Page 1

SOLDER FEED STATION

Index

Page

English 1

Español 8

Deutsch 15

Reference Guide

AL

Page 2

Page 3

1

ENGLISH

We appreciate the trust you have placed in JBC in purchasing this station.

It is manufactured to the strictest quality standards in order to give you the best possible

service. Before turning on your station, we recommend you read these instructions

carefully.

Technical specifications

- AL 230V control unit Ref. AL-2A

Input: 230V 50Hz. Output: 24V

- AL 120V control unit Ref. AL-1A

Input: 120V 60Hz. Output: 24V

- AL 100V control unit Ref. AL-9A

Input: 100V 60Hz. Output: 24V

- Power: 60W.

- ESD protected housing.

Typical surface resistance: 105-1011Ohms/square.

Solder feed station

AL 230V Ref.AL-2A

AL 120V Ref.AL-1A

AL 100V Ref.AL-9A

Solder feed stand AL

Ref. AL-SA

Solder feed handpiece

Ref. AL-A

Cartridge

Control unit

Guide set for solder thread 0,9 - 1 ø

Ref. 0002401

- Complies with CE standards on electrical safety,

electromagnetic compatibility and antistatic

protection.

- Equipotential connector and the tool tip are connected to station mains ground supply for ESD

protection.

- RoHS compliant.

- Total weight of unit: 6,1 Kgs (13,5lbs).

This product should not be thrown in the

garbage.

Page 4

ENGLISH

2

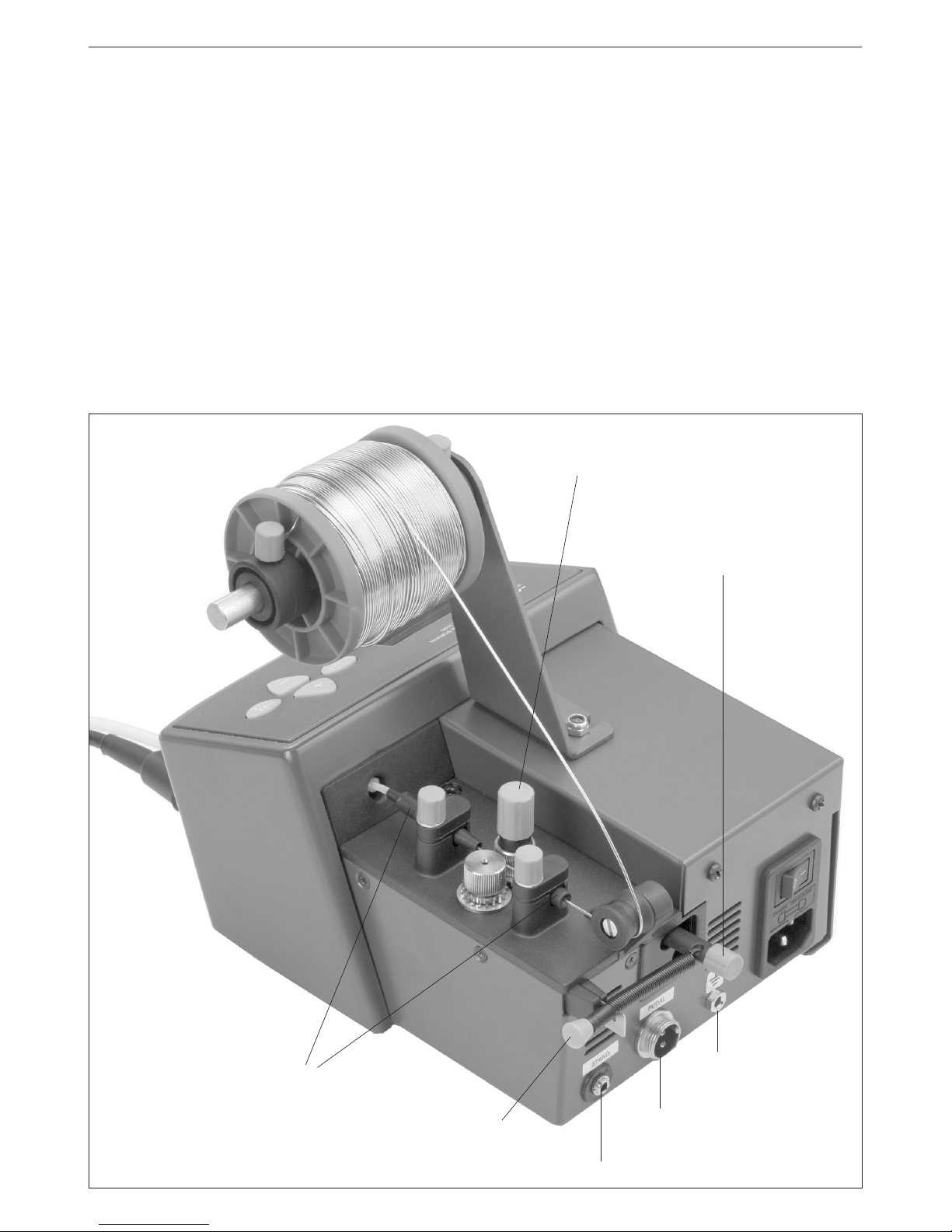

Stand connector

Pedal connector or

external command

Equipotential

connector

Solder thread guide tube

Dragging to adjust the solder

thread strength

Command to release the pressure of the wheels of the solder

dragging mechanism

Pressure regulation of

the spring tightening

control

AL Solder feed station

- AL 230V Ref. AL-2A

- AL 120V Ref. AL-1A

- AL 100V Ref. AL-9A

This station allows you to keep the hand that would

normally hold the solder wire free. If you plan to

use accessories such as pedal switch and stand

arm, then both hands will remain free. This system

is also designed to work as an automatic solder

feed station.

The system includes:

- Control unit.

- Solder feed handpiece Ref. AL-A

with the 250-403 cartridge Ref. C250403

- AL solder feed stand Ref. AL-SA

RECOMMENDATIONS FOR USE

For soldering

- Preferably select a temperature below 350°C

(662ºF). Excess temperature reduce tip life.

- The tip must be well tinned for good heat

conduction.

Safety measures

- Place the tool back on its stand in order to let it

cool down before you store it.

- Guide set for solder thread 0,9 - 1 øRef. 0002401

- Connection cable to mains.

- Transport packaging.

