Page 1

www.jbctools.com

English

Auto-Feed Soldering station

Ref. AL-A

Page 2

ww w.jb ct oo ls. co m

2 3

www.jbc too ls.c om

Packing List

The followin g items should be i ncluded:

Metal Br ush .................... 1 unit

Ref. CL6217

Auto-Fee d Iron ............. 1 unit

Ref. AL250-B

Stand ............................... 1 unit

Ref. AL-SD

Power Cord .................... 1 unit

Ref. 0009417 (100V/120V)

0009401 (230V )

Sponge ........................... 1 unit

Ref. S0354

Manual ............................ 1 unit

Ref. 0016966

Solder Reel Stand ....... 1 unit

Ref. 008745

Auto-Fee d Soldering

station ............................. 1 unit

Ref. AL-1A (120V)

AL-2A (230V)

AL-9A (100V)

Tip Cleaner .................... 1 unit

Ref. CL9885

Allen Key 2,5mm .......... 1 unit

Ref. 0780493

Auto-Feed Soldering station

Ref. AL-A

Features

Stand

Ref. AL-SD

Power

Socket

Equipotential

connection

Pedal connection

(optional)

Auto-feed Iron

Ref. AL250-B

Fuse

Main switch

Page 3

ww w.jb ct oo ls. co m

4 5

4

4

3

2

1

4

1. Open dragging mechanism

2. Place the guide set and

tighten the screws

Guide Set

3. Take the solder wire from the reel until the guide tube start

4. Close the dragging mechanism

Guide Tube

Start

3

1

2

2

Reel Stand Assembly

Adjusting System Assembly

Page 4

+

LOADING

SOLDER WIRE

+

-

ww w.jb ct oo ls. co m

6 7

A

B

5. Connect the handpiece to the station and switch it on. With the handpiece out of the stand, press

the WIRE LOAD key till the solder leaves by the end of the guide tube.

