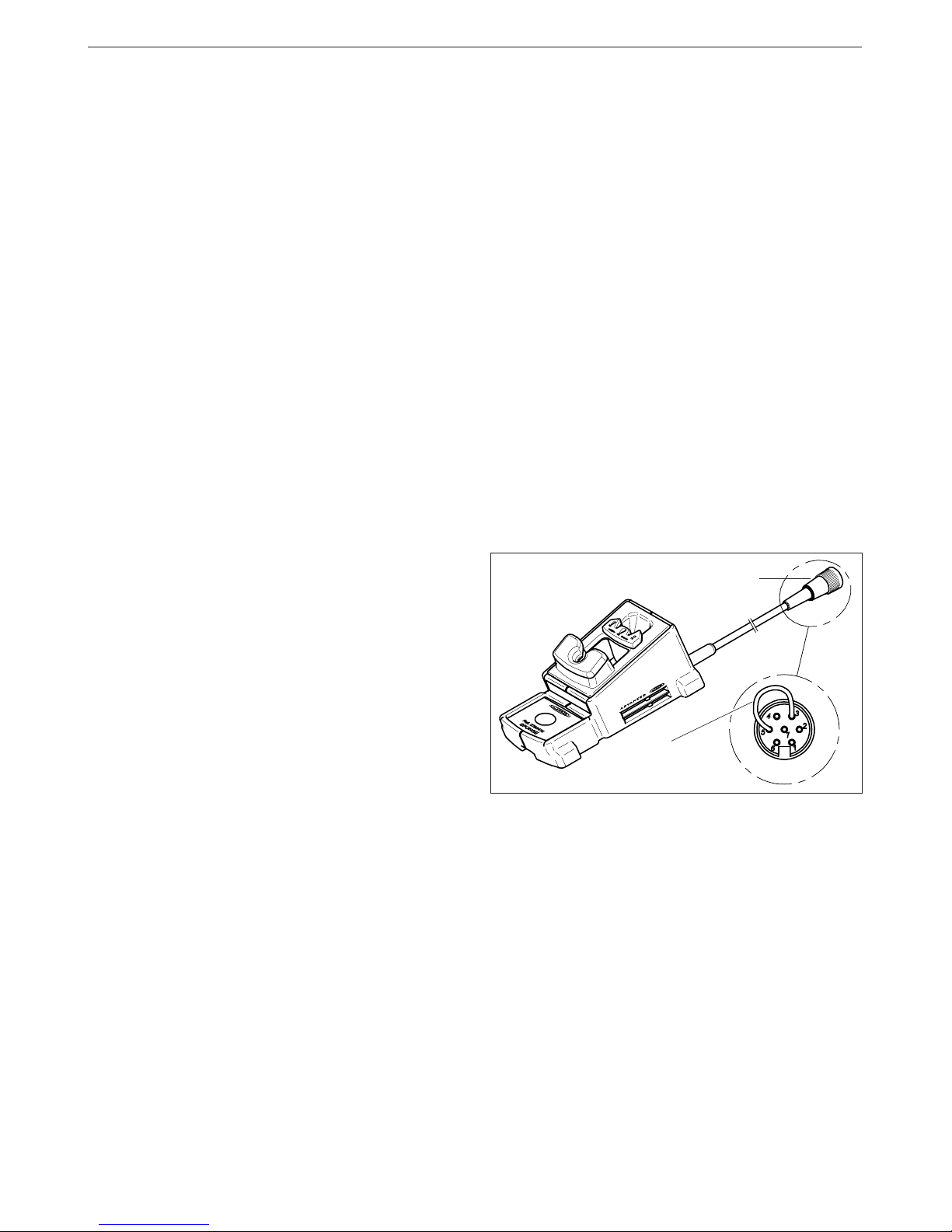

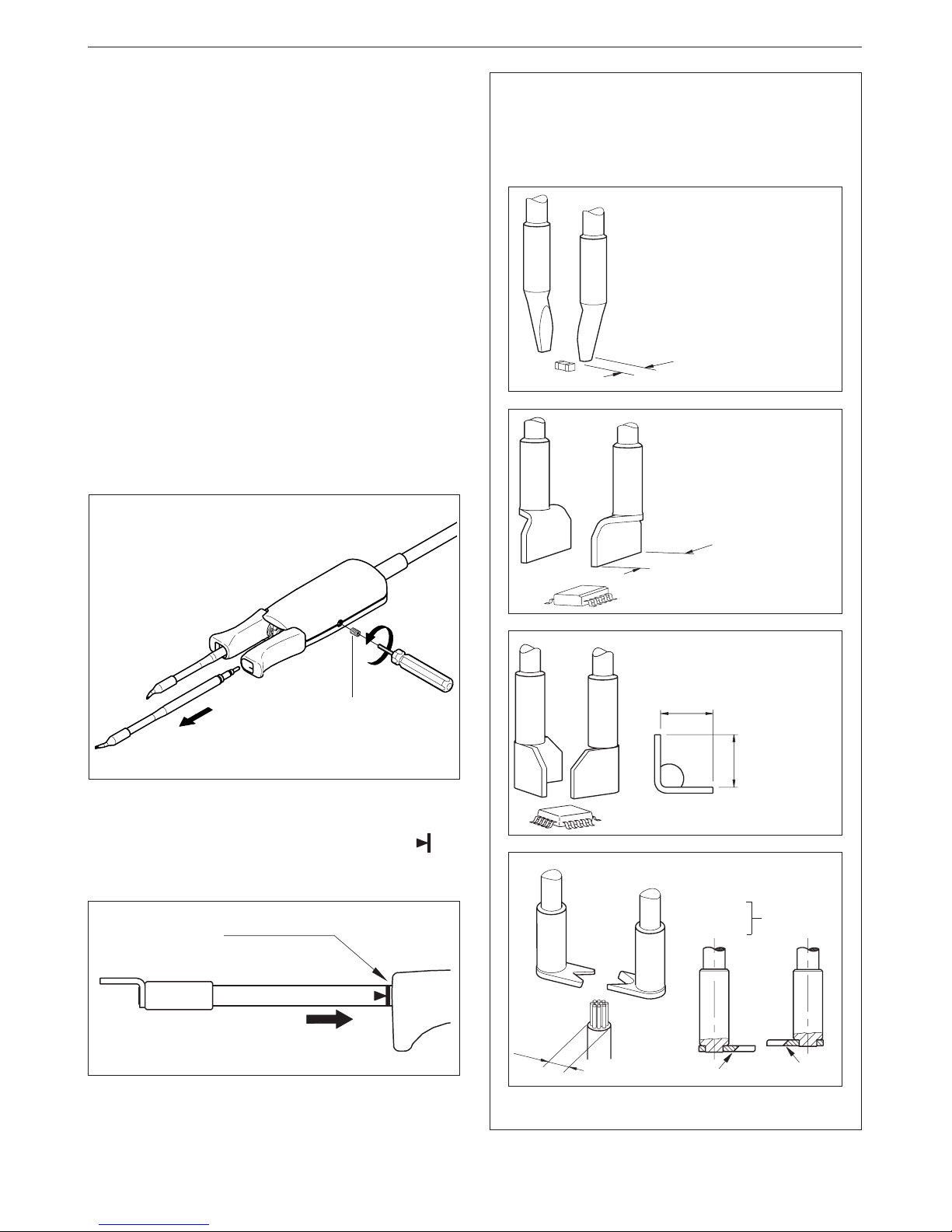

Extractor stand

Ref.0932845

Tripod 20

Ref.0932050

Tripod 40

Ref.0932250

Soldering iron stand

AD 8200

Ref.0268200

Desoldering iron

DR 5600

Ref.5600000

* Handpiece 2210

Ref.2210000

Cartridges 2245

Pick & Place

MP 2260

Ref.2260000

AM 6000

rework station

Pick & Place and extractors

vacuum selection

Heater stand JT 8700

Ref.0828700

Equipotential

terminal

* These elements are not

supplied with the station

Spare filters

Ref.0781046

* Hot tweezers stand

PA 8120

Ref.0748120

* Hot tweezers stand

PA 8110

Ref.0748110

Handpiece 2245

Ref.2245000

* Hot tweezers

PA 4200

Ref.4200000

* Cartridges for the hot tweezers PA 4200

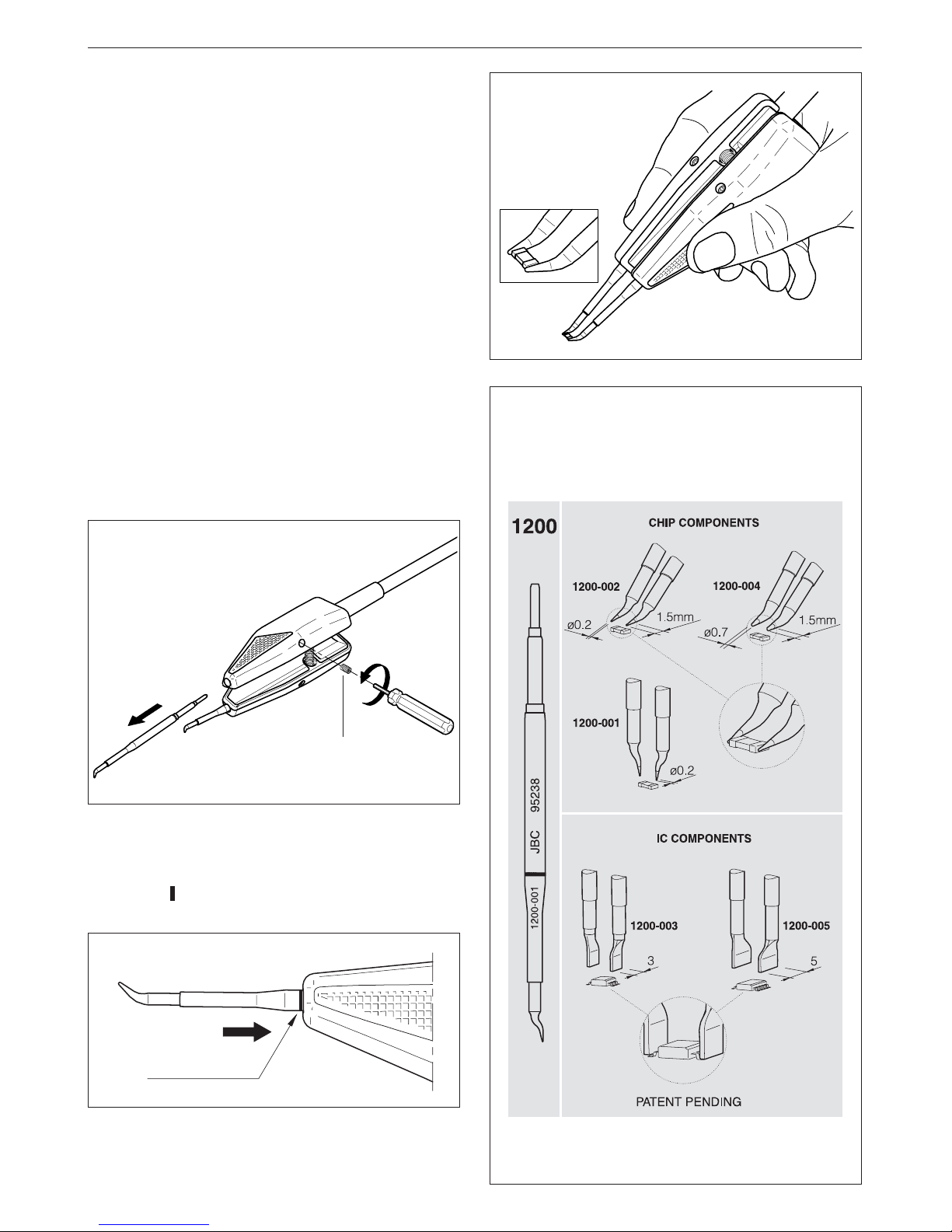

* Micro hot tweezers

PA 1200

Ref.1200000

* Cartridges 1200

Desoldering iron stand

DR 8500

Ref.0788500

External desoldering air filter

Ref.0821830

Page 3

2

ENGLISH

SPECIFICATIONS

The AM 6000 is a rework station for through-hole and

SMT boards.

- AM 6000 230V Ref. 6000200

It contains 4 modules which cover the main rework

tasks:

- Hot air for desoldering any size of SMD

components.

The station uses the exclusive JBC system,

based on protectors-extractors and hot-air flow,

which makes desoldering clean and quick,

concentrating the heat on the IC, and protecting

the rest of the circuit at the same time.

A medium-sized SMD can be desoldered in less

than 20 seconds.

- Desoldering SMTs and cleaning of through-hole

components and pads by using the desoldering

iron DR 5600, which contains a self-contained

vacuum pump.

- Pick & Place MP 2260 pencil by suction to aid

components positioning.

- Soldering of all types of components, with the

swift response, power and temperature recovery

of the Advanced series. You can connect the

Advanced 2010, 2210, 2045 or 2245 handpieces

and the hot tweezers PA 1200 or PA 4200.

The station’s components

- Control Unit with 900 W heater

- Handpiece 2245 Ref. 2245000

with the cartridge 2245-003 Ref. 2245003

- Desoldering iron DR 5600 Ref. 5600000

with the tip 5600-003 Ref. 5600003

- Pick & Place MP 2260 Ref. 2260000

Accessories for the heater:

- Heater stand JT 8700 Ref. 0828700

- Extractor stand Ref. 0932845

- Set of 5 protectors (Fig. 1, page 128)

- Set of 5 extractors (Fig. 2, page 128)

-2 tripods for the protectors (Fig. 1, page 128)

- Set of 4 suction cups Ref. 0930110

-3 nozzles

In order to make the nozzles removal easier, the

stand has a special bushing.(Fig. 3, page 128).

- Suction tube with connectors Ref. 0932330

- Pedal with cable and connector Ref. 0964551

Accessories for the handpiece:

- Soldering iron stand AD 8200 Ref. 0268200

Accessories for the desoldering iron:

- Desoldering iron stand DR 8500 Ref. 0788500

- External desoldering air filter Ref. 0821830

- Spare filters Ref. 0781046

- Set of accessories Ref. 0780593

Accessories for the Pick & Place:

- Set of suction cups Pick & Place Ref. 0940163

- Set of straight needles Ref. 0901546

- Set of bent needles Ref. 0861660

- Instruction manual Ref. 0780448

The AM 6000 station has the following

complementary products:

- Handpiece 2010 Ref. 2010000

- Handpiece 2210 Ref. 2210000

- Handpiece 2045 Ref. 2045000

- Micro hot tweezers PA 1200 Ref. 1200000

- Hot tweezers PA 4200 Ref. 4200000

Page 4

ENGLISH

3

OPERATION

Description of controls

- PEDAL:

Hot air is produced when it is held down.

Releasing it the heater is disconnected,

though the turbine continues to operate until

the air temperature falls below 100°C.

- BUTTONS:

Activates or desactivates the hot-air flow. After a

function-time of two minutes the hot-air flow

switches automatically off.

The red light indicates, that the heating element

is functioning. A malfunction is indicated by the

pulsing of the red led.

On/off switch for the self-contained suction pump.

The yellow light of the switch indicates that the

self-contained vacuum pump is activated.

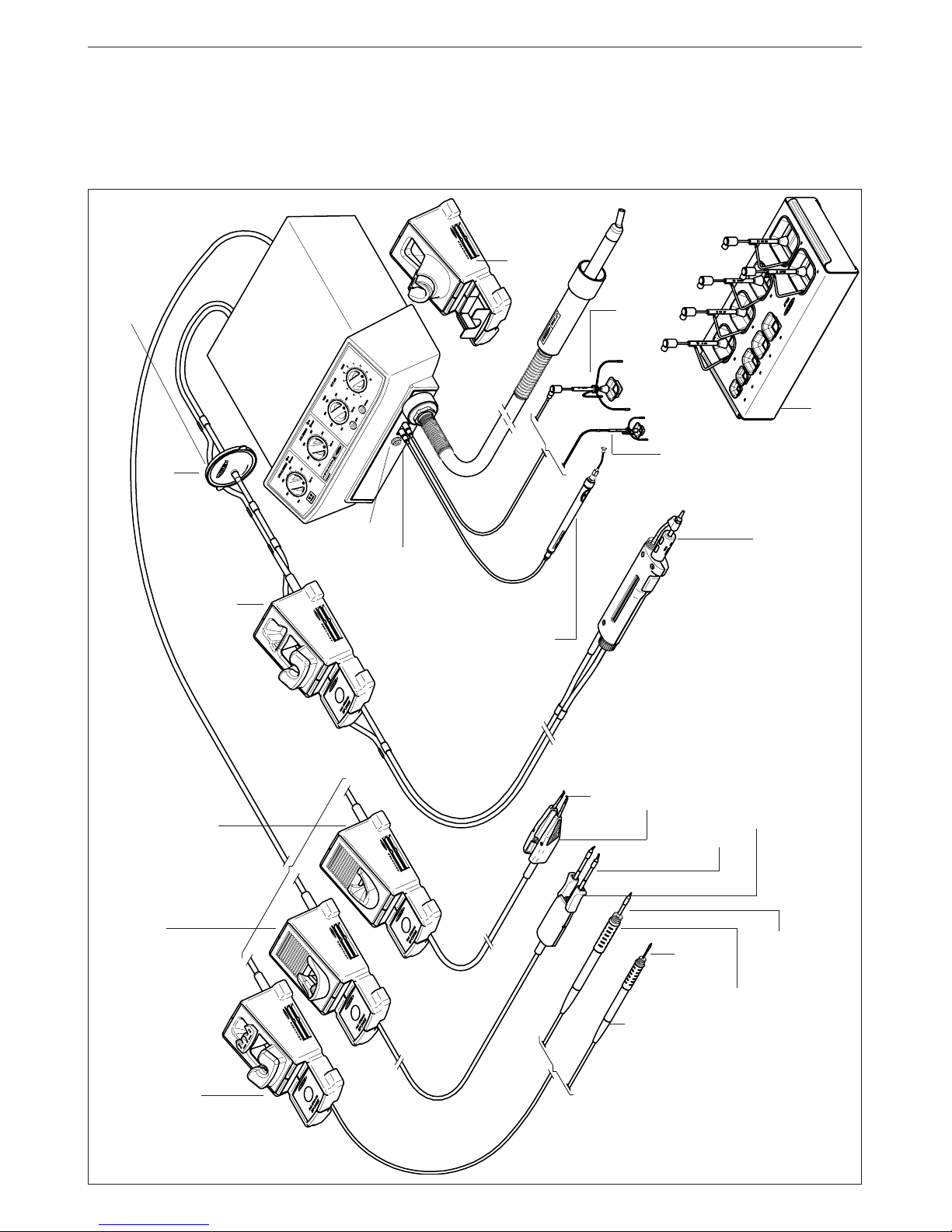

- CONTROLS:

TEMPERATURE

Allows fixing the temperature of the heater

between 150 and 455°C. The selected

temperatures are reference values which may

change depending on the distance between

the heating element and the nozzle.

Allows fixing the temperature of the soldering

and desoldering iron between 100 and 371°C.

AIR FLOW

This enables the air flow to be set on a scale

from 1 (corresponding to the lowest setting

of 6 l/min) to 10 (corresponding to the highest

of 45 l/min).