Page 5

3

ENGLISH

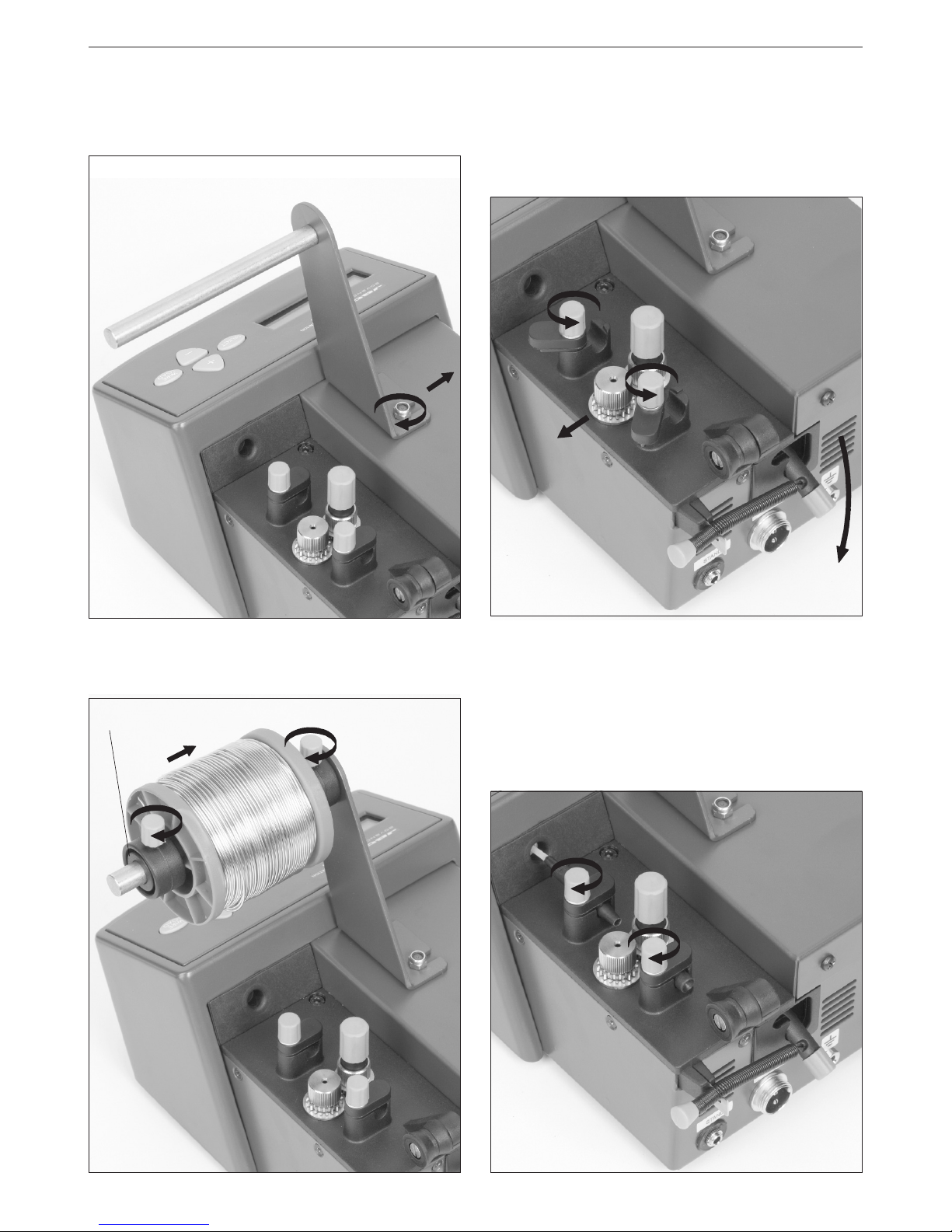

For a proper installation, please proceed as follow:

1. Place the control in the position showed in the

graphic in order to open the dragging mechanism.

2. Loosen the solder reel guide screws of the control

unit.

OPERATION

Place the solder reel in the stand and set the 2

screws.

Place the toolholder metal base and the solder reel

(maximum weight 1kg). Press the 2 screws.

1

1

2

2

3. Place the tubes and guides set in the control unit.

Tighten the screws.

3

3

Toolholder metalbase

The guide set for the solder thread supplied with

the control unit is specially designed for solder reels

diammeter of 0,9 to 1 mm.

If you wish to use other solder reel sizes, you

can order other 3 guide sets as accessory (see

accessories).