Fast wire

dragging

Solder wire dragging button

A. Adjust the dragging strength

to allow the forwarding of the

solder wire and to avoid stall

and or clogging situations when

any cause arises

B. Tighten the dragging

mechanism

Clutch Regulation

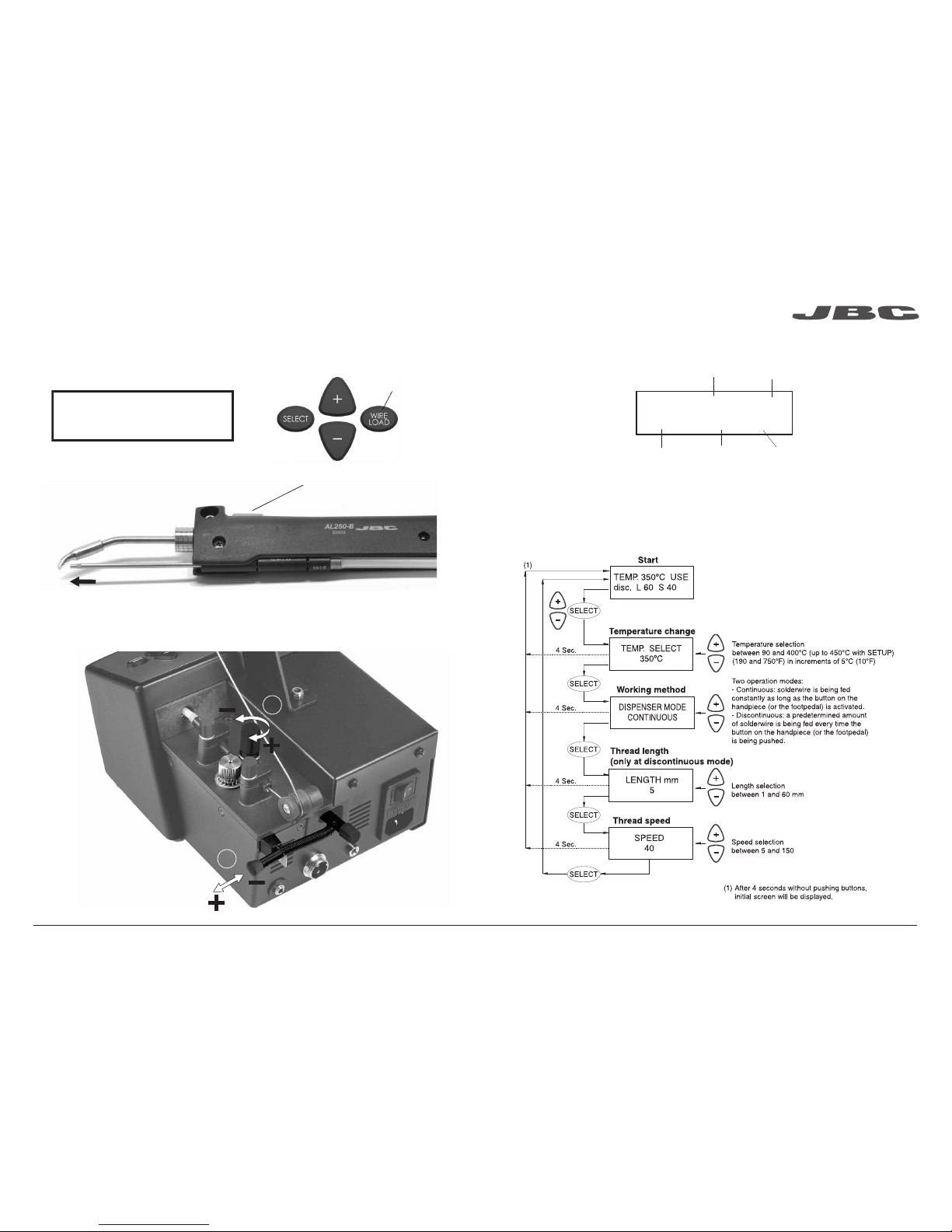

Control Screen

There are 4 tool status:

USE (Use). The tool is ready to work.

STD (Stand). The tool is placed in the stand but still not in the sleep mode.

SLP (Sleep). The tool is in the sleep mode in the stand, its temperature has dropped till the sleep temperature.

OL. The power circuit is overheated. The power is temporarily not supplied.

TEMP. 230ºC USE

disc. L 10 S 11

Tool temperature

Tool status

Length of

wire

Speed

Working method

Page 5

ww w.jb ct oo ls. co m

8 9

CONTINUE ON NEXT PAGE

Parameters Modification of the Tool and the Station

To enter into this mode, you must hold the SELECT key for 3 seconds.

Page 6

ww w.jb ct oo ls. co m

10 11

Page 7

1

3

4

2

ø 0,4

ø 0,6

1,8x0,8

ø 0,8

4,8x1,5

1,2x0,7

3,2x1,5

ø 2,2

2,2 x 1

1,2x0,7

2,2x1

4,8x1,5

ø 2,2

ø 3,8

2,2x1

ø 1,7

ø 1

ww w.jb ct oo ls. co m

8-10 mm

12 13

1. Loosen the cartridge screw to release it.

Place the new cartridge in the Auto-feed iron.

Alignment

Guide tube

Ref . 0002401 - Ø 0,9 - 1,1 mm

Changing cartridge

For a safe cartridge change, unplug the tool or turn the station off before following these guidelines:

2. Align the tip of the cartridge with the

solder Guide tube.

Important: It is essential to insert the

cartridge till the end for a good connection.

Use the mark as reference. Tighten the

cartridge screw.

3. You must leave a gap of 8-10 mm

between the tip and the end of the Guide

tube.

4. Loosen the guide screw.

Adjust the Guide tube and tighten

the screw.

Adjustable Stand

Adjust the tool holder angle to suit your work position. The AL250-B Auto-feed Iron works with C250 cartridge range. Find the model that best suits your

soldering needs in www.jbctools.com

Compatible Cartridges

C250-420 C250-401

C250-405

C250-402

C250-406

C250-403

C250-412C250-404 C250-418

C250-409 C250-410

C250-413C250-407 C250-408 C250-411 C250-414 C250-415

Note: All the cartridges shown are actual size.

Page 8

ww w.jb ct oo ls. co m

14 15

Accessories

Fume Extr actor

Ref. F4468

Suppor t

Ref. AL-IA

Optional Guide set

Ref. 0002399 - Ø 0.4 - 0. 5 mm

0002402 - Ø 0.6 - 0.8 mm

0002843 - Ø 1.1 - 1.5 mm

0013915 - Ø 1.6 - 1.8 mm

Driver Ge ar

Ref. 0002863

*Only included in the Ø 1.1 - 1.5 / Ø 1.6 - 1.8

Guide set for a correct draggi ng of the solder

wire.

Improve thermal transfer by cle aning the tip after each solder j oint.

Tip Cleaner

Brass Wool

Ref. CL6210

Splashg uard

Non-slip b ase

Sponge

Ref. S0354

Wiper

Ref. CL0236

Very effe ctive cleaning m ethod.

It leaves a small l ayer of

solder on the t ip to

prevent oxidati on

between c leaning

and rewetting.

It prevents splashing of

solder par ticles whe n using

the brass wool.