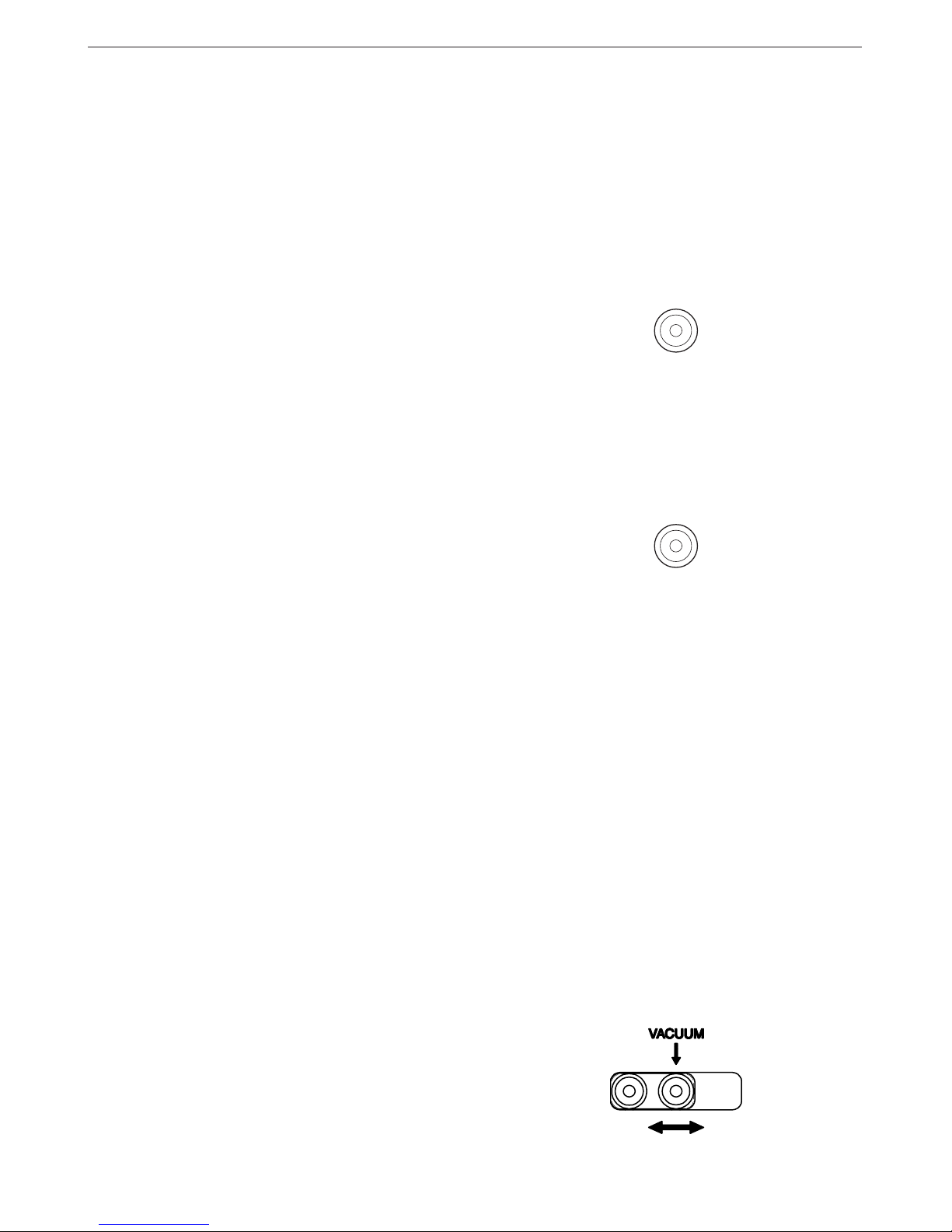

- VACUUM SELECTOR:

Two vacuum inlets avalaible, being active

the one that coincides with the arrow.

HEAT

VACUUM

Control Unit technical specifications

- Maximum power soldering iron 50W

- Maximum power desoldering iron 75W

- Power heating unit 900W

- Temperature selection of the soldering part :

100 to 371°C (±5%)

- Temperature selection of the desoldering part:

100 to 371°C (±5%)

- Temperature selection hot air:

150 to 455°C (±5%)

- Air flow regulation: 6-45 l/min

- Self-contained vacuum pump for holding ICs

- Station's maximum power: 1150W

- ESD protected housing.

Typical surface resistance: 105-1011Ohms/square

- Complies with CE standards on electrical safety,

electromagnetic compatibility and antistatic

protection.

- Equipotential connector is earth connected to the

plug feed of the station.

- Weight of complete unit: 17.6 kg

- In the SOLD. connector you can only connect

handpieces 2010, 2210, 2045 and 2245 and the

hot tweezers PA 1200 and PA 4200.

- In the DESOLD. connector you can only connect

the desoldering iron DR 5600.

Safety measures

- Incorrect use of this tool may cause fire.

- Be cautious when using the tool in places

where inflamable products are stored.

- Heat can fire up inflamable products even

when they are not at sight.

- Do not use when the atmosphere is explosive.

- Place the tool back on its stand in order to let

it cool down before you store it.

Page 5

4

ENGLISH

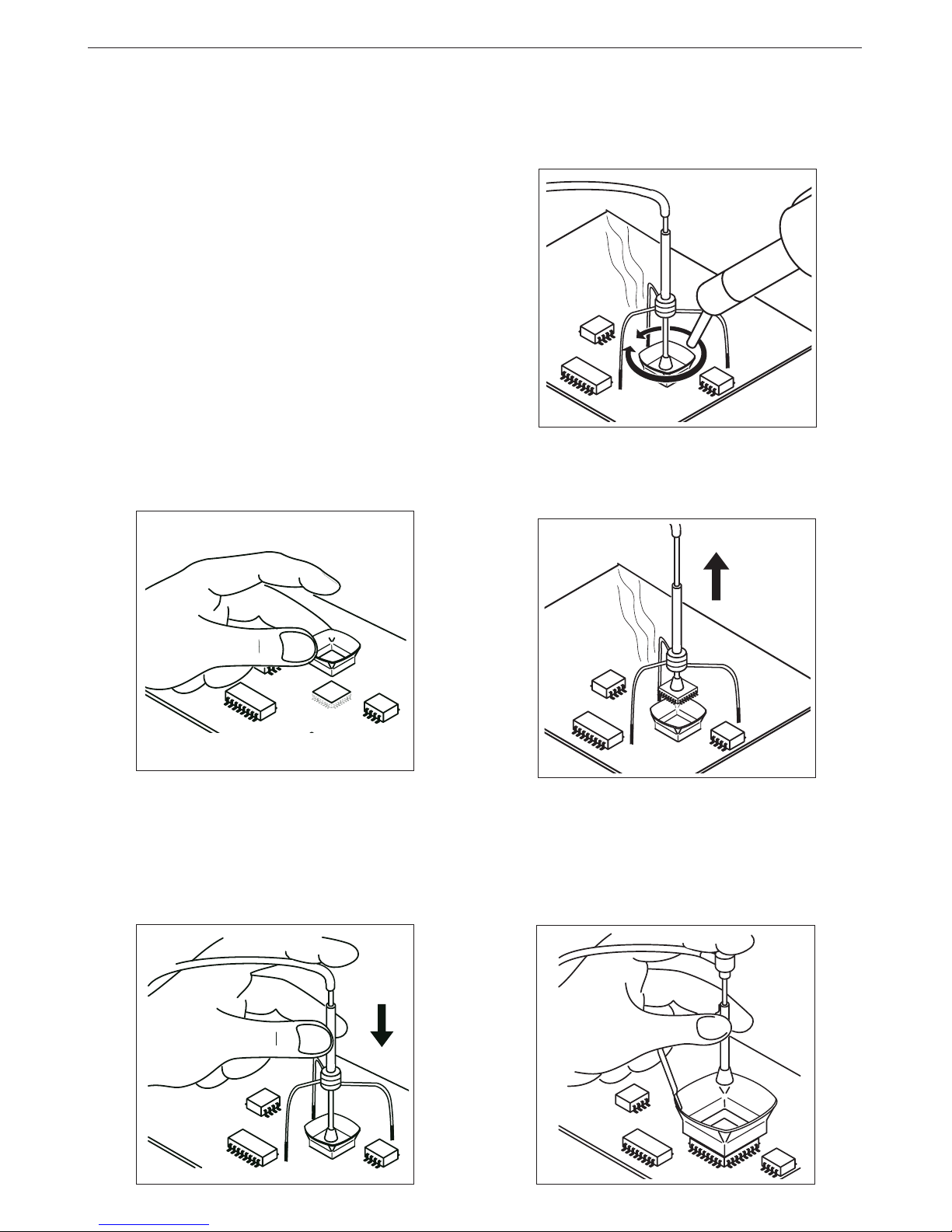

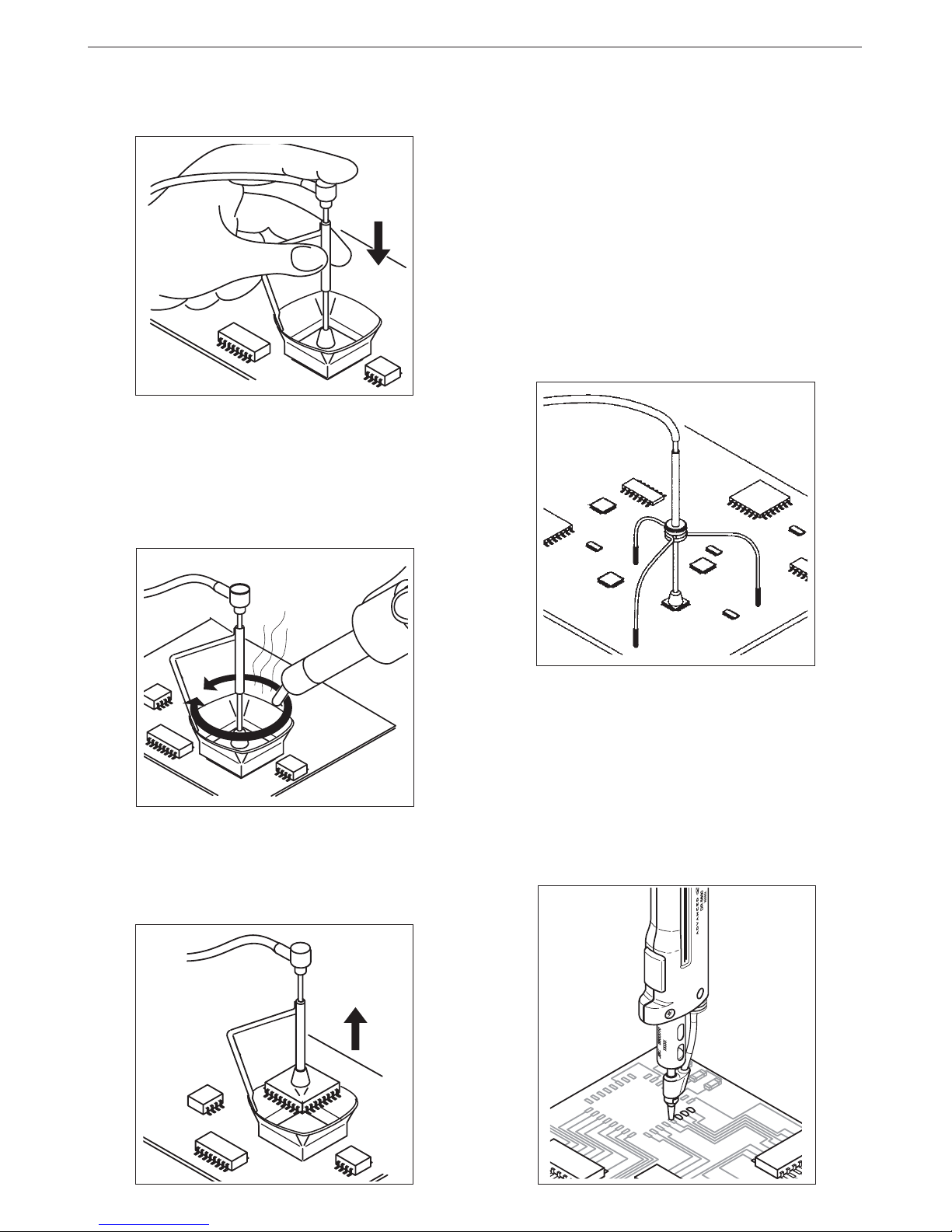

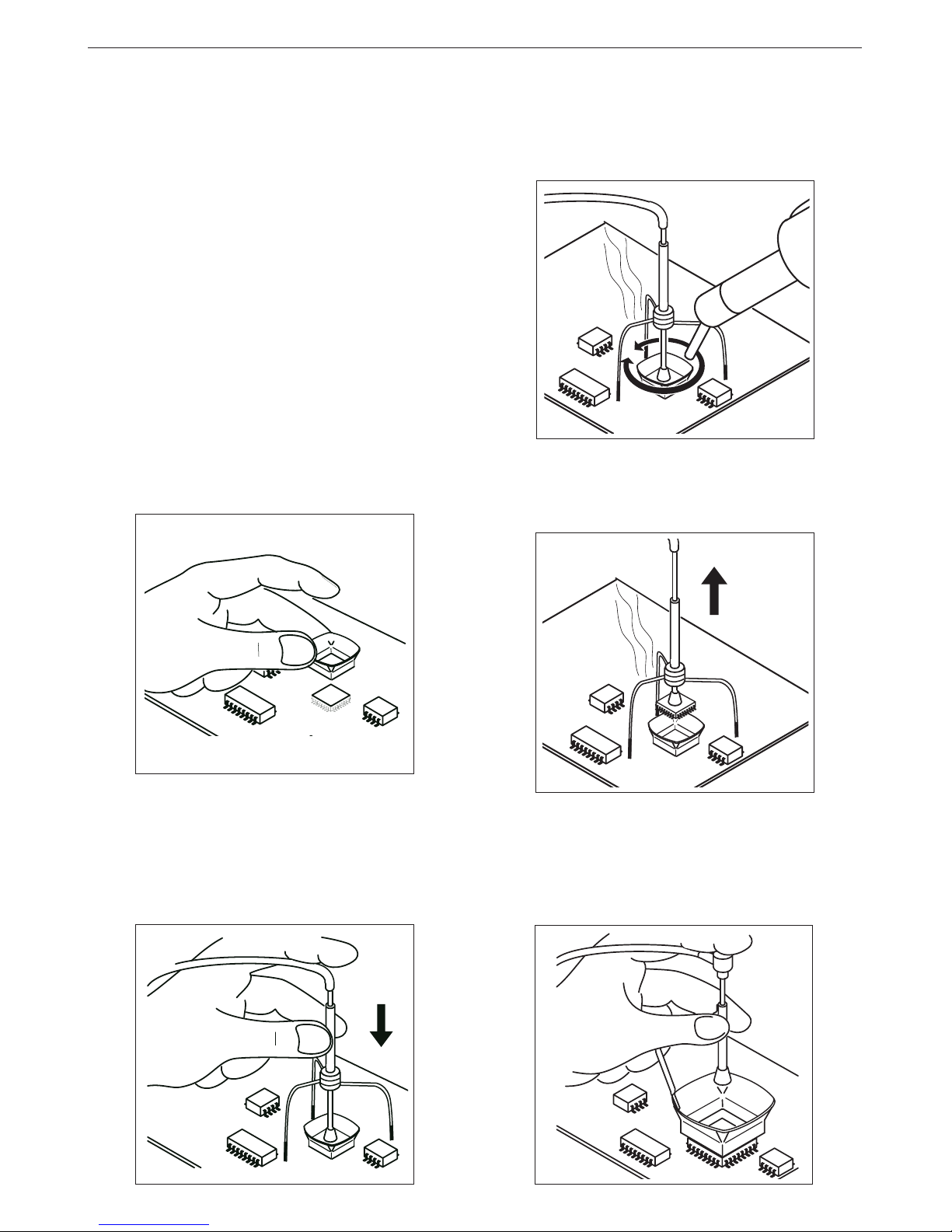

- Use the pedal or the HEAT button to start the

self-contained hot-air pump, directing it with a

circular movement at the component terminals

and taking care to distribute the heat evenly.

- When the soldering flux turns liquid the extractor

will automatically lift the component.

B) Extractor:

- Select extractor size in function of the IC to be

desoldered. Use the VACUUM button to start

the pump.

DESOLDERING PROCEDURE WITH THE

HEATER

We would also recommend the use of the nozzles of

larger diameter, reserving the smallest one (diam. 4

mm) for desoldering small components such as

resistors, condensers and the like, bearing in mind

that with this small nozzle the concentration of heat

is greater and care must be taken to avoid burning

the printed circuit; we recommend keeping below a

temperature of 350 °C and air flow of 6.

Depending on the size of the integrated circuit to be

desoldered, you will have to use:

A) Protector + tripod.

B)Extractor.

C) Tripod.

A) Protector + tripod:

- Select protector and tripod size in function of

the IC to be desoldered and place it over the

component.

- Use the VACUUM button to start the pump and

then fit the tripod. Press the sucker down until it

sticks onto the component.

Page 6

ENGLISH

5

There are different models of protectors and

extractors as accessories.

The measurements of all the extractors and

protectors are given on page 128 of instructions

manual.

C) Tripod:

For small components for which an extractor

cannot be used, we recommend use of tripod 20

Ref. 0932050, as shown in the figure.

Use the tripod 40 Ref. 0932250 for larger integrated

circuits.