Page 6

5

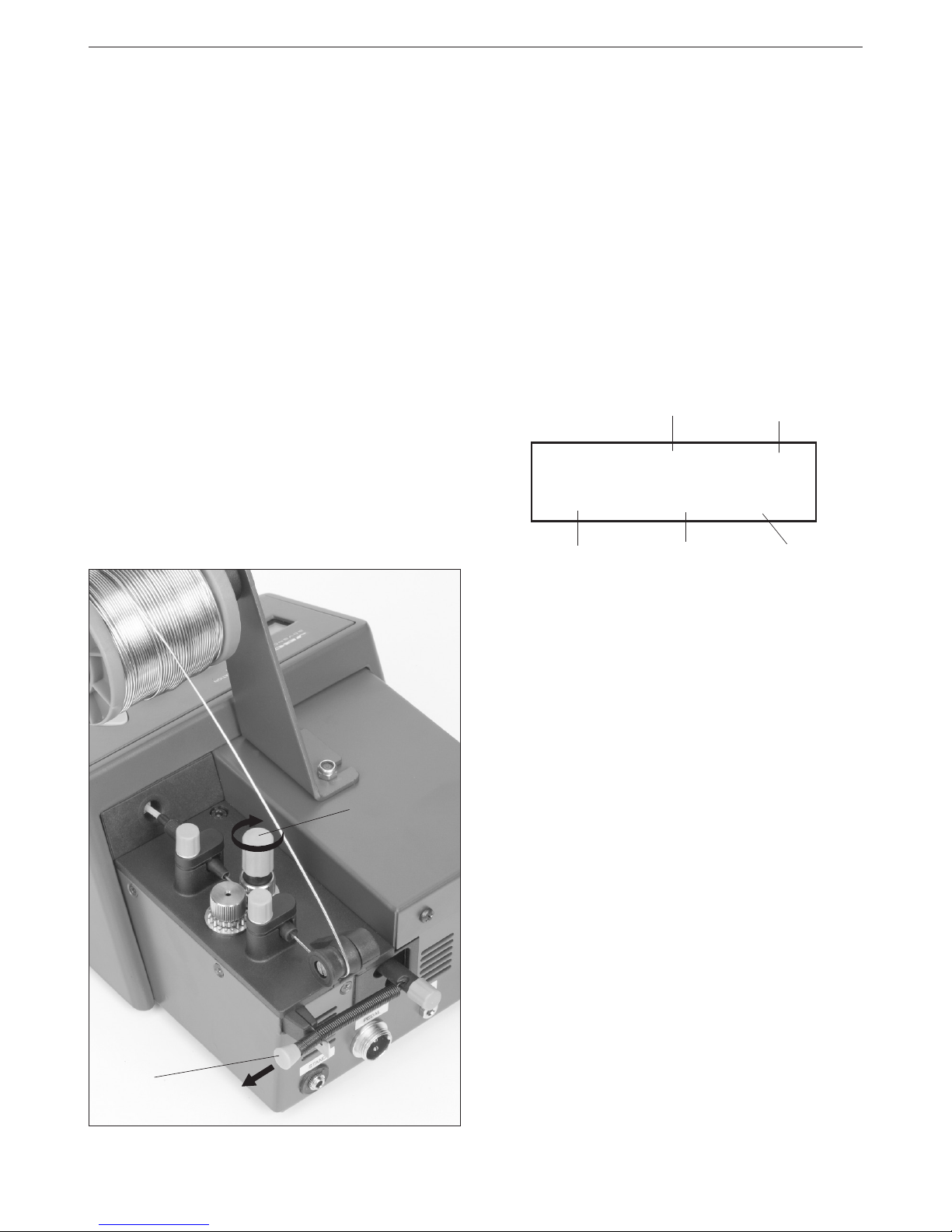

Guide tube screw

Guide tube

8 - 10 mm

4. Place the solder feed handpiece.

¡Warning!

As a safety measure and in order to avoid burns,

when the cartridge is manipulated you must switch off

the station or disconnect the solder feed handpiece.

Take into account that it only takes a few seconds to

reach the working temperature.

4

ENGLISH

7. Take the solder thread from the solder reel until

the guide tube start.

Place the control in the indicated position in order

to close the dragging mechanism.

5. Place the guide tube for the solder threat in the

solder feed handpiece. You must leave a distance

between 8-10mm from the tip of the cartridge and

the end of the guide tube end. Tighten the screw of

the guide tube.

6. Point the tip of the cartridge to the solder guide

tube exit. Tighten the cartridge screws.

7

7

Connect the handpiece to the station and switch

it on. Press the WIRE LOAD key (Fast dragging

thread) till the solder leaves by the end of the guide

tube. Display will show the message "LOADING

SOLDER WIRE".

Thread dragging

button

Important.

- It is essential to insert the cartridge till the

end for a good connection. Take the mark

as reference.

Fast dragging thread

Alignment

6

C a r t r i d g e a n d

electric connection

screw

4

WARNING: It is esential

to tighten this screw for

the tool to function.

Page 7

ENGLISH

5

CLUTCH REGULATION

The dragging mechanism of the station has one

clutch A.

Its function is to allow the forwarding of the solder

threat when the station is working properly but also

avoid stall and or clugging situations when any

cause arises.

The dragging strengh must be adjusted with the

command A. If we rotate it the dragging strengh

is increased.

A

B

With command B the dragging system is tauten.

The more gap, the more strenght will be obtained.

The station is ready to work.

In order to make a solder joint you only need to

press over the thread dragging button in the handle.

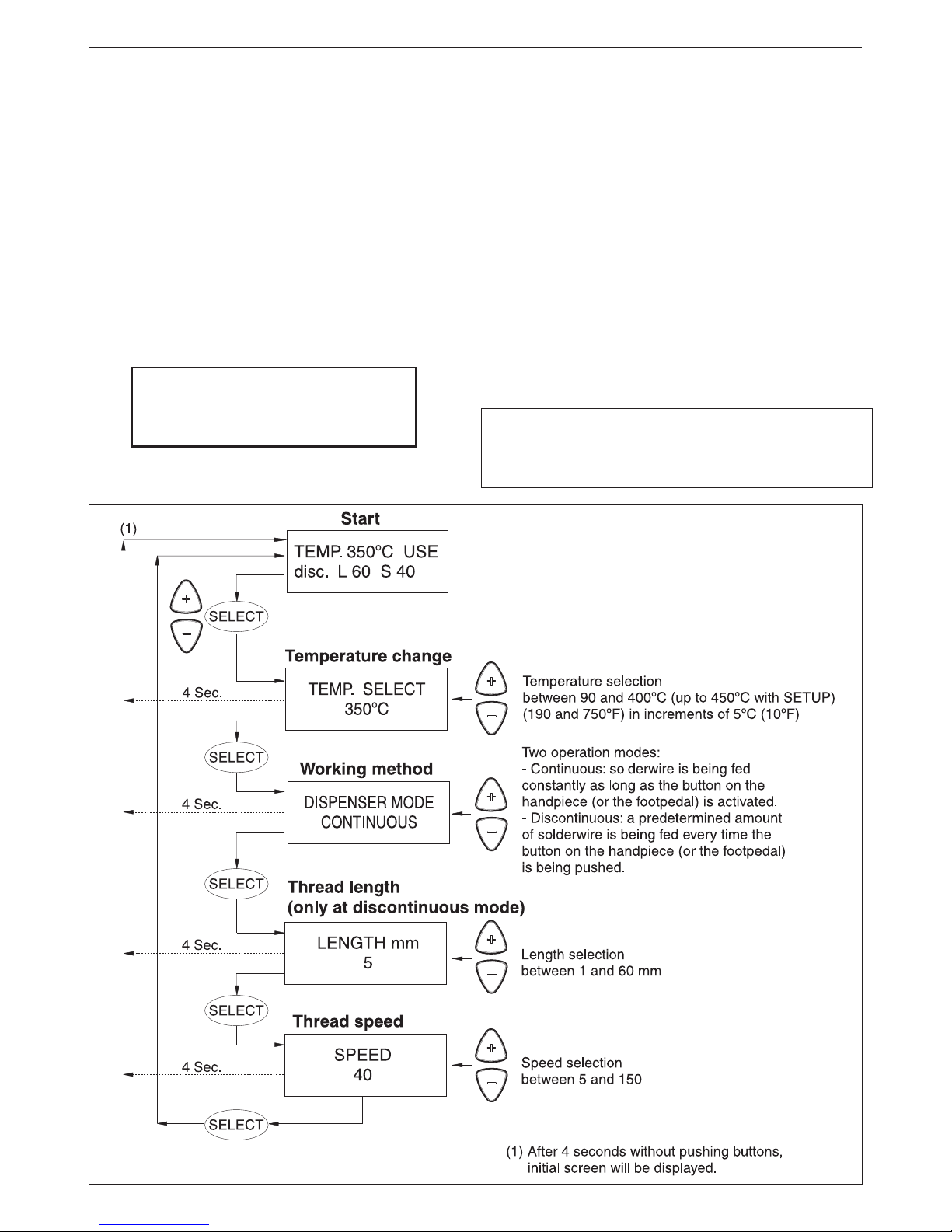

The programm of the station will allow you to modify

all the working parameters. You can display the

parameters with the SELECT key and modify them

with + and - keys.