No need to hold the bas e

while cleaning tips.

The least har mful cleaning m ethod.

Keep the sponge d amp with

distilled wate r when working to

avoid tip wear.

A temperature resistant receptacle lets the

operator rem ove excess solder by ge ntly

tapping or wiping.

Tapping: Wiping:

Tap gently to remove

excess solde r.

Use the slots to

remove remain ing

particl es.

Optional

Inox Wool

Ref. CL6205

Metal Br ush

Ref. CL6220

Tip-Tinner

Ref. TT-A

Sand

Ref. CL6211

Page 9

ww w.jb ct oo ls. co m

16 17

Safety

- Do not use the uni ts for any purpose other than solde ring or rework. Inc orrect use may c ause fire.

- The power cord must be plugged into approved bases. Be sure that it is properly grounded

before use. When unplugging it, hol d the plug, not the wire.

- Do not work on ele ctrically li ve parts.

- The tool should be placed in the s tand when not in us e in order to activate the sleep mode.

The soldering ti p, the metal part of the to ol and the stand may s till be hot even when th e station is

turned off. Handle w ith care, includ ing when adjus ting the stand position.

- Do not leave the ap pliance unat tended when it i s on.

- Do not cover the ven tilation grills. H eat can cause i nflamable products to ignite.

- Use a “non resid ue” classifi ed flux and avoid c ontact with skin or eyes to prevent irritation.

- Be careful with the fumes prod uced when sol dering.

- Keep your work place clean a nd tidy. Wear appropria te protective glasse s and gloves whe n

working to avoid perso nal harm.

- Utmost care mu st be taken with liq uid tin waste which c an cause burn s.

- This appli ance can be use d by children over the a ge of eight and als o persons with re duced

physical, sensor y or mental ca pabilities or lack of experie nce provided that they have been give n

adequate super vision or instr uction conce rning use of the ap pliance and un derstand the h azards

involved. Children mu st not play with the ap pliance.

- Maintenanc e must not be carr ied out by childr en unless sup ervised.

It is imperative to follow safe ty guideli nes to prevent ele ctric

shock, inj ury, fire or expl osion.

Before carr ying out mai ntenance, always al low the equipme nt to cool.

- Clean the station screen with a g lass cleane r

or a damp cloth.

Clean

periodically

- Use a damp cloth to cl ean the casing a nd

the tool. Alcoh ol can only be use d to clean

the metal par ts.

- Periodica lly check that th e metal parts of

the tool and stan d are clean so that th e

station can de tect the tool status.

- Maintain tip s urface cle an and tinned pr ior

to storage in order to avoi d tip oxidation.

Rusty and dirty sur faces reduce h eat

transfer to the so lder joint.

- Periodica lly check all c ables and tubes.

Maintenance

1. Pull off the fuse holder and remove th e

fuse. If nece ssary use a too l to lever it off.

2. Press the new fuse into the fuse ho lder

and replace i t in the station.

- Replace a bl own fuse as follows:

- Replace any d efective or dama ged pieces. Us e original JBC s pare parts on ly.

- Repairs sh ould only be performed by a JBC a uthorized techn ical serv ice.

Page 10

ww w.jb ct oo ls. co m

18 19

Exploded View

Page 11

0016966-0915

www.jbctools.com

AL-1A 120V 50/60Hz. Input fuse: 2A. Output: 23.5V

AL-2A 230V 50/60Hz. Input fuse: 1A. Output: 23.5V

AL-9A 100V 50/60Hz. Input fuse: 2A. Output: 23.5V

- Total weight: 5.8 kg (12.9 lb)

- Dimensions: 195 x 200 x 240 mm

- Output Peak Power: 130W

- Temperature range: 90 - 450°C (190 - 840°F) (±5%)

- Complies with CE standards on electrical safety, electromagnetic compatibility

and ESD protected housing “skin effect”

- RoHS compliant

- Equipotential connector and the tool tip are connected to station mains ground supply

for ESD protection

- Diameter of solder wire: 0.4 - 1.8 mm / 0.02 - 0.07 in

Complies with CE standards

ESD protected housing “skin effect”

Warranty

JBC’s 2 year warranty covers this equipment

against all manufacturing defects, including the

replacement of defective parts and labour.

Warranty does not cover product wear due to use

or mis-use.

In order for the warranty to be valid, equipment

must be returned, postage paid, to the dealer

where it was purchased.

This product should not be thrown in the garbage.

In accordance with the European directive 2002/96/EC, electronic equipment at the end of their life

must be collected and returned to an authorized recycling facility.

Specifications

Loading...

Loading...