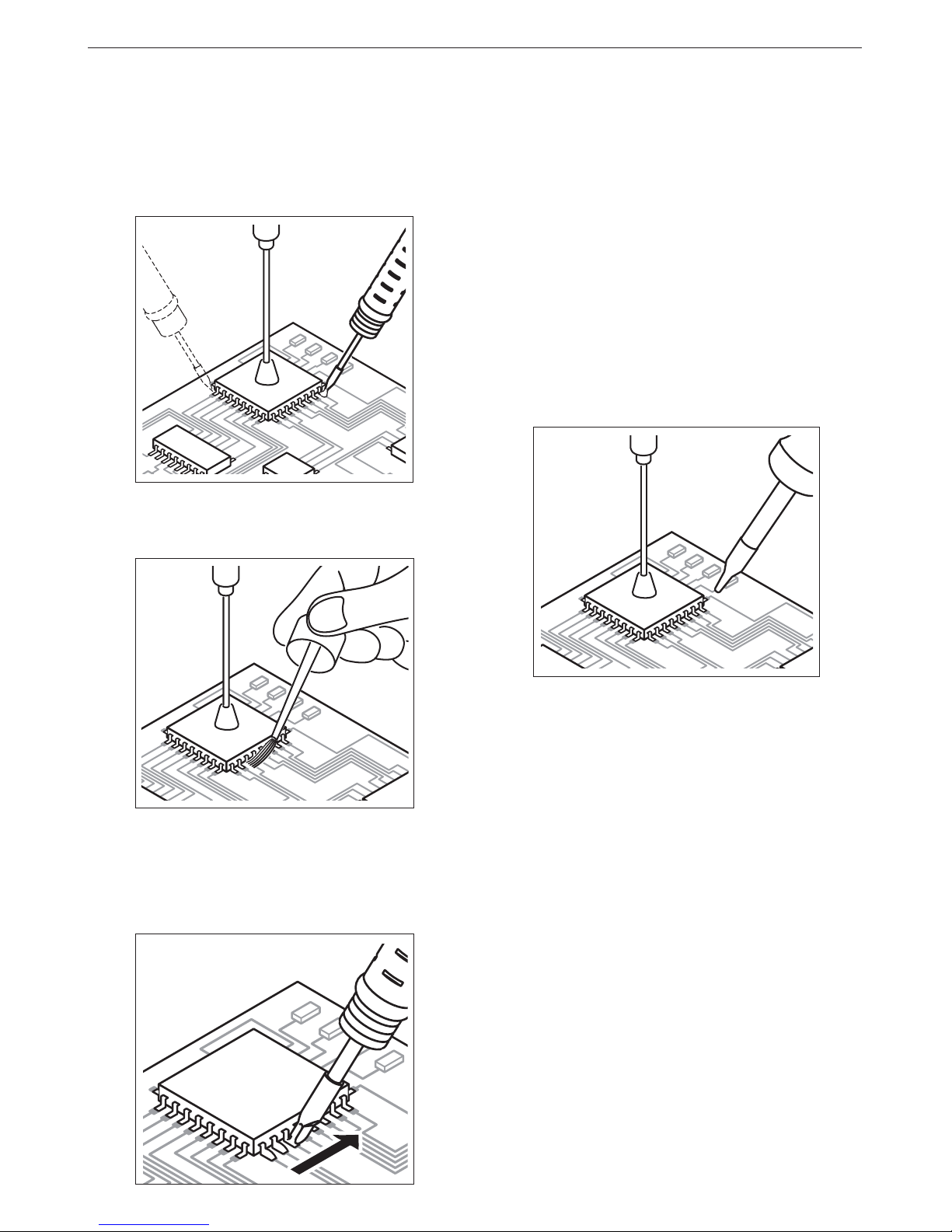

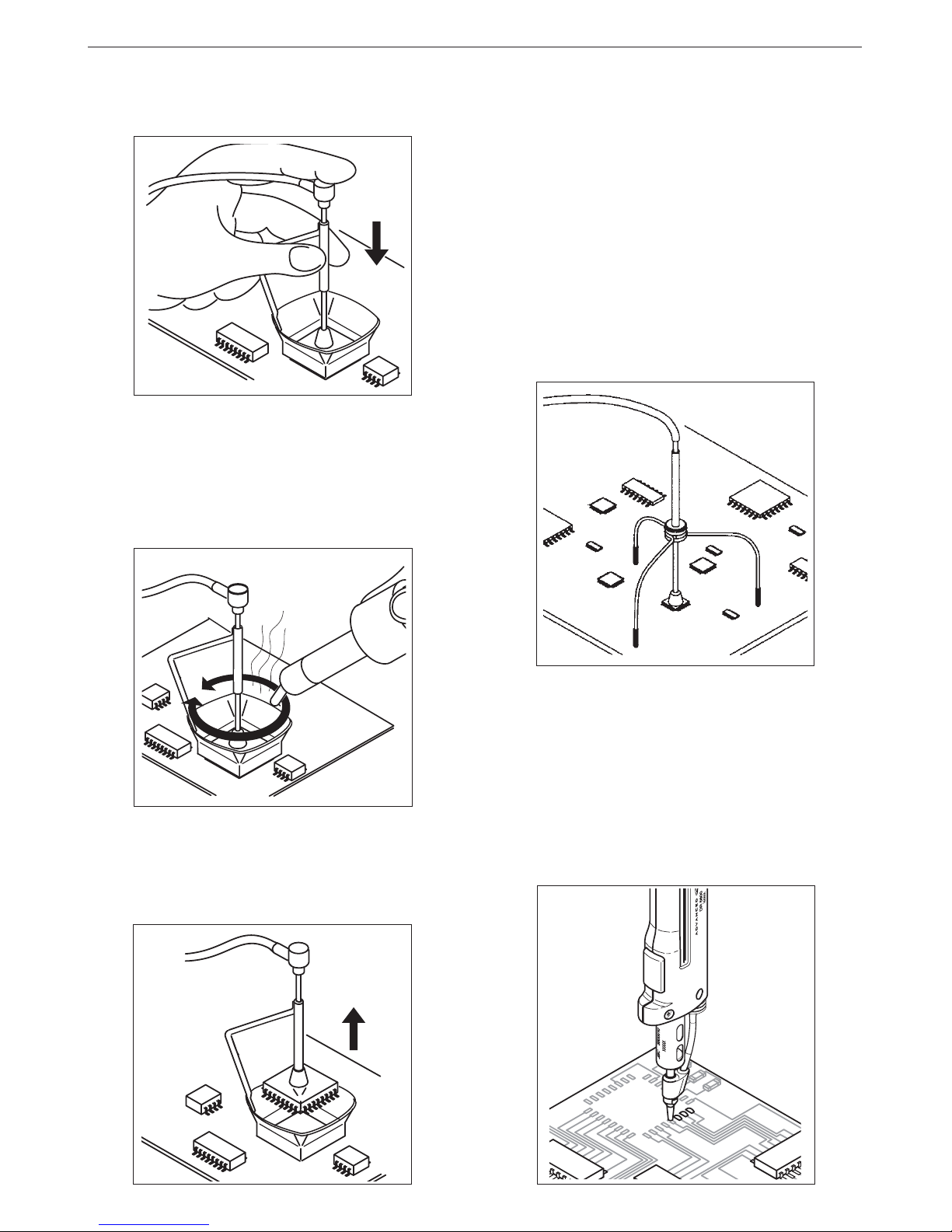

SOLDERING PROCEDURE

1 After desoldering the component, any solder

left on the printed circuit should be removed

with our desoldering iron DR 5600 ref. 5600000.

- Fit the extractor and press the sucker down until

it sticks onto the component.

- Use the pedal or the HEAT button to start the

self-contained hot-air pump, directing it with a

circular movement at the component terminals

and taking care to distribute the heat evenly.

- When the soldering flux turns liquid the extractor

will automatically lift the component.

Page 7

6

ENGLISH

Soldering Iron 2210 ref. 2210000 for great

precision tasks, like SMD solders, etc.

Soldering Iron 2245 ref. 2245000 for general

soldering tasks in professional electronics.

These soldering irons have a wide range of

cartridges with different models of tips. The

cartridge 2245-009 and 2245-010 are specially

designed for soldering SMD circuits of the

QFP and PLCC types.

Solder wire with a diameter of between 0.5 and

0.7 mm should be used.

6 Depending on the nature of the component to be

soldered, use soldering paste together with our

hot air station TE 5000, which gives very

accurate air-flow regulation, between 4 and 11

l/min.

2 Place the component or printed circuit with

the Pick & Place MP 2260 ref. 2260000.

3 When the component is correctly placed, solder

its pins.In the case of integrated circuits of the

Flat Pack type, first solder one pin of every IC

angle to fix it in place in the circuits.

4 Apply Flux FL 9582 ref. 0046565 in pads and

leads.

5 Solder the remaining pins. For this we

recommend to use our soldering irons of the

Advanced series, which are available in two

different models:

Page 8

ENGLISH

7

MAINTENANCE

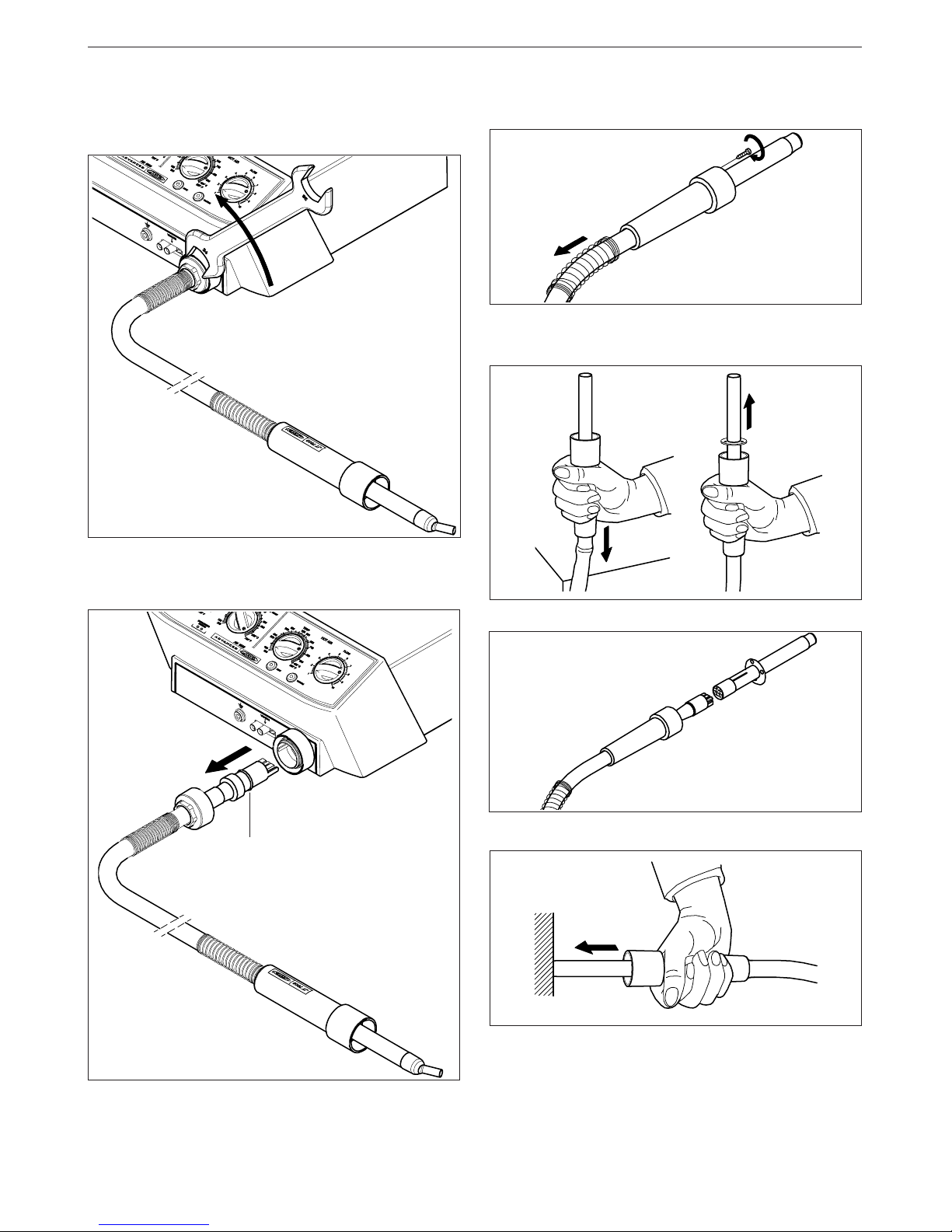

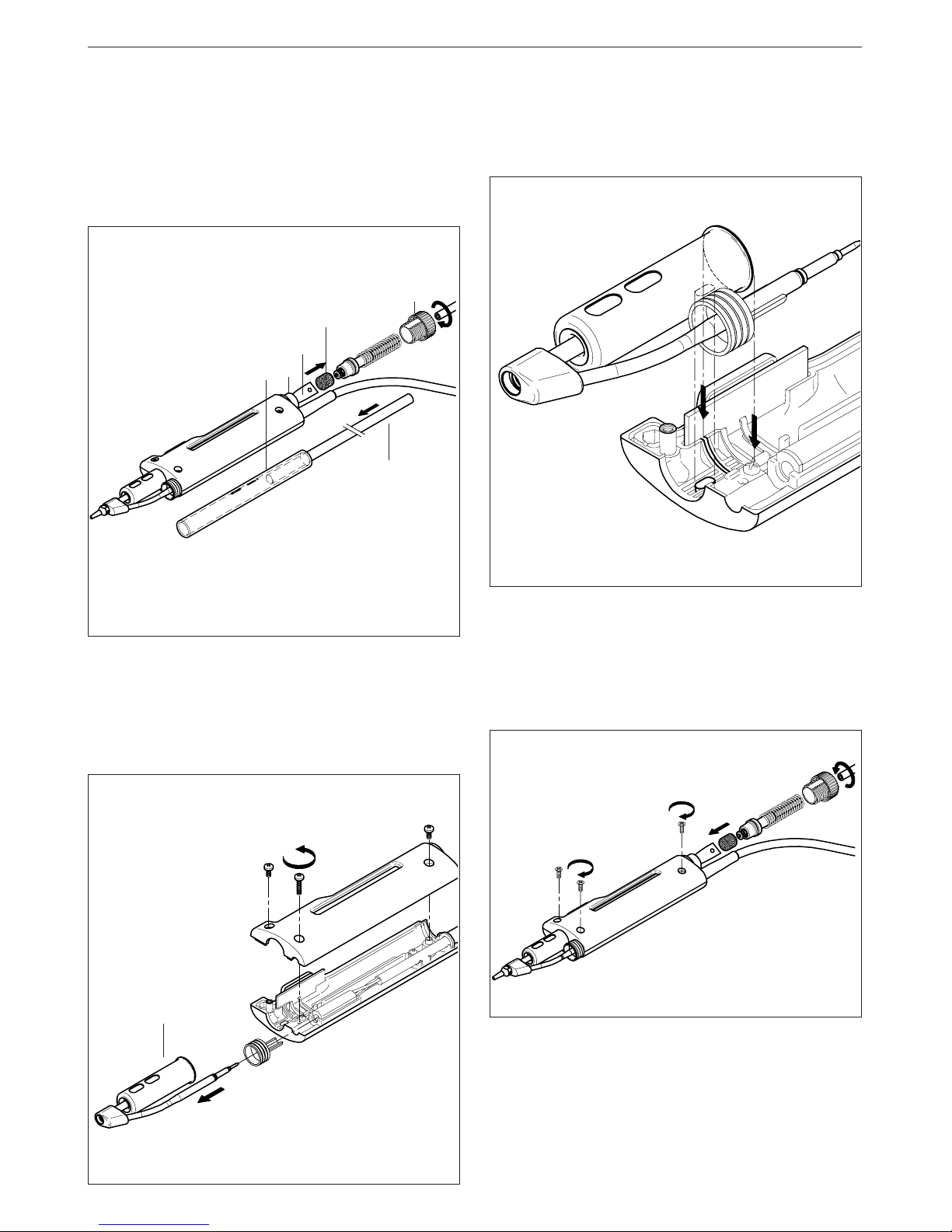

Exchanging the heater.

Use a wrench to unscrew the cover.

Exchanging the resistor from the heater.

1. Move back the spring. Untighten the screws.

Follow this process inverted to re-connect the heater.

Move back the spring and the cover. Pull the

connector from the socket to disconnect the heater

from the station.

2. To take out the resistor, press down the lower

part of the heater on a fixed surface.

4. Connect the new resistor, pushing it’s extreme.

5. Fix the screws tightly to avoid air-loss which

could reduce the resistor’s lifetime. Finally put

the spring back in it’s place.

3. Separate the resistor from the heater’s cable.

O-ring ø17 x ø1,8

Page 9

8

ENGLISH

OPERATING INCIDENTS

The suction cup does not adhere to the

component.

Deficient aspiration, Vacuum.

1 Verify if the suction cup is well placed and in

perfect condition.

Possible errors

In the case of malfunction, the control unit

interrupts the connection.

Following a list of the most common

malfunctions:

- Power failure.

Check for blown fuses.

- The temperature will not rise.

Possible causes:

· Heating element open.

· In case of a long low-power period.

- No reading from the thermocouple.

Possible cause: open thermocouple.

- Insufficient air flow which causes an excesive

rise of the heating temperature.

Before recuperating this type of error you must

wait until the temperature goes down.

Possible causes: leaking or blocked air conducts

or faulty self-contained air pump.

Filter

Ref. 0861800

2 Check the incoming air filter in the interior of

the station and replace it if dirty or obstructed.

- Faulty reading of the rotationsmeter of the selfcontained air pump.

Possible causes: air pump damaged or faulty

function of the optical sensor circuit.

To recuperate any of these errors actuate the

general switch at the back of the station, the

pedal should not be pushed at this moment.

Page 10

ENGLISH

9

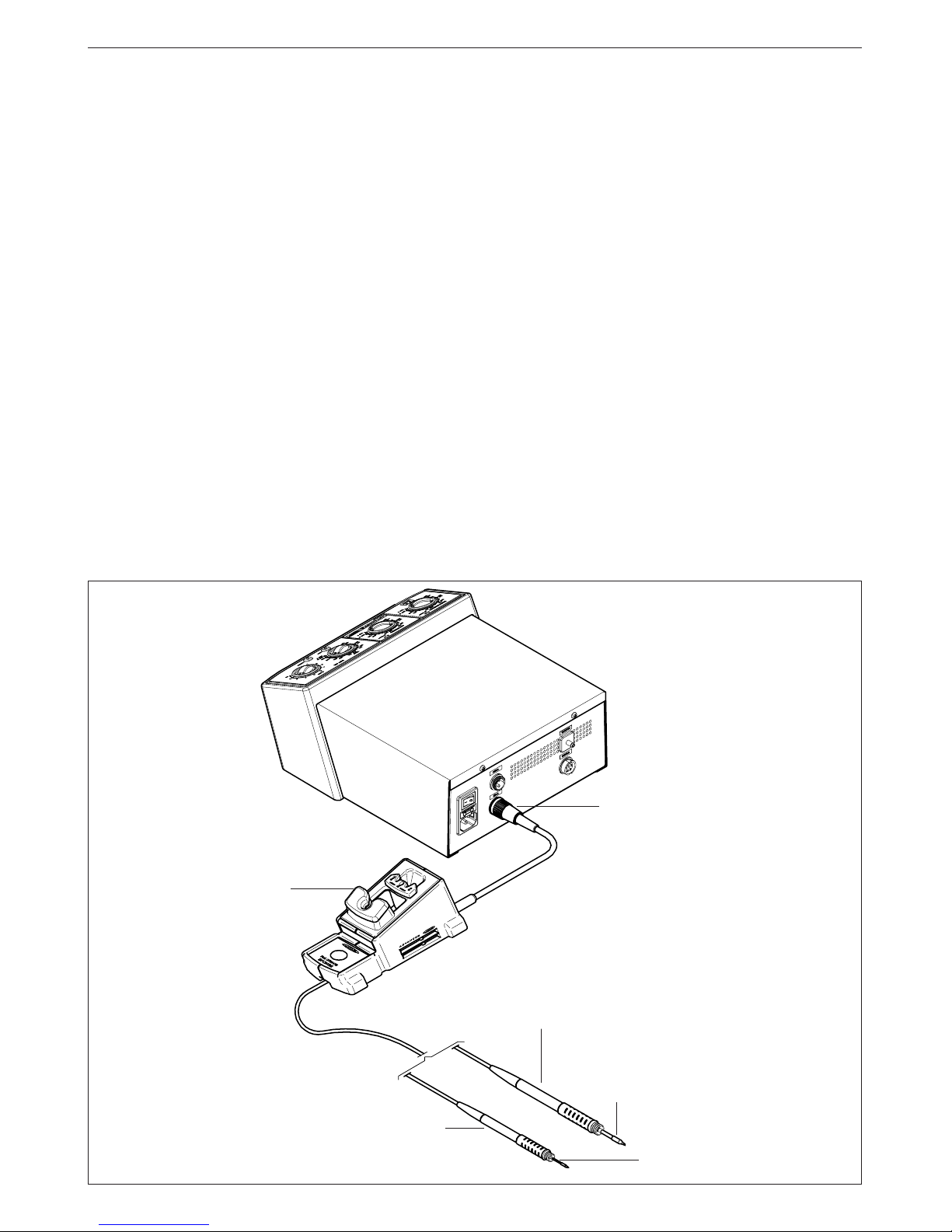

DESOLDERING IRON DR 5600

The AM 6000 station includes the following:

- Desoldering iron DR 5600 ref. 5600000 with the

tip 5600-003 ref.5600003.