PROGRAMMING

The system allow us to modify and adjust the following

working parameters directly:

- Temperature between 90 and 400ºC (up to 450ºC

with SETUP).

- Working mode.

- Length thread.

- Speed advance thread.

In order to modify the initial installation parameters

and have access to the counters, you must hold the

SELECT key for 3 seconds.

You will find the operation diagrams are on the

following pages.

STATION DISPLAY

There are 4 tool status:

USE (Use). The tool is ready to work.

STD (Stand). The tool is placed in the stand but still

not in the sleep mode.

SLP (Sleep). The tool is in the sleep mode in the

stand, its temperature has dropped till the sleep

temperature.

OL. The power circuit is overheated. The power is

temporarily not supplied.

TEMP. 230ºC USE

disc. L 10 S 11

Tool temperature

Tool status

Length thread

Speed

Working method

ERROR MESSAGES

No cartridge/tool

Either no tool is connected with the correct cartridge

or the heating element of the cartridge is open.

Wrong tool

The tool which is connected is not valid.

Shortcircuit

The cartridge is in shortcircuit

System stopped by overload (100ºC / 210ºF)

The station has reached a dangerous temperature

and the station stops.

WARNING MESSAGES

Overload (85ºC /185ºF)

When the temperature of the station is close to its

maximum limit, a warning appears for 2 seconds

each 8 seconds as long the station is not cooled

down. The station does not stop.

Page 8

ENGLISH

6

SLEEP FUNCTION

Tool in sleep mode

As son as the soldering iron is left on the stand,

the tip's temperature automatically drops to the

sleep temperature. This is possible because of its

extremely fast thermal response, which allows to

reach the working temperature from the sleep one

without interruption. The oxidation rates on the tin

coating of the tip are drastically reduced, which

increases the tip's lifespan from 2 to 3 times.

To indicate that the tool is in sleep-mode, the display

will show the text SLP.

TEMP. 230ºC SLP

disc. L 10 S 11

HIBERNATION MODE

It is only a "Sleep" second what makes the station

to be in hibernation status, that is to say, the station

keeps runnning but without heating their tools.

It is an state of minimum consumption, but when

it detects that we are using a tool, it turns out

operatively again.

The timing of the hiberation mode is independent

from the sleep mode. It activates by default after

30 minutes.

The hibernation function parameters can be

modified.

In order to take full advantage of the sleep

function and as a security measure, it is

necessary to place the tool in the stand when it

is not being used.

If you would like to change the SLEEP and

HIBERNATION parameters, as any other function,

see page 22.

The sleep function parameters can be modified

using the station program.

Page 9

7

ENGLISH

Accessories

There are other 3 guide sets, apart from the one

supplied with the equipment, for the following solder

thread diameters:

- 0,4 - 0,5 ø Ref. 0002399

- 0,6 - 0,8 ø Ref. 0002402

- 1,1 - 1,5 ø Ref. 0002843

Each set is supplied with 2 thread guides, the leading tube and the exit guide in the iron.

Hands free soldering

stand AL

Ref. AL-IA

The pedal can be plugged to the connector placed

at the rear of the station. Pedal is an option.

Foot switch has the same function as button on the

handle used to feed solder.

Accessory blower

AL

Ref.0003293

Solder feed handpiece

Ref: AL-A

Fume extractor accessory

AL-A Ref: 0004468

You must screw the parts by

the subjection bridle to join the

solder feed handpiece.

You will find all the information about control unit AL

in our web site:

http://www.jbctools.com

JBC reserves the right to make technical changes without prior

notification.

Pedal

Ref. 0964551

AB Air blower

Ref.AB-2A (230V)

Ref.AB-1A (120V)

Page 10

Agradecemos la confianza depositada en JBC al adquirir esta estación. Ha sido

fabricada con las más estrictas normas de calidad para prestarle el mejor servicio.

Antes de poner en marcha el aparato, recomendamos leer con atención las

instrucciones que a continuación se detallan.

8

ESPAÑOL

Datos técnicos

- Unidad de control AL 230V Ref. AL-2A

Entrada: 230V 50Hz. Salida: 24V

- Unidad de control AL 120V Ref. AL-1A

Entrada: 120V 60Hz. Salida: 24V

- Unidad de control AL 100V Ref. AL-9A

Entrada: 100V 60Hz. Salida: 24V

- Potencia: 60W.

- Caja antiestática.

Resistencia típica superficial: 105-1011 Ohms/

cuadro.

Alimentador de estaño

AL 230V Ref.AL-2A

AL 120V Ref.AL-1A

AL 100V Ref.AL-9A

Soporte soldador AL

Ref. AL-SA

Lápiz alimentador estaño

Ref. AL-A

Cartucho

Unidad de control

Conjunto guía para hilo 0,9 - 1 ø

Ref. 0002401

- Cumple la normativa CE sobre seguridad

eléctrica, compatibilidad electromagnética y

protección antiestática.

- El borne equipotencial y la punta del soldador

están en conexión directa a la toma de tierra de

red para protección ESD.

- Cumple la normativa RoHS.

- Peso unidad completa: 6,1 Kgs.

Este producto no debe ser tirado a la basura.

Page 11

ESPAÑOL

9

RECOMENDACIONES DE USO

Para soldar

- Con preferencia seleccione una temperatura

inferior a 350°C. El exceso de temperatura

reduce la vida de la punta.

- La punta debe estar bien estañada para

conducir bien el calor.

Medidas de seguridad

- Coloque la herramienta en su soporte después

de usarla y dejela enfriar antes de almacenarla.

Alimentador de estaño AL

- AL 230V Ref. AL-2A

- AL 120V Ref. AL-1A

- AL 100V Ref. AL-9A

Esta estación permite disponer de la mano que

estaría ocupada con el hilo de soldadura. Si utiliza

accesorios como el pedal y el brazo soporte Ref.

AL-IA permite disponer de las dos manos libres. Se

puede utilizar también como estación en un sistema

automático de soldadura.

Relación de componentes que se entregan:

- Unidad de control.