Power desoldering iron: 75W.

- Desoldering iron stand DR 8500 ref. 0788500.

- External desoldering air filter ref. 0821830.

- Set of accessories ref. 0780593 with tips for the

desoldering iron: 5600-003, 5600-004 and 5600-

005.

The desoldering iron is connected to the station

following the below procedure:

The cable connection of the desoldering iron is

connected to the plug in the desoldering iron stand

DR 8500 and the vacuum hose is connected to the

external desoldering air filter, which is connected to

the vacuum connection SUCTION of the station. The

cable connection of the desoldering iron stand is

plugged into the terminal DESOLD of the station.

Very important, it is essential to connect the mentioned

filter to prevent from damaging the vacuum pump.

Desoldering iron stand

DR 8500

Ref.0788500

Desoldering iron

DR 5600

Ref.5600000

Spare filters

Ref.0781046

Heating element

Ref.5600010

Vacuum inlet

SUCTION

Desoldering

connector

DESOLD

External desoldering air filter

Ref.0821830

Page 11

10

ENGLISH

OPERATION

LED lights

Red LED -ON- when lit, it indicates that the station is

plugged in the mains.

Green LED -READY- when lit, it indicates that the

system is ready and correctly set for working.

The green led light is on after a few seconds, is the

time needed to carry on the self-checking system.

The green light is pulsing when the desoldering iron

is in sleep mode.

If the green led is not lit, the reason why, will be one

of the following:

1. The desoldering iron is not plugged in.

2. The maximum available power has been

exceeded for too long - e.g. in a very thick

desoldering at the high repetition rates.

3. The desoldering heating element has a short

circuit or an open circuit.

4. Any other trouble preventing the system from

working properly.

The handpiece will reset itself automatically should

the cartridge short circuit or go open circuit.

Should the handpiece be subject to:

- An electrical surge or the cartridge has not been

fitted correctly.

Please turn the unit off and switch on again to reset.

When pressing the button of the desoldering iron

handle, one of the two leds in the area marked

SUCTION will light up:

Green light -SUCTION- indicates the correct

functioning of the desoldering iron.

Red light -SUCTION- indicates a blockade within

the vacuum circuit.

This can be caused by the following:

- The tip of the desoldering iron is blocked.

Sleep function

One of the Series Advanced features is that when

the desoldering iron is placed in the holder, the

temperature at the tip drops automatically to th e

sleep temperature. This function is only

possible because of the quick response time

which does not make the user realise the

temperature rise to reach the selected

temperature. Also by this, the oxidation of the

tinning of the tip is considerably reduced and

tip life is extended.

To indicate that the desoldering iron is in sleepmode, the green led starts pulsing. These

parameters can be modified using the Console

AC 2600 Ref. 2600000.

In order to take advantage of the above

mentioned feature and as a security measure,

it is necessary to place the desoldering iron

on stand when the iron is not being used.

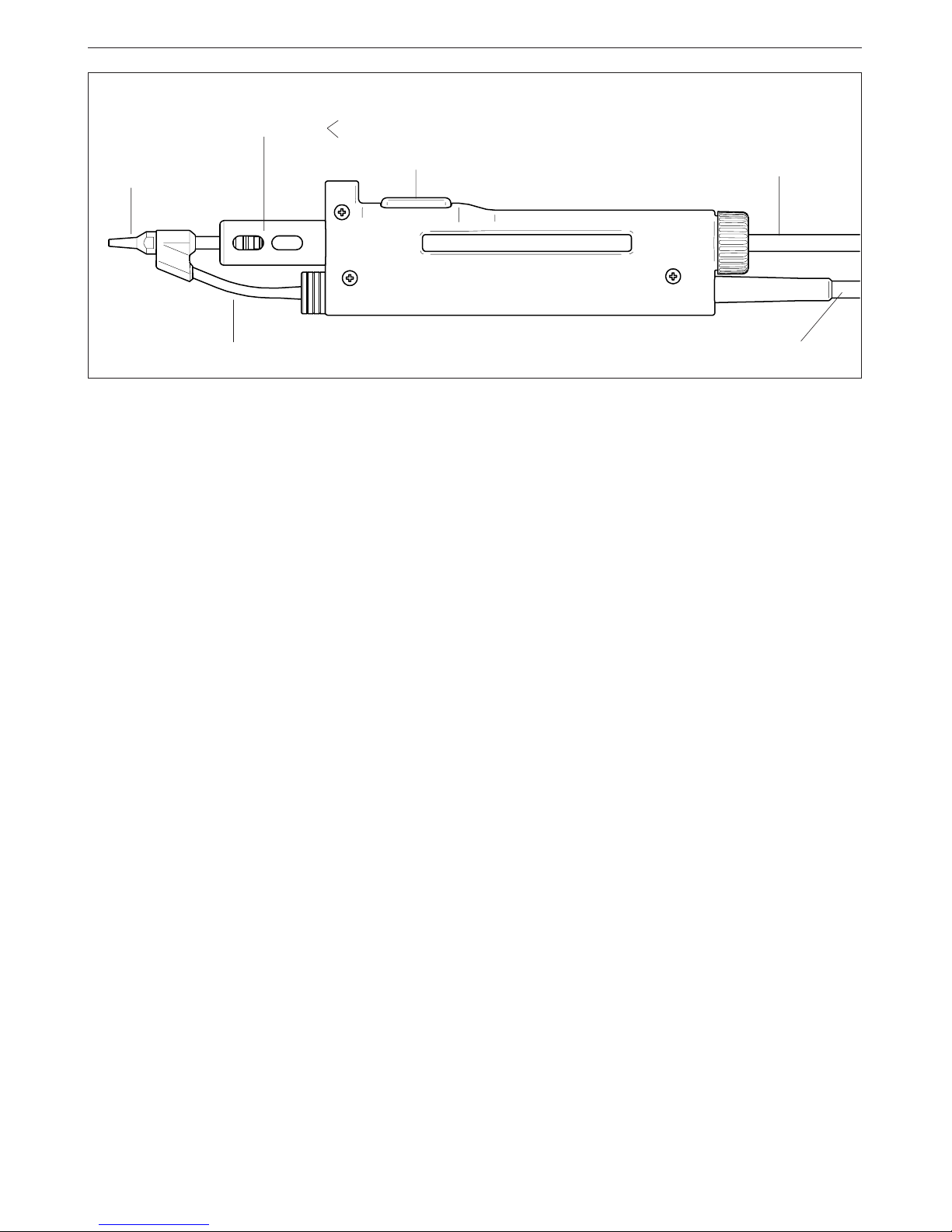

DR 5600 Ref.5600000

Desoldering tip

Heating element

Pushbutton vacuum pump

Vacuum hose

Desoldering iron cable

Solder tin deposit

Metal

Glass

- The solder tin deposit is full.

- The filter of the desoldering iron is dirty.

- The station’s external desoldering air filter is

dirty.

Only for users of AC 2600 console ref. 2600000.

If you lock the working temperature thanks to the

console, the green LED -READY- will remain on

while the dial is set at the locked temperature.

If the dial is not set at the locked temperature,

the green LED -READY- will be blinking. The

farther the dial will be set from the locked

temperature the slower the blinking pace will be.

Page 12

ENGLISH

11

RECOMMENDATIONS FOR USE

For soldering and desoldering

- Clean the contacts and the printed circuit to

be desoldered of dust or dirt.

- Preferably select a temperature below 350°C.

Excess temperature may cause the printed

circuit tracks to break loose.

- The tip must be well tinned for good heat

conduction. If it has been inoperative for any

length of time, it should be retinned.

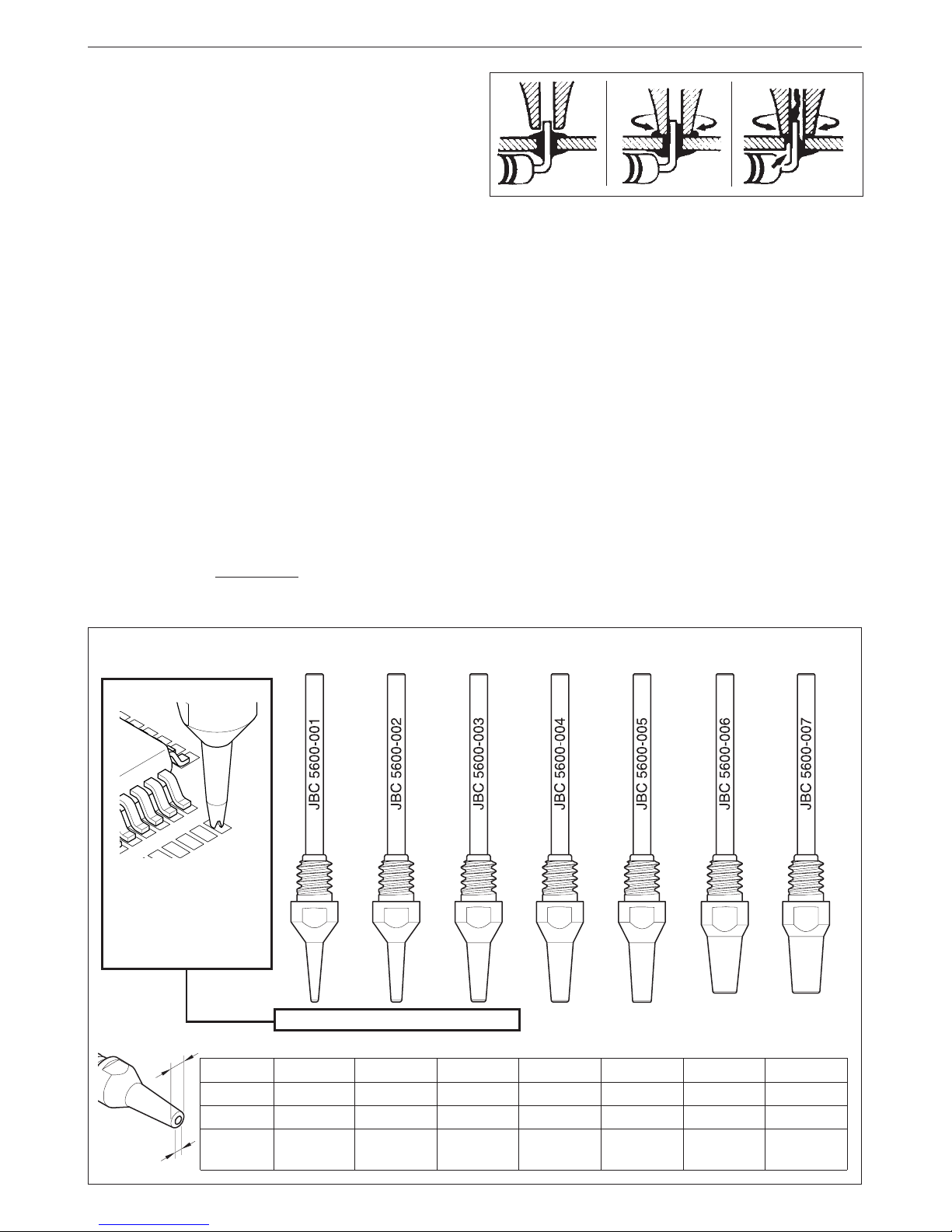

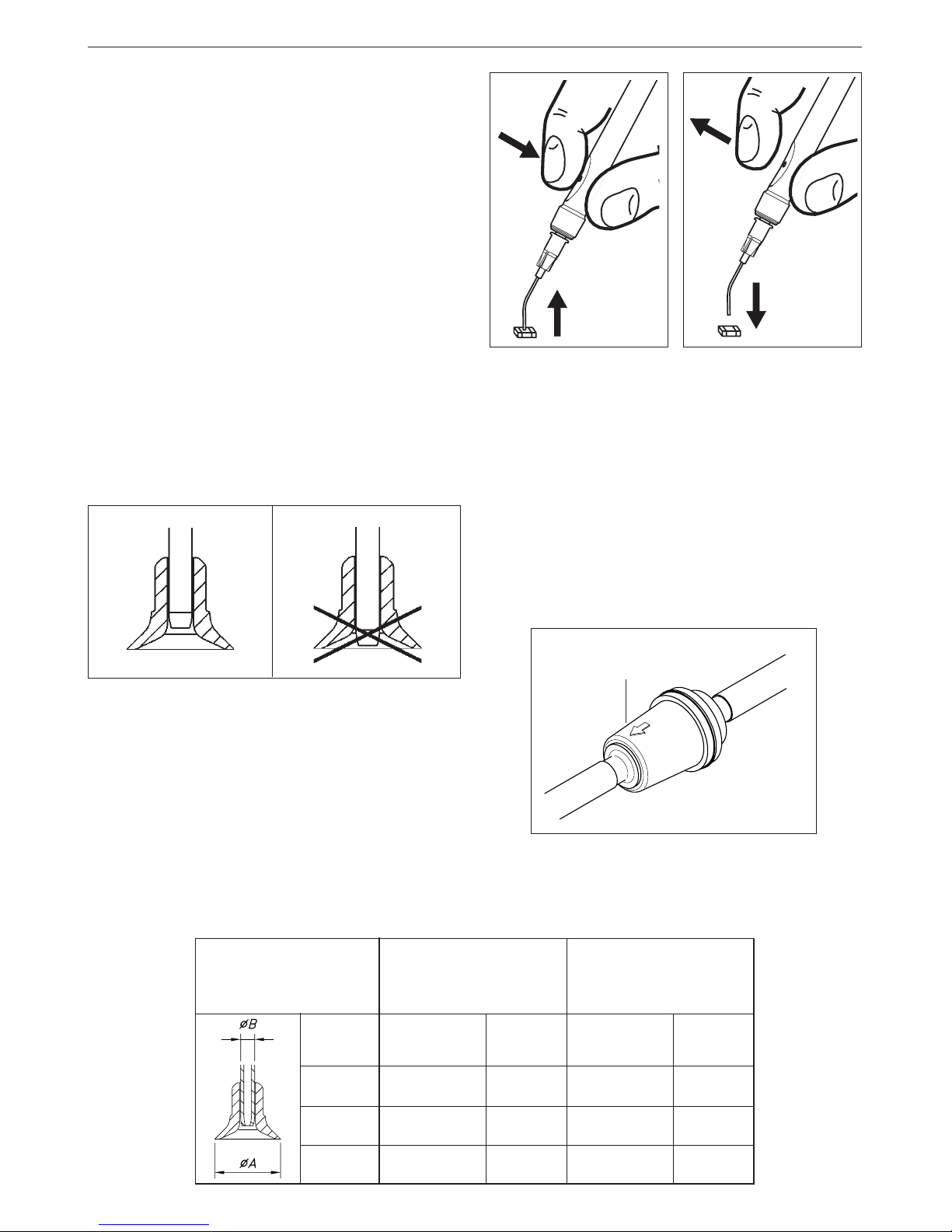

Desoldering process

Use the tip model with a larger diameter than the

pad to be desoldered, so as to achieve maximum

aspiration and thermal efficiency.

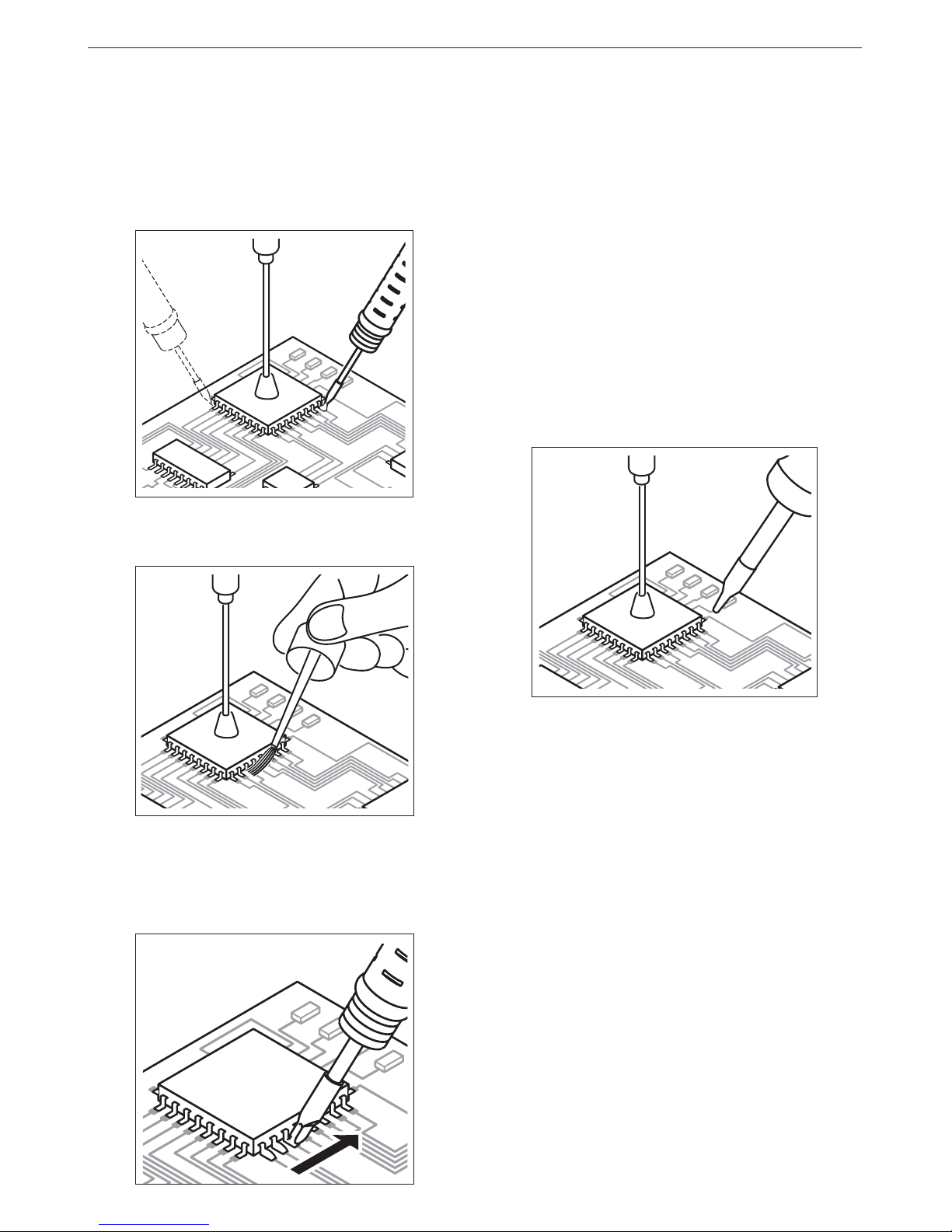

1 Apply the desoldering iron tip so that the

component terminal penetrates within its

orifice.

2 When the solder liquefies, start gently to rotate

the desoldering tip so that the component’s

terminal can be eased away from the sides.

3 Press then, not before, the vacuum pump

push-button just long enough to aspirate the

solder.

After pressing the desoldering key there is a

slight delay until the self-contained vacuum

pump stops, this is to make sure that the

vacuum circuit is completely empty.

If any solder remains are left on any terminal after

attempting to desolder it, resolder it with fresh

solder and repeat the desoldering operation.