- Lápiz alimentador de estaño Ref. AL-A

con el cartucho 250-403 Ref. C250403

- AL soporte soldador Ref. AL-SA

- Conjunto guía + tubo

para hilo 0,9 - 1 ø Ref. 0002401

- Cable de conexión a red.

- Envase de transporte.

Conector soporte

Conector pedal o

comando externo

Conector

equipotencial

Guías del hilo

Embrague para el ajuste de la fuerza

de arrastre del hilo

Mando para liberar la presión

de las ruedas de arrastre sobre

el hilo

Regulación presión del

muelle tensor

Page 12

10

ESPAÑOL

Para su instalación siga los pasos que se indican

a continuación:

1. Ponga el mando en la posición señalada en el

gráfico para que se abra el mecanismo de arrastre.

2. Afloje los tornillos de sujección de las guías del

hilo de estaño de la unidad de control.

FUNCIONAMIENTO

Ponga el soporte para la bobina y apriete las 2

tuercas.

Ponga los casquillos portacarrete y la bobina (peso

máximo 1kg). Apriete los 2 tornillos.

1

1

2

2

3. Coloque el juego de tubos y guías en la unidad

de control. Apriete los tornillos de sujección.

3

3

Toolholder metalbase

El juego de tubos y guías que se suministra, es para

hilo de 0,9 a 1mm de diámetro.

Para otros diámetros de hilo ver accesorios.

Page 13

11

ESPAÑOL

5

Tornillo de sujección del tubo guía

Tubo guía

8 - 10 mm

4. Coloque el cartucho en el lápiz alimentador.

¡Atención!

Como medida de seguridad y para evitar quemaduras,

cuando manipule el cartucho debe apagar la estación

o desconectar el lápiz alimentador de la estación.

Tenga en cuenta que en tan sólo unos segundos el

cartucho alcanza la temperatura de trabajo.

7. Pase el hilo de estaño desde la bobina hasta el

inicio de los tubos de guía.

Ponga el mando en la posición indicada para que

se cierre el mecanismo de arrastre.

5. Coloque el tubo guía para el hilo de estaño en el

lápiz alimentador. Deje una separación de unos 8 a

10mm entre el extremo de la punta del cartucho y

el final del tubo guía. Apriete el tornillo de sujección

del tubo guía.

6. Oriente la punta del cartucho hacia la salida del

tubo guía de estaño. Apriete el tornillo de sujección

del cartucho.

7

7

Conecte el lápiz a la estación y pongala en marcha.

Pulse en el botón WIRE LOAD (avance rápido del hilo)

hasta que salga estaño por el extremo del tubo guía.

En el display se muestra el mensaje "CARGANDO

HILO SOLDADURA".

Pulsador avance

hilo estaño

Importante.

- Es indispensable introducir el cartucho hasta

el fondo, para conseguir una buena conexion.

Utilice la marca como referencia.

Avance rápido del hilo

Alineación

6

Tornillo de sujección

y conexión eléctrica

del cartucho

4

ATENCION: para que el

soldador funcione es

indispensable apretar

este tornillo.

Page 14

ESPAÑOL

12

REGULACIÓN DEL EMBRAGUE

El mecanismo de arrastre de la estación dispone

de un embrague A.

Su función es la de permitir el avance del hilo de

estaño cuando la estación funciona correctamente

pero además impide que se formen atascos de

estaño cuando haya alguna causa que impida el

avance del hilo de estaño.

La fuerza de arrastre se debe ajustar con el mando

A. Si giramos en sentido horario aumenta la fuerza

de arrastre.

Con el mando B se tensa el sistema de arrastre.

Cuanto más separado esté, más fuerza se hará.

La estación ya está lista para trabajar.

Para realizar una soldadura sólo debe pulsar sobre

el botón de aportación de estaño del mango.

El programa de la estación le permitirá modificar

todos los parámetros de trabajo. Podrá visulizar

los parámetros con la tecla SELECT y modificarlos

con las teclas + y -.

PROGRAMACIÓN

El sistema permite modificar y ajustar directamente

los siguientes parámetros de trabajo:

- La temperatura entre 90 y 400ºC (hasta 450ºC

con SETUP).

- El modo de trabajo.

- La longitud del hilo.

- La velocidad de avance del hilo.

Para modificar los parámetros de instalación inicial

y tener acceso a los contadores se debe mantener

pulsada durante 3 segundos la tecla SELECT.

En las páginas siguientes tiene los diagramas de

funcionamiento del programa.

DISPLAY DE LA ESTACION

Hay 4 estados de la herramienta:

USE (Use). La herramienta está preparada para

trabajar.

STD (Stand). La herramienta está colocada en el

soporte pero aún no ha entrado en modo "Sleep".

SLP (Sleep). La herramienta está en el soporte y

en modo "Sleep", su temperatura ha bajado hasta

la temperatura de sleep.

OL. Sobrecalentamiento del circuito de poténcia, se

detiene la potencia momentáneamente.

TEMP. 230ºC USE

disc. L 10 S 11

Temperatura

de la herramienta

Estado

herramienta

Longitud hilo VelocidadModo de trabajo

A

B

MENSAJES DE ERROR

No hay cartucho o herramienta (No cartridge/

tool)

No hay herramienta conectada con cartucho

correcto, o el cartucho está abierto.

Herramienta incorrecta (Wrong tool)

La herramienta conectada no es válida.

Cortocircuito (Shortcircuit)

El cartucho está cortocircuitado.

Enfriando (System stopped by overload)(100ºC)

La estación se encuentra a una temperatura

peligrosa y se detiene para enfriarse.

MENSAJES DE WARNING

Sobrecarga (Overload) (85ºC)

Aviso de la temperatura de la estación que está

acercándose al límite máximo, aparece durante 2

segundos en intervalos de 8 segundos mientras

la estación no se haya enfriado. La estación, NO

se detiene.

Page 15

ESPAÑOL

13

SISTEMA SLEEP

Herramienta en reposo

Una de las cualidades de la serie JBC, es que

cuando una herramienta se coloca en el soporte,

la temperatura baja automáticamente hasta la

temperatura de reposo (sleep). Esto es posible,

gracias a la rapidez de su respuesta térmica, que

permite pasar de la temperatura de reposo a la

de trabajo sin interrupción. Con lo cual se evita la

oxidación del estañado de la punta y aumenta de

2 a 3 veces la vida de la punta.

Para indicar que la herramienta está en reposo, en

el display aparece el texto SLP.

TEMP. 230ºC SLP

disc. L 10 S 11

Modo HIBERNACIÓN

Es un segundo Sleep que hace que la estación

entre en hibernación, es decir, la estación sigue

funcionando pero sin calentar sus herramientas.

Es un estado de mínimo consumo, pero que cuando

detecta que se ha cogido una herramienta, vuelve

a estar operativa.

La temporización del modo hibernación es

independiente del modo Sleep, por defecto, se

activa a los 30 minutos.

Los parámetros de la función hibernación son

modificables.

Para beneficiarse del sistema sleep y como

medida de seguridad, es necesario colocar la

herramienta en el soporte cuando no se utilice.

Si desea cambiar los parámetros de SLEEP e

HIBERNACIÓN, así como cualquier otra función,

vea página 22.

Los parámetros de la función sleep se pueden

modificar con el programa de la estación.

Page 16

14

ESPAÑOL

A la estación se le puede conectar el pedal en

el conector que existe en la parte posterior de la

estación.

Cuando se presiona sobre el pedal, equivale a

pulsar el boton de avance del hilo que hay en el

mango del lápiz.

Accesorios

Existen 3 conjuntos guía + tubo, además del que

se suministra con el equipo, para los siguientes

diámetros de hilo de soldadura:

- 0,4 - 0,5 ø Ref. 0002399

- 0,6 - 0,8 ø Ref. 0002402

- 1,1 - 1,5 ø Ref. 0002843

Cada conjunto se compone de 2 guías hilos, el tubo de

conducción y la guía de salida en el soldador.

Lápiz alimentador estaño

Ref: AL-A

Accesorio aspira-humos

AL-A Ref: 0004468

Para unir el lápiz alimentador

de estaño atornillar las piezas

con la brida de sujeción.

Encontrará toda la información sobre la unidad de

control AL en nuestra web:

http://www.jbctools.com

JBC se reserva el derecho de introducir modificaciones sin

previo aviso

Brazo soporte

soldador AL

Ref. AL-IA

Accesorio

soplador AL

Ref. 0003293

Pedal

Ref. 0964551

AB Air blower

Ref.AB-2A (230V)

Ref.AB-1A (120V)

Page 17

Wir danken Ihnen für das JBC mit dem Kauf dieser Station erwiesene Vertrauen. Bei

ihrer Fertigung wurden die strengsten Qualitätsmaßstäbe zugrunde gelegt, so dass

Sie optimale Lötergebnisse erwarten dürfen. Vor Inbetriebnahme des Geräts lesen

Sie bitte die vorliegende Betriebsanleitung aufmerksam durch.

15

DEUTSCH

Lötstation mit Zinnzuführung

AL 230V Ref.AL-2A

AL 120V Ref.AL-1A

AL 100V Ref.AL-9A

Lötkolbenständer AL

Ref. AL-SA

Zinnzuführungs-Handstück

Ref. AL-A

Kartusche

Steuereinheit

Zuleitungsgarnitur für Draht 0,9 - 1 ø

Réf. 0002401

- Er füllt die EG-Sicherheitsvorschriften über

elektrische Sicherheit, elektromagnetische

Kompatibilität und antistatischen Schutz.

- Die Equipotentialausgleichsbuchse und die

Lötspitze sind zum Schutz gegen elektrostatische

Entladungen mit der Erdung des Netzsteckers

verbunden.

- Erfüllt die RoHS-Vorschriften.

- Gewicht der kompletten Anlage: 6,1 kg

Dieses Produkt darf nicht mit dem Hausmüll

entsorgt werden.

Technische Daten

- Steuereinheit AL 230V Ref. AL-2A

Eingangsspannung: 230V 50 Hz

Ausgangsspannung: 24V

- Steuereinheit AL 120V Ref. AL-1A

Eingangsspannung: 120V 60Hz

Ausgangsspannung: 24V

- Steuereinheit AL 100V Ref. AL-9A

Eingangsspannung: 100V 60Hz

Ausgangsspannung: 24V

- Leistung: 60W

- Astatisches Gehäuse.

Typischer Oberflächenwiderstand: 105-1011

Ohm/Quadrat

Page 18

16

DEUTSCH

Lötstation mit Zinnzuführung AL

- AL 230V Ref. AL-2A

- AL 120V Ref. AL-1A

Diese Station ermöglicht es, über die andere Hand

zu verfügen, die eigentlich den Löhtdraht hält. Wenn

man ein Pedal und einen verstellbaren Haltearm für

den Lötkolben Ref. AL-IA einsetzt, hat man sogar

beide Hände frei. Sie kann auch als Station innerhalb

eines automatischen Lötsystems betrieben werden.

Aufstellung der zum Lieferumfang gehörenden

Komponenten:

- Steuereinheit

- Zinnzuführungs-Handstück Ref. AL-A

mit der Kartusche 250-403 Ref. C250403

- AL Lötkolbenständer Ref. AL-SA

EMPFEHLUNGEN FÜR DEN GEBRAUCH

Zum Löten und Entlöten

- Möglichst immer mit Temperaturen unter 350°

C arbei ten. Zu hohe Temperaturen verkürzen

die Standzeit der Lötspitze.

- Damit die Spitze gut die Wärme leitet, muss

sie gut verzinnt sein.

Sicherheitsvorkehrungen

- Nach dem Gebrauch das Werkzeug in seinem

Ständer abstellen und abkühlen lassen, bevor

es aufbewahrt wird.

Ständeranschluss

Anschluss für Pedal oder

externe Steuerung

Equipotentialausg l e i c h s buch se

Führungsschläuche des

Zinndrahts

Kupplung für die Einstellung der

Vorschubkraft des Drahts

Regler zur Entriegelung der

Drahtvorschubkraft

Regulierung des Drucks

der Spannfeder

- Garnitur einer Führungseinheit

für Zinndraht 0,9 - 1 ø Ref. 0002401

- Kaltgerätestecker

- Transportverpackung

Page 19

17

DEUTSCH

Befolgen Sie bei ihrem Einbau die anschließend

genannten Arbeitsschritte:

1. Bringe n Sie den Regler in die auf der

Abbildung gezeigte Stellung, damit sich der

Vorschubmechanismus öffnet.

2. Lockern Sie die Befestigungsschrauben der

Zinndrahtführungen an der Steuereinheit.

FUNKTIONSWEISE

Setzen Sie den Spulenhalter ein und ziehen Sie die

2 Muttern fest.

Setzen Sie die Drahthaspelmuffen und die Spule ein

(Höchstgewicht 1 kg). Ziehen Sie die 2 Schrauben

fest.