1

2

3

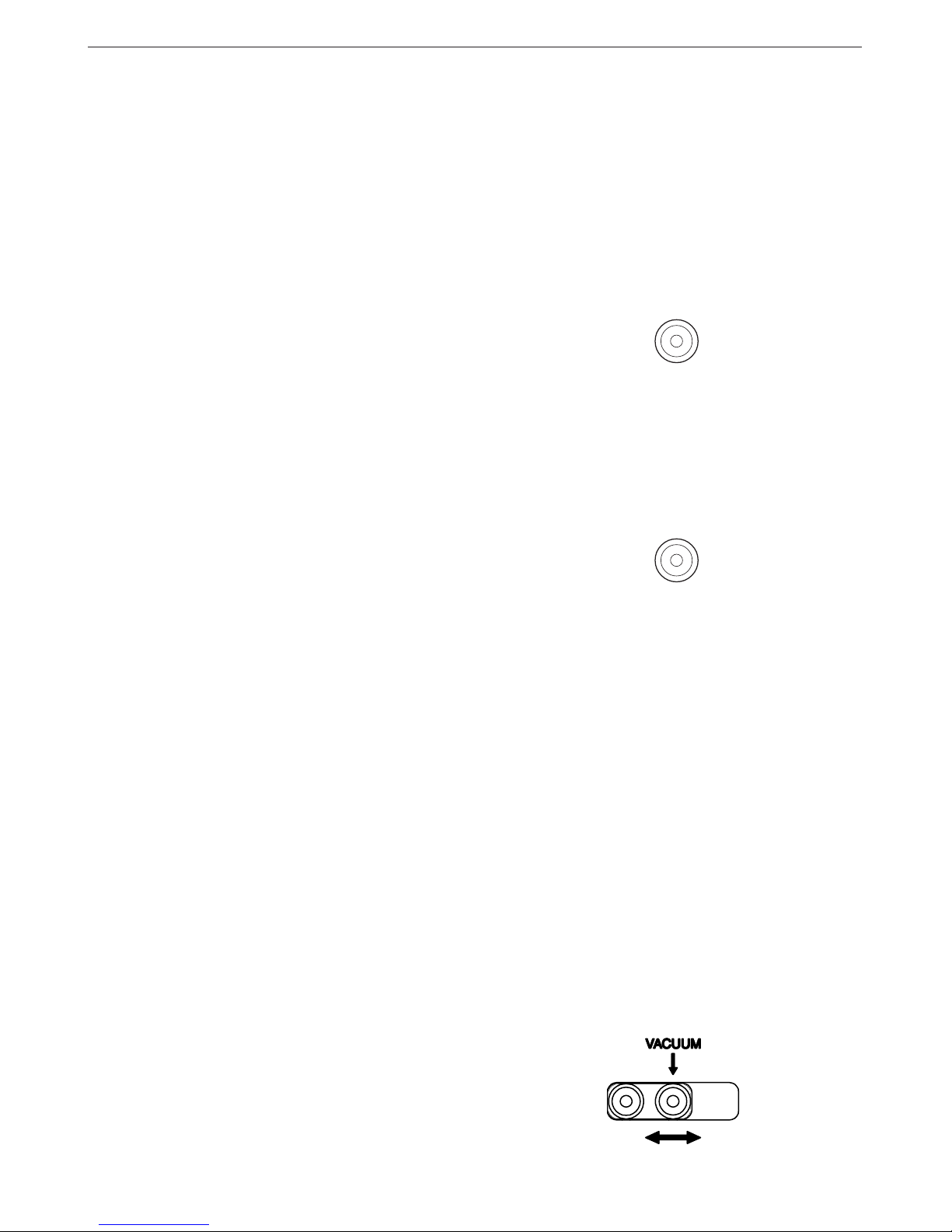

DESOLDERING TIPS

These tips are

specially designed

to clean the pads.

Ref. 5600-001 5600-002 5600-003 5600-004 5600-005 5600-006 5600-007

5600

A ø (mm)

B ø (mm)

max. pin ø

(mm)

001 / 011

1.4

0.6

0.4

002 / 012

1.8

0.8

0.6

003 / 013

2.7

1

0.8

004

3.2

1.3

1.1

005

3.4

1.6

1.4

006

4.2

2

1.7

007

4.8

2.5

2.3

A ø

B ø

5600-012 5600-0135600-011

Page 13

12

ENGLISH

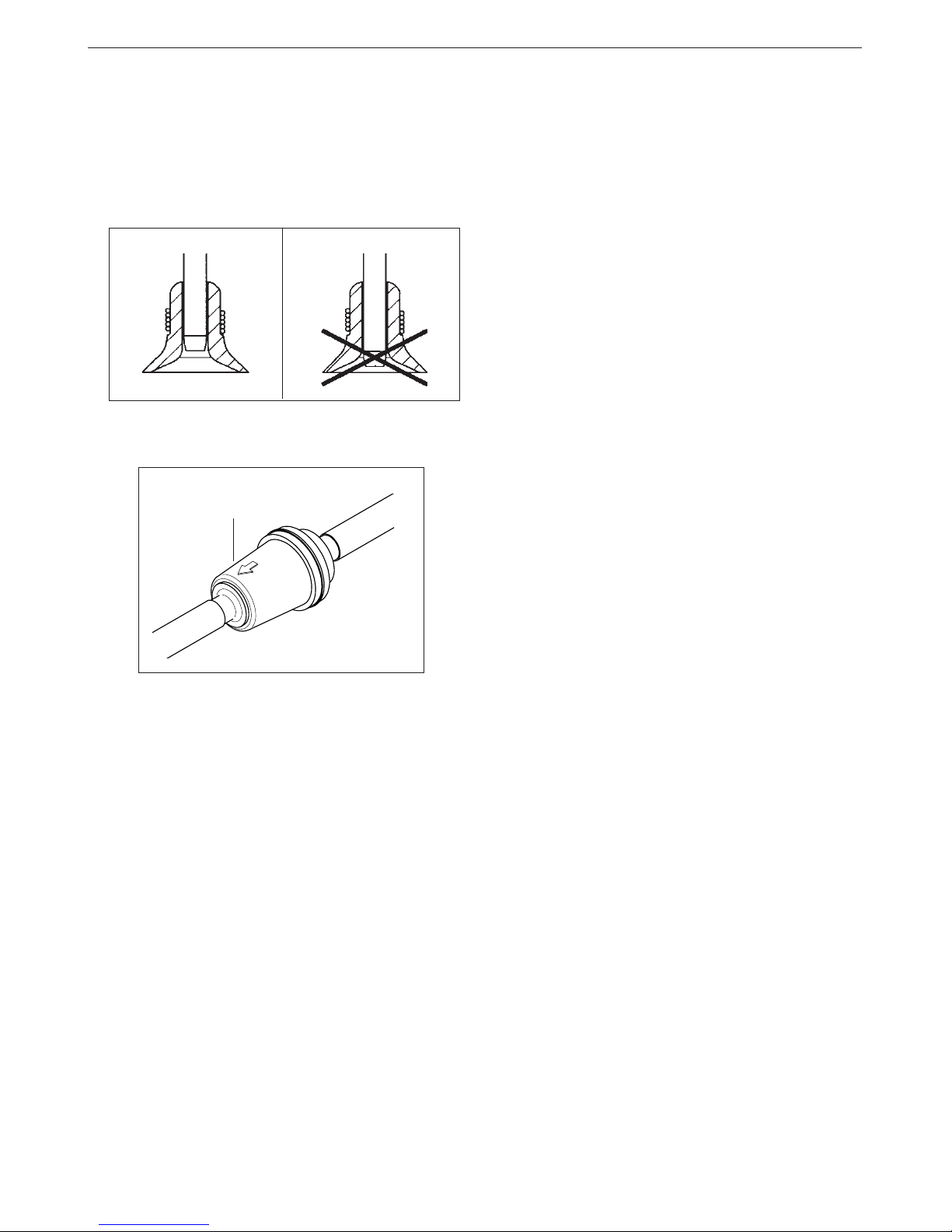

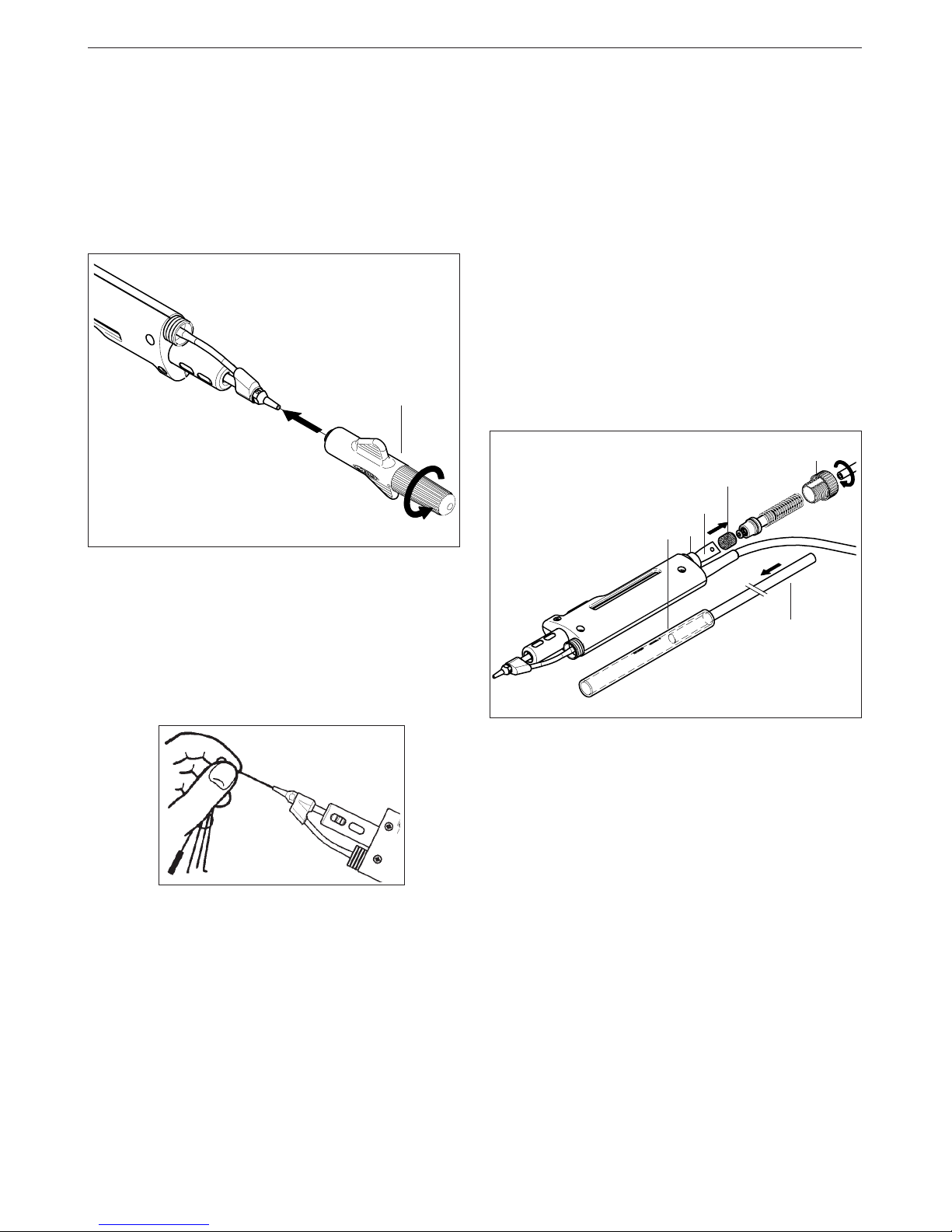

Change of desoldering tip

This operation should be done while the tip is hot,

at a minimum temperature of 250°C, so that any

tin left inside is in molten state.

- Unscrew the tip to be replaced, with the aid of

the spanner supplied.

- Fit the new tip, and tighten up with the spanner

to achieve a good air tightness.

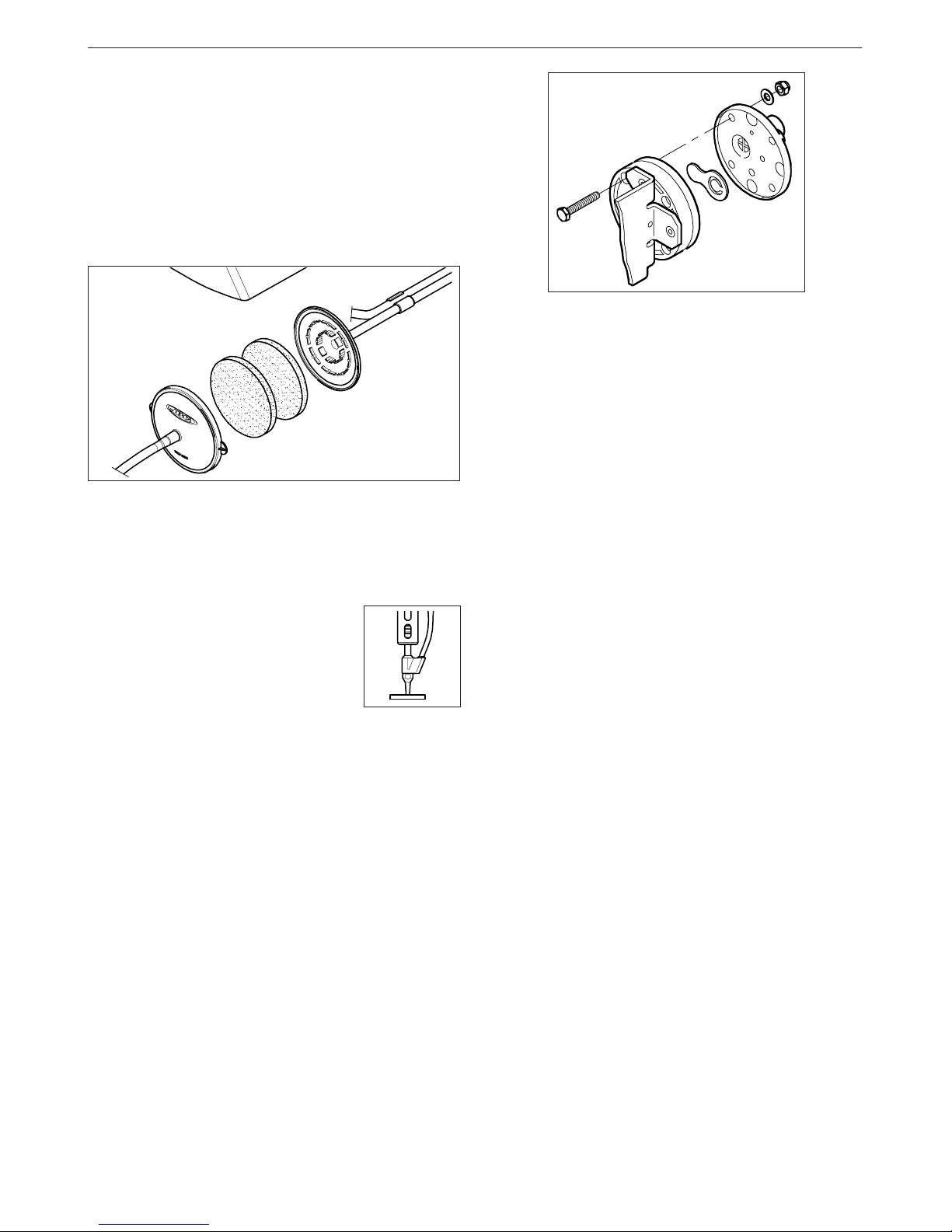

To empty the solder tin deposit and change

the filter

For this, the lid needs to be unscrewed and first

the tin deposit and then its spiral must be removed

to clean the inner part of the deposit with a brush.

- The condition of the filter must be checked

and replaced if dirty or damaged.

- The deposit needs to be inserted with spiral

filter put into place. Then the whole must be

closed by screwing the lid shut.

Solder tin deposits

It can be chosen between two different deposit

types:

- Metal Ref. 0812630.

- Glass Ref. 0812620.

Lid

Brush

Ref. 0786640

Filter Ref.0780840

Deposit

Spiral

Ref. 0780550

Tip care

- The largest rod that fits in the tip hole should

periodically be passed through in order to

clean the intake tube.

- To clean the tips, use the sponge included

with the stand and check it is slightly moisted.

Only deionised water (car battery water)

should be used in order to wet the sponge.

If normal water was to be used, it is very likely

that the tip will become dirty due to the salts

dissolved within the water.

- Do not file the tips or use abrasive tools

which may damage the tip’s protective

surface coating and avoid knocking them

about.

- If the tip has been a long time without being

tinned, use a metal brush to remove any dirt

and oxid.

IMPORTANT: DO NOT press the pushbutton

vacuum pump while tinning the desoldering tip,

as the fumes given off by the flux would quickly

soil the ducts and filter of the air circuit.

Page 14

ENGLISH

13

- Place the new heating element. Check that

the right extremity of the upper part of the

heating element is inserted in the slot

located inside the body of the desoldering

iron (see drawing hereunder).

- Screw out the body of the desoldering

iron. Open up the body and remove the

heating element.

- Screw in the body of the desoldering iron.

Put the spiral and the filter back into the

deposit. Place the deposit inside the body

of the desoldering iron and screw in the

shut lid.

Lid

Brush

Ref. 0786640

Filter Ref. 0780840

Deposit

Spiral

Heating element

Ref. 5600010

Change of the heating element of the

desoldering iron (Ref. 5600010)

- To realize this operation, the lid needs to

be unscrewed and first the tin deposit and

then its spiral and filter must be removed

to clean the inner part of the deposit with

a brush.

Page 15

14

ENGLISH

Cleaning the vacuum pump valve

Open the control unit as follow:

- Disconnect the control unit.

- Turn it upside down, remove the fixing

screws.

- Return the station to its normal position and

lift up the lid.

- Undo the four screws fastening the pump cover.

- Clean the valve with a cloth dampened in

alcohol. If it is too soiled, replace it with new

one. Ref. 0982970.

Detecting air leaks in the circuit

To detect air leaks in the circuit:

- Obstruct the tip inlet orifice

by pressing down on a

silicone disc, or bend the

tube connecting the

desoldering iron to the filter.

- Press the pushbutton vacuum pump.

If the red led lights up, there is no loss of

suction. Otherwise air gets into the system at

some point. This can occur at the desoldering

tip, or may be caused by the lid of the deposit,

lids of filters or because the air pump does not

function correctly due to dirty valves which

occurs when the air filter has not been used

correctly.

Changing the pump inlet filter

Verify the filter at the entrance of the pump, and

change it if dirty or obstructed, therefor:

Open the filter pulling the flap.

Take out the 2 cotton filters, throw away those

which are soiled and replace them with new

ones. Always use 2 filters.

Close the filter and check the airtightness.

Page 16

ENGLISH

15

PICK & PLACE PEN MP 2260

The pick & place pen MP 2260 ref. 2260000 for

the placing of SMD is also delivered with the AM

6000.

The pen is connected to the plug VACUUM of the

station. Please find the connection plan on page 1.

A set of straight and bent needles as well as a

set of different sized suction cups is delivered

with the station:

- Set of suction cups Ref. 0940163

- Set of straight needles Ref. 0901546

- Set of bent needles Ref. 0861660

The suction cups can be adjusted to the needles

in order to make the placement of SMD of different

sizes on boards easier.

These accessories allows the adjustment to weight

and size of any type of component.

Component pick-up (Fig. A)

Place the needle tip on the component and block

the control orifice with the first finger of the other

hand so that the component may be held to the

needle by suction.