3. Bringen Sie die Führungsschlauch-Garnitur

an d er Ste ue rein heit an. Z iehen Sie d ie

Befestigungsschrauben fest.

Die zum Lieferumfang gehörende Garnitur der

Schläuche und Zuführungen eignet sich für Draht

mit einem Durchmesser von 0,9 bis 1 mm.

Für andere Drahtdurchmesser siehe Zubehör auf

der vorherigen Seite.

1

1

2

2

3

3

Toolholder metalbase

Page 20

18

DEUTSCH

5

Befestigungsschraube des Führungsschlauch

Führungsschlauch

8 - 10 mm

4. Bauen Sie die Kartusche in das Zuführungs-

Handstück ein.

Vorsicht!

Als Vorsichtsmaßnahme und um Verbrennungen zu

vermeiden, müssen Sie die Station abschalten oder das

Zuführungs-Handstück aus der Station abziehen, wenn

Sie Arbeiten an der Kartusche ausführen. Denken Sie

daran, dass die Kartusche in nur wenigen Sekunden

die Arbeitstemperatur erreicht.

7. Führen Sie den Zinndraht von der Spule bis zum

Beginn der Führungsschläuche.

Bringen Sie den Regler in die angegebene Stellung,

damit sich der Vorschubmechanismus verriegelt.

5. Stecken Sie den Führungsschlauch für den

Zinndraht in das Zuführungs-Handstück. Lassen

Sie dabei einen Abstand von etwa 8 bis 10 mm

zwischen dem Ende der Kartuschenspitze und

dem Ende des Führungsschlauch. Ziehen Sie die

Befestigungsschraube des Führungsschlauch fest.

6. Richten Sie die Kartuschenspitze auf das Ende

des Zinnführungsschlauch aus. Ziehen Sie die

Befestigunsschraube der Kartusche an.

7

7

Schließen Sie das Handstück an die Station an und

schalten Sie diese ein. Betätigen Sie die Taste WIRE

LOAD (schneller Drahtvorschub) solange, bis Zinn

am Ende des Führungsschlauch herauskommt. Auf

dem Display wird die Meldung "LOADING SOLDER

WIRE" angezeigt.

Taste Zinndrahtvorschub

Wichtig.

- F ür ei ne gu t e Ve rb in d un g i st es

ausschlaggebend, die Kartusche bis zum

Anschlag einzustecken. Orientieren Sie sich

dabei an der Markierung.

Schneller Drahtvorschub

Ausrichtung

6

Befestigungsschraube und

elektrischer Anschluss der

Kartusche

4

V O R S I C H T : D i e s e

Schraube muss unbedingt

angezogen werden, sonst

kann der Lötkolben nicht

funktionieren.

Page 21

DEUTSCH

19

ABSTIMMUNG DER KUPPLUNG

Der Vorschubmechanismus der Station verfügt über

eine Kupplung A.

Ihre Aufgabe ist es, bei reibungslosem Stationsbetrieb

den Zinndrahtvorschub zu gewährleisten, doch

zudem verhindert sie, dass sich Zinnstaus bilden,

wenn der Zinndrahtvorschub aus irgendeinem

Grund beeinträchtigt wird.

Die Vorschubkraft muss mit dem Regler A reguliert

werden. Wenn wir ihn im Uhrzeigersinn drehen, nimmt

die Vorschubkraft zu.

Mit dem Regler B wird das Vorschubsystem gespannt. Je weiter er entfernt ist, umso stärkere Kraft

übt es aus.

Jetzt ist die Station schon einsatzbereit.

Um eine Lötung vorzunehmen, müssen Sie nur die

Taste Zinnzufuhr am Griff betätigen.

Das Programm der Station erlaubt Ihnen, alle

Arbeitsparameter zu ändern. Sie können die

Parameter mit der Taste SELECT anzeigen und mit

den Tasten + und - ändern.

PROGRAMMIERUNG

Das System erlaubt, direkt die folgenden

Arbeitsparameter zu ändern und einzustellen:

- die Temperatur zwischen 90 und 400ºC (bis

450ºC mit SETUP)

- die Betriebsart

- die Drahtlänge

- die Vorschubgeschwindigkeit des Drahts

Um die ursprünglichen Installationsparameter zu

ändern und Zugriff auf die Zähler zu erlangen, die

Taste SELECT 3 Sekunden lang gedrückt halten.

Auf den folge nden Sei ten sehen Sie die

Ablaufdiagramme des Programms.

ANZEIGE DER STATION

Es gibt 4 Werkzeugzustände:

USE (Use). Das Werkzeug ist betriebsbereit.

STD (Stand). Das Werkzeug steht im Ständer,

befindet sich allerdings noch nicht in der Betriebsart

"Sleep".

SLP (Sleep). Das Werkzeug steht im Ständer und

befindet sich in der Betriebsart "Sleep". Seine

Temperatur ist auf die Sleep-Temperatur abgesenkt

worden.

OL. Überhitzung des Hochstromkreises, der

Hochstrom wird zeitweise gestoppt.

TEMP. 230ºC USE

disc. L 10 S 11

Werkzeugtemperatur

Werkzeugzustand

Drahtlänge

Geschwindigkeit

Betriebsart

A

B

FEHLERMELDUNGEN

Kein Werkzeug vorhanden oder Werkzeug

geöffnet (No cartridge/tool)

Es gibt kein mit korrekter Kartusche angeschlossenes

Werkzeug oder die Kartusche ist geöffnet.

Falsches Werkzeug (Wrong tool)

Das angeschlossene Werkzeug ist nicht gültig.

Kurzschluss (Shortcircuit)

In der Kartusche liegt ein Kurzschluss vor.

Abkühlung (System stopped by overload)(100ºC)

Die Station hat eine gefährliche Temperatur erreicht

und hält an, um abzukühlen.

WARNMELDUNGEN

Überhitzung (Overload) (85ºC)

Warnung zur Stationstemperatur, die sich der

Obergrenze annähert. Erscheint 2 Sekunden lang in

Intervallen von 8 Sekunden, solange sich die Station

nicht abgekühlt hat. Die Station hält NICHT an.

Page 22

DEUTSCH

20

Betriebsart Hibernation

Ist eine zweite Stufe der Sleep-Funktion, die dafür

sorgt, dass die Station in eine Art Winterschlaf fällt,

d.h. die Station bleibt weiterhin in Betrieb, heizt

allerdings nicht die Werkzeuge auf. Dies ist ein

Zustand mit äußerst geringem Verbrauch, aber

sobald das Werkzeug in die Hand genommen wird,

ist es erneut einsatzbereit.