Component placing (Fig. B)

Place the component in position on the printed

circuit. Remove your finger from the orifice

allowing air to enter whereby the component will

be released in the desired position.

Faults and remedies

We list below the most frequent faults and the

possible remedies which you yourself may be

able to apply. In any case, the JBC technical

assistance service will attend to you if required.

Insufficient suction

The tubes have to be checked for possible air

escapes and the correct connection of the tubes

to their terminals must be observed. Check the

incoming air filter in the interior of the station and

replace it if dirty or obstructed.

If in spite of this the suction is insufficient, the

self-contained vacuum pump should be checked.

Filter

Ref. 0861800

When you assemble the suction cup with the needle,

you should avoid the needle to stick out of the

lower part.

Fig. A

Fig. B

CUPS

Ref.: 0940163

STRAIGHT

NEEDLES

Ref.: 0901546

Ø A

mm

COLOR

2 x 4,3

BLACK

YELLOW2 x 7

PINK2 x 10

Ø B

mm

2 x 0,7

2 x 0,9

2 x 1,2

BENT

NEEDLES

Ref.: 0861660

COLOR

GREEN

YELLOW

PINK

Ø B

mm

2 x 0,8

2 x 0,9

2 x 1,2

Page 17

16

ENGLISH

ADVANCED HANDPIECES RANGE

All the Advanced soldering handpieces range can

be connected to the AM 6000 station.

The station AM 6000 includes the following products:

- Handpiece 2245 ref. 2245000 with the cartridge

2245-003 Ref. 2245003. Power: 50W. For general

soldering work.

- Soldering iron stand AD 8200 ref. 0268200.

- Set of accessories ref. 0780593 with cartridge

2245-007 Ref. 2245007. It can be chosen from a

wide range of different cartridges 2245 to adapt

perfectly to the needs of the job (pag. 126).

The following soldering handpieces can be

connected to the AM 6000 station:

- Handpiece 2010 ref. 2010000. Power: 20W. For

high precision work, SMD etc. Available

cartridges 2010: see page 127.

- Handpiece 2210 ref. 2210000. Power: 20W. For

high precision work, SMD etc. Available

cartridges 2210: see page 127.

- Handpiece 2045 ref. 2045000. Power: 50W. For

general soldering work. Available cartridges

2045: see page 126.

Two versions of soldering iron handpieces covered

with heat isolater are available:

- 2045 Thermo-isolated handpiece ref. 2045110.

- 2245 Thermo-isolated handpiece ref. 2245110.

These articles are not delivered with the station.

The handpieces and cartridges 2210 and 2245

comply with the MIL-SPEC-2000 referring to the

potential difference between the soldering tip and

ground connection, must be less than 2 mV.

For a soldering handpiece to work properly, the

following components are required: control unit,

soldering iron stand, one handpiece and one

cartridge.

The soldering iron is connected to the station in the

following way:

The cable connection of the soldering iron is

connected to the plug in the soldering iron stand

AD 8200 and the cable connection of the soldering

iron stand is plugged into the terminal SOLD of the

station. Please find the connection plan on figure.

Soldering iron stand

AD 8200

Ref.0268200

Handpiece 2010 Ref. 2010000

Handpiece 2210 Ref. 2210000

Handpiece 2045 Ref. 2045000

Handpiece 2245 Ref. 2245000

Cartridges 2045

Cartridges 2245

Cartridges 2010

Cartridges 2210

Soldering

connector

SOLD

Page 18

ENGLISH

17

Sleep function

One of the Series Advanced features is that when

the handpiece is placed in the holder, the

temperature at the tip drops automatically to the

sleep temperature. This function is only possible

because of the quick response time which does

not make the user realise the temperature rise to

reach the selected temperature. Also by this, the

oxidation of the tinning of the tip is considerably

reduced and tip life is extended.

To indicate that the soldering iron is in sleep-mode,

the green led starts pulsing. These parameters can

be modified using the Console AC 2600 Ref. 2600000.

In order to take advantage of the above

mentioned feature and as a security measure,

it is necessary to place the handpiece on stand

when the iron is not being used.

When connecting an old version solder stand, it may

happen that the sleep function does not work.

To resolve this problem, you should make a bridge

between pins number 3 and 5 from the aerial

connector of the cable of the stand, that plugs in

the station.

Aerial connector

Bridge between

pin number 3 & 5

OPERATION

LED lights

Red LED -ON- when lit, it indicates that the station is

plugged in the mains.

Green LED -READY- when lit, it indicates that the

system is ready and correctly set for working.

The green led light is on after a few seconds, is the

time needed to carry on the self-checking system.

The green light is pulsing when the soldering iron is

in sleep mode.

If the green led is not lit, the reason why, will be one

of the following:

1. The handpiece or the cartridge are not plugged

in.

2. The maximum available power has been

exceeded for too long - e.g. in a very thick

soldering at the high repetition rates.

3. The handpiece or cartridge has a short

circuit or an open circuit.

4. Any other trouble preventing the system from

working properly.

The green led goes off when the cartridge tip

touches the extractor and the station stops the

power supply.

The handpiece will reset itself automatically should

the cartridge short circuit or go open circuit.

Should the handpiece be subject to:

- An electrical surge or the cartridge has not been

fitted correctly.

Please turn the unit off and switch on again to

reset.

Only for users of AC 2600 console ref. 2600000.

If you lock the working temperature thanks to the

console, the green LED -READY- will remain on

while the dial is set at the locked temperature.

If the dial is not set at the locked temperature,

the green LED -READY- will be blinking. The

farther the dial will be set from the locked

temperature the slower the blinking pace will be.

Page 19

18

ENGLISH

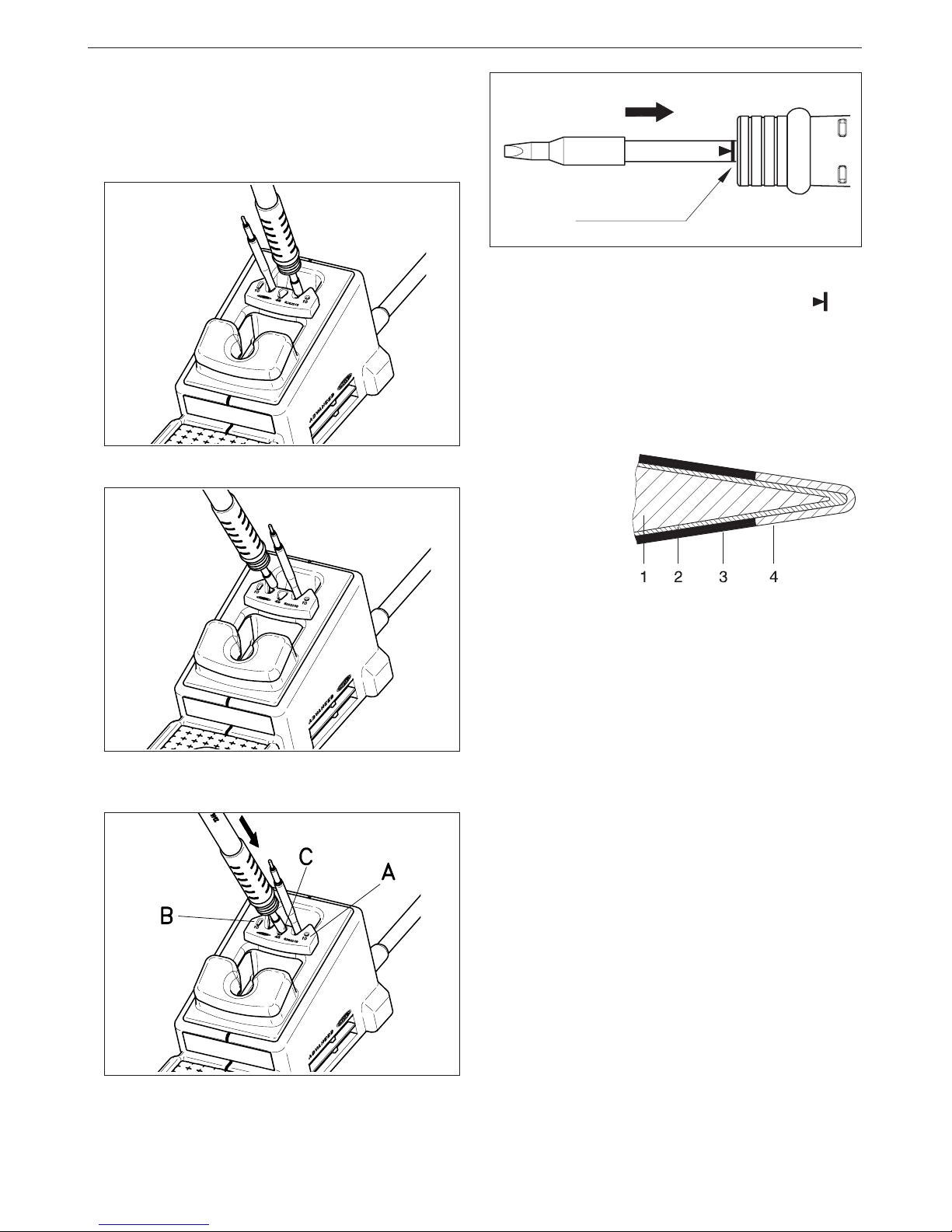

Alignment

XX

XXXXX

Important.

- It is essential to insert the cartridge till the end

for a good connection. Take the mark a s

reference.

Advanced series cartridge

Cartridge is made of the heating element which has the

heating system, temperature sensor and long life tip.

Long-life tip is basically made of:

1 Copper

2 Iron

3 Chromium

4 Tin plate

Long-life tip care

Except for the copper core, the rest of metals are

placed galvanically on layers relatively thin, so it

is necessary to avoid the reasons which can

cause its destruction.

To clean the tips, use the sponge included with

the stand and check it is slightly moisted.

Only deionised water (car battery water)

should be used in order to wet the sponge. If

normal water was to be used, it is very likely that

the tip will become dirty due to the salts dissolved

within the water.

To re-tin the soldering tips, we recommend using

the tip tinner/cleaner TT 9400 ref. 9400000.

2 - Place the handpiece on top of the new cartridge,

press it slightly down and remove the handpiece.

Changing the handpiece's cartridge

With the Advanced system, the cartridge can be

changed quickly, without turning off the station,

so you have two soldering irons in one. Here is

what to do to change the cartridge:

1 - Place the handpiece and remove the cartridge.

3 - Press the cartridge into the opening A, B or C:

A. For straight cartridges 2010 and 2210.

B. For curved cartridges 2010 and 2210.

C. For cartridges 2045 and 2245.

Page 20

ENGLISH

19

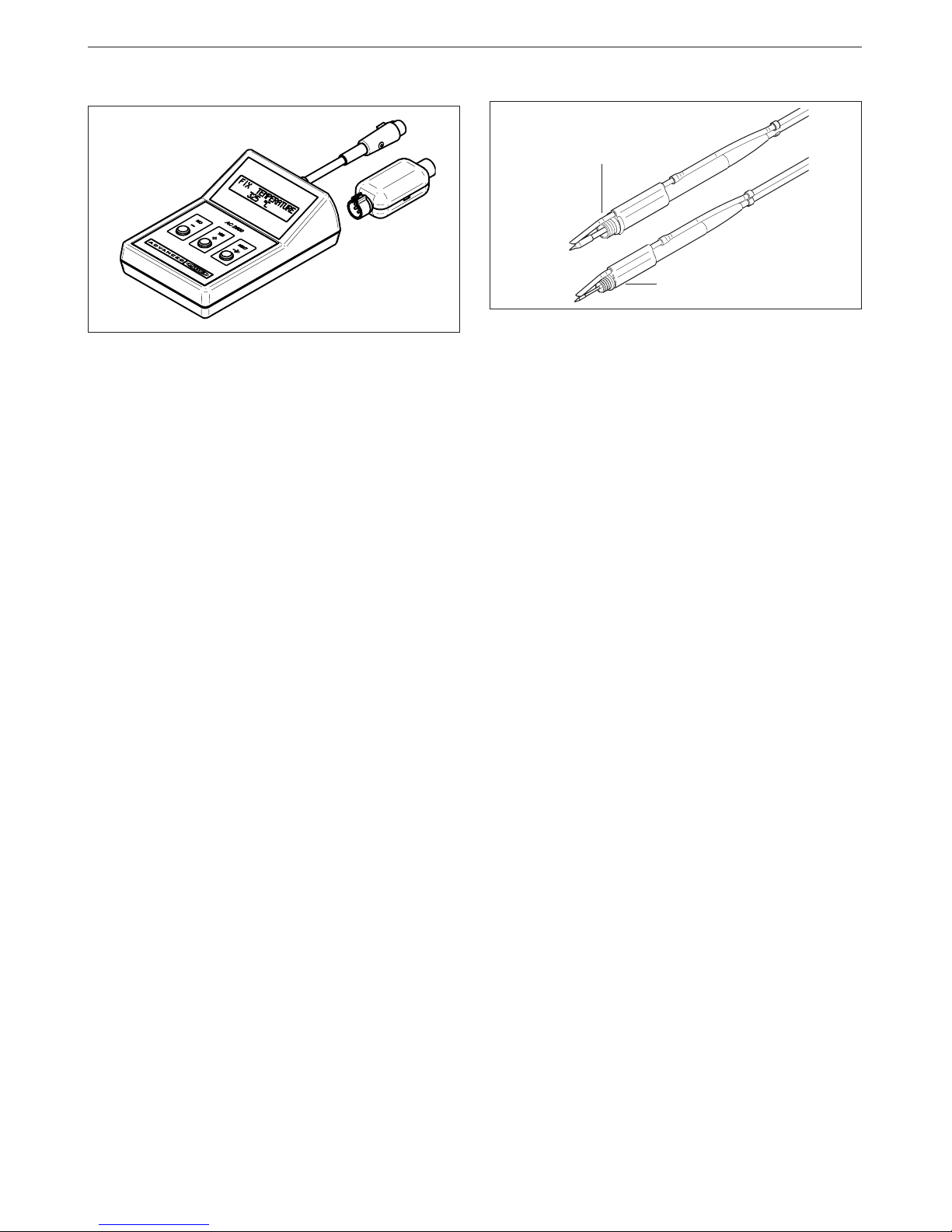

Console AC 2600

The console AC 2600 is designed for modifying the

original regulation program parameters of the following

Advanced control units:

- AD 2000 soldering station.

- AD 2200 soldering station.

- AD 4200 and AD 4300 dual soldering stations.

- AR 5500, AR 5800 (*) and DS 5300 (*) desoldering

stations.

- AM 6000 and AM 6500 (*) rework stations.

(*) These stations need a console whose

program version is 4.0 or higher.

Changes avalaible to perform:

- Fixing the the working temperature.

- Selection of temperature units in Celsius grades

-°C- or Fahrenheit -°F-.

- Modification of sleep temperatures and standby

times.

- Adjustment of temperature.

- Set the parameters back to the original parameters.

- Read-out data:

Working hours.

Sleep cycles and sleep hours.

Cartridge and iron changes.

Program version.

Fume extractor accessories

Specially designed for the Advanced Series

handpieces 2010/2210 and 2045/2245. Easily clips

onto the handpiece and can be quickly removed

for easy maintenance.

AC 2600

Ref. 2600000

For handpieces 2045/2245:

Standard Ref.0495000

+20mm longer Ref.0455002

For handpieces 2010/2210

Ref.0265000

Page 21

20

ENGLISH

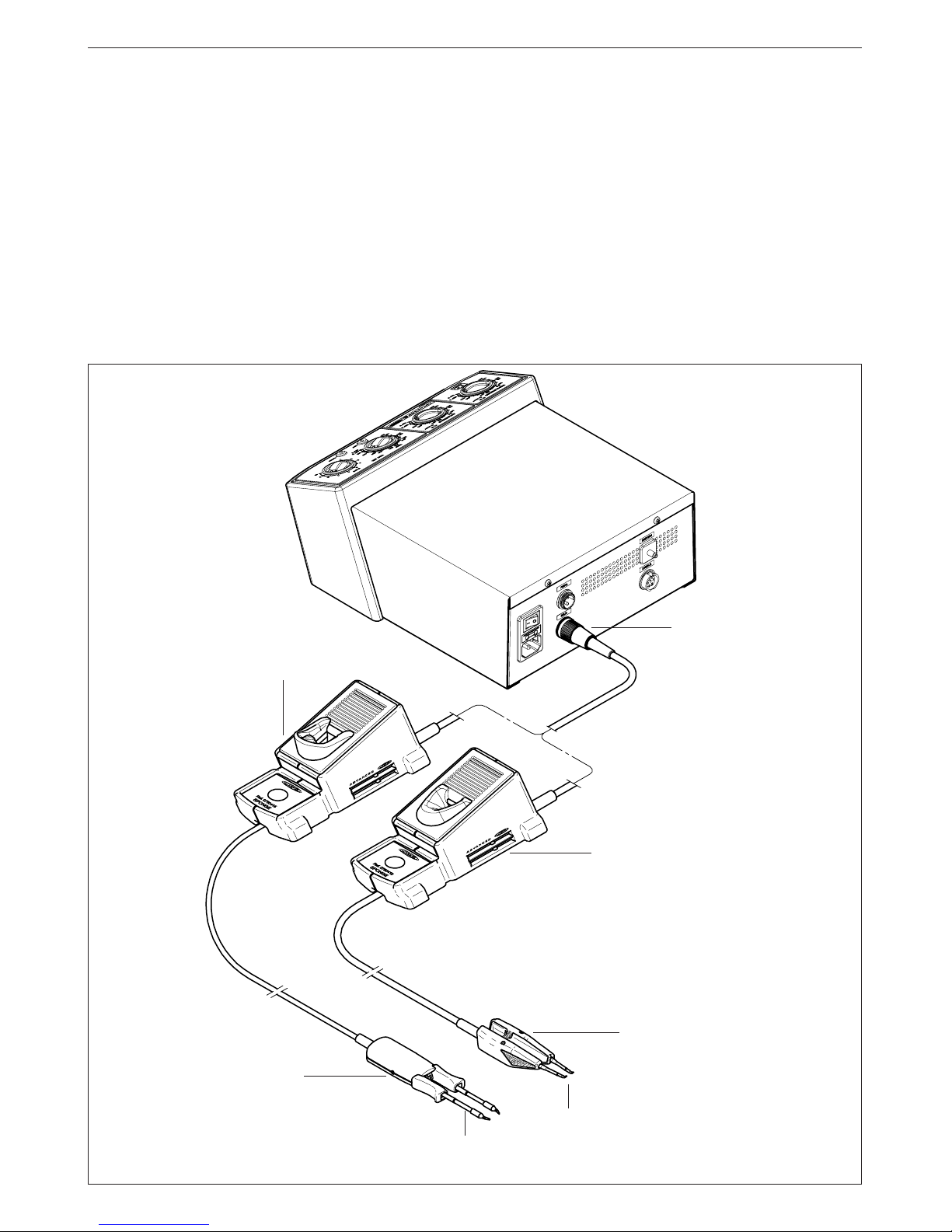

HOT TWEEZERS

AM 6000 station allows to connect two different

models of tweezers, each one with its respective

range of cartridges and stand:

-Micro hot tweezers PA 1200 ref. 1200000.

- Hot tweezers PA 4200 ref. 4200000.

These articles are not delivered with the station.

For tweezers to work properly, the following

components are required: control unit, hot tweezers,

a stand and a set of cartridges corresponding to

the chosen tweezer.