Die zeitliche Umschaltung in die Betriebsart

Hib er nat i on ist von der Be triebs art S le ep

unabhängig. Standardmäßig wird sie nach 30

Minuten aktiviert.

Die Parameter der Funktion Hibernation können

geändert werden.

Um das Sleep-System auszunutzen, ist es

erforderlich, das Werkzeug bei Nichtbenutzung

im Ständer abzulegen.

TEMP. 230ºC SLP

disc. L 10 S 11

SLEEP-SYSTEM

Werkzeuge in Standby-Funktion

Eine der Stärken der JBC-Serie liegt darin, dass

die Temperatur automatisch auf die StandbyTemperatur abgesenkt wird, wenn ein Werkzeug

im Ständer abgestellt wird. Das direkte thermische

Ansprechen macht es möglich, ohne Unterbrechung

von der Standby-Temperatur zur Arbeitstemperatur

zu wechseln. Dadurch wird die Oxidierung der

Spitze vermieden und die Lebensdauer der Spitze

um das 2- bis 3 fache verlängert.

Um anzuzeigen, dass sich das Werkzeug im

Standby befindet, erscheint im Display der Text SLP.

Wenn Sie die Parameter für SLEEP und

HIBERNATION sowie irgendeine andere Funktion

ändern möchten, Sehen Sie auf Seite 22.

Die Parameter der Sleep-Funktion lassen sich mit

dem Programm der Station ändern.

Page 23

21

DEUTSCH

Zubehör

Neben der zum Lieferumfang des Geräts gehörenden

Zuleitungsgarnitur gibt es 3 Zuleitungsgarnituren

+ Schlauch für Lötdraht mit den folgenden

Durchmessern:

- 0,4 - 0,5 ø Ref. 0002399

- 0,6 - 0,8 ø Ref. 0002402

- 1,1 - 1,5 ø Ref. 0002843

Jede Garnitur besteht aus 2 Drahtführungen, dem

Führungsschlauch und der Ausgangsführung am

Lötkolben.

Haltearm Lötstation

AL

Ref. AL-IA

An die Station kann das Pedal Ref. 0964551 durch

den auf der Rückseite der Station befindlichen Stecker

angeschlossen werden. Nicht im Lieferumfang

enthalten.

Wenn man das Pedal betätigt, entspricht dies dem

Drücken der Taste Drahtvorschub am Griff des

Handstücks.

Gebläsezubehör

AL

Ref. 0003293

Zinnzuführungs-Handstück

Ref: AL-A

Rauch-Zangenzubehör

AL-A Ref: 0004468

S i e m üs s e n d i e Te i l e

vo m U nt erwer fu ng sza um

schrauben, um das handstück

zu verbinden.

Pedal

Ref. 0964551

Gebläse AB

Ref. AB-2A (230V)

Ref. AB-1A (120V)

Unter dem Web: http://www.jbctools.com finden Sie

die vollständige Information über die Steuereinheit AL.

JBC behält sich das Recht vor, technische oder konstruktive

Änderungen ohne vorherige Ankündigung vorzunehmen

Page 24

22

Page 25

23

Page 26

Page 27

WARRANTY ENGLISH

The JBC 2 years warranty, guarantees

this equipment against all manufacturing

defects, covering the replacement of

defective parts and all necessary labour.

Warranty does not cover product wear

due to use or mis-use.

In order for the warranty to be valid,

equipment must be returned, postage

paid, to the dealer where it was

purchased enclosing this, fully filled

in, sheet.

GARANTIA ESPAÑOL

JBC garantiza este aparato durante 2

años, contra todo defecto de fabricación,

cubriendo la reparación con sustitución

de las piezas defectuosas e incluyendo

la mano de obra necesaria.

Quedan excluidas de esta garantía las

averías provocadas por mal uso del

aparato y desgaste por uso.

Es indispensable para acogerse a

esta garantía el envio del aparato

al distribuidor donde se adquirió, a

portes pagados, adjuntando esta hoja

debidamente cumplimentada.

GARANTIE FRANÇAIS

JBC garantit cet appareil 2 ans

contre tout défaut de fabrication.

Cela comprend la réparation, le

remplacement des pièces défectueuses

et la main d'oeuvre nécessaire.

La garantie ne couvre pas l’usure liée

à l’utilisation et à la mauvaise utilisation

du matériel.

Pour bénéficier de cette garantie il

est indispensable d'envoyer l'appareil

chez le distributeur où il a été acquis,

en ports payés, en joignant cette fiche

dûment remplie.

✂

Page 28

0008879-0210

GARANTIE DEUTSCH

Für das vorliegende Gerät übernimmt

JBC eine Garantie von 2 Jahren, für

alle Fabrikationsfehler. Diese Garantie

schliesst die Reparatur bzw. den

Ersatz der defekten Teile sowie die

entsprechenden Arbeitskosten ein.

Au s ges c hl o s se n vo n die s er

Gar an t ie lei stu ng s ind d ur c h

u n sach g e m ä s s e n Geb r a u c h

hervorgerufene Betriebsstörungen

und normale Gebrauchsabnützungen.

Zur Inanspruchnahme dieser Garantie

muss das Gerät portofrei an den

Vertriebshändler geschickt werden,

bei dem es gekauft wurde. Fügen Sie

dieses vollständig ausgefüllte Blatt bei.

GARANZIA ITALIANO

La JBC garantisce quest'apparato 2

anni contro ogni difetto di fabbricazione,

e copre la riparazione e la sostituzione

dei pezzi difettosi, includendo la mano

d'opera necessaria.

Sono escluse da questa garanzia

le avarie provocate da cattivo uso

dell'apparato e logorio da utilizzo.

Per usufruire di questa garanzia, è

indispensabile inviare, in porto franco,

l'apparato al distributore presso il quale

è stato acquistato, unitamente a questo

foglio debitamente compilato.

DATE OF PURCHASE

FECHA DE COMPRA

DATE D'ACHAT

KAUFDATUM

DATA DI ACQUISTO

STAMP OF DEALER

SELLO DEL DISTRIBUIDOR

CACHET DU DISTRIBUTEUR

STEMPEL DES HÄNDLERS

TIMBRO DEL DISTRIBUTORE

SERIAL Nº

MANUFACTURED BY

JBC Industrias, S.A.

Ramón y Cajal, 3 - 08750 MOLINS DE REI

BARCELONA - SPAIN

Tel.: +34 93 325 32 00 - Fax: +34 93 680 49 70

http://www.jbctools.com e-mail:info@jbctools.com

Loading...

Loading...