The tweezers are connected to the station in the

following way:

The cable connector of the tweezers is plugged

into the connector of the stand. The cable connector

of the stand is connected to the terminal of the

station. Please find the connection plan on figure.

Hot tweezers

PA 4200

Ref. 4200000

Cartridges for the hot

tweezers PA 4200

Stand PA 8120

Ref. 0748120

Cartridges 1200

Micro hot tweezers

PA 1200

Ref. 1200000

Stand PA 8110

Ref. 0748110

Soldering

connector

SOLD

Page 22

ENGLISH

21

OPERATION

LED lights

Red LED -ON- when lit, it indicates that the station is

plugged in the mains.

Green LED -READY- when lit, it indicates that the

system is ready and correctly set for working.

The green led light is on after a few seconds, is the

time needed to carry on the self-checking system.

The green light is pulsing when the hot tweezers are

in sleep mode.

If the green led is not lit, the reason why, will be one

of the following:

1. The hot tweezers or the cartridge are not

plugged in.

2. The maximum available power has been

exceeded for too long - e.g. in a very thick

soldering at the high repetition rates.

3. The hot tweezers or cartridge has a short circuit

or an open circuit.

4. Any other trouble preventing the system from

working properly.

The hot tweezers will reset itself automatically should

the cartridge short circuit or go open circuit.

Should the hot tweezers be subject to:

- An electrical surge or the cartridge has not been

fitted correctly.

Please turn the unit off and switch on again to reset.

Only for users of AC 2600 console ref. 2600000.

If you lock the working temperature thanks to the

console, the green LED -READY- will remain on

while the dial is set at the locked temperature.

If the dial is not set at the locked temperature,

the green LED -READY- will be blinking. The

farther the dial will be set from the locked

temperature the slower the blinking pace will be.

Sleep function

One of the Series Advanced features is that when

the hot tweezers are placed in the holder, the

temperature at the tip drops automatically to the

sleep temperature. This function is only possible

because of the quick response time which does

not make the user realise the temperature rise

to reach the selected temperature. Also by

this, the oxidation of the tinning of the tip is

considerably reduced and tip life is extended.

To indicate that the hot tweezers are in sleepmode, the green led starts pulsing. These

parameters can be modified using the Console

AC 2600 Ref. 2600000.

In order to take advantage of the above

mentioned feature and as a security measure,

it is necessary to place the hot tweezers on

stand when the iron is not being used.

Page 23

22

ENGLISH

Changing the cartridge

To extract the cartridge the screw needs to be

unfastened and the cartridge pulled out. Insert

the new cartridge and push it thoroughly. Then

check that both tips of the tweezers coincide

and screw it.

Important.

- It is essential to insert the cartridge till

the end for a good connection. Take the

mark as reference and check that both

parts of the tweezer coincide.

Alignment

MICRO HOT TWEEZERS PA 1200

For micro hot tweezers to work properly, the

following components are required:

-Control unit.

-Micro hot tweezers PA 1200 ref. 1200000. For

general precision desoldering with SMD

components.

Power: 40W.

Effective power per cartridge fitted: 20W.

- Stand PA 8110 ref. 0748110.

-A set of cartridges (see range).

RANGE OF CARTRIDGES

PA 1200 has an individual temperature control

for each cartridge so it is supplied individually.

All the cartridges shown are actual size.

Screw

Ref. 0780841

Page 24

ENGLISH

23

JBC reserves the right to make technical changes without

prior notification.

HOT TWEEZERS PA 4200

For hot tweezers to work properly, the following

components are required:

-Control unit.

-Hot tweezers PA 4200 ref. 4200000. For general

desoldering and soldering work in professional

electronics.

Power: 100W.

Effective power per cartridge fitted: 50W.

- Stand PA 8120 ref. 0748120.

-A set of cartridges (see range).

Changing the cartridge

To extract the cartridge the screw needs to be

unfastened and the cartridge pulled out. Insert

the new cartridge and push it thoroughly. Then

check that both tips of the tweezers coincide

and screw it.

Important.

- It is essential to insert the cartridge till the end

for a good connection. Take the mark as

reference and check that both parts of the

tweezer coincide.

Alignment

A

A

A

ØA

A

Ref. A mm

2245-271 1,5

2245-272 2,5

Chip components

Ref. A mm

2245-273 4,0

2245-274 6,0

2245-275 8,0

2245-276 10,0

2245-277 15,0

2245-278 20,0

Dual in line IC

Ref. A mm

2245-279 8,0

2245-280 11,0

QFP and PLCC

Ref. A mm

2245-281

2245-282

Cable stripper

RANGE OF CARTRIDGES

PA 4200 has an individual temperature contr ol

for each cartridge so it is supplied

individually.

2245-281

2245-282

3,5 max

PATENT PENDING

Screw

Ref. 0780841

Page 25

ESPAÑOL

25

Agradecemos la confianza depositada en JBC al adquirir esta estación. Ha sido

fabricada con las más estrictas normas de calidad para prestarle el mejor servicio.

Antes de poner en marcha el aparato, recomendamos leer con atención las

instrucciones que a continuación se detallan.

Soporte extractores

Ref.0932845

Tripode 20

Ref.0932050

Tripode 40

Ref.0932250

Soporte soldador

AD 8200

Ref.0268200

Desoldador DR 5600

Ref.5600000

* Lápiz 2210

Ref.2210000

* Cartuchos 2210

Cartuchos 2245

Pick & Place

MP 2260

Ref.2260000

Estación de reparación

multifunción AM 6000

Selector de aspiración del

Pick & Place y los extractores

Sop. calefactor JT 8700

Ref.0828700

Borne

equipotencial

* Estos elementos no se

suministran con la estación

Filtros de recambio

Ref.0781046

* Soporte pinza

PA 8120

Ref.0748120

* Soporte pinza

PA 8110

Ref.0748110

Lápiz 2245

Ref.2245000

* Pinza desoldadora

PA 4200

Ref.4200000

* Cartuchos para la pinza PA 4200

* Micro pinza desoldadora

PA 1200

Ref.1200000

* Cartuchos 1200

Soporte desoldador

DR 8500

Ref.0788500

Conjunto filtro aspiración

Ref.0821830

Page 26

ESPAÑOL

26

CARACTERISTICAS

La AM 6000 es una estación de reparación de

circuitos con componentes de inserción y SMD.

- AM 6000 230V Ref. 6000200

Está compuesta por 4 módulos que permiten

realizar las principales operaciones de reparación:

- Aire caliente para la desoldadura de

componentes SMD, de cualquier tamaño.

Utiliza el sistema exclusivo de JBC de

protectores-extractores y aire caliente pudiendo

realizar la desoldadura de una manera rápida y

limpia, concentrando el calor en el componente

a desoldar, protegiendo al mismo tiempo el

resto del circuito.

Se puede desoldar un integrado SMD de tamaño

medio en menos de 20 segundos.

- Desoldadura de componentes de inserción y

limpieza de pads en la desoldadura de SMT.

Para realizar esta función la estación dispone

del desoldador DR 5600, con bomba de

aspiración incorporada.

- Posicionador MP 2260 lápiz por aspiración

para la ayuda en la colocación de componentes.

- Soldadura de todo tipo de componentes, con

la rapidez de respuesta, potencia y recuperación

de temperatura de la serie Advanced. Puede

conectar los lápices Advanced 2010, 2210,

2045 o 2245 y las pinzas desoldadoras PA 1200

o PA 4200.

Composición de la estación

- Unidad de Control con calefactor 900 W

- Lápiz 2245 Ref. 2245000

con el cartucho 2245-003 Ref. 2245003

- Desoldador DR 5600 Ref. 5600000

con la punta 5600-003 Ref. 5600003

- Pick & Place MP 2260 Ref. 2260000

Accesorios para el calefactor:

- JT 8700 soporte calefactor Ref. 0828700

- Soporte extractores Ref. 0932845

- Conjunto de 5 protectores (Fig. 1, pág. 128)

- Conjunto de 5 extractores (Fig. 2, pág. 128)

-2 trípodes para los protectores (Fig. 1, pág. 128)

- Conjunto de ventosas JT Ref. 0930110

-3 Boquillas

Para facilitar la extracción de las boquillas el

soporte del calefactor dispone de un útil especial

(Fig. 3, pág. 128).

- Tubo aspiración con conectores Ref. 0932330

- Pedal con cable y conector Ref. 0964551

Accesorios para el lápiz:

- AD 8200 soporte soldador Ref. 0268200

Accesorios para el desoldador:

- DR 8500 soporte desoldador Ref. 0788500

- Conjunto filtro aspiración Ref. 0821830

- Filtros de recambio Ref. 0781046

- Conjunto de accesorios Ref. 0780593

Accesorios para el Pick & Place:

- Conjunto ventosas Pick & Place Ref. 0940163

- Conjunto agujas rectas Ref. 0901546

- Conjunto agujas dobladas Ref. 0861660

- Manual de instrucciones Ref. 0780448

La estación AM 6000 tiene los siguientes

accesorios, que no se incluyen con la estación:

- Lápiz 2010 Ref. 2010000

- Lápiz 2210 Ref. 2210000

- Lápiz 2045 Ref. 2045000

- Micro pinza desoldadora PA 1200 Ref. 1200000

- Pinza desoldadora PA 4200 Ref. 4200000

Page 27

ESPAÑOL

27

Datos técnicos de la Unidad de Control

- Potencia máxima soldador 50W.

- Potencia máxima desoldador 75W.

- Potencia calefactor 900W.

- Selección temperatura de soldadura:

100 a 371°C (±5%).

- Selección temperatura de desoldadura:

100 a 371°C (±5%).

- Selección temperatura del calefactor:

150 a 455°C (±5%).

- Regulación del caudal de aire de 6 a 45 l/min.

- Bomba de aspiración para la sujeción de los

CI.

- Potencia máxima de la estación: 1150W.

- Caja antiestática.

Resistencia típica superficial: 105-1011 Ohms/

cuadro.

- Cumple la normativa CE sobre seguridad

eléctrica, compatibilidad electromagnética y

protección antiestática.

- El borne equipotencial y la punta del soldador

están en conexión directa a la toma de tierra

de red.

- Peso del equipo completo: 17,6 kg.

- En el conector SOLD. sólo se pueden conectar

los lápices 2010, 2210, 2045 y 2245 y las pinzas

desoldadoras PA 1200 y PA 4200.

- En el conector DESOLD. sólo se puede conectar

el desoldador DR 5600.

FUNCIONAMIENTO

Descripción de los mandos

- PEDAL:

Activa la producción de aire caliente mientras

se mantiene accionado.

Cuando se deja de presionar, el sistema

desconecta el calefactor, pero la turbina

continua funcionando hasta que la temperatura

del aire es inferior a 100 °C.

- PULSADORES:

En cada pulsación, se activa o desactiva la

produción de aire caliente. Se para

automáticamente después de estar dos

minutos en marcha.

Cuando la luz roja del botón está encendida

indica que el calefactor está en marcha. Si

está parpadeando indica que hay un error.

A cada pulsación, se activa o desactiva la

bomba de aspiración.

Cuando la luz amarilla del botón está

encendida indica que la bomba de vacío está

en marcha.

- MANDOS:

TEMPERATURE

Permite seleccionar la temperatura entre

150 y 455°C para el calefactor. Las

temperaturas seleccionadas son valores de

referencia y su valor varía en función de la

distancia a la boquilla del calefactor.

Permite seleccionar la temperatura entre 100 y

371°C para las unidades de soldadura y

desoldadura.

AIR FLOW

Permite regular el caudal de aire en una escala

de 1 a 10, equivalente a un mínimo de 6 l/min,

y un máximo de 45 l/min.

- SELECTOR DE VACIO:

Dispone de dos tomas de aspiración, estando

activada la que coincida con la flecha.

HEAT

VACUUM

Medidas de seguridad

- El uso incorrecto de la herramienta puede ser

la causa de un incendio.

- Sea muy prudente cuando utilice la

herramienta en lugares donde hay materiales

inflamables.

- El calor puede producir la combustión de

materiales inflamables incluso cuando no

esten a la vista.

- No usar en la presencia de una atmósfera

explosiva.

- Coloque la herramienta en su soporte después

de usarla y dejela enfriar antes de

almacenarla.

Page 28

ESPAÑOL

28

PROCESO PARA DESOLDAR CON EL

CALEFACTOR

Recomendamos utilizar las boquillas de mayor

diámetro y reservar la mas pequeña (ø4mm) para

la desoldadura de pequeños componentes como

resistencias, condensadores, etc, téngase en

cuenta que con esta boquilla la concentración de

calor es mayor, por lo que para evitar quemar el

circuito impreso, aconsejamos no sobrepasar la

temperatura de 350 °C y el caudal de aire de 6.

Dependiendo del tamaño del circuito integrado a

desoldar, deberá utilizar:

A) Protector + trípode.

B)Extractor.

C) Trípode.

A) Protector + trípode:

- Seleccione el tamaño de protector y trípode en

función del IC a desoldar y colóquelo sobre el

componente.

- Ponga en marcha la bomba de aspiración

mediante el pulsador de VACUUM y coloque

el trípode. Presione la ventosa hasta que quede

adherida al componente.

- Mediante el pedal o el pulsador HEAT ponga

en marcha el generador de aire caliente,

dirigiéndolo con un movimiento circular a

los terminales del componente, procurando

repartir el calor de una forma homogénea.

- Cuando la soldadura pase al estado liquido, el

extractor levantará automáticamente el

componente.

B) Extractor:

- Seleccione el tamaño del extractor en función

del IC a desoldar. Ponga en marcha la bomba

de aspiración mediante el pulsador de

VACUUM.

Page 29

ESPAÑOL

29

- Coloque el extractor y presione la

ventosa hasta que quede adherida al

componente.

- Mediante el pedal o el pulsador HEAT ponga

en marcha el generador de aire caliente,

dirigiéndolo con un movimiento circular a los

terminales del componente, procurando repartir

el calor de una forma homogénea.

- Cuando la soldadura pase al estado liquido, el

extractor levantará automáticamente el

componente.

Existen como accesorio varios modelos de

protectores y extractores.

Las medidas de todos los protectores y

extractores se detallan en la página 128 del

manual.

C) Trípode:

Para los componentes pequeños y los que no se

puede utilizar extractor, recomendamos el uso

del trípode 20 Ref. 0932050 según la figura.

Use el trípode 40 Ref. 0932250 para integrados

de mayor tamaño.

PROCESO PARA SOLDAR

1 Una vez desoldado el componente, deberá

eliminar la soldadura que haya quedado en el

circuito impreso, usando nuestro desoldador

DR 5600 ref. 5600000.

Page 30

ESPAÑOL

30

2 Posicionar el componente o circuito integrado

con el Pick & Place MP 2260 ref. 2260000.

3 Una vez colocado el componente en su posición

correcta, suelde las patas. Si se trata de un

circuito integrado tipo "Flat Pack", suelde primero

una pata de cada ángulo del C I para fijarlo al

circuito.

4 Aplicar el Flux FL 9582 ref. 0046565 en los pads

y leads.

5Soldar las patas restantes. Para ello,

recomendamos utilizar nuestros soldadores

Advanced series, que disponen de

2 modelos de soldador:

Soldador 2210 ref. 2210000 para trabajos de

gran precisión, como soldadura SMD,etc.

Soldador 2245 ref. 2245000 para trabajos

generales de soldadura en electrónica

profesional.

Estos soldadores disponen de una amplia

gama de cartuchos con diferentes modelos de

puntas. Los cartuchos 2245-009 y 2245-010

están especialmente diseñados para soldar

circuitos SMD tipo QFP y PLCC.

Deberá utilizar hilo de estaño entre 0.5 - 0.7mm

de diámetro.

6 Dependiendo de las características del

componente utilice pasta de soldar y nuestra

estación de aire caliente TE 5000, que permite

una regulación muy fina del caudal de aire,

entre 4 y 11 l/min.

Page 31

ESPAÑOL

31

Cambio de la resistencia del calefactor.

1. Separe el muelle. Desenrosque los tornillos.

Siga el proceso inverso para volver a colocar el

calefactor.

Separe el muelle y la tapa. Estire del casquillo para

desconectar el calefactor de la estación.

2. Para sacar la resistencia, presione sobre una

superficie la parte inferior del mango.

MANTENIMIENTO

Cambio del calefactor.

Utilice una llave para desenroscar la tapa.

4. Coloque la nueva resistencia, presionando sobre

su extremo.

5. Enrosque los tornillos fuertemente para evitar

escapes de aire que pueden reducir la duración

de la resistencia. Por último ponga el muelle en

el extremo del mango.

3. Separe la resistencia del cable del calefactor.

Junta tórica ø17 x ø1,8

Page 32

ESPAÑOL

32

Filtro

Ref. 0861800

ANOMALIAS DE FUNCIONAMIENTO

La ventosa no queda adherida al componente.

Aspiración deficiente, Vacuum.

1 Compruebe que la ventosa este colocada

correctamente y en perfecto estado.

2 Compruebe el filtro de entrada de la bomba de

aspiración que hay en el interior de la estación

y cambielo si está sucio u obturado.

Posibles errores

El aparato se desconecta por completo cuando

aparece un error.

Esta es una lista de los errores más habituales:

- Falla la alimentación.

Compruebe si está fundido el fusible de

alimentación.

- La temperatura no aumenta.

Causas posibles:

· Resistencia calefactora abierta.

· Tensión de red baja, muy por debajo de la

nominal.

- No hay lectura del termopar.

Causas posibles: termopar abierto.

- Caudal de aire insuficiente, lo que ha provocado

una subida excesiva de la temperatura del

calefactor.

Antes de recuperar este tipo de error, deberá

esperar a que la temperatura descienda.

Causas posibles: conductos de aire rotos u

obstruidos o bomba de aire estropeada.

- Error en lecturas del cuenta vueltas de la bomba

de aire.

Causas posibles: bomba de aire estropeada o

funcionamiento defectuoso del circuito sensor

óptico.

Para recuperar cualquiera de los errores

anteriores es necesario accionar el interruptor

general situado en la parte posterior de la

estación; en este momento el pedal no puede

estar apretado.

Page 33

ESPAÑOL

33

DESOLDADOR DR 5600

La estación AM 6000 se suministra con:

- El desoldador DR 5600 ref. 5600000 con la punta

5600-003 ref. 5600003.

Potencia desoldador: 75W.

- El soporte desoldador DR 8500 ref. 0788500.

- El conjunto filtro aspiración ref. 0821830.

- El conjunto de accesorios ref. 0780593 que

incluye, las puntas del desoldador: 5600-003,

5600-004 y 5600-005.

El desoldador se conecta a la estación de la

siguiente forma:

El cable del desoldador se debe conectar al soporte

desoldador DR 8500 y el tubo de aspiración al

CONJUNTO FILTRO ASPIRACION y este a la toma

de aspiración SUCTION de la estación. El cable del

soporte desoldador se conecta al conector DESOLD

de la estación. Muy importante, es indispensable

intercalar el CONJUNTO FILTRO ASPIRACION de lo

contrario se inutilizará la bomba de aspiración.

Soporte desoldador

DR 8500

Ref.0788500

Desoldador DR 5600

Ref.5600000

Filtros de recambio

Ref.0781046

Cartucho desoldador

Ref.5600010

Toma de aspiración

SUCTION

Conector

desoldador

DESOLD

Conjunto filtro aspiración

Ref.0821830

Page 34

ESPAÑOL

34

FUNCIONAMIENTO

Luces de señalización

Luz roja -ON- encendida indica que la estación está

conectada a tensión de red.

Luz verde -READY- encendida indica que el

sistema está dispuesto y en correctas condiciones

de trabajo.

La luz verde se enciende después de unos pocos

segundos, que es el tiempo necesario para que se

realice el autochecking del sistema.

La luz verde parpadea cuando el desoldador está en

reposo.

Si la luz verde está apagada, será debido a alguno

de los siguientes motivos:

1. Que el desoldador no está conectado.

2. Que se ha superado la potencia máxima disponible

durante un tiempo excesivo, por ejemplo

desoldaduras muy gruesas y repetidas, etc.

3. Que la resistencia desoldadora está en

cortocircuito o circuito abierto.

4. Cualquier otra anomalía que haga funcionar

defectuosamente el sistema.

El reset de errores es automático cuando el desoldador

o el cartucho están en cortocircuito o circuito abierto.

El reset de errores no es automático ,se debe apagar

y volver a conectar la estación, cuando:

- Existe un error de exceso de aporte de energía.

Cuando se aprieta el pulsador del desoldador se

encenderá una de las dos luces que hay en SUCTION:

Luz verde -SUCTION- si se enciende esta luz

indica que el desoldador está dispuesto y en

correctas condiciones de trabajo.

Luz roja -SUCTION- si se enciende esta luz indica

que está obstruido el circuito de vacío.

Desoldador en reposo

Una de las cualidades de la serie Advanced,

es que cuando el desoldador se coloca en el

soporte, la temperatura baja automáticamente

hasta la temperatura de reposo. Esto es

posible, gracias a la rapidez de su respuesta

térmica, que permite pasar de la temperatura

de reposo a la de trabajo sin interrupción. Con

lo cual se consigue una gran reducción en la

oxidación del estañado y aumenta de una forma

muy importante la duración de la punta.

Para indicar que el desoldador está en reposo,

la luz verde de la unidad de control se pone a

parpadear. Estos parámetros se pueden

modificar con la Consola AC 2600 Ref.

2600000.

Para beneficiarse de la cualidad anterior y como

medida de seguridad, es necesario colocar el

desoldador en el soporte cuando no se utilice.

DR 5600 Ref.5600000

Punta desoldador

Cartucho

Pulsador aspiración

Tubo aspiración

Cable desoldador

Depósito estaño

Metal

Vidrio

Esto será debido a alguna de las siguientes

causas:

- La punta de desoldador está embozada.

- El depósito de estaño está lleno.

- El filtro del desoldador está sucio.

- El filtro de la toma de aspiración de la estación

está sucio.

Sólo para usuarios de la cónsola AC 2600 ref.

2600000.

Si se fija la temperatura con la consola, el led verde

READY sólo permanece encendido contínuamente

cuando el dial señalice la temperatura fijada.

Si el dial no está posicionado en la temperatura

fijada, el led verde READY parpadeará a una

velocidad más lenta cuanto más lejos de la

temperatura fijada se encuentre.

Page 35

ESPAÑOL

35

RECOMENDACIONES DE USO

Para soldar y desoldar

- Los componentes y el circuito deben estar

limpios y desengrasados.

- Con preferencia seleccione una temperatura

inferior a 350°C. El exceso de temperatura

puede provocar el desprendimiento de las

pistas del circuito impreso.

- La punta debe estar bien estañada para

conducir bien el calor. Si permanece mucho

tiempo en reposo, estáñela de nuevo.

Proceso para desoldar

Utilice un modelo de punta de mayor diámetro

interior que el pin a desoldar, con el fin de

conseguir el máximo de aspiración y de

transmisión térmica, asegurese de que la punta

está bien estañada.

1 Apoye la punta del desoldador, de forma

que el terminal del componente penetre dentro

del orificio de la punta.

2 Cuando la soldadura se licúe, imprima a la

punta del desoldador un movimiento de

rotación que permita desprender de los

laterales el terminal del componente.

3 Accione entonces, no antes, el pulsador de

la bomba de vacío el tiempo necesario para

succionar la soldadura.

1

2

3

Después de cada pulsación del botón del

desoldador hay un breve retardo hasta el paro

de la bomba de aspiración, con la finalidad de

asegurar que se vacía completamente el circuito

de aspiración.

Si algún terminal ha quedado con restos de

soldadura, después de intentar desoldarlo,

suéldelo nuevamente aportando estaño y repita

la operación de desoldar.

Ref. 5600-001 5600-002 5600-003 5600-004 5600-005 5600-006 5600-007

5600

A ø (mm)

B ø (mm)

max. pin ø

(mm)

001 / 011

1.4

0.6

0.4

002 / 012

1.8

0.8

0.6

003 / 013

2.7

1

0.8

004

3.2

1.3

1.1

005

3.4

1.6

1.4

006

4.2

2

1.7

007

4.8

2.5

2.3

A ø

B ø

5600-012 5600-0135600-011

PUNTAS DESOLDADOR

Estas puntas están

especialmente

deseñadas para la

limpieza de pads.

Page 36

ESPAÑOL

36

- Para la limpieza de las puntas utilice la

esponja del soporte, que debe estar húmeda

pero no empapada de agua.

Es necesario utilizar sólo agua

desionizada para humedecer la esponja.

Si utiliza agua normal es muy probable que

la punta se ensucie con las sales disueltas

que hay en el agua.

- No lime ni utilice herramientas abrasivas que

puedan destruir la capa de protección

superficial de la punta y evite los golpes.

- Si la punta ha estado mucho tiempo sin

ser estañada, utilice un cepillo metálico para

eliminar el óxido y la suciedad.

Cambio de la punta del desoldador

Esta operación debe realizarse en caliente a una

temperatura mínima de 250°C, para que los

residuos de estaño que hayan quedado en el

interior estén fundidos.

- Desenrosque la punta a sustituir, con la ayuda

de la llave que se suministra.

- Coloque la nueva punta. Apriete con la llave

para conseguir una buena estanqueidad.

Conservación de las puntas

- Periódicamente se debe pasar la baqueta del

diámetro mayor que permita en el interior de la

punta, para limpiar el conducto de aspiración.

Vaciado depósito del desoldador y cambio del

filtro

Para realizar esta operación debe desenroscar el

tapón y retirar el depósito, seguidamente

extraemos el filtro y la espiral y con una baqueta

limpiaremos el interior del depósito.

- Observe el estado del filtro y cámbielo si

estuviera sucio o degradado.

- Vuelva a poner el depósito con el filtro y la

espiral. Cierre el conjunto enroscando el

tapón.

Tipos de deposito de estaño

Se puede escoger entre dos tipos de depósitos:

- Metálico Ref. 0812630.

- Vidrio Ref. 0812620.

Ref. 0780550

Tapón depósito

Baqueta

Ref. 0786640

Filtro Ref.0780840

Depósito

Espiral

IMPORTANTE: NO hacer funcionar la bomba de

vacío durante la operación de estañado de la

punta del desoldador, ya que el humo que

desprende el flux ensuciará rápidamente los

conductos y el filtro de entrada de la bomba.

Page 37

ESPAÑOL

37

- Enrosque los tornillos de la tapa. Coloque

de nuevo la espiral y el filtro en el

depósito. Ponga el depósito dentro del

desoldador y finalmente enrosque el tapón

del depósito.

Cartucho

Ref. 5600010

Tapón depósito

Baqueta

Ref. 0786640

Filtro Ref.0780840

Depósito

Espiral

Cambio del cartucho del desoldador (Ref.

5600010)

- Para realizar está operación debe

desenroscar el tapón y retirar el depósito,

seguidamente extraiga el filtro y la espiral

y con una baqueta limpie el interior del

depósito.

- Desenrosque los tres tornillos de fijación

de la tapa del desoldador. Levante la tapa

y retire el cartucho.

- Coloque el nuevo cartucho. Compruebe

que el extremo del tubo se sitúa en la

ranura del mango (ver figura).

Page 38

ESPAÑOL

38

Limpieza de la válvula interna de la bomba de

vacío

Debe abrir la unidad de control, para ello:

- Desconecte la estación de la red eléctrica.

- Invierta la unidad, quite los tornillos

de fijación.

- Ponga la estación en posición normal y

levante la tapa superior.

- Desenrosque los cuatro tornillos que sujetan

la tapa de la bomba.

- Limpie la válvula con un paño mojado

en alcohol. Si estuviera excesivamente

impregnada, cámbiela por una nueva.

Ref. 0982970.

Detección de perdidas de aspiración.

Para detectar pérdidas de aspiración en el circuito:

- Obstruya el orificio de entrada

de la punta, presionando

sobre un disco de silicona, o

estrangule el tubo que va

del desoldador al filtro.

- Pulse el botón de puesta en marcha de la

bomba de vacío.

El indicador del led rojo de SUCTION deberá

encenderse, esto significa que no habrá perdida

de vacío. Si no es así, significa que hay una

entrada de aire por cualquiera de las juntas,

como pueden ser la punta del desoldador, el

tapón de cierre del depósito, los tapones del

filtro de entrada de la bomba, o bien la bomba no

aspira suficiente por estar sucia la válvula interna

motivado por haber trabajado sin el conjunto filtro

aspiración o sin filtros.

Cambio del filtro de entrada de la bomba

Compruebe el filtro de entrada de la bomba y

cambielo si está sucio u obturado, para ello:

- Abra el filtro tirando de las lengüetas.

- Extraiga los 2 filtros de algodón, deseche los

que estuvieran sucios y coloque unos nuevos

en su lugar. Use siempre 2 filtros.

Cierre el filtro y verifique que no hayan perdidas

de aspiración.

Page 39

ESPAÑOL

39

LAPIZ POSICIONADOR MP 2260

La estación AM 6000 se suministra con el lápiz

Pick & Place MP 2260 ref. 2260000 que es un

posicionador de componentes de montaje

superficial SMD.

El lápiz se debe conectar al conector de VACUUM

de la estación. Vea el gráfico de conexionado de

la estación en la pag. 25.

Se entrega un juego de agujas rectas, un juego

de agujas dobladas y un juego de ventosas de

diferentes diámetros:

- Juego de ventosas Ref. 0940163

- Juego de agujas rectas Ref. 0901546

- Juego de agujas dobladas Ref. 0861660

Las ventosas son adaptables a las agujas para

facilitar la colocación de componentes SMD de

distintos tamaños sobre circuitos impresos.

Estos accesorios le permitirán adaptarse al peso

y tamaño de cualquier componente.

Recoger un componente (Fig. A)

Coloque la punta de la aguja sobre el componente y

obture con el dedo el orificio del lápiz para que por

aspiración, el componente quede sujeto a la aguja.

Posicionar un componente (Fig. B)

Deposite el componente en su posición del circuito

impreso. Retire el dedo del orificio dejando libre

la entrada de aire con lo que el componente

quedará suelto y en la posición deseada.

Anomalías y solución

Le relacionamos las anomalías mas frecuentes y

su posible solución, que posiblemente podrá Vd.

mismo reparar. En cualquier caso, el servicio de

asistencia técnica JBC le atenderá en lo que

precise.

No hay suficiente aspiración

Verifique que no hay fugas y que todos los tubos

estén bien introducidos en sus alojamientos.

Compruebe el filtro de entrada de la bomba de

aspiración que hay en el interior de la estación y

cambielo si está sucio u obturado.

Si a pesar de ello la aspiración es insuficiente se

debe revisar la bomba de vacío.

Filtro

Ref. 0861800

Al montar la ventosa en la aguja, evitar que ésta

salga por la parte inferior.

Fig. A

Fig. B

VENTOSAS

Ref.: 0940163

AGUJAS

RECTAS

Ref.: 0901546

Ø A

mm

COLOR

2 x 4,3

NEGRO

AMARILLO

2 x 7

ROSA2 x 10

Ø B

mm

2 x 0,7

2 x 0,9

2 x 1,2

AGUJAS

DOBLADAS

Ref.: 0861660

COLOR

VERDE

AMARILLO

ROSA

Ø B

mm

2 x 0,8

2 x 0,9

2 x 1,2

Page 40

ESPAÑOL

40

LAPICES SOLDADORES ADVANCED

La estación AM 6000 permite conectar todos los

lápices soldadores de la gama Advanced.

La estación AM 6000 se suministra con:

- El lápiz 2245 ref. 2245000 con el cartucho 2245-

003 ref. 2245003. Potencia: 50W. Se utiliza en

trabajos de soldadura en electrónica general.

- El soporte soldador AD 8200 ref. 0268200.

- El conjunto de accesorios ref. 0780593 que

incluye, el cartucho 2245-007 Ref. 2245007. Existe

una amplia gama de cartuchos 2245 para que

pueda escoger el más adecuado al trabajo a

realizar (pag. 126).

La estación AM 6000 también permite conectar:

- El lápiz 2010 ref. 2010000. Potencia: 20W. Se

utiliza para trabajos de precisión, SMD, etc. Vea

la gama de cartuchos 2010 en la pag. 127.

- El lápiz 2210 ref. 2210000. Potencia: 20W. Se

utiliza para trabajos de precisión, SMD, etc. Vea

la gama de cartuchos 2210 en la pag. 127.

- El lápiz 2045 ref. 2045000. Potencia: 50W. Se

utiliza en trabajos de soldadura en electrónica

general. Vea la gama de cartuchos 2045 en la

pag. 126.

Existe una versión de los lápices 2045 y 2245 con

mangos cubiertos de un aislante térmico.

- Lápiz 2045 termo-aislado ref. 2045110.

- Lápiz 2245 termo-aislado ref. 2245110.

Estos productos están disponibles como un

accesorio, no se incluyen en la estación.

Los lápices y cartuchos 2210 y 2245 cumplen las

especificaciones MIL-SPEC-2000 en cuanto a

diferencia de potencial entre la punta del soldador

y la toma de tierra, que debe ser menor de 2mV.

Para tener el soldador operativo se necesita: la

unidad de control, el soporte soldador, un lápiz y

un cartucho.

El lápiz se conecta a la estación de la siguiente

forma:

El cable del lápiz se debe conectar al conector que

existe en el soporte soldador AD 8200 y el cable del

soporte soldador se conecta en el conector SOLD

de la estación. Vea el gráfico de conexionado en la

figura.

Soporte soldador

AD 8200

Ref.0268200

Lápiz 2010 Ref. 2010000

Lápiz 2210 Ref. 2210000

Lápiz 2045 Ref. 2045000

Lápiz 2245 Ref. 2245000

Cartuchos 2045

Cartuchos 2245

Cartuchos 2010

Cartuchos 2210

Conector

soldador

SOLD

Page 41

ESPAÑOL

41

Soldador en reposo

Una de las cualidades de la serie Advanced, es que

cuando el lápiz se coloca en el soporte, la temperatura

baja automáticamente hasta la temperatura de

reposo. Esto es posible, gracias a la rapidez de su

respuesta térmica, que permite pasar de la

temperatura de reposo a la de trabajo sin interrupción.

Con lo cual se consigue una gran reducción en la

oxidación del estañado y aumenta de una forma

muy importante la duración de la punta.

Para indicar que el soldador está en reposo, la luz

verde de la unidad de control se pone a parpadear.

Estos parámetros se pueden modificar con la

Consola AC 2600 Ref. 2600000.

Para beneficiarse de la cualidad anterior y como

medida de seguridad, es necesario colocar el

lápiz en el soporte cuando no se utilice.

Si se conecta un soporte para soldador que

corresponda a versiones anteriores, puede suceder

que no funcione la función reposo.

Para solucionarlo deberá hacer un puente entre los

terminales 3 y 5 del conector aereo del cable del

soporte que se conecta a la estación.

Conector aereo

Puente entre los

terminales 3 y 5

FUNCIONAMIENTO

Luces de señalización

Luz roja -ON- encendida indica que la estación está

conectada a tensión de red.

Luz verde -READY- encendida indica que el

sistema está dispuesto y en correctas condiciones

de trabajo.

La luz verde se enciende después de unos pocos

segundos, que es el tiempo necesario para que se

realice el autochecking del sistema.

La luz verde parpadea cuando el soldador está en

reposo.

Si la luz verde está apagada, será debido a alguno de

los siguientes motivos:

1. Que el lápiz con cartucho no está conectado.

2. Que se ha superado la potencia máxima disponible

durante un tiempo excesivo, por ejemplo

soldaduras muy gruesas y repetidas, etc.

3. Que el lápiz con cartucho está en cortocircuito

o circuito abierto.

4. Cualquier otra anomalía que haga funcionar

defectuosamente el sistema.

La luz verde se apaga y el soldador deja de ser

alimentado mientras esté en contacto con el

extractor de cartuchos. Esto sucede cuando el

soldador lleva tres segundos en contacto con el

extractor.

El reset de errores es automático cuando el lápiz o el

cartucho están en cortocircuito o circuito abierto.

El reset de errores no es automático, se debe apagar

y volver a conectar la estación, cuando:

- Existe un error de exceso de aporte de energía.

Sólo para usuarios de la cónsola AC 2600 ref.

2600000.

Si se fija la temperatura con la consola, el led verde

READY sólo permanece encendido contínuamente

cuando el dial señalice la temperatura fijada.

Si el dial no está posicionado en la temperatura

fijada, el led verde READY parpadeará a una

velocidad más lenta cuanto más lejos de la

temperatura fijada se encuentre.

Page 42

ESPAÑOL

42

Importante.

- Es indispensable introducir el cartucho hasta

el fondo, para conseguir una buena conexion.

Utilice la marca como referencia.

Alineación

XX

XXXXX

Cartuchos de la serie Advanced

El cartucho está compuesto por el elemento calefactor

que incorpora el sistema de calentamiento y el sensor

de la temperatura y también la punta de larga duración.

La punta de larga duración está compuesta

básicamente por:

1 Cobre

2 Hierro

3 Cromo

4 Estaño

Conservación de las puntas de larga duración

Salvo el núcleo que es de cobre el resto de

metales está depositado galvánicamente en

capas relativamente finas por lo cual es necesario

evitar las causas que puedan provocar su

destrucción.

Para la limpieza de las puntas utilice la esponja

del soporte, que debe estar húmeda pero no

empapada de agua.

Es necesario utilizar sólo agua desionizada

para humedecer la esponja. Si utiliza agua

normal es muy probable que la punta se ensucie

con las sales disueltas que hay en el agua.

Si la punta está muy oxidada recomendamos

utilizar la pasta restañadora de puntas TT 9400

ref. 9400000.

2 - Sitúe el lápiz sobre el cartucho a cambiar,

presione ligeramente y retírelo.

Cambio del cartucho del lápiz

El sistema Advanced permite el cambio rápido

del cartucho, sin parar la estación, con lo que

dispondrá de dos soldadores en uno. Para ello

siga el proceso que se indica a continuación.

1 - Coloque el lápiz y extraiga el cartucho.

3 - Presione a fondo el lápiz sobre el orificio A, B

o C:

A. Para cartuchos 2010 y 2210 rectos.

B. Para cartuchos 2010 y 2210 curvados.

C. Para cartuchos 2045 y 2245.

Page 43

ESPAÑOL

43

Consola AC 2600

La consola AC 2600 está diseñada para modificar

los parámetros originales del programa de regulación

de las siguienes estaciones de la gama Advanced:

- Estación soldadora AD 2000.

- Estación soldadora AD 2200.

- Estaciones soldadoras dual AD 4200 y AD 4300.